| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: LTC1876EG | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

LTC1876

1

1876fa

APPLICATIO S

U

FEATURES

DESCRIPTIO

U

TYPICAL APPLICATIO

U

High Efficiency, 2-Phase,

Dual Synchronous Step-Down Switching

Controller and Step-Up Regulator

The LTC

Æ

1876 is a high performance triple output switching

regulator. It incorporates a dual step-down switching con-

troller that drives all N-channel synchronous power MOSFET

stages. A step-up regulator with an internal 1A, 36V switch

provides the third output.

The step-down controllers minimize power loss and noise

by operating the output stage of each controller out of

phase. OPTI-LOOP compensation allows the transient

response to be optimized over a wide range of output

capacitance and ESR values. A RUN/SS pin for each

controller provides both soft-start and an optional timed,

short-circuit shutdown that can be configured to latch off

one or both controllers. Current foldback provides

additional short-circuit protection. In an overvoltage

condition, the bottom MOSFET is latched on until V

OUT

returns to normal. The FCB pin can be used to inhibit Burst

Mode operation or to enable regulation of a secondary

output voltage.

The step-up regulator operates at 1.2MHz, allowing the

use of tiny low cost capacitors and inductors. In addition,

its internal 1A switch allows high current outputs to be

generated. Its current mode control scheme provides

excellent line and load regulation.

Step-Down Controller

s

Out-of-Phase Controllers Reduce Required Input

Capacitance and Power Supply Induced Noise

s

Power Good Output Voltage Indicator

s

OPTI-LOOP

TM

Compensation Minimizes C

OUT

s

DC Programmed Fixed Frequency 150kHz to 300kHz

s

Wide V

IN

Range: 3.5V to 36V Operation

s

Very Low Dropout Operation: 99% Duty Cycle

s

Adjustable Soft-Start Current Ramping

s

Latched Short-Circuit Shutdown with Defeat Option

s

Remote Output Voltage Sense and OV Protection

s

5V and 3.3V Standby Regulators

s

Selectable Const. Freq. or Burst Mode

TM

Operation

Step-Up Regulator

s

High Operating Switching Frequency of 1.2MHz

s

Low Internal V

CESAT

Switch: 400mV @ 1A, V

IN

= 3V

s

Wide V

IN

Range: 2.6V to 16V Operation

s

High Output Voltage: Up to 34V

s

3.3V Input Step-Down Converter

s

Notebook and Palmtop Computers, PDAs

s

Battery-Operated Digital Devices

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode and OPTI-LOOP are trademarks of Linear Technology Corporation.

