| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: LT1935ES5 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1

LT1935

1935f

DESCRIPTIO

U

FEATURES

APPLICATIO S

U

TYPICAL APPLICATIO

U

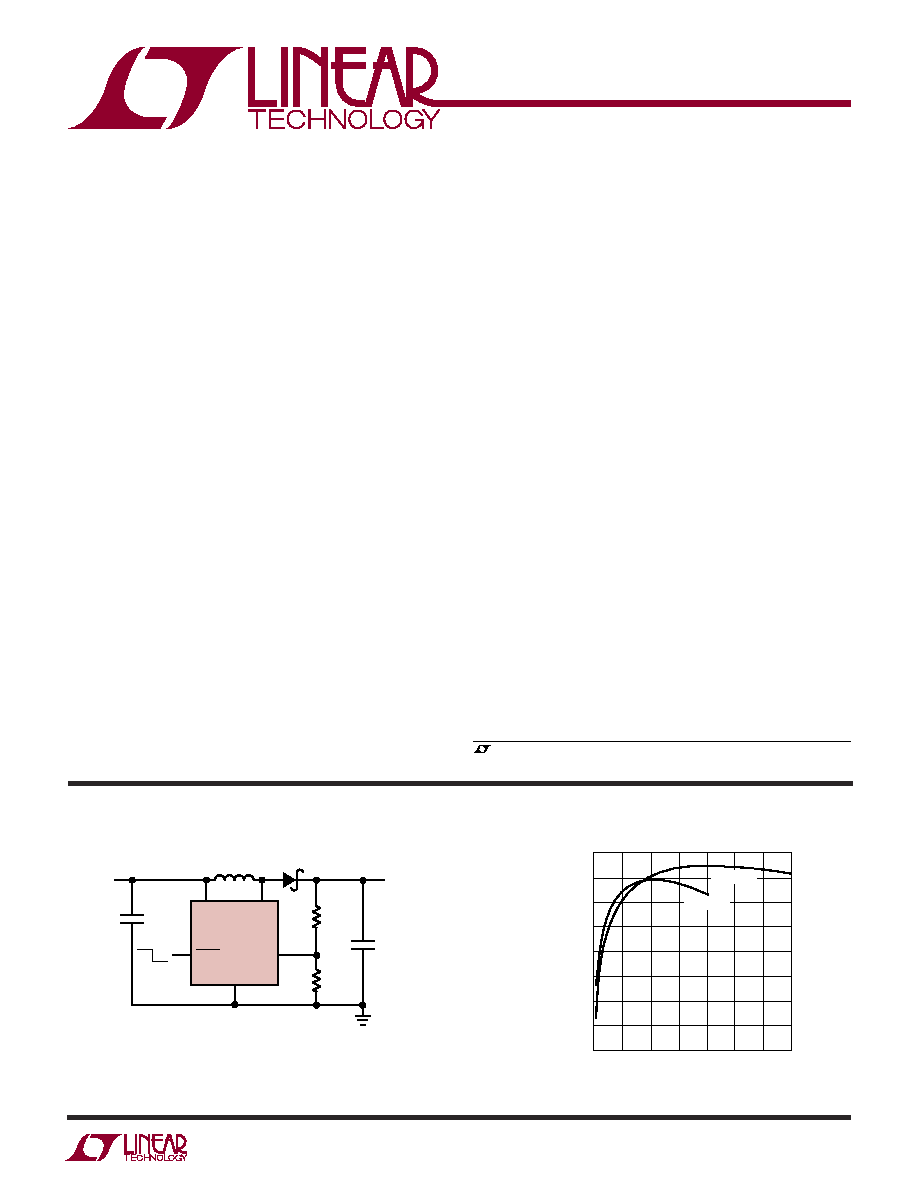

1.2MHz Boost DC/DC

Converter in ThinSOT

with 2A Switch

1.2MHz Switching Frequency

High Output Voltage: Up to 38V

Wide Input Range: 2.3V to 16V

Low V

CESAT

Switch: 180mV at 2A

Soft-Start

Uses Small Surface Mount Components

5V at 1A from 3.3V Input

12V at 600mA from 5V Input

Low Shutdown Current: < 1µA

Pin-for-Pin Compatible with the LT1613 and LT1930

Low Profile (1mm) SOT-23 (ThinSOT

TM

) Package

The LT

Æ

1935 is the industry's highest power SOT-23

switching regulator. Its unprecedented 2A, 40V internal

switch allows high output currents to be generated in a

small footprint. Intended for space-conscious applica-

tions, the LT1935 switches at 1.2MHz, allowing the use of

tiny, low profile inductors and capacitors 2mm or less in

height. The NPN switch achieves a V

CESAT

of just 180mV

at 2A independent of supply voltage, resulting in high

efficiency even at maximum power levels from a 3V input.

A constant frequency, internally compensated, current

mode PWM architecture results in low, predictable output

noise that is easy to filter. Low ESR ceramic capacitors can

be used on the output, further reducing noise to the

millivolt level. The high voltage switch on the LT1935 is

rated at 40V, making the device ideal for boost converters

up to 38V as well as for single-ended primary inductance

converter (SEPIC) and flyback designs. The device can

generate 5V at up to 1A from a 3.3V supply or 5V at 550mA

from four alkaline cells in a SEPIC design.

The LT1935 is available in a 5-lead SOT-23 package.

