| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: EL6202 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1

Æ

FN7217.1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

|

Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2003-2004. All Rights Reserved. Elantec is a registered trademark of Elantec Semiconductor, Inc.

All other trademarks mentioned are the property of their respective owners.

EL6202

Laser Driver Oscillator

The EL6202 consists of a variable

amplitude, push only, oscillator that

also supplies the laser DC current. It is

designed to easily interface to existing ROM controllers,

reducing parts count, and power dissipation.

The reduction of parts count and the small package allows

the oscillator to be placed closer to the laser, thus reducing

EMI. Also, the turn-on and turn-off edges are slew rate

limited to reduce higher harmonics.

The total current drawn from the power supply can be less

than the laser threshold current due to the unique push-only

modulation method. The average current is less than the

peak oscillator current, and can be less than half of the

oscillator current. The power control current supplied from

the main board is reduced to less than 2mA.

One external resistor sets the oscillator frequency. A current

applied to the I

IN

terminal determines the amplitude of the

oscillator and laser DC current. If the oscillator amplitude is

set very low, the output and oscillator are disabled. The part

is available in the space-saving SOT23-5 package. It is

specified for operation from 0∞C to +70∞C.

Pinout

EL6202

(5-PIN SOT-23)

TOP VIEW

Features

∑ Low power dissipation

∑ Reduced parts count from the conventional solution

∑ User-selectable frequency from 60MHz to 600MHz

controlled with a single resistor

∑ User-selectable amplitude from 15mA

PK-PK

to

100mA

PK-PK

controlled by 0.3mA to 2mA input current

∑ Auto turn-off threshold

∑ Soft edges for reduced EMI

∑ Small SOT23-5 package

Applications

∑ DVD players

∑ DVD-ROM drives

∑ Combo drives

∑ MO drives

∑ General purpose laser noise reduction

∑ Local oscillator capability

1

2

3

5

4

VDD

RFREQ

GND

IOUT

IIN

Ordering Information

PART NUMBER

PACKAGE

TAPE & REEL PKG. DWG. #

EL6202CW-T7

5-Pin SOT-23

7" (3K pcs)

MDP0038

EL6202CW-T7A

5-Pin SOT-23

7" (250 pcs)

MDP0038

Data Sheet

June 11, 2004

2

Absolute Maximum Ratings

(T

A

= 25∞C)

Voltages Applied to:

V

DD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to +6.0V

I

OUT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to +6.0V

R

FREQ

, I

IN

. . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to +6.0V

Operating Ambient Temperature . . . . . . . . . . . . . . . . . 0∞C to +70∞C

Maximum Die Operating Temperature . . . . . . . . . . . . . . . . . . +150∞C

Storage Temperature Range . . . . . . . . . . . . . . . . . . -65∞C to +150∞C

Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100mA

PK-PK

Power Dissipation (max) . . . . . . . . . . . . . . . . . . . . . . . . See Curves

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

IMPORTANT NOTE: All parameters having Min/Max specifications are guaranteed. Typical values are for information purposes only. Unless otherwise noted, all tests

are at the specified temperature and are pulsed tests, therefore: T

J

= T

C

= T

A

Supply & Reference Voltage Characteristics

V

DD

= +5V, T

A

= 25∞C, R

L

= 10

, R

FREQ

= 5210

(F

OSC

= 350MHz), I

IN

= 1mA

(I

OUT

= 50mA

P-P

measured at 60MHz), V

OUT

= 2.2V

PARAMETER

DESCRIPTION

CONDITIONS

MIN

TYP

MAX

UNIT

PSOR

Power Supply Operating Range

4.5

5.5

V

I

SO

Supply Current Disabled

I

IN

100µA

550

750

µA

I

STYP

Supply Current Typical Conditions

R

FREQ

= 5.21k

(includes laser current)

25

30

35

mA

I

SLO

Supply Current Low Conditions

R

FREQ

= 30.5k

, I

IN

= 300µA (includes laser

current)

10

mA

I

SHI

Supply Current High Conditions

R

FREQ

= 3.05k

,

I

IN

= 2mA (includes laser current)