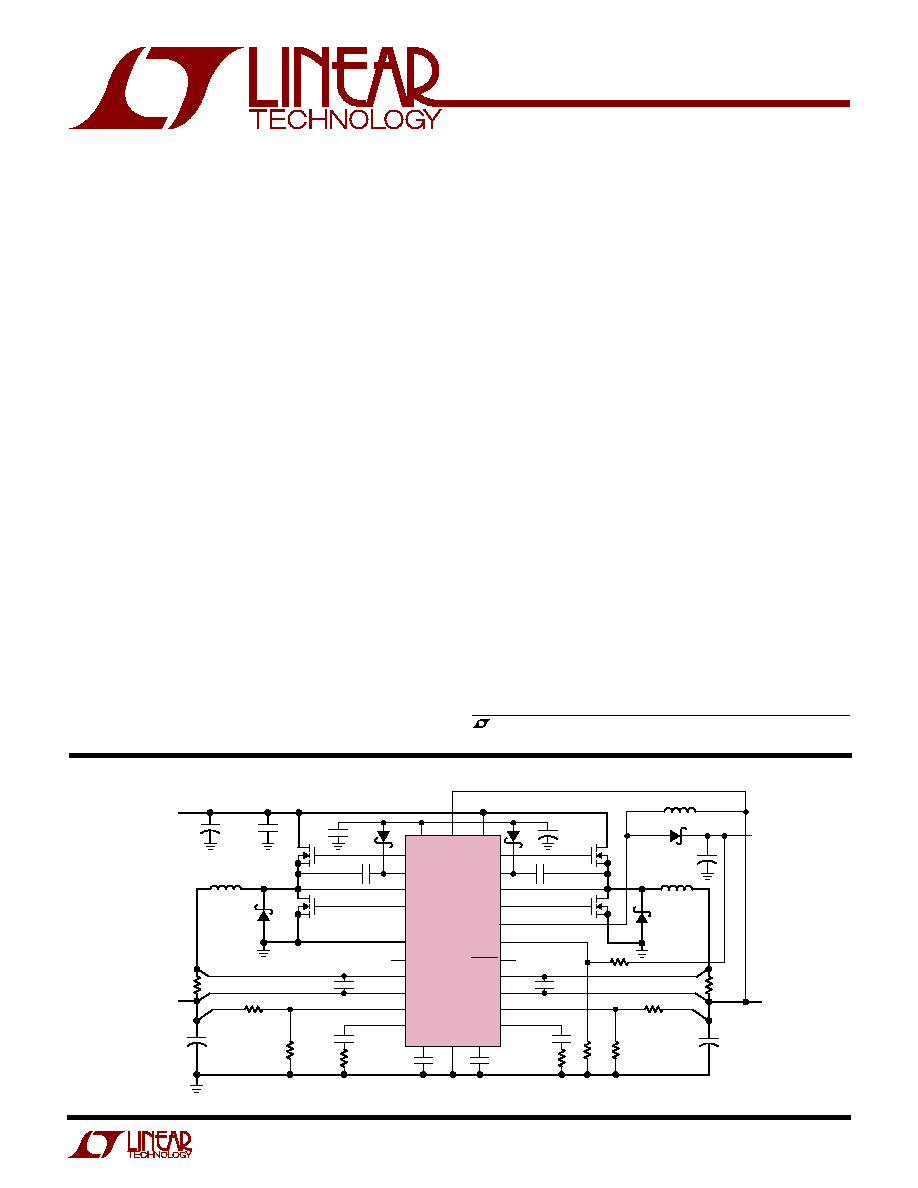

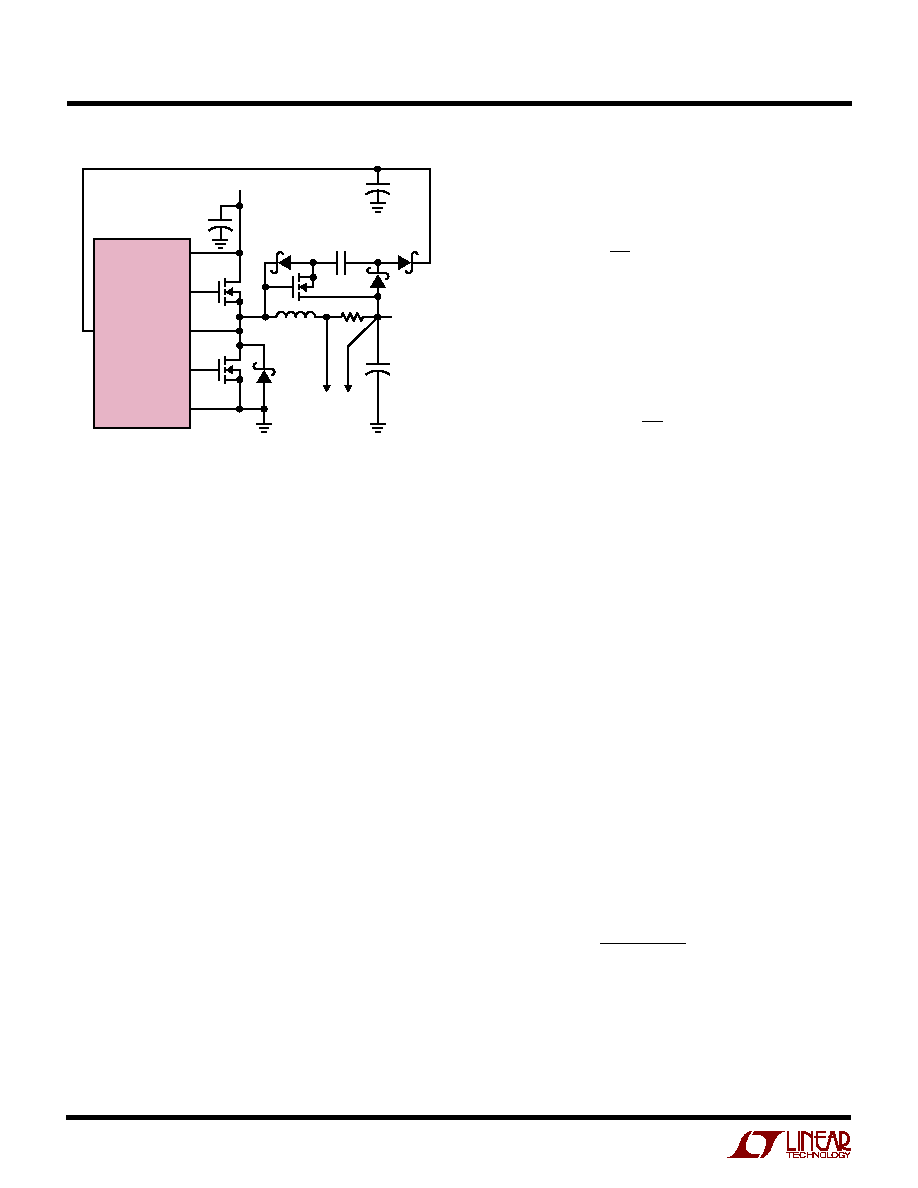

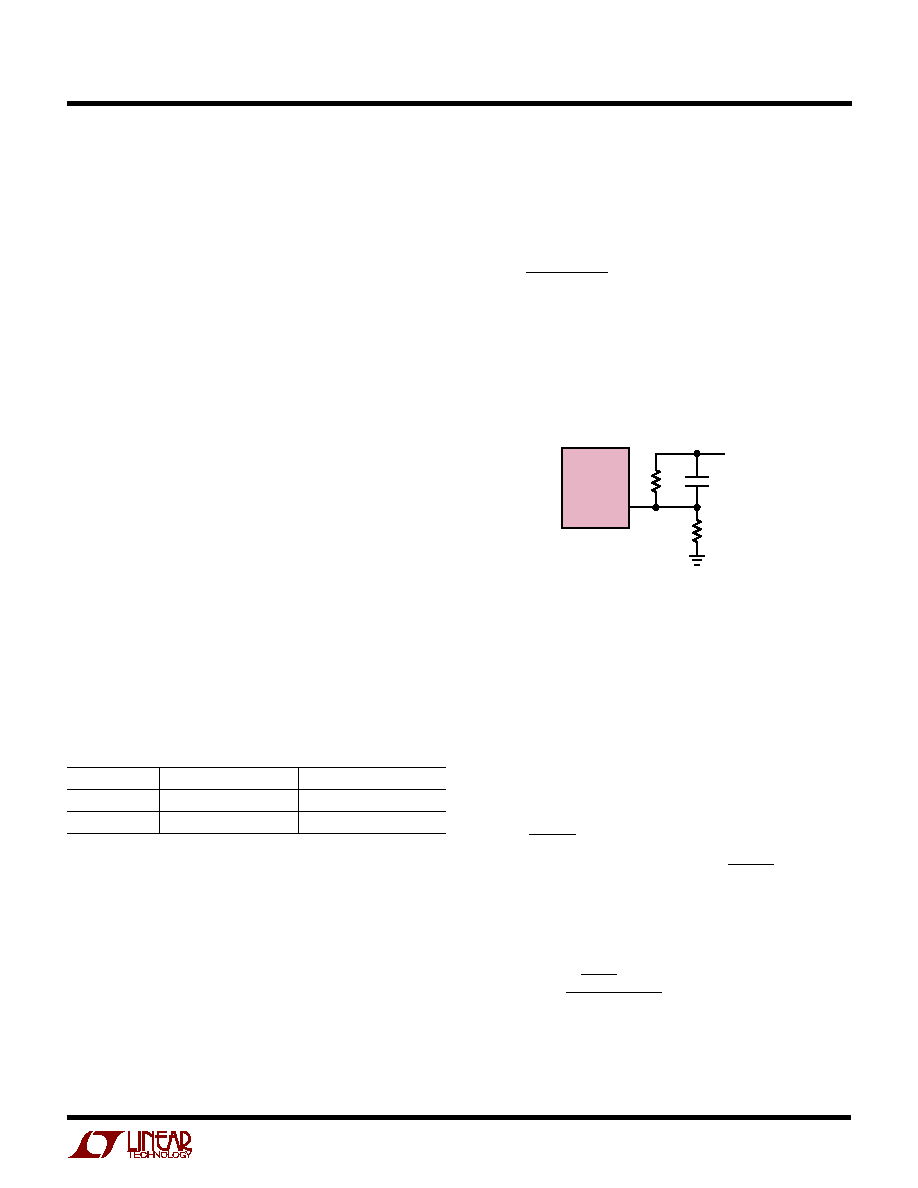

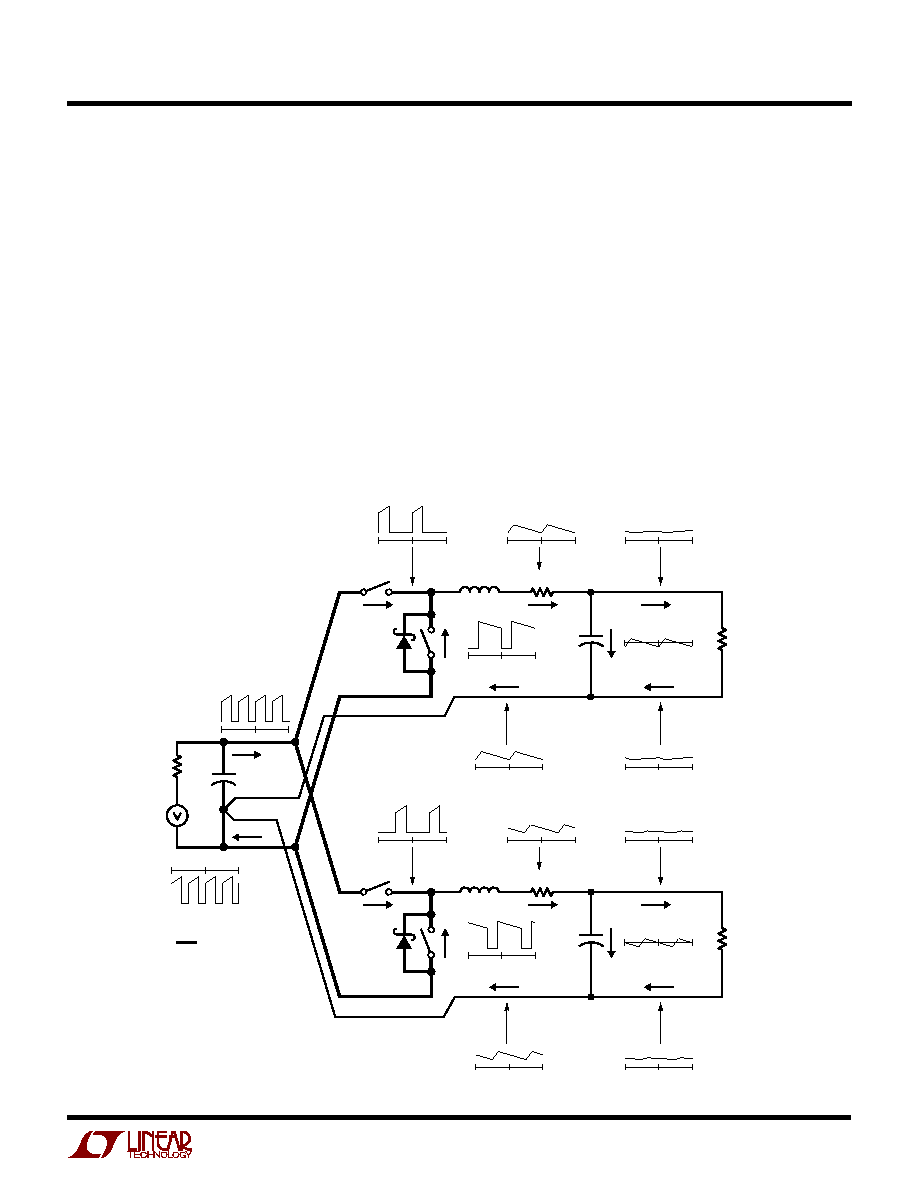

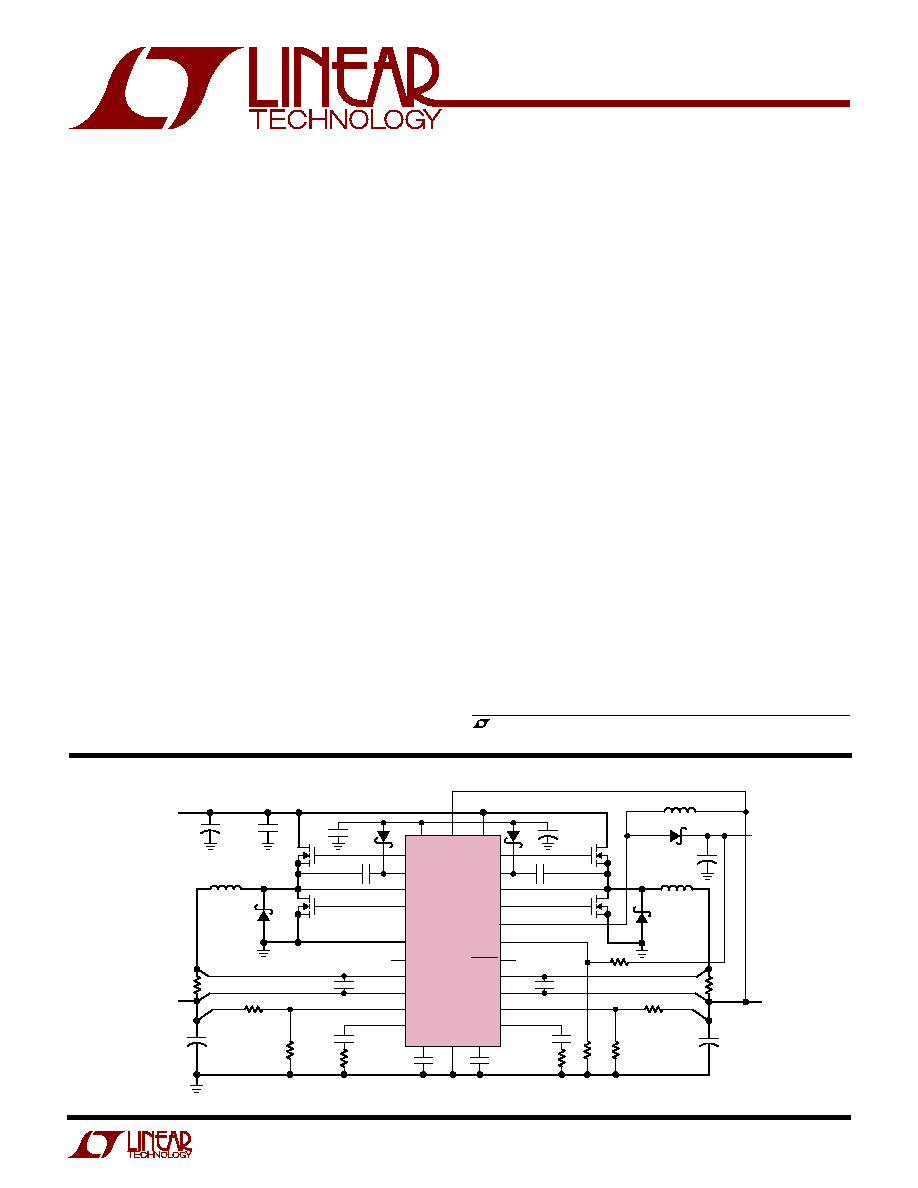

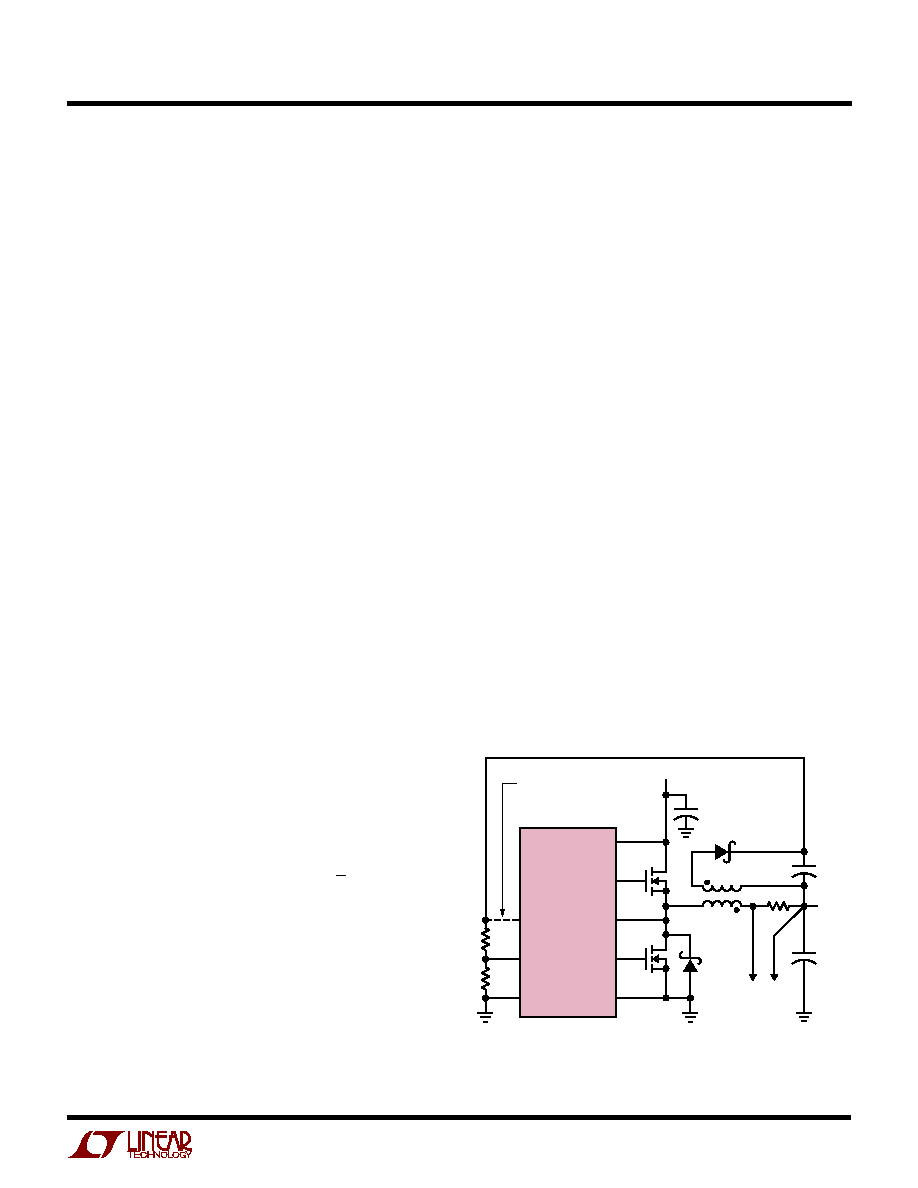

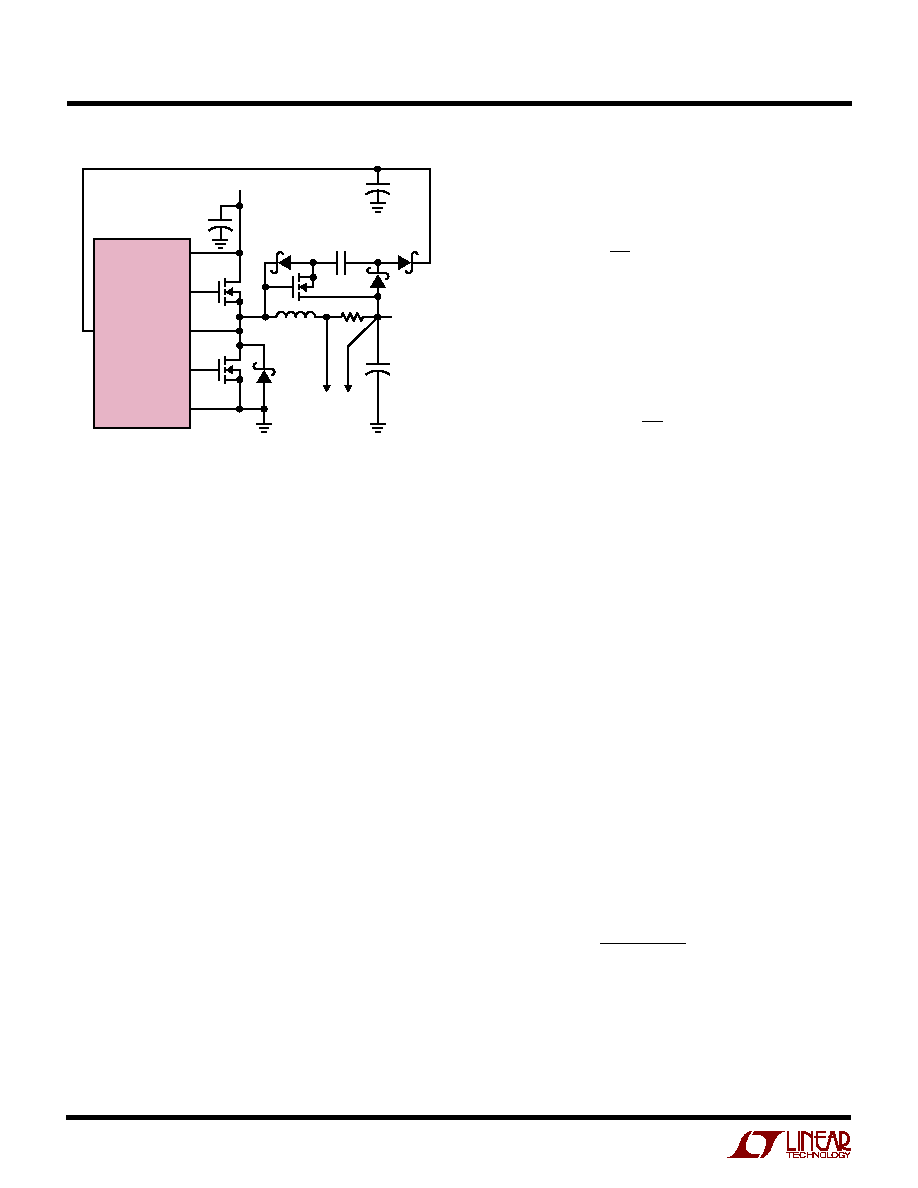

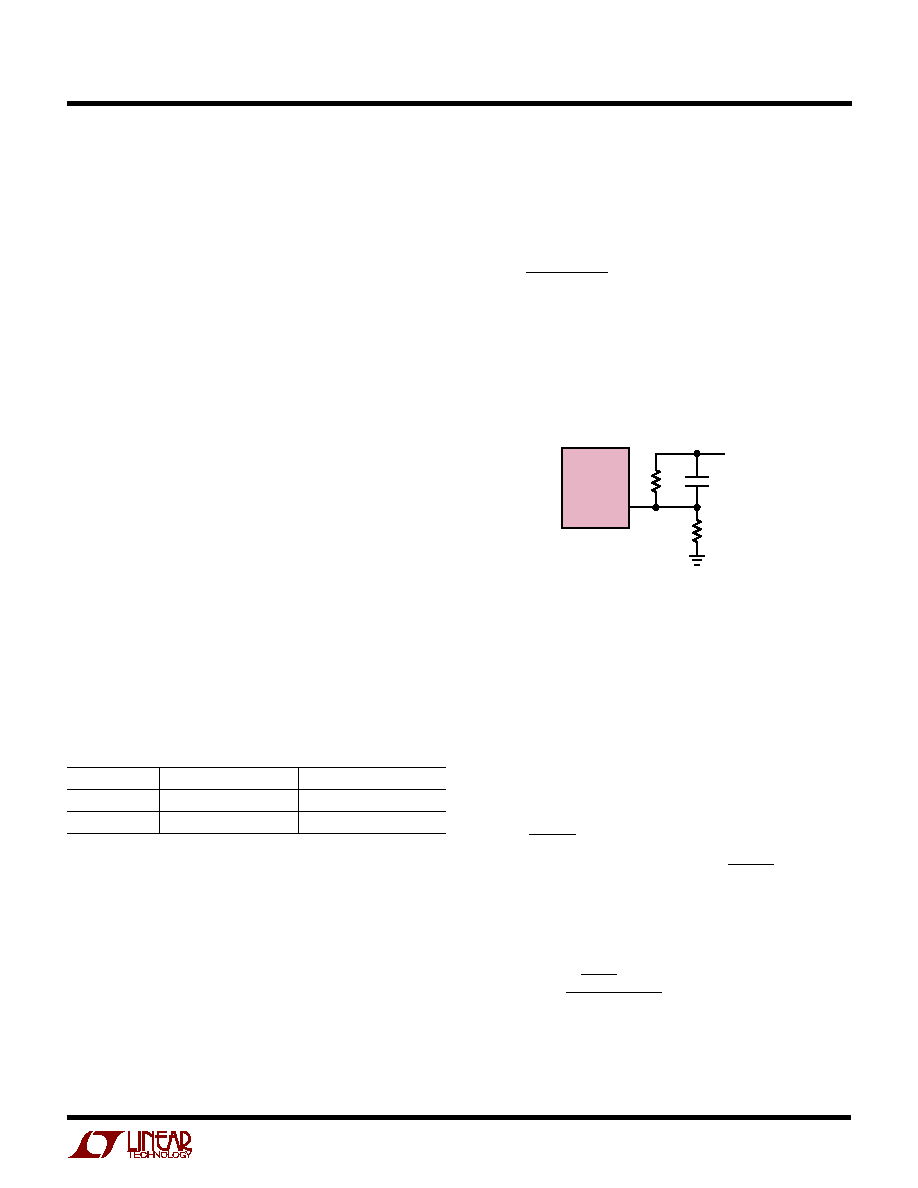

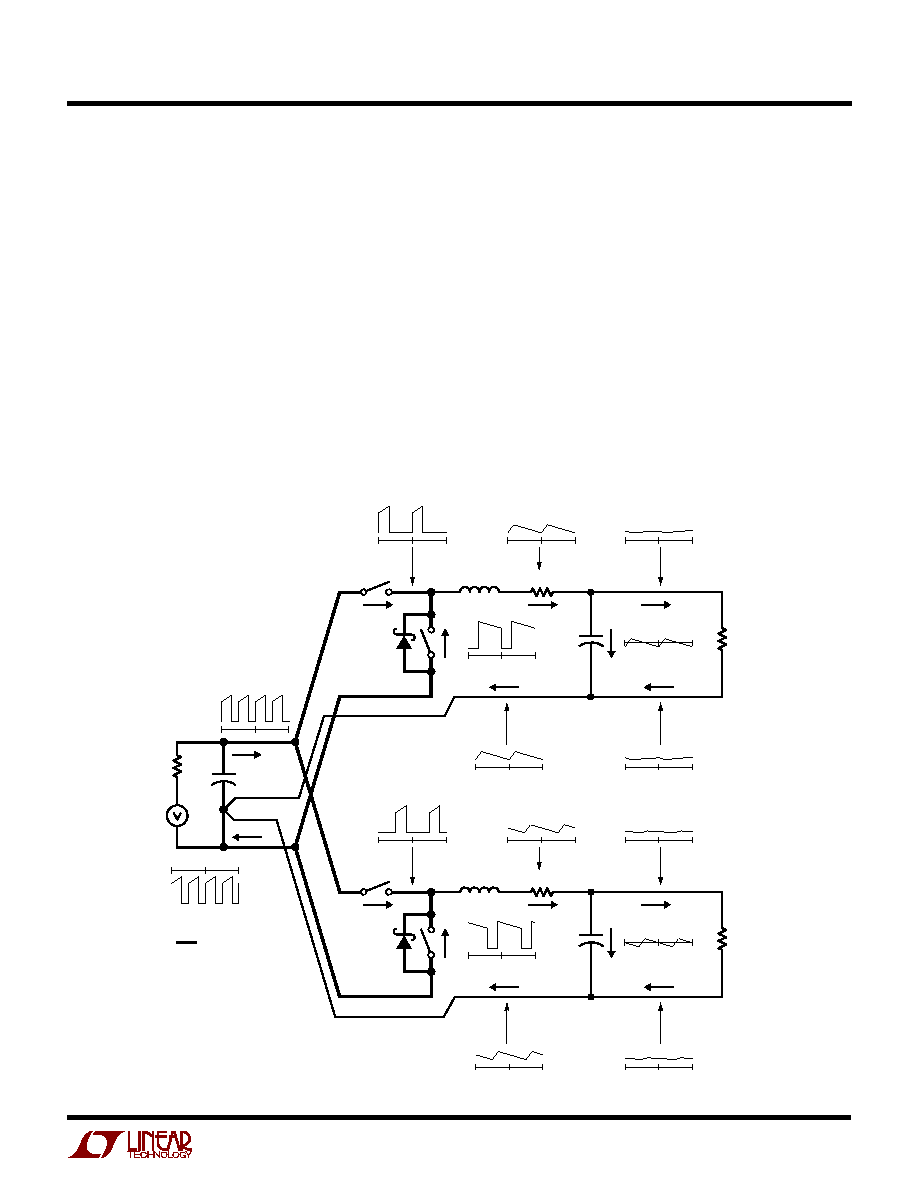

Figure 1. High Efficiency Triple 5V/3.3V/12V Power Supply

4.7

µ

F

10V

M4

M3

0.1

µ

F

63.4k

1%

1000pF

6.3

µ

H

220pF

1

µ

F

CER

33

µ

F

35V

ALUM

10

µ

F

35V

CER

+

56

µ

F

4V

SP

0.01

20k

1%

15k

V

OUT2

3.3V

5A

M2

M1

0.1

µ

F

105k

1%

6.8

µ

H

220pF

1000pF

+

+

+

+

47

µ

F

6.3V

SP

0.01

20k

1%

10.2k

1%

15k

V

OUT1

5V

4A

V

OUT3

12V

200mA

TG2

TG1

BOOST2

BOOST1

SW2

SW1

BG2

BG1

PGND

PGOOD

AUXSW

AUXV

FB

AUXSD

SENSE2

+

SENSE1

+

SENSE2

≠

SENSE1

≠

V

OSENSE2

V

OSENSE1

I

TH2

I

TH1

AUXV

IN

V

IN

INTV

CC

RUN/SS2

RUN/SS1

V

IN

5.2V

TO 28V

M1, M2, M3, M4: FDS6680A

1876 TA01

0.1

µ

F

0.1

µ

F

LTC1876

SGND

86.6k, 1%

10

µ

H

10

µ

F

20V

LTC1876

2

1876fa

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

Main Control Loops

V

OSENSE1, 2

Regulated Feedback Voltage

I

TH1, 2

Voltage = 1.2V (Note 4)

q

0.792

0.800

0.808

V

I

VOSENSE1, 2

Feedback Current

(Note 4)

≠5

≠50

nA

V

REFLNREG

Reference Voltage Line Regulation

V

IN

= 3.6V to 30V (Note 4)

0.002

0.02

%/V

V

LOADREG

Output Voltage Load Regulation

(Note 4)

Measured in Servo Loop;

I

TH

Voltage = 1.2V to 0.7V

q

0.1

0.5

%

Measured in Servo Loop;

I

TH

Voltage = 1.2V to 2V

q

≠0.1

≠0.5

%

g

m1, 2

Transconductance Amplifier g

m

I

TH1, 2

= 1.2V; Sink/Source 5

µ

A; (Note 4)

1.3

mmho

g

mOL1, 2

Transconductance Amplifier GBW

I

TH1, 2

= 1.2V; (Note 4)

3

MHz

I

Q

Input DC Supply Current

(Note 5)

Normal Mode

V

IN

= 15V; EXTV

CC

Tied to V

OUT1

; V

OUT1

= 5V

350

µ

A

Standby

V

RUN/SS1, 2

= 0V, V

STBYMD

> 2V

125

µ

A

Shutdown

V

RUN/SS1, 2

= 0V, V

STBYMD

= Open

20

35

µ

A

V

FCB

Forced Continuous Threshold

q

0.76

0.800

0.84

V

I

FCB

Forced Continuous Current

V

FCB

= 0.85V

≠0.3

≠0.18

≠0.1

µ

A

V

BINHIBIT

Burst Inhibit (Constant Frequency)

Measured at FCB pin

4.3

4.8

V

Threshold

Input Supply Voltage (V

IN

)......................... 36V to ≠0.3V

Topside Driver Voltages

(BOOST1, BOOST2) ................................... 42V to ≠0.3V

Switch Voltage (SW1, SW2) ......................... 36V to ≠5V

INTV

CC,

EXTV

CC

, RUN/SS1, RUN/SS2, PGOOD,

(BOOST1-SW1), (BOOST2-SW2), ...............7V to ≠ 0.3V

SENSE1

+

, SENSE2

+

, SENSE1

≠

, SENSE2

≠

Voltages ................................... (1.1)INTV

CC

to ≠ 0.3V

FREQSET, STBYMD, FCB, PGOOD

Voltages .................................................. 7V to ≠ 0.3V

I

TH1,

I

TH2

, V

OSENSE1

, V

OSENSE2

Voltages ... 2.7V to ≠0.3V

Peak Output Current <10

µ

s (TG1, TG2, BG1, BG2) ... 3A

INTV

CC

Peak Output Current ................................ 50mA

AUXV

IN ..................................................................

16V to ≠0.3V

AUXSD ..................................................................... 10V

AUXSW ..................................................... 36V to ≠0.3V

AUXV

FB

Voltage ....................................... 2.5V to ≠0.3V

Current into AUXV

FB .......................................................

±

1mA

Operating Temperature Range (Note 2) ...≠40

∞

C to 85

∞

C

Junction Temperature (Note 3) ............................. 125

∞

C

Storage Temperature Range ..................≠65

∞

C to 150

∞

C

Lead Temperature (Soldering, 10 sec).................. 300

∞

C

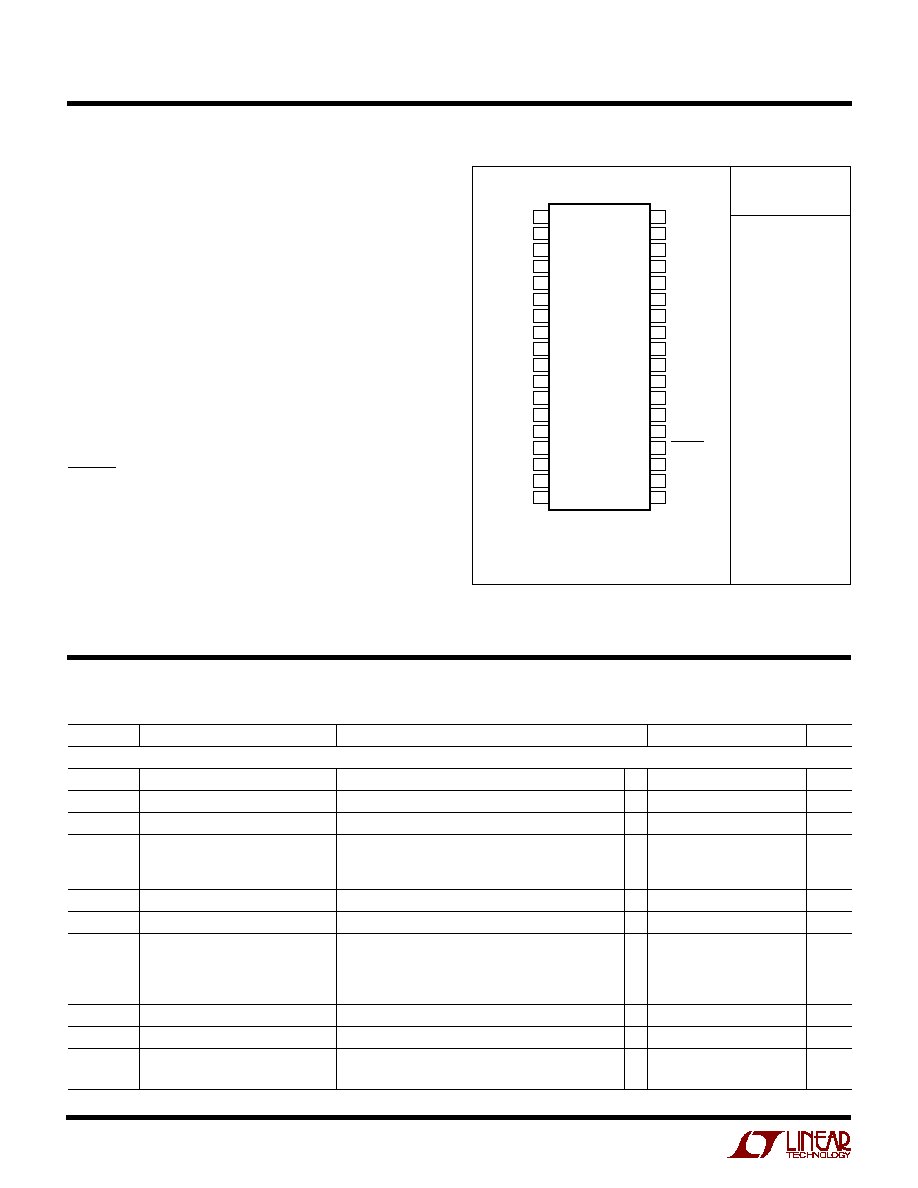

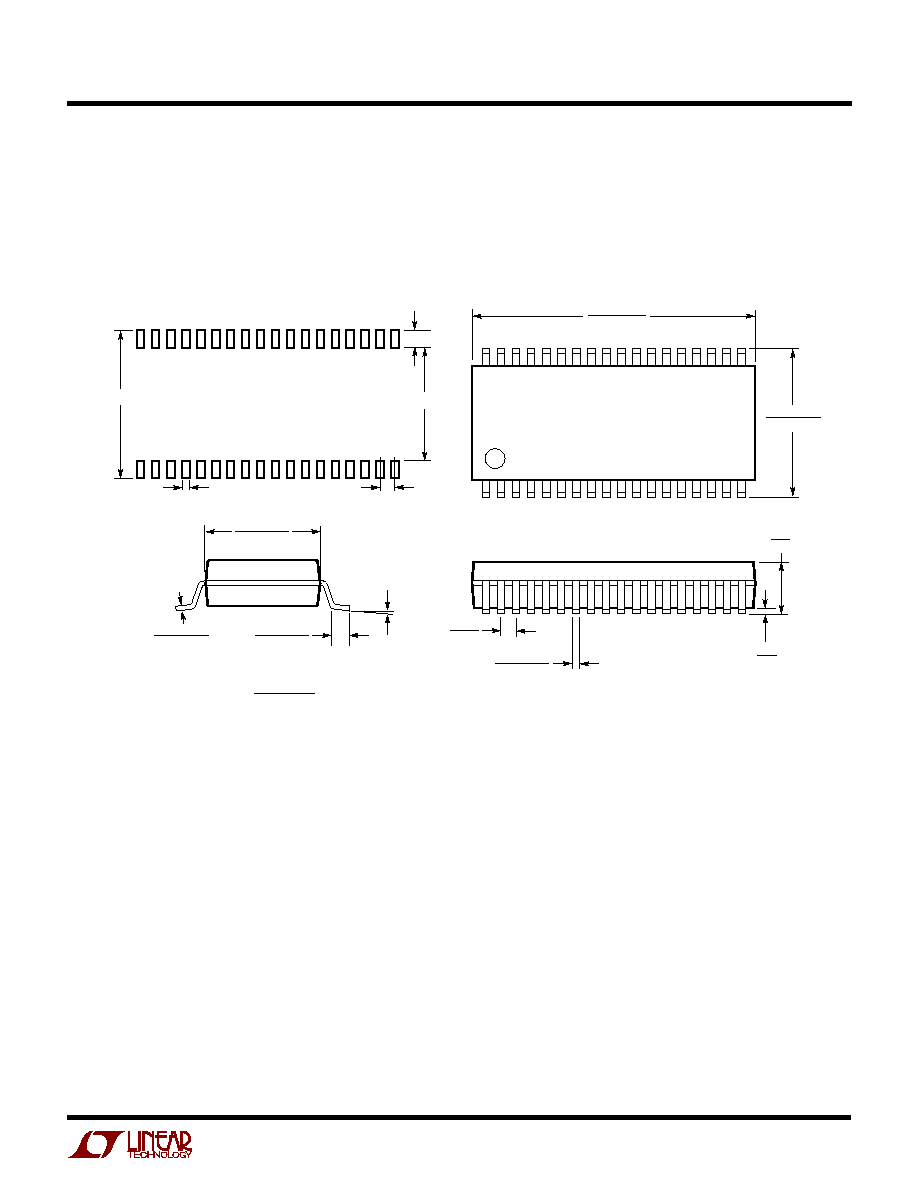

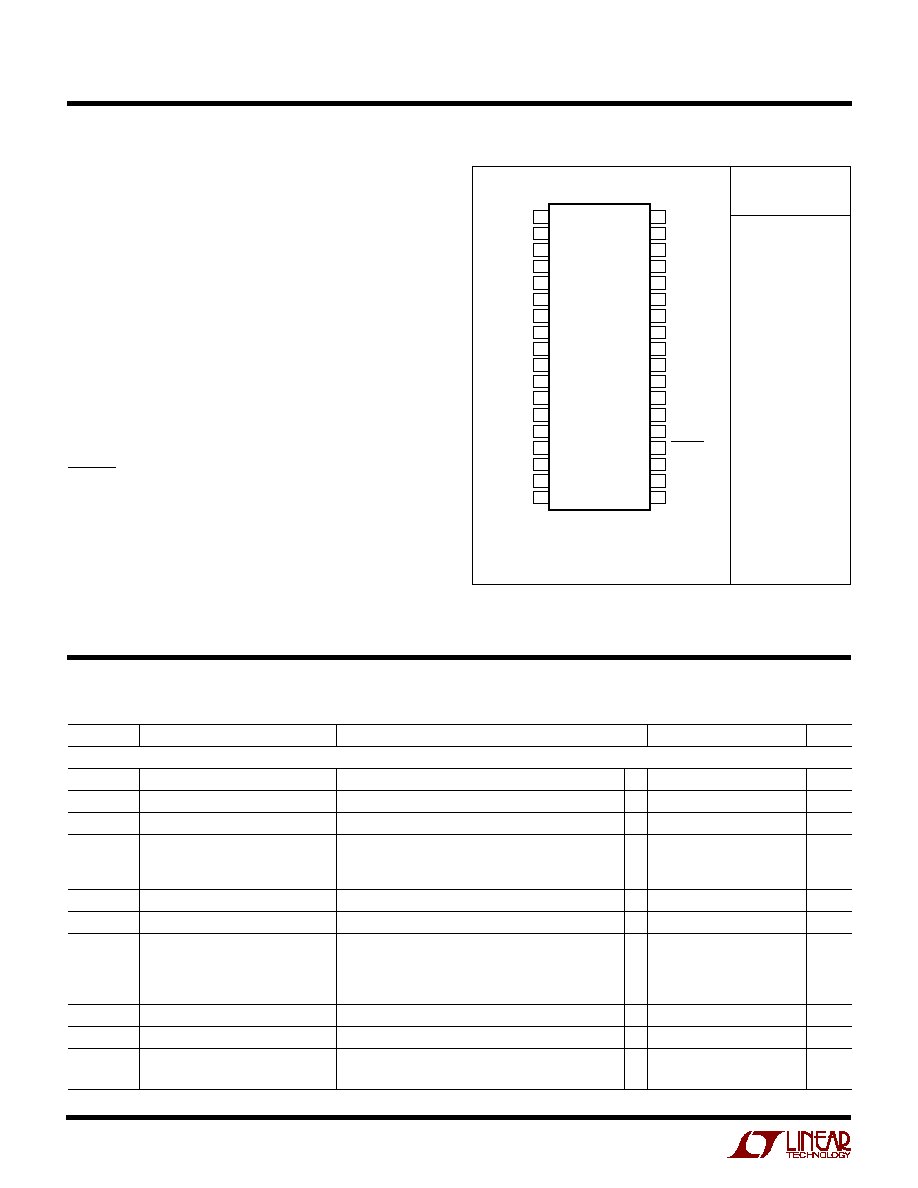

ORDER PART

NUMBER

T

JMAX

= 125

∞

C,

JA

= 95

∞

C/W

Consult factory for parts specified with wider operating temperature ranges.

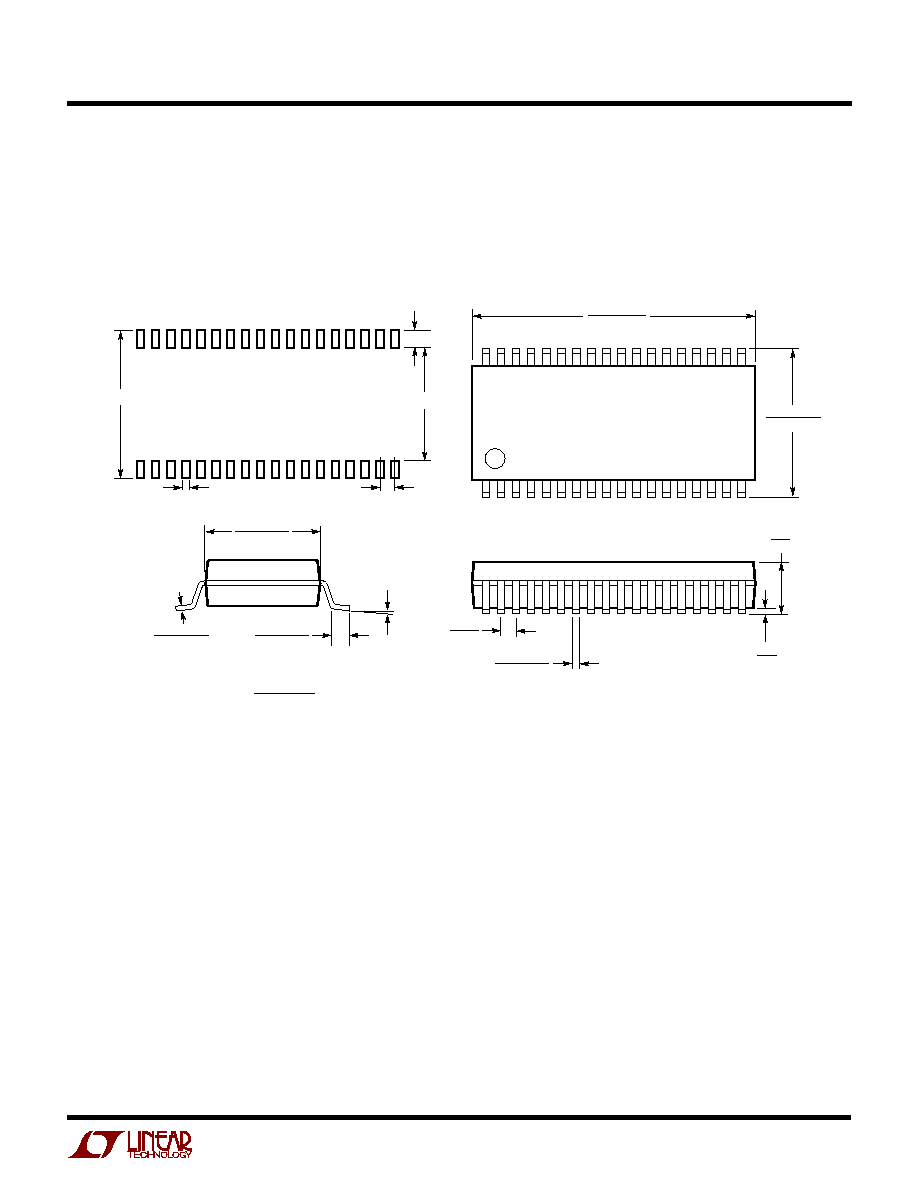

LTC1876EG

ABSOLUTE AXI U

RATI GS

W

W

W

U

PACKAGE/ORDER I FOR ATIO

U

U

W

(Note 1)

ELECTRICAL CHARACTERISTICS

The

q

denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at T

A

= 25

∞

C. V

IN

= 15V, V

RUN/SS1, 2

= 5V, AUXV

IN

= 3V unless otherwise noted.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

TOP VIEW

G PACKAGE

36-LEAD PLASTIC SSOP

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

PGOOD

TG1

SW1

BOOST1

V

IN

BG1

EXTV

CC

INTV

CC

PGND

BG2

BOOST2

SW2

TG2

RUN/SS2

AUXSD

AUXV

IN

AUXPGND

AUXPGND

RUN/SS1

SENSE1

+

SENSE1

≠

V

OSENSE1

FREQSET

STBYMD

FCB

I

TH1

SGND

3.3V

OUT

I

ITH2

V

OSENSE2

SENSE2

≠

SENSE2

+

AUXSGND

AUXV

FB

AUXSW

AUXSW

LTC1876

3

1876fa

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

UVLO

Undervoltage Lockout

V

IN

Ramping Down

q

3.5

4

V

V

OVL

Overvoltage Feedback Threshold

Measured at V

OSENSE1, 2

q

0.84

0.86

0.88

V

I

SENSE

Sense Pins Total Source Current

(Each Channel); V

SENSE1

≠

, 2

≠

= V

SENSE1

+

, 2

+

= 0V

≠85

≠60

µ

A

V

STBYMD

MS

Master Shutdown Threshold

V

STBYMD

Ramping Down

0.4

0.6

V

V

STBYMD

KA

Keep-Alive Power On-Threshold

V

STBYMD

Ramping Up, RUN

SS1, 2

= 0V

1.5

2

V

DF

MAX

Maximum Duty Factor

In Dropout

98

99.4

%

I

RUN/SS1, 2

Soft-Start Charge Current

V

RUN/SS1, 2

= 1.9V

0.5

1.2

µ

A

V

RUN/SS1, 2

ON RUN/SS Pin ON Threshold

V

RUN/SS1,

V

RUN/SS2

Rising

1.0

1.5

1.9

V

V

RUN/SS1, 2

LT

RUN/SS Pin Latchoff Arming Threshold

V

RUN/SS1,

V

RUN/SS2

Rising from 3V

4.1

4.5

V

I

SCL1, 2

RUN/SS Discharge Current

Soft Short Condition V

OSENSE1, 2

= 0.5V;

0.5

2

4

µ

A

V

RUN/SS1, 2

= 4.5V

I

SDLHO

Shutdown Latch Disable Current

V

OSENSE1, 2

=0.5V

1.6

5

µ

A

V

SENSE(MAX)

Maximum Current Sense Threshold

V

OSENSE1, 2

= 0.7V

,

V

SENSE1

≠

, 2

≠

= 5V

q

62

75

88

mV

TG Transition Time:

TG1, 2 t

r

Rise Time

C

LOAD

= 3300pF

50

90

ns

TG1, 2 t

f

Fall Time

C

LOAD

= 3300pF

50

90

ns

BG Transition Time:

BG1, 2 t

r

Rise Time

C

LOAD

= 3300pF

40

90

ns

BG1, 2 t

f

Fall Time

C

LOAD

= 3300pF

40

80

ns

TG/BG t

1D

Top Gate Off to Bottom Gate On Delay

Synchronous Switch-On Delay Time

C

LOAD

= 3300pF Each Driver

90

ns

BG/TG t

2D

Bottom Gate Off to Top Gate On Delay

Top Switch-On Delay Time

C

LOAD

= 3300pF Each Driver

90

ns

t

ON(MIN)

Minimum ON-Time

Tested with a Square Wave (Note 7)

180

ns

INTV

CC

Linear Regulator

V

INTVCC

Internal V

CC

Voltage

6V < V

IN

< 30V, V

EXTVCC

= 4V

4.8

5.0

5.2

V

V

LDO

INT

INTV

CC

Load Regulation

I

CC

= 0 to 20mA, V

EXTVCC

= 4V

0.2

1.0

%

V

LDO

EXT

EXTV

CC

Voltage Drop

I

CC

= 20mA, V

EXTVCC

= 5V

80

160

mV

V

EXTVCC

EXTV

CC

Switchover Voltage

I

CC

= 20mA, EXTV

CC

Ramping Positive

q

4.5

4.7

V

V

LDOHYS

EXTV

CC

Hysteresis

0.2

V

Oscillator

f

OSC

Oscillator frequency

V

FREQSET

= Open (Note 8)

190

220

250

kHz

f

LOW

Lowest Frequency

V

FREQSET

= 0V

120

140

160

kHz

f

HIGH

Highest Frequency

V

FREQSET

= 2.4V

280

310

360

kHz

I

FREQSET

FREQSET

Input Current

V

FREQSET

= 2.4V

≠2

≠1

µ

A

ELECTRICAL CHARACTERISTICS

The

q

denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at T

A

= 25

∞

C. V

IN

= 15V, V

RUN/SS1, 2

= 5V, AUXV

IN

= 3V unless otherwise noted.

