| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: FMC | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

MODEL

B3-13

DESCRIPTION

The FMC-461TM EMI filter has been specifically designed to reduce

the input line reflected ripple current of Interpoint's MHF, MTR, MTO,

MHV, MHF+, MHD, MTW, MHE, and MLP series of DC/DC

converters. It is intended for use in applications which have high

frequency switch-mode DC/DC converters and which must meet

MIL-STD-461C levels of conducted and radiated noise.

The FMC filter is built using thick-film hybrid technology and is

hermetically sealed in metal packages for military, aerospace, and

other high-reliability applications. The filter uses only ceramic

capacitors for reliable high temperature operation.

MIL-STD N

OISE

M

ANAGEMENT

When used in conjunction with Interpoint converters, the FMC-461

filter reduces input ripple current by 40 dB within the frequency band

of 200 kHz to 50 MHz. This gives the filter/converter combination a

performance which exceeds the CEO3 test of MIL-STD-461C.

Typical FMC-461 filter frequency response and output impedance

behavior are shown in Figures 4 and 5. CEO3 performance of a

typical converter with the FMC-461 filter connected is shown in

Figure 3.

T

RANSIENT

S

UPPRESSION

The FMC-461 filter also features a fast-reacting (1 pico second)

transient suppressor which begins clamping the input voltage at

approximately 47 VDC, protecting the DC/DC converter from

damage from induced line transients.

O

PERATING

T

EMPERATURE

The filter is rated to operate with no degradation of performance

over the temperature range of -55∞C to +125∞C (as measured at the

baseplate). Above +125∞C, current must be derated as specified on

the following page.

I

NSERTION

L

OSS

The maximum DC insertion loss for the FMC-461 filter (at a load of

22 watts) represents a power loss of less than 2% at typical input

voltage.

L

AYOUT

R

EQUIREMENT

The case pin, and ideally the case, should be tied to the case of the

converter through a low-inductance connection.

EMI I

NPUT

F

ILTER

28 V

OLT

I

NPUT

FMC EMI FILTER

2.7 AMP

F

EATURES

∑ ≠55∞C to +125∞C operation

∑ Up to 50 dB attenuation

400 kHz to 50 MHz

∑ Transient suppression

∑ Compliant to

MIL-STD-461C, CE03

∑ Compatible with

MIL-STD-704E

DC power bus

Size (max): Non-flanged, case H1

2.125 x 1.125 x 0.400 (53.98 x 28.58 x 10.16 mm)

Flanged, case K2

2.910 x 1.125 x 0.400 inches (73.91 x 28.58 x 10.16 mm)

See Section B8, cases H1 and K2, for dimensions.

Weight:

48 grams maximum

Screening: Standard, ES, or 883 (Class H). See Section C2 for

screening options, see Section A5 for ordering information.

FMC-461

FMC-461NT

2.7 Amp

2.7 Amp

TYPICAL CHARACTERISTICS

RECOMMENDED OPERATING CONDITIONS

ABSOLUTE MAXIMUM RATINGS

Input Voltage

∑ 0 to 40 VDC continuous

Lead Soldering Temperature (10 sec per lead)

∑ 300∞C

Storage Temperature Range (Case)

∑ ≠65∞C to +150∞C

B3-14

FMC EMI FILTER

2.7 AMP

Input Voltage Range

∑ 16 to 40 VDC continuous for 40 W load

Case Operating Temperature (Tc)

∑ ≠55∞C to +125∞C full power

Derating

∑ DC input and output current

Derate linearly from 100% at 125∞C to 0%

at 135∞C case

Electrical Characteristics: 25∞C Tc, nominal Vin, unless otherwise specified.

