SPEC NO: CDA0370

REV NO: V.1

DATE:OCT/25/2001

PAGE: 1 OF 4

APPROVED: J.LU

CHECKED:

DRAWN: Y.F.XU

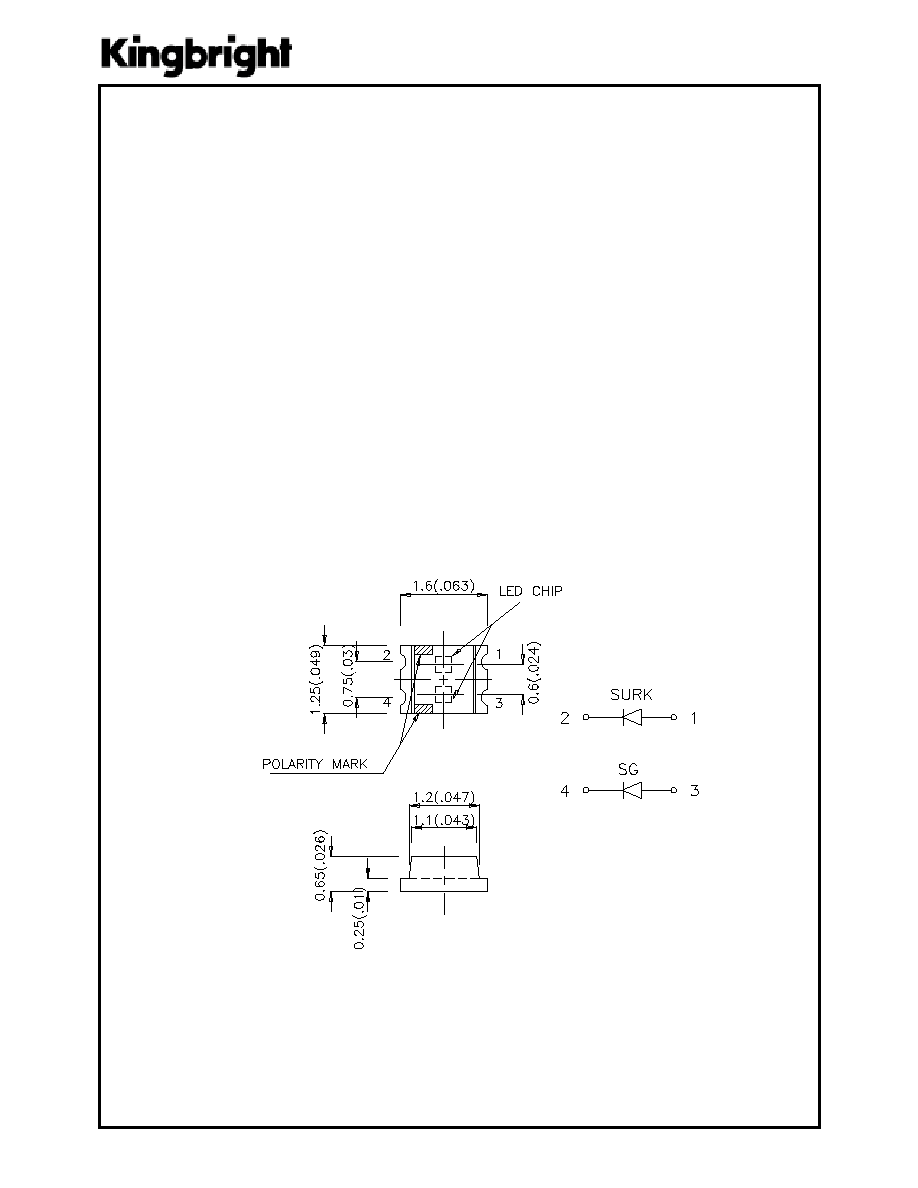

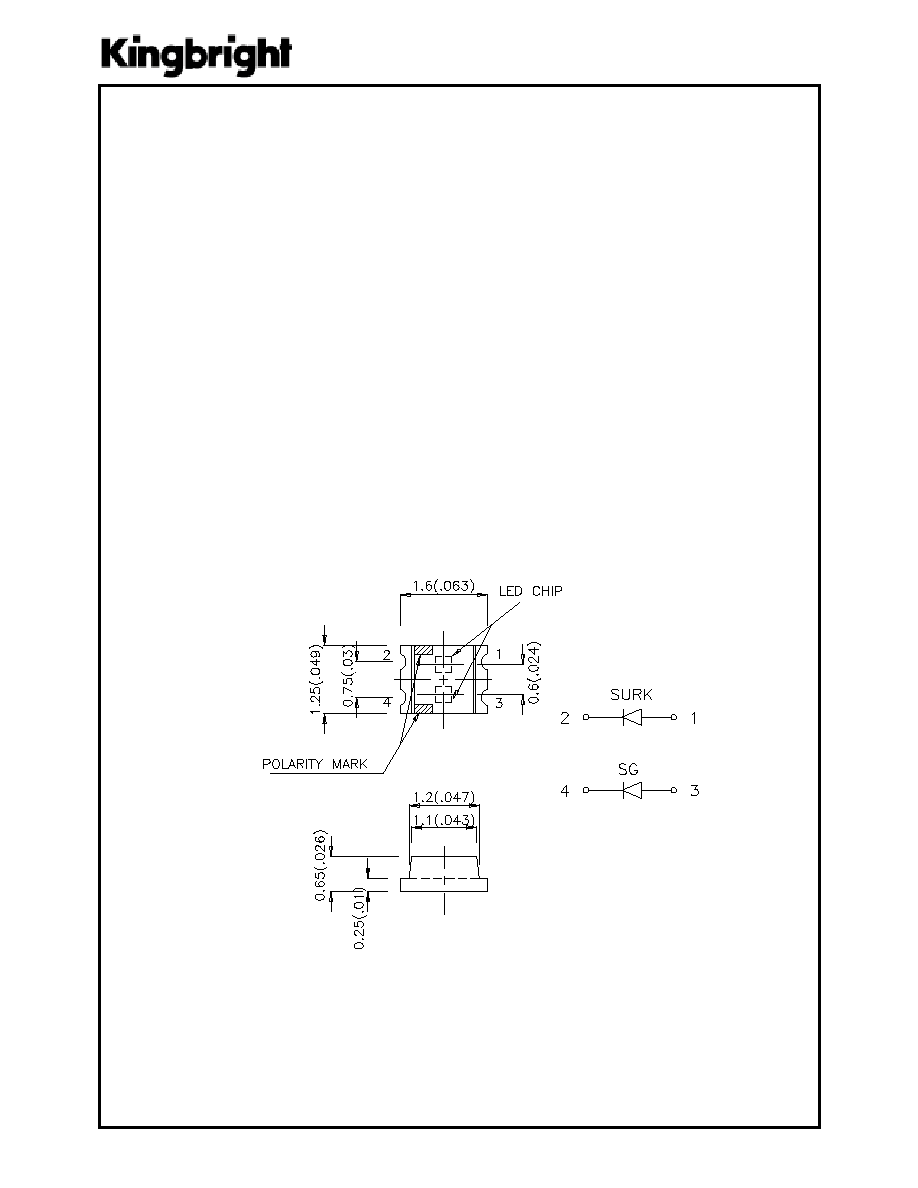

1.6x1.2mm BI-COLOR SMD CHIP LED LAMP

APTB1612SURKSGC HYPER RED/SUPER BRIGHT GREEN

Notes:

1. All dimensions are in millimeters (inches).

2. Tolerance is

±

0.2(0.0079") unless otherwise noted.

3. Lead spacing is measured where the lead emerge package.

4. Specifications are subject to change without notice.

Package Dimensions

Features

!

1.6mmx1.2mm SMT LED, 0.65mm THICKNESS.

!

BI -COLOR,LOW POWER CONSUMPTION.

!

WIDE VIEWING ANGLE.

!

IDEAL FOR BACKLIGHT AND INDICATOR.

!

VARIOUS COLORS AND LENS TYPES AVAILABLE.

!

PACKAGE : 2000PCS / REEL.

Description

The Hyper Red source color devices are made with DH

InGaAlP on GaAs substrate Light Emitting Diode.

