B4-33

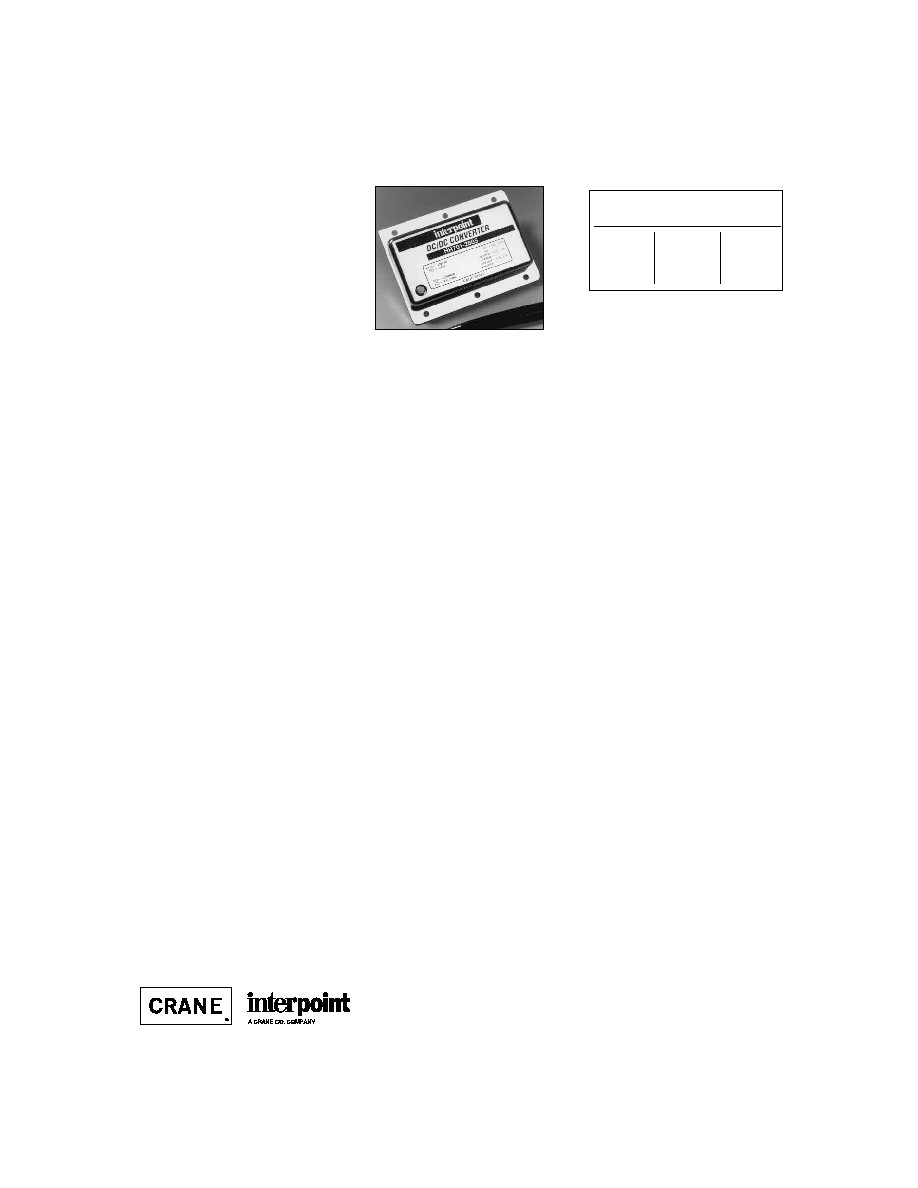

HR700 SERIES

70 WATT

F

EATURES

∑ ≠40∞C to + 85∞C operation

∑ 19 to 40 VDC input

∑ Fully Isolated

∑ Optocoupler feedback

∑ Fixed frequency, 245 kHz typical

∑ Topology ≠ Push-Pull Forward

∑ 50 V for up to 50 ms transient protection

∑ Inhibit/sync function

∑ Indefinite short circuit protection

∑ Remote sense on single models

∑ Up to 84% efficiency

MODELS

VDC O

UTPUT

SINGLE

5

12

15

DUAL

±12

±15

TRIPLE

+5 & ±12

+5 & ±15

DC/DC C

ONVERTERS

28 V

OLT

I

NPUT

Size (max.): 3.20 x 2.46 x 0.595 inches

(81.3 x 62.5 x 15.11 mm)

See Section B8, case L, for dimensions.

Weight:

140 grams typical

Screening:

Standard only.

See Section B9 for screening description.

DESCRIPTION

HR700 Series DC/DC converters offer up to 70 watts of power from

single, dual, or triple outputs in one package. The converters

combine the small size and high reliability of hybrid-based compo-

nents, the high efficiency of switching regulators, and the isolation,

regulation, and low noise characteristics of linear regulators.

SMALL SIZE

The HR700 converters are manufactured using techniques that

provide very small size and low profile components. Each converter

uses less than eight square inches of board areas and is 0.595

inches high or less. The overall power density is 20 watts per cubic

inch.

HIGH RELIABILITY

Assembled using thick-film technology, the HR700 parts use the

same manufacturing procedures and quality controls that we apply

to converters designed for commercial airliners, the space shuttle,

advanced fighter aircraft, and other high reliability applications. The

steel cases are hermetically sealed in a dry nitrogen environment

and are guaranteed a maximum leak rate of less than 10

-3

atm-

cc/sec. All devices are 100% electrically tested.

HIGH PERFORMANCE

The HR700 series parts are high efficiency, low noise, pulse-width

modulated converters which use a quasi-square wave forward

converter design with a nominal switching frequency of 245 kHz.

Isolation between input an output is provided with a transformer in

the forward power loop and a wide band, temperature insensitive,

optical link in the feedback control loop. Short circuit protection is

provided by detecting peak primary switching current on a cycle

basis and limiting it to approximately 130% of the full load input

current. This method results in quick and positive current limiting

under short circuit conditions.

HR700 Series DC/DC converters are designed to provide full power

operation over the input voltage range of 19 to 40 VDC. Operation

below an input of 19 volts is possible with derated output power.

Outputs are available as 5, 12, and 15 VDC single, dual and triple

outputs. The converters typically provide greater than 80% effi-

ciency over the entire input range. Line regulation is typically within

0.1% and load regulation within 0.2%.

LOW NOISE

The HR700 Series converters offer low noise on both the input and

output lines. A two section, four pole, LC input filter is included to

provide very low reflected line ripple current. Output ripple is main-

tained at less than 50 mV p-p for single and dual models and 85 mV

p-p for triple output models.

INHIBIT

/

SYNC FEATURE

An inhibit/sync pin is standard on all models of the HR700 Series

converters. The pin serves as both an output inhibit and as a

synchronization input. In the inhibit mode an open collector TTL

compatible low (<0.8 V) will disable internal switching thereby

inhibiting the unit's output. Inhibiting in this manner results in an

extremely low quiescent current.