EMI I

NPUT

F

ILTERS

Capacitance

∑ 0.038 µF max, any pin to case

Isolation

∑ 100 megohm minimum at 500 V

∑ Any pin to case, except case pin

FMC-461

FMC-461NT

1

PARAMETER

CONDITIONS

MIN TYP MAX

MIN TYP MAX

UNITS

INPUT VOLTAGE

CONTINUOUS

0

28

40

0

28

40

VDC

INPUT CLAMPING

≠55∞C

40.8

45.1

49.4

--

--

--

VOLTAGE

25∞C

44.7

47.0

49.4

--

--

--

VDC

125∞C

44.7

49.5

54.2

--

--

--

INPUT CURRENT

--

--

2.7

--

--

2.7

A

DIFFERENTIAL MODE

200 kHz

40

--

--

40

--

--

dB

NOISE REJECTION

400 kHz - 50 MHz

50

--

--

50

--

--

COMMON MODE

NOISE REJECTION

2 MHz - 50 MHz

40

--

--

40

--

--

dB

DC RESISTANCE (R

DC

)

TC = 25∞C

--

--

0.20

--

--

0.20

OUTPUT VOLTAGE

2

STEADY STATE

V

OUT

= V

IN

- I

IN

(R

DC

)

V

OUT

= V

IN

- I

IN

(R

DC

)