The Super Bright Green source color devices are made

with Gallium Phosphide Green Light Emitting Diode.

SPEC NO: CDA0370

REV NO: V.1

DATE: OCT/25/2001

PAGE: 2 OF 4

APPROVED: J.LU

CHECKED:

DRAWN: Y.F.XU

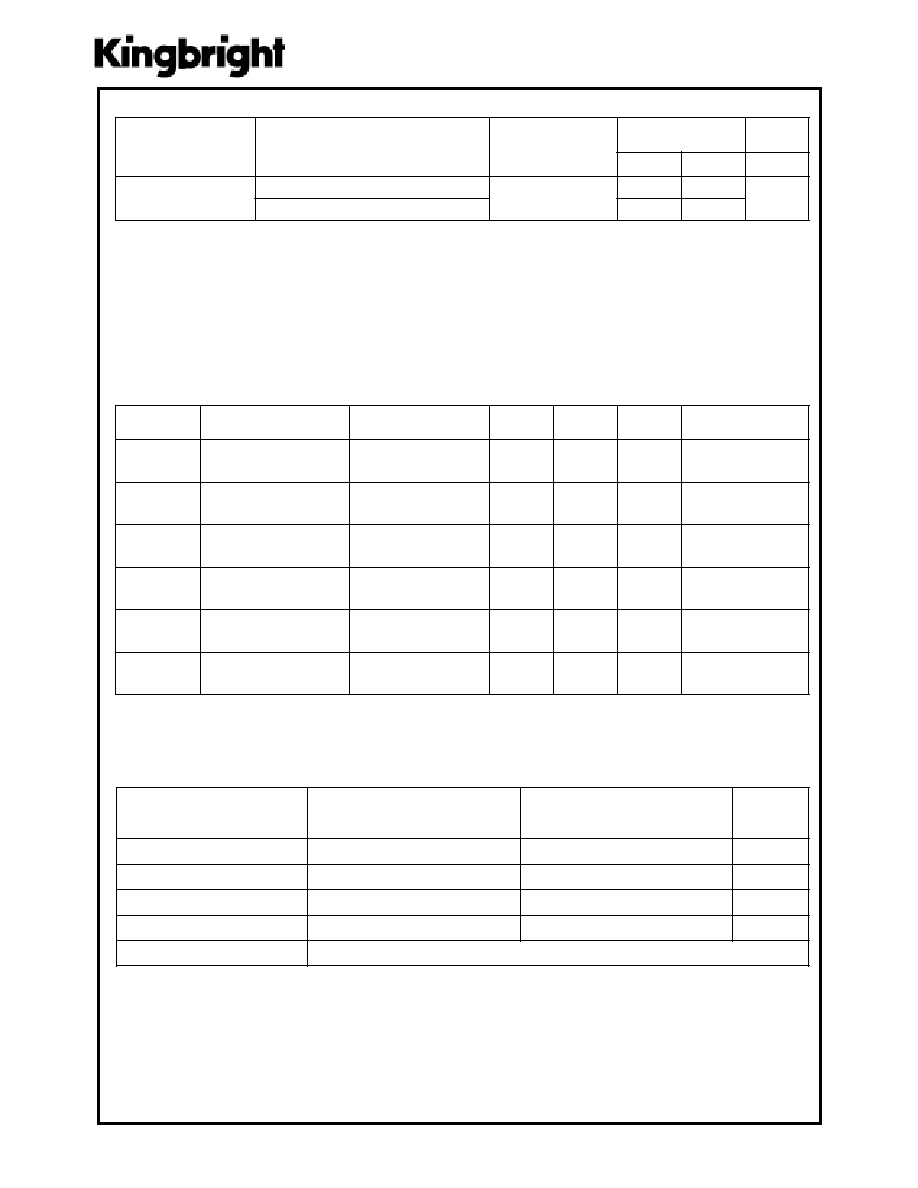

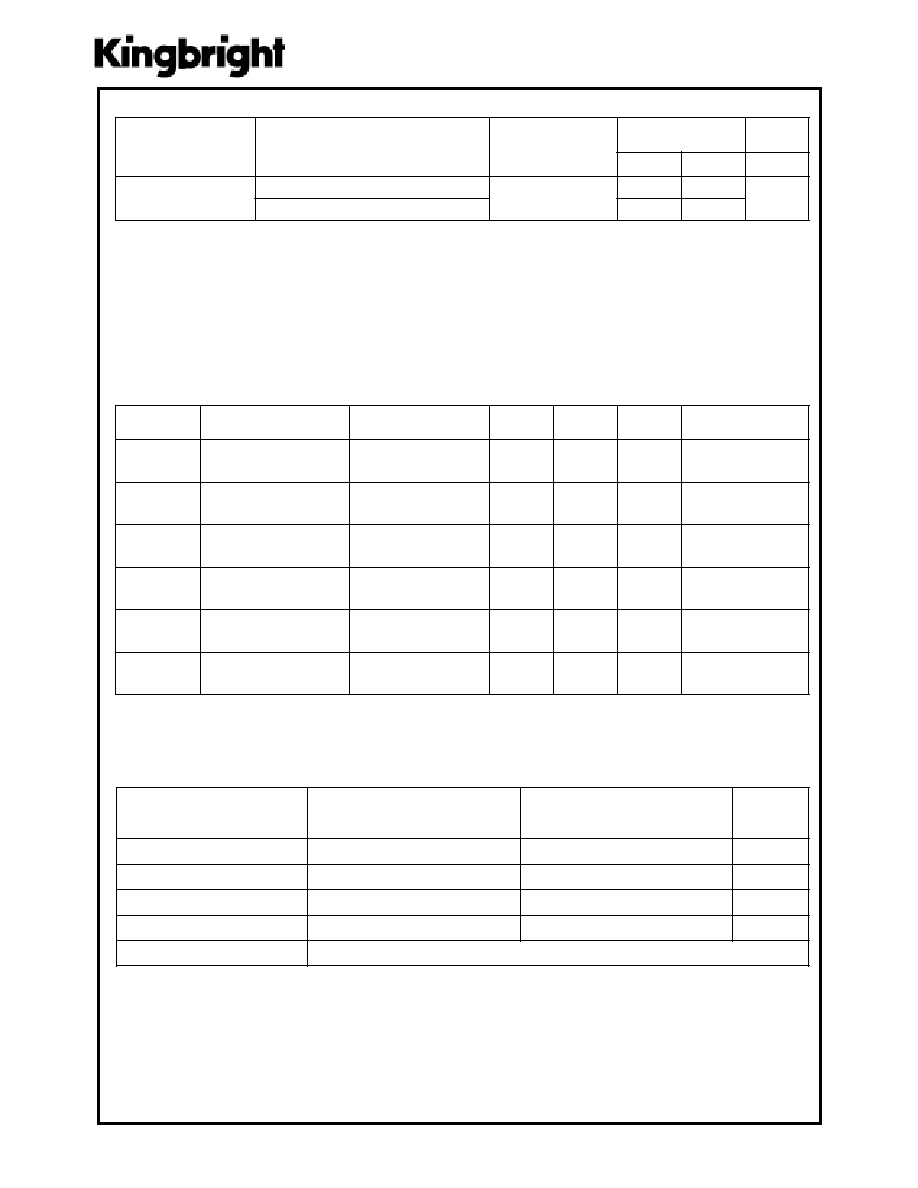

Selection Guide

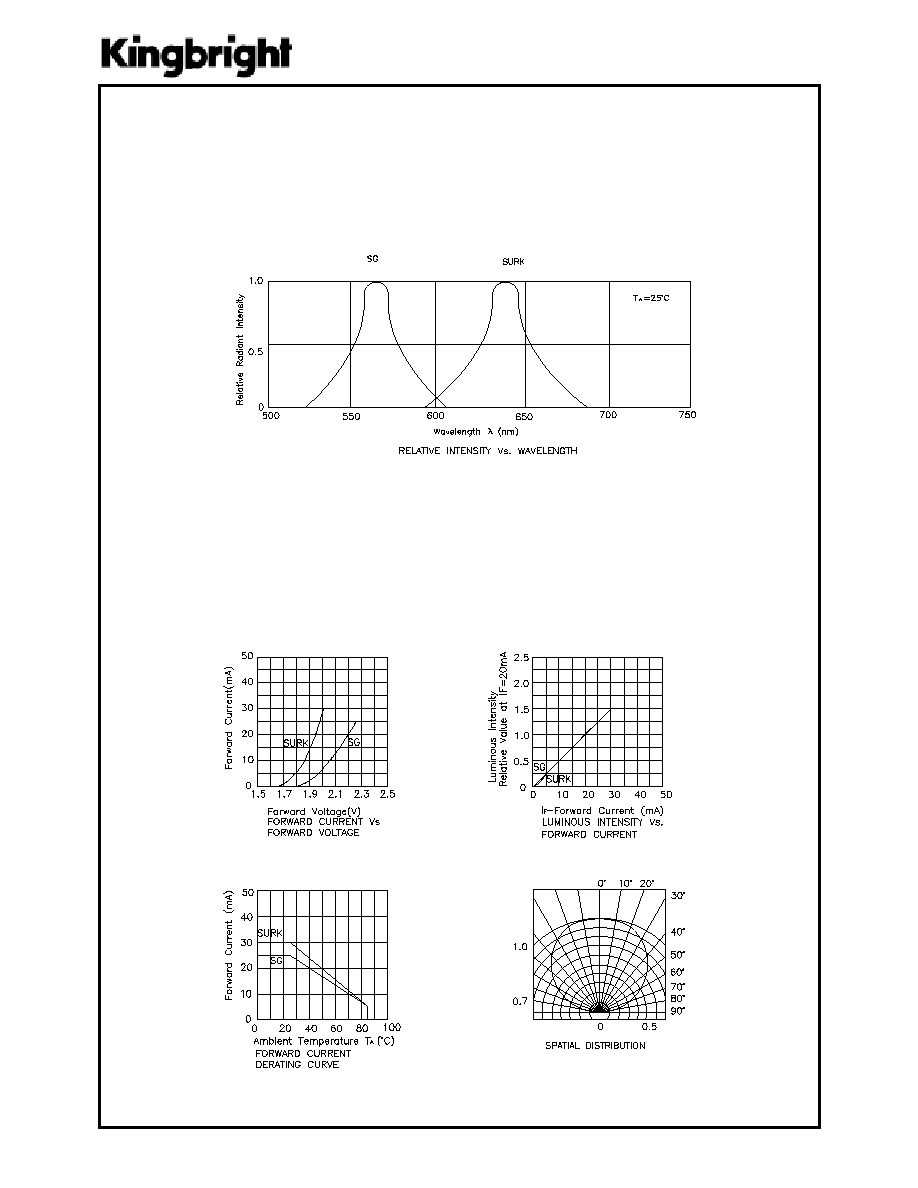

Electrical / Optical Characteristics at T

)

=25

°°

°°

°

C