SYNC AND INHIBIT

B4-34

HR700 SERIES

70 WATT

DC/DC C

ONVERTERS

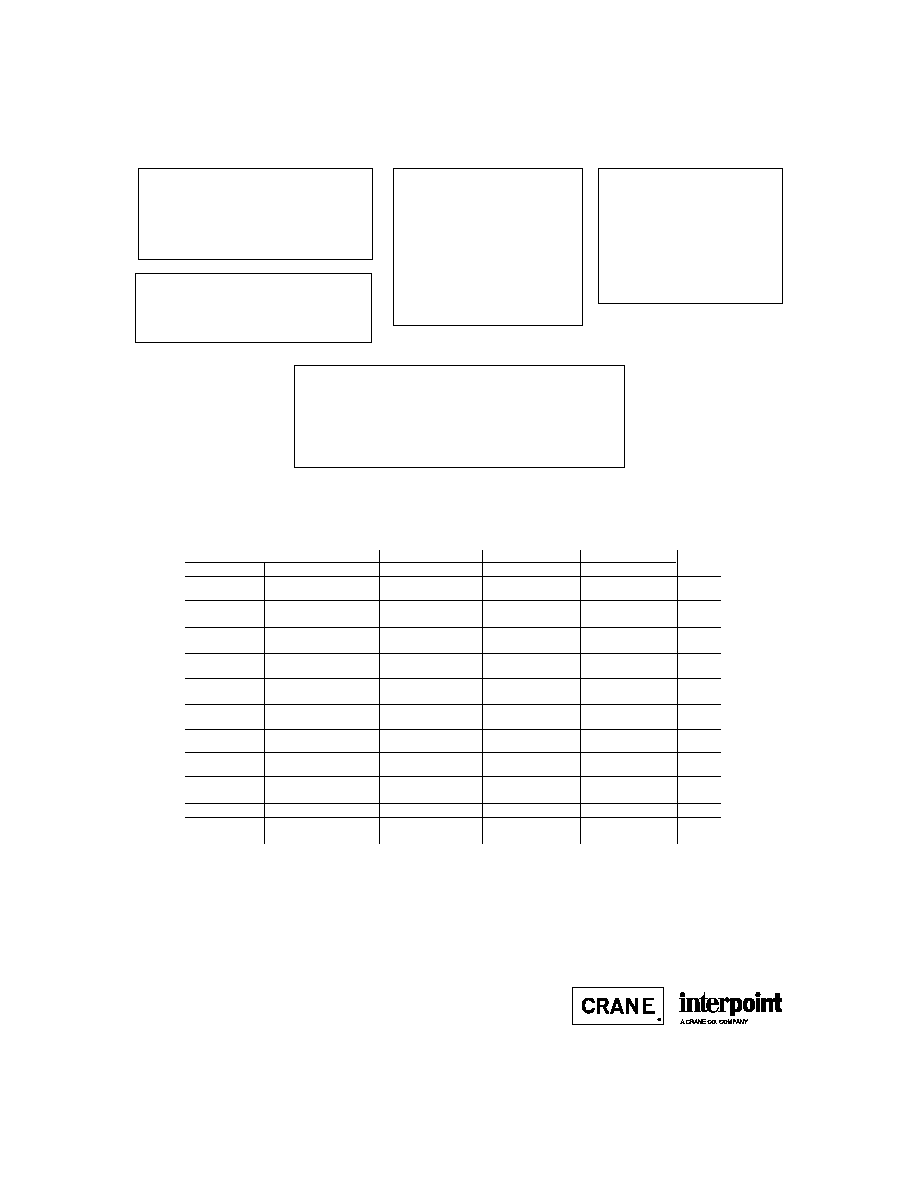

DERATING OUTPUT POWER/CURRENT AND INPUT VOLTAGE

RECOMMENDED OPERATING CONDITIONS

ABSOLUTE MAXIMUM RATINGS

TYPICAL CHARACTERISTICS

SINGLE OUTPUTS

HR701-2805

HR701-2812

HR701-2815

PARAMETER

CONDITION

MIN

TYP

MAX

MIN

TYP MAX

MIN.

TYP

MAX

UNITS

OUTPUT

FULL LOAD

4.90

5.00

5.10

11.75 12.00 12.25

14.75 15.00 15.25

VDC

VOLTAGE

OUTPUT

V

IN

= 19 TO 40

--

--

12.00

--

--

5.83

--

--

4.67

A

CURRENT

OUTPUT

Tc = ≠55∞C TO +85∞C

--

--

60

--

--

70

--

--

70

W

POWER

OUTPUT

FULL LOAD BW

2 MHz

--

30

100

--

30

100

--

30

100

mV p-p

RIPPLE

LINE

V

IN

= 19 TO 40

--

10

30

--

10

30

--

10

30

mV

REGULATION

LOAD

NO LOAD TO FULL

--

10

30

--

10

30

--

10

30

mV

REGULATION

INPUT

VOLTAGE

19

28

40

19

28

40

19

28

40

VDC

INPUT

NO LOAD

--

75

100

--

70

100

--

70

100

mA

CURRENT

INHIBITED

--

30

35

--

30

35

--

30

35

INPUT REFL.

FULL LOAD

--

10

50

--

10

50

--

10

50

mA p-p

RIPPLE

BW

10 MHz

EFFICIENCY

77

80

--

80

83

--

80

83

--

%

STARTUP

WITH LOW

--

5

10

--

8

10

--

8

10

ms

DELAY

IMPEDANCE SOURCE

Output Power

∑ 60 to 70 watts depending on model

Lead Soldering Temperature (10 sec per lead)

∑ 300∞C

Storage Temperature Range (Case)

∑ ≠55∞C to +125∞C

Output Voltage Temperature Coefficient

∑ 150 ppm/∞C, typical

Input to Output Capacitance

∑ 160 pF, typical

Isolation

∑ 100 megohm minimum at 500 V

Conversion Frequency

∑ Free run mode 245 kHz, typical

Inhibit Pin Voltage (unit enabled)

∑ 4.5 to 5.5 V

Sync In (245 to 370 kHz.)

∑ Duty cycle 70% min, 98% max.

∑ Logic low 0.8V max

∑ Logic high 4.5 V min

∑ Referenced to input common

∑ If sync is not used, leave unconnected

Inhibit TTL Open Collector

∑ Logic low (output disabled)

Inhibit pin current 1 mA max

∑ Referenced to input common

∑ Logic high (output enabled)

V =

4.5V

Temperatures are referenced to the temperature at the converter's baseplate

∑ Linearly derate output power/current from 100% at 85∞C to 0% at 125∞C.

∑ Above 105∞C linearly derate steady state input voltage to 33 volts at 125∞C.

∑ Indefinite short circuit protection is not guaranteed above 85∞C case.

∑ Operation below an input voltage of 19 volts, including operation in MIL-

STD-704E emergency power conditions, is possible with derated output

power. See Figures 10 and 11.

Electrical Characteristics: 25∞C Tc, 28 VDC Vin, 100% load, free run, unless otherwise specified.