VDC

OUTPUT CURRENT

RIPPLE

--

--

1.0

--

--

1.0

A rms

STEADY STATE

--

--

2.7

--

--

2.7

A

INTERNAL POWER

DISSIPATION

MAXIMUM CURRENT

--

--

1.6

--

--

1.6

W

Notes

1. The FMC-461NT does not have a transorb and does not clamp the input voltage

2. Typical applications result in Vout within 2% of Vin.

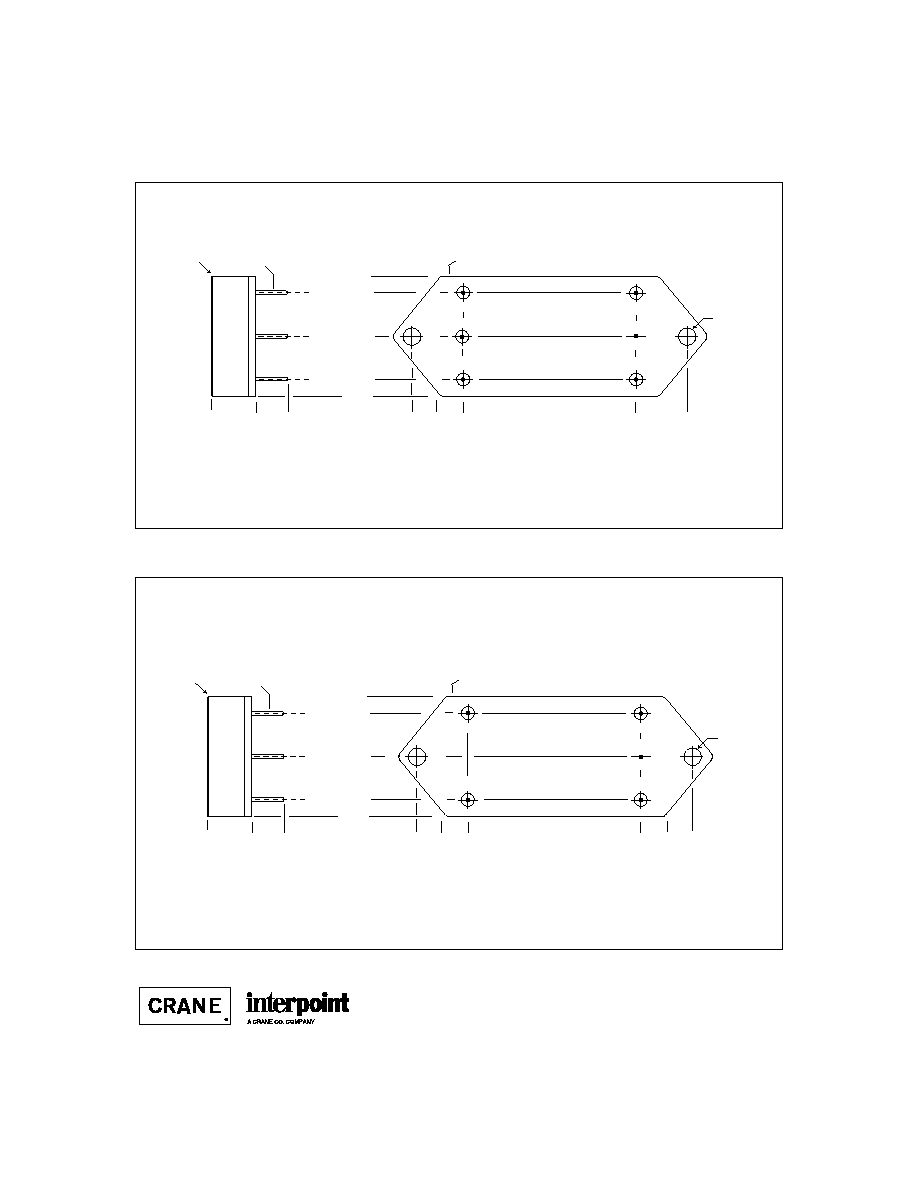

PIN OUT

MODEL NUMBERING KEY

1

2

3

4

5

Dot on top of package indicates pin one

Dotted line outlines flanged package option.

BOTTOM VIEW

FMC

NON-FLANGED AND FLANGED

FMC - 461 NT F / 883

Base Model

MIL-STD-461 Reference

Screening

(Standard screening has no designator

in this position.)

No Transorb Option

(Standard FMC-461 has no designator

in this position)

Case Option

(Non-flanged case has no designator in

this position)

B3-15

EMI I

NPUT

F

ILTERS

See Section B8, cases H1 and K2 for dimensions.

Pin

Designation

1

Positive Input

2

Positive Output

3

Case Ground

4

Output Common

5

Input Common

F

IGURE

2: P

IN

O

UT

DSCC NUMBER

DSCC D

RAWING

(5915)

94010-01HXC

94010-01HZC

94010-02HXC

1

94010-02HZC

1

FMC-461 F

ILTER

S

IMILAR

P

ART

FMC-461/883

FMC-461F/883

FMC-461NT/883

1

FMC-461NTF/883

1

For exact specifications for a DSCC product, refer to the

DSCC drawing. See Section A3, "SMD/DSCC Lists", for

more information.

