| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: SLIM5050 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

B1-11

SLIM SERIES

50 - 250 WATT

L

INE

I

NTERFACE

M

ODULE

40

TO

80 VDC I

NPUT

50

OR

250 W

ATT

O

UTPUT

SLIM5050

Size (max.): Non flanged

1.460 x 1.130 x 0.330 (37.08 x 28.70 x 8.38 mm)

Flanged

2.005 x 1.130 x 0.330 (50.93 x 28.70 x 8.38 mm)

See Section B8, cases E1 and G1, for dimensions.

Weight:

30 grams typical

Screening:

Standard, Class H, or Class K (MIL-PRF-38534)

Radiation hardness levels O, L, and R

Section C2 for screening and radiation hardness

options, see Section A5 for ordering information.

F

EATURES

∑ Fully qualified to Class H or K

∑ Radiation hardened

∑ -55∞C to +125∞C operating temp

∑ 40 to 80 VDC input

∑ Fixed frequency, 550 kHz typical

∑ Topology ≠ Non-isolated buck

∑ 35 VDC input with lowered efficiency

∑ Up to 90 V for up to 120 ms

transient protection

∑ 35 VDC output

∑ Inhibit function

∑ Power readiness function

∑ Load fault/short circuit protection

∑ Up to 94% efficiency, 90 W/in

3

MODEL

THROUGHPUT POWER

MODEL

SLIM5050TM

SLIM50250TM

WATTS

50

250

DESCRIPTION

The SLIM50TM Series of line interface modules for space provide a

nominal output voltage of 35 VDC from input voltages of 45 to 75

VDC with efficiencies of 94% or higher. Sustained operation at volt-

ages as high at 80 or as low as 35 are possible with reduced effi-

ciency. The SLIM5050 module delivers 50 watts of output power

over the full military temperature range of ≠55∞C to +125∞C and fits

in a package of 1.460 x 1.130 x 0.330 inches (37.08 x 28.70 x 8.38

mm) maximum, resulting in a power density of over 91 watts/in

3

.

S

CREENING AND

R

EPORTS

The SLIM5050 module offers three screening options ≠ Standard,

Class H, or Class K ≠ and three levels of radiation hardness. See

Section C2, Quality Assurance, pages C2-7 through C2-9, for

descriptions. Detailed reports on product performance are also

available and are listed on page C2-9.

C

ONVERTER

D

ESIGN

The SLIM5050 modules are non-isolated converters operating at a

frequency between 500 kHz and 600 kHz. The control circuitry uses

average current mode control to achieve a wide bandwidth with little

or no overshoot over a wide range of loads. These converters are

specifically designed to accommodate loads with a negative imped-

ance such as those presented by Interpoint DC/DC converters with

a constant power consumption.

P

ARALLEL

O

PERATION

: U

P TO

10 M

ODULES

Up to 10 SLIM SeriesTM modules can be paralleled for increased

power. Current sharing is typically within 2%.

O

VERLOAD AND

C

URRENT

L

IMIT

Current overload protection is accomplished by monitoring the

output current resulting in a constant current mode when the load

exceeds approximately 125% of rated load at full output voltage.

When the overload condition forces the output voltage to drop the

maximum current delivered falls from approximately 1.9 amps to

less than 1.5 amps. This feature keeps the short circuit dissipation

low and forces the output voltage to collapse rapidly thereby

preventing operation in an abnormal condition. Combined with the

"Power Ready" signal (see below), this foldback of the output

current prevents power cycling of the downstream converters.

P

OWER

R

EADY

S

IGNAL

To avoid high current surges during power up, the interface module

has a signal intended to connect to the inhibit lines of Interpoint

converters to keep these converters turned off until the interface

module's output exceeds approximately 13 volts thereby assuring

that, in an overload condition, the converters powered by the inter-

face module will shut off before the power ready signal turns them

off. This feature prevents repeated limit cycling in an overload condi-

tion.

I

NHIBIT

The SLIM Series modules have an open collector TTL compatible

inhibit terminal that can be used to disable power conversion,

resulting in a very low quiescent input current and no generation of

switching noise.