Input Voltage Range

∑ 19 to 40 VDC continuous (see Derating)

Case Operating Temperature (Tc)

∑ ≠40∞C to +85∞C full power

B4-35

HR700 SERIES

70 WATT

DC/DC C

ONVERTERS

DUAL AND TRIPLE OUTPUTS

HR702-2812

HR702-2815

HR703-28512

HR703-28515

PARAMETER

CONDITION

MIN

TYP

MAX

MIN

TYP

MAX

MIN

TYP

MAX

MIN

TYP

MAX

UNITS

OUTPUT

FULL

MAIN

--

--

--

--

--

--

4.90

5.05

5.15

4.90

4.95

5.10

VOLTAGE

LOAD

DUAL

±11.75 ±12.00 ±12.25

±14.75 ±15.00 ±15.25 ±11.50

±11.80 ±12.10 ±15.05 ±15.30 ±15.75

VDC

OUTPUT

V

IN

=

MAIN

--

--

--

--

--

--

--

4.0

10.0

--

4.0

10.0

A

CURRENT

1, 2

19 TO 40

DUAL

--

2.92

5.5

--

2.33

4.4

--

1.67

4.2

--

1.33

3.33

OUTPUT

MAIN

--

--

--

--

--

--

--

20

50

--

20

50

POWER

1, 2

±DUAL

--

35

66.5

--

35

66.5

--

20

50

--

20

50

W

TOTAL

--

--

70

--

--

70

--

--

60

--

--

60

OUTPUT

FULL LOAD

MAIN

--

--

--

--

--

--

--

50

100

--

50

100

mV p-p

RIPPLE

BW

2 MHz

DUAL

--

30

100

--

30

100

--

50

100

--

50

100

LINE

V

IN

=

MAIN

--

--

--

--

--

--

--

2

25

--

2

25

mV

REGULATION 19 TO 40

DUAL

--

10

30

--

10

30

--

100

225

--

100

225

LOAD

3

NO LOAD

MAIN

--

--

--

--

--

--

--

5

30

--

5

30

mV

REGULATION TO FULL

DUAL

--

25

50

--

25

50

--

480

750

--

300

600

CROSS

4

DUAL

REGULATION +P

O

= 3 W TO 35 W

≠P

O

= 35 W

--

1.5

3.0

--

1.5

3.0

--

--

--

--

--

--

+P

O

= 20 W TO 50 W

%

%

≠P

O

= 50 W TO 20 W

--

2.0

4.0

--

2.0

3.5

--

--

--

--

--

--

CROSS

5

MAIN +P

O

= 30 W

REGULATION DUAL

+P

O

= 3 W TO 27 W

--

--

--

--

--

--

--

2.3

6.0

--

2.3

5.0

≠P

O

= 27 W TO 3 W

MAIN

%

+P

O

= 3 W TO 30 W

DUAL ±P

O

= 15 W

--

--

--

--

--

--

--

5.4

9.0

--

5.0

7.0

INPUT

VOLTAGE

19

28

40

19

28

40

19

28

40

19

28

40

VDC

INPUT

NO LOAD

--

75

100

--

75

100

--

85

115

--

60

115

mA

CURRENT

INHIBITED

--

25

35

--

25

35

--

30

35

--

30

35

INPUT REFL.

FULL LOAD

--

15

50

--

15

50

--

15

50

--

15

50

mA p-p

RIPPLE

BW

10 MHz

EFFICIENCY

80

83

--

80

83

--

79

84

--

79

84

--

%

STARTUP

--

15

25

--

15

25

--

6

10

--

6

10

ms

DELAY

Electrical Characteristics: 25∞C Tc, 28 VDC Vin, 100% load, free run, unless otherwise specified.

Notes

1. On dual output models the maximum combined output power is 70 watts.

A maximum of 95% (66.5 W) is available from any single output.

2. On triple output models the maximum combined output power is 60 watts.

A maximum of 50 watts is available from a single output.

