MP03XXX360H

1/8

www.dynexsemi.com

FEATURES

I

Dual Device Module

I

Electrically Isolated Package

I

Pressure Contact Construction

I

International Standard Footprint

I

Alumina (Non Toxic) Isolation Medium

APPLICATIONS

I

Motor Control

I

Controlled Rectifier Bridges

I

Heater Control

I

AC Phase Control

VOLTAGE RATINGS

ORDERING INFORMATION

Order As:

MP03HBT360-18 or MP03HBT360-16

MP03HBN360-18 or MP03HBN360-16

MP03HBP360-18 or MP03HBP360-16

Note: When ordering, please use the complete part number.

KEY PARAMETERS

V

DRM

1800V

I

T(AV)

355A

I

TSM(per arm)

8100A

V

isol

3000V

MP03XXX360H

Dual Thyristor, Thyristor/Diode Module

DS5560-1.0 July 2002

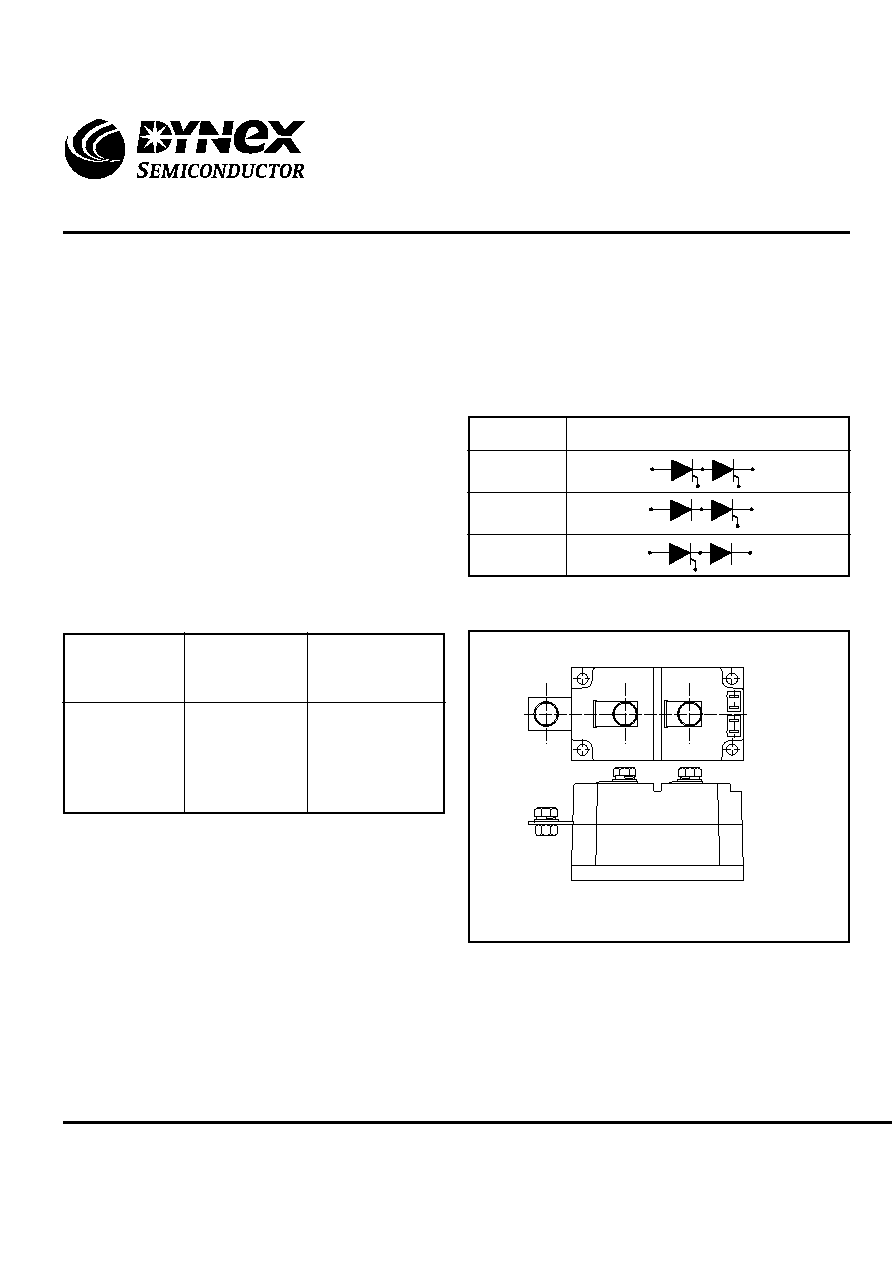

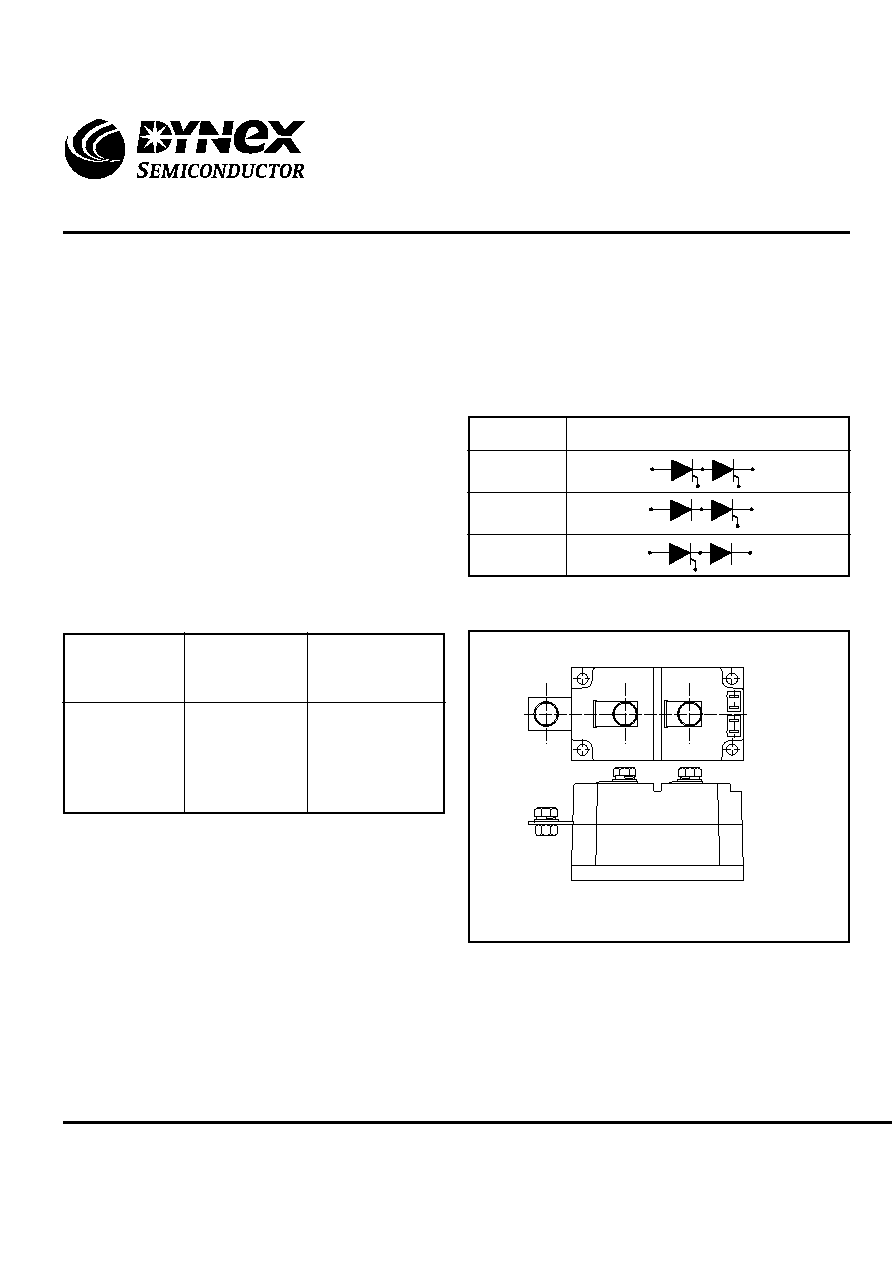

Fig. 2 Electrical connections - (not to scale)

Outline type code: MP03

1800

1600

MP03XXX360-18

MP03XXX360-16

Conditions

T

vj

= 0∞ to 130∞C,

I

DRM

= I

RRM

= 50mA

V

DSM

= V

RSM

=

V

DRM

= V

RRM

+ 100V

respectively

Lower voltage grades available.

Type Number

Repetitive Peak

Voltages

V

DRM

V

RRM

V

1

2

3

K

2

G

2

G

1

K

1

Code

Circuit

HBT

HBP

HBN

Fig.1 Circuit diagrams

MP03XXX360H

2/8

www.dynexsemi.com

Test Conditions

Half wave resistive load

T

case

= 75∞C

T

case

= 85∞C

T

heatsink

= 75∞C

T

heatsink

= 85∞C

T

case

= 75∞C

10ms half sine, T

j

= 130∞C

V

R

= 0

10ms half sine, T

j

= 130∞C

V

R

= 50% V

DRM

Commoned terminals to base plate.

AC RMS, 1 min, 50Hz

Symbol

I

T(AV)

I

T(RMS

I

TSM

I

2

t

I

TSM

I

2

t

V

isol

Units

A

A

A

A

A

kA

A

2

s

kA

A

2

s

V

Max.

355

312

276

242

560

8.1

330 x10

3

6.5

210 x10

3

3000

ABSOLUTE MAXIMUM RATINGS - PER ARM