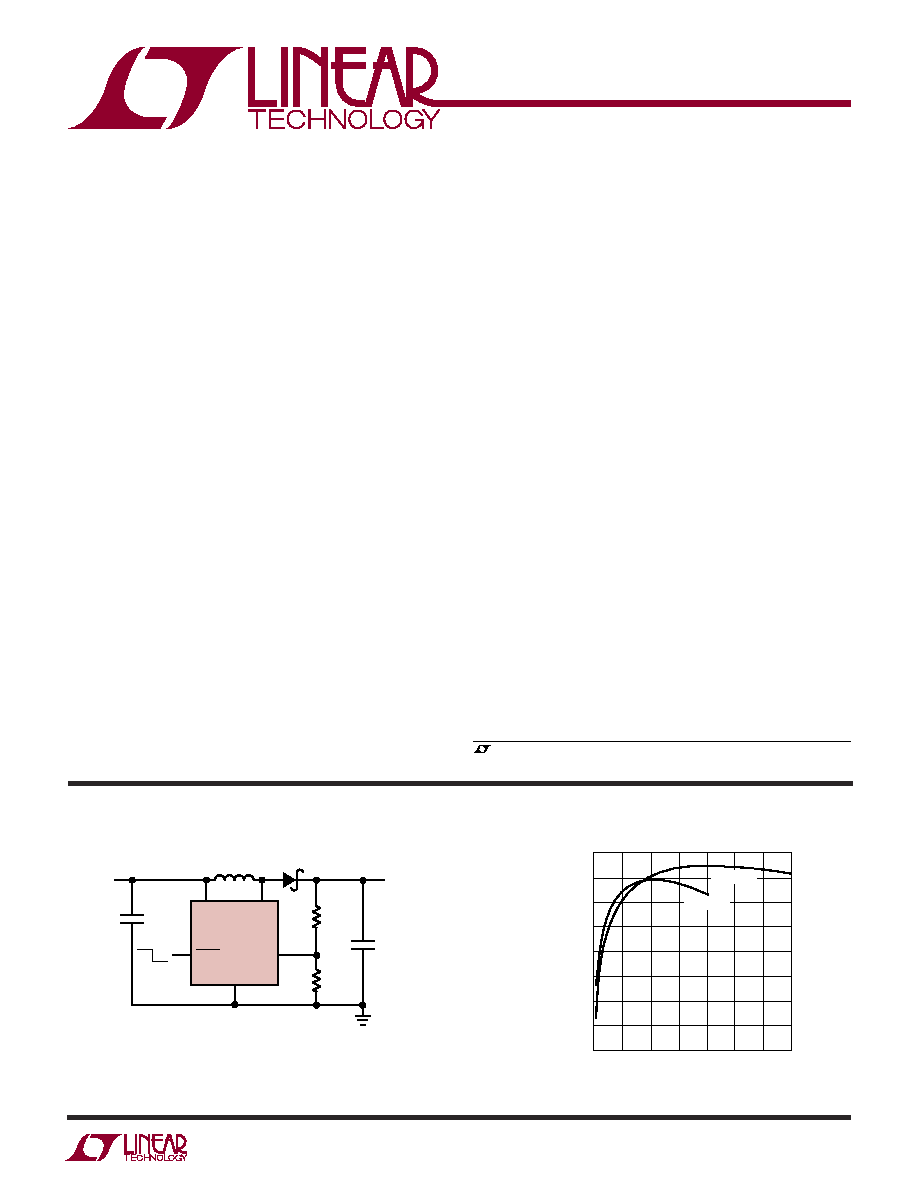

Figure 1. 5V to 12V, 600mA Step-Up DC/DC Converter

Digital Cameras

Battery Backup

LCD Bias

Local 5V or 12V Supply

PC Cards

xDSL Power Supply

TFT-LCD Bias Supply

, LTC and LT are registered trademarks of Linear Technology Corporation.

GND

V

IN

SW

SHDN

FB

V

IN

5V

D1

L1

4.2µH

84.5k

LT1935

1935 F01

10µF

4.7µF

10k

V

OUT

12V

600mA

D1: ON SEMI MBRM120

L1: SUMIDA CDRH5D28-4R2

ON OFF

ThinSOT is a trademark of Linear Technology Corporation.

LOAD CURRENT (mA)

0

EFFICIENCY (%)