3. Balanced loads

4. Regulation effect on the negative dual output during the defined conditions.

5. Regulation effect on both dual outputs during the defined conditions.

B4-36

HR700 SERIES

70 WATT

DC/DC C

ONVERTERS

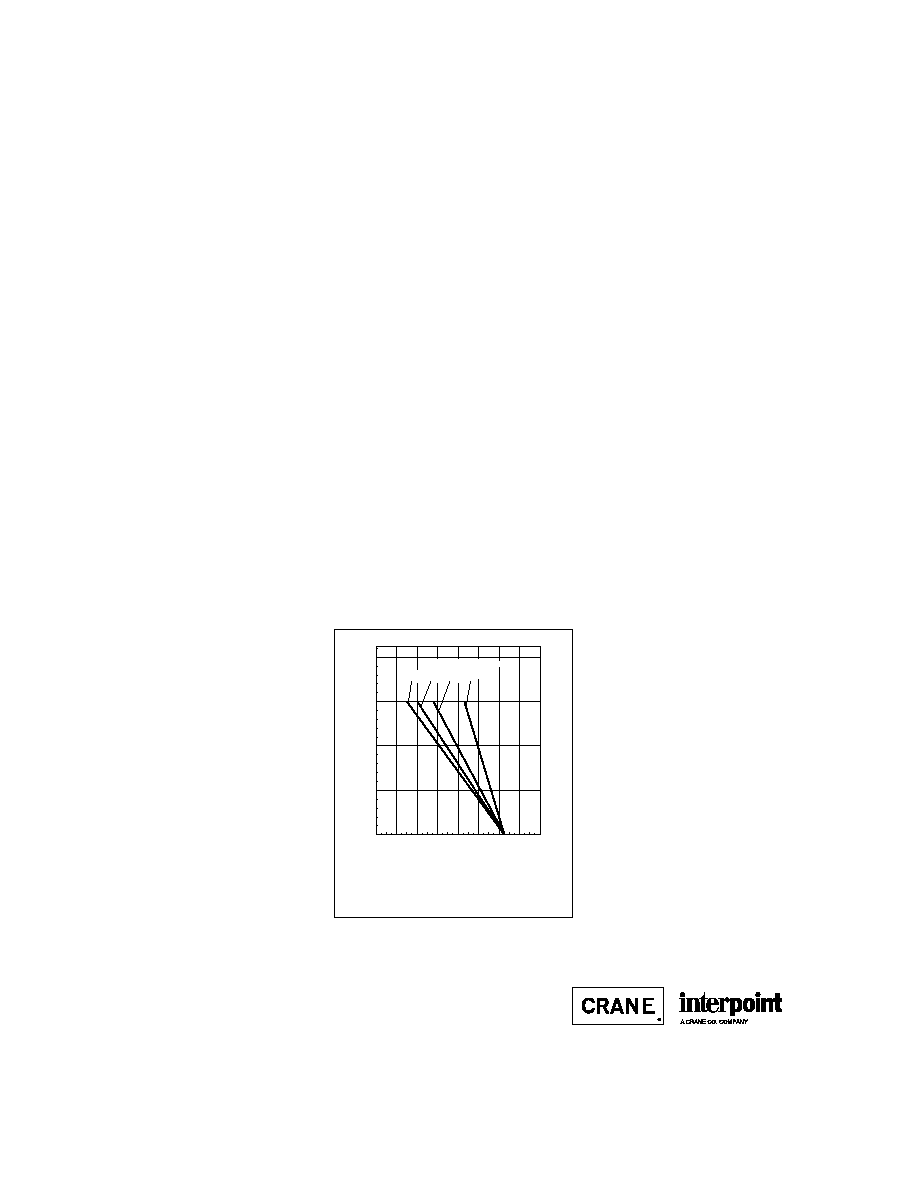

C

ALCULATING

M

AXIMUM

A

MBIENT

T

EMPERATURE

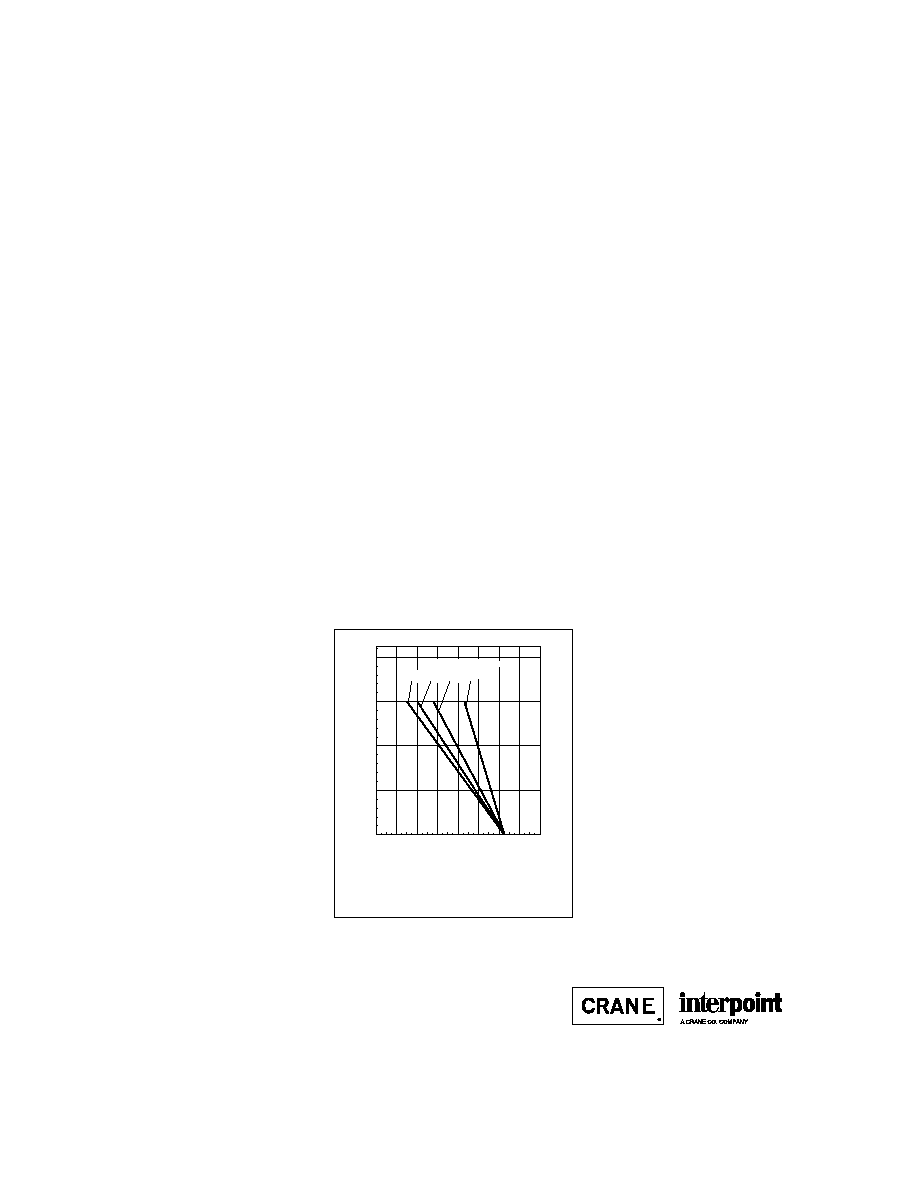

The HR700 Series of DC/DC converters has an upper operating

temperature of + 85∞C at the baseplate of the case. The degree of

heat sinking required to remain within this limit may be determined

from Figure 1 which shows the maximum allowed internal power

dissipation (P

DISS

vs. ambient temperature for various heat sink

thermal resistances. P

DISS

may be calculated as:

P

DISS

= P

OUT

/ efficiency ≠ P

OUT

The efficiency for all combinations of P

OUT

and V

IN

for the various

models may be obtained from the graphs on the preceding pages.

Example:

Converter = HR702-2815, T

AMB

= 70∞C,

V

IN

= 28 VDC, P

OUT

= 45 watts

Efficiency = 85% (From Figure 7)

P

DISS

= (45 / 85) ≠ 45 = 7.95 watts

From Figure 1 we can see that this situation will require thermal

resistance of approximately 4.5∞C / watt.

Conversely we may also find the maximum ambient temperature

which can be tolerated if we know the heat sink thermal resistance.

Example:

Converter = HR701-2805, V

IN

= 28 VDC, P

OUT

= 45 W.

Thermal Resistance = 3∞C / watt.

Efficiency = 83.5% (From Figure 3)

P

DISS

= (45 / 0.835) ≠ 45 = 8.89 watts.

From Figure 1 we can see that the maximum allowed ambient

temperature is approximately 75∞C.

H

EAT

S

INK

R

ECOMMENDATIONS

An HR700 Series converter in still air (other than convective

currents) and with no conductive cooling paths other than through

electrical connections at the pins will exhibit a thermal resistance of

approximately 4∞C / watt. In cases where this value proves to be too

high it is recommended that additional heat sinking be supplied. The

simplest method of accomplishing this is to firmly attach the

converter to a PCB thereby providing a conductive thermal path.

Secondly it is recommended that airflow be provided over the

converter. Although each situation requires a thorough thermal

analysis these two measures can reduce the thermal resistance to

as low as 2∞C / watt. If calculations indicate further heat sinking is

required it is recommended that additional thermal mass be

provided either under the base plate or on top of the converter's

mounting flanges or both.

THERMAL MANAGEMENT

Degrees Centigrade

Watts

20

∞

40

∞

60

∞

80

∞

100

∞

120

∞

140

∞

20

15

10

5

U=4

∞

C/W

U=3

∞

C/W

U=2

∞

C/W

U=0

∞

C/W

Internal Power Dissipation (max)