53

mA

V

FREQ

Voltage at R

FREQ

Pin

1.27

V

R

IN

Input Impedance

500

Oscillator Characteristics

V

DD

= +5V, T

A

= 25∞C, R

L

= 10

, R

FREQ

= 5210

(F

OSC

= 350MHz), I

IN

= 1mA (I

OUT

= 50mA

P-P

measured

at 60MHz), V

OUT

= 2.2V

PARAMETER

DESCRIPTION

CONDITIONS

MIN

TYP

MAX

UNIT

F

OSC

Frequency Tolerance

Unit-unit frequency variation

300

350

400

MHz

F

HIGH

Frequency Range High

R

FREQ

= 3.05k

600

MHz

F

LOW

Frequency Range Low

R

FREQ

= 30.5k

60

MHz

TC

OSC

Frequency Temperature Sensitivity

0∞C to 70∞C ambient

50

ppm/∞C

PSRR

OSC

Frequency Change

F/F

V

DD

from 4.5V to 5.5V

1

%

Driver Characteristics

V

DD

= +5V, T

A

= 25∞C, R

L

= 10

, R

FREQ

= 30.5k

(F

OSC

= 60MHz), I

IN

= 1mA (I

OUT

= 50mA

P-P

measured at

60MHz), V

OUT

= 2.2V

PARAMETER

DESCRIPTION

CONDITIONS

MIN

TYP

MAX

UNIT

AMP

HIGH

Amplitude Range High

I

IN

= 2mA

100

mA

P-P

AMP

LOW

Amplitude Range Low

I

IN

= 300µA

15

mA

P-P

I

AVG

Average Output Current @ 2.2V

R

FREQ

= 5210

19

mA

I

OUTP-P

Output Current Tolerance

Defined as one standard deviation

2

%

Duty Cycle

Output Push Time/Cycle Time

R

FREQ

= 5210

43

%

PSRR

AMP

Amplitude Change of Output

I/I

VDD from 4.5V to 5.5V

-54

dB

T

ON

Auto Turn-on Time

Input current step from 0mA to 1mA

15

µs

T

OFF

Auto Turn-off Time

Input current step from 1mA to 0mA

0.5

µs

IN

OUT

I

OUT

Current Output Noise Density

R

FREQ

= 5490

,

F

MEASURE

= 10MHz

2.5

nA/

Hz

EL6202

3

Control Table

I

IN

I

OUT

100µA

OFF

300µA

Normal Operation

Pin Descriptions

PIN NUMBER

PIN NAME

PIN DESCRIPTION

1

VDD

Positive power for chip and laser driver (3.3V - 5V)

2

GND

Chip ground pin (0V)

3

IOUT

Current output to laser anode

4

IIN

Set pin for output current amplitude

5

RFREQ

Set pin for oscillator frequency

Recommended Operating Conditions

V

DD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5V ±10%

V

OUT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2V-3V

R

FREQ

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3k

(min)

I

IN

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2mA (max)

F

OSC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60-600MHz

I

OUT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-100mA

PK-PK

EL6202

4

Typical Performance Curves

V

DD

= 5V, T

A

= 25∞C, R

L

= 10

, R

FREQ

= 5.21k

, I

IN

= 1mA, V

OUT

= 2.2V unless otherwise specified.

FIGURE 1. FREQUENCY DISTRIBUTION

FIGURE 2. FREQUENCY DRIFT WITH TEMPERATURE

FIGURE 3. FREQUENCY vs R

FREQ

FIGURE 4. FREQUENCY vs 1/R

FREQ

FIGURE 5. AMPLITUDE vs I

IN

FIGURE 6. FREQUENCY vs SUPPLY VOLTAGE

NU

MBER O

F

P

A

R

T

S

0

100

500

FREQUENCY (MHz)

310

318

334

350

366

326

342

358

200

300

400

374

382

390

Typical

Production

Distortion

NU

MBER O

F

P

A

R

T

S

0

1

8

FREQUENCY TC (ppm/∞C)

6

30

54

18

42

3

5

7

66

78

90

Measured from

-40∞C to +85∞C

2

4

6

FREQ

U

E

NC

Y (M

Hz)

0

200

400

500

600

700

R

FREQ

(k

)

0

5

15

25

35

10

20

30

100

300

Frequency=1824 * 1k

/ R

FREQ

(MHz)

FREQ

U

E

NC

Y (M

Hz)