600

1935 F01b

200

100

300

500

700

400

90

85

80

75

70

65

60

55

50

V

IN

= 5V

V

IN

= 3.3V

Efficiency, V

OUT

= 12V

2

LT1935

1935f

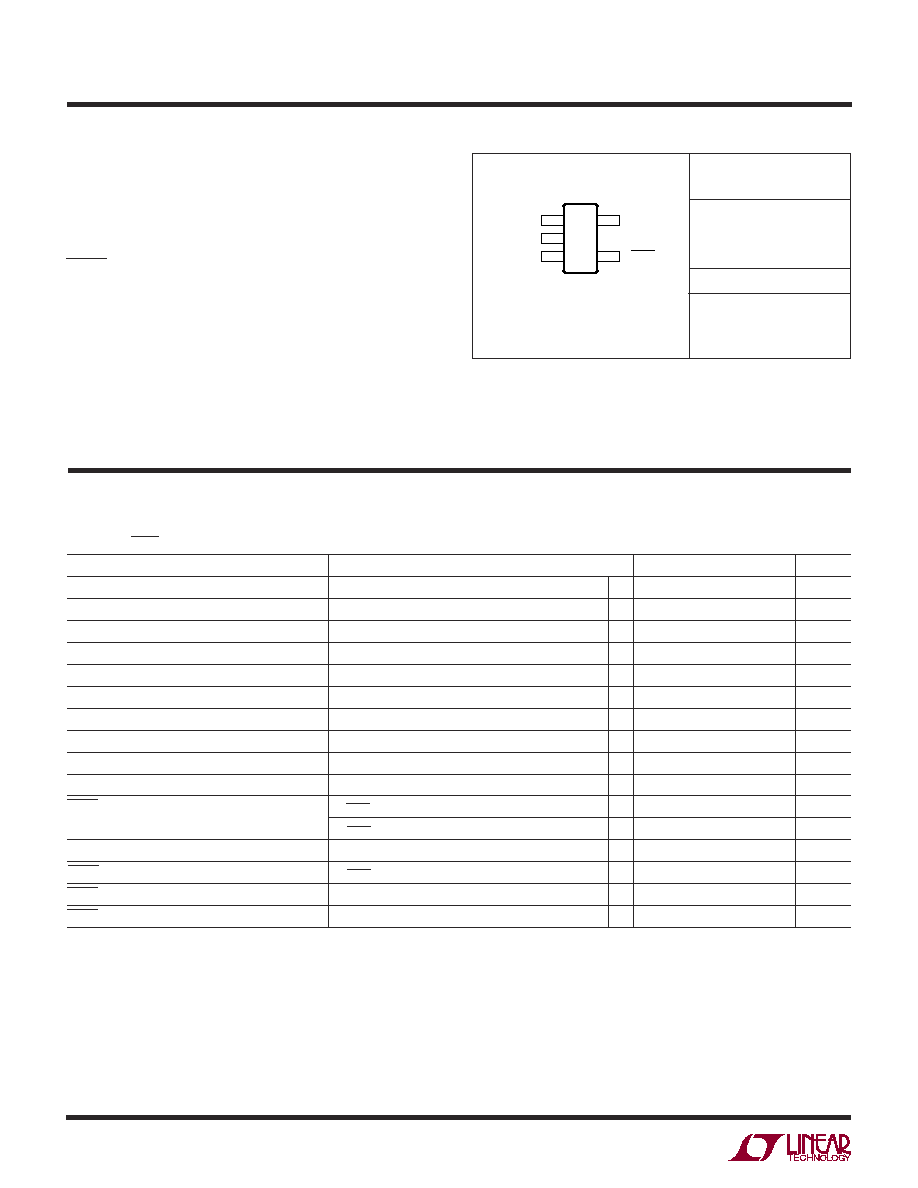

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

Feedback Voltage

Measured at the FB Pin

1.240

1.265

1.280

V

Feedback Voltage Line Regulation

2.5V V

IN

16V

0.01

%/V

FB Pin Bias Current

V

FB

= V

REF

12

60

nA

Undervoltage Lockout Threshold

2.1

2.3

V

Maximum Input Voltage

16

V

Switching Frequency

1

1.2

1.4

MHz

Maximum Duty Cycle

85

93

%

Switch Current Limit

(Note 3)

2

3.2

A

Switch Saturating Voltage

I

SW

= 2A

180

280

mV

Switch Leakage Current

V

SW

= 5V

0.01

1

µA

SHDN Pin Input Current

V

SHDN

= 1.8V

14

40

µA

V

SHDN

= 0V

0.1

µA

Operating Supply Current

V

FB

= 1.5V

3

mA

SHDN Supply Current

V

SHDN

= 0V

0.1

1

µA

SHDN Input High Voltage

1.8

V

SHDN Input Low Voltage

0.5

V

(Note 1)

V

IN

Voltage .............................................................. 16V

SW Voltage ................................................ ≠ 0.4V to 40V

FB Voltage ................................................................. 6V

Current Into FB Pin .............................................. ±1mA

SHDN Voltage ......................................................... 16V

Maximum Junction Temperature ......................... 125∞C

Operating Ambient Temperature Range

(Note 2) .............................................. ≠ 40∞C to 85∞C

Storage Temperature Range ................. ≠ 65∞C to 150∞C

Strict adherence to JDEC 020B solder attach and rework

for assemblies containing lead is recommended.

Consult LTC marketing for parts specified with wider operating temperature ranges.

The

denotes specifications which apply over the full operating temperature range, otherwise specifications are T

A

= 25∞C.

V

IN

= 3V, V

SHDN

= V

IN

unless otherwise noted. (Note 2)

