© 2004 IXYS All rights reserved

1 - 2

DSI 45

420

IXYS reserves the right to change limits, test conditions and dimensions.

Dimensions in mm (1 mm = 0.0394")

V

RSM

V

RRM

Type

V

V

900

800

DSI 45-08A

1300

1200

DSI 45-12A

1700

1600

DSI 45-16A

DSI 45-16AR

V

RRM

= 800-1600 V

I

F(AV)M

= 48 A

Symbol

Conditions

Maximum Ratings

I

F(AV)M

T

C

= 105∞C; 180∞ sine

48

A

I

FSM

T

VJ

= 45∞C;

t = 10 ms (50 Hz), sine

475

A

V

R

= 0 V;

t = 8.3 ms (60 Hz), sine

520

A

T

VJ

= 150∞C;

t = 10 ms (50 Hz), sine

380

A

V

R

= 0 V;

t = 8.3 ms (60 Hz), sine

420

A

I

2

t

T

VJ

= 45∞C;

t = 10 ms (50 Hz), sine

1120

A

2

s

V

R

= 0 V;

t = 8.3 ms (60 Hz), sine

1120

A

2

s

T

VJ

= 150∞C;

t = 10 ms (50 Hz), sine

720

A

2

s

V

R

= 0 V;

t = 8.3 ms (60 Hz), sine

720

A

2

s

T

VJ

-40...+150

∞C

T

VJM