vs. Ambient Temperature

F

IGURE

1

B4-37

HR700 SERIES

70 WATT

DC/DC C

ONVERTERS

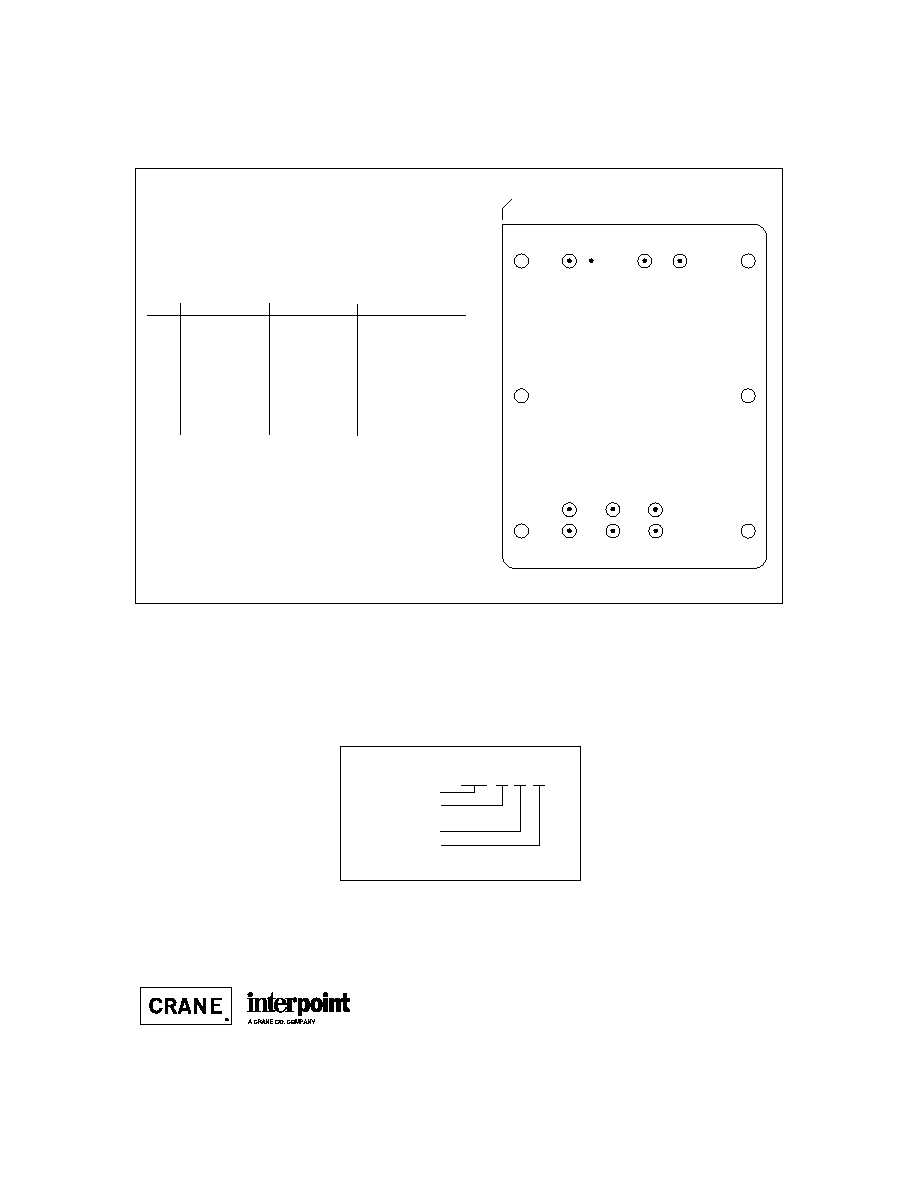

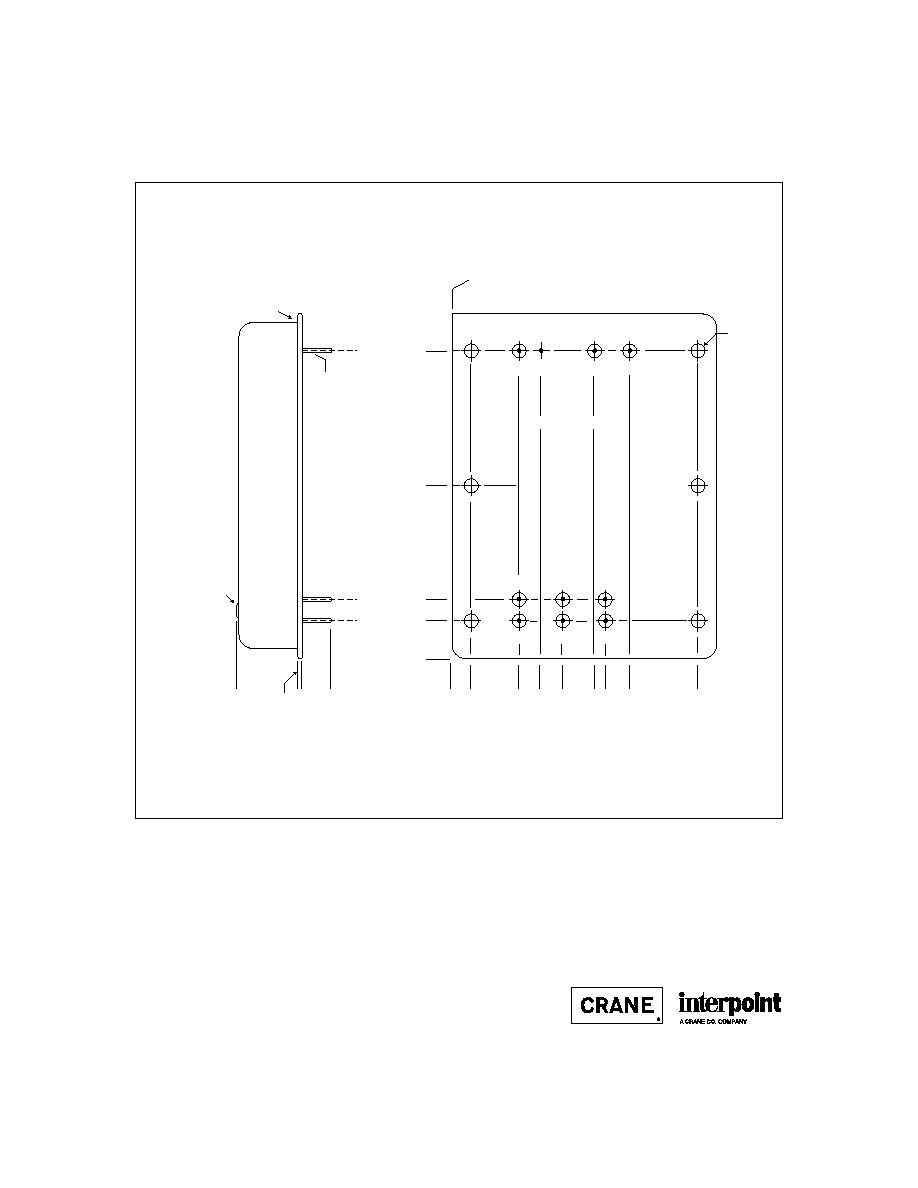

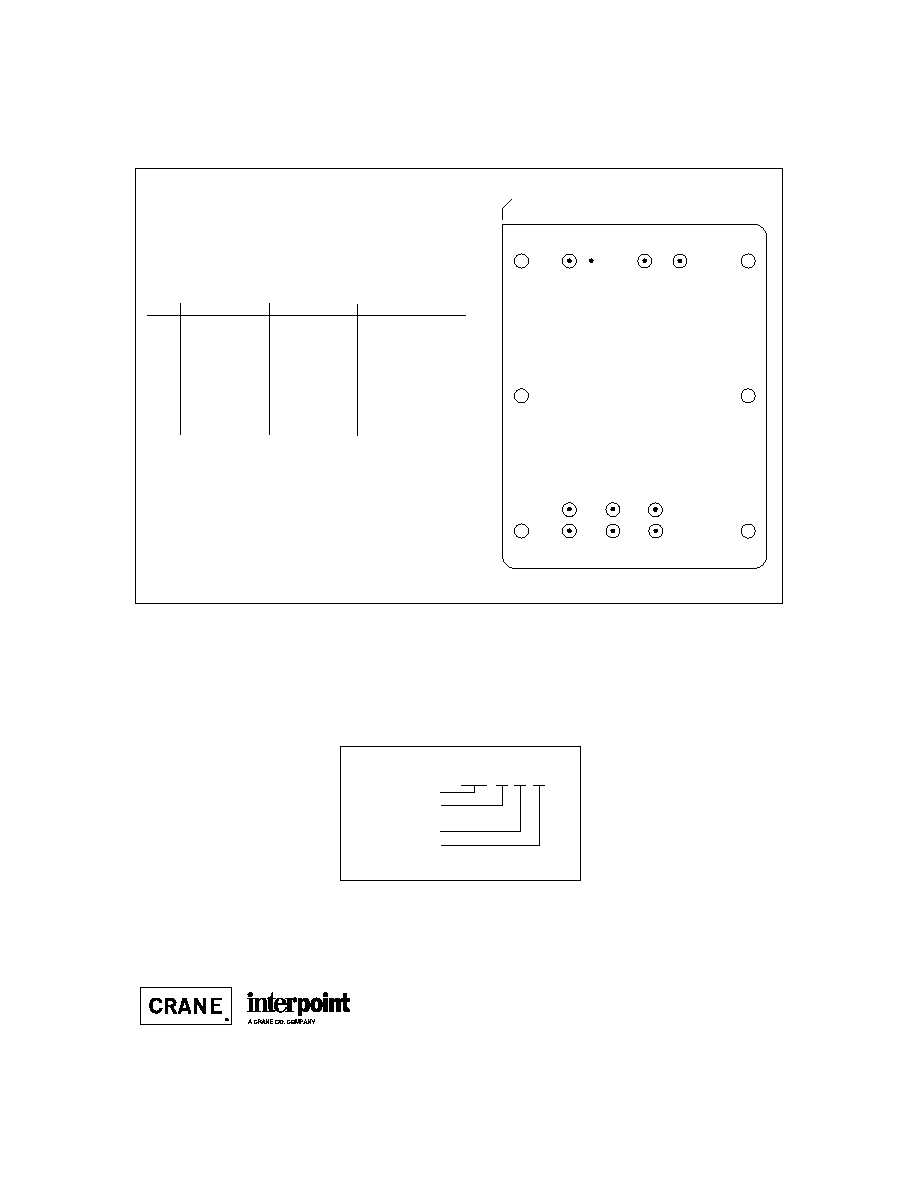

PIN OUT

Pin

Single Output

Dual Output

Triple Output

1

Positive Input

Positive Input

Positive Input

2

Case Ground

Case Ground

Case Ground

3

Input Common

Input Common

Input Common

4

Inhibit/Sync In

Inhibit/Sync In

Inhibit/Sync In

5

Negative Sense

Negative Output

Negative Aux. Output

6

Positive Sense

Positive Output

Positive Aux. Output

7, 8

Output Common

Output Common

Output Common

9, 10

Positive Output

No Connection

Main (+5) Output

Squared corner indicates pin one.

BOTTOM VIEW

HR700

1

2

3

4

5

6

7

8

9

10

F

IGURE

2: P

IN

O

UT

MODEL NUMBERING KEY

HR70 2 - 28 12

Base Model

Input Voltage

Output Voltage

Number of Outputs

(1 = single, 2 = dual, 3 = triple)

(Main and aux. Vout for triple models)

See Section B8, case L, for dimensions.

