© 2000 IXYS All rights reserved

1 - 2

VGO 36

Features

∑ Package with DCB ceramic

base plate

∑ Isolation voltage 3000 V~

∑ Planar passivated chips

∑ Low forward voltage drop

∑ Leads suitable for PC board soldering

Applications

∑ Supplies for DC power equipment

∑ Input rectifiers for PWM inverter

∑ Battery DC power supplies

∑ Field supply for DC motors

Advantages

∑ Easy to mount with two screws

∑ Space and weight savings

∑ Improved temperature and power

cycling capability

∑ Small and light weight

Data according to IEC 60747 refer to a single diode/thyristor unless otherwise stated

x

for resistive load at bridge output. IXYS reserves the right to change limits, test conditions and dimensions.

I

dAV

= 36 A

V

RRM

= 800-1600 V

Symbol

Test Conditions

Maximum Ratings

I

dAV

x

T

H

= 85∞C, module

36

A

I

dAVM

x

module

40

A

I

FRMS

, I

TRMS

per leg

31

A

I

FSM

, I

TSM

T

VJ

= 45∞C;

t = 10 ms (50 Hz), sine

320

A

V

R

= 0 V

t = 8.3 ms (60 Hz), sine

350

A

T

VJ

= T

VJM

t = 10 ms (50 Hz), sine

280

A

V

R

= 0 V

t = 8.3 ms (60 Hz), sine

310

A

I

2

t

T

VJ

= 45∞C

t = 10 ms (50 Hz), sine

500

A

2

s

V

R

= 0 V

t = 8.3 ms (60 Hz), sine

520

A

2

s

T

VJ

= T

VJM

t = 10 ms (50 Hz), sine

390

A

2

s

V

R

= 0 V

t = 8.3 ms (60 Hz), sine

400

A

2

s

(di/dt)

cr

T

VJ

= 125∞C

repetitive, I

T

= 50 A

150

A/

m

s

f = 50 Hz, t

P

= 200

m

s

V

D

= 2/3 V

DRM

I

G

= 0.3 A,

non repetitive, I

T

= 1/2 ∑ I

dAV

500

A/

m

s

di

G

/dt = 0.3 A/

m

s

(dv/dt)

cr

T

VJ

= T

VJM

; V

DR

= 2/3 V

DRM

1000

V/

m

s

R

GK

=

•

; method 1 (linear voltage rise)

V

RGM

10

V

P

GM

T

VJ

= T

VJM

t

p

=

30

m

s

£

10

W

I

T

= I

TAVM

t

p

= 500

m

s

£

5

W

t

p

=

10 ms

£

1

W

P

GAVM

0.5

W

T

VJ

-40...+125

∞C

T

VJM

125

∞C

T

stg

-40...+125

∞C

V

ISOL

50/60 Hz, RMS

t = 1 min

2500

V~

I

ISOL

£

1 mA

t = 1 s

3000

V~

M

d

Mounting torque (M4)

1.5 - 2

Nm

14 - 18

lb.in.

Weight

typ.