150

∞C

T

stg

-40...+150

∞C

M

d

*

mounting torque

0.8...1.2

Nm

V

ISOL

**

50/60 Hz, RMS, t = 1 minute, leads-to-tab

2500

V~

Weight

typical

6

g

* Verson A only; ** Version AR only

Features

∑

International standard package

∑

Planar glassivated chips

∑ Version AR isolated and

UL registered E153432

∑

Epoxy meets UL 94V-0

Applications

∑

Supplies for DC power equipment

∑

DC supply for PWM inverter

∑

Field supply for DC motors

∑

Battery DC power supplies

Advantages

∑

Space and weight savings

∑

Simple mounting

∑

Improved temperature and power cycling

∑

Reduced protection circuits

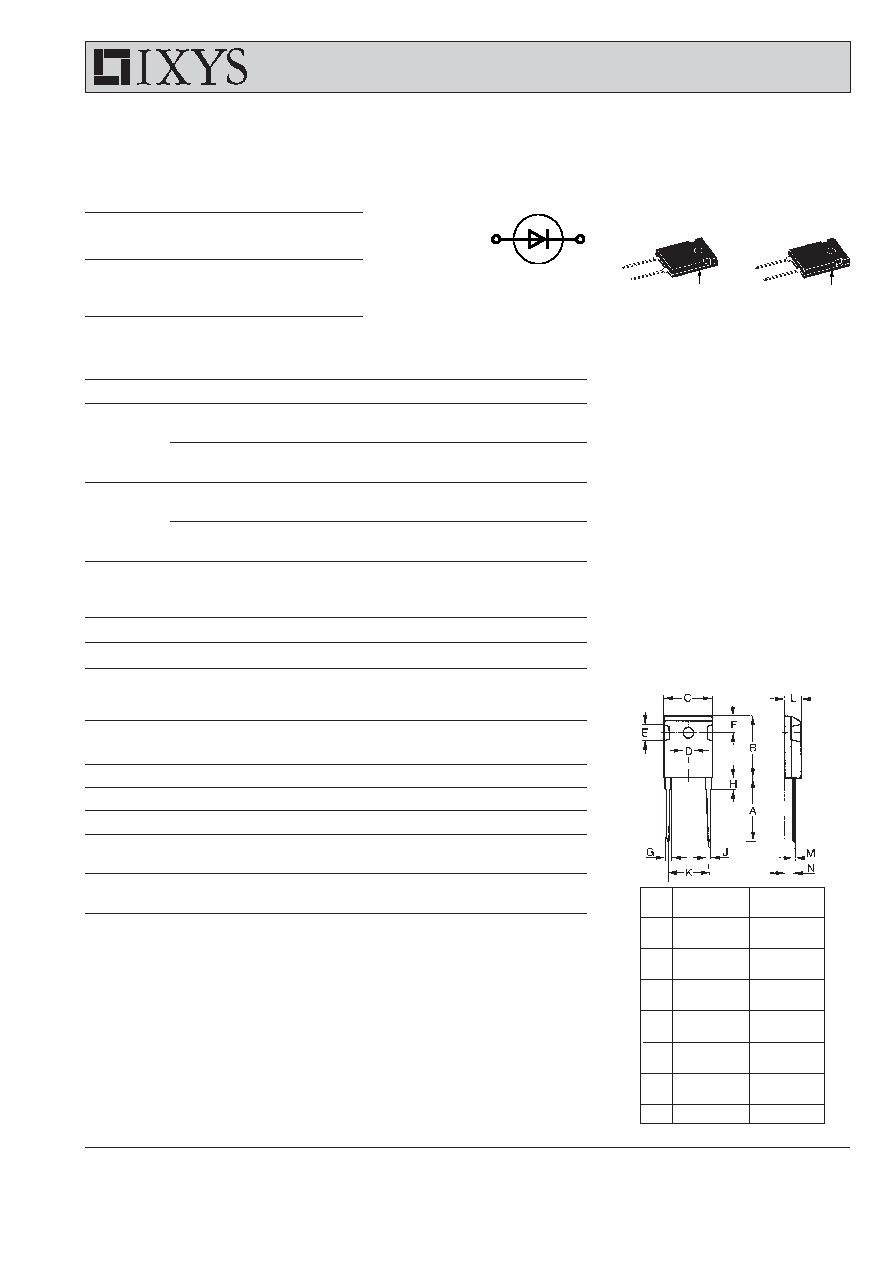

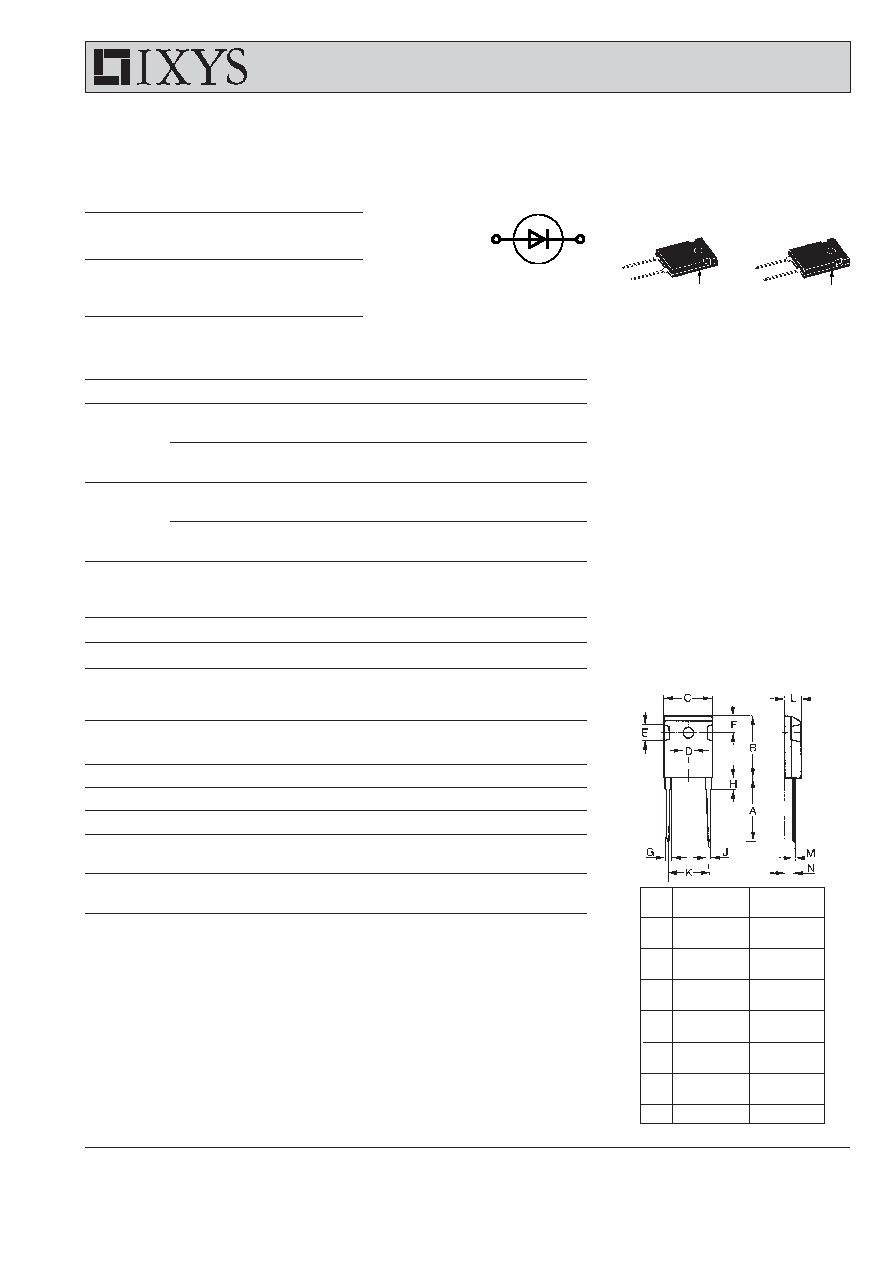

Rectifier Diode

* ISOPLUS 247

TM

without hole

Dim.

Millimeter

Inches

Min.

Max.

Min.

Max.

A

19.81 20.32

0.780

0.800

B

20.80 21.46

0.819

0.845

C

15.75 16.26

0.610

0.640

D*

3.55

3.65

0.140

0.144

E

4.32

5.49

0.170

0.216

F

5.4

6.2

0.212

0.244

G

1.65

2.13

0.065

0.084

H

-

4.5

-

0.177

J

1.0

1.4

0.040

0.055

K

10.8

11.0

0.426

0.433

L

4.7

5.3

0.185

0.209

M

0.4

0.8

0.016

0.031

N

2.2

2.59

0.087

0.102

Symbol

Conditions

Characteristic Values

I

R

T

VJ

= T

VJM

; V

R

= V

RRM

3

mA

V

F

I

F

= 40 A; T

VJ

= 25

∞C

1.18

V

V

T0

For power-loss calculations only

0.8

V

r

T

T

VJ

= T

VJM

8

m

R

thJC

DC current

0.55

K/W

R

thCH

typical

0.2

K/W

Data according to IEC 60747

A = Anode, C = Cathode

TO-247 AD

ISOPLUS 247

TM

Version A

Version AR

C (TAB)

C

A

TAB

C

A

A

C

© 2004 IXYS All rights reserved

2 - 2

DSI 45

420

IXYS reserves the right to change limits, test conditions and dimensions.

