| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: 208CNQ060 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

I

F(AV)

Rectangular

200

A

waveform

V

RRM

range

60

V

I

FSM

@ tp = 5 µs sine

16,000

A

V

F

@

100Apk, T

J

=125∞C

0.59

V

(per leg)

T

J

range

- 55 to 150

∞C

Characteristics

208CNQ... Units

Major Ratings and Characteristics

The 208CNQ center tap Schottky rectifier module series has

been optimized for low reverse leakage at high temperature.

The proprietary barrier technology allows for reliable opera-

tion up to 150 ∞C junction temperature. Typical applications

are in high current switching power supplies, plating power

supplies, UPS systems, converters, free-wheeling diodes,

welding, and reverse battery protection.

150 ∞C T

J

operation

Center tap module

High purity, high temperature epoxy encapsulation for

enhanced mechanical strength and moisture resistance

Low forward voltage drop

High frequency operation

Guard ring for enhanced ruggedness and long term

reliability

Description/Features

TO-244AB

SCHOTTKY RECTIFIER

200 Amp

208CNQ060

Bulletin PD-20743 rev. A 07/01

BASE

ANODE 2

63.50 [2.500]

60.96 [2.400]

23.55 [.927]

20.42 [.804]

14.99 [.590]

15.75 [.620]

20.32 [.800]

17.78 [.700]

39.75 [1.565]

40.26 [1.585]

80.01 [3.150]

34.925 [1.375]

3.35 [.132]

3.02 [.119]

90.17 [3.550]

92.71 [3.650]

7.49 [.295]

6.99 [.275]

2X ÿ

10.41 [.410]

9.65 [.380]

ÿ

4.70 [.185]

4.95 [.195]

1/4-20 SLOTTED HEX

COMMON

CATHODE

REF.

TERMINAL

LUG

COMMON CATHODE

ANODE 1

TERMINAL

LUG

ÿ

NOTES:

1. DIMENSIONS ARE SHOWN IN MILLIMETERS [INCHES].

2. CONTROLLING DIMENSION: MILLIMETER

Modified JEDEC

Outline TO-244AB

Dimensions in millimeters and (inches)

1

www.irf.com

208CNQ060

2

Bulletin PD-20743 rev. A 07/01

www.irf.com

V

FM

Max. Forward Voltage Drop

0.68

V

@ 100A

(Per Leg) * See Fig. 1

(1)

0.83

V

@ 200A

0.59

V

@ 100A

0.75

V

@ 200A

I

RM

Max. Reverse Leakage Current

1.1

mA

T

J

= 25 ∞C

(Per Leg) * See Fig. 2

(1)

300

mA

T

J

= 125 ∞C

V

F(TO)

Threshold Voltage

0.32

V

T

J

= T

J

max.

r

t

Forward Slope Resistance

2.1

m

C

T

Max. Junction Capacitance (Per Leg)

6000

pF

V

R

= 5V

DC

, (test signal range 100Khz to 1Mhz) 25∞C

L

S

Typical Series Inductance (Per Leg)

7.0

nH

From top of terminal hole to mounting plane

dv/dt Max. Voltage Rate of Change

10000

V/ µs

(Rated V

R

)

I

F(AV)

Max. Average Forward

(Per Leg)

100

A

50% duty cycle @ T

C

= 115 ∞C, rectangular wave form

Current * See Fig. 5

(Per Device)

200

I

FSM

Max. Peak One Cycle Non-Repetitive

16,000

5µs Sine or 3µs Rect. pulse

Surge Current (Per Leg) * See Fig. 7

2,100

10ms Sine or 6ms Rect. pulse

E

AS

Non-Repetitive Avalanche Energy

15

mJ

T

J

= 25 ∞C, I

AS

= 1 Amps, L = 30 mH

(Per Leg)

I

AR

Repetitive Avalanche Current

1

A

Current decaying linearly to zero in 1 µsec

(Per Leg)

Frequency limited by T

J

max. V

A

= 1.5 x V

R

typical

Part number

208CNQ060

V

R

Max. DC Reverse Voltage (V)

V

RWM

Max. Working Peak Reverse Voltage (V)