B4-38

HR700 SERIES

70 WATT

DC/DC C

ONVERTERS

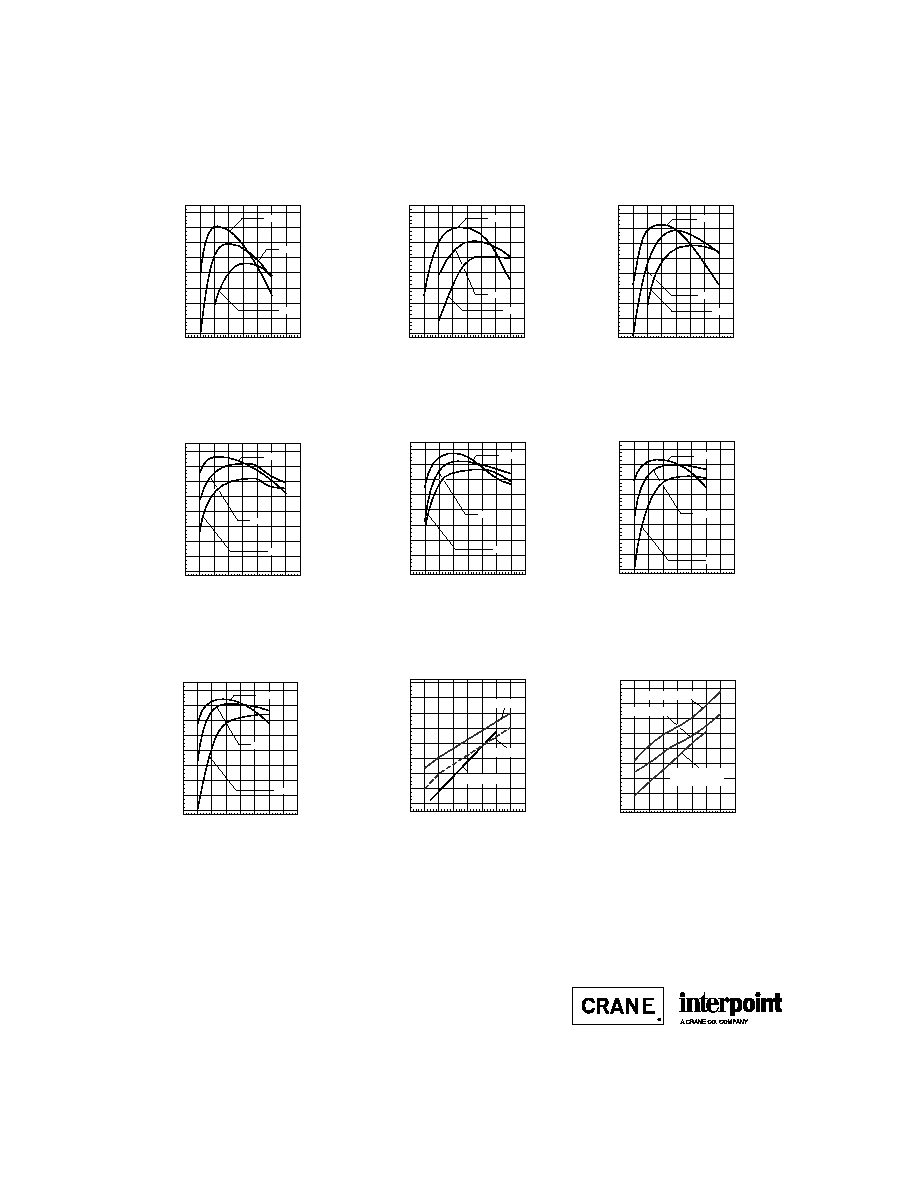

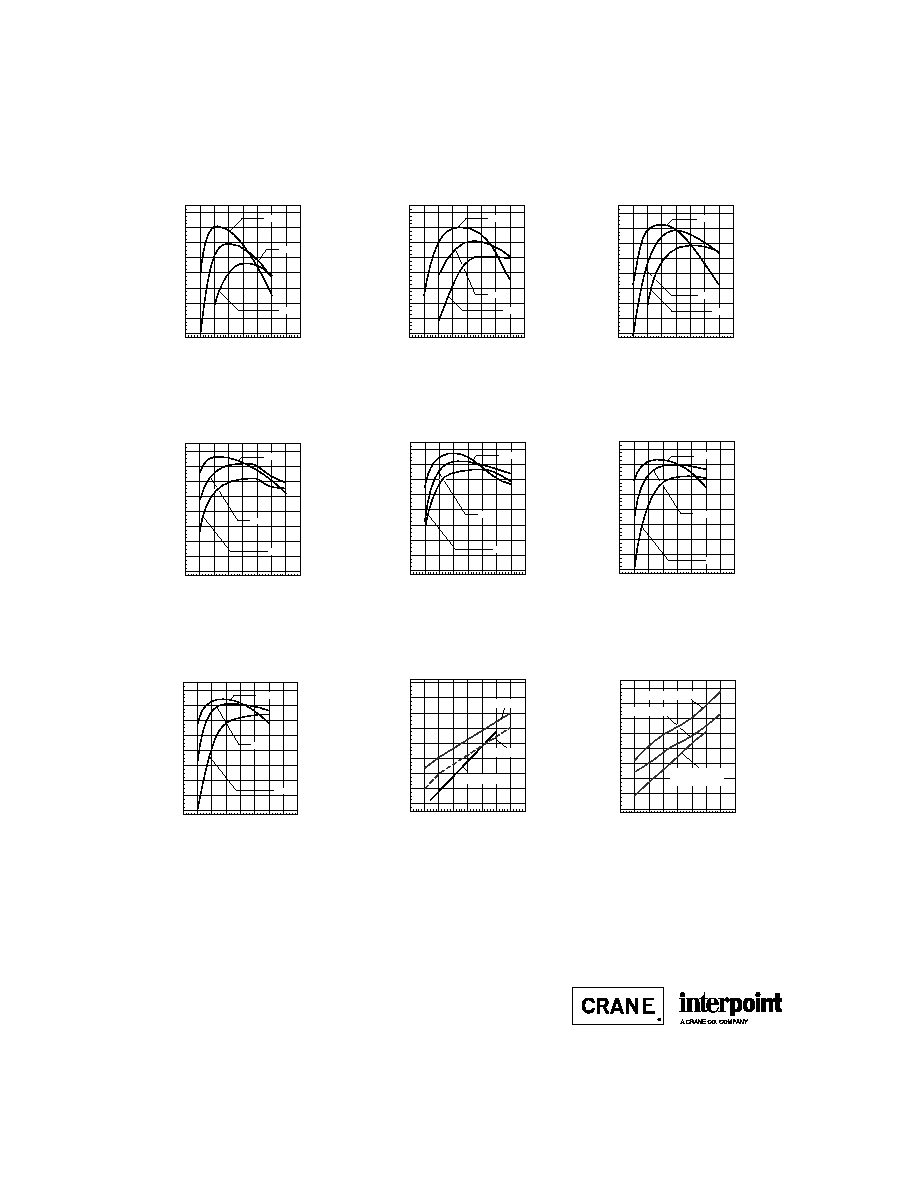

Typical Performance Curves: 25∞C Tc , 28 VDC Vin, 100% load, free run, unless otherwise specified.

F

IGURE

6

F

IGURE

8

OUTPUT POWER (WATTS)

HR702-2812

EFFICIENCY VS. LINE & LOAD

EFFICIENCY (%)

10

20

30

40

50

60

70

87

85

83

81

79

77

75

73

71

40 V

28 V

19 V

OUTPUT POWER (WATTS)

HR703-28512

EFFICIENCY VS. LINE & LOAD

EFFICIENCY (%)

10

20

30

40

50

60

70

87

85

83

81

79

77

75

73

71

40 V

28 V

19 V

OUTPUT POWER (WATTS)

HR701-2805

EFFICIENCY VS. LINE & LOAD

EFFICIENCY (%)

10

20

30

40

50

60

70

86

85

84

83

82

81

80

79

78

40 V

28 V

20 V

F

IGURE

3

OUTPUT POWER (WATTS)

HR701-2812

EFFICIENCY VS. LINE & LOAD

EFFICIENCY (%)

10

20

30

40

50

60

70

89

88

87

86

85

84

83

82

81

40 V

28 V

19 V

F

IGURE

4

OUTPUT POWER (WATTS)

HR702-2815

EFFICIENCY VS. LINE & LOAD

EFFICIENCY (%)

10

20

30

40

50

60

70

87

85

83

81

79

77

75

73

71

40 V

28 V

19 V

F

IGURE

7

F

IGURE

5

OUTPUT POWER (WATTS)

HR701-2815

EFFICIENCY VS. LINE & LOAD

EFFICIENCY (%)

10

20

30

40

50

60

70

89

88

87

86

85

84

83

82

81

40 V

28 V

19 V

OUTPUT POWER (WATTS)

HR703-28515

EFFICIENCY VS. LINE & LOAD

EFFICIENCY (%)

10

20

30

40

50

60

70

87

85

83

81

79

77

75

73

71

40 V

28 V

19 V

F

IGURE

9

OUTPUT POWER (WATTS)

LOW LINE DROPOUT VS

LOAD (50mV DROP)

INPUT VOLTAGE (VOLTS)

15

10

20

30

40

50

60

70

16

17

18

HR701-2815

HR701-2812

HR701-2815

F

IGURE

10

F

IGURE

11

OUTPUT POWER (WATTS)

LOW LINE DROPOUT VS LOAD

(50mV DROP)

INPUT VOLTAGE (VOLTS)

15

10

20

30

40

50

60

70

16

17

18

19

HR702-2815

HR702-2812

HR703-28512

HR703-28515

20621-009-DTS Rev A

DQ# 2008

All technical information is believed to be accurate, but no responsibility is assumed

for errors or omissions. Interpoint reserves the right to make changes in products

or specifications without notice. HR700 Series is a trademark of Interpoint.

Copyright © 1992 - 1999 Interpoint. All rights reserved.

