| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: OM9369SP | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

11/21/03

www.irf.com

1

FULL-FEATURED POWER MODULE OM9369SP

FOR HIGH VOLTAGE DIRECT DRIVE OF

3-PHASE BRUSHLESS DC MOTOR

F-43 / MP3-43L Packages

Features:

n

Fully Integrated 3-Phase Brushless DC Motor

Control Subsystem includes Power Stage,

Non-Isolated Driver Stage and Controller Stage

n

Rugged IGBT Power Output Stage with Soft

Recovery Diode

n

25A Average Phase Current with 300V

Maximum Bus Voltage

n

Internal Precision Current Sense Resistor

(6W Max. Dissipation)

n

Speed and Direction Control of Motor

n

Brake Input for Dynamic Braking of Motor

n

Overvoltage/Coast Input for Shutdown of

All Power Switches

n

Soft Start for Safe Motor Starting

n

Unique Hermetic or Plastic Ring Frame Power

Flatpacks

Hermetic (3.10" X 2.10" X 0.385")

Plastic Ring Frame (4.13" X 2.00" X 0.49")

Applications:

n

Fans and Pumps

n

Hoists

n

Actuator Systems

The OM9369 is one of a series of versatile, integrated

three-phase brushless DC motor controller/driver

subsystems housed in a 43 pin power flatpack. The

OM9369 is best used as a two quadrant speed

controller for controlling/driving fans, pumps, and

motors in applications which require small size.

Typical size brushless DC motors that the OM9369

can effectively control range from fractional HP up to

several HP. The OM9369 is ideal for use on DC

distribution buses up to and including 270Vdc. Many

integral control features provide the user much

flexibility in adapting the OM9369 to specific system

requirements.

MP3-43L

Description:

F-43

The small size of the complete subsystem is ideal for

aerospace, military, and high-end industrial applications.

Two package types provide a broad range of cost

and screening options to fit any application.

25A Push-Pull

3-Phase Brushless DC Motor

Controller / Driver Module

in a Power Flatpack

OM9369SF

OM9369

PD- 95806

OM9369

2

www.irf.com

* T

CASE

= 25∞C

* * T

CASE

= 25∞C, Maximum pulse width = 10 mS

Note 1: Logic Inputs: Direction, Hall Inputs (H1--- H3) Overvoltage - Coast, Speed, and Quad Select.

Note 2: The internal 5m

current sense resistor is limited to 6 Wdc power dissipation. Other values are avaliable.

Please contact International Rectifier for more information.