18

g

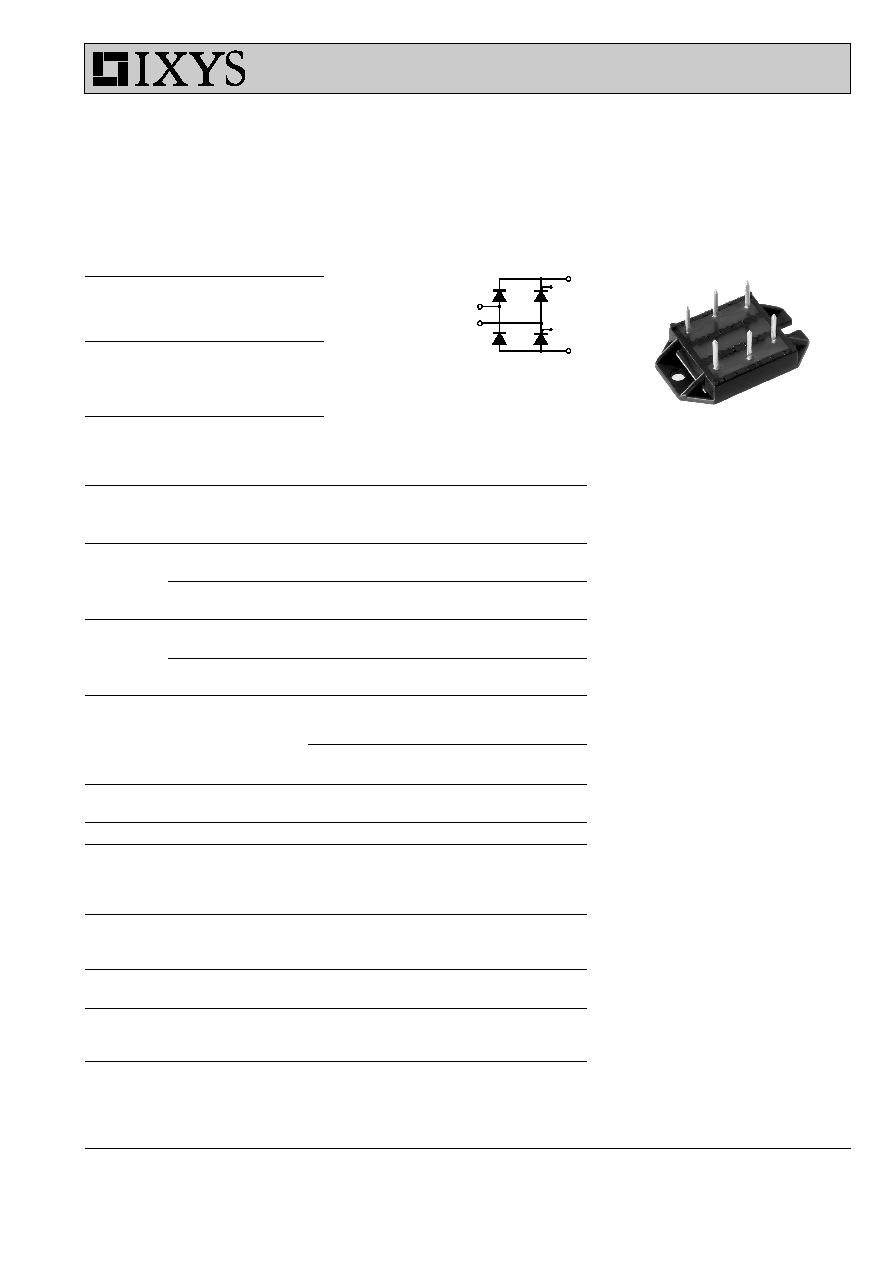

Single Phase Rectifier Bridge

V

RSM

V

RRM

Type

V

DSM

V

DRM

V

V

900

800

VGO 36-08io7

1300

1200

VGO 36-12io7

1500

1400

VGO 36-14io7

1700

1600

VGO 36-16io7

H

N

K

D

G

A

002

Preliminary data

© 2000 IXYS All rights reserved

2 - 2

Dimensions in mm (1 mm = 0.0394")

Symbol

Test Conditions

Characteristic Values

I

R

, I

D

V

R

= V

RRM

; V

D

= V

DRM

T

VJ

= T

VJM

£

5

mA

T

VJ

= 25

∞

C

£

0.3

mA

V

T

, V

F

I

T

, I

F

= 45 A; T

VJ

= 25

∞

C

£

1.45

V

V

T0

For power-loss calculations only (T

VJ

= 125

∞

C)

0.85

V

r

T

13

m

W

V

GT

V

D

= 6 V;

T

VJ

= 25

∞

C

£

1.0

V

T

VJ

= -40

∞

C

£

1.2

V

I

GT

V

D

= 6 V;

T

VJ

= 25

∞

C

£

65

mA

T

VJ

= -40

∞

C

£

80

mA

T

VJ

= 125

∞

C

£

50

mA

V

GD

T

VJ

= T

VJM

;

V

D

= 2/3 V

DRM

£

0.2

V

I

GD

T

VJ

= T

VJM

;

V

D

= 2/3 V

DRM

£

5

mA

I

L

I

G

= 0.3 A; t

G

= 30

m

s;

T

VJ

= 25

∞

C

£

150

mA

di

G

/dt = 0.3 A/

m

s;

T

VJ

= -40

∞

C

£

200

mA

T

VJ

= 125

∞

C

£

100

mA

I

H

T

VJ

= 25

∞

C; V

D

= 6 V; R

GK

=

•

£

100

mA

t

gd

T

VJ

= 25

∞

C; V

D

= 1/2 V

DRM

£

2

m

s

I

G

= 0.3 A; di

G

/dt = 0.3 A/

m

s

t

q

T

VJ

= 125

∞

C, I

T

= 15 A, t

P

= 300

m

s, V

R

= 100 V

typ.

150

m

s

di/dt = -10 A/

m

s, dv/dt = 20 V/

m

s, V

D

= 2/3 V

DRM

R

thJC

per thyristor (diode); DC current

1.4

K/W

per module

0.35

K/W

R

thJK

per thyristor (diode); DC current

2.0

K/W

per module

0.5

K/W

d

S

Creepage distance on surface

12.6

mm

d

A

Creepage distance in air

6.3

mm

a

Max. allowable acceleration

50

m/s

2

Fig. 1 Gate trigger range

Fig. 2 Gate controlled delay time t

gd

1

10

100

1000

0.1

1

10

I

G

V

G

mA

1: I

GT

, T

VJ

= 125∞C

2: I

GT

, T

VJ

= 25∞C

3: I

GT

, T

VJ

= -40∞C

V

4: P

GAV

= 0.5 W

5: P

GM

= 1 W

6: P

GM

= 10 W

I

GD

, T

VJ

= 125∞C

4

2

1

5

6

10

100

1000

1

10

100

1000

µ

s

t

gd

T

VJ

= 25∞C

typ.

Limit

mA

I

G

3

VGO 36

002