Future offerings are planned for the SLIM Series of modules.

Please contact your Interpoint representative listed in Section

A5, for more details.

All technical information is believed to be accurate, but no responsibility is assumed for errors

or omissions. Interpoint reserves the right to make changes in products or specifications

without notice. SLIM Series, SLIM50, SLIM5050, and SLIM50250 are trademarks of Interpoint.

Copyright © 1999 Interpoint. All rights reserved.

B8-10

CASE E

C

ASES

CASE E

BOTTOM VIEW

See Figures 16 ≠ 18

for pin configurations.

Squared corner and dot on top

of case indicate pin one.

1.460 max

(37.08)

1.130 max

(28.70)

Materials

Header Cold Rolled Steel/Nickel/Gold

Cover Kovar/Nickel

(SMHF Series

Cold Rolled Steel/Nickel/Gold)

Pins #52

alloy/Gold

compression glass seal

Case dimensions in inches (mm)

Tolerance

±

0.005 (0.13) for three decimal places

±

0.01 (0.3) for two decimal places

unless otherwise specified

CAUTION

Heat from reflow or wave soldering may damage

the device. Solder pins individually with heat

application not exceeding 300

∞

C for 10 seconds

per pin.

0.000

0.205

(5.21)

0.505

(12.83)

0.705

(17.91)

0.905

(22.99)

1.105

(28.07)

0.330 max

(8.38)

0.000

0.25 (6.35)

0.000

0.160

(4.06)

0.960

(24.38)

1

2

3

4

5

0.030 dia.

(0.76)

8

7

6

MHF+ Series Single and Dual: Screening ≠ Standard, ES, or 883

MHF Series and LIM5050 Module: Screening ≠ Standard or ES

SMHF Series Single and Dual and SLIM5050 Module:

Screening ≠ Space Standard, H, or K

HR120 Series: No screening options

BOTTOM VIEW CASE E1

0.330 max

(8.38)

0.000

0.25 (6.35)

Projection Weld

Seam Seal

Squared corner and dot on top

of case indicate pin one.

F

IGURE

16: C

ASE

E1

F

IGURE

15: C

ASE

E M

AXIMUM

D

IMENSIONS

Note: Although every effort has been made to render the case drawings at actual size, variations in the printing process may cause some distortion. Please refer

to the numerical dimensions for accuracy.

B8-15

CASE G

C

ASES

Materials

Header Cold Rolled Steel/Nickel/Gold

Cover

MHF+ Series and FMH Filter

Kovar/Nickel

SMHF

Cold Rolled Steel/Nickel

Pins

#52 alloy (all cases)

compression glass seal

Case dimensions in inches (mm)

Tolerance

±

0.005 (0.13) for three decimal places

±

0.01 (0.2) for two decimal places

unless otherwise specified

CASE G

BOTTOM VIEW

Flanged package

See Figures 25 - 27

for pin configuration

2.005 max

(50.93)

1.130 max

(28.70)

Squared corner and dot on top

of case indicate pin one.

CAUTION

Heat from reflow or wave soldering may damage

the device. Solder pins individually with heat

application not exceeding 300

∞

C for 10 seconds

per pin.

Flange Thickness: 0.047 (1.19)

1.590 (40.39)

0.128 dia

(3.25)

0.030 dia.

(0.76)

Flanged cases: Designator required in Case Option position of model number

MHF+ Series Single and Dual, LIM5050 Module: Screening ≠ Standard, ES, or 883

SMHF Series, SLIM5050 Module: Screening ≠ Space Standard, H, or K

BOTTOM VIEW CASE G1

0.000

0.205 (5.21)

0.505 (12.83)

0.705 (17.91)

0.905 (22.99)

1.105 (28.07)

0.000

0.160

(4.06)

0.960

(24.38)

1

2

3

4

5

8

7

6

0.140 (3.56)

0.560

(14.22)

0.330 max.

(8.38)

0.000

0.25 (6.35)

0.330 max.

(8.38)

0.000

0.25 (6.35)

Squared corner and dot on top

of case indicate pin one.