60

Voltage Ratings

Absolute Maximum Ratings

Following any rated

load condition and with

rated V

RRM

applied

A

Parameters

208CNQ Units Conditions

T

J

= 25 ∞C

T

J

= 125 ∞C

V

R

= rated V

R

Electrical Specifications

(1) Pulse Width < 300µs, Duty Cycle <2%

T

J

Max. Junction Temperature Range

-55 to 150

∞C

T

stg

Max. Storage Temperature Range

-55 to 150

∞C

R

thJC

Max. Thermal Resistance Junction

0.40

∞C/W DC operation

* See Fig. 4

to Case (Per Leg)

R

thJC

Max. Thermal Resistance Junction

0.20

∞C/W DC operation

to Case (Per Package)

R

thCS

Typical Thermal Resistance, Case

0.10

∞C/W Mounting surface , smooth and greased

to Heatsink

wt

Approximate Weight

79 (2.80)

g (oz.)

T

Mounting Torque

Min.

24 (20)

Max.

35 (30)

Mounting Torque Center Hole Typ.

13.5 (12)

Terminal Torque

Min.

35 (30)

Max.

46 (40)

Case Style

TO - 244AB

Modified JEDEC

Thermal-Mechanical Specifications

Kg-cm

(Ibf-in)

Parameters

208CNQ Units Conditions

Parameters

208CNQ Units Conditions