0

200

400

500

600

700

1k

/ R

FREQ

0

0.05

0.15

0.25

0.35

0.1

0.2

0.3

100

300

Frequency=1824 * 1k

/ R

FREQ

(MHz)

AM

PLITUD

E (mA

PK-PK

)

0

20

40

60

80

100

I

IN

(mA)

0

1

2

Amplitude = 50 * I

IN

FREQ

UEN

C

Y (

M

Hz)

340

345

355

360

SUPPLY VOLTAGE (V)

4.4

4.6

4.8

5.2

5.6

5

5.4

350

EL6202

5

Block Diagram

FIGURE 7. FREQUENCY vs TEMPERATURE

Typical Performance Curves

V

DD

= 5V, T

A

= 25∞C, R

L

= 10

, R

FREQ

= 5.21k

, I

IN

= 1mA, V

OUT

= 2.2V unless otherwise specified.

FREQ

UEN

C

Y (M

Hz)

300

320

380

400

AMBIENT TEMPERATURE (∞C)

-50

0

150

50

100

340

360

1

3

6

4

BANDGAP

REFERENCE

DRIVER

AUTO

SHUT-OFF

OSCILLATOR

V

DD

I

OUT

R

FREQ

IN

2

GND

EL6202

6

Typical Application Circuit

Applications Information

Product Description

The EL6202 is a solid state, low-power, high-speed laser

modulation oscillator with external resistor-adjustable

operating frequency. It is designed to interface easily to laser

diodes to break up optical feedback resonant modes and

thereby reduce laser noise. The output of the EL6202 is

composed of a push current source switched at the oscillator

frequency. The output and oscillator are automatically

disabled for power saving when the average input current

drops to less than 100µA. The EL6202 has the operating

frequency from 60MHz to 600MHz and the output current

from 10mA

P-P

to 100mA

P-P

. The supply current is only

30mA (includes laser current) for the output current of

50mA

P-P

at the operating frequency of 350MHz.

1

2

3

5

4

VDD1

RFREQ

GND

IOUT

IIN

CONTROLLER

LOOP

COMPENSATION-

NOISE

REDUCTION

CAPACITOR

FREQUENCY

SETTING

RESISTOR

EMI

REDUCTION

SUPPLY

FILTER

GAIN

SETTING

RESISTOR

TYPICAL

ROM LASER

DRIVER

LASER DIODE

PHOTO DIODE

BEAD

+5V

FLEX

GND

0.1µF

4.7µF

EMI

BLOCKING

RESISTOR

Either the high current controller resistor can be

reduced to 2mA full scale, or the transistor and resistor

can be replaced with a resistor from the controller DAC.

DAC

LASER OUTPUT

POWER

LASER CURRENT

0mW

~10mW

0mA

~60mA

OSCILLATOR CURRENT

LASER OUTPUT POWER

THRESHOLD

CURRENT

optional

EL6202

7

Theory of Operation

A typical semiconductor laser will emit a small amount of

incoherent light at low values of forward laser current. But

after the threshold current is reached, the laser will emit

coherent light. Further increases in the forward current will

cause rapid increases in laser output power. A typical

threshold current is 35mA and a typical slope efficiency is

0.7mW/mA.

When the laser is lasing, it will often change its mode of

operation slightly, due to changes in current, temperature, or

optical feedback into the laser. In a DVD-ROM, the optical

feedback from the moving disk forms a significant noise

factor due to feedback-induced mode hopping. In addition to

the mode hopping noise, a diode laser will roughly have a

constant noise level regardless of the power level when a

threshold current is exceeded.

The oscillator is designed to produce a low noise oscillating

current that is provided to the laser diode. The current is to

cause the laser power to change at the oscillator frequency.

This change causes the laser to go through rapid mode

hopping. The low frequency component of laser power noise

due to mode hopping is translated up to sidebands around

the oscillator frequency by this action. Since the oscillator

frequency can be filtered out of the low frequency read and

serve channels, the net result is that the laser noise seems

to be reduced. The second source of laser noise reduction is

caused by the increase in the laser power above the average

laser power during the pushing-current time. The signal-to-

noise ratio (SNR) of the output power is better at higher laser

powers because of the almost constant noise power when a

threshold current is exceeded. In addition, when the laser is

off during no output current time, the noise is also very low.