Stresses above those listed under 'Absolute Maximum Ratings' may cause permanent damage to the device. In extreme

conditions, as with all semiconductors, this may include potentially hazardous rupture of the package. Appropriate safety

precautions should always be followed. Exposure to Absolute Maximum Ratings may affect device reliability.

Parameter

Mean on-state current

RMS value

Surge (non-repetitive) on-current

I

2

t for fusing

Surge (non-repetitive) on-current

I

2

t for fusing

Isolation voltage

Test Conditions

dc

Half wave

3 Phase

Mounting torque = 5Nm

with mounting compound

Reverse (blocking)

-

Mounting - M5

Electrical connections - M8

-

Parameter

Thermal resistance - junction to case

(per thyristor or diode)

Thermal resistance - case to heatsink

(per thyristor or diode)

Virtual junction temperature

Storage temperature range

Screw torque

Weight (nominal)

THERMAL AND MECHANICAL RATINGS

Symbol

R

th(j-c)

R

th(c-hs)

T

vj

T

stg

-

-

Units

∞C/kW

∞C/kW

∞C/kW

∞C/kW

∞C

∞C

Nm (lb.ins)

Nm (lb.ins)

g

Max.

0.105

0.115

0.12

0.05

135

135

5(44)

9(80)

950

Min.

-

-

-

-

-

≠40

-

-

-

MP03XXX360H

3/8

www.dynexsemi.com

Units

mA

V/

µs

A/

µs

V

m

Test Conditions

At V

RRM

/V

DRM

, T

j

= 130∞C

To 67% V

DRM

, T

j

= 130∞C

From 67% V

DRM

to 600A, gate source 10V, 5

t

r

= 0.5

µs, T

j

= 130∞C

At T

vj

= 135∞C. See note 1

At T

vj

= 135∞C. See note 1

Parameter

Peak reverse and off-state current

Linear rate of rise of off-state voltage

Rate of rise of on-state current

Threshold voltage

On-state slope resistance

DYNAMIC CHARACTERISTICS - THYRISTOR

Symbol

I

RRM

/I

DRM

dV/dt

dI/dt

V

T(TO)

r

T

Max.