Projection Weld

Seam Seal

F

IGURE

25: C

ASE

G1

F

IGURE

24: C

ASE

G M

AXIMUM

D

IMENSIONS

Note: Although every effort has been made to render the case drawings at actual size, variations in the printing process may cause some distortion. Please refer

to the numerical dimensions for accuracy.

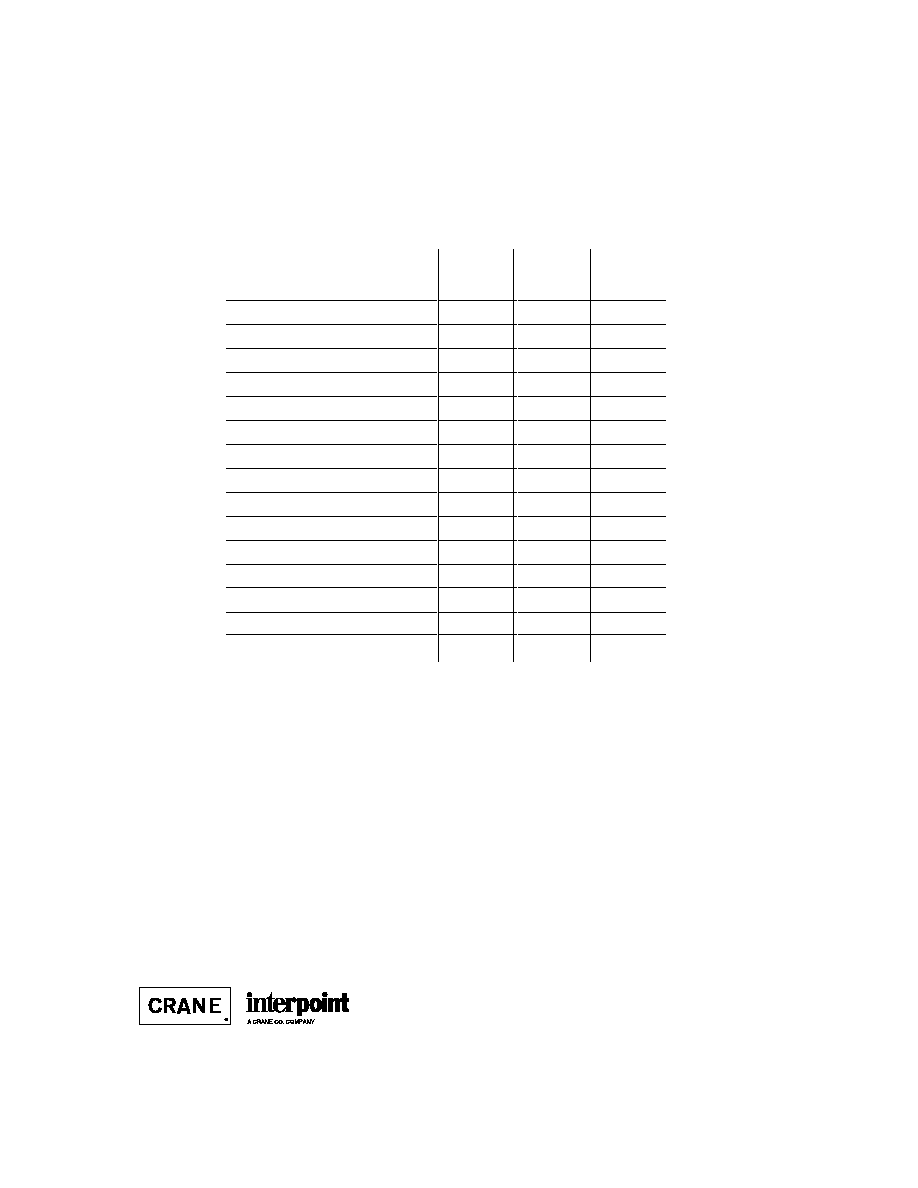

C2-7

QA SCREENING

SPACE PRODUCTS

S

PACE

P

RODUCTS

E

LEMENT

E

VALUATION

S

TANDARD

C

LASS

C

LASS

T

EST

P

ERFORMED

(O)