Setting the I

IN

Current

By looking the typical application circuit, it can be seen that

the push only oscillator is more efficient at the laser than the

conventional push-pull oscillator. The significant current from

the main board is reduced to be I

IN

(

2mA), while the

oscillator takes on the role of supplying the total laser

current.

The I

IN

current is the previous read current (reduced in

amplitude). Thus it does not need to be set, since it is within

the control loop. The current capability of the external source

for I

IN

should be made large enough to power the worst,

hottest old laser.

R

FREQ

Pin Interfacing

Figure 8 shows an equivalent circuit of pins associated with

the R

FREQ

resistor. V

REF

is roughly 1.27V. The resistor

R

FREQ

should be connected to the non-load side of the

power ground to avoid noise. This resistor should also return

to the EL6202's ground very directly to prevent noise pickup.

They also should have minimal capacitance to ground.

Trimmer resistors can be used to adjust initial operating

points.

External voltage sources can be coupled to the R

FREQ

pin

to effect frequency modulation or adjustment. It is

recommended that a coupling resistor be installed in series

with the control voltage and mounted directly next to the pin.

This will keep the inevitable high-frequency noise of the

EL6202's local environment from propagating to the

modulation source, and it will keep parasitic capacitance at

the pin minimized.

Supply Bypassing and Grounding

The resistance of bypass-capacitors and the inductance of

bonding wires prevent perfect bypass action, and 150mV

P-P

noise on the power lines is common. There needs to be a

lossy series bead inductance and secondary bypass on the

supply side to control signals from propagating down the

wires. Figure 9 shows the typical connection.

Also important is circuit-board layout. At the EL6202's

operating frequencies, even the ground plane is not low-

impedance. High frequency current will create voltage drops

in the ground plane. Figure 10 shows the output current loop.

-

+

PIN

V

REF

FIGURE 8. R

FREQ

PIN INTERFACE

FIGURE 9. RECOMMENDED SUPPLY BYPASSING

+5V

V

S

L Series: 70

reactance at

300MHz (see text)

0.1µF

Chip

EL6202

GND

0.1µF

Chip

FIGURE 10. OUTPUT CURRENT LOOP

SOURCING CURRENT LOOP

SUPPLY

BYPASS

LOAD

R

FREQ

R

AMP

GND

(8-PIN

PACKAGE)

EL6202

8

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation's quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

For the current loop, the current flows through the supply

bypass-capacitor. The ground end of the bypass thus should

be connected directly to the EL6202 ground pin and laser

ground. A long ground return path will cause the bypass

capacitor currents to generate voltage drops in the ground

plane of the circuit board, and other components (such as

R

FREQ

) will pick this up as an interfering signal. Similarly,

the ground return of the load should be considered, as noisy

and other grounded components should not connect to this

path. Slotting the ground plane around the load's return will

reduce adjacent grounded components from seeing the

noise.

Power Dissipation

It is important to calculate the maximum junction

temperature for the application to determine if the conditions

need to be modified for the oscillator to remain in the safe

operating area.

The maximum power dissipation allowed in a package is

determined according to:

where:

P

DMAX

= Maximum power dissipation in the package

T

JMAX

= Maximum junction temperature

T

AMAX

= Maximum ambient temperature

JA

= Thermal resistance of the package

The supply current of the EL6202 depends on the peak-to-

peak output current and the operating frequency which is

determined by resistor R

FREQ

. The supply current can be

predicted approximately by the following equations:

The power dissipation can be calculated from the following

equation:

Here, V

SUP

is the supply voltage and V

LAS

is the average

voltage of the laser diode. Figure 11 provides a convenient

way to see if the device may overheat. The maximum safe

power dissipation can be found graphically, based on the

ambient temperature and JEDEC standard single layer PCB.

For flex circuits, the

JA

could be higher. By using the

previous equation, it is possible to estimate if P

D

exceeds

the device's power derating curve. To ensure proper

operation, it is important to observe the recommended

derating curve shown in Figure 12.