Note:

1

.

1/2 is the angle from optical centerline where the luminous intensity is 1/2 the optical centerline value.

Absolute Maximum Ratings at T

)

=25

°°

°°

°

C

Note:

1. 1/10 Duty Cycle, 0.1ms Pulse Width.

.

o

N

t

r

a

P

.

o

N

t

r

a

P

.

o

N

t

r

a

P

.

o

N

t

r

a

P

.

o

N

t

r

a

P

e

c

i

D e

c

i

D e

c

i

D e

c

i

D e

c

i

D

e

p

y

T

s

n

e

L

e

p

y

T

s

n

e

L

e

p

y

T

s

n

e

L

e

p

y

T

s

n

e

L

e

p

y

T

s

n

e

L

)

d

c

m

(

v

I

)

d

c

m

(

v

I

)

d

c

m

(

v

I

)

d

c

m

(

v

I

)

d

c

m

(

v

I

A

m

0

2

@

g

n

i

w

e

i

V

g

n

i

w

e

i

V

g

n

i

w

e

i

V

g

n

i

w

e

i

V

g

n

i

w

e

i

V

e

l

g

n

A

.

n

i

M .

n

i

M .

n

i

M .

n

i

M .

n

i

M

.

p

y

T .

p

y

T .

p

y

T .