LTC1876

4

1876fa

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

3.3V Linear Regulator

V

3.3OUT

3.3V Regulator Output Voltage

No Load

q

3.25

3.35

3.45

V

V

3.3IL

3.3V Regulator Load Regulation

I

3.3

= 0mA to 10mA

0.5

2

%

V

3.3VL

3.3V Regulator Line Regulation

6V < V

IN

< 30V

0.05

0.2

%

PGOOD Output

V

PGL

PGOOD Voltage Low

I

PGOOD

= 2mA

0.1

0.3

V

I

PGOOD

PGOOD Leakage Current

V

PGOOD

= 5V

±

1

µ

A

V

PG

PGOOD Trip Level, Either Controller

V

OSENSE

with Respect to Set Output Voltage

V

OSENSE

Ramping Negative

≠6

≠7.5

≠9.5

%

V

OSENSE

Ramping Positive

6

7.5

9.5

%

Aux Output

AUXV

INMIN

AUX Minimum Operating Voltage

q

2.4

2.6

V

AUXV

FB

AUX Regulated Feedback Voltage

q

1.23

1.26

1.28

V

AUXI

FB

AUX Feedback Pin Bias Current

q

120

360

nA

AUXI

Q

AUX Input DC Supply Current

Normal Mode

V

AUXSD

= 2.4V, Not Switching

4

mA

Shutdown

V

AUXSD

= 0V

0.01

1

µ

A

AUXV

LINEREG

AUX Line Regulation

2.6V

AUXV

IN

16V

0.01

0.05

%/V

AUXf

OSC

AUX Oscillator Frequency

q

0.8

1.2

1.6

MHz

AUXDC

MAX

AUX Oscillator Maximum Duty Cycle

q

84

86

%

AUXI

LIMIT

AUX Switch Current Limit

(Note 9)

1

1.4

2

A

AUXV

CESAT

AUX Switch Saturation Voltage

I

SW

= 900mA (Note 10)

330

550

mV

AUXI

LEAKAGE

AUX Switch Leakage Current

V

SW

= 5V

0.01

1

µ

A

AUXV

AUXSD

AUX Shutdown Input Voltage

AUX Shutdown Upper Trip Point

2.4

V

AUX Shutdown Lower Trip Point

0.5

V

I

AUXSD

AUXSD Pin Bias Current

V

AUXSD

= 3V

16

32

µ

A

V

AUXSD

= 0V

0.01

0.1

µ

A

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC1876E is guaranteed to meet performance specifications

from 0

∞

C to 70

∞

C. Specifications over the ≠ 40

∞

C to 85

∞

C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: T

J

is calculated from the ambient temperature T

A

and power

dissipation P

D

according to the following formulas:

LTC1876EG: T

J

= T

A

+ (P

D

∑ 95

∞

C/W)

Note 4: The LTC1876 is tested in a feedback loop that servos V

ITH1, 2

to a

specified voltage and measures the resultant V

OSENSE1, 2.

Note 5: Dynamic supply current is higher due to the gate charge being

delivered at the switching frequency. See Applications Information.

Note 6: Rise and fall times are measured using 10% and 90% levels.

Delay times are measured using 50% levels.

Note 7: The minimum on-time condition is specified for an inductor peak-

to-peak ripple current

40% of I

MAX

(see Minimum On-Time

Considerations in the Applications Information section).

Note 8: V

FREQSET

pin internally tied to 1.19V reference through a large

resistance.

Note 9: Current limit guaranteed by design and/or correlation to static test.

Note 10: 100% tested at wafer level.

ELECTRICAL CHARACTERISTICS

The

q

denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at T

A

= 25

∞

C. V

IN

= 15V, V

RUN/SS1, 2

= 5V, AUXV

IN

= 3V unless otherwise noted.

LTC1876

5

1876fa

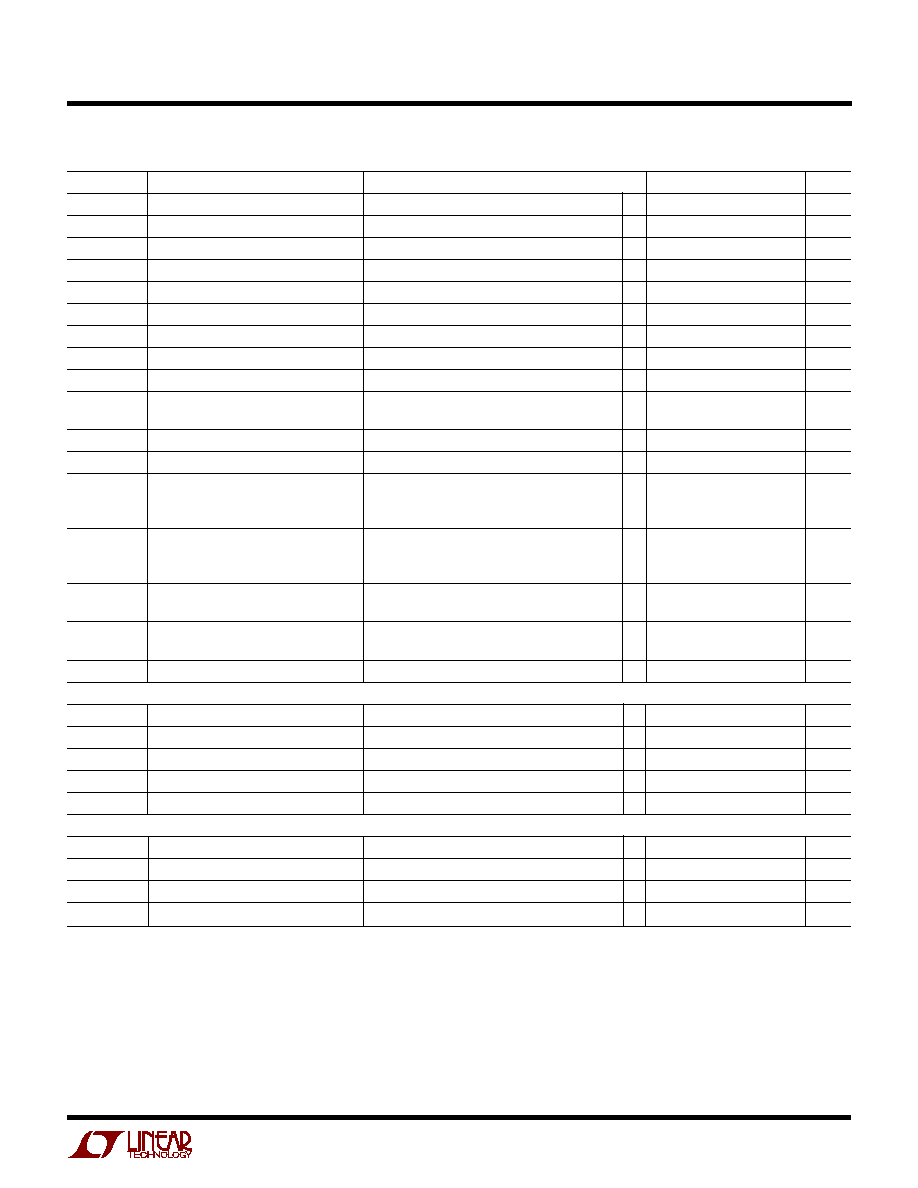

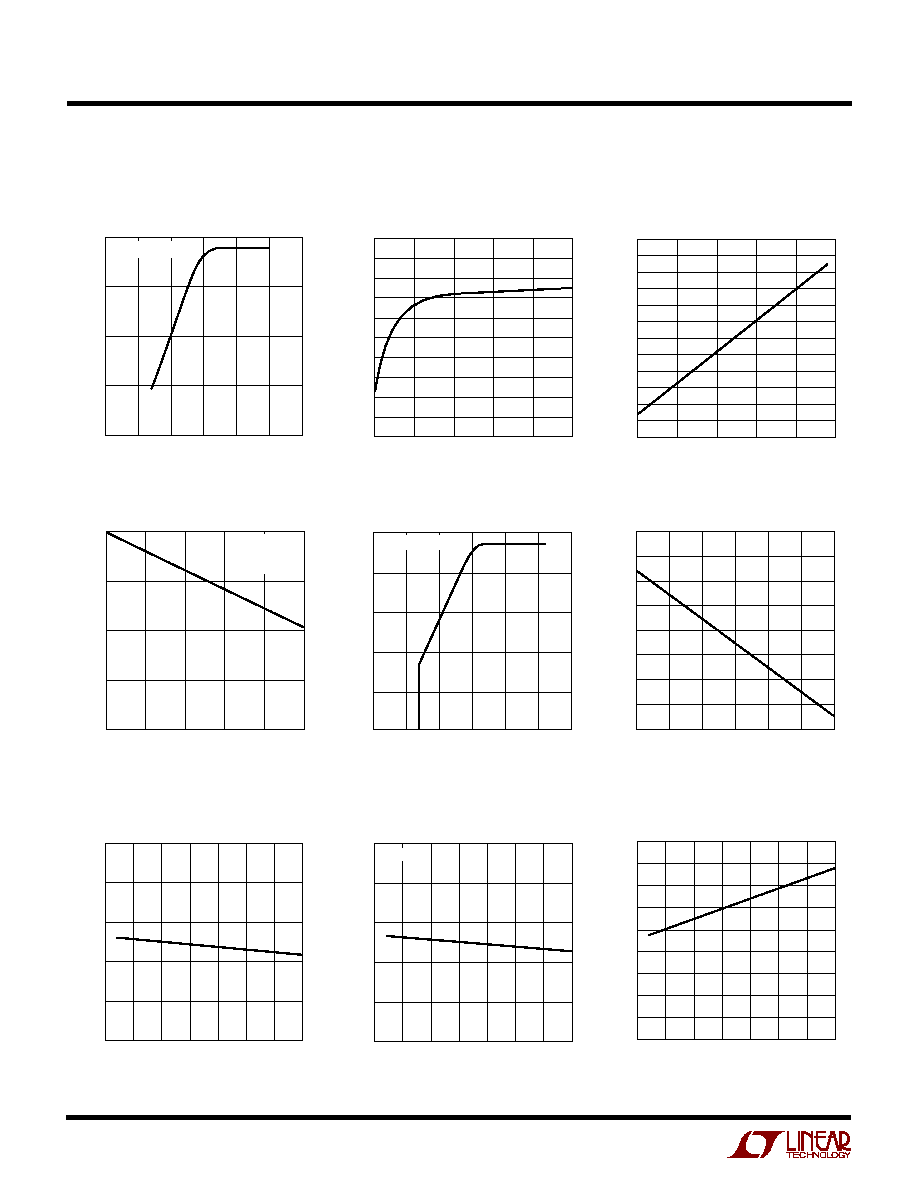

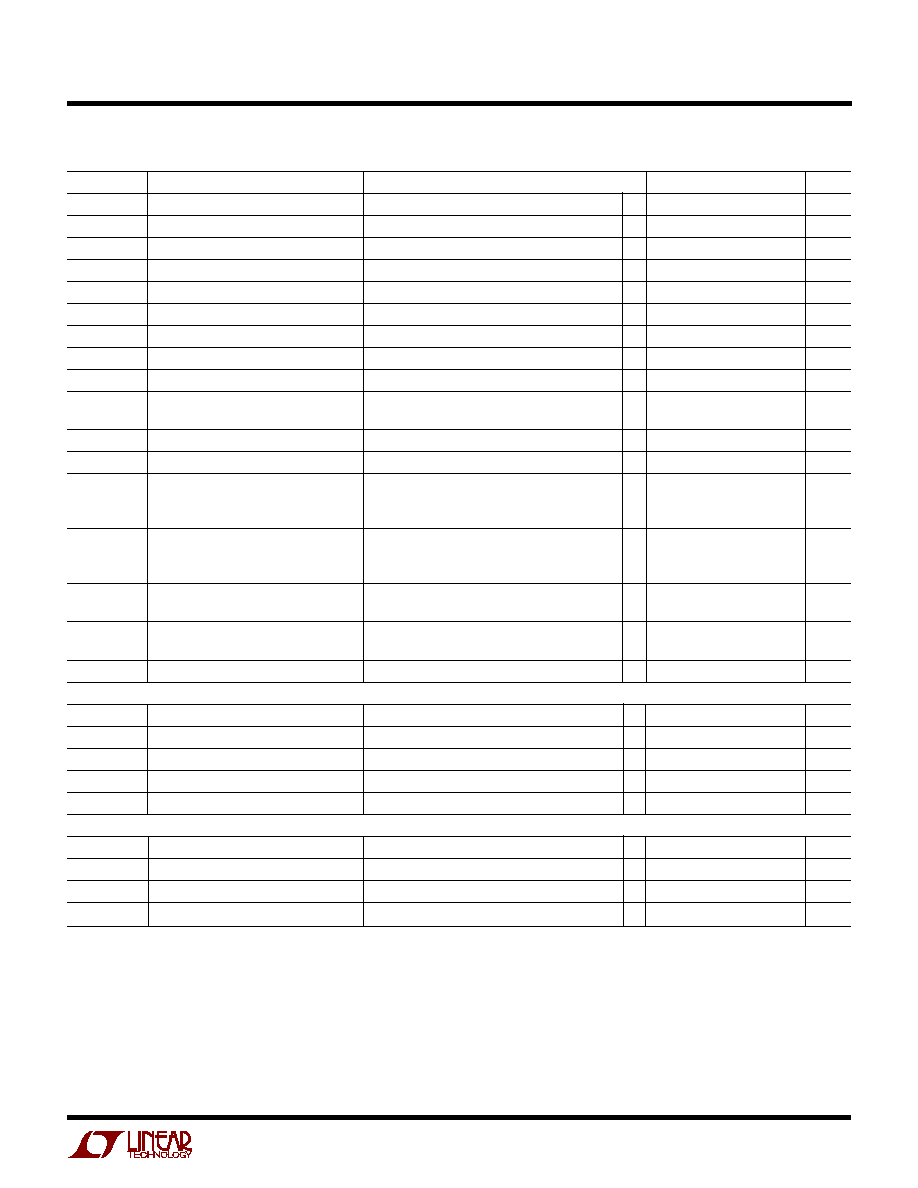

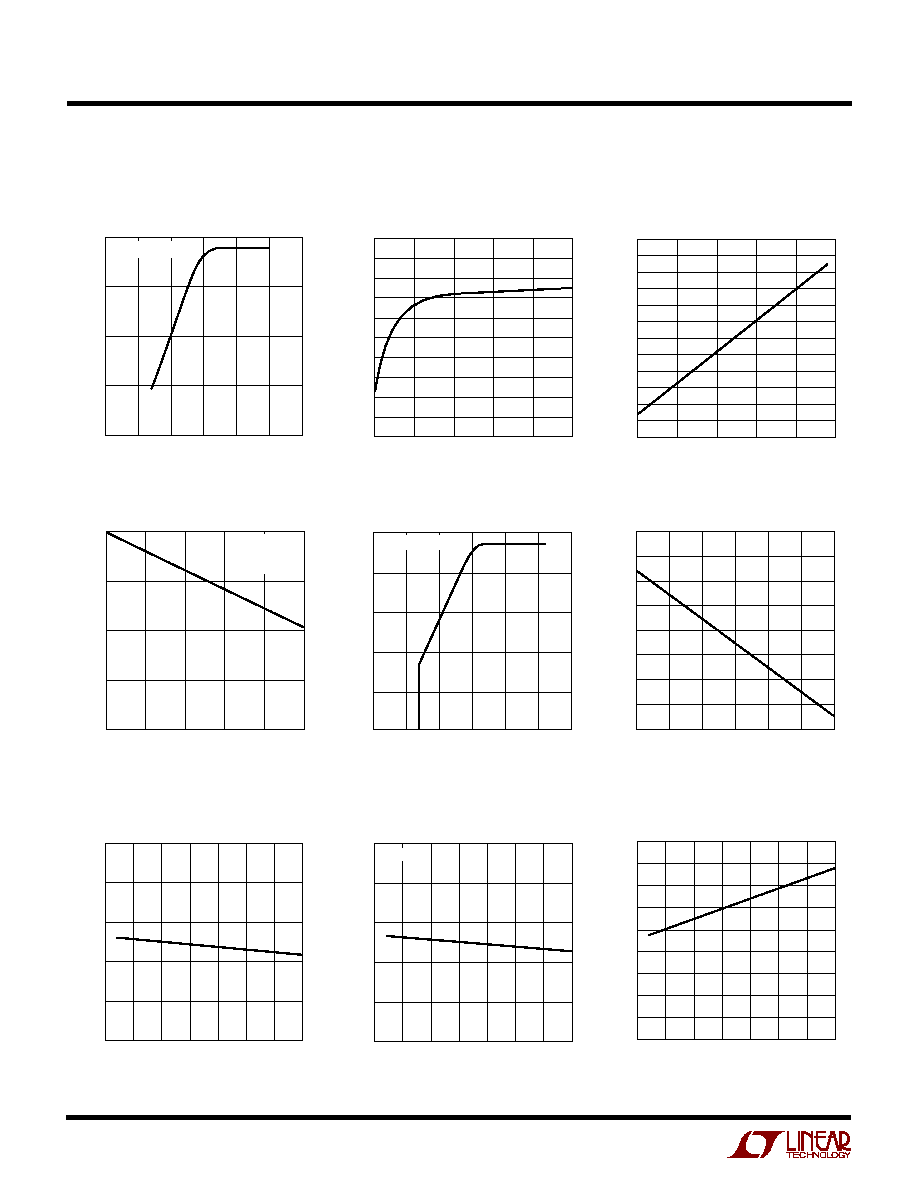

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

OUTPUT CURRENT (A)

0.001

0

EFFICIENCY (%)

10

30

40

50

100

70

0.01

0.1

1

1876 G01

20

80

90

60

10

FORCED

CONTINUOUS

MODE

CONSTANT

FREQUENCY

(BURST DISABLE)

Burst Mode

OPERATION

V

IN

= 15V

V

OUT

= 5V

OUTPUT CURRENT (A)

0.001

EFFICIENCY (%)

70

80

10

1876 G02

60

50

0.01

0.1

1

100

90

V

IN

= 10V

V

IN

= 15V

V

IN

= 7V

V

IN

= 20V

V

OUT

= 5V

INPUT VOLTAGE (V)

5

EFFICIENCY (%)

70

80

1876 G03

60

50

15

25

35

100

V

OUT

= 5V

I

OUT

= 3A

90

Efficiency vs Output Current and

Mode (Figure 1)

INPUT VOLTAGE (V)

0

5

0

SUPPLY CURRENT (

µ

A)

400

1000

10

20

25

1876 G04

200

800

600

15

30

35

BOTH

CONTROLLERS ON

STANDBY

SHUTDOWN

CURRENT (mA)

0

EXTV

CC

VOLTAGE DROP (mV)

150

200

250

40

1876 G05

100

50

0

10

20

30

50

TEMPERATURE (

∞

C)

≠ 50

INTV

CC

AND EXTV

CC

SWITCH VOLTAGE (V)

4.95

5.00

5.05

25

75

1876 G06

4.90

4.85

≠ 25

0

50

100

125

4.80

4.70

4.75

INTV

CC

VOLTAGE

EXTV

CC

SWITCHOVER THRESHOLD

INPUT VOLTAGE (V)

0

4.8

4.9

5.1

15

25

1876 G07

4.7

4.6

5

10

20

30

35

4.5

4.4

5.0

INTV

CC

VOLTAGE (V)

I

LOAD

= 1mA

Internal 5V LDO Line Regulation

V

IN

Supply Current vs Input

Voltage and Mode (Figure 1)

DUTY FACTOR (%)

0

0

V

SENSE

(mV)

25

50

75

20

40

60

80

1876 G08

100

PERCENT ON NOMINAL OUTPUT VOLTAGE (%)

0

V

SENSE

(mV)

40

50

60

100

1876 G09

30

20

0

25

50

75

10

80

70

Efficiency vs Output Current

(Figure 1)

Efficiency vs Input Voltage

(Figure 1)

EXTV

CC

Voltage Drop

INTV

CC

and EXTV

CC

Switch

Voltage vs Temperature

Maximum Current Sense

Threshold vs Duty Factor

Maximum Current Sense

Threshold vs Percent of Nominal

Output Voltage (Foldback)