P

DMAX

T

JMAX

- T

AMAX

JA

---------------------------------------------

=

I

SUP1

35mA

1k

◊

R

FREQ

----------------------------------

0.5mA

+

=

I

SUP2

50

I

IN

0.5

◊

◊

=

P

D

V

SUP

I

SUP1

V

(

SUP

- V

LAS

)

I

SUP2

◊

+

◊

=

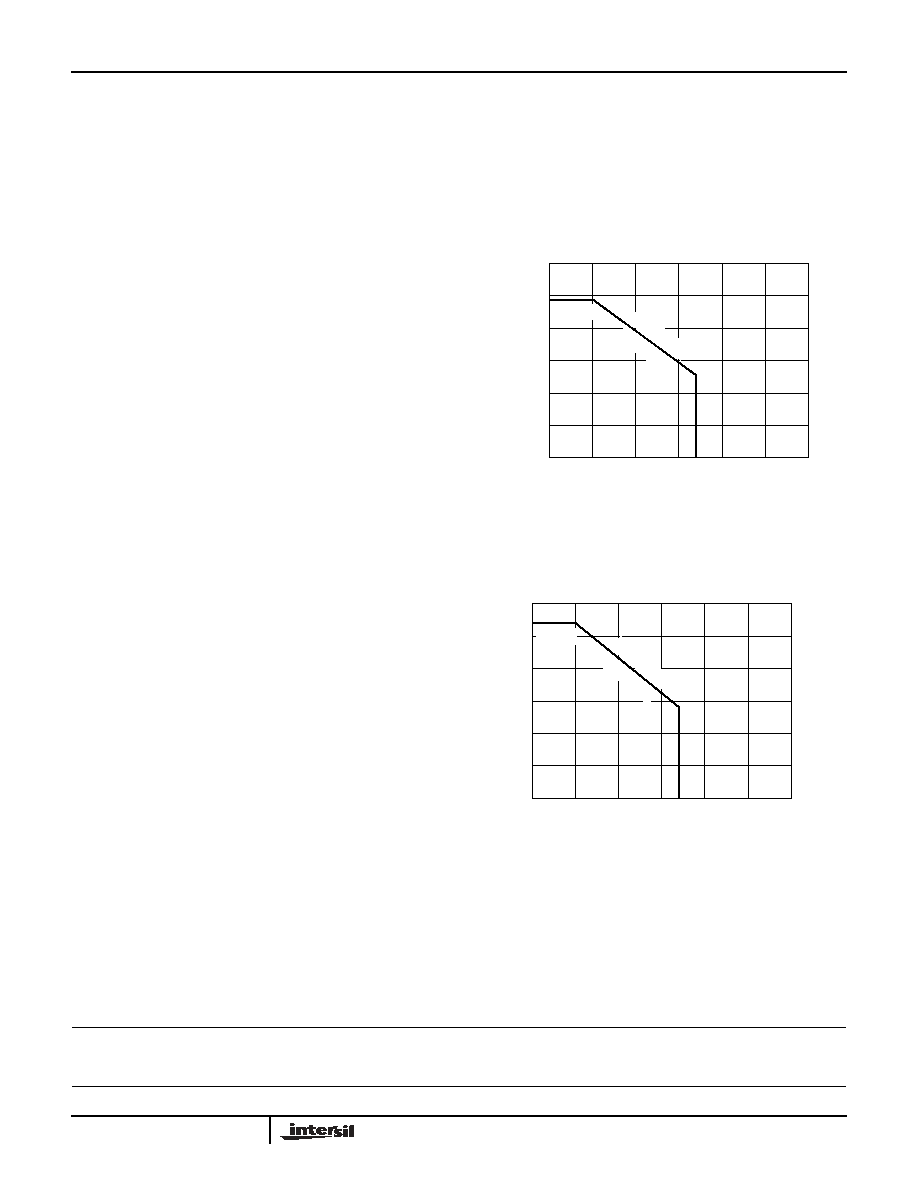

FIGURE 11. PACKAGE POWER DISSIPATION vs

AMBIENT TEMPERATURE

0.6

0.5

0.4

0.3

0.2

0.1

0

0

25

50

75

100

125

150

AMBIENT TEMPERATURE (∞C)

PO

WER DISSIP

A

T

I

O

N (W

)