0.001

0.01

0.1

1

0

100

200

300

400

500

2

3

4

5 6 7 8 9

1

10

10

2

10

3

10

4

0.0

0.4

0.8

1.2

1.6

0

10

20

30

40

50

60

70

0

10

20

30

40

0

20

40

60

80

100

0

20

40

60

80 100 120 140

0.001

0.01

0.1

1

10

0.0

0.2

0.4

0.6

I

2

t

I

FSM

I

F

A

V

F

t

s

t

ms

P

tot

W

I

d(AV)M

A

T

amb

t

s

K/W

A

2

s

0

20 40 60 80 100 120 140

0

10

20

30

40

50

I

F(AV)M

T

C

A

V

A

∞C

∞C

DSI45

T

VJ

= 45∞C

50Hz, 80% V

RRM

V

R

= 0 V

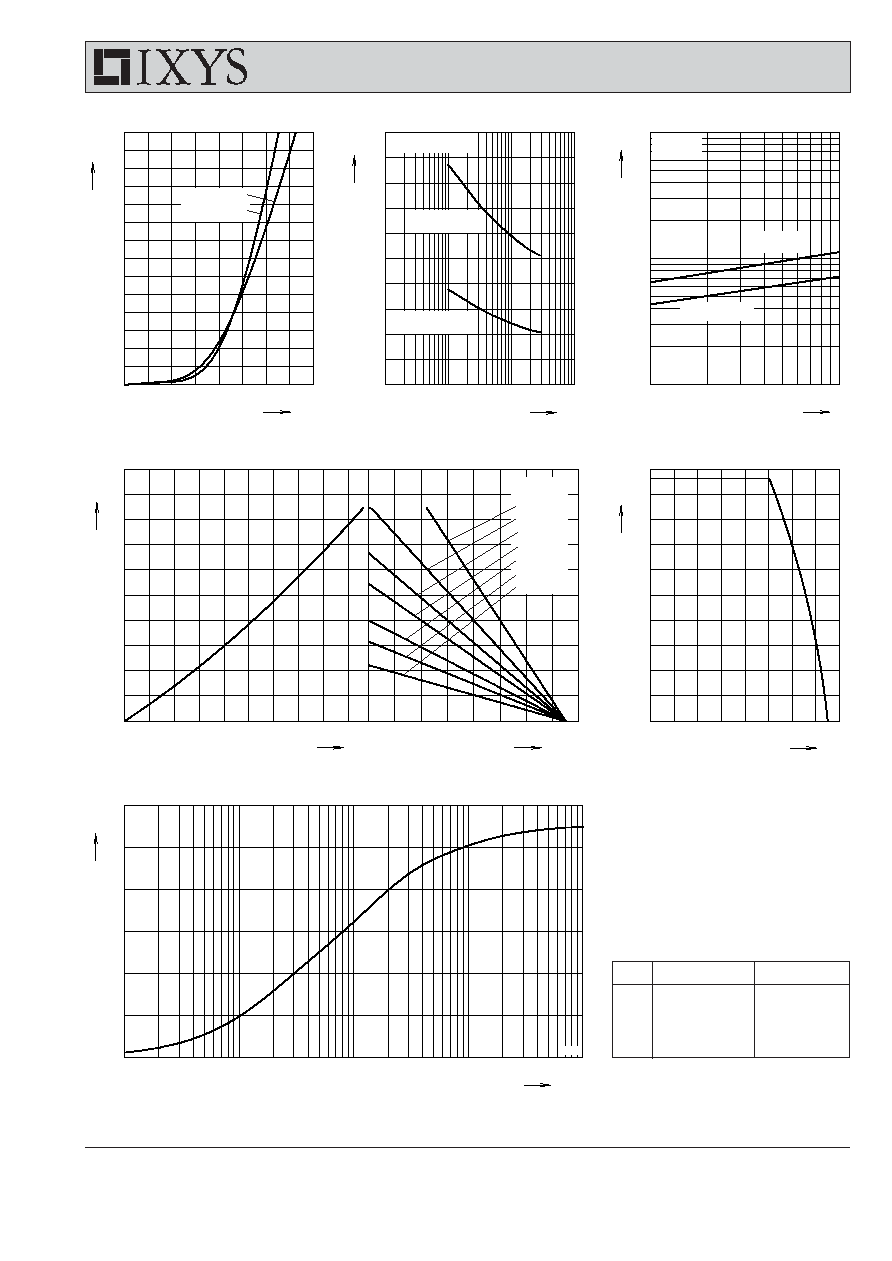

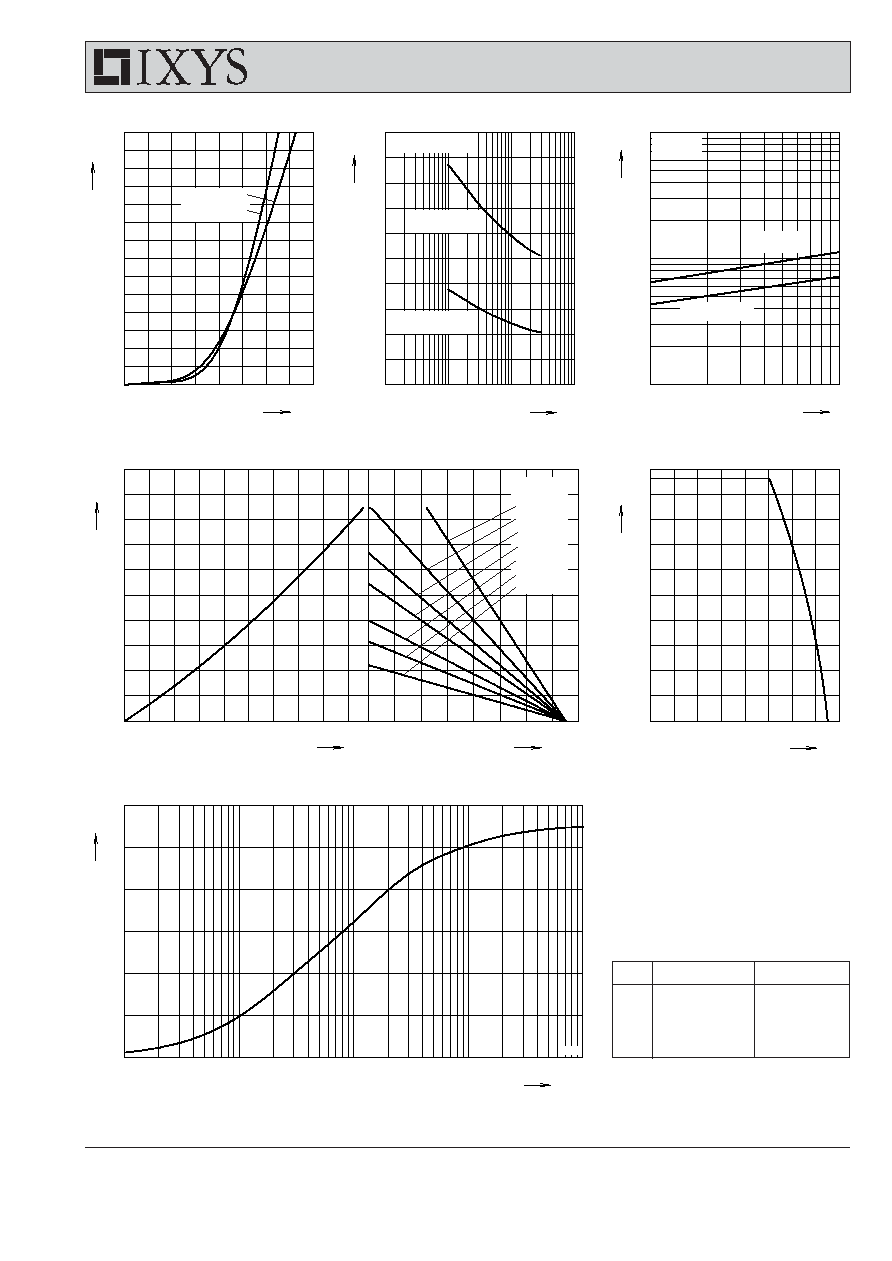

Fig. 1 Forward current versus voltage

drop per diode

Fig. 2 Surge overload current

Fig. 3 I

2

t versus time per diode

Fig. 4 Power dissipation versus direct output current and ambient temperature, sine 180∞

Fig. 5 Max. forward current versus

case temperature

Fig. 6 Transient thermal impedance junction to case

R

thHA

:

0.5 K/W

1.0 K/W

1.5K/W

2.0 K/W

3.0 K/W

4.0 K/W

6.0 K/W

T

VJ

= 150∞C

T

VJ

= 45∞C

T

VJ

=150∞C

T

VJ

= 25∞C

T

VJ

= 150∞C

Z

thJC

Constants for Z

thJC

calculation:

i

R

thi

(K/W)

t

i

(s)

1

0.1633

0.016

2

0.2517

0.118

3

0.0933

0.588

4

0.04167

2.6