50

1000

500

0.78

0.79

Min.

-

-

-

-

-

Parameter

Gate trigger voltage

Gate trigger current

Gate non-trigger voltage

Peak forward gate voltage

Peak forward gate voltage

Peak reverse gate voltage

Peak forward gate current

Peak gate power

Mean gate power

Test Conditions

V

DRM

= 5V, T

case

= 25

o

C

V

DRM

= 5V, T

case

= 25

o

C

At V

DRM

T

case

= 125

o

C

Anode positive with respect to cathode

Anode negative with respect to cathode

-

Anode positive with respect to cathode

See table fig. 5

-

Symbol

V

GT

I

GT

V

GD

V

FGM

V

FGN

V

RGM

I

FGM

P

GM

P

G(AV)

GATE TRIGGER CHARACTERISTICS AND RATINGS

Max.

3

150

0.25

30

0.25

5

10

100

5

Units

V

mA

V

V

V

V

A

W

W

Note 1: The data given in this datasheet with regard to forward voltage drop is for calculation of the power dissipation in the

semiconductor elements only. Forward voltage drops measured at the power terminals of the module will be in excess of these

figures due to the impedance of the busbar from the terminal to the semiconductor.

MP03XXX360H

4/8

www.dynexsemi.com

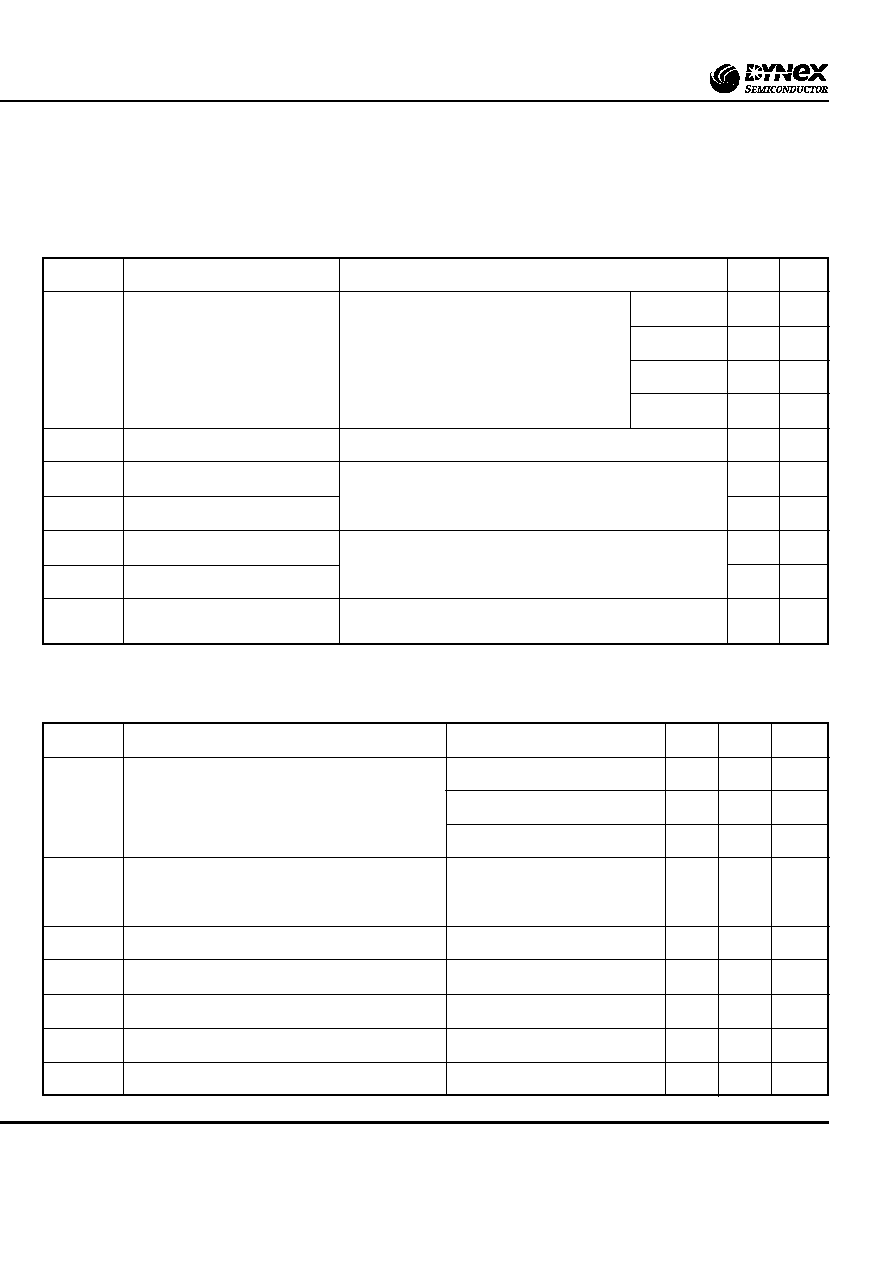

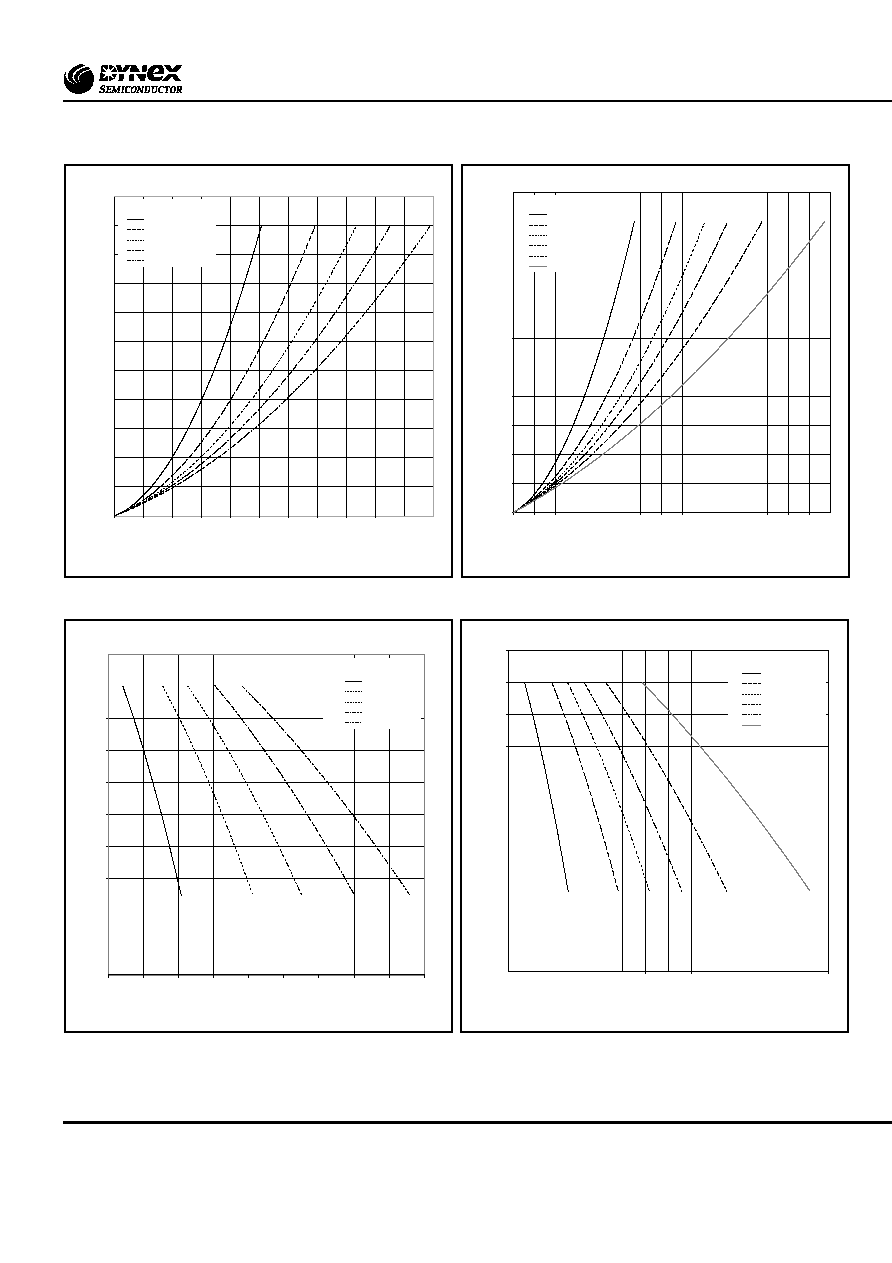

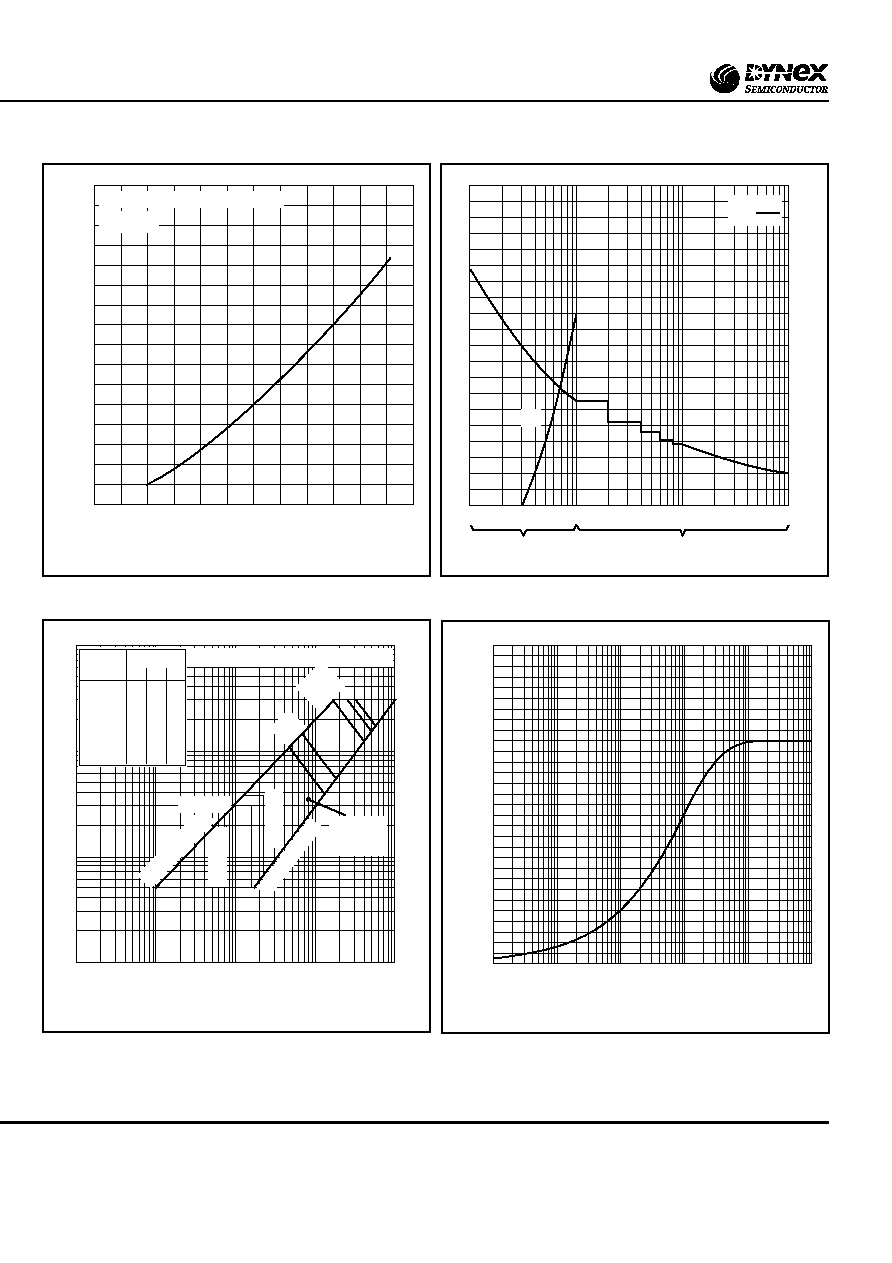