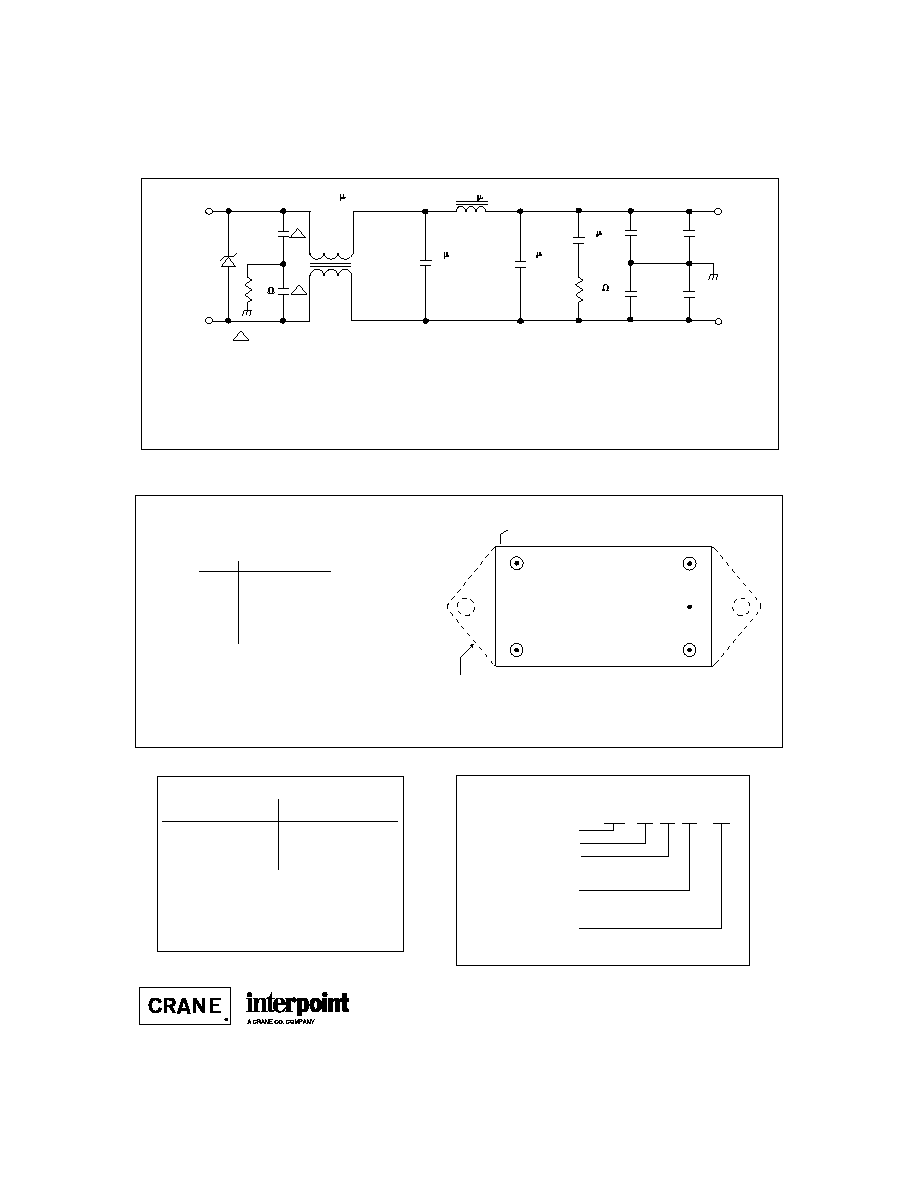

6 F

6800 pF / 500 V

(4 times)

Positive

Input

Input

Common

Positive

Output

Output

Common

FMC-461

FMC-461/883

35.6 H

1 F

68

3300 pF / 500 V

IN5649A

277 H

6 F

4.7

1

1

1

F

IGURE

1: S

CHEMATIC

≠ T

YPICAL

V

ALUES

FMC EMI FILTER

2.7 AMP

1. No transorb (NT)

Flanged SMDs have the suffix HZC instead of HXC.

The case ground connection between the filter and the converter should be as low an impedance as possible

to minimize EMI. Direct contact of baseplate to chassis ground provides the lowest impedance.

B3-16

Typical Performance Curves: 25∞C Tc , nominal Vin, unless otherwise specified.

EMI I

NPUT

F

ILTERS

FMC EMI FILTER

2.7 AMP

90

70

50

30

.015

0.1

1

10

50

10

EMISSION LEVEL (dmA)

FREQUENCY (MHz)

F

IGURE

3

FREQUENCY (Hz)

1 K

Attenuation (dB)

10 K

100 K

1 M

-95

-75

-55

-35

-15

5

F

IGURE

4

F

IGURE

5

-10

0

10

FREQUENCY (Hz)

1 K

10 K

100 K

1 M

-20

dB Ohms = 20 log Z

out

DC/DC Converter Typical Worst Case

EMI With FMC-461 Filter

FMC-461 Typical Amplitude

Response vs. Frequency

Typical Output Impedance (Z)

With Input Shorted

25621-001-DTS Rev A

DQ# 4003

All technical information is believed to be accurate, but no responsibility is

assumed for errors or omissions. Interpoint reserves the right to make changes in

products or specifications without notice. FMC-461 is a trademark of Interpoint.

Copyright © 1991 - 1999 Interpoint. All rights reserved.