LTC1876

6

1876fa

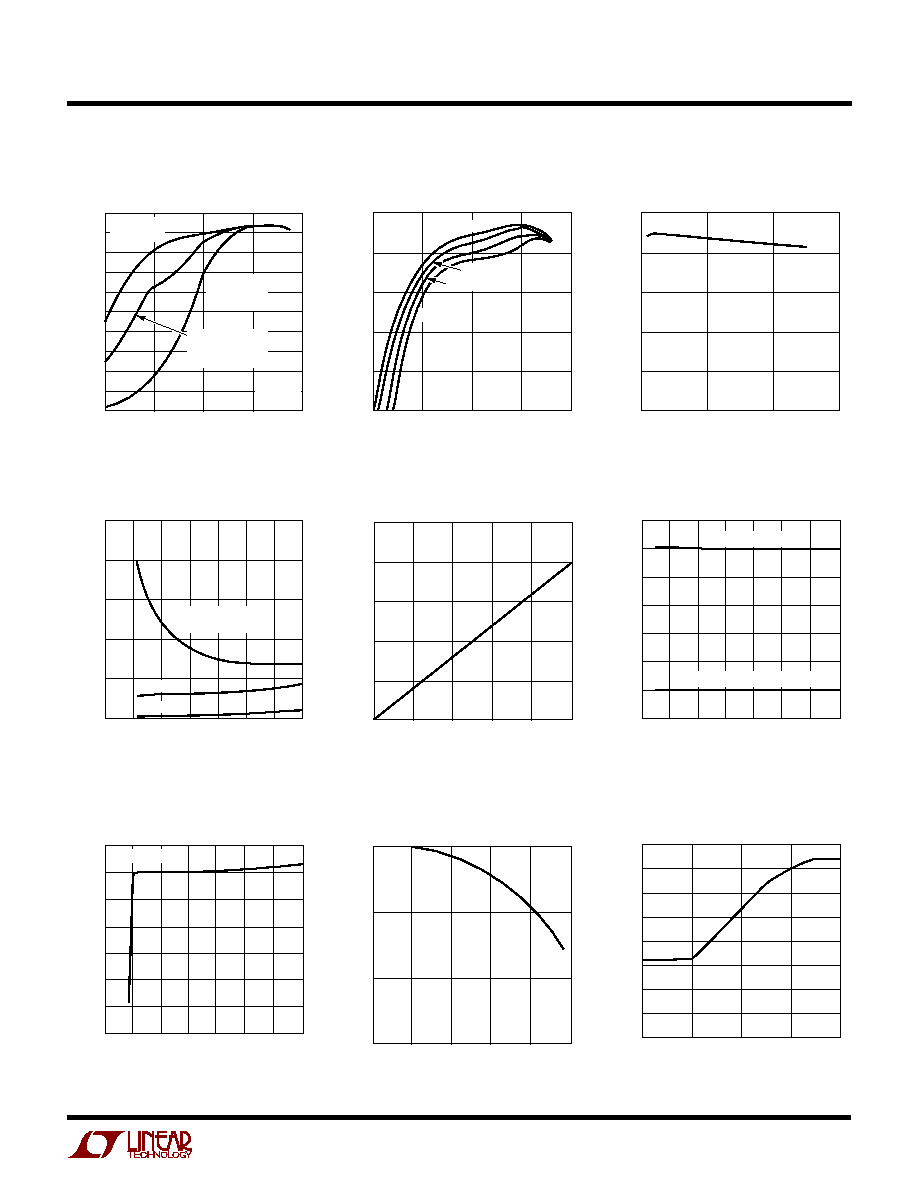

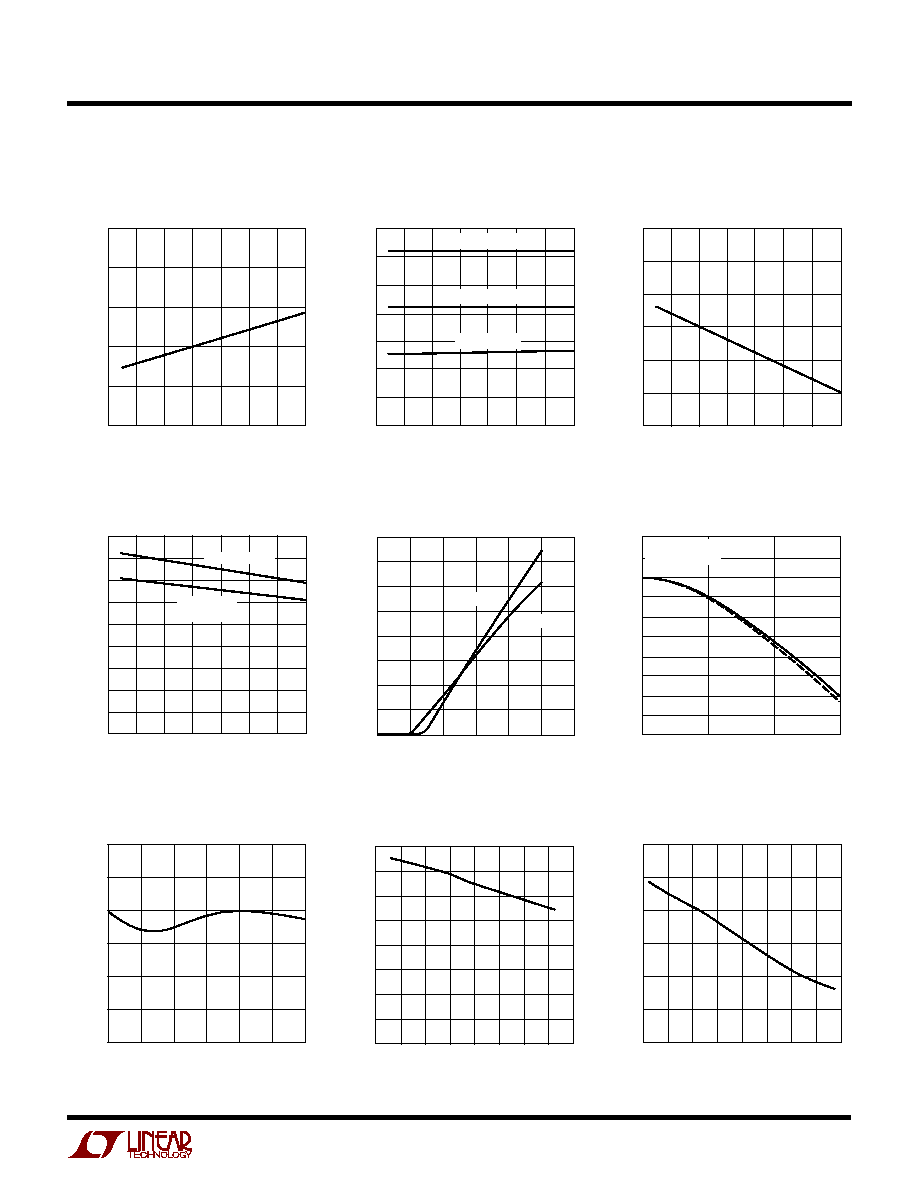

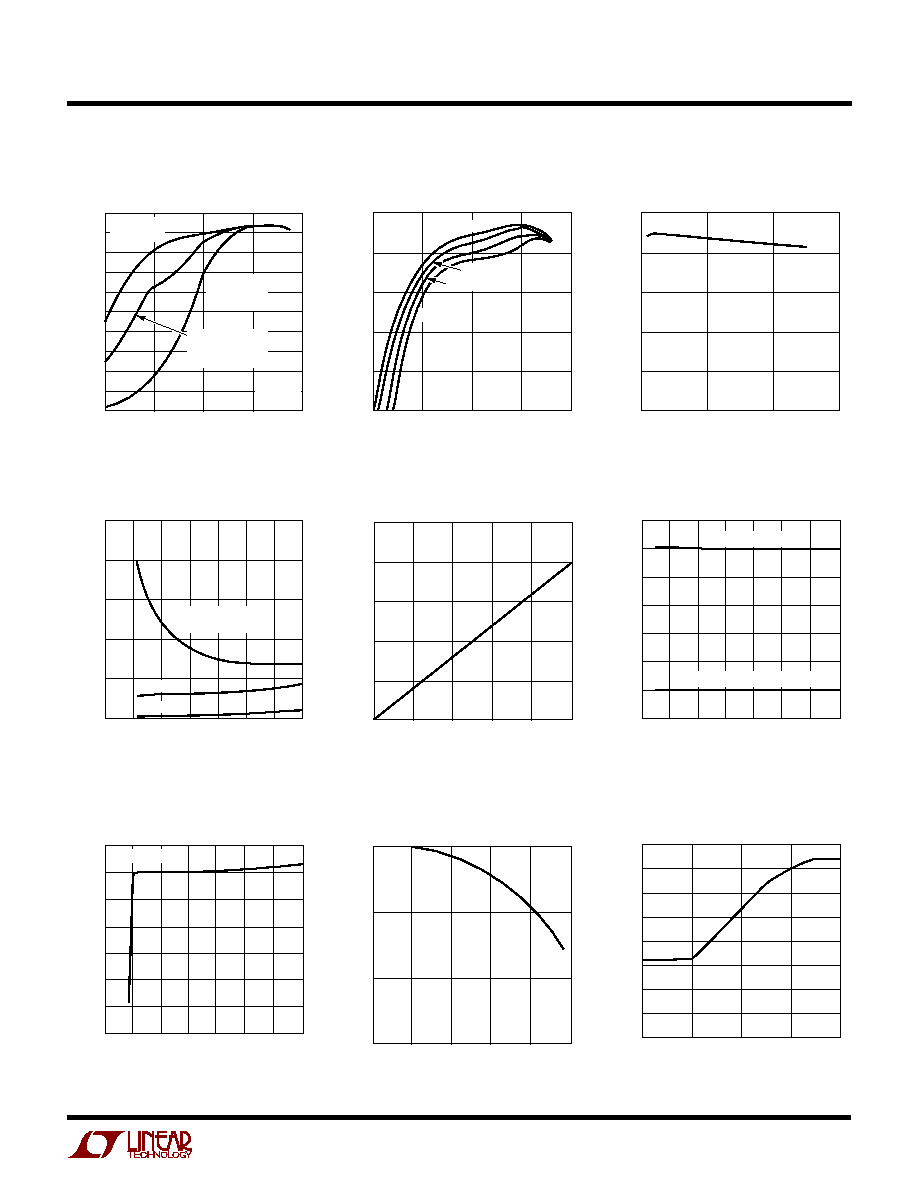

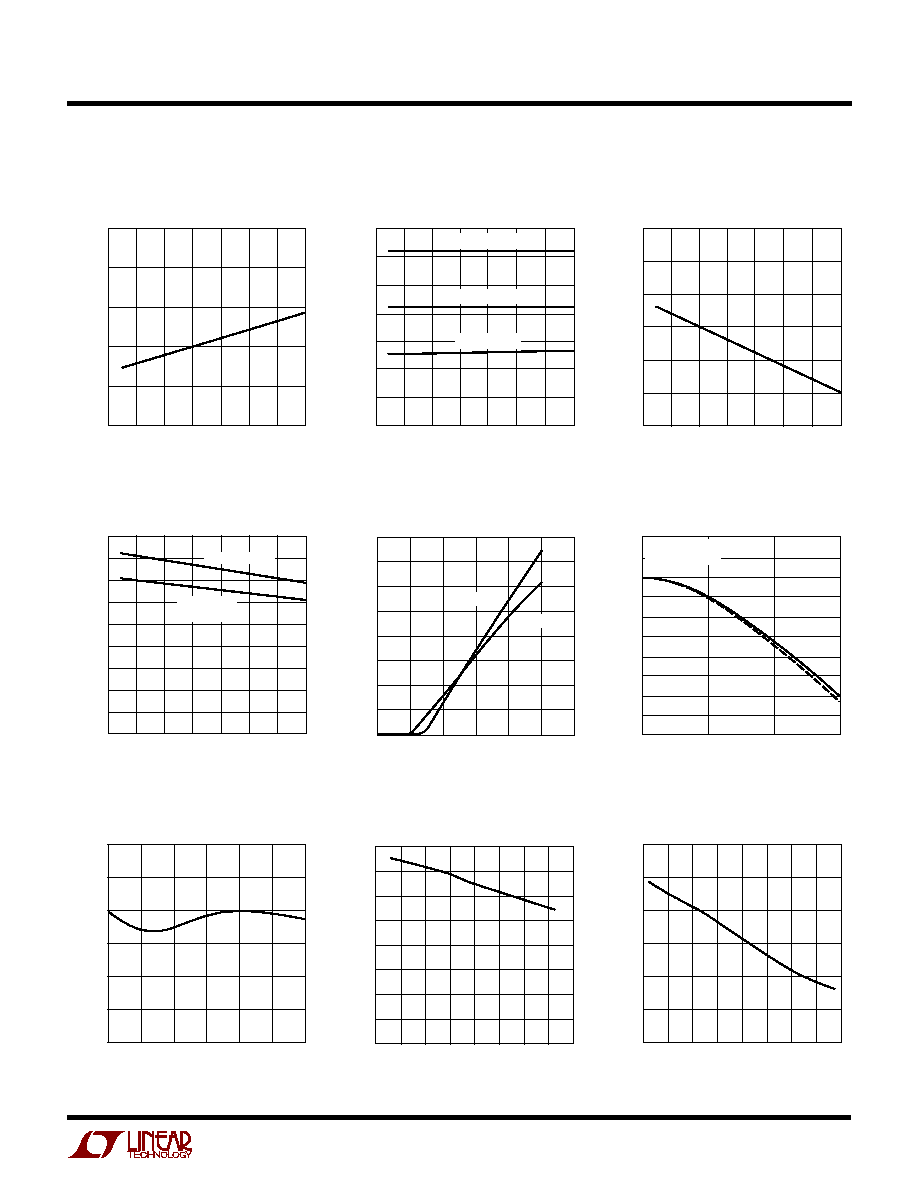

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

V

RUN/SS

(V)

0

0

V

SENSE

(mV)

20

40

60

80

1

2

3

4

1876 G10

5

6

V

SENSE(CM)

= 1.6V

COMMON MODE VOLTAGE (V)

0

V

SENSE

(mV)

72

76

80

4

1876 G11

68

64

60

1

2

3

5

V

ITH

(V)

0

V

SENSE

(mV)

30

50

70

90

2

1876 G12

10

≠10

20

40

60

80

0

≠20

≠30

0.5

1

1.5

2.5

LOAD CURRENT (A)

0

NORMALIZED V

OUT

(%)

≠0.2

≠0.1

4

1876 G13

≠0.3

≠0.4

1

2

3

5

0.0

FCB = 0V

V

IN

= 15V

FIGURE 1

V

RUN/SS

(V)

0

0

V

ITH

(V)

0.5

1.0

1.5

2.0

2.5

1

2

3

4

1876 G14

5

6

V

OSENSE

= 0.7V

V

SENSE

COMMON MODE VOLTAGE (V)

0

I

SENSE

(

µ

A)

0

1876 G15

≠50

≠100

2

4

50

100

6

TEMPERATURE (

∞

C)

≠50

≠25

70

V

SENSE

(mV)

74

80

0

50

75

1876 G16

72

78

76

25

100

125

TEMPERATURE (

∞

C)

≠50

≠25

0

RUN/SS CURRENT (

µ

A)

0.2

0.6

0.8

1.0

75

100

50

1.8

1876 G18

0.4

0

25

125

1.2

1.4

1.6

Maximum Current Sense

Threshold vs V

RUN/SS

(Soft-Start)

Maximum Current Sense

Threshold vs Sense Common

Mode Voltage

Current Sense Threshold

vs I

TH

Voltage

Load Regulation (Controller)

V

ITH

vs V

RUN/SS

SENSE Pins Total Source Current

Maximum Current Sense

Threshold vs Temperature

Current Sense Pin Input Current

vs Temperature

RUN/SS Current vs Temperature

TEMPERATURE (

∞

C)

≠50

≠25

25

CURRENT SENSE INPUT CURRENT (

µ

A)

27

35

0

50

75

1876 G17

31

33

29

25

100

125

V

OUT

= 5V

LTC1876

7

1876fa

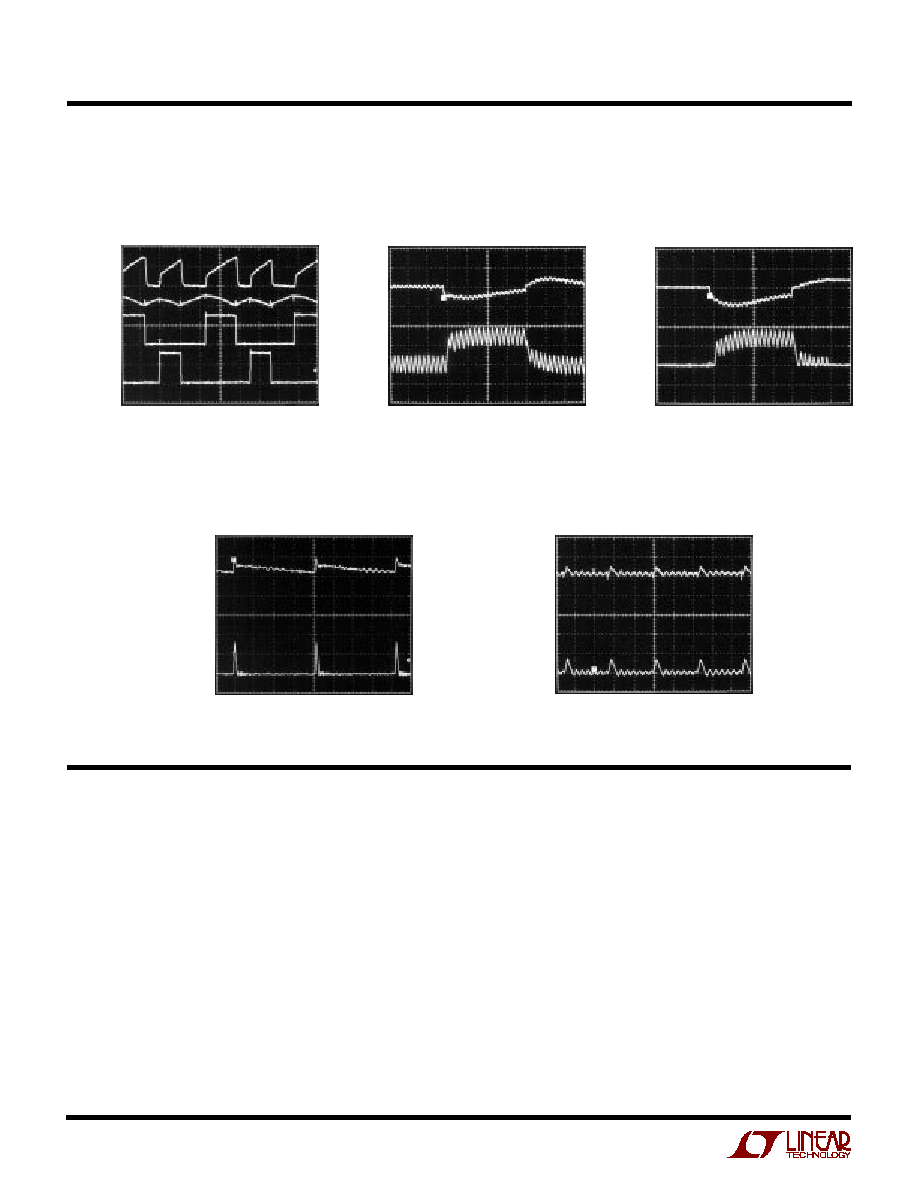

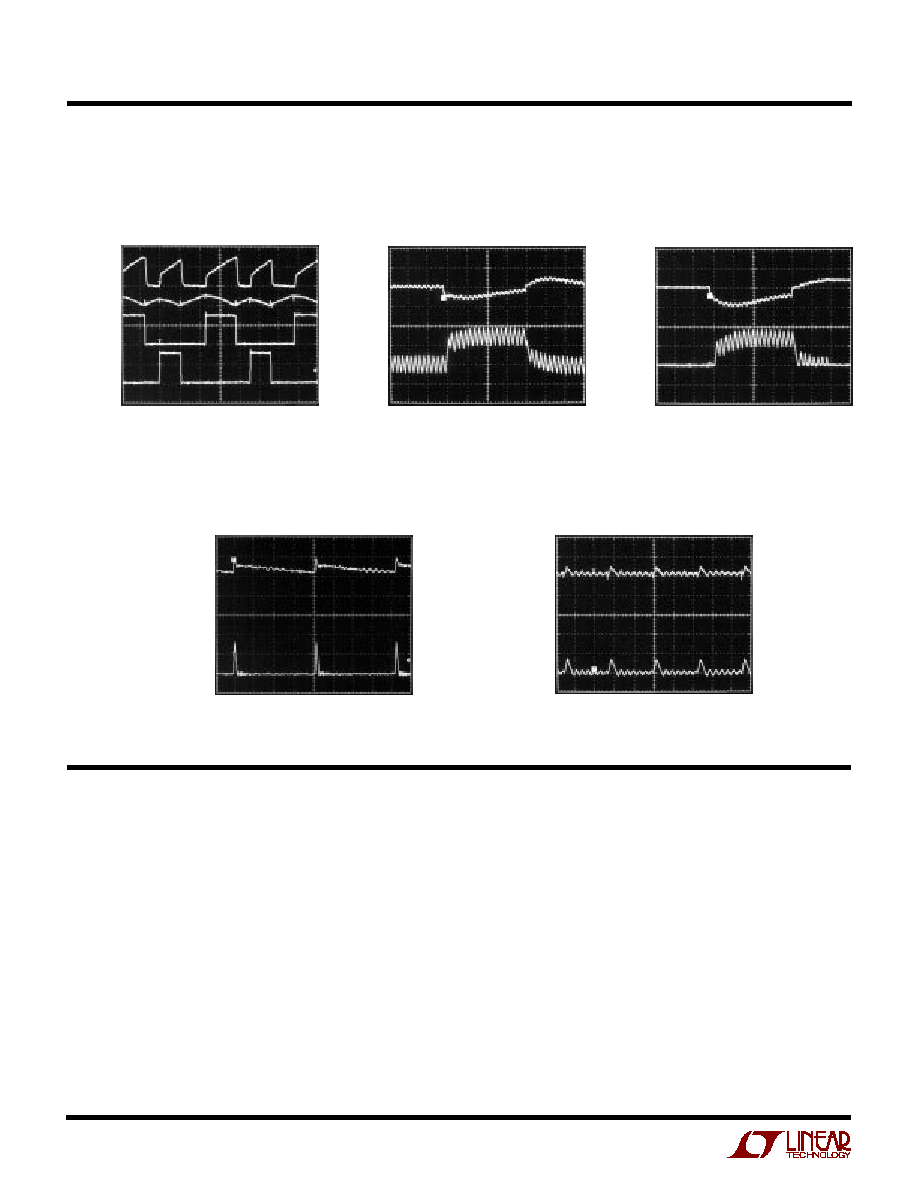

TEMPERATURE (

∞

C)

≠50

≠25

0

EXTV

CC

SWITCH RESISTANCE (

)

4

10

0

50

75

1876 G19

2

8

6

25

100

125

TEMPERATURE (

∞

C)

≠ 50

200

250

350

25

75

1876 G20

150

100

≠ 25

0

50

100

125

50

0

300

FREQUENCY (kHz)

V

FREQSET

= 5V

V

FREQSET

= OPEN

V

FREQSET

= 0V

TEMPERATURE (

∞

C)

≠50

UNDERVOLTAGE LOCKOUT (V)

3.40

3.45

3.50

25

75

1876 G21

3.35

3.30

≠25

0

50

100

125

3.25

3.20

TEMPERATURE (

∞

C)

≠50

≠25

0

SHUTDOWN LATCH THRESHOLDS (V) 0.5

1.5

2.0

2.5

75

100

50

4.5

1876 G22

1.0

0

25

125

3.0

3.5

4.0

LATCH ARMING

LATCHOFF

THRESHOLD

SHUTDOWN PIN VOLTAGE (V)

0

SHUTDOWN PIN CURRENT (

µ

A)

15

20

25

3

5

1876 G23

10

5

0

1

2

4

30

35

40

6

T

A

= 25

∞

C

T

A

= 100

∞

C

TEMPERATURE (

∞

C)

≠50

3.6

QUIESCENT CURRENT (mA)

3.8

3.9

4.0

4.1

4.2

4.3

0

50

1876 G24

4.4

4.5

4.6

3.7

100

V

IN

= 5V

V

FB

= 1.3V

NOT SWITCHING

V

IN

= 3.3V

TEMPERATURE (

∞

C)

≠50

1.22

FEEDBACK VOLTAGE (V)

1.23

1.24

1.25

1.26

1.28

≠25

0

25

50

1876 G25

75

100

1.27

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

EXTV

CC

and Switch Resistance vs

Temperature

Undervoltage Lockout vs

Temperature (Controller)

Oscillator Frequency vs

Temperature (Controller)

Shutdown Latch Thresholds vs

Temperature

Shutdown Pin Current (I

AUXVFB

)

Quiescent Current for Auxillary

Regulator

Feedback Pin Voltage (AUXV

FB

)

Current Limit for Auxillary

Regulator

Auxillary Regulator Switch

Oscillator Frequency

TEMPERATURE (

∞

C)

≠50 ≠30 ≠10

1.05

FREQUENCY (MHz)

1.10

1.15

1.20

1.25

1.35

10

30

50

70

90

110

1876 G28

1.30

DUTY CYCLE (%)

10

CURRENT LI MIT (A)

0.8

1.2

90

1876 G26

0.4

0

30

50

70

20

40

60

80

1.6

0.6

1.0

0.2

1.4

LTC1876

8

1876fa

RUN/SS1, RUN/SS2 (Pins 1, 23): Combination of Soft-Start,

Run Control Inputs and Short-Circuit Detection Timers. A

capacitor to ground at each of these pins sets the ramp time

to full output current. Forcing either of these pins back below

1V causes the IC to shut down the circuitry required for that

particular controller. Latchoff overcurrent protection is also

invoked via this pin as described in the Applications Informa-

tion section.

SENSE1

+

, SENSE2

+

(Pins 2, 14): The (+) Input to each

Differential Current Comparator. The I

TH

pin voltage and

controlled offsets between the SENSE

≠

and SENSE

+

pins in

conjunction with R

SENSE

set the current trip threshold.

SENSE1

≠

, SENSE2

≠

(Pins 3, 13): The (≠) Input to the

Differential Current Comparators.

V

OSENSE1

, V

OSENSE2

(Pins 4, 12): Receives the remotely-

sensed feedback voltage for each controller from an external

resistive divider across the output.

FREQSET (Pin 5): Frequency Control Input to the Oscillator.

This pin can be left open, tied to ground, tied to INTV

CC

or

driven by an external voltage source. This pin can also be used

with an external phase detector to build a true phase-locked

loop.

STBYMD (Pin 6): Control pin that determines which circuitry

remains active when the controllers are shut down and/or

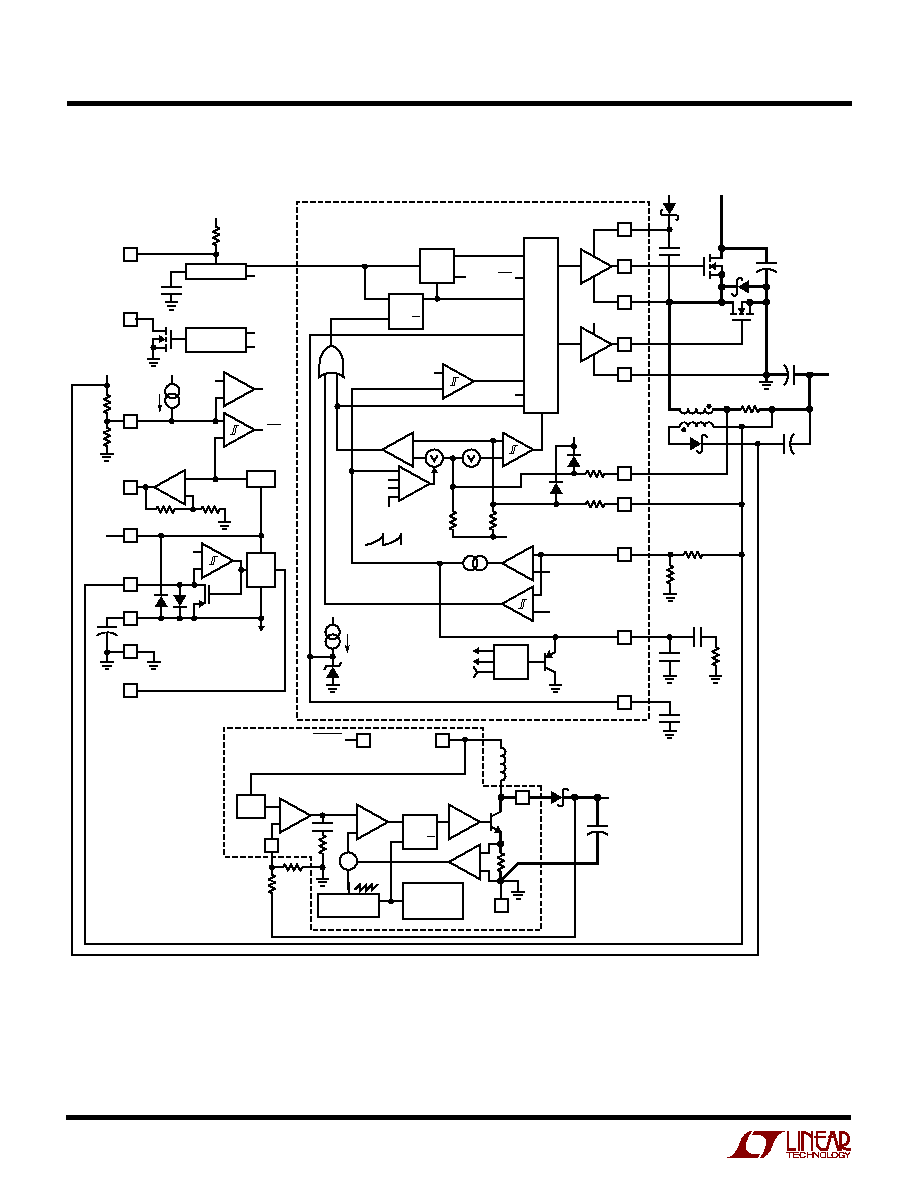

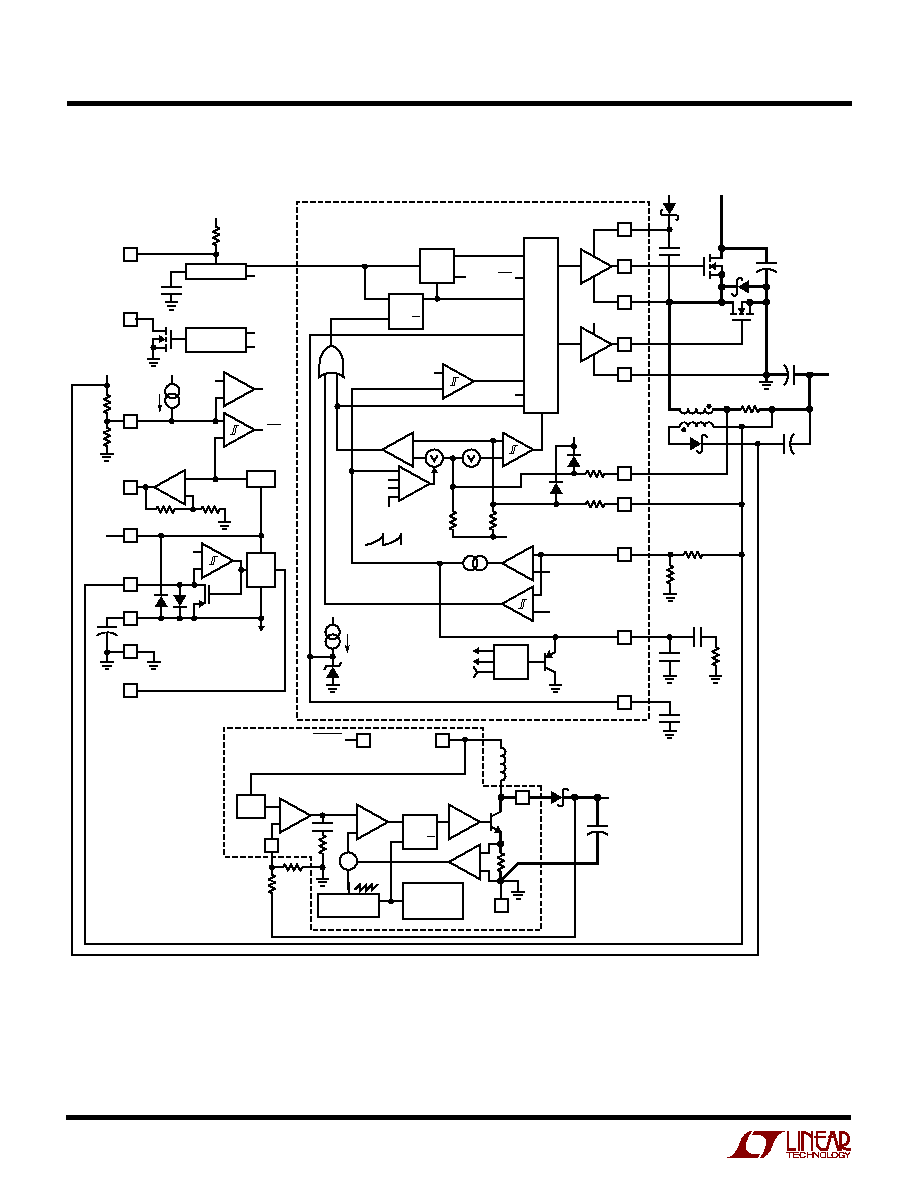

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

PI

N

FU

N

CTIO

N

S

U

U

U

V

IN

= 15V

V

OUT

= 5V

LOAD STEP = 0A TO 3A

Burst Mode OPERATION

20

µ

s/DIV

1876 G30

V

OUT

200mV/DIV

I

OUT

2A/DIV

Load Step (Figure 1)

Constant Frequency (Burst

Inhibit) Operation (Figure 1)

Input Source/Capacitor

Instantaneous Current (Figure 1)

Burst Mode Operation (Figure 1)

I

IN

2A/DIV

V

IN

200mV/DIV

V

SW2

10V/DIV

V

IN

= 15V

V

OUT

= 5V

I

OUT5

= I

OUT3.3

= 2A

1

µ

s/DIV

1876 G31

V

SW1

10V/DIV

V

OUT

20mV/DIV

I

OUT

0.5A/DIV

V

IN

= 15V

V

OUT

= 5V

V

FCB

= OPEN

I

OUT

= 20mA

10

µ

s/DIV

1876 G32

V

OUT

20mV/DIV

I

OUT

0.5A/DIV

V

IN

= 15V

V

OUT

= 5V

V

FCB

= 5V

I

OUT

= 20mA

2

µ

s/DIV

1876 G33

V

IN

= 15V

V

OUT

= 5V

LOAD STEP = 0A TO 3A

CONTINUOUS MODE

Load Step (Figure 1)

V

OUT

200mV/DIV

I

OUT

2A/DIV

LTC1876

9

1876fa

provides a common control point to shut down both control-

lers. See the Operation section for details.

FCB (Pin 7): Forced Continuous Control Input. This input acts

on both controllers and is normally used to regulate a

secondary winding. Pulling this pin below 0.8V will force

continuous synchronous operation on both controllers. Do

not leave this pin floating.

I

TH1,

I

TH2

(Pins 8, 11): Error Amplifier Output and Switching

Regulator Compensation Point. Each associated channel's

current comparator trip point increases with this control

voltage.

SGND (Pin 9): Small signal ground common to both control-

lers, must be routed separately from high current grounds to

the common (≠) terminals of the C

OUT

capacitors.

3.3V

OUT

(Pin 10): Output of a linear regulator capable of

supplying up to 10mA DC with peak currents as high as

50mA.

AUXSGND (Pin 15): Small Signal Ground of the Auxiliary

Boost Regulator.

AUXV

FB

(Pin 16): Auxiliary Boost Regulator Feedback Volt-

age. This pin receives the feedback voltage from an external

resistive divider across the auxiliary output.

AUXSW (Pins 17, 18): Switch Node Connections to Inductor

for the Auxiliary Regulator. Voltage swing at these pins are

from ground to (V

OUT

+ voltage across Shottky diode).

Minimize trace area at these pins to keep EMI down.

AUXPGND (Pins 19, 20): The Auxiliary Power Ground Pins.

Its gate drive currents are returned to these pin.

AUXV

IN

(Pin 21): Auxiliary Boost Regulator Controller Sup-

ply Pin. Must be closely decoupled to AUXPGND.

AUXSD (Pin 22): Shutdown Pin for the Auxiliary Regulator.

Connect to 2.4V or more to enable the auxiliary regulator or

ground to shut the auxiliary regulator off.