H

K

(

COMPONENT LEVEL

)

M/S

P

M/S

P

M/S

P

Element Electrical

yes

no

yes

yes

yes

yes

Element Visual

no

no

yes

yes

yes

yes

Internal Visual

no

no

yes

no

yes

no

Temperature Cycling

no

no

no

no

yes

yes

Constant Acceleration

no

no

no

no

yes

yes

Interim Electrical

no

no

no

no

yes

no

Burn-in

no

no

no

no

yes

no

Post Burn-in Electrical

no

no

no

no

yes

no

Steady State Life

no

no

no

no

yes

no

Voltage Conditioning /Aging

no

no

no

no

no

yes

Visual Inspection

no

no

no

no

no

yes

Final Electrical

no

no

yes

yes

yes

yes

Wire Bond Evaluation

*

no

no

yes

yes

yes

yes

SEM

no

no

no

no

yes

no

SLAMTM/C-SAM:

Input capacitors only

no

no

no

yes

no

yes

(Add'l test, not req. by H or K)

Definitions

Element Evaluation: Component testing/screening per MIL-STD-883 as determined by MIL-PRF-38534

SEM: Scanning Electron Microscopy

SLAMTM: Scanning Laser Acoustic Microscopy

C-SAM: C - Mode Scanning Acoustic Microscopy

Notes

M/S

Active components (Microcircuit and Semiconductor Die)

P

Passive components

*

Not applicable to EMI filters that have no wirebonds

SMFLHP Series

SMFL Series

SMHP Series (O&H only)

SMTR Series

SSP Series

SMHF Series

SMSA Series

SLH Series

SLIM Module

SFME120 EMI Filter

SFME28 EMI Filter

SFCS EMI Filter

SFMC EMI Filter

STF EMI Filter

Applies to the following products:

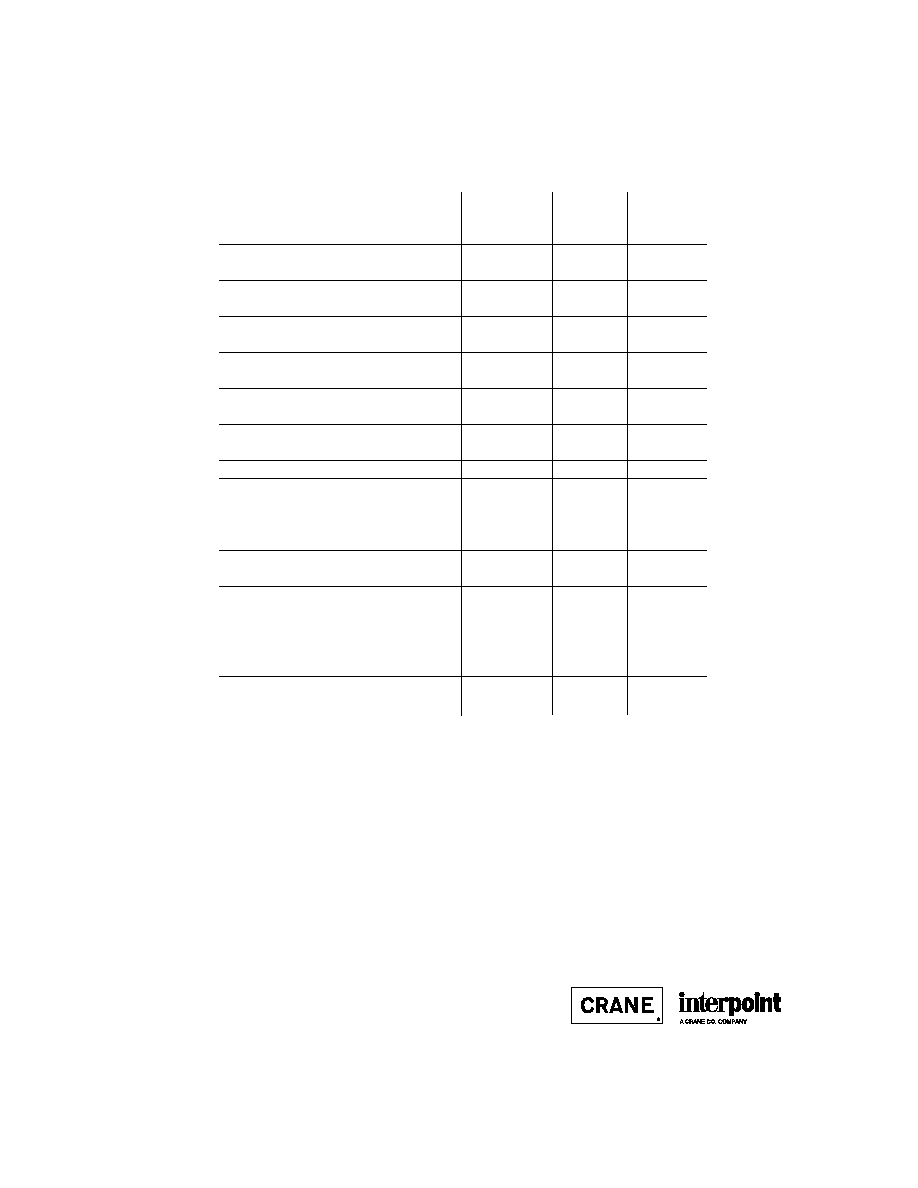

C2-8

QA SCREENING

SPACE PRODUCTS

E

NVIRONMENTAL

S

CREENING

T

EST

P

ERFORMED

S

TANDARD

C

LASS

C

LASS

(

END ITEM LEVEL

)

(O)

H

K

Non-destruct bond pull*

Method 2023

no

no

yes

Pre-cap inspection

Method 2017, 2032

yes

yes

yes

Temperature cycle

Method 1010, Cond. C

yes

yes

yes

Constant acceleration

Method 2001, 3000 g

yes

yes

yes

PIND Test

Method 2020, Cond. B

no

no

yes

Radiography

Method 2012

no

no

yes

Pre burn-in test

yes

yes

yes

Burn-in, Method 1015, 125∞C

96 hours

yes

no

no

160 hours

no

yes

no

2 x 160 hour (includes mid BI test)

no

no

yes

Final electrical test

MIL-PRF-38534, Group A

yes

yes

yes

Hermeticity test

Fine Leak,

Method 1014, Cond. A

yes

yes

yes

Gross Leak,

Method 1014, Cond. C

yes

yes

yes

Final visual inspection

Method 2009

yes

yes

yes

Test methods are referenced to MIL-STD-883 as determined by MIL-PRF-38534.

Note

* Not applicable to EMI filters that have no wirebonds.

SMFLHP Series

SMFL Series

SMHP Series (O&H only)

SMTR Series

SSP Series

SMHF Series

SMSA Series

SLH Series

SLIM Module

SFME120 EMI Filter

SFME28 EMI Filter

SFCS EMI Filter

SFMC EMI Filter

STF EMI Filter

Applies to the following products:

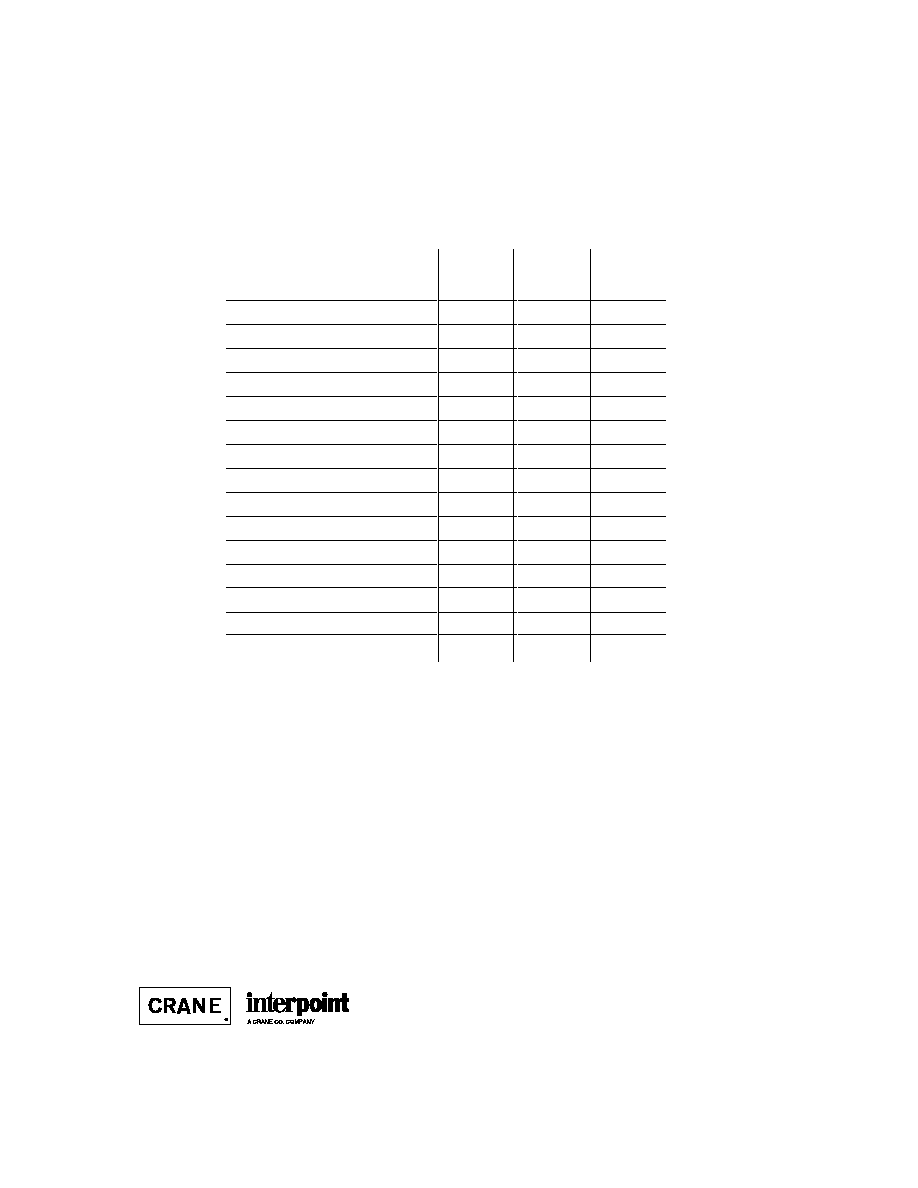

C2-9

QA SCREENING

SPACE PRODUCTS

PRODUCT LEVEL AVAILABILITY

ENVIRONMENTAL SCREENING LEVELS

STANDARD CLASS

CLASS

RADIATION HARDNESS LEVELS

(O)

H

K

O: Standard, no radiation guarantee

For system evaluation, electrically

OO

HO

Not

and mechanically comparable to

available

H and K level.

L: Radiation hardened ≠ Tested lots

Not

Up to 50 k Rads (Si) total dose

available

HL

KL

No SEU guarantee

R: Radiation hardened ≠ Tested lots

Not

Up to 100 k Rads (Si) total dose

available

HR

KR

SEU guarantee up to 40 MeV

R

EPORTS

: I

NCLUDED WITH PURCHASE OF PRODUCT

HL, KL, HR, or KR

1.Radiation Susceptibility Analysis

2.Electrical/Thermal Stress Analysis and Derating Report

3.MTBF Report

4.FMEA Report

OO option: Select reports available as separate purchases.

R

ADIATION

H

ARDNESS

L

EVELS

FOR

DC/DC C

ONVERTERS AND

L

INE

I

NPUT

M

ODULES1

Note

1. Interpoint's EMI filters are designed exclusively with passive components providing

maximum tolerance for space environment requirements.

SMFLHP Series (levels O and L only)

SMFL Series (levels O and L only)

SMTR Series

SSP Series

SMHF Series

SMSA Series

SLH Series

SLIM Series Modules

Applies to the following products:

L and R are referenced to MIL-PRF-38534, appendix G, Radiation Hardness

Assurance (RHA) levels.