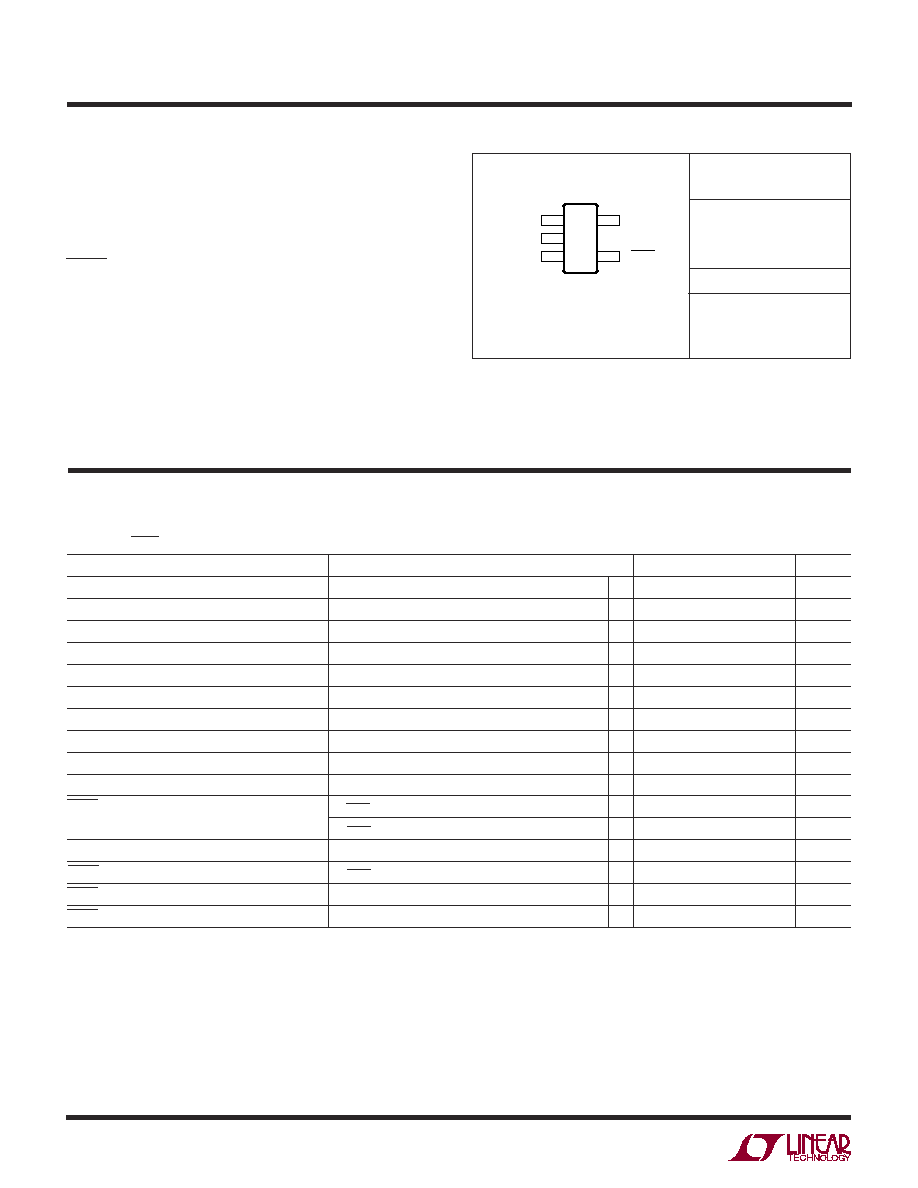

ORDER PART

NUMBER

LT1935ES5

S5 PART MARKING

LTRX

T

JMAX

= 125∞C,

JA

= 113∞C/ W,

ELECTRICAL CHARACTERISTICS

PACKAGE/ORDER I FOR ATIO

U

U

W

ABSOLUTE AXI U RATI GS

W

W

W

U

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LT1935ES5 is guaranteed to meet performance specifications

from 0∞C to 70∞C. Specifications over the ≠ 40∞C to 85∞C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: Current limit guaranteed by design and/or correlation to static test.