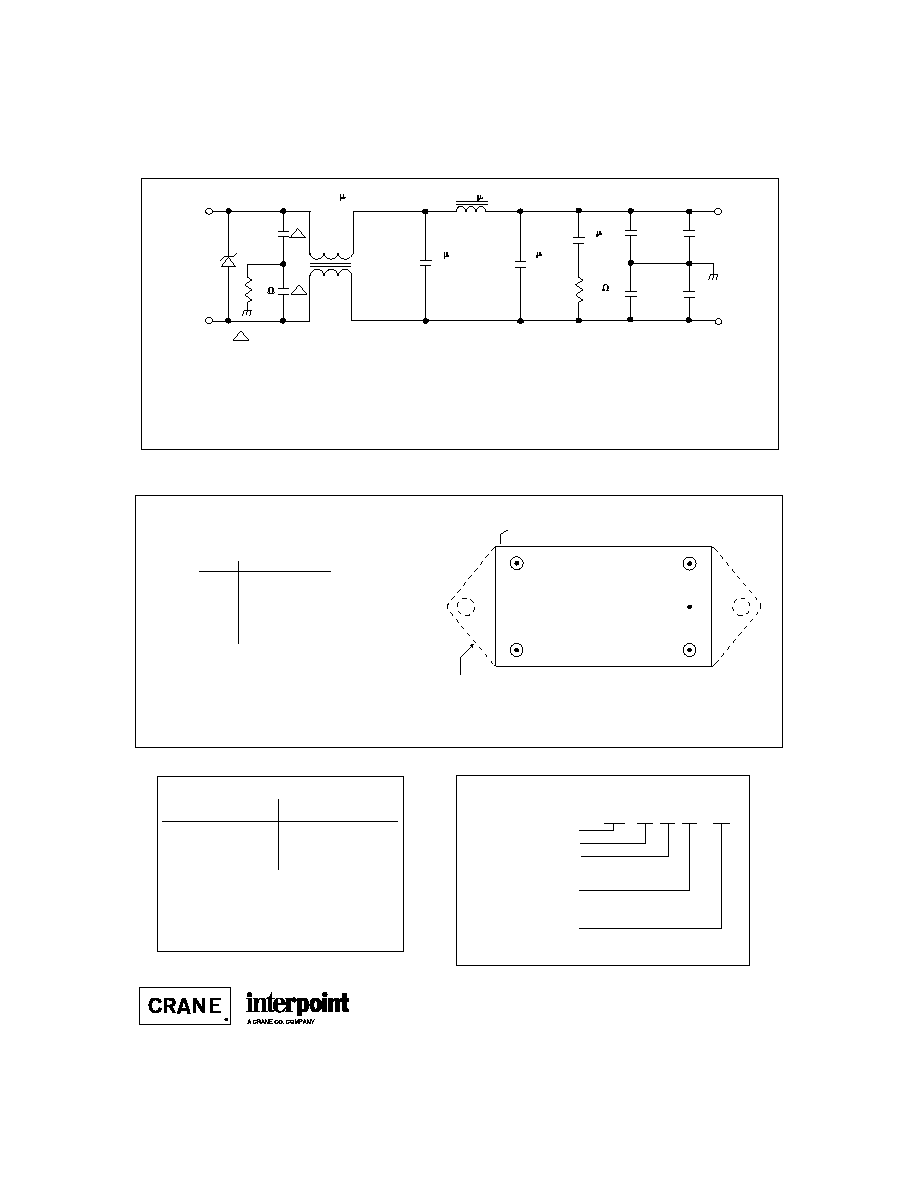

B8-17

CASE H

C

ASES

CASE H

BOTTOM VIEW

See Figures 29 ≠ 34

for pin configurations.

2.125 max

(53.98)

1.125 max

(28.58)

Materials

Header Cold Rolled Steel/Nickel/Gold

cases H1 and H2

Cold Rolled Steel/Nickel/Tin

cases H3, H4, and H5

Cover Kovar/Nickel

cases H1 and H2

Cold Rolled Steel/Nickel/Tin

cases H3, H4, and H5

Pins #52

alloy

ceramic seal

case H1

case H2 (except MHV Series Single and Dual)

compression glass seal

MHV Series Single and Dual

case H3, H4, H5

Case dimensions in inches (mm)

Tolerance

±

0.005 (0.13) for three decimal places

±

0.01 (0.3) for two decimal places

unless otherwise specified

CAUTION

Heat from reflow or wave soldering may damage

the device. Solder pins individually with heat

application not exceeding 300

∞

C for 10 seconds

per pin.

Dot on top of case indicates pin one

0.155 (3.94)

0.955 (24.26)

Seam Seal

0.000

0.040 dia

(1.02)

0.000

0.000

0.400 max.

(10.16)

0.25

±

0.03

(6.4

±

0.8)

0.555 (14.1)

0.245

(6.22)

1.845

(46.86)

2.090

(53.01)

1.110 (28.19)

1

2

3

4

5

FMC EMI Filter: Screening ≠ Standard, ES, or 883

SFMC EMI Filter: Screening ≠ Space Standard, H, or K

BOTTOM VIEW CASE H1

Squared corner and dot on top

of case indicate pin one.

F

IGURE

29: C

ASE

H1

F

IGURE

28: C

ASE

H M

AXIMUM

D

IMENSIONS

Note: Although every effort has been made to render the case drawings at actual size, variations in the printing process may cause some distortion. Please refer

to the numerical dimensions for accuracy.