Fig. 6 Transient thermal impedance - dc

Fig. 3 Maximum (limit) on-state characteristics

Fig. 4 Surge (non-repetitive) on-state current vs time

(with 50% V

RSM

at T

case

= 130∞C)

Fig. 5 Gate characteristics

1600

1200

800

400

1400

1000

600

200

0

Instantaneous on-state current, I

T

- (A)

0.6

1.0

1.4

1.8

Instantaneous on-state voltage, V

T

- (V)

Measured under pulse conditions

T

j

= 135∞C

0.8

1.2

1.6

20

15

10

5

0

Peak half sine wave on-state current - (kA)

1

10

1

2

3 4 5

50

ms

Cycles at 50Hz

Duration

150

175

200

I

2

t value - (A

2

s x 10

3

)

I

2

t

I

2

t = Œ

2

x t

2

10

20 30

100

10

1

0.1

0.001

0.1

0.01

I

GD

0.1

10

I

FGM

V

FGM

Lower Limit 1%

Upper Limi

t 99%

T

j

=

≠

40

∞

C

T

j

= 25∞C

T

j

= 125

∞

C

Gate trigger voltage, V

GT

- (V)

Gate trigger current, I

GT

- (A)

100

W

75

W

50W

10

W

5W

Table gives pulse power P

GM

in Watts

Pulse width

µs

20

25

100

500

1ms

10ms

Frequency Hz

50

100

100

100

100

100

10

100

100

100

100

100

50

-

400

100

100

100

25

-

-

Region of

certain

triggering

100

10

1.0

0.1

0.01

0.001

Time - (s)

0.15

0

0.10

0.05

Thermal impedance, R

th(j-c)

- (

∞

C/W)

d.c.