p

y

T .

p

y

T

2

/

1

2 2

/

1

2 2

/

1

2 2

/

1

2 2

/

1

2

C

G

S

K

R

U

S

2

1

6

1

B

T

P

A

)

P

l

A

a

G

n

I(

D

E

R

R

E

P

Y

H

R

A

E

L

C

R

E

T

A

W

0

8

0

5

1

°

0

2

1

)

P

a

G

(

N

E

E

R

G

T

H

G

I

R

B

R

E

P

U

S

3

2

1

l

o

b

m

y

S

l

o

b

m

y

S

l

o

b

m

y

S

l

o

b

m

y

S

l

o

b

m

y

S

r

e

t

e

m

a

r

a

P

r

e

t

e

m

a

r

a

P

r

e

t

e

m

a

r

a

P

r

e

t

e

m

a

r

a

P

r

e

t

e

m

a

r

a

P

e

c

i

v

e

D

e

c

i

v

e

D

e

c

i

v

e

D

e

c

i

v

e

D

e

c

i

v

e

D

.

p

y

T .

p

y

T .

p

y

T .

p

y

T .

p

y

T

.

x

a

M .

x

a

M .

x

a

M .

x

a

M .

x

a

M

s

ti

n

U s

ti

n

U s

ti

n

U s

ti

n

U s

ti

n

U

s

n

o

it

i

d

n

o

C

t

s

e

T

s

n

o

it

i

d

n

o

C

t

s

e

T

s

n

o

it

i

d

n

o

C

t

s

e

T

s

n

o

it

i

d

n

o

C

t

s

e

T

s

n

o

it

i

d

n

o

C

t

s

e

T

k

a

e

p

h

t

g

n

e

l

e

v

a

W

k

a

e

P

d

e

R

r

e

p

y

H

n

e

e

r

G

t

h

g

ir

B

r

e

p

u

S

0

4

6

5

6

5

m

n

A

m

0

2

=

F

I

D

h

t

g

n

e

l

e

v

a

W

e

t

a

n

i

m

o

D

d

e

R

r

e

p

y

H

n

e

e

r

G

t

h

g

ir

B

r

e

p

u

S

0

3

6

8

6

5

m

n

A

m

0

2

=

F

I

2

/

1

h

t

d

i

w

fl

a

H

e

n

i

L

l

a

rt

c

e

p

S

d

e

R

r

e

p

y

H

n

e

e

r

G

t

h

g

ir

B

r

e

p

u

S

8

2

0

3

m

n

A

m

0

2

=

F

I

C

e

c

n

a

ti

c

a

p

a

C

d

e

R

r

e

p

y

H

n

e

e

r

G

t

h

g

ir

B

r

e

p

u

S

5

3

5

1

F

p

z

H

M

1

=

f;

V

0

=

R

V

V

F

e

g

a

tl

o

V

d

r

a

w

r

o

F

d

e

R

r

e

p

y

H

n

e

e

r

G

t

h

g

ir

B

r

e

p

u

S

5

9

.

1

2

.

2

5

.

2

5

.

2

V

A

m

0

2

=

F

I

I

R

t

n

e

rr

u

C

e

s

r

e

v

e

R

ll

A

0

1

A

u

V

5

=

R

V

r

e

t

e

m

a

r

a

P

r

e

t

e

m

a

r

a

P

r

e

t

e

m

a

r

a

P

r

e

t

e

m

a

r

a

P

r

e

t

e

m

a

r

a

P

d

e

R

r

e

p

y

H

d

e

R

r

e

p

y

H

d

e

R

r

e

p

y

H

d

e

R

r

e

p

y

H

d

e

R

r

e

p

y

H

n

e

e

r

G

t

h

g

ir

B

r

e

p

u

S

n

e

e

r

G

t

h

g

ir

B

r

e

p

u

S

n

e

e

r

G

t

h

g

ir

B

r

e

p

u

S

n

e

e

r

G

t

h

g

ir

B

r

e

p

u

S

n

e

e

r

G

t

h

g

ir

B

r

e

p

u

S

s

ti

n

U s

ti

n

U s

ti

n

U s

ti

n

U s

ti

n

U

n

o

it

a

p

i

s

s

i

d

r

e

w

o

P

0

7

1

5

0

1

W

m

t

n

e

rr

u

C

d

r

a

w

r

o

F

C

D

0

3

5

2

A

m

]