TG1, TG2 (Pins 35, 24): High Current Gate Drives for Top

N-Channel MOSFETs. These are the outputs of floating

drivers with a voltage swing equal to INTV

CC

≠ 0.5V superim-

posed on the switch node voltage SW.

SW1, SW2 (Pins 34, 25): Switch Node Connections to

Inductors. Voltage swing at these pins is from a Schottky

diode (external) voltage drop below ground to V

IN

.

BOOST1, BOOST2 (Pins 33, 26): Bootstrapped Supplies to

the Top Side Floating Drivers. Capacitors are connected

between the boost and switch pins and Schottky diodes are

tied between the boost and INTV

CC

pins. Voltage swing at the

boost pins is from INTV

CC

to (V

IN

+ INTV

CC

).

BG1, BG2 (Pins 31, 27): High Current Gate Drives for Bottom

(synchronous) N-Channel MOSFETs. Voltage swing at these

pins is from ground to INTV

CC

.

PGND (Pin 28): Driver Power Ground. Connects to sources

of bottom (synchronous) N-channel MOSFETs, anode of the

Schottky rectifier and the (≠) terminal(s) of C

IN

.

INTV

CC

(Pin 29): Output of the Internal 5V Linear Low

Dropout Regulator and the EXTV

CC

Switch. The driver and

control circuits are powered from this voltage source. Must

be decoupled to power ground with a minimum of 4.7

µ

F

tantalum or other, low ESR capacitor. The INTV

CC

regulator

standby operation is determined by the STBYMD pin.

EXTV

CC

(Pin 30): External Power Input to an Internal Switch

Connected to INTV

CC

. This switch closes and supplies V

CC

power, bypassing the internal

low dropout regulator, when-

ever EXTV

CC

is higher than 4.7V. See EXTV

CC

connection in

Applications section. Do not exceed 7V on this pin.

V

IN

(Pin 32): Main Supply Pin. A bypass capacitor should be

tied between this pin and the signal ground pin.

PGOOD (Pin 36): Open-Drain Logic Output. PGOOD is pulled

to ground when the voltage on either V

OSENSE

pin is not within

7.5% of its setpoint.

PI

N

FU

N

CTIO

N

S

U

U

U

LTC1876

10

1876fa

FU

N

CTIO

N

AL DIAGRA

U

U

W

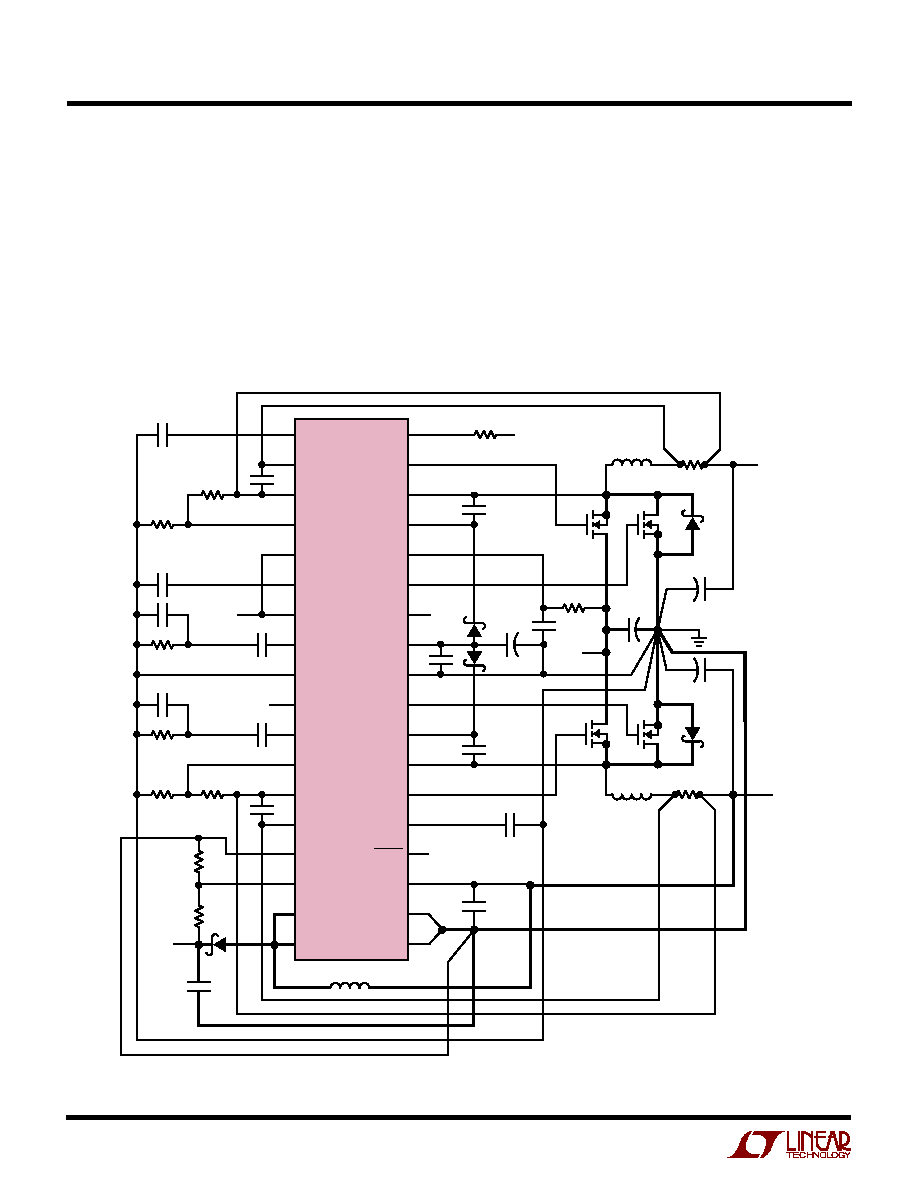

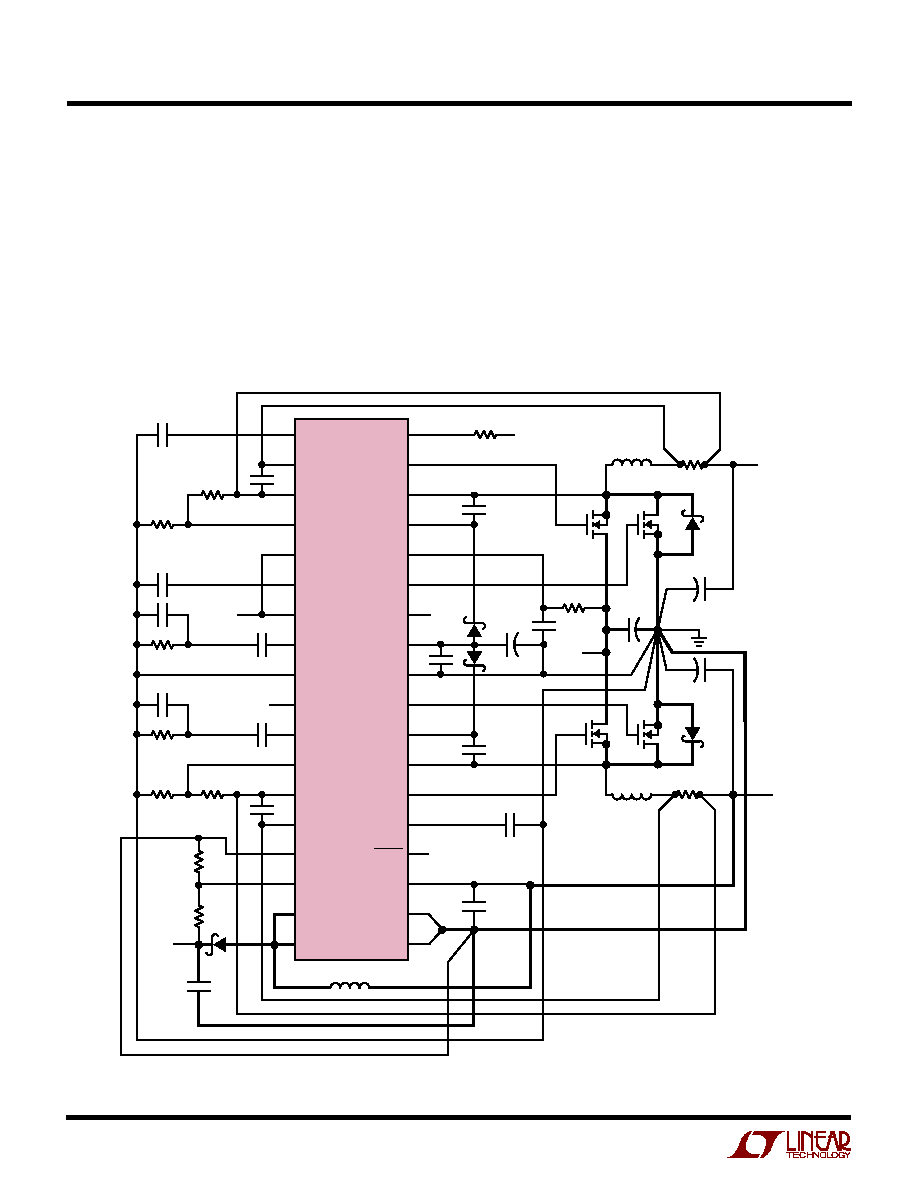

SWITCH

LOGIC

≠

+

0.8V

4.8V

5V

V

IN

V

IN

4.5V

BINH

V

OSENSE1

V

OSENSE2

CLK2

CLK1

0.18

µ

A

R6

R5

+

≠

+

≠

+

≠

+

≠

FCB

+

≠

≠

+

≠

+

≠

+

V

REF

WINDOW

COMPARATOR

INTERNAL

SUPPLY

3.3V

OUT

V

SEC

FCB

PGOOD

EXTV

CC

INTV

CC

SGND

STBYMD

+

+

5V

LDO

REG

SW

SHDN

0.55V

TOP

BOOST

TG

C

B

C

IN

D

1

D

B

PGND

BOT

BG

INTV

CC

INTV

CC

V

IN

+

C

SEC

C

OUT

V

OUT

1876 FD/F02

D

SEC

R

SENSE

R2

+

V

OSENSE

DROP

OUT

DET

RUN

SOFT

START

BOT

TOP ON

S

R

Q

Q

S

Q

Q

OSCILLATOR

FREQSET

FCB

EA

0.86V

0.80V

OV

V

FB

1.2

µ

A

6V

R1

≠

+

R

C

4(V

FB

)

RST

SHDN

RUN/SS

I

TH

C

C

C

C2

C

SS

1.19V

1M

+

4(V

FB

)

0.86V

SLOPE

COMP

3mV

+

≠

≠

+

SENSE

≠

SENSE

+

INTV

CC

30k

45k

2.4V

45k

30k

I1

I2

B

DUPLICATE FOR SECOND

CONTROLLER CHANNEL

+

≠

≠

+

RUN/SS1

1.26V

V

REF

C

C

R

C

RAMP

GENERATOR

1.2MHz

OSCILLATOR

OSC

AUX

EA

AUX

A1

AUX

R

R7

R8

AUXSW

AUXSD

D5

L3

AUXV

FB

AUXV

OUT

AUXV

IN

C

OUTAUX

AUXPGND

BOOST

REGULATOR

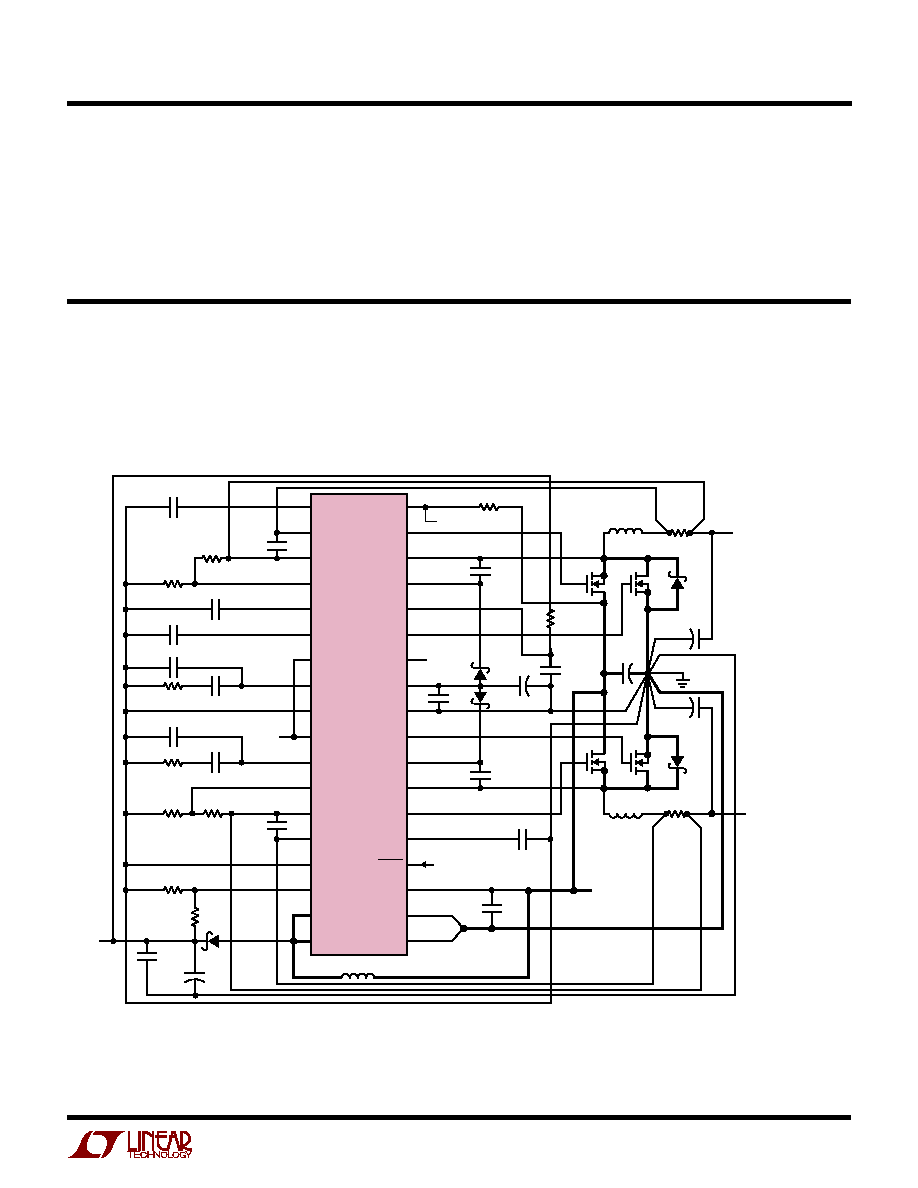

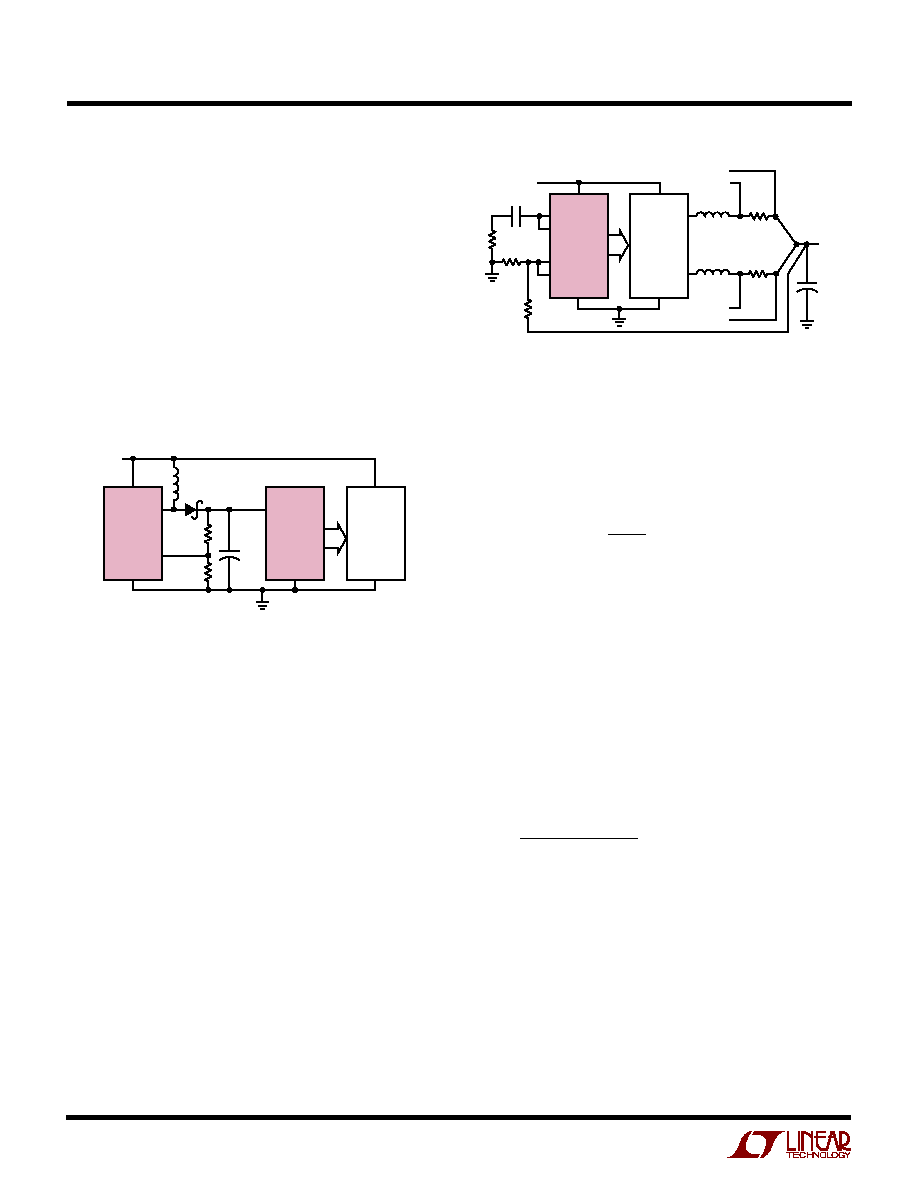

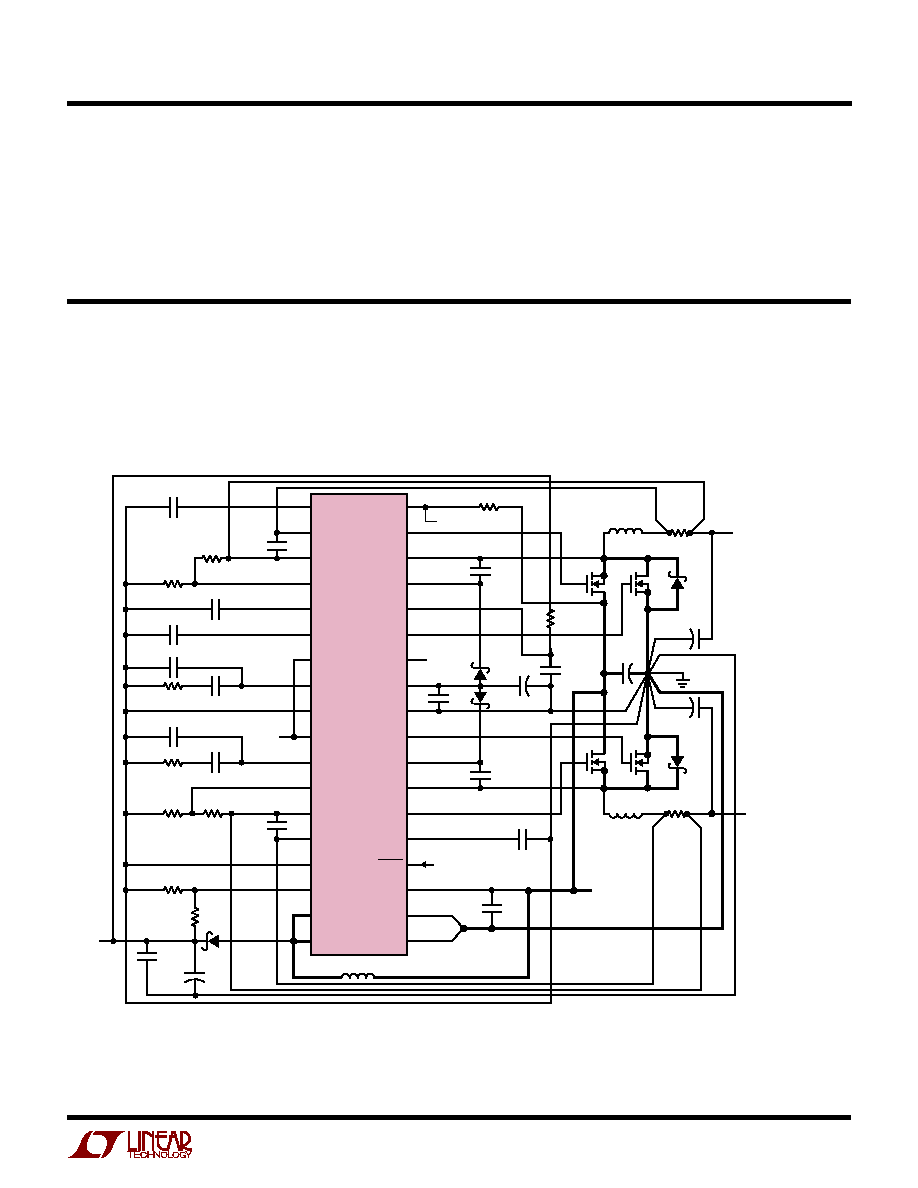

Figure 2

LTC1876

11

1876fa

Main Control Loop

The LTC1876 uses a constant frequency, current mode

scheme to provide excellent line and load regulation for all

its outputs. The step-down controllers have two of its

switch drivers operating at 180 degrees out of phase from

each other. During normal operation, each top MOSFET is

turned on when the clock for that channel sets the R

S

latch,

and turned off when the main current comparator, I1,

resets the R

S

latch. The peak inductor current at which I1

resets the R

S

latch is controlled by the voltage on the I

TH

pin, which is the output of each error amplifier EA. The

V

OSENSE

pin receives the voltage feedback signal, which is

compared to the internal reference voltage by the EA.

When the load current increases, it causes a slight de-

crease in V

OSENSE

relative to the 0.8V reference, which in

turn causes the I

TH

voltage to increase until the average

inductor current matches the new load current. After the

top MOSFET has turned off, the bottom MOSFET is turned

on until either the inductor current starts to reverse, as

indicated by current comparator I2, or the beginning of the

next cycle.

The top MOSFET drivers are biased from floating boot-

strap capacitor C

B

, which normally is recharged during

each off cycle through an external diode when the top

MOSFET turns off. As V

IN

decreases to a voltage close to

V

OUT

, the loop may enter dropout and attempt to turn on

the top MOSFET continuously. The dropout detector de-

tects this and forces the top MOSFET off for about 500ns

every tenth cycle to allow C

B

to recharge.

The main control loop is shut down by pulling the RUN/SS

pin low. Releasing RUN/SS allows an internal 1.2

µ

A

current source to charge soft-start capacitor C

SS

. When

C

SS

reaches 1.5V, the main control loop is enabled with the

I

TH

voltage clamped at approximately 30% of its maximum

value. As C

SS

continues to charge, the I

TH

pin voltage is

gradually released allowing normal, full-current opera-

tion. When both RUN/SS1 and RUN/SS2 are low, all

LTC1876 controller functions are shut down, and the

STBYMD pin determines if the standby 5V and 3.3V

regulators are kept alive.

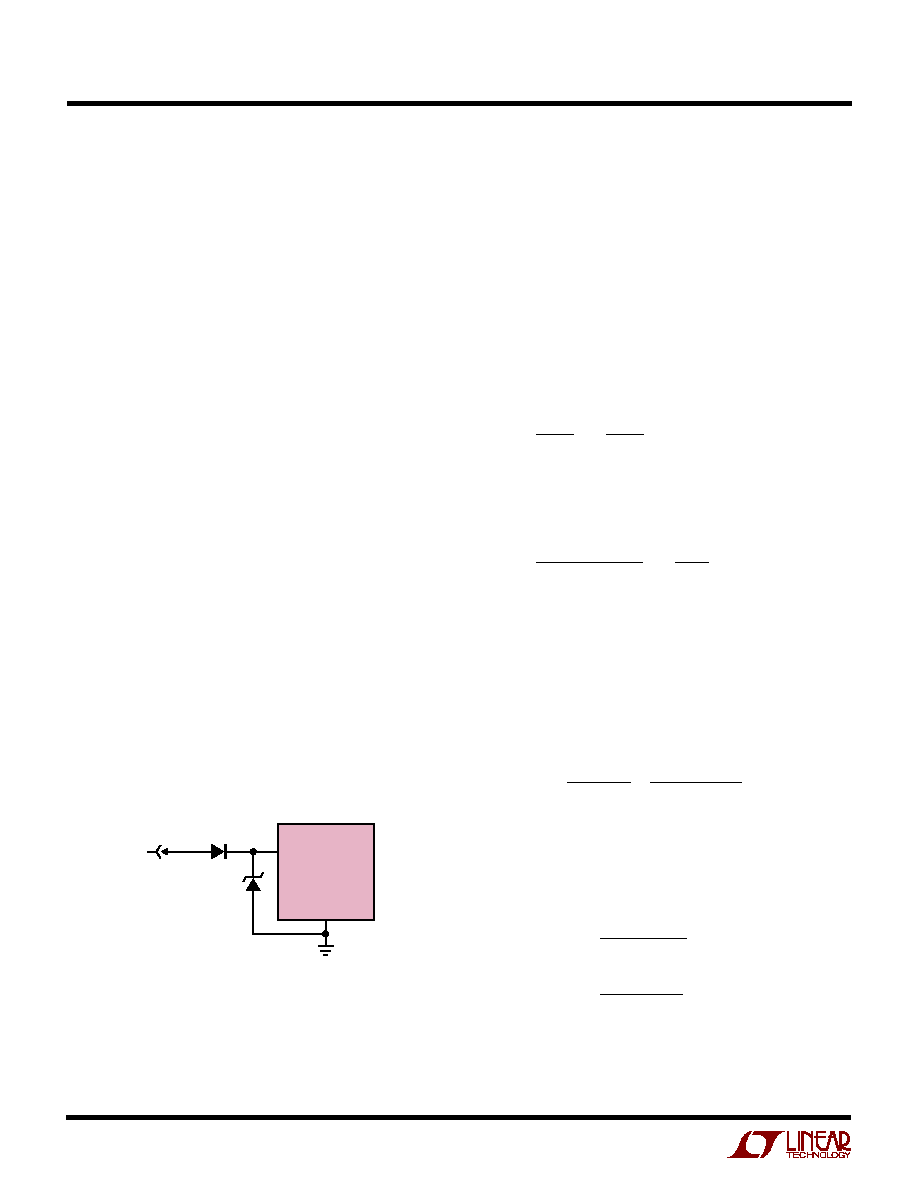

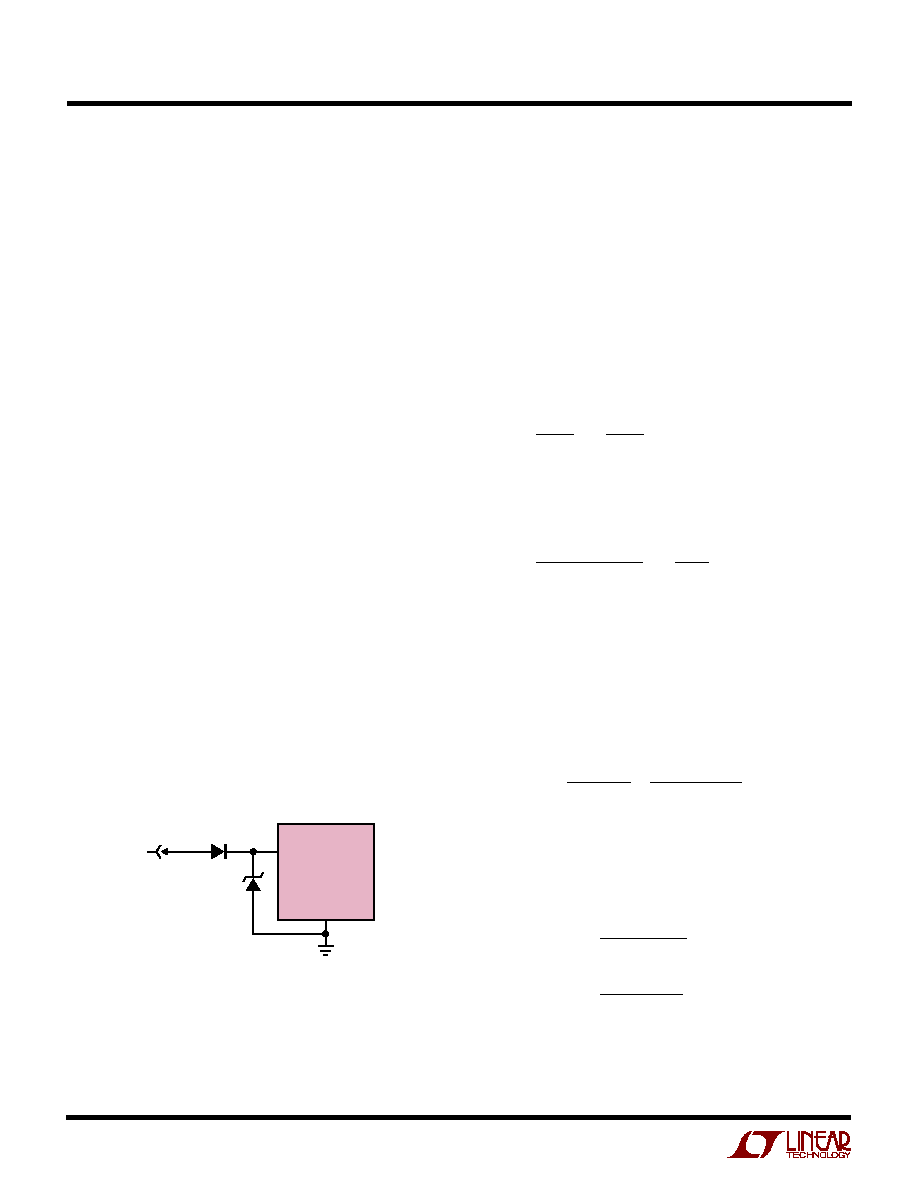

AUX Regulator

The auxiliary boost regulator is completely independent

from other LTC1876 circuits. It can be operated even

though the LTC1876 step-down controllers are in shut-

down. The operation of the boost regulator is similar to the

controllers. The oscillator, OSC

AUX

, sets the R

S

latch and

turns on the monolithic power switch. A voltage propor-

tional to the switch current is added to a stabilizing ramp

and the resulting sum is fed into the positive terminal of the

PWM comparator, A1

AUX

. When this voltage exceeds the

level at the negative input of A1

AUX

, the SR latch is reset,

turning off the power switch. The level at the negative input

of A1

AUX

is set by the error amplifier EA

AUX

and is simply

an amplified version of the difference between the feed-

back voltage and the reference voltage. Hence the error

amplifier sets the correct peak current level to keep the

output in regulation. To protect the power switch from

excessive current, a 1A minimum limit is internally set.