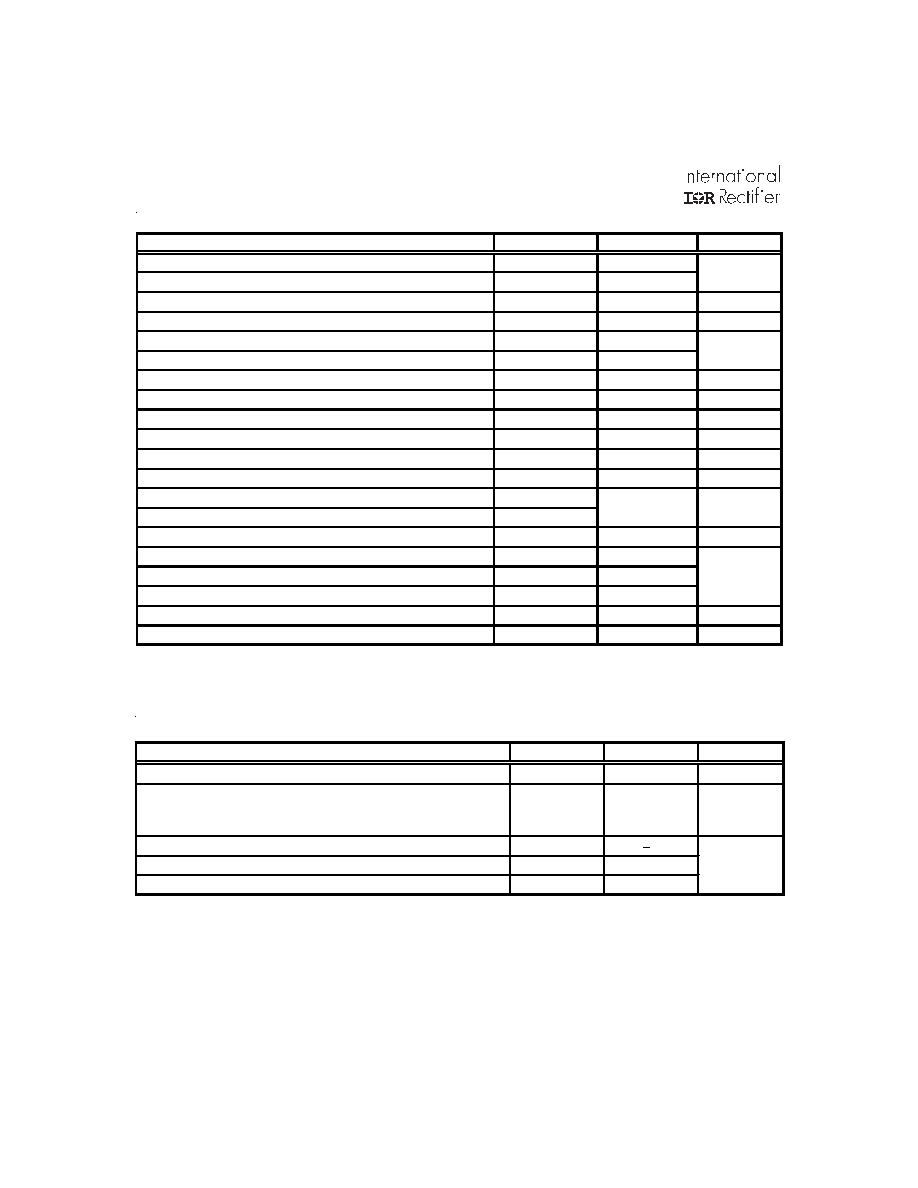

Absolute Maximum Ratings

Parameter

Symbol

Value

Units

Motor Supply Voltage

V

m

300

Peak Motor Supply Voltage

V

m pk

500

Average Phase Output Current

I

o

25

A*

Peak Phase Output Current

I

om

50

Apeak **

Control Supply Voltage

V

cc

18

Logic Input Voltage (Note 1)

-0.3 to 8.0

Reference Source Current

-30

mA

Error Amplifier Input Voltage Range

( EA1+ / EA1-)

-0.3 to 10

V

Error Amplifier Output Current

±8

mA

Spare Amplifier Input Voltage

( EA2+ / EA2-)

-0.3 to 10

V

Spare Amplifier Output Current

±8

mA

Current Sense Amplifier Input Voltage

(ISH / ISL)

-0.3 to 6.0

V

Current Sense Amplifier Output Current

Tachometer Output Current

PWM Input Voltage

-0.3 to 6.0

V

Operating Junction Temperature

-55 to 150

Storage Temperature Range

-65 to 150

∞C

Lead Soldering Temperature, 10s maximum, 0.125" from case

300

Package Isolation Voltage

600

Vrms

Power Switch Junction-to-Case Thermal Resistance

R

JC

0.48

∞C/W

V

±10

mA

V

Recommended Operating Conditions

( Tcase = 25∞C

)

Parameter

Symbol

Value

Units

Motor Power Supply Voltage

V

m

270

V

Average Phase Output Current

With Internal Current Sense Resistor

( Note2 )

I

o

25

A

Each Power Switch

Control Supply Voltage

V

cc

15+10%

Logic Low Input Voltage (maximum)

V

il

0.8

V

Logic High Input Voltage (minimum)