SW 1

GND 2

TOP VIEW

S5 PACKAGE

5-LEAD PLASTIC TSOT-23

FB 3

5 V

IN

4 SHDN

3

LT1935

1935f

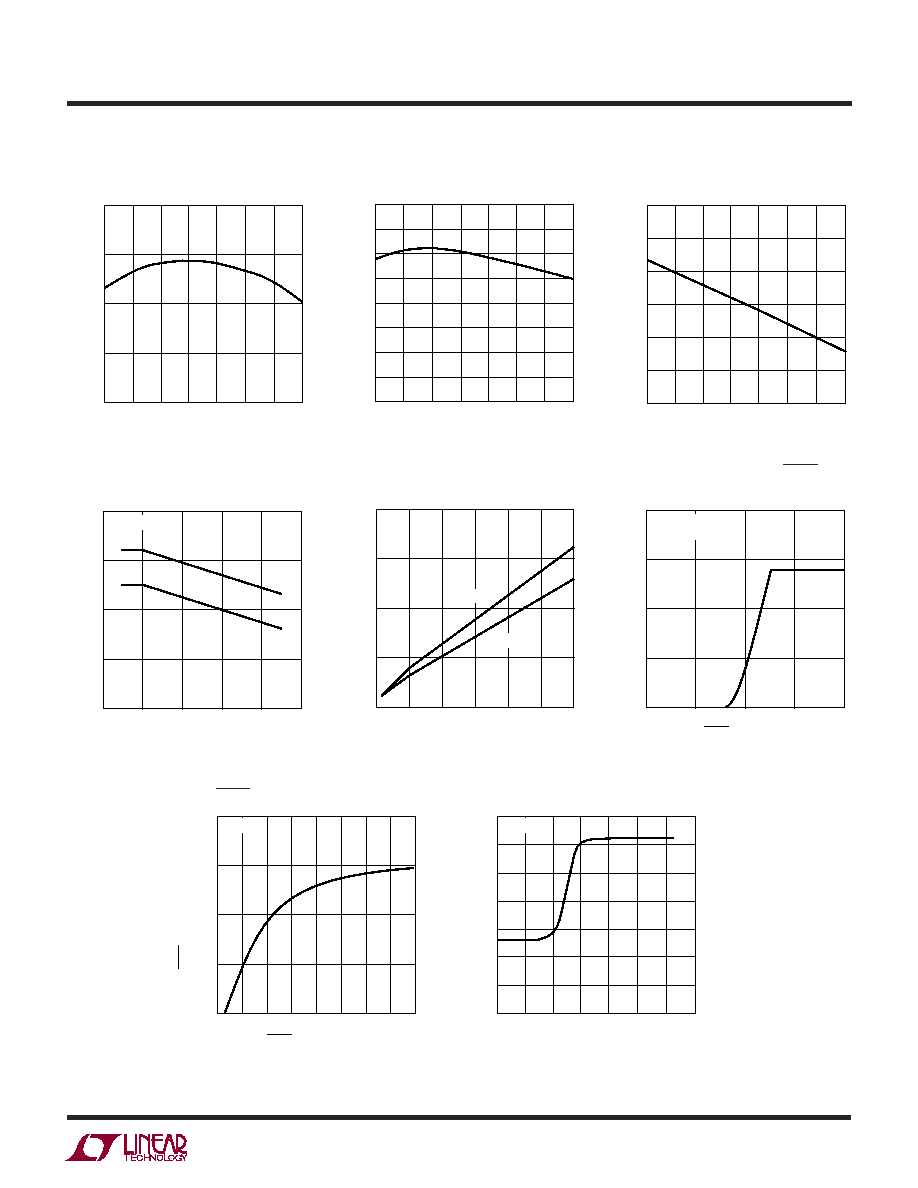

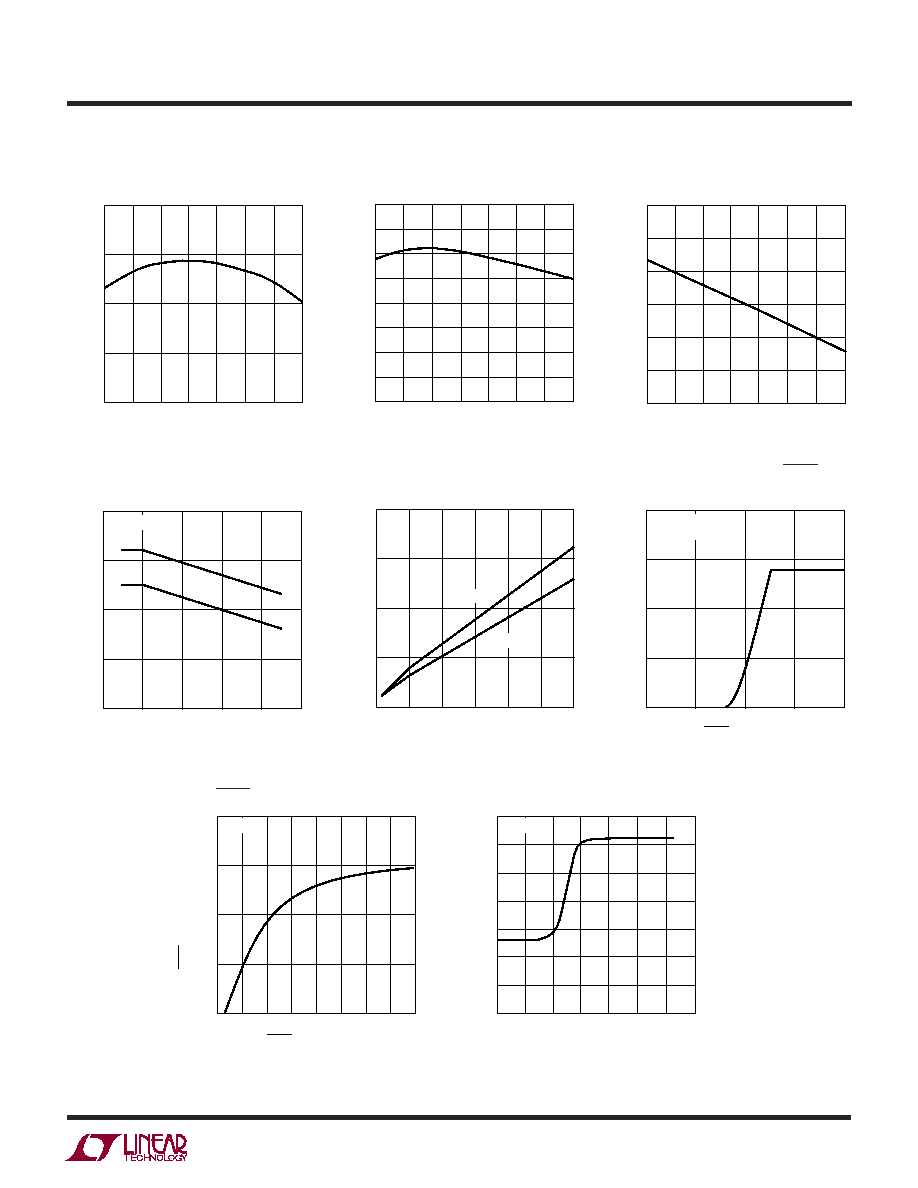

1.28

1.27

1.26

1.25

1.24

1935 G01

V

FB

(V)

TEMPERATURE (∞C)

≠50

FREQUENCY (MHz)

100

1935 G02

0

50

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

≠25

25

75

125

TEMPERATURE (∞C)

≠50

100

0

50

≠25

25

75

125

TEMPERATURE (∞C)

≠50

UVLO (V)

2.4

2.3

2.2

2.1

2.0

1.9

1.8

25

75

1935 G03

≠25

0

50

100

125

DUTY CYCLE (%)

0

CURRENT LIMIT (A)

2

3

80

1935 G04

1

0

20

40

60

100

4

SWITCH CURRENT (A)

0

SWITCH SATURATION VOLTAGE (mV)

400

300

200

100

0

0.5

1.0

1.5

2.0

1935 G05

2.5

3.0

SHDN VOLTAGE (V)

0

CURRENT LIMIT (A)

2

3

2.0

1935 G06

1

0

0.5

1.0

1.5

4

SHDN PIN VOLTAGE (V)

2

SHDN PIN CURRENT (

µ

A)

0

1935 G07

6

10

14

80

60

40

20

0

4

8

12

16

FEEDBACK VOLTAGE (V)

0

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

0.6

1.0

1935 G08

0.2

0.4

0.8

1.2

1.4

SWITCHING FREQUENCY (MHz)

T

A

= 25∞C

T

A

= 25∞C

T

A

= 25∞C

T

A

= 25∞C

T

A

= 85∞C

50% DUTY CYCLE

T

A

= 25∞C

TYP

MIN

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

FB Pin Voltage

Oscillator Frequency

Undervoltage Lockout

Current Limit

Switch Saturation Voltage

Peak Switch Current vs SHDN Pin

Voltage (Soft-Start)

SHDN Pin Current

Frequency Foldback

4

LT1935

1935f

SW (Pin 1): Switch Pin. Connect inductor/diode here.