When the switch reaches this limit, it will force the latch to

reset, turning it off. Applying a voltage less than 0.5V on

the shutdown pin will put the boost regulator in shutdown.

Low Current Operation

The FCB pin is a multifunction pin providing two functions:

1) to provide regulation for a secondary winding by

temporarily forcing continuous PWM operation on both

controllers; and 2) select between

two modes of low

current operation. When the FCB pin voltage is below 0.8V,

the controller forces continuous PWM current operation.

In this mode, the top and bottom MOSFETs are alternately

turned on to maintain the output voltage independent of

direction of inductor current. When the FCB pin is below

V

INTVCC

≠ 2V but greater than 0.8V, the controller enters

Burst Mode operation. Burst Mode operation sets a mini-

mum output current level before turning off the top switch

and turns off the synchronous MOSFET(s) when the

inductor current goes negative. This combination of re-

quirements will, at low currents, force the I

TH

pin below a

voltage threshold that will temporarily inhibit turn-on of

both output MOSFETs until the output voltage drops

slightly. There is 60mV of hysteresis in the burst compara-

tor B tied to the I

TH

pin. This hysteresis produces output

signals to the MOSFETs that turn them on for several

(Refer to Functional Diagram)

OPERATIO

U

LTC1876

12

1876fa

cycles, followed by a variable "sleep" interval depending

upon the load current. The resultant output voltage ripple

is held to a very small value by having the hysteretic

comparator after the error amplifier gain block.

Constant Frequency Operation

When the FCB pin is tied to INTV

CC

, Burst Mode operation

is disabled and the forced minimum output current re-

quirement is removed. This provides constant frequency,

discontinuous (preventing reverse inductor current) cur-

rent operation over the widest possible output current

range. This constant frequency operation is not as efficient

as Burst Mode operation, but does provide a lower noise,

constant frequency operating mode down to approxi-

mately 1% of designed maximum output current.

Constant Current (PWM) Operation

Tying the FCB pin to ground will force continuous current

operation. This is the least efficient operating mode, but

may be desirable in certain applications. The output can

source or sink current in this mode. When sinking current

while in forced continuous operation, current will be

forced back into the main power supply potentially boost-

ing the input supply to dangerous voltage levels--

BEWARE!

Frequency Setting

The FREQSET pin provides frequency adjustment to the

controllers' internal oscillator from approximately 140kHz

to 310kHz. This input is nominally biased through an

internal resistor to the 1.19V reference, setting the oscil-

lator frequency to approximately 220kHz. This pin can be

driven from an external AC or DC signal source to control

the instantaneous frequency of the oscillator. The auxillary

boost regulator operates at a constant 1.2MHz frequency.

INTV

CC

/EXTV

CC

Power

Power for the top and bottom MOSFET drivers and most

other internal circuitry is derived from the INTV

CC

pin.

When the EXTV

CC

pin is left open, an internal 5V low

dropout linear regulator supplies INTV

CC

power. If EXTV

CC

is taken above 4.7V, the 5V regulator is turned off and an

internal switch is turned on connecting EXTV

CC

to INTV

CC

.

This allows the INTV

CC

power to be derived from a high

efficiency external source such as the output of the regu-

lator itself or a secondary winding, as described in Appli-

cations Information.

Standby Mode Pin

The STBYMD pin is a three-state input that controls

common circuitry within the IC as follows: When the

STBYMD pin is held at ground, both controller RUN/SS

pins are pulled to ground providing a single control pin to

shut down both controllers. When the pin is left open, the

internal RUN/SS currents are enabled to charge the

RUN/SS capacitor(s), allowing the turn-on of either con-

troller and activating necessary common internal biasing.

When the STBYMD pin is taken above 2V, both internal

linear regulators are turned on independent of the state of

the two switching regulator controllers, providing output

power to "wake-up" other circuitry. Decouple the pin with

a small capacitor (0.01

µ

F) to ground if the pin is not

connected to a DC potential.

Output Overvoltage Protection

An overvoltage comparator, OV, guards against transient

overshoots (>7.5%) as well as other more serious condi-

tions that may overvoltage the output. In this case, the top

MOSFET is turned off and the bottom MOSFET is turned on

until the overvoltage condition is cleared.

Power Good (PGOOD) Pin

The PGOOD pin is connected to an open drain of an internal

MOSFET. The MOSFET turns on and pulls the pin low when

both the outputs are not within

±

7.5% of their nominal

output levels as determined by their resistive feedback

dividers. When both controller outputs meet the

±

7.5%

requirement, the MOSFET is turned off within 10

µ

s and the

pin is allowed to be pulled up by an external resistor to a

source of up to 7V. The auxiliary regulator's output is not

monitored.

Foldback Current, Short-Circuit Detection and Short-

Circuit Latchoff

The RUN/SS capacitors are used initially to limit the inrush

current of each step-down switching regulator. After the

(Refer to Functional Diagram)

OPERATIO

U

LTC1876

13

1876fa

controller has been started and been given adequate time

to charge up the output capacitors and provide full-load

current, the RUN/SS capacitor is used as a short-circuit

time-out circuit. If the output voltage falls to less than 70%

of its nominal output voltage, the RUN/SS capacitor be-

gins discharging on the assumption that the output is in an

overcurrent and/or short-circuit condition. If the condition

lasts for a long enough period as determined by the size of

the RUN/SS capacitor, both controllers will be shut down

until the RUN/SS pin(s) voltage(s) are recycled. This built-

in latchoff can be overridden by providing a >5

µ

A pull-up

at a compliance of 5V to the RUN/SS pin(s). This current

shortens the soft start period but also prevents net dis-

charge of the RUN/SS capacitor(s) during an overcurrent

and/or short-circuit condition. Foldback current limiting is

also activated when the output voltage falls below 70% of

its nominal level whether or not the short-circuit latchoff

circuit is enabled. Even if a short is present and the short-

circuit latchoff is not enabled, a safe, low output current is

provided due to internal current foldback and actual power

wasted is low due to the efficient nature of the current

mode switching regulator.

Theory and Benefits of 2-Phase Operation

The LTC1876 dual high efficiency DC/DC controller brings

the considerable benefits of 2-phase operation to portable

applications for the first time. Notebook computers, PDAs,

handheld terminals and automotive electronics will all

benefit from the lower input filtering requirement, reduced

electromagnetic interference (EMI) and increased effi-

ciency associated with 2-phase operation.

Why the need for 2-phase operation? In most dual con-

stant-frequency switching regulators, both regulators are

operated in phase (i.e., single-phase operation). This

means that both switches turned on at the same time,

causing current pulses of up to twice the amplitude of

those for one regulator to be drawn from the input capaci-

tor and battery. These large amplitude current pulses

increased the total RMS current flowing from the input

capacitor, requiring the use of more expensive input

capacitors and increasing both EMI and losses in the input

capacitor and battery.

With 2-phase operation, the two channels of the dual-

switching regulator are operated 180 degrees out of

phase. This effectively interleaves the current pulses

coming from the switches, greatly reducing the overlap

time where they add together.

The result is a significant

reduction in total RMS input current, which in turn allows

less expensive input capacitors to be used, reduces shield-

ing requirements for EMI and improves real world operat-

ing efficiency.

Figure 3 compares the input waveforms for a representa-

tive single-phase dual switching regulator to the LTC1876

2-phase dual switching regulator. An actual measurement

of the RMS input current under these conditions shows

that 2-phase operation dropped the input current from

2.53A

RMS

to 1.55A

RMS

. While this is an impressive reduc-

tion in itself, remember that the power losses are propor-

tional to I

RMS

2

, meaning that the actual power wasted is

reduced by a factor of 2.66. The reduced input ripple

voltage also means less power is lost in the input power

(Refer to Functional Diagram)

OPERATIO

U

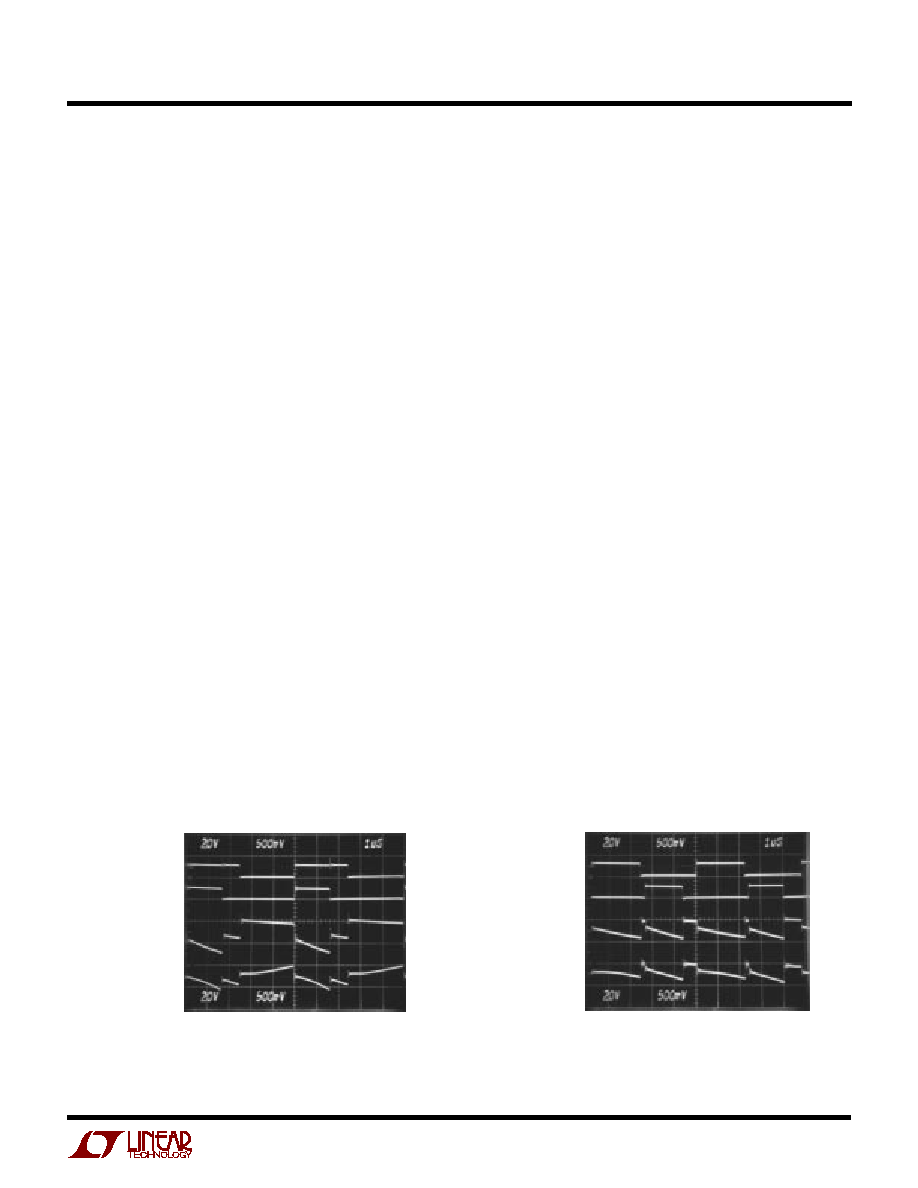

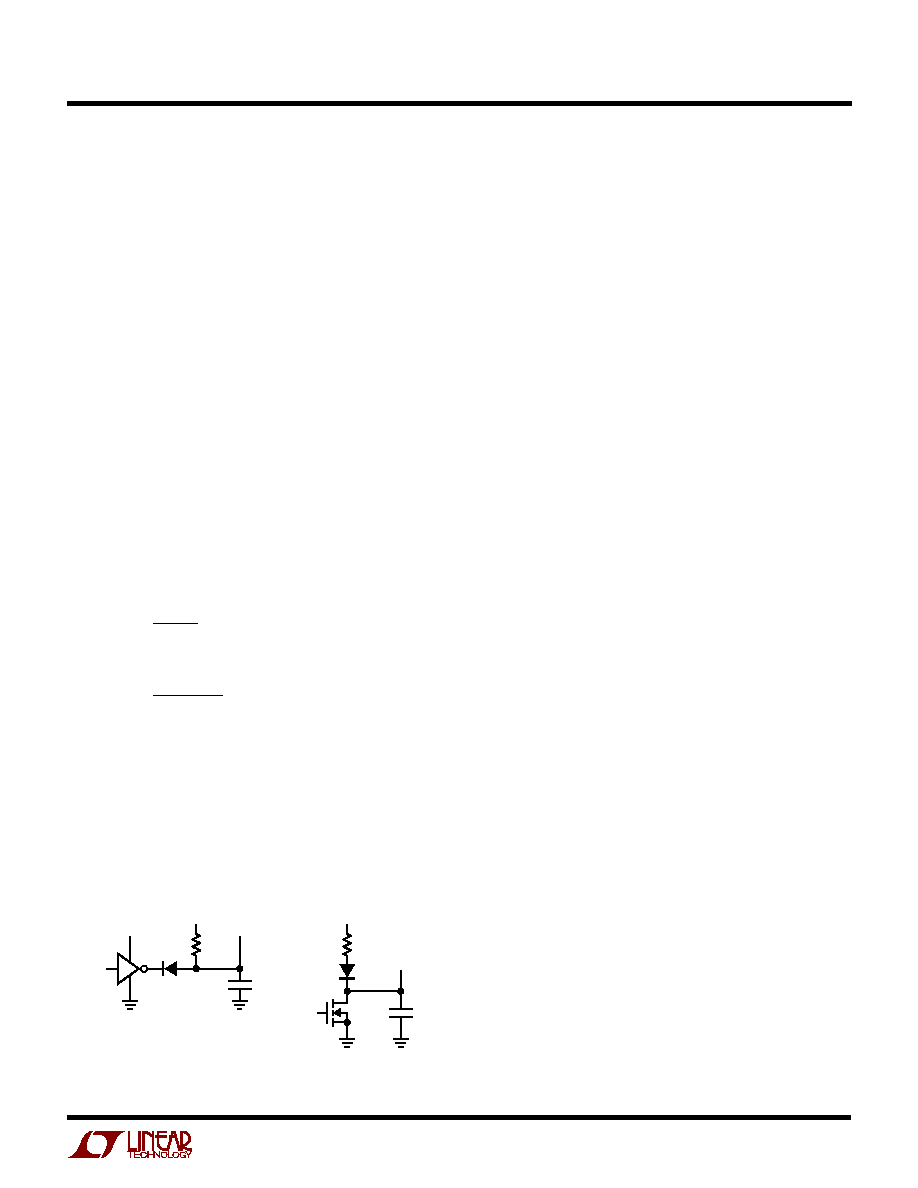

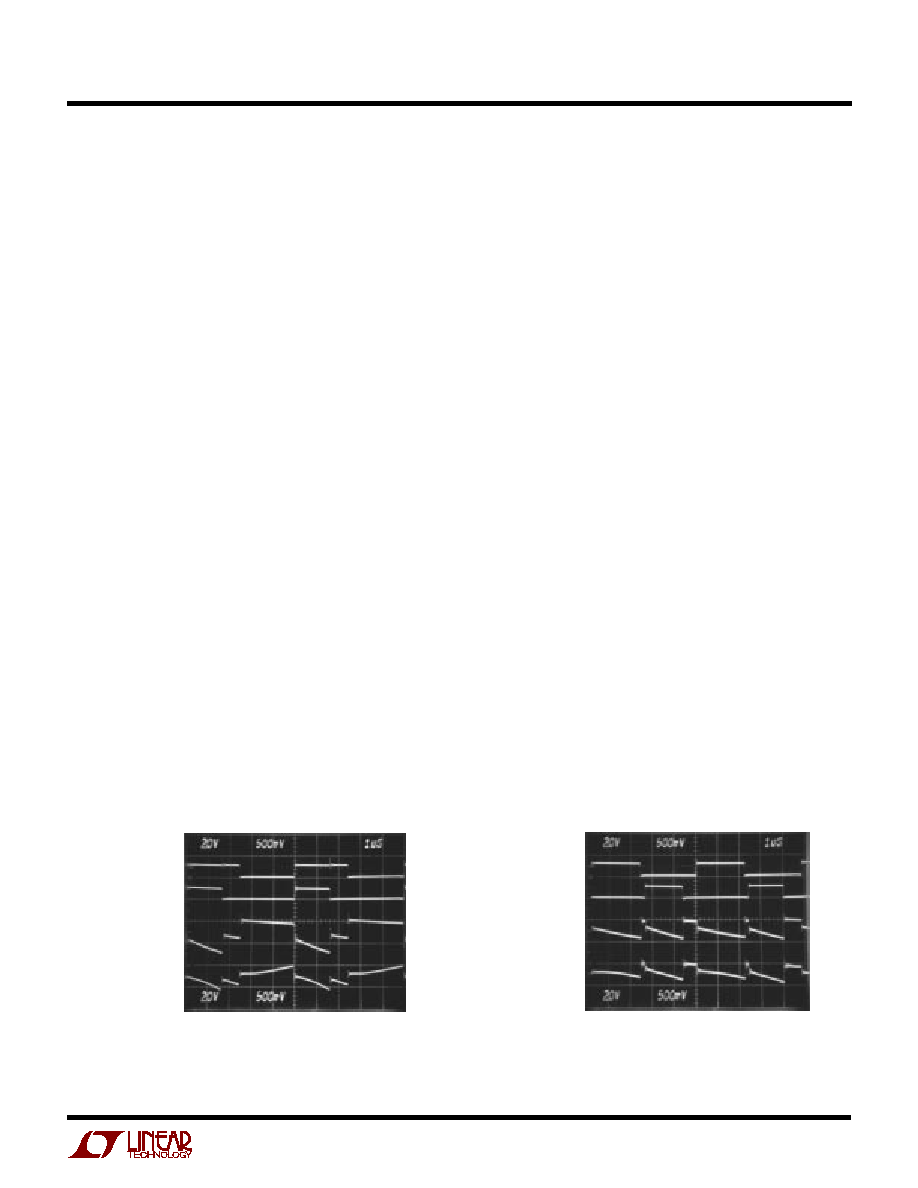

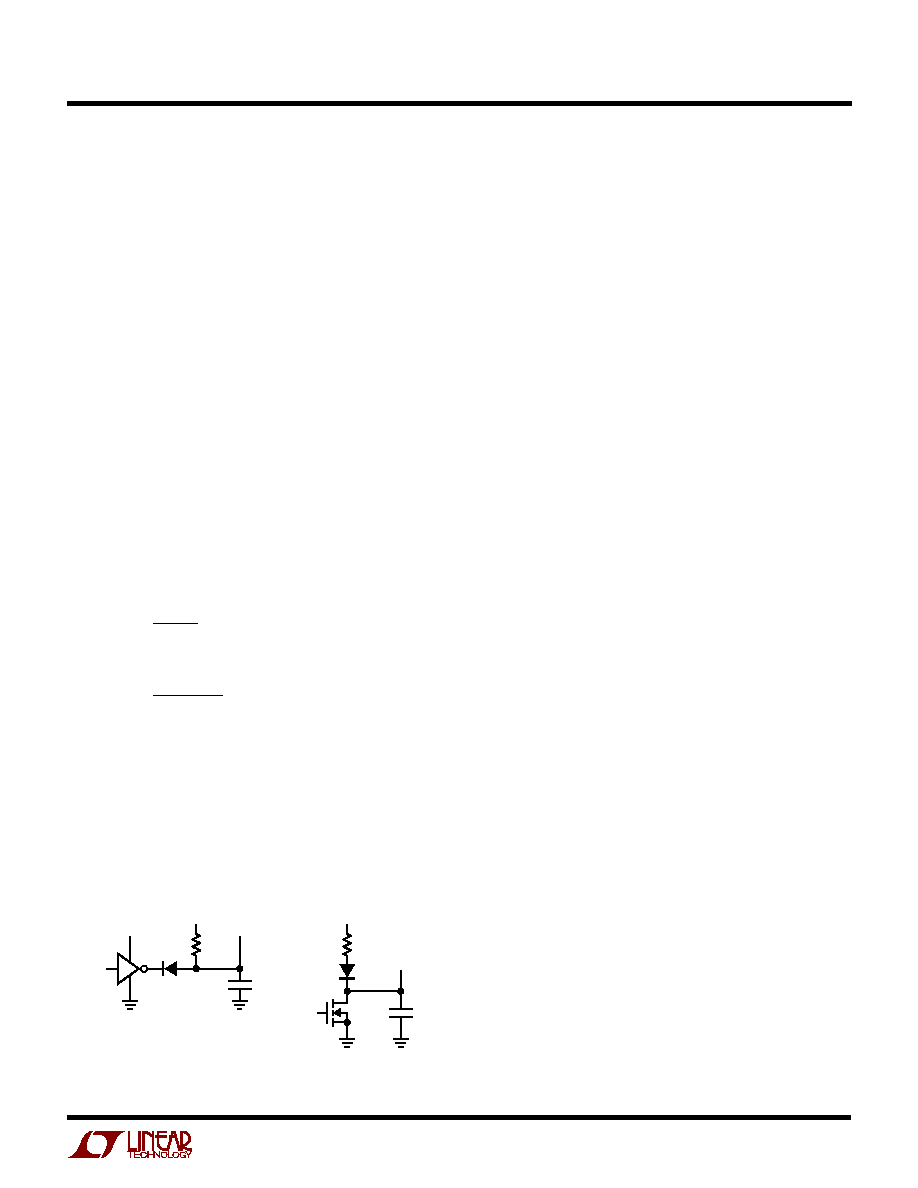

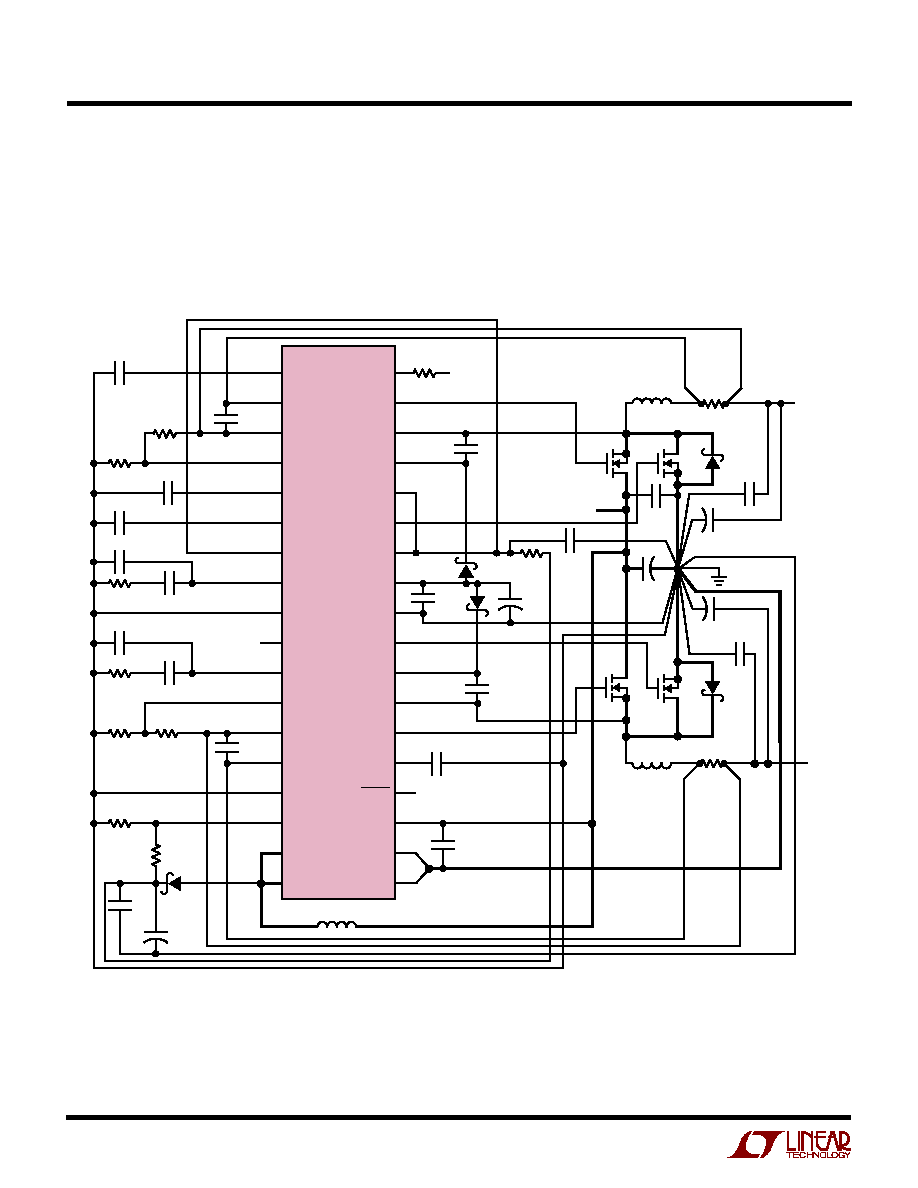

Figure 3. Input Waveforms Comparing Single-Phase (a) and 2-Phase (b) Operation for Dual Switching Regulators

Converting 12V to 5V and 3.3V at 3A Each. The Reduced Input Ripple with the LTC1876 2-Phase Regulator Allows

Less Expensive Input Capacitors, Reduces Shielding Requirements for EMI and Improves Efficiency

I

IN(MEAS)

= 2.53A

RMS

(a) Single-Phase

I

IN(MEAS)

= 1.55A

RMS

(b) 2-Phase

5V SWITCH

20V/DIV

1876 F03a

1876 F03b

3.3V SWITCH

20V/DIV

INPUT CURRENT

5A/DIV

INPUT VOLTAGE

500mV/DIV

5V SWITCH

20V/DIV

3.3V SWITCH

20V/DIV

INPUT CURRENT

5A/DIV

INPUT VOLTAGE

500mV/DIV

LTC1876

14

1876fa

path, which could include batteries, switches, trace/con-

nector resistances and protection circuitry. Improvements

in both conducted and radiated EMI also directly accrue as

a result of the reduced RMS input current and voltage.