V

ih

2.0

www.irf.com

3

OM9369

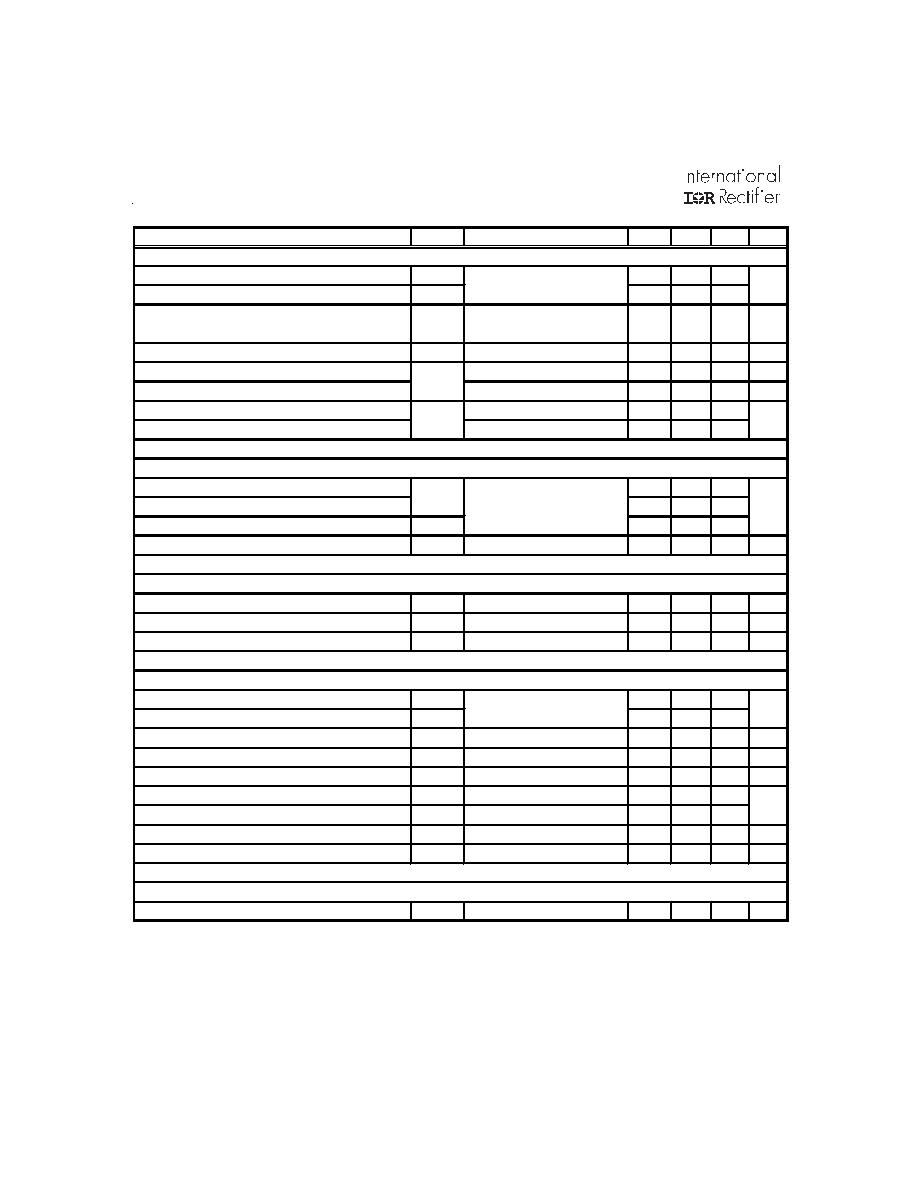

Electrical Characteristics

Parameter

Symbol

Test Conditions (Note 1)

Min.

Typ. Max. Units

Power Output Section

IGBT Leakage Current

I

ces

V

ce

= 600V

dc

, V

ge

= 0V

-

-

300

µ

IGBT c-e Saturation Voltage

V

ce(sat)