Minimize trace area at this pin to reduce EMI.

GND (Pin 2): Ground. Tie directly to local ground plane.

FB (Pin 3): Feedback Pin. Reference voltage is 1.265V.

Connect resistive divider tap here. Minimize trace area at

FB. Set V

OUT

according to V

OUT

= 1.265V(1 + R1/R2).

U

U

U

PI FU CTIO S

SHDN (Pin 4): Shutdown Pin. Tie to 1.8V or more to enable

device. Ground to shut down. This pin also provides a soft-

start function; see Applications Information section.

V

IN

(Pin 5): Input Supply Pin. Must be locally bypassed.

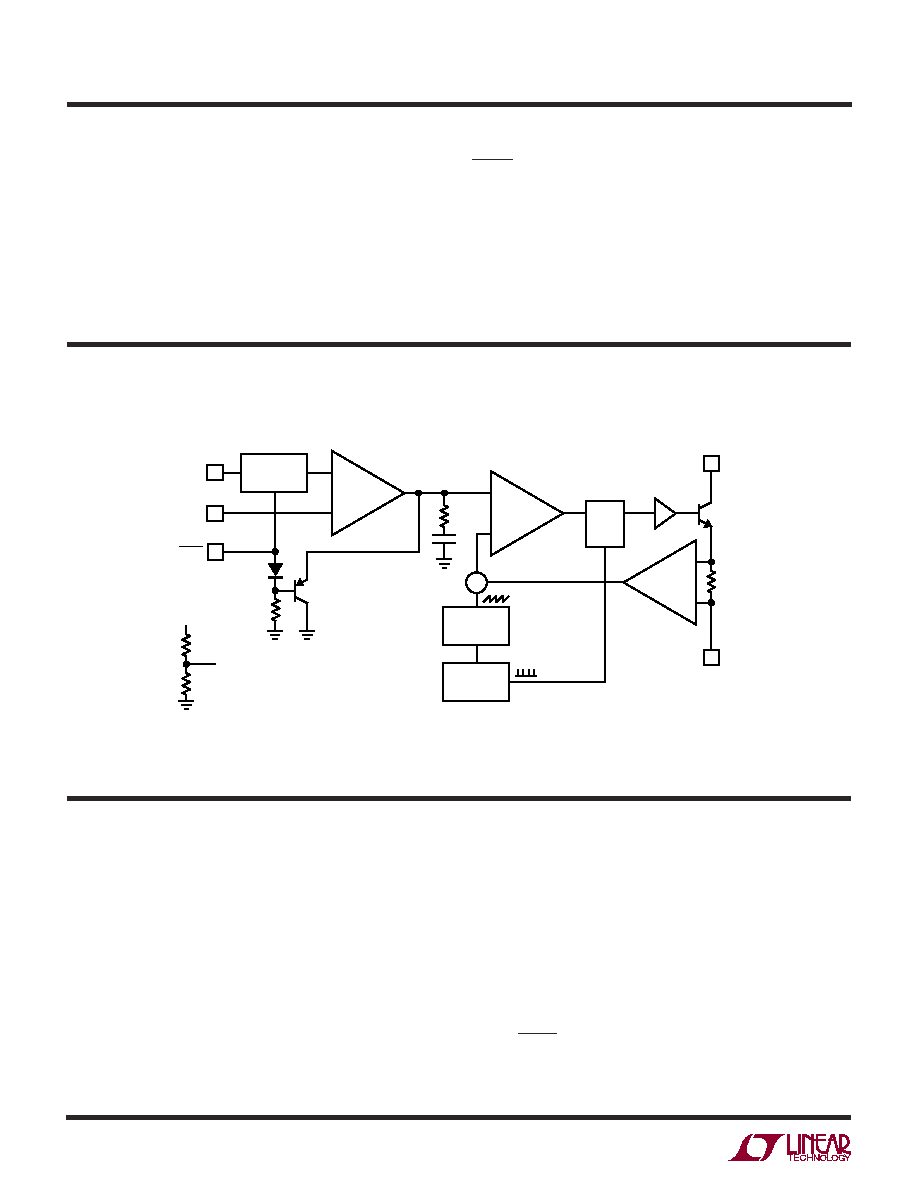

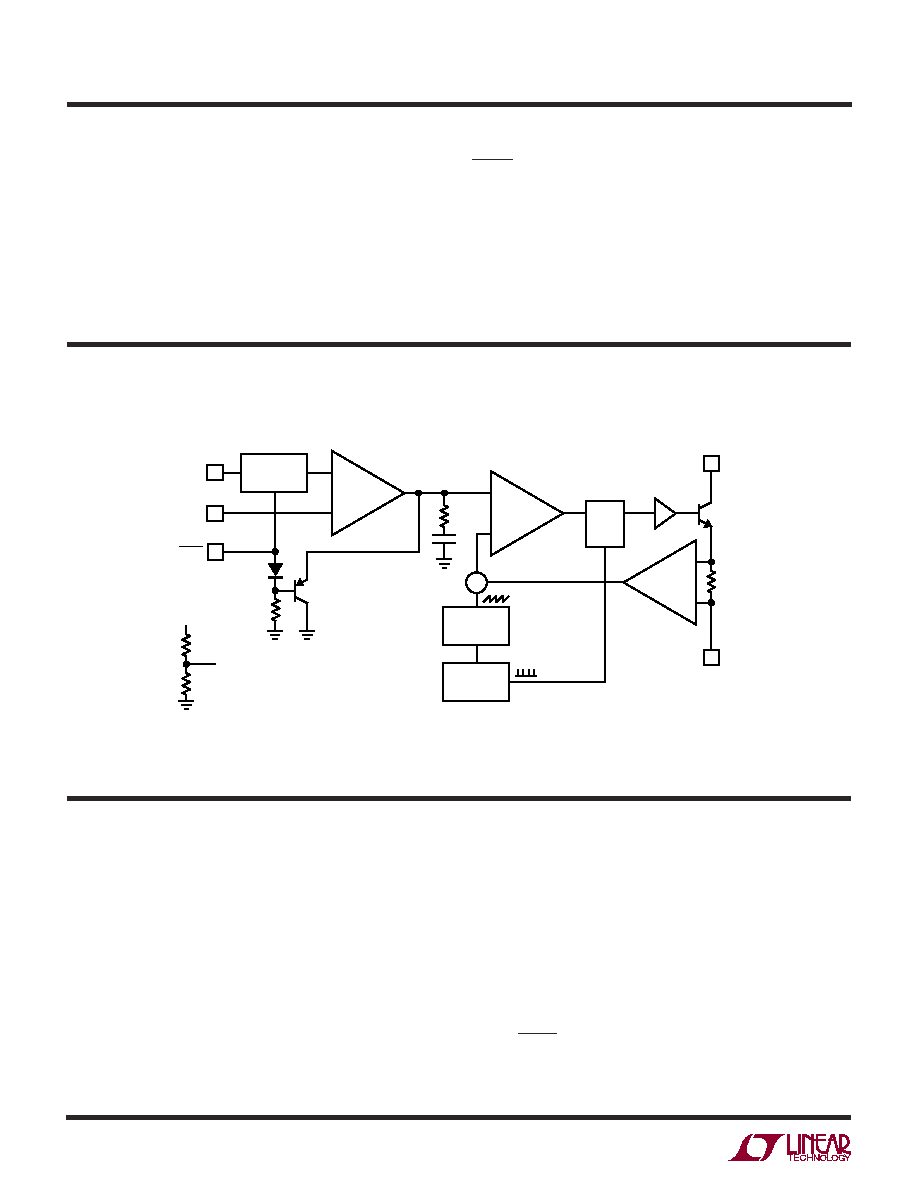

BLOCK DIAGRA

W

Figure 2. Block Diagram

≠

+

≠

+

R

Q

S

0.01

SW

DRIVER

COMPARATOR

2

1

V

IN

5

SHDN

4

FB

3

≠

+

RAMP

GENERATOR

1.265V

REFERENCE

R

C

C

C

1.2MHz

OSCILLATOR

GND

1935 BD

Q1

A2

A1

R1 (EXTERNAL)

R2 (EXTERNAL)

FB

V

OUT

x15

OPERATIO

U

The LT1935 uses a constant frequency, current mode

control scheme to provide excellent line and load regula-

tion. Operation can be best understood by referring to the

Block Diagram in Figure 2. At the start of each oscillator

cycle, the SR latch is set, turning on the power switch Q1.

A voltage proportional to the switch current is added to a

stabilizing ramp and the resulting sum is fed into the

positive terminal of the PWM comparator, A2. When this

voltage exceeds the level at the negative input of A2, the

SR latch is reset, turning off the power switch. The level

at the negative input of A2 is set by error amplifier A1, and

is simply an amplified version of the difference between

the feedback voltage and the reference voltage of 1.265V.

In this manner, the error amplifier sets the correct peak

current level to keep the output in regulation. If the error