B8-26

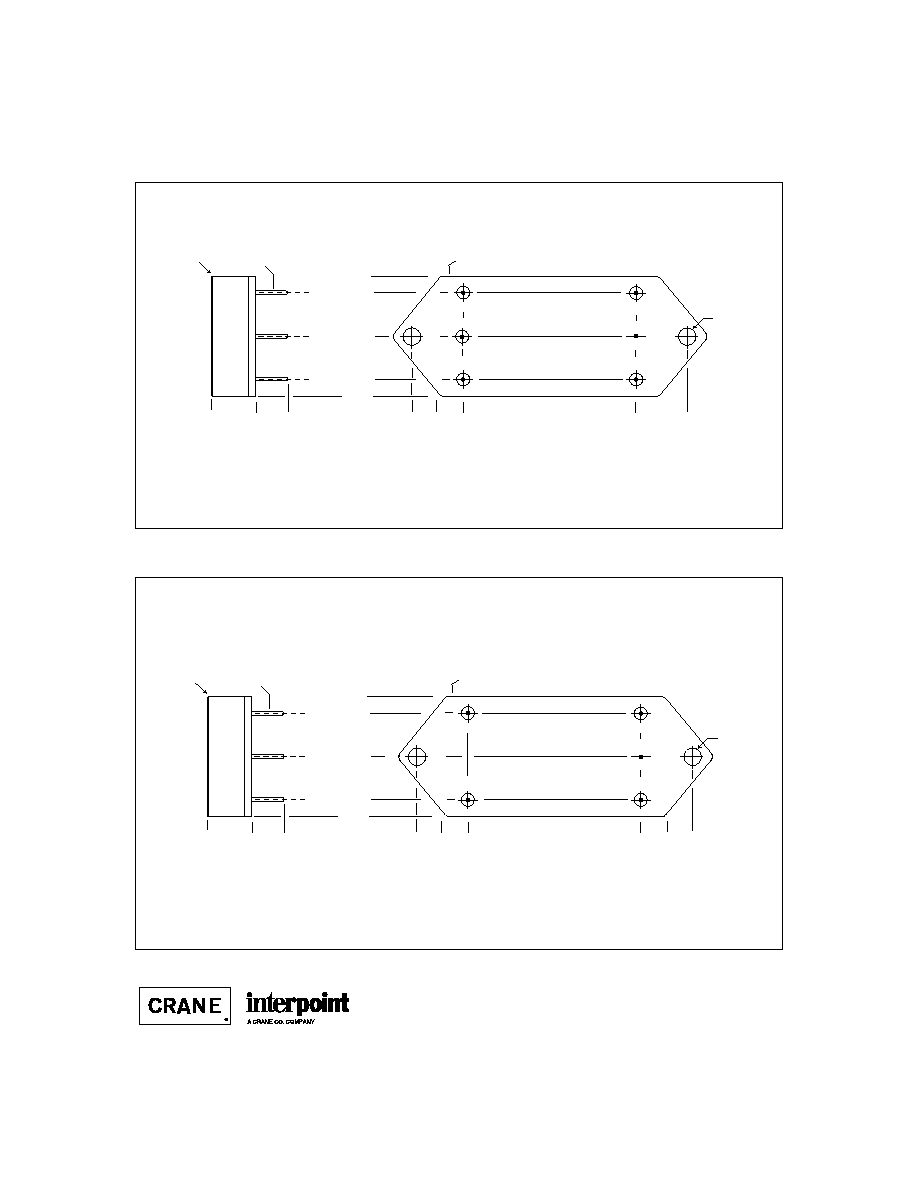

CASE K

C

ASES

Materials

Header Case K1 - K3

Cold Rolled Steel/Nickel/Gold

Cases K4 - K8

Cold Rolled Steel/Nickel/Tin

Cover

Case K1 - K3

Kovar/Nickel

Case K4 - K8

Cold Rolled Steel/Nickel/Tin

Pins

#52 alloy (all cases)

Case K1, K2, and K3 (except MHV Series Single and Dual)

ceramic seal

Cases K4 - K8 and MHV Series Single and Dual (K3)

compression glass seal

Case dimensions in inches (mm)

Tolerance

±

0.005 (0.13) for three decimal places

±

0.01 (0.2) for two decimal places

unless otherwise specified

CASE K

BOTTOM VIEW

See Figures 42 - 48

for pin configuration

CAUTION

Heat from reflow or wave soldering may damage

the device. Solder pins individually with heat

application not exceeding 300

∞

C for 10 seconds

per pin.