I

c

= 50Adc, V

ge

= 15V

-

-

3.2

V

Diode Leakage Current

I

r

V

r

= 600V

dc

-

-

100

µ

A

Diode Forward Voltage

V

f

I

f

= 37A

-

-

1.7

V

Diode Reverse Recovery Time

t

rr

I

o

= 1.0A, di/dt = -100A/

µ

sec, V

r

= 30V

-

-

50

nS

Control Section

Control Supply Current

I

cc

V

cc

over operating range

-

-

100

mA

Control Turn-On Threshold

9.45

-

-

Driver Turn-On Threshold

13

-

-

Reference Section

Output Voltage

4.9

5.0

5.1

Output Voltage

4.7

5.0

5.3

Output Current

I

o

-

-

30

mA

Load Regulation

I

load

= 0mA to -20mA

-40

-5.0

-

mV

Short Circuit Current

I

sc

T

c

over operating range

50

100

150

mA

Error / Spare Amplifier Sections

EA1 / EA2 Input Offset Current

I

os

V(pin 2) = V(pin 4) = 0V,

-30

-3.0

0

V(pin 3) = V(pin 6) = 0V

EA1 / EA2 Input Bias Current

I

in

V(pin 2) = V(pin 4) = 0V,

-50

-45

0

V(pin 3) = V(pin 6) = 0V

Input Offset Voltage

V

os

0V < Vcommon-mode < 3.0V

-

-

7.0

mV

Amplifier Output Voltage Range

-

0

-

6.0

V

PWM Comparator Section

PWM Input Current

I

in

V(pin 9) = 2.5V

0

3.0

30

µ

Current-Sense Amplifier Section

ISH / ISL Input Current

I

in

V(pin 12) = V(pin 13) = 0V,

-850

-320

0

Input Offset Current

I

os

V(pin 12) = V(pin 13) = 0V,

-

±2.0

±12

Peak Current Threshold Voltage

V

pk

V(pin 12) = 0V, V(pin 13)

0.14

0.20

0.26

Over Current Threshold Voltage

V

oc

Varied to Threshold

0.26

0.30

0.36

V

ISH / ISL Input Voltage Range

-

( Note 2 )

-1.0

-

2.0

Amplifier Voltage Gain

A

v

V(pin 12) = 0.3V, V(pin 13) = 0.5V to 0.7V

1.75

1.95

2.15

V/V

Amplifier Level Shift

-

V(pin 12) = V(pin 13) = 0.3V

2.4

2.5

2.65

V

µ

V

cc

(+)

T

c

over operating range

V

V

ref

T

c

over operating range

V

nA

OM9369

4

www.irf.com

1. All parameters specified for Ta = 25∞C, Vcc = 15Vdc, Rosc= 75K

(to Vref), Cosc = 1800pF, and all Phase Outputs unloaded (Ta-Tj).

All negative currents shown are sourced by (flow from) the pin under test.

2. Either ISH or ISL may be driven over the range shown.

3. Bold parameters tested over temperature range.

Specification Notes:

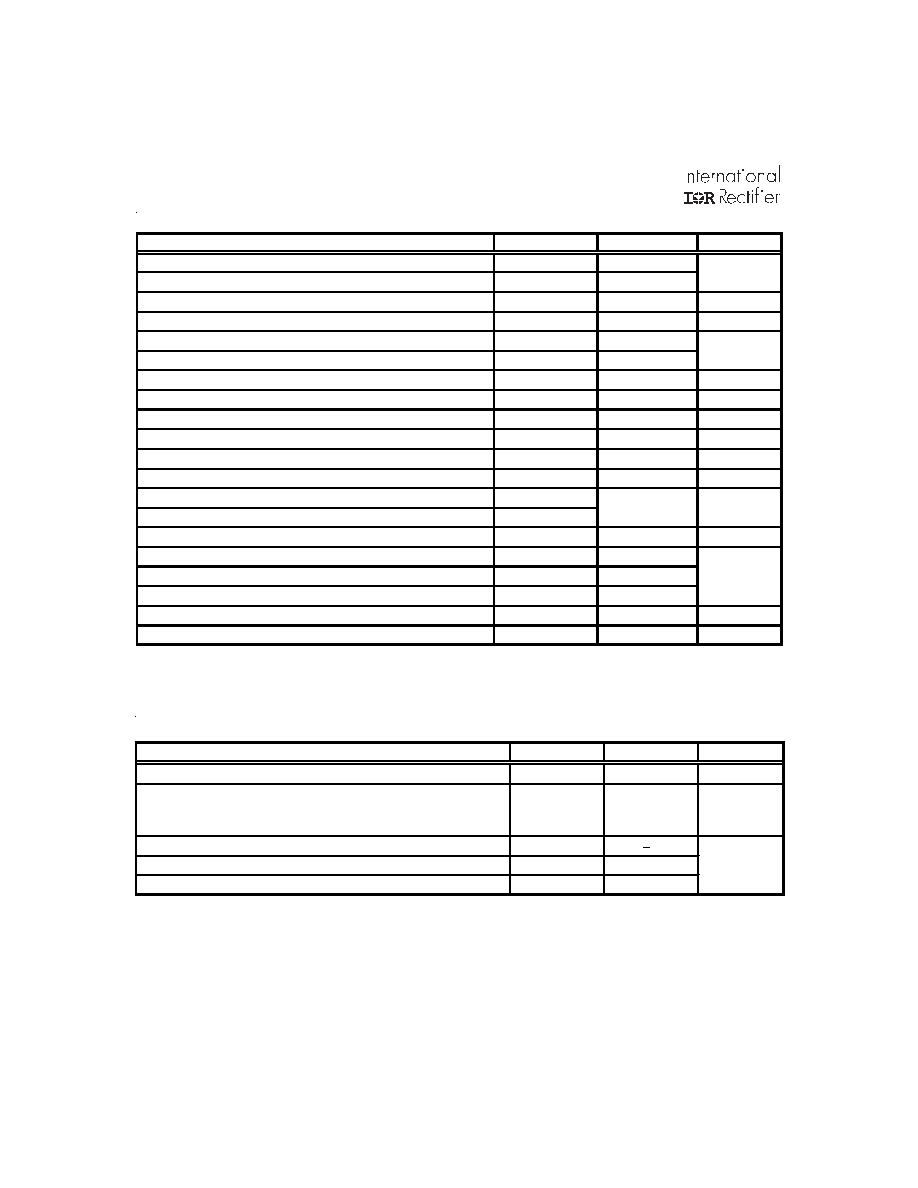

Electrical Characteristics -

Continued

Parameter

Symbol Test Conditions (Note 1) Min.