MP03XXX360H

5/8

www.dynexsemi.com

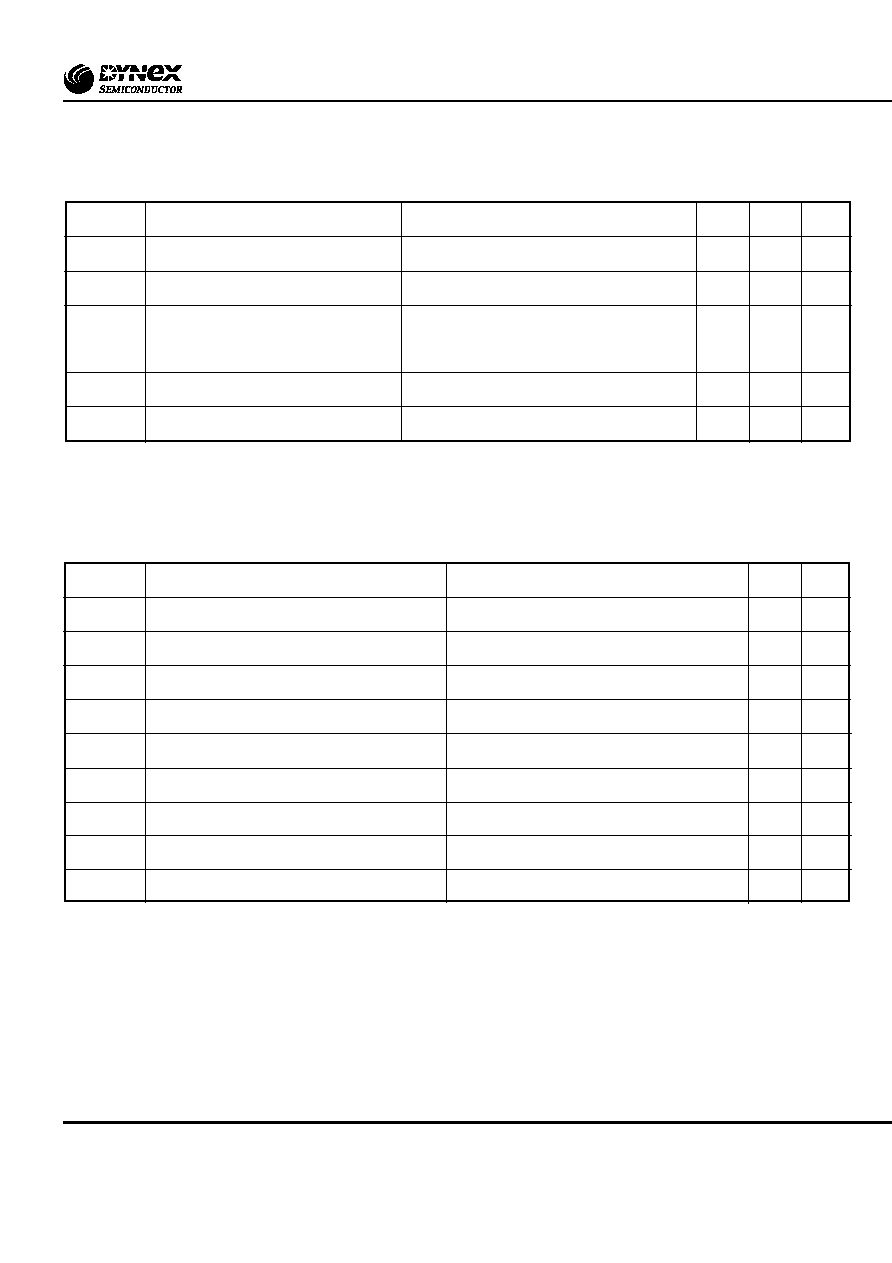

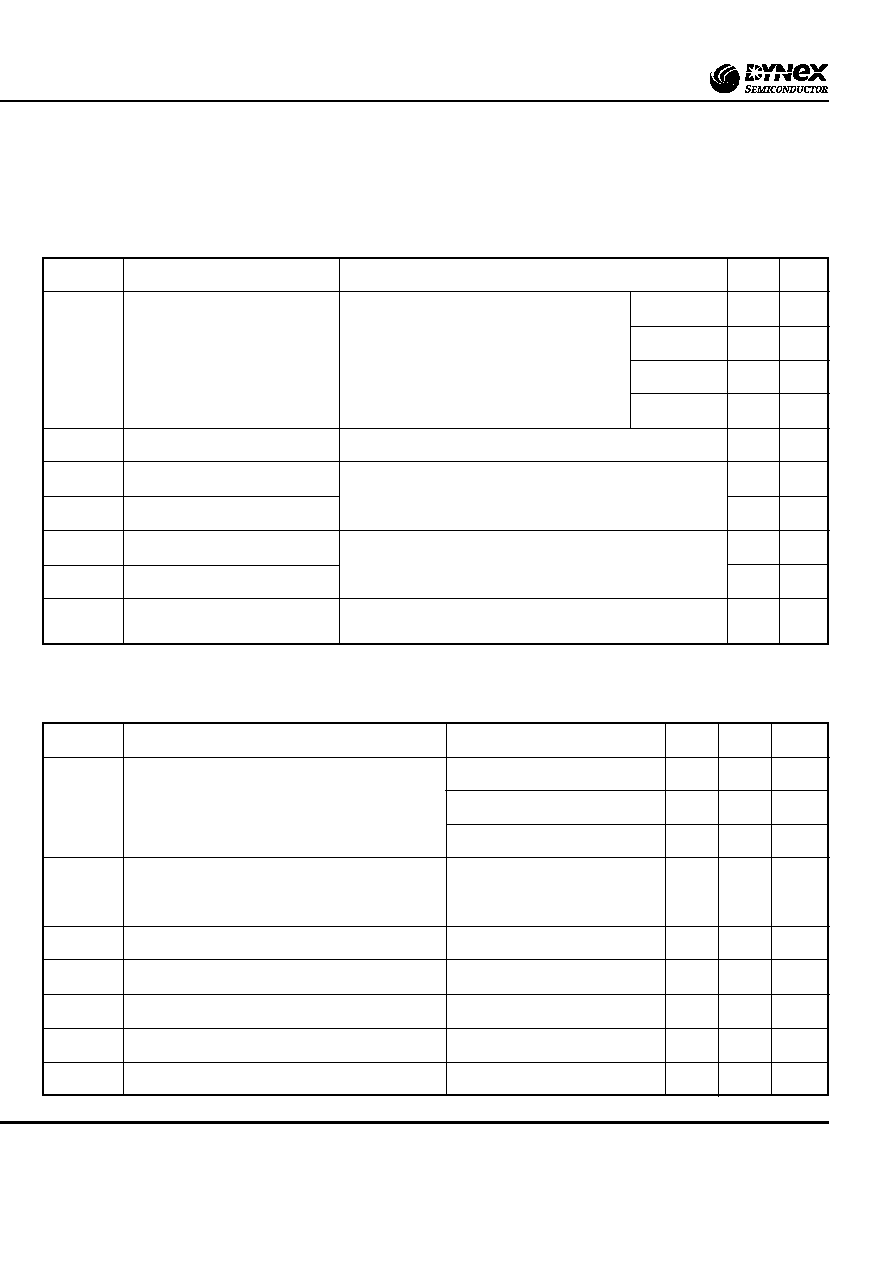

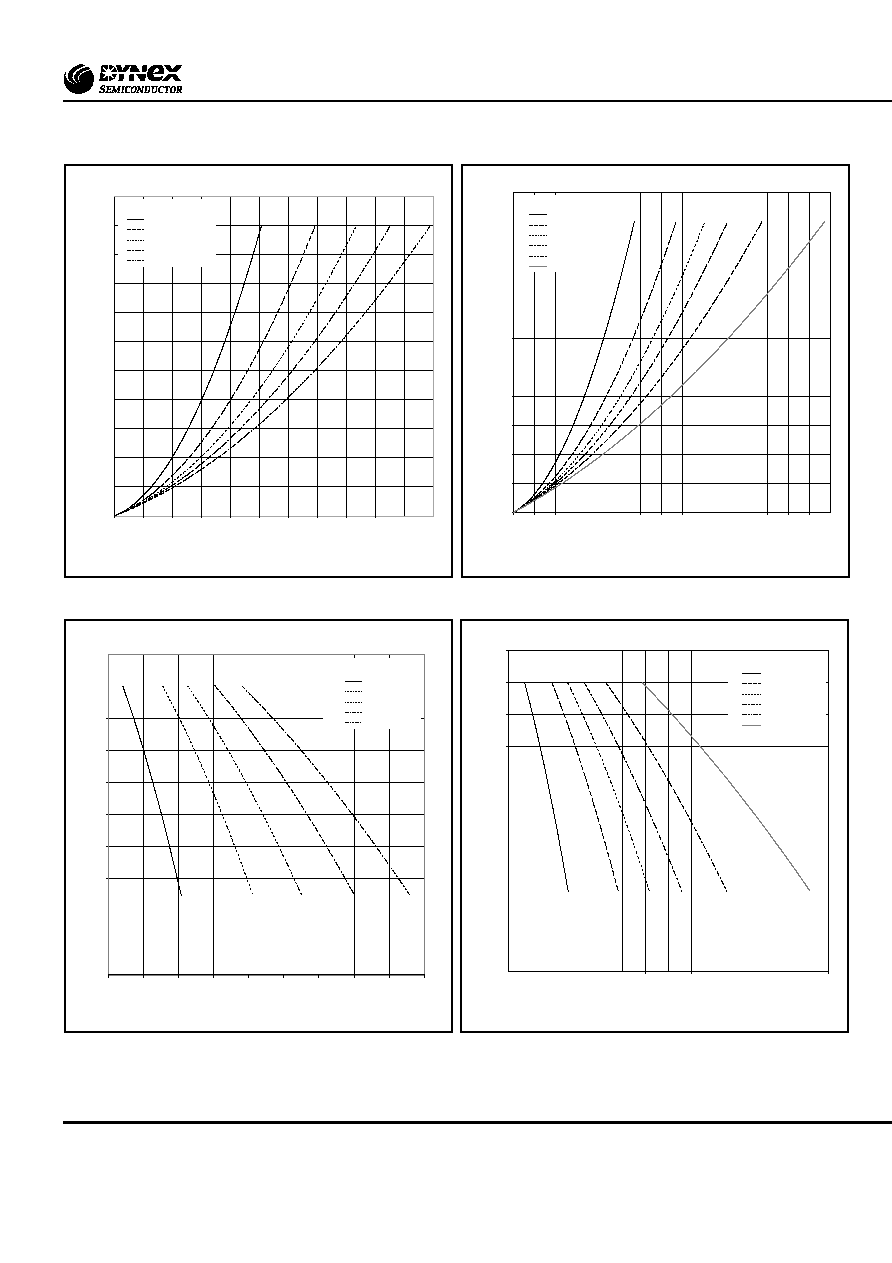

Fig. 7 On-state power loss per arm vs on-state current at

specified conduction angles, sine wave 50/60Hz

Fig. 8 On-state power loss per arm vs on-state current at

specified conduction angles, square wave 50/60Hz

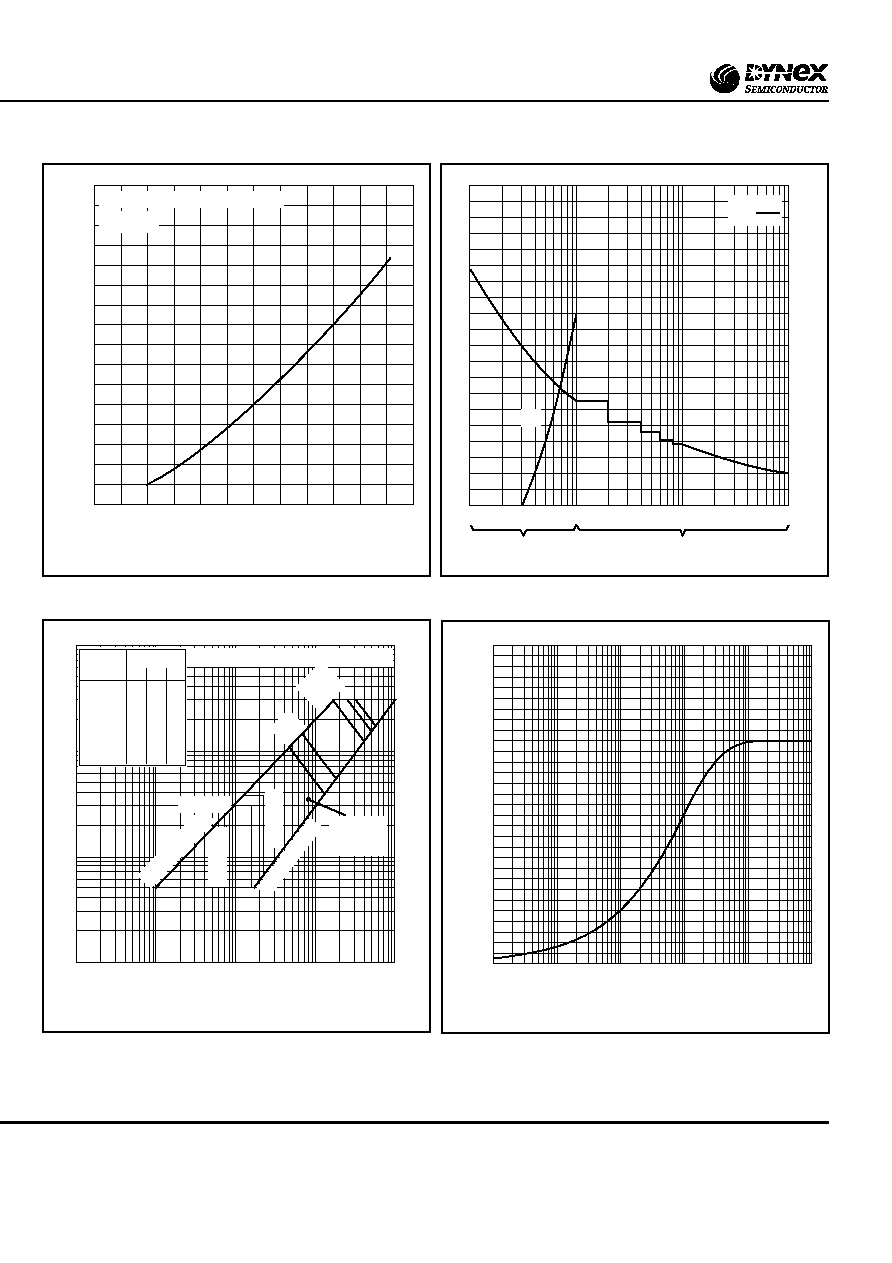

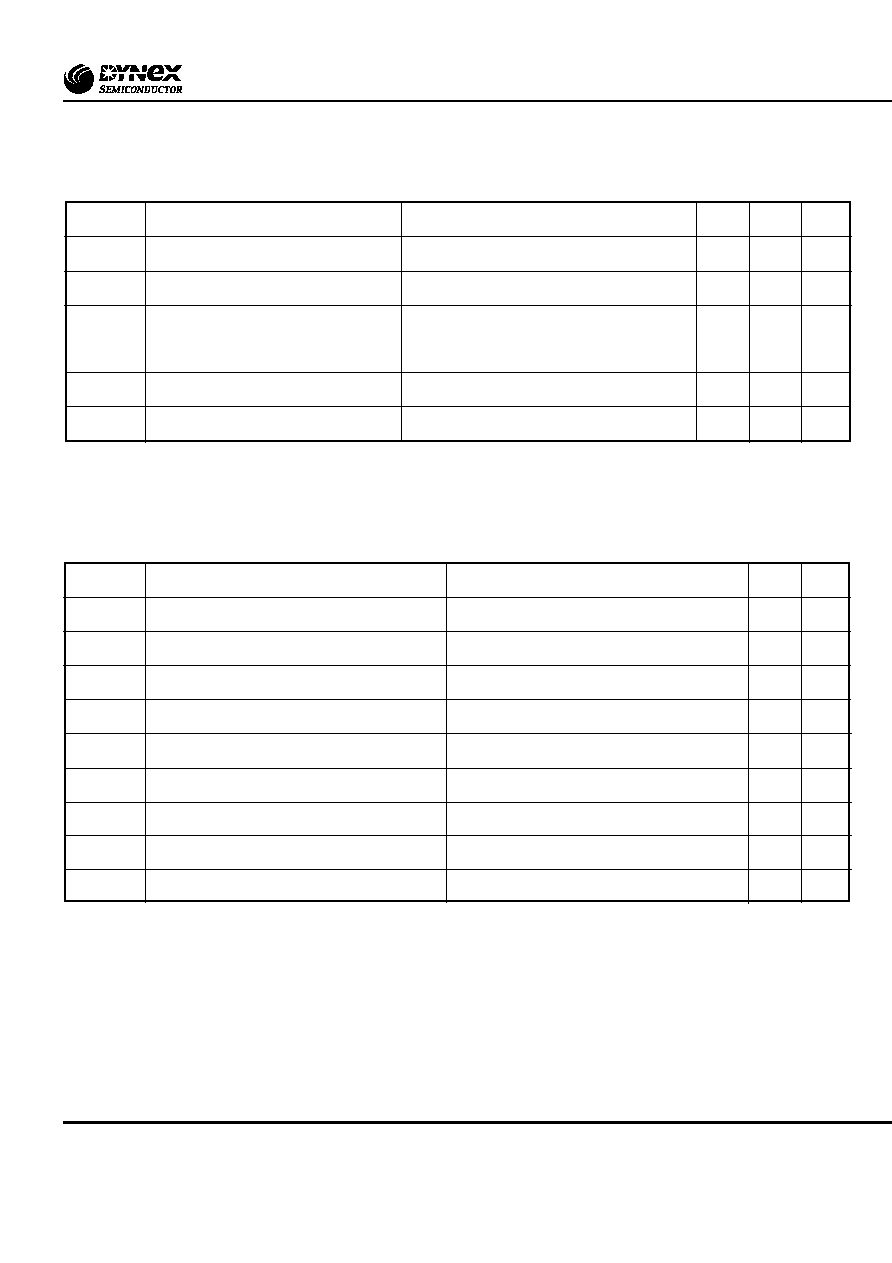

Fig. 9 Maximum permissible case temperature vs

on-state current at specified conduction angles,

sine wave 50/60Hz

Fig. 10 Maximum permissible case temperature vs

on-state current at specified conduction angles,

square wave 50/60Hz

0

100

200

300

400

500

600

700

800

900

1000

1100

0

50 100 150 200 250 300 350 400 450 500 550

Sine wave current (Average, per arm)

Power dissipation (Watts, per arm)

30∞

60∞

90∞

120∞

180∞

Conduction angle

0

100

200

300

400

500

600

700

800

900

1000

1100

0

50

150

250

350

450

550

650

750

Square wave current (Average, per arm)

Power dissipation (Watts, per arm)

30∞

60∞

90∞

120∞

180∞

DC

Conduction angle

0

10

20

30

40

50

60

70

80

90

100

100

150

200

250

300

350

400

450

500

550

Sine wave current (Average, per arm) - (A)

Maximum permissble case temperature - (

∞

C)

30∞

60∞

90∞

120∞

180∞

Conduction angle

0

10

20

30

40

50

60

70

80

90

100

100

200

300

400

500

600

700

800

Square wave current (Average, per arm) - (A)

Maximum permissible case temperature - (

∞

C)

30∞

60∞

90∞

120∞

180∞

DC

Conduction angle