Flange Thickness:

Cases K1, K2, K3 and MLP Series (K5)

0.060 (1.52)

Cases K4, K5 (except MLP Series), K6, K7, and K8

0.067 +0.005/-0.007 (1.70 +0.13/-0.8)

1.125 max

(28.58)

2.910 max

(73.91)

Dot on top of case indicates pin one

F

IGURE

41: C

ASE

K M

AXIMUM

D

IMENSIONS

B8-27

CASE K

C

ASES

0.155 (3.94)

0.955 (24.26)

0.000

0.040 dia

(1.02)

0.000

0.000

0.400 max.

(10.16)

0.25

±

0.03

(6.4

±

0.8)

0.555 (14.1)

0.245

(6.22)

1.845

(46.86)

1.110 (28.19)

1

2

4

5

Flanged case

FM-704A EMI Filter: Screening ≠ Standard, ES, or 883

BOTTOM VIEW CASE K1

0.162 dia

(4.11)

Seam Seal

0.230

(5.84)

2.320

(58.93)

Dot on top of case indicates pin one

3

6

F

IGURE

42: C

ASE

K1

0.155 (3.94)

0.955 (24.26)

Seam Seal

0.000

0.040 dia

(1.02)

0.000

0.000

0.400 max.

(10.16)

0.25

±

0.03

(6.4

±

0.8)

0.555 (14.1)

0.245

(6.22)

1.845

(46.86)

2.090

(53.01)

1.110 (28.19)

1

2

4

5

Flanged cases: Designator required in Case Option position of model number.

FMC EMI Filter: Screening ≠ Standard, ES, or 883

SFMC EMI Filter: Screening ≠ Space Standard, H, or K

BOTTOM VIEW CASE K2

0.162 dia

(4.11)

0.230

(5.84)

2.320

(58.93)

Dot on top of case indicates pin one

3

F

IGURE

43: C

ASE

K2

C2-10

TEST (125∞C Products)

STANDARD

/ES

/883 (Class H)*

PRE-CAP INSPECTION

Method 2017, 2032

yes

yes

yes

TEMPERATURE CYCLE (10 times)

Method 1010, Cond. C, -65∞C to 150∞C

no

no

yes

Method 1010, Cond. B, -55∞C to 125∞C

no

yes

no

CONSTANT ACCELERATION

Method 2001, 3000 g

no

no

yes

Method 2001, 500 g

no

yes

no

BURN-IN

Method 1015, 160 hours at 125∞C

no

no

yes

96 hours at 125∞C case (typical)

no

yes

no

FINAL ELECTRICAL TEST MIL-PRF-38534, Group A

Subgroups 1 through 6: -55∞C, +25∞C, +125∞C

no

no

yes

Subgroups 1 and 4: +25∞C case

yes

yes

no

HERMETICITY TESTING

Fine Leak, Method 1014, Cond. A

no

yes

yes

Gross Leak, Method 1014, Cond. C

no

yes

yes

Gross Leak, Dip (1 x 10

-3

)

yes

no

no

FINAL VISUAL INSPECTION

Method 2009

yes

yes

yes

Test methods are referenced to MIL-STD-883 as determined by MIL-PRF-38534.

*883 products are built with element evaluated components and are 100% tested and guaranteed over

the full military temperature range of ≠55∞C to +125∞C.

MOR Series

MFLHP Series

MFL Series

MHP Series

MTR Series

MQO Series**

MHD Series

MHV Series

MHF+ Series

MHF Series**

MGA Series

MSA Series

MGH Series

MCH Series

FM-704A EMI Filter

FMD**/FME EMI Filter

FMC EMI Filter

FMH EMI Filter

FMGA EMI Filter

FMSA EMI Filter

HUM Modules**

LCM Modules**

LIM Modules

QA SCREENING

125∞C PRODUCTS

125∞C P

RODUCTS

Applies to the following products

**MFLHP Series, MQO Series, MHF Series, FMD EMI Filters, Hum Modules, and LCM Modules do not offer

`883" screening.