Of course, the improvement afforded by 2-phase opera-

tion is a function of the dual switching regulator's relative

duty cycles which, in turn, are dependent upon the input

voltage V

IN

(Duty Cycle = V

OUT

/V

IN

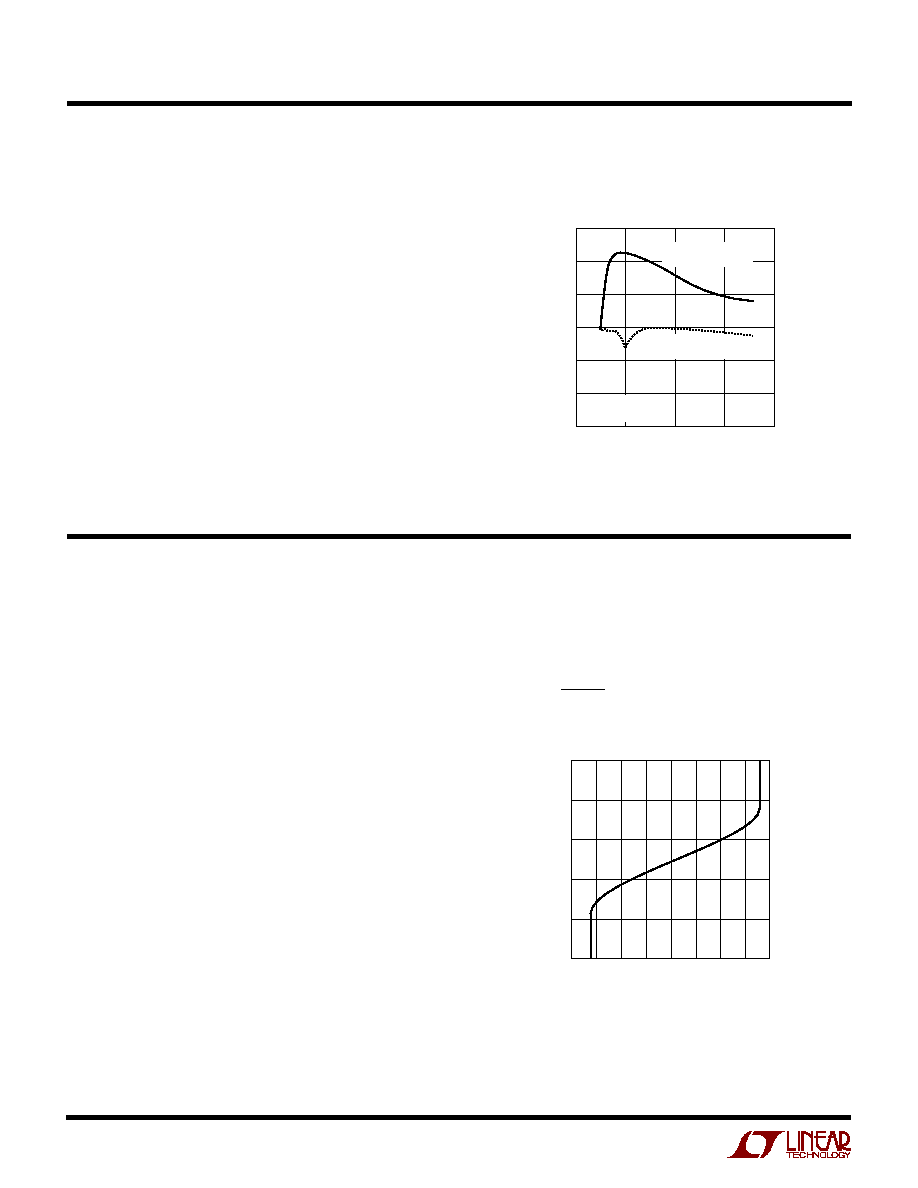

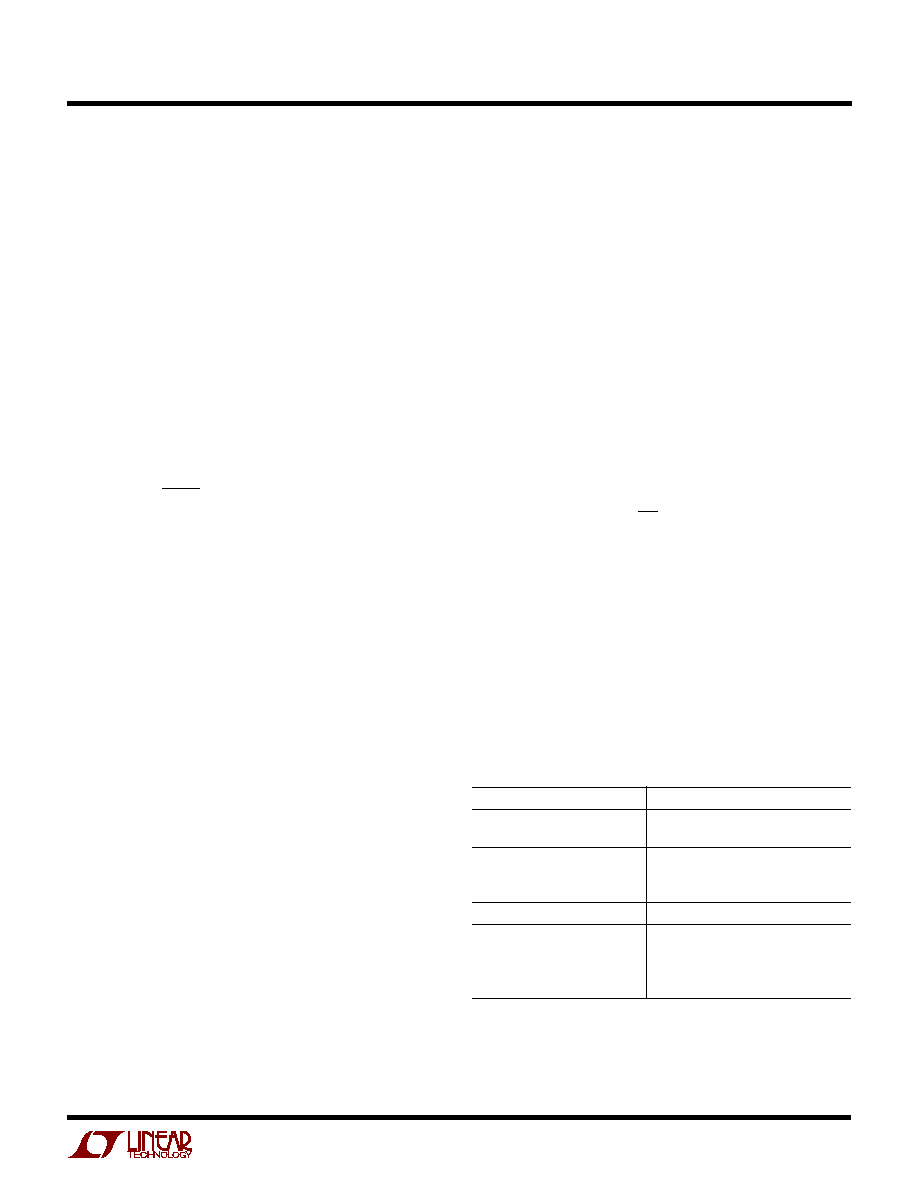

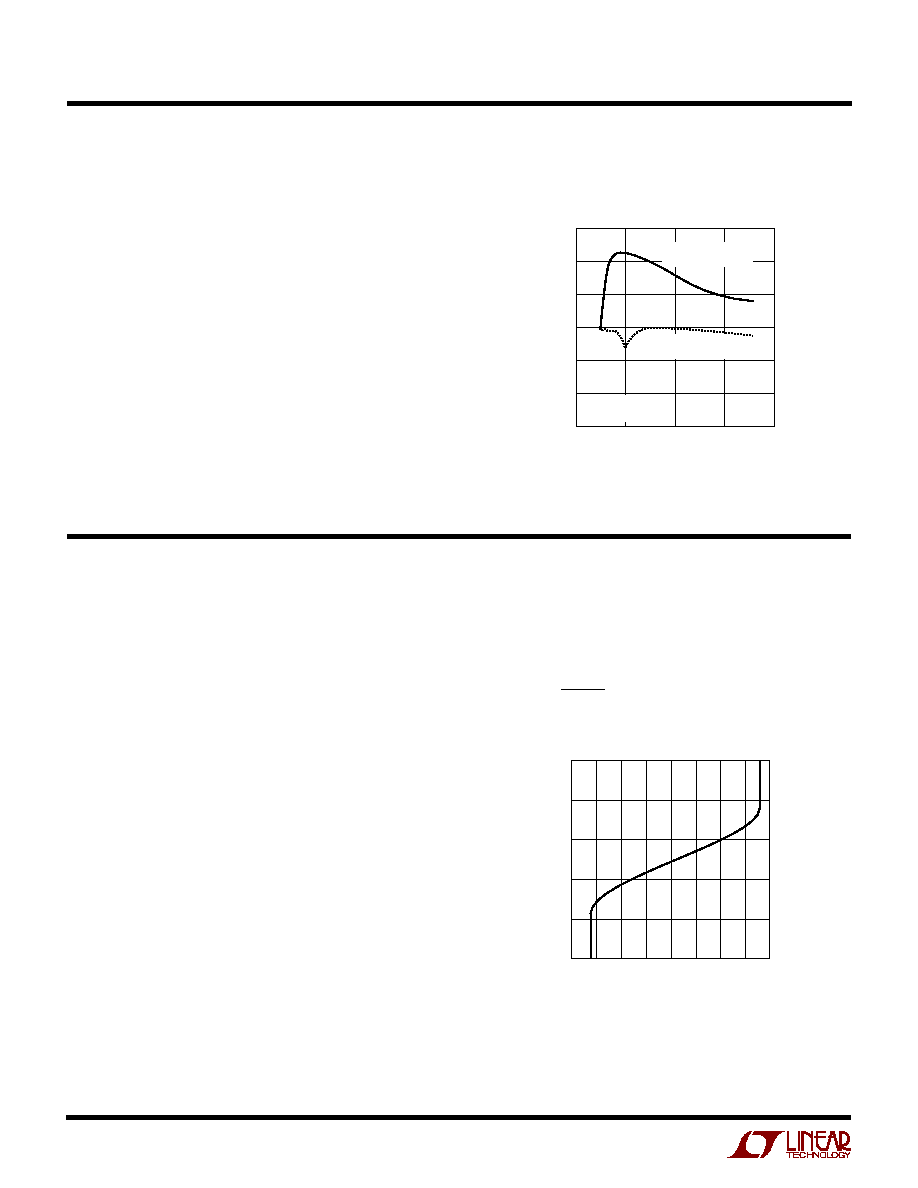

). Figure 4 shows how

the RMS input current varies for single-phase and 2-phase

operation for 3.3V and 5V regulators over a wide input

voltage range.

It can readily be seen that the advantages of 2-phase

operation are not just limited to a narrow operating range,

but in fact extend over a wide region. A good rule of thumb

for most applications is that 2-phase operation will reduce

Allowing a margin for variations in the LTC1876 and

external component values yields:

R

mV

I

SENSE

MAX

=

50

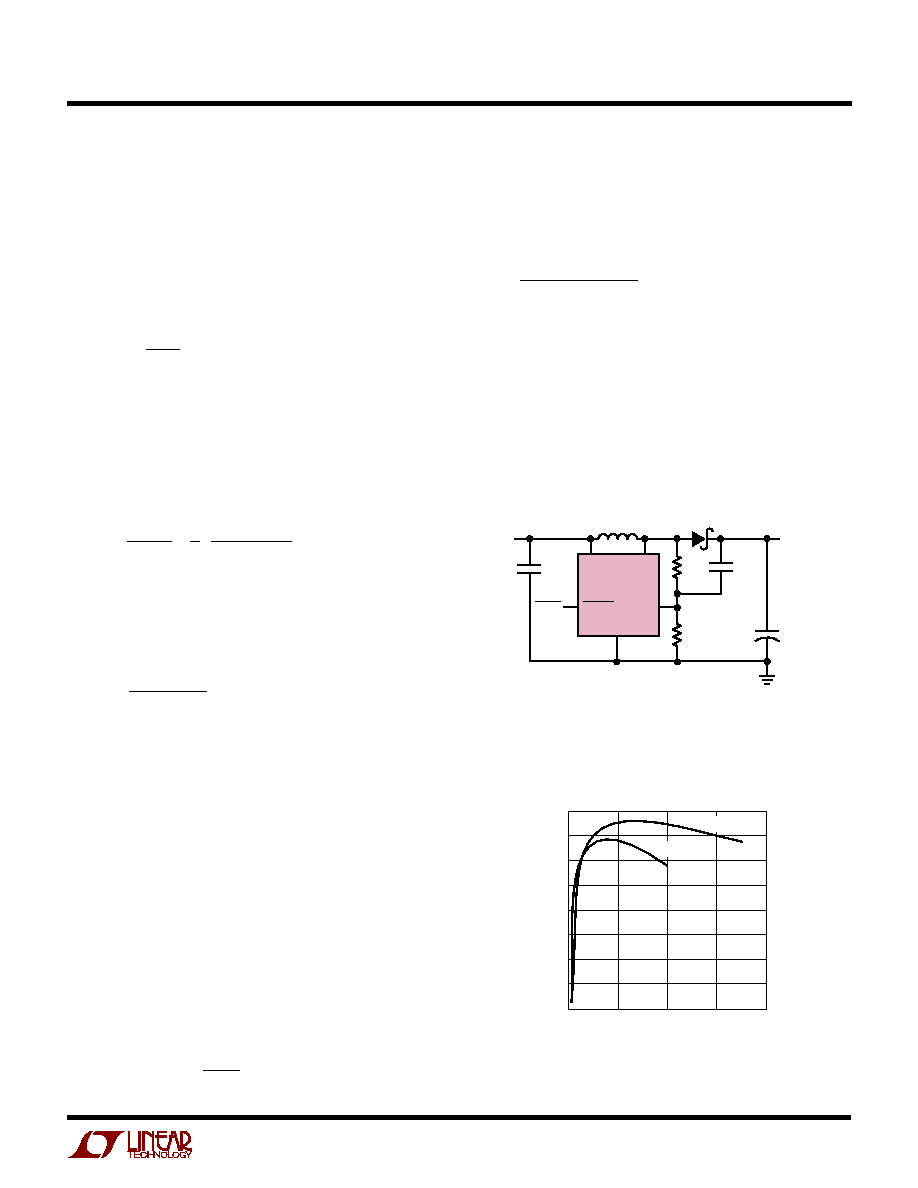

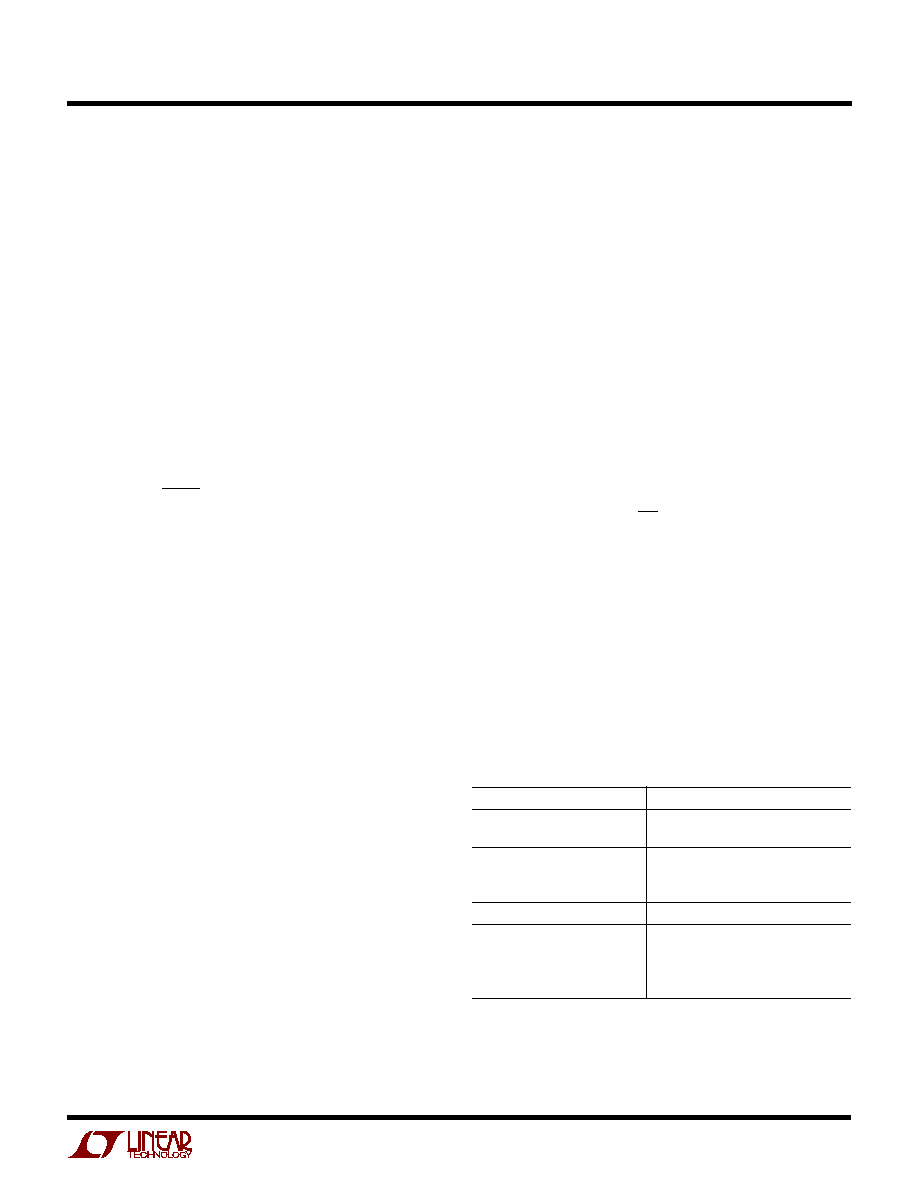

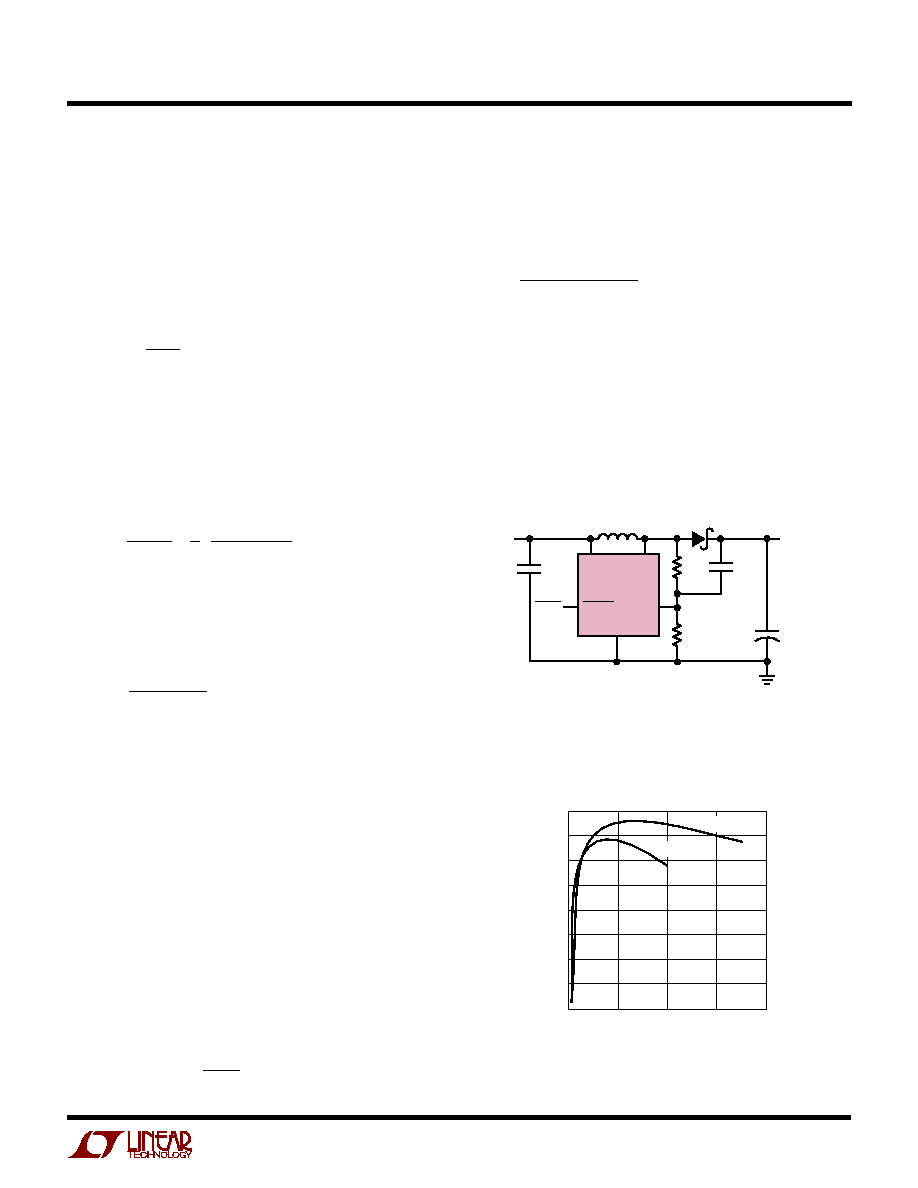

Figure 4. RMS Input Current Comparison

(Refer to Functional Diagram)

OPERATIO

U

APPLICATIO S I FOR ATIO

W

U

U

U

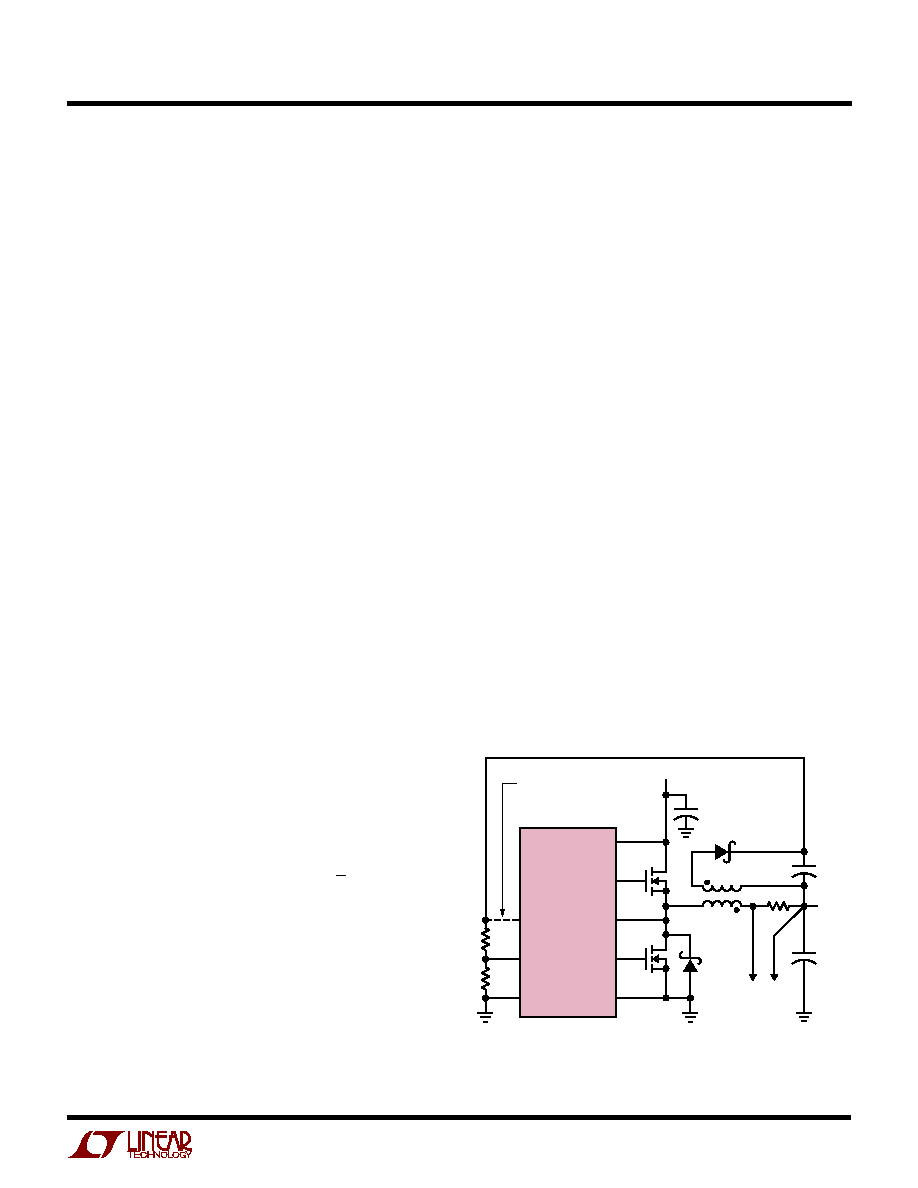

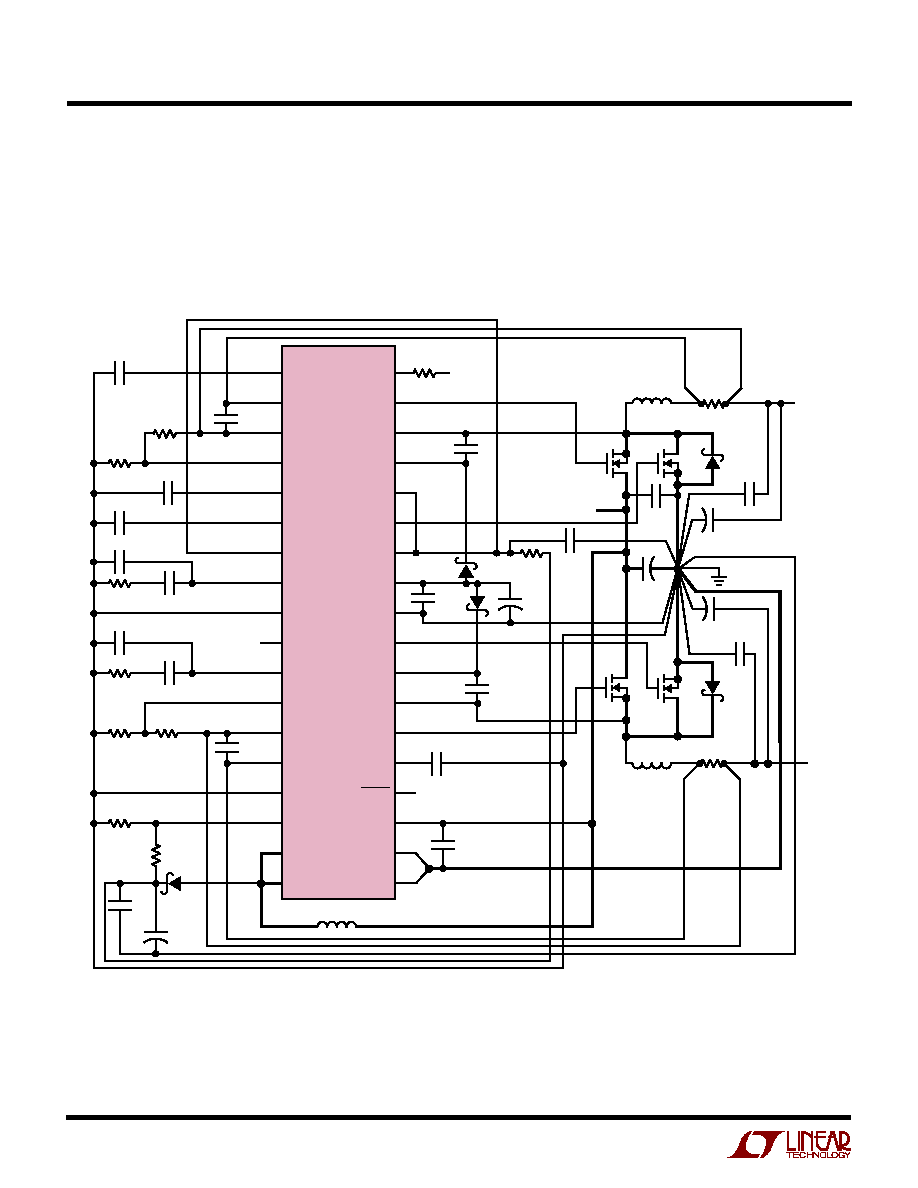

Figure 1 on the first page is a basic LTC1876 application

circuit. For the step-down regulators, the external compo-

nent selection is driven by the load requirement, and

begins with the selection of R

SENSE

. Once R

SENSE

is

known, L can be chosen. Next, the power MOSFETs and D1

are selected. Finally, C

IN

and C

OUT

are selected . The circuit

shown in Figure 1 can be configured for operation up to an

input voltage of 28V (limited by the external MOSFETs).