208CNQ060

3

Bulletin PD-20743 rev. A 07/01

www.irf.com

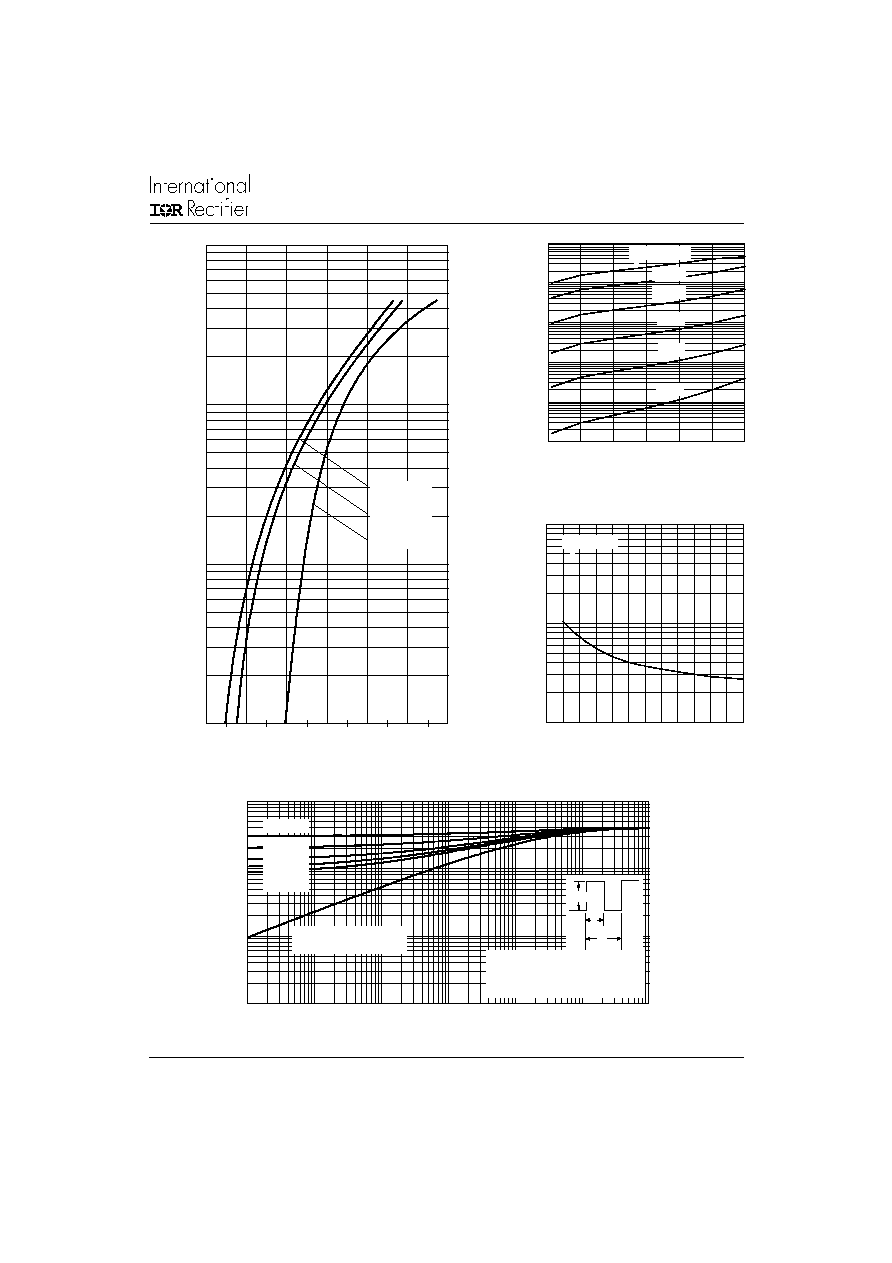

Fig. 4 - Max. Thermal Impedance Z

thJC

Characteristics (Per Leg)

Fig. 1 - Max. Forward Voltage Drop Characteristics

Forward Voltage Drop - V

FM

(V)

Instantaneous Forward Current - I

F

(A)

Reverse Current - I

R

(mA)

Reverse Voltage - V

R

(V)

Reverse Voltage - V

R

(V)

Junction Capacitance - C

T

(pF)

t

1

, Rectangular Pulse Duration (Seconds)

Thermal Impedance Z

thJC

(∞C/W)

Fig. 3 - Typical Junction Capacitance

Vs. Reverse Voltage

Fig. 2 - Typical Values Of Reverse Current

Vs. Reverse Voltage

1

10

100

1000

0

0.2

0.4

0.6

0.8

1

1.2

T = 150∞C

T = 125∞C

T = 25∞C

J

J

J

0.01

0.1

1

10

100

1000

0

10

20

30

40

50

60

125∞C

T = 150∞C

75∞C

J

25∞C

100∞C

50∞C

1000

10000

100000

0

10

20

30

40

50

60

T = 25∞C

J

0.001

0.01

0.1

1

0.00001

0.0001

0.001

0.01

0.1

1

10

Single Pulse

(Thermal Resistance)

D = 0.75

D = 0.50

D = 0.33

D = 0.25

D = 0.20

Notes:

1. Duty factor D = t1/ t2

2. Peak Tj = Pdm x ZthJC + Tc

2

t

1

t

P

DM

208CNQ060

4

Bulletin PD-20743 rev. A 07/01

www.irf.com

FR EE-W HE EL

D IO D E

40H FL40S02

C UR RE N T

M O N ITO R

H IG H -SPE ED

SW ITC H

IRFP460

L

D UT

Rg = 25 ohm

V d = 25 V olt

+

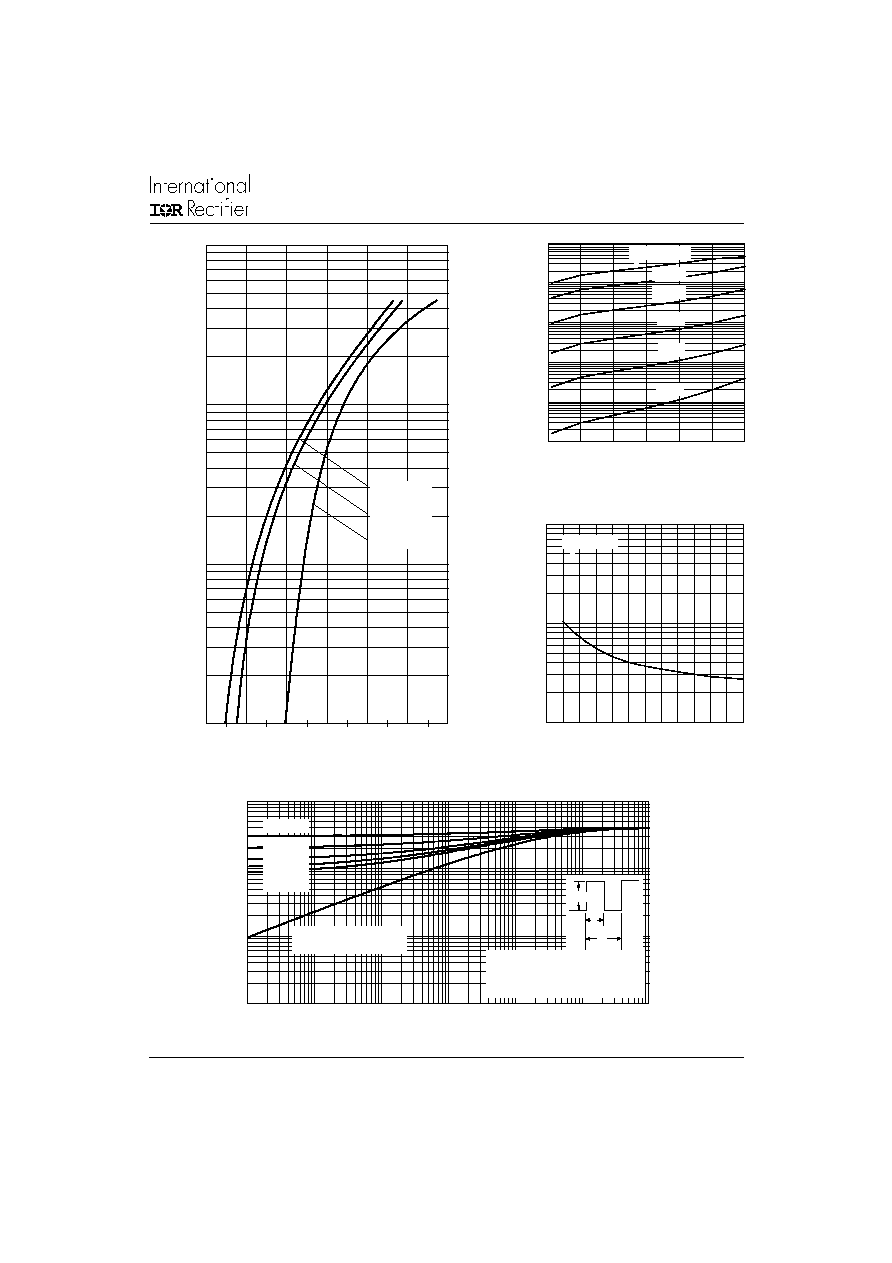

Fig. 5 - Max. Allowable Case Temperature

Vs. Average Forward Current

Average Forward Current - I

F(AV)

(A)

Square Wave Pulse Duration - t

p

(microsec)

Fig. 7 - Max. Non-Repetitive Surge Current

Allowable Case Temperature (∞C)

Non-Repetitive Surge Current - I

FSM

(A)

Fig. 6 - Forward Power Loss Characteristics

Average Forward Current - I

F(AV)

(A)

Average Power Loss (Watts)

Fig. 8 - Unclamped Inductive Test Circuit

(2) Formula used: T

C

= T

J

- (Pd + Pd

REV

) x R

thJC

;

Pd = Forward Power Loss = I

F(AV)

x V

FM

@ (I

F(AV)

/

D) (see Fig. 6);

Pd

REV

= Inverse Power Loss = V

R1

x I

R

(1 - D); I

R

@ V

R1

= 80% rated V

R

90

100

110

120

130

140

150

0

20

40

60

80 100 120 140 160

DC

see note (2)

Square wave (D = 0.50)

80% Rated Vr applied

0

20

40

60

80

100

0

30

60

90

120

150

DC

RMS Limit

D = 0.75

D = 0.50

D = 0.33

D = 0.25

D = 0.20

1000

10000

100000

10

100

1000

10000

At Any Rated Load Condition

And With Rated Vrrm Applied

Following Surge

208CNQ060

5

Bulletin PD-20743 rev. A 07/01

www.irf.com

IR WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245, USA Tel: (310) 252-7105

TAC Fax: (310) 252-7309

Visit us at www.irf.com for sales contact information. 07/01

Data and specifications subject to change without notice.

This product has been designed and qualified for Industrial Level.

Qualification Standards can be found on IR's Web site.