amplifier's output increases, more current is delivered to

the output; if it decreases, less current is delivered. A

clamp on the output of A1 (not shown) limits the switch

current to 3A. A1's output is also clamped to the voltage

on the SHDN pin, providing a soft-start function by con-

trolling the peak switch current during start-up.

5

LT1935

1935f

APPLICATIO

N

S I

N

FOR

M

ATIO

N

W

U

U

U

Inductor Selection

Use inductors that are intended for high frequency power

applications. The saturation current rating should be at

least 2A. The RMS current rating, which is usually based

on heating of the inductor, should be higher than the

average current in the inductor in your application. For

best efficiency, the DC resistance should be less than

100m.

A good first choice for the inductor value results in a ripple

current that is 1/3 of the maximum switch current:

L = 3 (V

IN

/V

OUT

) (V

OUT

≠ V

IN

)/(I

MAX

∑ f)

I

MAX

is the maximum switch current of 2A and f is the

switching frequency. At lower duty cycles (less than 70%),

this value can be lowered somewhat in order to use a

physically smaller inductor.

Table 1 lists several inductor manufacturers, along with

part numbers for inductors that are a good match to the

LT1935.

Table 1. Inductor Suppliers

Supplier

Model Prefix

Sumida

CDRH4D18, CDRH4D28,

CDRH5D18, CDRH5D28, CR43

Coiltronics/Cooper

SD10, SD12, SD18, SD20

Wurth Elektronik

WE-PD2S, WE-PD3S, WE-PD4S

Coilcraft

MSS5131, MSS6132, DO1608

Diode Selection

Use a Schottky rectifier with a 1A or higher current rating,

such as the On Semiconductor MBRM120. Its 20V reverse

voltage rating is adequate for most applications. Higher

output voltages may require a 30V of 40V diode.