For the step-up regulator, its component selection is much

simpler. A 4.7

µ

H or 10

µ

H inductor that can handle at least

1A without saturating will work well with most design. A

Shottky diode is recommended and a MBR0520 from ON

Semiconductor is a very good choice.

R

SENSE

Selection For Output Current

R

SENSE

is chosen based on the required output current.

The LTC1876 current comparator has a maximum thresh-

old of 75mV/R

SENSE

and an input common mode range of

SGND to 1.1(INTV

CC

). The current comparator threshold

sets the peak of the inductor current, yielding a maximum

average output current I

MAX

equal to the peak value less

half the peak-to-peak ripple current,

I

L

.

INPUT VOLTAGE (V)

0

INPUT RMS CURRENT (A)

3.0

2.5

2.0

1.5

1.0

0.5

0

10

20

30

40

1876 F04

SINGLE PHASE

DUAL CONTROLLER

2-PHASE

DUAL CONTROLLER

V

O1

= 5V/3A

V

O2

= 3.3V/3A

the input capacitor requirement to that for just one channel

operating at maximum current and 50% duty cycle.

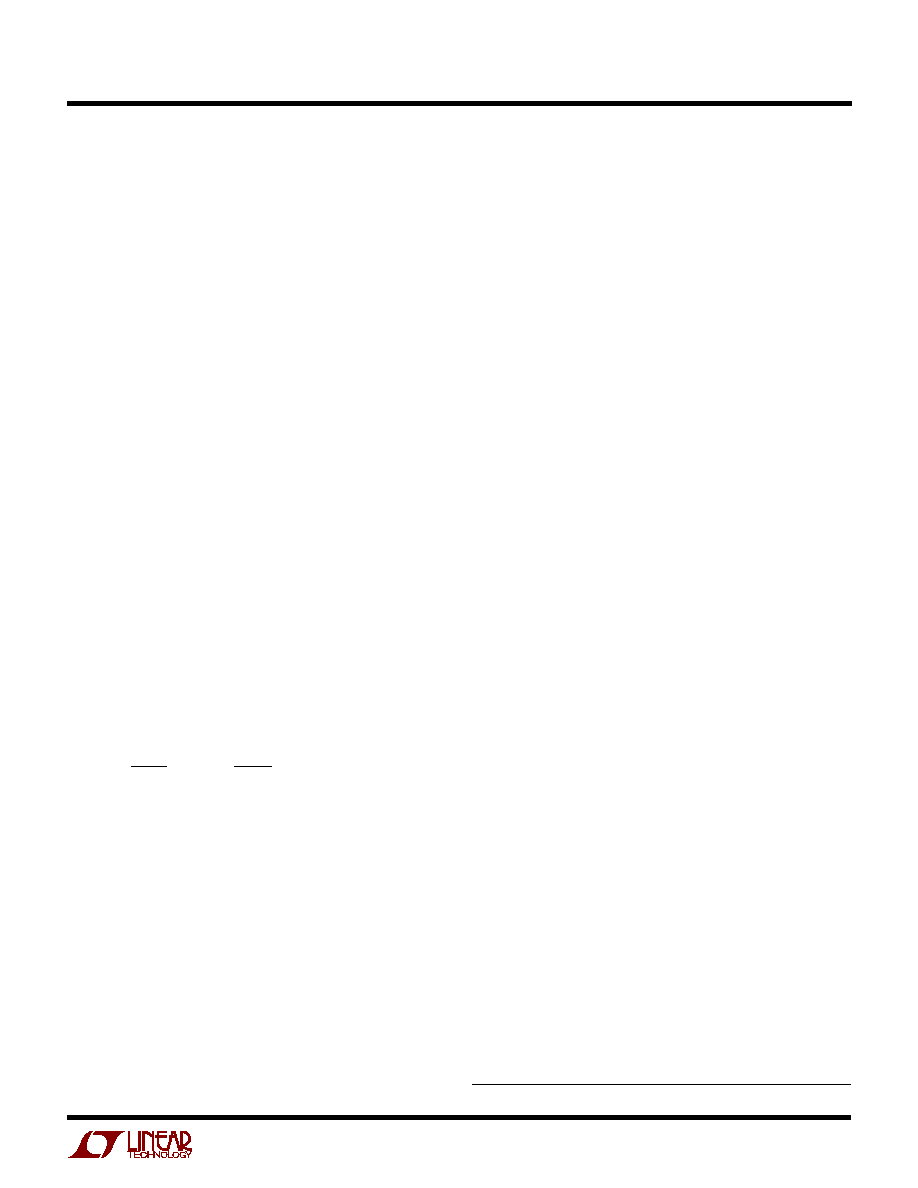

OPERATING FREQUENCY (kHz)

120

170

220

270

320

FREQSET PIN VOLTAGE (V)

1876 F05

2.5

2.0

1.5

1.0

0.5

0

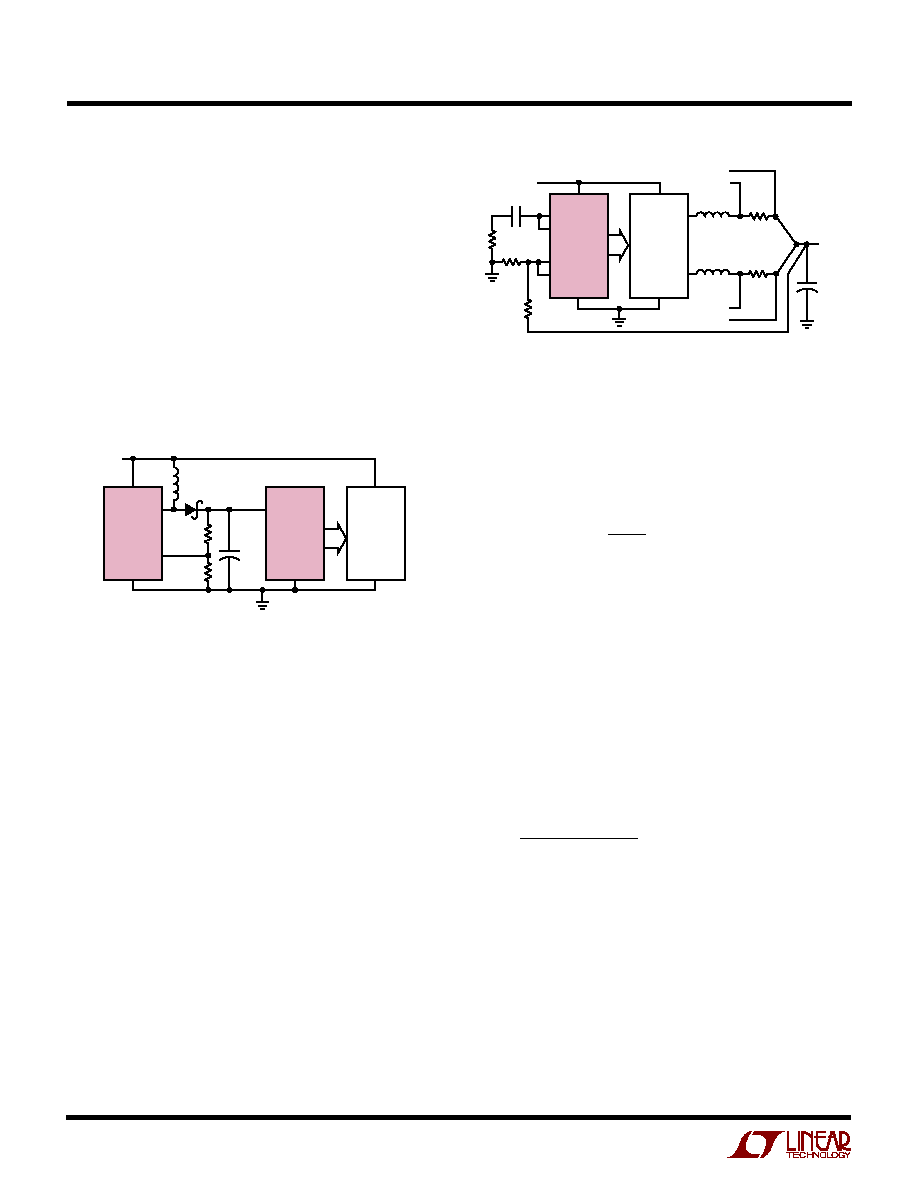

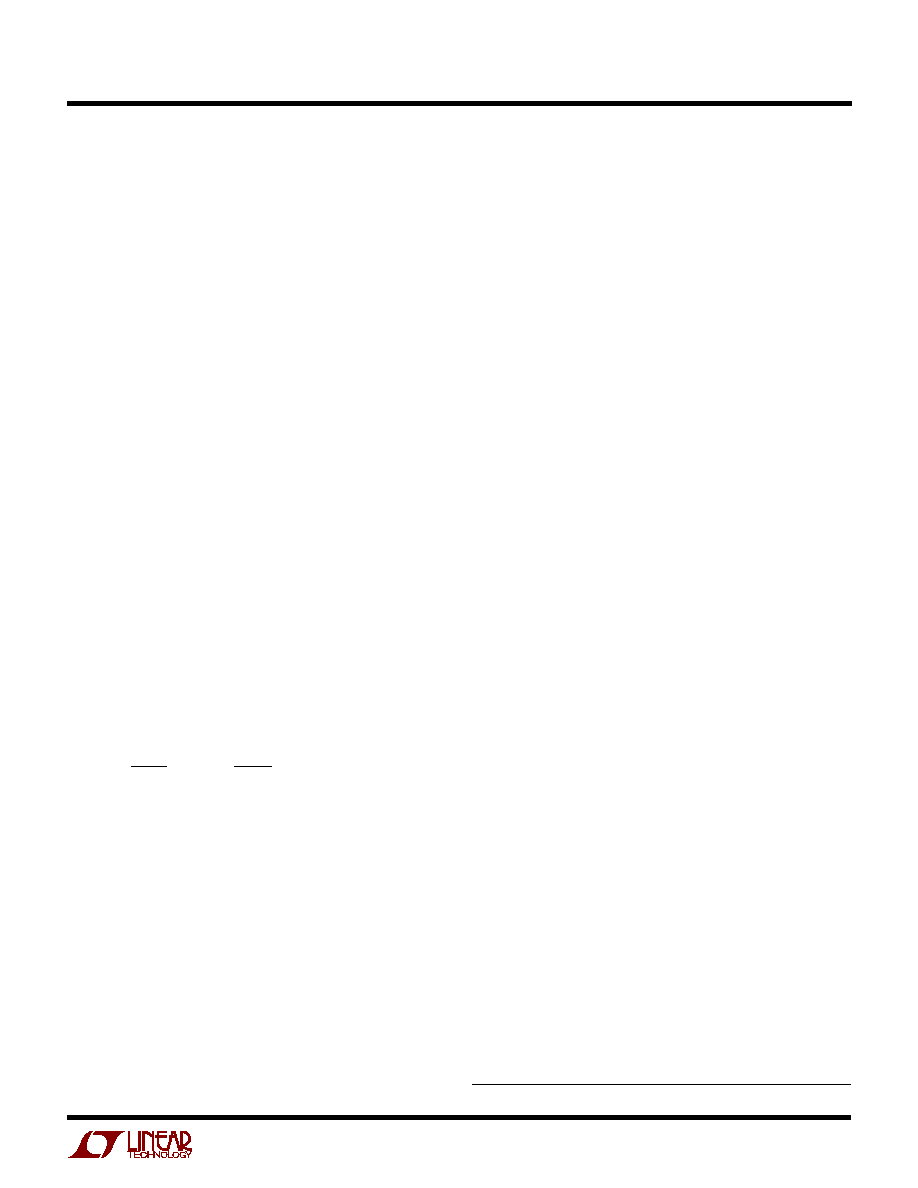

Figure 5. FREQSET Pin Voltage vs Frequency

LTC1876

15

1876fa

Selection of Operating Frequency

The LTC1876 uses a constant frequency architecture with

the frequency determined by an internal oscillator

capacitor. This internal capacitor is charged by a fixed

current plus an additional current that is proportional to

the voltage applied to the FREQSET pin.

A graph for the voltage applied to the FREQSET pin vs

frequency is given in Figure 5. As the operating frequency

is increased the gate charge losses will be higher, reducing

efficiency (see Efficiency Considerations). The maximum

switching frequency is approximately 310kHz.

Inductor Value Calculation

The operating frequency and inductor selection are inter-

related in that higher operating frequencies allow the use

of smaller inductor and capacitor values. So why would

anyone ever choose to operate at lower frequencies with

larger components? The answer is efficiency. A higher

frequency generally results in lower efficiency because of

MOSFET gate charge losses. In addition to this basic

trade-off, the effect of inductor value on ripple current and

low current operation must also be considered.

The inductor value has a direct effect on ripple current. The

inductor ripple current

I

L

decreases with higher induc-

tance or frequency and increases with higher V

IN

or V

OUT

:

I

f L

V

V

V

L

OUT

OUT

IN

=

1

1

( )( )

≠

Accepting larger values of

I

L

allows the use of low

inductances, but results in higher output voltage ripple

and greater core losses. A reasonable starting point for

setting ripple current is

I

L

=0.3(I

MAX

). Remember, the

maximum

I

L

occurs at the maximum input voltage.

The inductor value also has secondary effects. The transi-

tion to Burst Mode operation begins when the average

inductor current required results in a peak current below

25% of the current limit determined by R

SENSE

. Lower

inductor values (higher

I

L

) will cause this to occur at

lower load currents, which can cause a dip in efficiency in

the upper range of low current operation. In Burst Mode

operation, lower inductance values will cause the burst

frequency to decrease.

Inductor Core Selection

Once the value for L is known, the type of inductor must be

selected. High efficiency converters generally cannot af-

ford the core loss found in low cost powdered iron cores,

forcing the use of more expensive ferrite, molypermalloy,

or Kool M

µ

Æ

cores. Actual core loss is independent of core

size for a fixed inductor value, but it is very dependent on

inductance selected. As inductance increases, core losses

go down. Unfortunately, increased inductance requires

more turns of wire and therefore copper losses will in-

crease.

Ferrite designs have very low core loss and are preferred

at high switching frequencies, so design goals can con-

centrate on copper loss and preventing saturation. Ferrite

core material saturates "hard," which means that induc-

tance collapses abruptly when the peak design current is

exceeded. This results in an abrupt increase in inductor

ripple current and consequent output voltage ripple. Do

not allow the core to saturate!

Molypermalloy (from Magnetics, Inc.) is a very good, low

loss core material for toroids, but it is more expensive than

ferrite. A reasonable compromise from the same manu-

facturer is Kool M

µ

. Toroids are very space efficient,

especially when you can use several layers of wire. Be-

cause they generally lack a bobbin, mounting is more

difficult. However, designs for surface mount are available

that do not increase the height significantly.

Power MOSFET and D1 Selection

Two external power MOSFETs must be selected for each

controller with the LTC1876: One N-channel MOSFET for

the top (main) switch, and one N-channel MOSFET for the

bottom (synchronous) switch.

The peak-to-peak drive levels are set by the INTV

CC

volt-

age. This voltage is typically 5V during start-up (see

EXTV

CC

Pin Connection). Consequently, logic-level thresh-

old MOSFETs must be used in most applications. The only

exception is if low input voltage is expected (V

IN

< 5V);

APPLICATIO S I FOR ATIO

W

U

U

U

Kool M

µ

is a registered trademark of Magnetics, Inc.

LTC1876

16

1876fa

then, sub-logic level threshold MOSFETs (V

GS(TH)

< 3V)

should be used. Pay close attention to the BV

DSS

specifi-

cation for the MOSFETs as well; most of the logic level

MOSFETs are limited to 30V or less.

Selection criteria for the power MOSFETs include the "ON"

resistance R

DS(ON)

, reverse transfer capacitance C

RSS

,

input voltage and maximum output current. When the

LTC1876 is operating in continuous mode the duty cycles

for the top and bottom MOSFETs are given by:

Main Switch Duty Cycle

V

V

OUT

IN

=

Synchronous Switch Duty Cycle

V

V

V

IN

OUT

IN

=

≠

The MOSFET power dissipations at maximum output

current are given by:

P

V

V

I

R

k V

I

C

f

MAIN

OUT

IN

MAX

DS ON

IN

MAX

RSS

=

( )

+

( )

+

( ) ( )( )( )

2

2

1

(

)

P

V

V

V

I

R

SYNC

IN

OUT

IN

MAX

DS ON

=

( )

+

( )

≠

(

)

2

1

where

is the temperature dependency of R

DS(ON)

and k

is a constant inversely related to the gate drive current.

Both MOSFETs have I

2

R losses while the topside N-channel

equation includes an additional term for transition losses,

which are highest at high input voltages. For V

IN

< 20V the

high current efficiency generally improves with larger

MOSFETs, while for V

IN

> 20V the transition losses rapidly

increase to the point that the use of a higher R

DS(ON)

device

with lower C

RSS

actually provides higher efficiency. The

synchronous MOSFET losses are greatest at high input

voltage when the top switch duty factor is low or during a

short-circuit when the synchronous switch is on close to

100% of the period.

The term (1 +

) is generally given for a MOSFET in the

form of a normalized R

DS(ON)

vs temperature curve, but

= 0.005/

∞

C can be used as an approximation for low

voltage MOSFETs. C

RSS

is usually specified in the MOS-

FET characteristics. The constant k = 1.7 can be used to

estimate the contributions of the two terms in the main

switch dissipation equation.

The Schottky diode D1 shown in Figure 1 conducts during

the dead-time between the conduction of the two power

MOSFETs. This prevents the body diode of the bottom

MOSFET from turning on, storing charge during the dead-

time and requiring a reverse recovery period that could

cost as much as 3% in efficiency at high V

IN

. A 1A to 3A

Schottky is generally a good compromise for both regions

of operation due to the relatively small average current.

Larger diodes result in additional transition losses due to

their larger junction capacitance.

C

IN

Selection

The selection of C

IN

is simplified by the multiphase archi-

tecture and its impact on the worst-case RMS current

drawn through the input network (battery/fuse/capacitor).

It can be shown that the worst case RMS current occurs

when only one controller is operating. The controller with

the highest (V

OUT

)(I

OUT

) product needs to be used in the

formula below to determine the maximum RMS current

requirement. Increasing the output current, drawn from

the other out-of-phase controller, will actually decrease

the RMS ripple current from this maximum value (see

Figure 4). The out-of-phase technique typically reduces

the input capacitor's RMS ripple current by a factor of 30%

to 70% when compared to a single phase power supply

solution.

The type of input capacitor, value and ESR rating have

efficiency effects that need to be considered in the selec-

tion process. The capacitance value chosen should be

sufficient to store adequate charge to keep high peak

battery currents down. 20

µ

F to 40

µ

F is usually sufficient

for a 25W output supply operating at 200kHz. The ESR of

the capacitor is important for capacitor power dissipation

as well as overall battery efficiency. All of the power (RMS

ripple current ∑ ESR) not only heats up the capacitor but

wastes power from the battery.

APPLICATIO S I FOR ATIO

W

U

U

U

LTC1876

17

1876fa

Medium voltage (20V to 35V) ceramic, tantalum, OS-CON

and switcher-rated electrolytic capacitors can be used as

input capacitors, but each has drawbacks: ceramic voltage

coefficients are very high and may have audible piezoelec-

tric effects; tantalums need to be surge-rated; OS-CONs

suffer from higher inductance, larger case size and limited

surface-mount applicability; electrolytics' higher ESR and

dryout possibility require several to be used. Multiphase

systems allow the lowest amount of capacitance overall.

As little as one 22

µ

F or two to three 10

µ

F ceramic capaci-

tors are an ideal choice in a 20W to 35W power supply due

to their extremely low ESR. Even though the capacitance

at 20V is substantially below their rating at zero-bias, very

low ESR loss makes ceramics an ideal candidate for

highest efficiency battery operated systems. Also con-

sider parallel ceramic and high quality electrolytic capaci-

tors as an effective means of achieving ESR and bulk

capacitance goals.

In continuous mode, the source current of the top N-chan-

nel MOSFET is a square wave of duty cycle V

OUT

/V

IN

. To

prevent large voltage transients, a low ESR input capacitor

sized for the maximum RMS current of one channel must

be used. The maximum RMS capacitor current is given by:

C

quired I

I

V

V

V

V

IN

RMS

MAX

OUT

IN

OUT

IN

Re

/

-

(

)

[

]

1 2

This formula has a maximum at V

IN

= 2V

OUT

, where

I

RMS

= I

OUT

/2. This simple worst case condition is com-

monly used for design because even significant deviations

do not offer much relief. Note that capacitor manufacturer's

ripple current ratings are often based on only 2000 hours

of life. This makes it advisable to further derate the

capacitor, or to choose a capacitor rated at a higher

temperature than required. Several capacitors may also be

paralleled to meet size or height requirements in the

design. Always consult the manufacturer if there is any

question.

The benefit of the LTC1876 multiphase controllers can be

calculated by using the equation above for the higher

power controller and then calculating the loss that would

have resulted if both controller channels switch on at the

same time. The total RMS power lost is lower when both

controllers are operating due to the reduced overlap of

current pulses required through the input capacitor's ESR.

This is why the input capacitor's requirement calculated

above for the worst-case controller is adequate for the

dual controller design. Remember that protection fuse

resistance, battery resistance and PC board trace resis-

tance losses are also reduced due to the reduced peak

currents in a multiphase system.

The overall benefit of a

multiphase design will only be fully realized when the

source impedance of the power supply/battery is included

in the efficiency testing. The drains of the two top MOSFETS

should be placed within 1cm of each other and share a

common C

IN

(s). Separating the drains and C

IN

may pro-

duce undesirable voltage and current resonances at V

IN

.

For the boost regulator, the ripple requirement for the

input capacitor is less stringent. If the supply to the

regulator is obtained from one of the LTC1876 step-down

outputs, a 1

µ

F to 4.7

µ

F ceramic capacitor is sufficient.

However, if the step-down output is within close proximity

(< 1cm) to the boost supply input, there is no need for the

capacitor.

C

OUT

Selection

The selection of C

OUT

is driven by the required effective

series resistance (ESR). Typically once the ESR require-

ment is satisfied the capacitance is adequate for filtering.

For the step-down regulators, the output ripple (

V

OUT

) is

determined by:

V

I ESR

fC

OUT

L

OUT

+

1

8

Where f = operating frequency, C

OUT

= output capacitance,

and

L

= ripple current in the inductor. The output ripple is

highest at maximum input voltage since

I

L

increases

with input voltage. With

I

L

= 0.4I

OUT(MAX)

the output

ripple will typically be less than 50mV at max V

IN

assum-

ing:

C

OUT

Recommended ESR < 2 R

SENSE

and C

OUT

> 1/(8fR

SENSE

)

The first condition relates to the ripple current into the ESR

of the output capacitance while the second term guaran-

tees that the output capacitance does not significantly

APPLICATIO S I FOR ATIO

W

U

U

U

LTC1876

18

1876fa

discharge during the operating frequency period due to

ripple current. The choice of using smaller output capaci-

tance increases the ripple voltage due to the discharging

term but can be compensated for by using capacitors of

very low ESR to maintain the ripple voltage at or below

50mV. The I

TH

pin OPTI-LOOP compensation compo-

nents can be optimized to provide stable, high perfor-

mance transient response regardless of the output

capacitors selected.

For the boost regulator, the output ripple (

V

OUT

) is

determined by:

V

I

ESR

I

f C

OUT

PK

OUT

OUT

+

1 5

.

Since the boost regulator is operating at high frequency,

the second term will be small even with a small value of

C

OUT

. Hence, all efforts can be concentrated on finding a

low ESR capacitor. A ceramic capacitor can be used for the

output capacitor.

Manufacturers such as Nichicon, United Chemicon and

Sanyo can be considered for high performance through-

hole capacitors. The OS-CON semiconductor dielectric

capacitor available from Sanyo has the lowest (ESR) (size)

product of any aluminum electrolytic at a somewhat

higher price. An additional ceramic capacitor in parallel

with OS-CON capacitors is recommended to reduce the

inductance effects.

In surface mount applications multiple capacitors may

need to be used in parallel to meet the ESR, RMS current

handling and load step requirements of the application.

Aluminum electrolytic, dry tantalum and special polymer

capacitors are available in surface mount packages. Spe-

cial polymer surface mount capacitors offer very low ESR

but have lower storage capacity per unit volume than other

capacitor types. These capacitors offer a very cost-effec-

tive output capacitor solution and are an ideal choice when

combined with a controller having high loop bandwidth.

Tantalum capacitors offer the highest capacitance density

and are often used as output capacitors for switching

regulators having controlled soft-start. Several excellent

surge-tested choices are the AVX TPS, AVX TPSV or the

KEMET T510 series of surface mount tantalums, available

in case heights ranging from 2mm to 4mm. Aluminum

electrolytic capacitors can be used in cost-driven applica-

tions providing that consideration is given to ripple current

ratings, temperature and long term reliability. A typical

application will require several to many aluminum electro-

lytic capacitors in parallel. A combination of the above

mentioned capacitors will often result in maximizing per-

formance and minimizing overall cost. Other capacitor

types include Nichicon PL series, NEC Neocap, Pansonic

SP and Sprague 595D series. For high value of ceramic

capacitors, Taiyo Yuden has a series of them. Select the

X5R or X7R series as these retain the capacitance over

wide voltage and temperature range. Consult manufactur-

ers for other specific recommendations.

INTV

CC

Regulator

An internal P-channel low dropout regulator produces 5V

at the INTV

CC

pin from the V

IN

supply pin. INTV

CC

powers

the drivers and internal circuitry within the LTC1876 step-

down controllers. The INTV

CC

pin regulator can supply a

peak current of 50mA and must be bypassed to ground

with a minimum of 4.7

µ

F tantalum, 10

µ

F special polymer,

or low ESR type electrolytic capacitor. A 1

µ

F ceramic

capacitor placed directly adjacent to the INTV

CC

and PGND

IC pins is highly recommended. Good bypassing is neces-

sary to supply the high transient currents required by the

MOSFET gate drivers and to prevent interaction between

channels.

Higher input voltage applications in which large MOSFETs

are being driven at high frequencies may cause the maxi-

mum junction temperature rating for the LTC1876 to be

exceeded. The system supply current is normally domi-

nated by the gate charge current. Additional external

loading of the INTV

CC

and 3.3V linear regulators also

needs to be taken into account for the power dissipation

calculations. The total INTV

CC

current can be supplied by

either the 5V internal linear regulator or by the EXTV

CC

input pin. When the voltage applied to the EXTV

CC

pin is

less than 4.7V, all of the INTV

CC

current is supplied by the

internal 5V linear regulator. Power dissipation for the IC in

this case is highest: (V

IN

)(I

INTVCC

), and overall efficiency

is lowered. The gate charge current is dependent on

APPLICATIO S I FOR ATIO

W

U

U

U

LTC1876

19

1876fa

operating frequency as discussed in the Efficiency Consid-

erations section. The junction temperature can be esti-

mated by using the equations given in Note 3 of the

Electrical Characteristics. For example, the LTC1876 V

IN

current is limited to less than 24mA from a 24V supply

when not using the EXTV

CC

pin as follows:

T

J

= 70

∞

C + (24mA)(24V)(95

∞

C/W) = 125

∞

C

Use of the EXTV

CC

input pin reduces the junction tempera-

ture to:

T

J

= 70

∞

C + (24mA)(5V)(95

∞

C/W) = 81

∞

C

Dissipation should be calculated and added for current

drawn from the internal 3.3V linear regulator. To prevent

maximum junction temperature from being exceeded, the

input supply current must be checked operating in con-

tinuous mode at maximum V

IN

.

EXTV

CC

Connection

The LTC1876 contains an internal P-channel MOSFET

switch connected between the EXTV

CC

and INTV

CC

pins.

When the voltage applied to EXTV

CC

rises above

4.7V, the

internal regulator is turned off and the switch closes,

connecting the EXTV

CC

pin to the INTV

CC

pin thereby

supplying internal power. The switch remains closed as

long as the voltage applied to EXTV

CC

remains above 4.5V.

This allows the MOSFET driver and control power to be

derived from the output during normal operation (4.7V <

V

OUT

< 7V) and from the internal regulator when the output

is out of regulation (start-up, short-circuit). If more cur-

rent is required through the EXTV

CC

switch than is speci-

fied, an external Schottky diode can be added between the

EXTV

CC

and INTV

CC

pins. Do not apply greater than 7V to

the EXTV

CC

pin and ensure that EXTV

CC

< V