Typ. Max. Units

Logic Input Section

H1, H2, H3 Low Voltage Threshold

V

il

0.8

1.0

1.2

H1, H2, H3 High Voltage Threshold

V

ih

1.6

1.9

2.0

H1, H2, H3 Input Current

I

in

T

c

over operating range,

-400

-250

-120

µ

V(pin 20, 21, or 22) = 0V

Quad Select / Direction Threshold Voltage

V

th

T

c

over operating range

0.8

1.4

2.0

V

Quad Select Voltage Hysteresis

-

70

-

mV

Direction Voltage Hysteresis

-

0.6

-

V

Quad Select Input Current

-30

50

150

Direction Input Current

-30

-1.0

30

Overvoltage / Coast Input Section

Overvoltage / Coast Inhibit Threshold Voltage

1.65

1.75

1.85

Overvoltage / Coast Restart Threshold Voltage

T

c

over operating range

1.55

1.65

1.75

V

Overvoltage / Coast Hysteresis Voltage

V

h

0.05

0.10

0.15

Overvoltage / Coast Input Current

I

in

-10

-1.0

0

µ

Soft-Start Section

Soft-Start Pull-Up Current

I

p

V(pin 18) = 0V

-16

-10

-5.0

µ

Soft-Start Discharge Current

I

d

V(pin 18) = 2.5V

0.1

0.4

3.0

mA

Soft-Start Reset Threshold Voltage

V

th

0.1

0.2

0.3

V

Tachometer/Brake Section

Tachometer Output High Level

V

oh

T

c

over operating range

4.7

5.0

5.3

Tachometer Output Low Level

V

ol

(pin15) 10K

to 2.5V

-

-

0.2

Tachometer On-Time

t

on

85

100

140

µ

S

Tachometer On-Time Variation

-

T

c

over operating range

-

0.1

-

%

Brake/Tach Timing Input Current

I

in

V(pin 16) = 0V

-4.0

-1.9

-

mA

Brake/Tach Timing Threshold Voltage

V

th

T

c

over operating range

0.8

1.0

1.2

Brake/Tach Timing Voltage Hysteresis

V

h

-

0.09

-

Speed Input Threshold Voltage

V

th

T

c

over operating range

220

257

290

mV

Speed Input Current

I

in

-30

-5.0

30

µ

A

Oscillator Section

Oscillator Frequency

f

o

Measured at pin 10

13.5

14.8

20

KHz

V

T

c

over operating range

V

th

V

V

l

in

µ

V

h

www.irf.com

5

OM9369

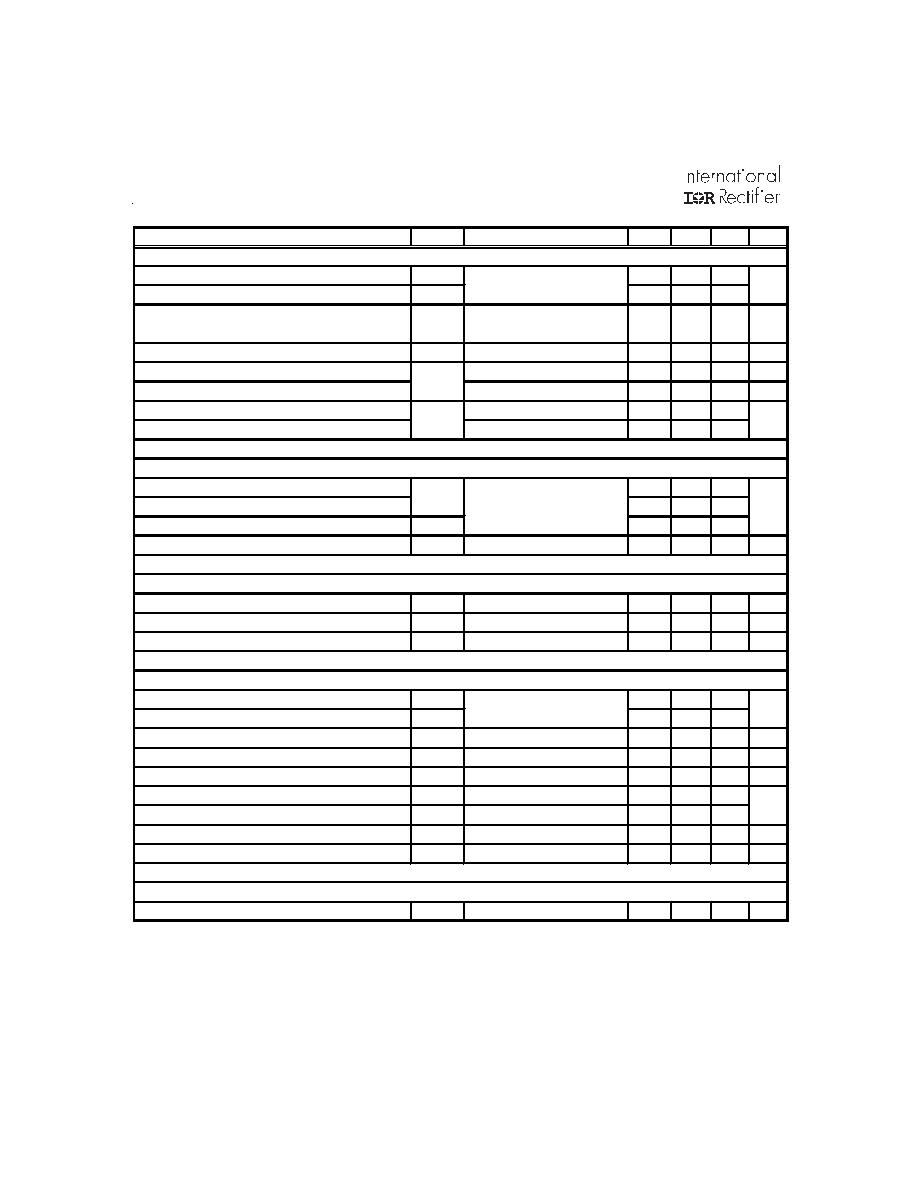

The OM9369 3-phase brushless DC motor controller/

driver is designed to drive fractional to integral

horsepower motors. To ensure proper operation, it is

necessary to ensure that the high-side bootstrap

capcitors are charged during initial start-up. However,

the method(s) used to ensure this may be dependant

upon the application. For example, some applications

may only require that OV_COAST (pin 17) be

connected to ground, either via a hardwire connection

or via a switch (Enable/Disable), before applying Vcc.

When Vcc is applied, the controller/driver is forced

into brake mode for approximately 200

µ

s (all high-

side drivers are disabled and all low-side drivers are

enabled).

APPLICATIONS

Start-Up Conditions

Fig 1: Start-Up Circuit

This may not be adequate for other applications;

while maintaining a constant speed command, (above

zero), RC_BRAKE (pin 16) may have to be momentarily

connected to ground via a switch, either manually or

electronically (ref. Figure 1). Note that with the

component values shown in Figure 1, RC_BRAKE

is pulled for low for approximately 300ms after

applying Vcc at pin 1.