Capacitor Selection

Use capacitors with low ESR (equivalent series resis-

tance). In most cases, multilayer ceramic capacitors are

the best choice. They offer high performance (very low

ESR) in a small package. Use only X5R or X7R types; they

maintain their capacitance over temperature and applied

voltage. Other suitable capacitor types include low-ESR

tantalum capacitors that are specified for power applica-

tions, and newer types of capacitors such as Sanyo's

POSCAP and Panasonic's SP CAP.

Use a 4.7µF ceramic capacitor to bypass the input of the

LT1935. Be aware that the switching regulators require a

low impedance input supply. Additional bulk capacitance

may be required if the LT1935 circuit is more than a few

inches away from the power source. If there are low ESR

capacitors nearby, the input bypass capacitor can be

reduced to 2.2µF.

The output capacitor supports the output under transient

loads and stabilizes the control loop of the LT1935. Look

at the typical application circuits as a starting point to

choose a value. Generally, a higher output capacitance is

required at higher load currents and lower input voltages.

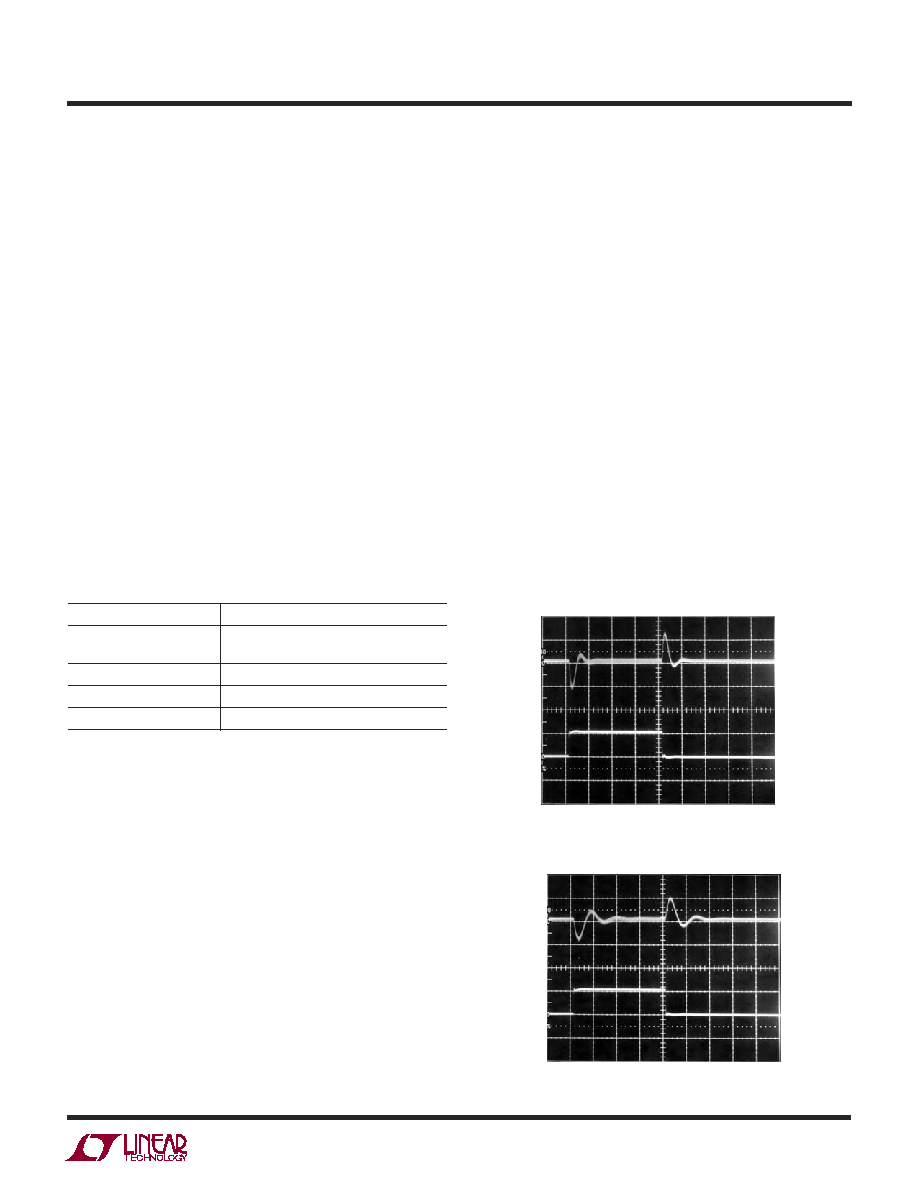

Figure 3 shows transient response of the circuit in Fig-

ure 1. The load is stepped from 200mA to 400mA and back

to 200mA. The transient performance can be improved by

increasing the output capacitance, but may require a

phase lead capacitor between the output and the FB pin.

Figure 4 shows the transient response with the output

capacitor increased to 20µF. Figure 5 shows the additional

improvement resulting from the phase lead capacitor.

Figure 4. Transient Response with C

OUT

= 20µF

Figure 3. Transient Response of the Circuit in Figure 1,

C

OUT

= 10µF

..

VOUT

100mV/DIV

ILOAD

200mA/DIV

50µs/DIV

1935 F03

0

VOUT

100mV/DIV

ILOAD

200mA/DIV

50µs/DIV

1935 F04