85

JEDEC JESD51-3 LOW EFFECTIVE THERMAL

CONDUCTIVITY TEST BOARD

488mW

5-P

in S

OT

-23

JA =

25

6∞C

/W

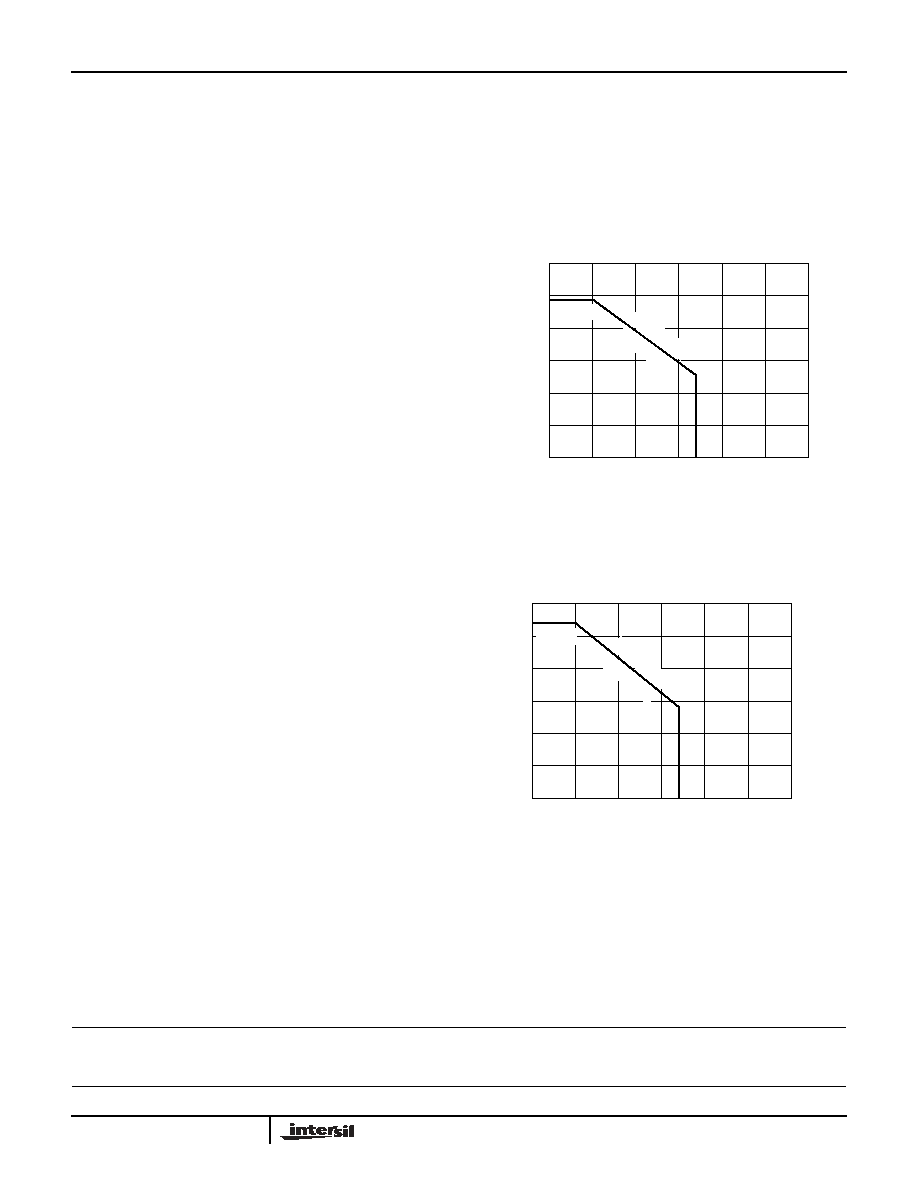

FIGURE 12. PACKAGE POWER DISSIPATION vs

AMBIENT TEMPERATURE

0.6

0.5

0.4

0.3

0.2

0.1

0

0

25

50

75

100

125

150

AMBIENT TEMPERATURE (∞C)

P

O

WE

R DISS

IP

A

T

ION (W

)

85

543mW

5-P

in

S

O

T-2

3

JA =

23

0∞C

/W

JEDEC JESD51-7 HIGH EFFECTIVE THERMAL

CONDUCTIVITY TEST BOARD

EL6202