1

[

t

n

e

rr

u

C

d

r

a

w

r

o

F

k

a

e

P

5

8

1

0

4

1

A

m

e

g

a

tl

o

V

e

s

r

e

v

e

R

5

5

V

e

r

u

t

a

r

e

p

m

e

T

e

g

a

r

o

t

S

/

g

n

it

a

r

e

p

O

0

4

-

°

5

8

+

o

T

C

°

C

SPEC NO: CDA0370

REV NO: V.1

DATE: OCT/25/2001

PAGE: 4 OF 4

APPROVED: J.LU

CHECKED:

DRAWN: Y.F.XU

APTB1612SURKSGC

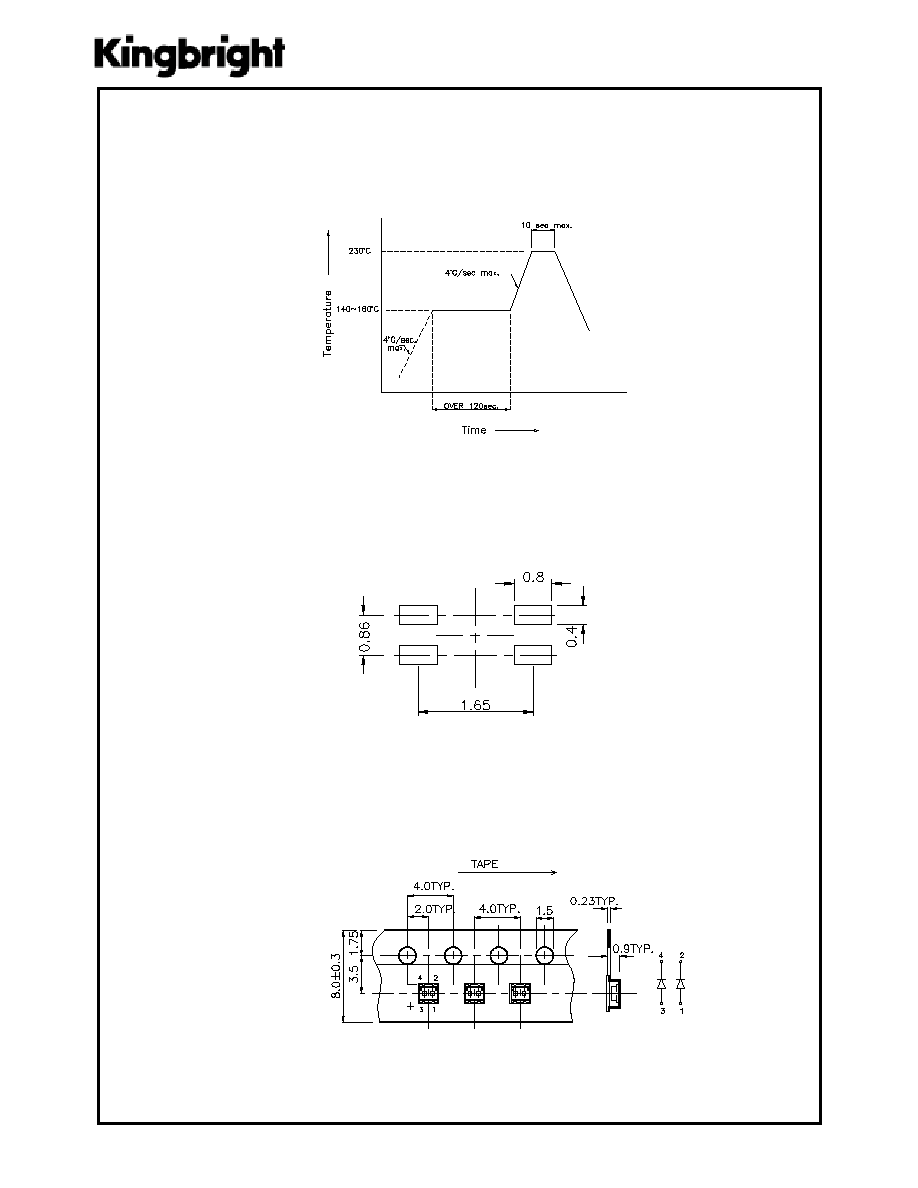

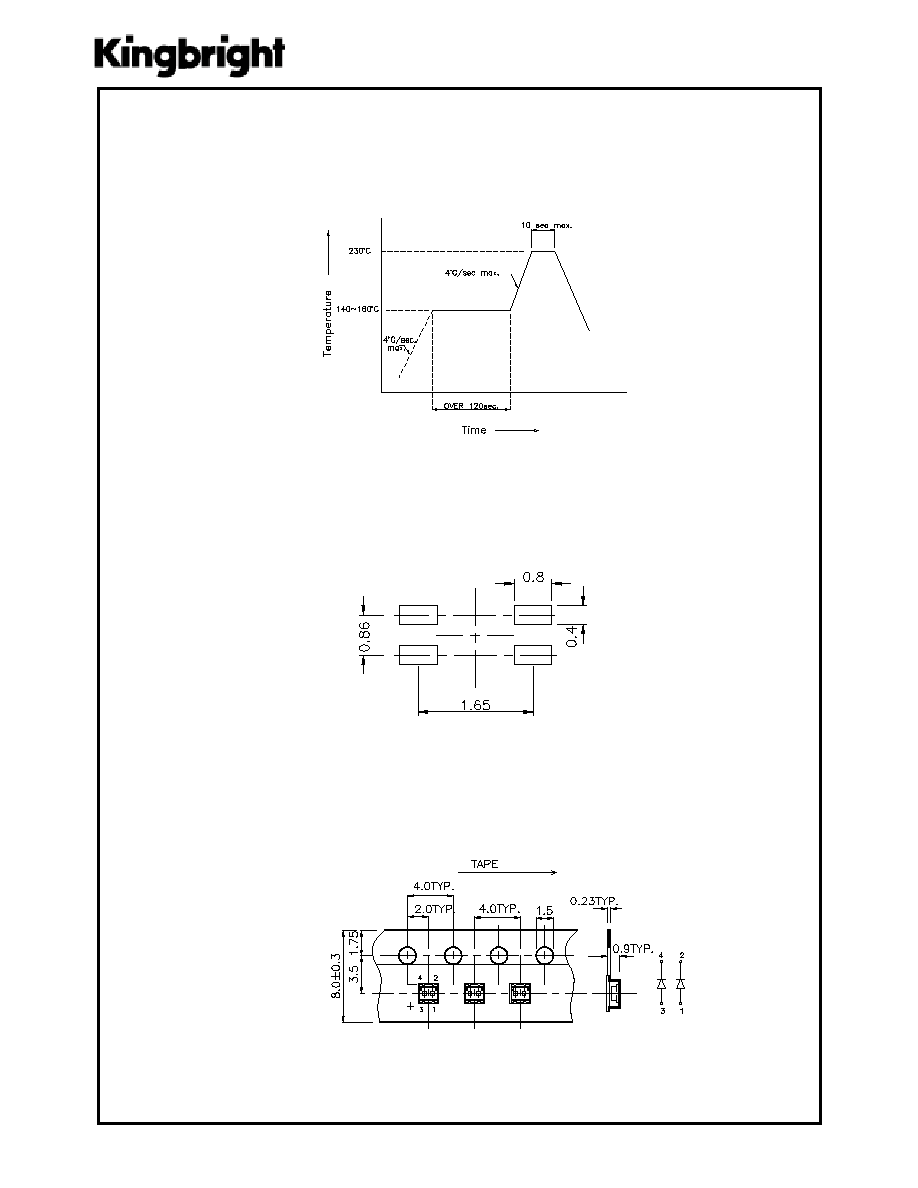

SMT Reflow Soldering Instructions

Recommended Soldering Pattern

(Units : mm)

Tape Specifications

(Units : mm)

Number of reflow process shall be less than 2 times and cooling

process to normal temperature is required between first and

second soldering process."