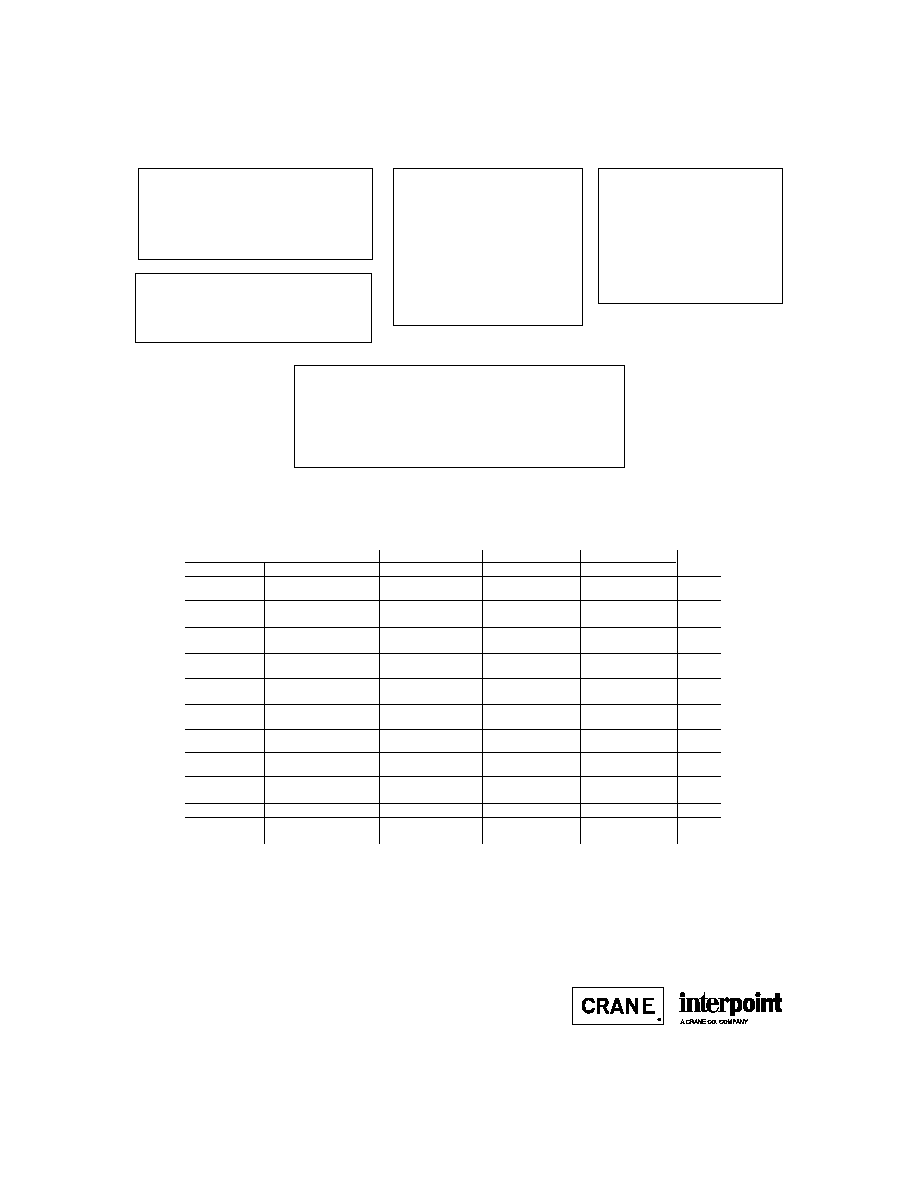

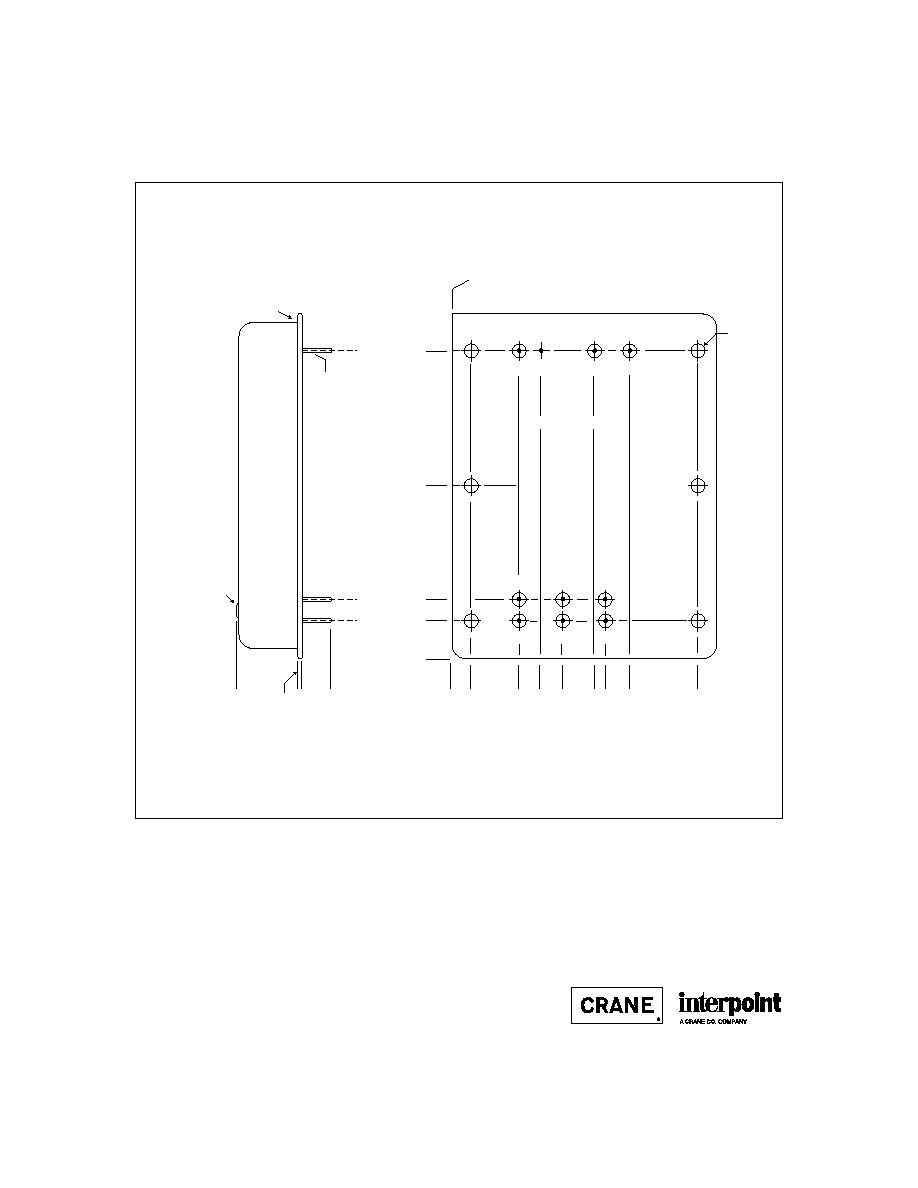

B8-31

CASE L

C

ASES

0.060 min

(1.52)

0.060 min

(1.52)

0.337 min

(8.56)

0.337 min

(8.56)

3.20 max (81.3)

2.46 max (62.5)

Materials

Header Cold Rolled Steel/Nickel/Tin

Cover

Cold Rolled Steel/Nickel/Tin

Pins

#52 alloy pins 1-4, and 9-10

#52 alloy with copper core pins 5-8

ceramic seal

Case dimensions in inches (mm)

Tolerance

±

0.005 (0.13) for three decimal places

±

0.01 (0.2) for two decimal places

unless otherwise specified

CAUTION

Heat from reflow or wave soldering may damage

the device. Solder pins individually with heat

application not exceeding 300

∞

C for 10 seconds

per pin.

Squared corner indicates pin one

CASE L

TOP VIEW

Cover Placement

and

Min/Max Dimensions

See Figure 50

for pin configuration

F

IGURE

49: C

ASE

L M

AXIMUM

D

IMENSIONS

B8-32

CASE L

C

ASES

Solder Seal

Solder Tip-off

2.850 (72.39)

0.550 (13.97)

1.600 (40.64)

0.350 (8.89)

0.000

0.00

0.000

0.180 (4.57)

0.040 +0.007/-0.000

(1.02 +0.18/-0.00)

0.595 max

(15.11)

0.250 +0.05/-0.00

(6.35 +1.3/-0.0)

0.625 (15.88)

0.825 (20.96)

1.025 (26.04)

1.325 (33.66)

1.425 (36.20)

1.625 (41.28)

2.280 (57.91)

.0.040 +0.005/-0.002

(1.02 +0.13/-0.05)

BOTTOM VIEW

1

2

3

4

5

6

7

8

9

10

Squared corner indicates pin one

MFW Series: Screening ≠ Standard or ES

HR700 Series: no screening options

CASE L

0.141 x 6

(3.58)

F

IGURE

50: C

ASE

L D

IMENSIONS

C2-13

QA SCREENING

HR PRODUCTS

HR P

RODUCTS

TEST (HR products)

STANDARD

PRE-CAP INSPECTION

Method 2017

yes

FINAL ELECTRICAL TEST MIL-PRF-38534, Group A

Subgroups 1 and 4: +25∞C case

yes

HERMETICITY TESTING

Gross Leak, Dip (1 x 10

-3

)

yes

FINAL VISUAL INSPECTION

Method 2009

yes

Test methods are referenced to MIL-STD-883 as determined by MIL-

PRF-38534.

HR700 Series

HR300 Series

HR150 Series

HR120 Series

HR40 Series

Applies to the following products: