1

LTC1911-1.5/LTC1911-1.8

1911f

APPLICATIO S

U

FEATURES

DESCRIPTIO

U

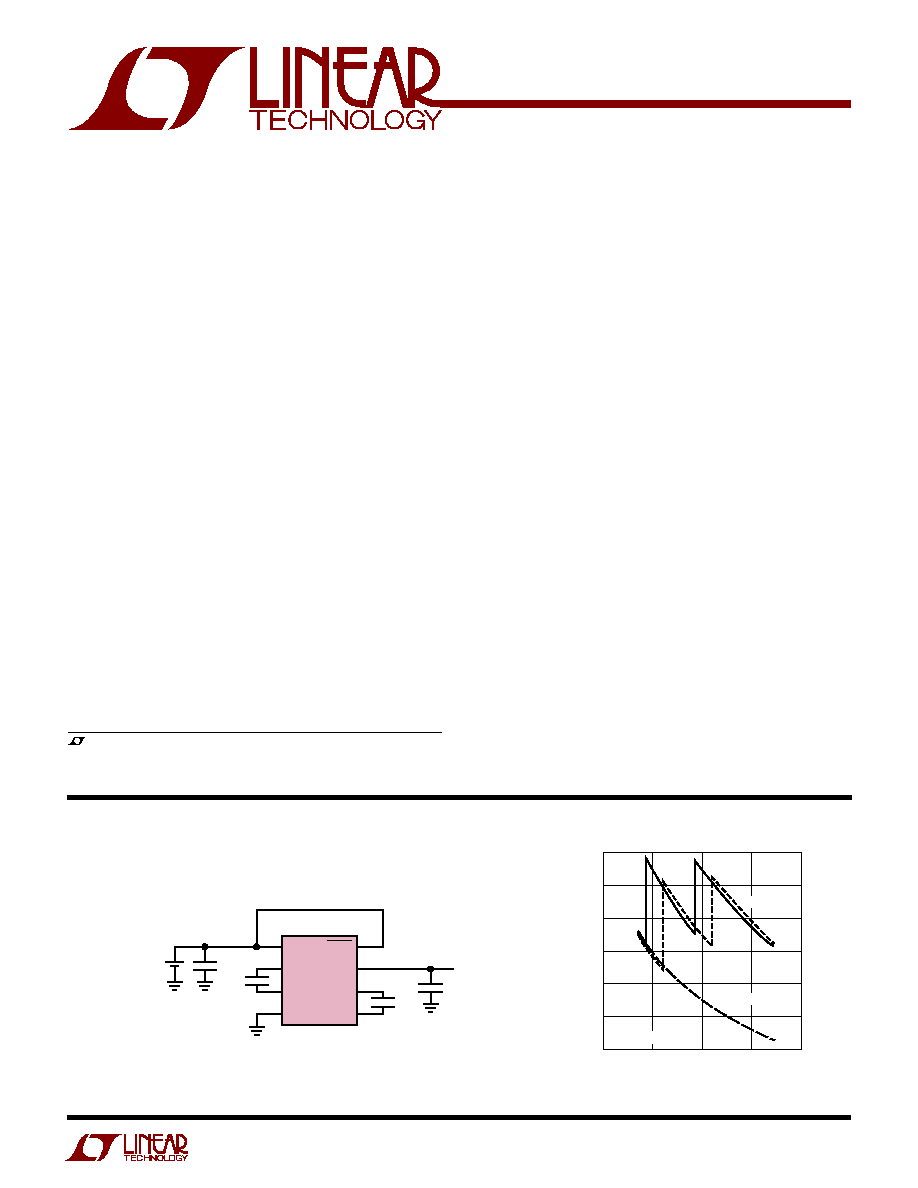

TYPICAL APPLICATIO

U

Low Noise, High Efficiency,

Inductorless Step-Down

DC/DC Converter

The LTC

Æ

1911 is a switched capacitor step-down DC/DC

converter that produces a 1.5V or 1.8V regulated output

from a 2.7V to 5.5V input. The part uses switched capaci-

tor fractional conversion to achieve high efficiency over the

entire input range. No inductors are required. Internal cir-

cuitry controls the step-down conversion ratio to optimize

efficiency as the input voltage and load conditions vary.*

Typical efficiency is over 25% higher than that of a linear

regulator.

A unique constant frequency architecture provides a low

noise regulated output as well as lower input noise than

conventional charge pump regulators. High frequency

operation (f

OSC

= 1.5MHz) simplifies output filtering to

further reduce conducted noise. To optimize efficiency,

the part enters Burst Mode

Æ

operation under light load

conditions.

Low operating current (180

µ

A with no load, 10

µ

A in

shutdown) and low external parts count (two 1

µ

F flying

capacitors and two 10

µ

F bypass capacitors) make the

LTC1911 ideally suited for space constrained battery-

powered applications. The part is short-circuit and

overtemperature protected, and is available in an 8-pin

MSOP package.

s

Low Noise Constant Frequency Operation

s

2.7V to 5.5V Input Voltage Range

s

No Inductors

s

Typical Efficiency 25% Higher Than LDOs

s

Shutdown Disconnects Load from V

IN

s

Output Voltage: 1.8V

±

4% or 1.5V

±

4%

s

Output Current: 250mA

s

Low Operating Current: I

IN

= 180

µ

A Typ

s

Low Shutdown Current: I

IN

= 10

µ

A Typ

s

Oscillator Frequency: 1.5MHz

s

Soft-Start Limits Inrush Current at Turn On

s

Short-Circuit and Overtemperature Protected

s

Available in an 8-Pin MSOP Package

, LTC and LT are registered trademarks of Linear Technology Corporation.

s

Handheld Computers

s

Cellular Phones

s

Smart Card Readers

s

Portable Electronic Equipment

s

Handheld Medical Instruments

s

Low Power DSP Supplies

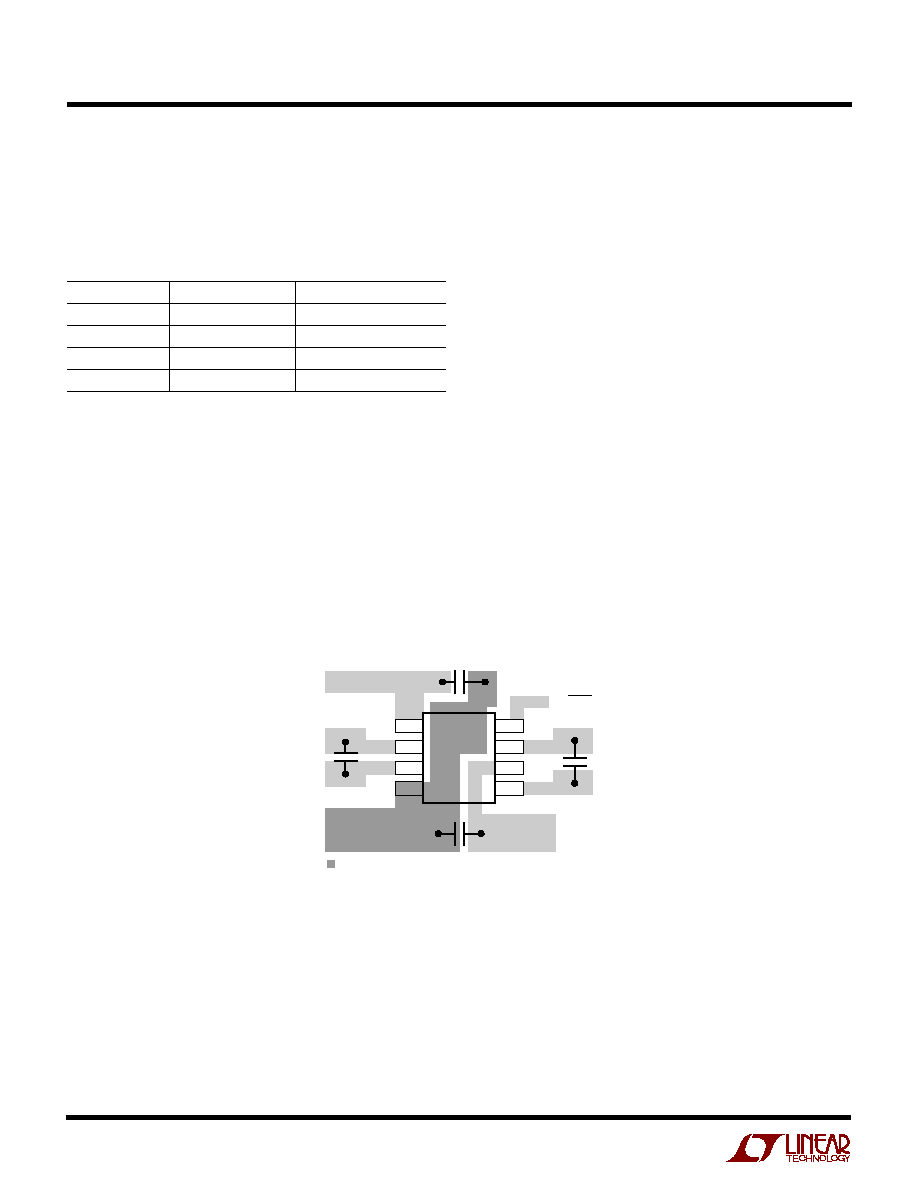

V

IN

C2

+

C2

≠

GND

8

6

7

5

1

2

3

4

SS/SHDN

V

OUT

C1

+

C1

≠

LTC1911-1.8

1

µ

F*

1-CELL Li-Ion

OR

3-CELL NiMH

10

µ

F*

*CERAMIC CAPACITOR

10

µ

F*

1911 TA01

V

OUT

= 1.8V

I

OUT

= 250mA

1

µ

F*

2.7V TO 5.5V INPUT

Single Cell Li-Ion to 1.8V DC/DC Converter

Efficiency

Burst Mode is a registered trademark of Linear Technology Corporation.

*U.S. Patent #6,438,005

INPUT VOLTAGE (V)

2

30

EFFICIENCY (%)

40

50

60

70

80

90

3

4

5

6

1911 G05

IDEAL LDO

250mA

100mA

V

OUT

= 1.8V

2

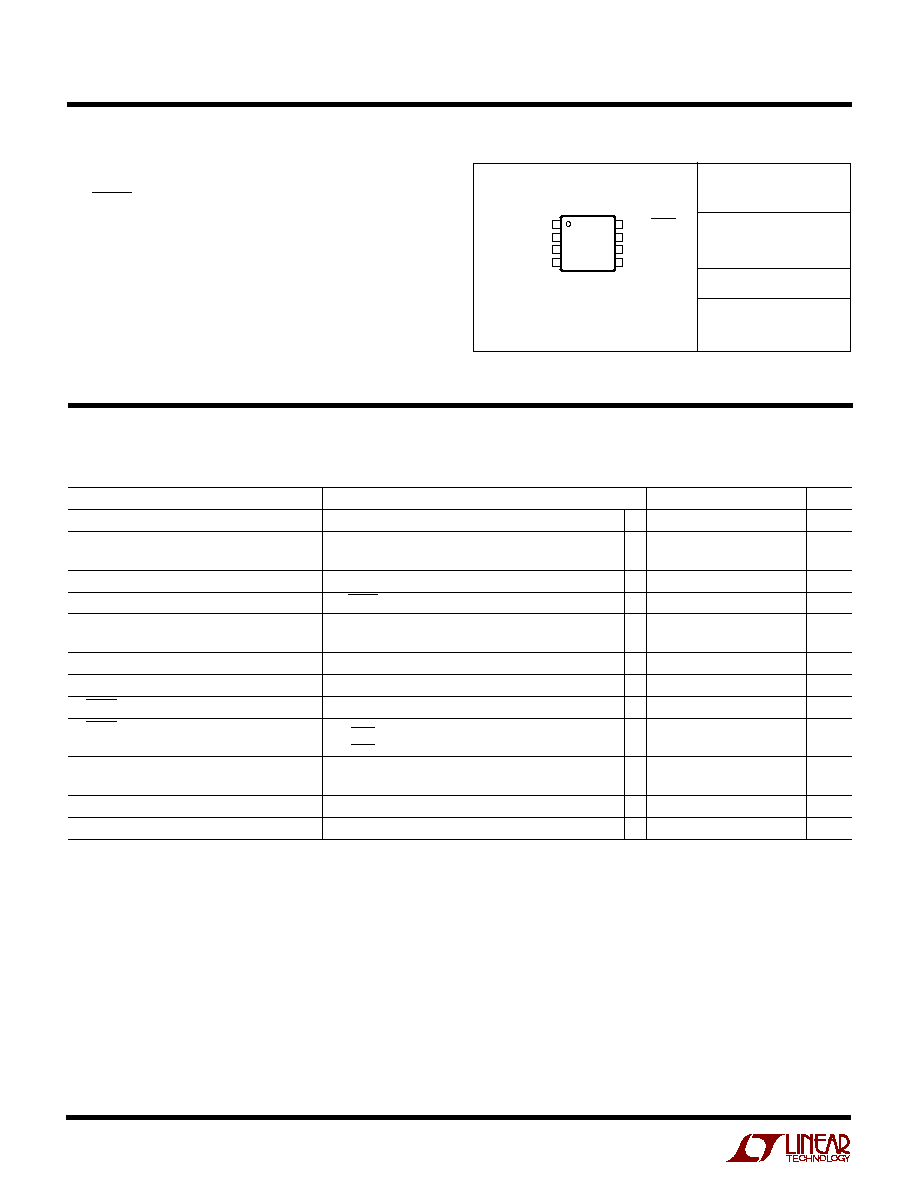

LTC1911-1.5/LTC1911-1.8

1911f

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

V

IN

Operating Voltage

q

2.7

5.5

V

V

OUT

LTC1911-1.5, 0mA

I

OUT

250mA, V

IN

= 2.7V to 5.5V

q

1.44

1.5

1.56

V

LTC1911-1.8, 0mA

I

OUT

250mA, V

IN

= 2.7V to 5.5V

q

1.73

1.8

1.87

V

V

IN

Operating Current

I

OUT

= 0mA, V

IN

= 2.7V to 5.5V

q

180

350

µ

A

V

IN

Shutdown Current

SS/SHDN = 0V, V

IN

= 2.7V to 5.5V

q

10

20

µ

A

Output Ripple

I

OUT

= 10mA

5

mV

P-P

I

OUT

= 250mA

12

mV

P-P

V

OUT

Short-Circuit Current

V

OUT

= 0V

600

mA

Switching Frequency

Oscillator Free Running

1.2

1.5

1.8

MHz

SS/SHDN Input Threshold

q

0.3

0.6

1

V

SS/SHDN Soft-Start Current

V

SS/SHDN

= 0V (Note 3)

q

≠ 5

≠ 2

≠1

µ

A

V

SS/SHDN

= V

IN

0.01

µ

A

Turn-On Time

C

SS

= 0pF, V

IN

= 3.3V

0.03

ms

C

SS

= 10nF, V

IN

= 3.3V

10

ms

Load Regulation

0V

I

OUT

250mA

0.13

mV/mA

Line Regulation

0V

I

OUT

250mA

0.3

%/V

(Note 1)

V

IN

to GND ...................................................≠ 0.3V to 6V

SS/SHDN to GND ........................ ≠ 0.3V to (V

IN

+ 0.3V)

V

OUT

Short-Circuit Duration ............................ Indefinite

Operating Temperature Range (Note 2) .. ≠ 40

∞

C to 85

∞

C

Storage Temperature Range ................. ≠ 40

∞

C to 150

∞

C

Lead Temperature (Soldering, 10 sec).................. 300

∞

C

ORDER PART

NUMBER

LTC1911EMS8-1.5

LTC1911EMS8-1.8

T

JMAX

= 125

∞

C,

JA

= 160

∞

C/ W

The

q

denotes specifications which apply over the full operating

temperature range, otherwise specifications are T

A

= 25

∞

C. V

IN

= 3.6V, C1 = 1

µ

F, C2 = 1

µ

F, C

IN

= 10

µ

F, C

OUT

= 10

µ

F unless

otherwise noted.

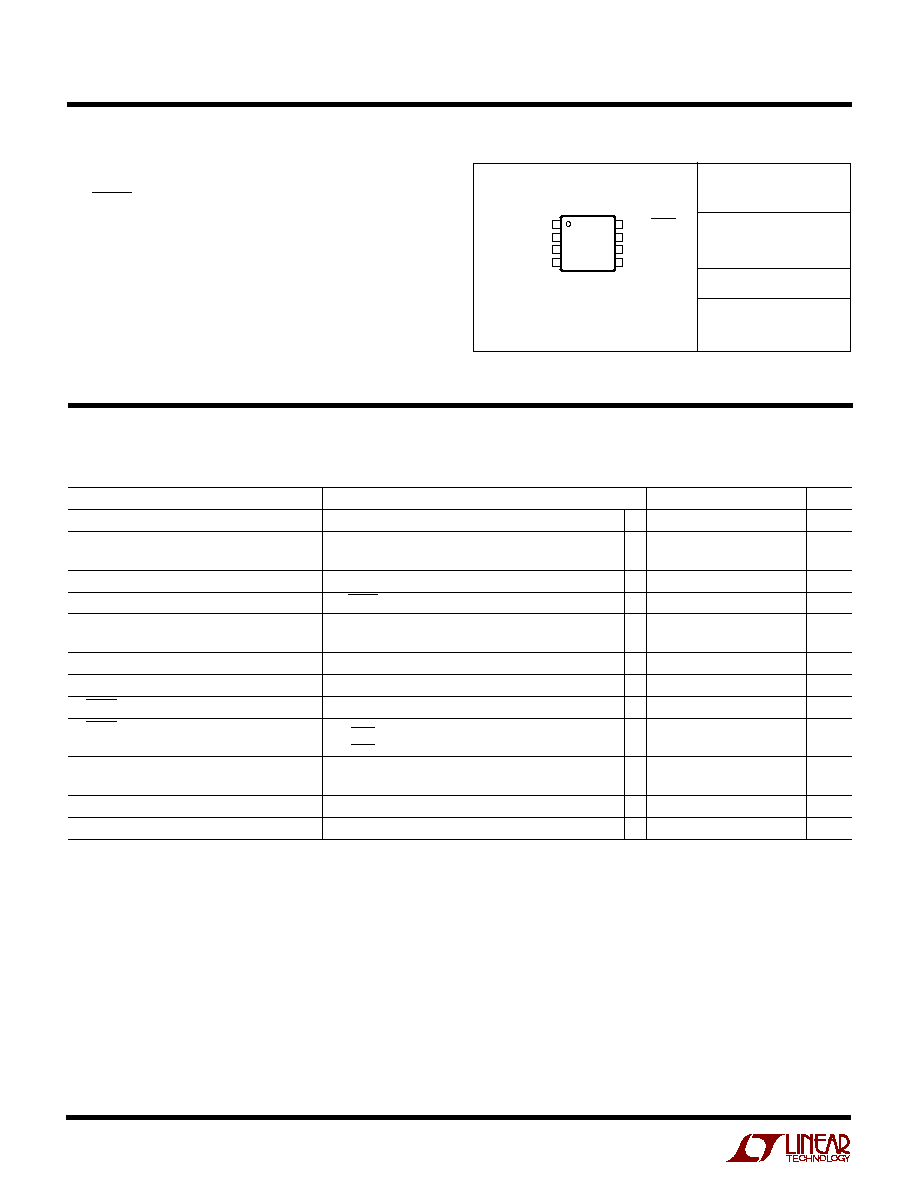

ABSOLUTE AXI U RATI GS

W

W

W

U

PACKAGE/ORDER I FOR ATIO

U

U

W

MS8 PART MARKING

1

2

3

4

V

IN

C2

+

C2

≠

GND

8

7

6

5

SS/SHDN

C1

+

V

OUT

C1

≠

TOP VIEW

MS8 PACKAGE

8-LEAD PLASTIC MSOP

LTMY

LTNU

ELECTRICAL CHARACTERISTICS

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC1911E is guaranteed to meet specified performance from

0

∞

C to 70

∞

C. Specifications over the ≠ 40

∞

C to 85

∞

C operating temperature

range are assured by design, characterization and correlation with

statistical process controls.

Note 3: Currents flowing into the device are positive polarity. Currents

flowing out of the device are negative polarity.

Consult LTC Marketing for parts specified with wider operating temperature ranges.

3

LTC1911-1.5/LTC1911-1.8

1911f

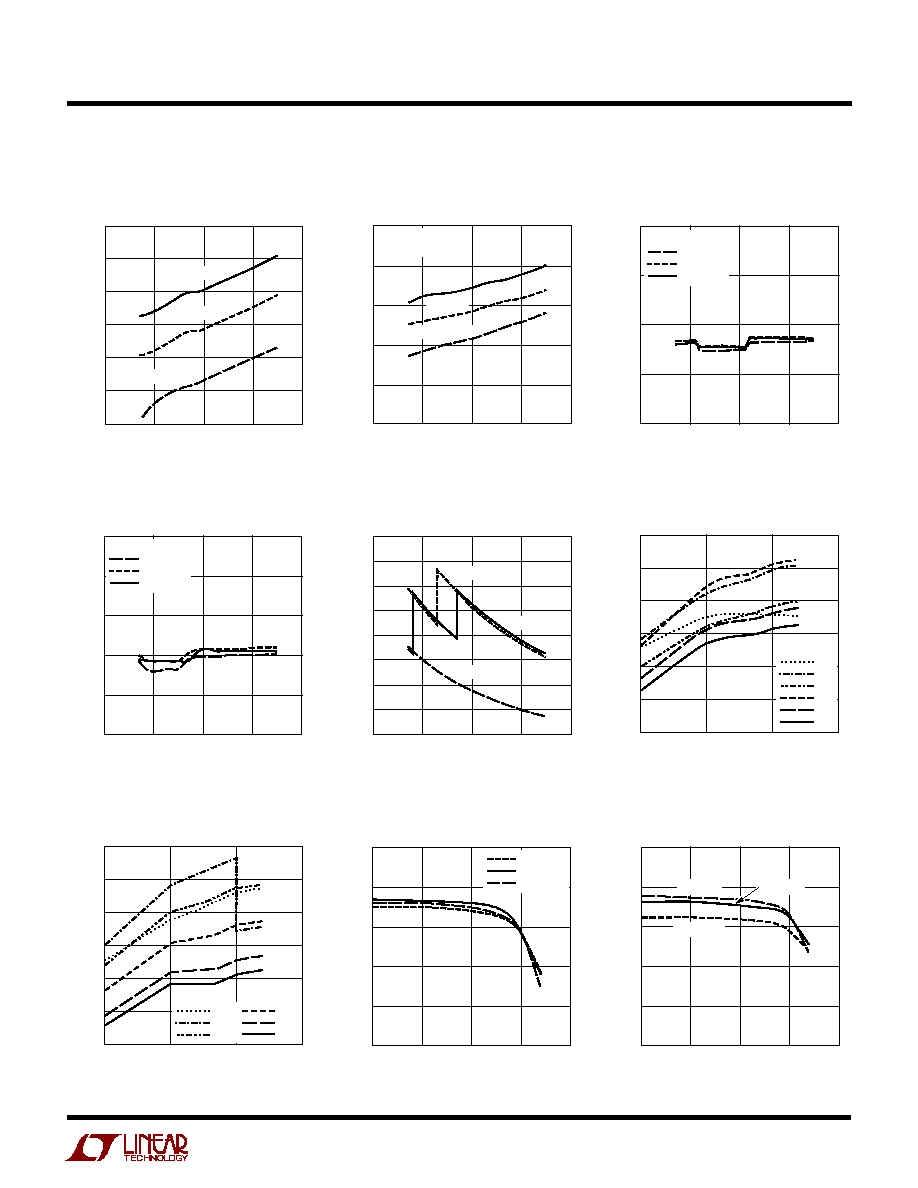

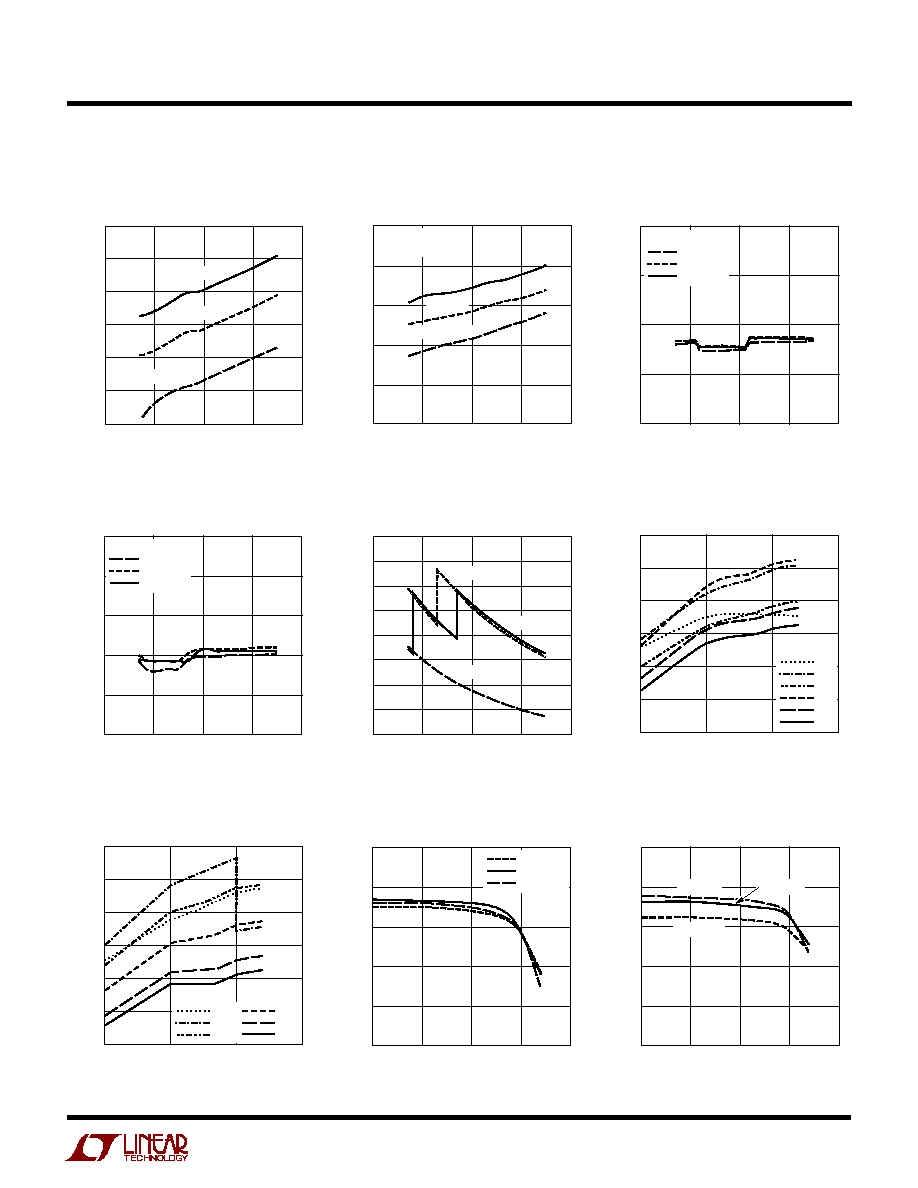

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

Input Operating Current

vs Input Voltage

Input Shutdown Current

vs Input Voltage

LTC1911-1.8

Output Voltage vs Input Voltage

LTC1911-1.5

Output Voltage vs Input Voltage

LTC1911-1.5 Efficiency vs Input

Voltage (Falling Input Voltage)

LTC1911-1.8

Efficiency vs Output Current

LTC1911-1.8

Output Voltage vs Output Current

INPUT VOLTAGE (V)

2

INPUT CURRENT (

µ

A)

180

190

200

6

1911 G01

170

160

3

4

5

150

210

T

A

= 85

∞

C

T

A

= 25

∞

C

T

A

= ≠40

∞

C

INPUT VOLTAGE (V)

2

INPUT CURRENT (

µ

A)

9

11

6

1911 G02

7

5

3

4

5

15

13

T

A

= 85

∞

C

T

A

= 25

∞

C

T

A

= ≠40

∞

C

V

OUT

= 0V

V

(SS/SHDN)

= 0V

INPUT VOLTAGE (V)

2

OUTPUT VOLTAGE (V)

1.80

1.85

6

1911 G03

1.75

1.70

3

4

5

1.90

T

A

= ≠40

∞

C

T

A

= 25

∞

C

T

A

= 85

∞

C

I

OUT

= 250mA

INPUT VOLTAGE (V)

2

EFFICIENCY (%)

60

70

80

6

1911 G05

50

40

20

3

4

5

30

100

90

IDEAL LDO

100mA

250mA

OUTPUT CURRENT (mA)

1

EFFICIENCY (%)

50

60

1911 G06

40

30

10

100

1000

90

80

70

2.7V

3.2V

3.7V

4.2V

5.1V

5.5V

V

IN

:

LTC1911-1.5

Efficiency vs Output Current

OUTPUT CURRENT (mA)

0.1

OUTPUT VOLTAGE (V)

1.78

1.80

1000

1911 G08

1.76

1.74

1

10

100

1.84

V

IN

= 3.6V

1.82

T

A

= ≠40

∞

C

T

A

= 25

∞

C

T

A

= 85

∞

C

LTC1911-1.5

Output Voltage vs Output Current

INPUT VOLTAGE (V)

2

OUTPUT VOLTAGE (V)

1.49

1.51

6

LTXXXX ∑ TPCXX

1.47

1.45

3

4

5

1.55

1.53

T

A

= ≠40

∞

C

T

A

= 25

∞

C

T

A

= 85

∞

C

I

OUT

= 250mA

OUTPUT CURRENT (mA)

1

30

EFFICIENCY (%)

40

50

60

70

90

10

100

1911 G07

1000

80

2.8V

3.3V

3.7V

4.3V

5.1V

5.5V

V

IN

:

OUTPUT CURRENT (mA)

0.1

OUTPUT VOLTAGE (V)

1.48

1.50

1000

1911 G09

1.46

1.44

1

10

100

1.54

1.52

T

A

= ≠40

∞

C

T

A

= 85

∞

C

T

A

= 25

∞

C

V

IN

= 3.6V

4

LTC1911-1.5/LTC1911-1.8

1911f

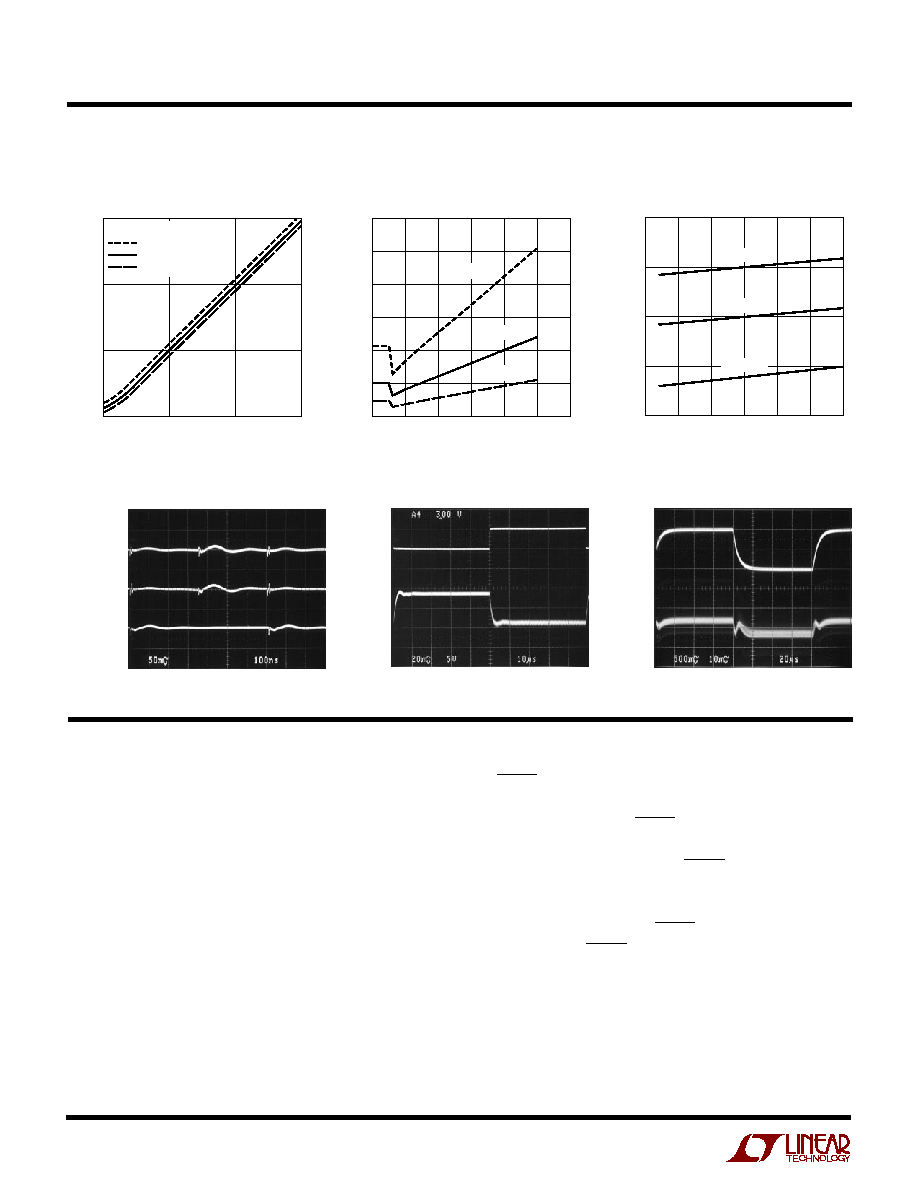

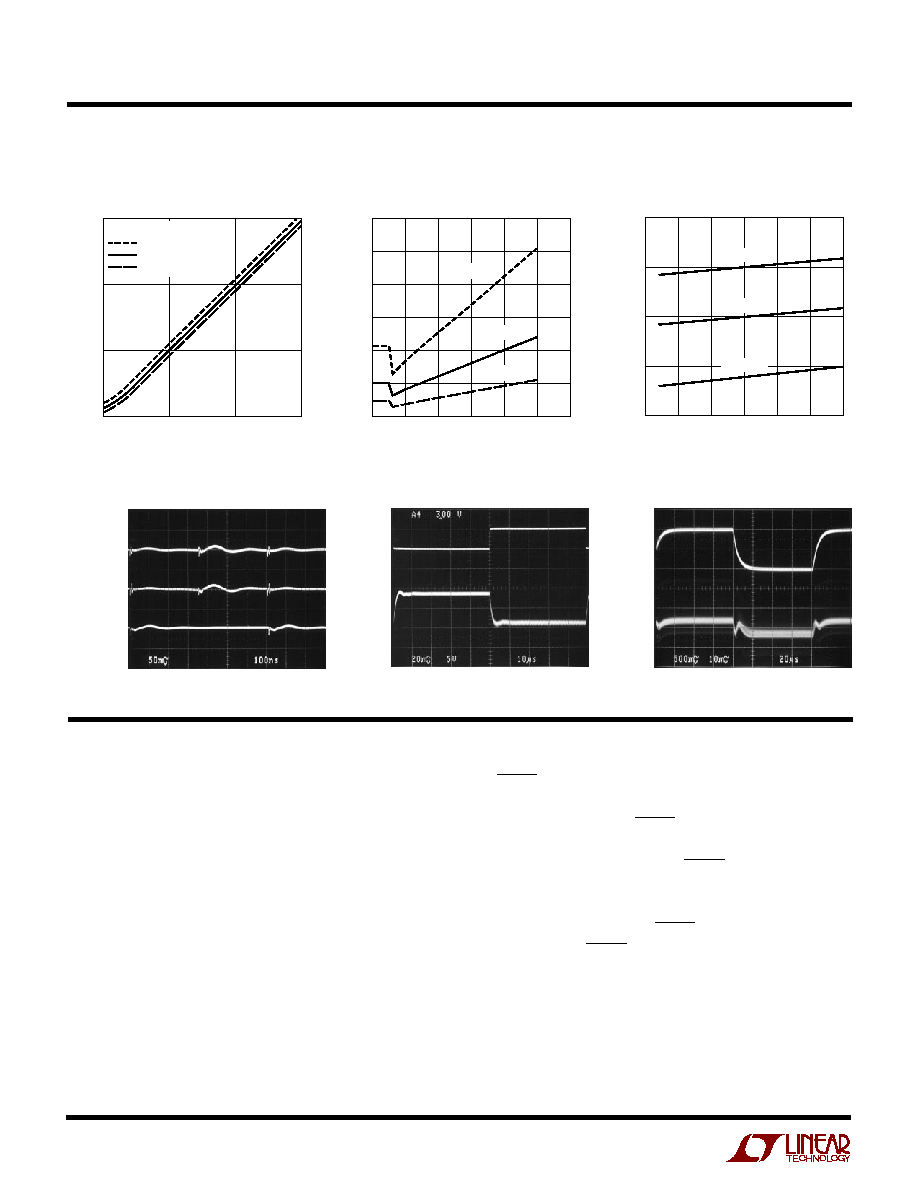

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

Start-Up Time

vs Soft-Start Capacitor

Output Ripple

vs Output Load Current

Output Current Transient Response

Line Transient Response

SOFT-START CAPACITOR (nF)

0.1

0.1

START-UP TIME (ms)

1

10

100

1

10

1911 G10

100

T

A

= ≠40

∞

C

T

A

= 25

∞

C

T

A

= 85

∞

C

V

IN

= 3.6V

4V

3V

V

IN

500mV/DIV

V

OUT

20mV/DIV

I

OUT

= 225mA

20

µ

s/DIV

1911 G14

250mA

25mA

I

OUT

V

OUT

20mV/DIV

V

IN

= 3.6V

10

µ

s/DIV

1911 G13

V

IN

(Pin 1): Input Supply Voltage. V

IN

may be between

2.7V and 5.5V. Suggested bypass for V

IN

is a 10

µ

F (1

µ

F

min) ceramic low ESR capacitor.

C2

+

(Pin 2): Flying Capacitor Two Positive Terminal.

C2

≠

(Pin 3): Flying Capacitor Two Negative Terminal.

GND (Pin 4): Ground. Connect to a ground plane for best

performance.

C1

≠

(Pin 5): Flying Capacitor One Negative Terminal.

V

OUT

(Pin 6): Regulated Output Voltage. V

OUT

is discon-

nected from V

IN

during shutdown. Bypass V

OUT

with a

10

µ

F ceramic low ESR capacitor (4

µ

F min, ESR < 0.1

max).

C1

+

(Pin 7): Flying Capacitor One Positive Terminal.

U

U

U

PI FU CTIO S

SS/SHDN (Pin 8): Soft-Start/Shutdown Control Pin. This

pin is designed to be driven with an external open-drain

output. Holding the SS/SHDN pin below 0.3V will force

the LTC1911-X into shutdown mode. An internal pull-up

current of 2

µ

A will force the SS/SHDN voltage to climb to

V

IN

once the device driving the pin is forced into a Hi-Z

state. To limit inrush current on start-up, connect a

capacitor between the SS/SHDN pin and GND. Capaci-

tance on the SS/SHDN pin will limit the dV/dt of the pin

during turn on which, in turn, will limit the dV/dt of V

OUT

.

By selecting an appropriate soft-start capacitor, the user

can control the inrush current for a known output capaci-

tor during turn-on (see Application Information). If nei-

ther of the two functions are desired, the pin may be left

floating or tied to V

IN

.

LTC1911-1.8 Output Voltage Ripple

V

OUT

50mV/DIV

2-TO-1 MODE

V

IN

= 5V

I

OUT

= 250mA

100ns/DIV

1911 G12

ALL WAVEFORMS AC COUPLED

OUTPUT LOAD CURRENT (mA)

0

0

OUTPUT RIPPLE (mV

P-P

)

5

10

15

20

30

50

100

150

200

1911 G11

250

300

25

C

OUT

= 4.7

µ

F

C

OUT

= 10

µ

F

C

OUT

= 22

µ

F

V

OUT

50mV/DIV

3-TO-2 MODE

V

IN

= 3.6V

V

OUT

50mV/DIV

1-TO-1 MODE

V

IN

= 2.7V

V

IN

(V)

2.5

1.40

FREQUENCY (MHz)

1.45

1.50

1.55

1.60

3.0

3.5

4.0

4.5

1911 G15

5.0

5.5

T

A

= ≠40

∞

C

T

A

= 25

∞

C

T

A

= 85

∞

C

Oscillator Frequency

vs Input Supply Voltage

5

LTC1911-1.5/LTC1911-1.8

1911f

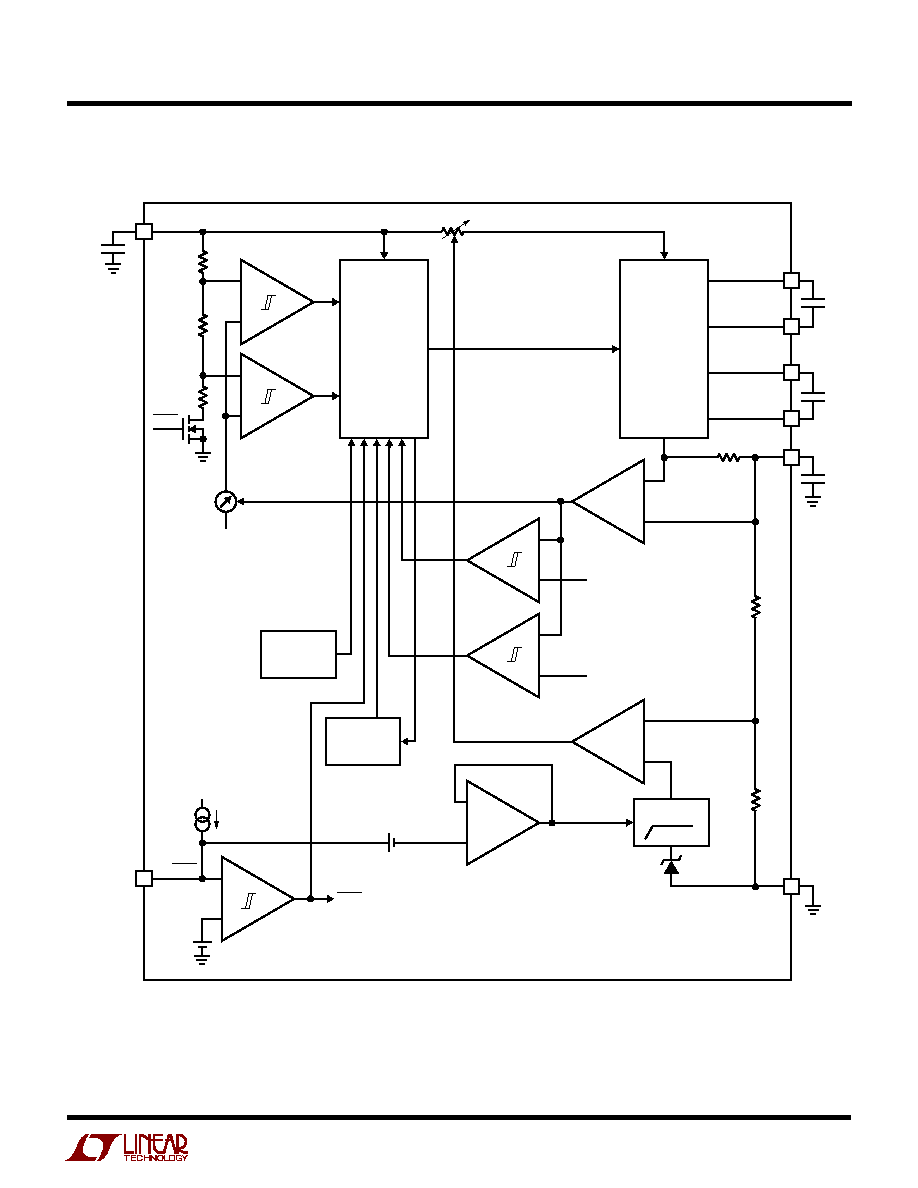

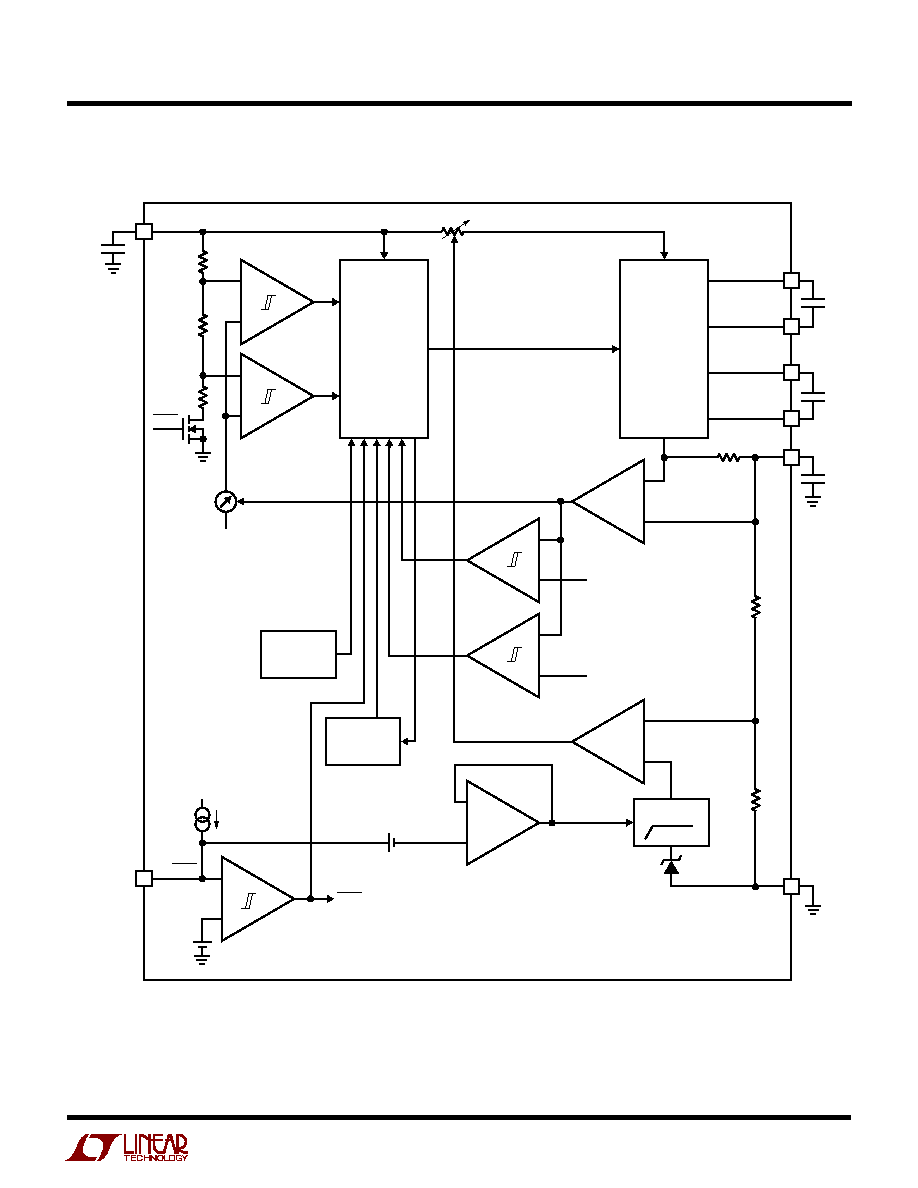

SI PLIFIED

W

BLOCK DIAGRA

W

≠

+

≠

+

300k

C

IN

V

IN

50k

150k

V

REF

+

≠

ADJ

OFFSET

MODE

CONTROL

STEP-DOWN

CHARGE

PUMP

1

R

A

≠

+

≠

+

AMP1

≠

+

≠

+

≠

+

AMP2

SOFT-START

1.26V

V

REF

COMP1

BURST

THRESHOLD

C1

+

C1

C2

C1

≠

C2

+

C2

≠

R

SENSE

V

OUT

C

OUT

6

GND

1911 BD

4

3

2

5

7

≠

+

COMP2

600mV

600mV

SHDN

SHORT-CIRCUIT

THRESHOLD

OVERTEMP

DETECT

1.5MHz

OSCILLATOR

60k

140k

V

REF

RAMP

+

2

µ

A

SS/SHDN

V

IN

8

+

SHDN

6

LTC1911-1.5/LTC1911-1.8

1911f

APPLICATIO S I FOR ATIO

W

U

U

U

General Operation

The LTC1911 uses a switch capacitor-based DC/DC con-

version to provide the efficiency advantages associated

with inductor-based circuits as well as the cost and

simplicity advantages of a linear regulator. The LTC1911's

unique constant frequency architecture provides a low

noise regulated output as well as lower input noise than

conventional switch-capacitor charge pump regulators.

The LTC1911 uses an internal switch network and frac-

tional conversion ratios to achieve high efficiency over

widely varying V

IN

and output load conditions. Internal

control circuitry selects the appropriate step-down con-

version ratio based on V

IN

and load conditions to optimize

efficiency. The part has three possible step-down modes:

2-to-1, 3-to-2 or 1-to-1 step-down mode. Only two exter-

nal flying caps are needed to operate in all three modes.

2-to-1 mode is chosen when V

IN

is greater than two times

the desired V

OUT

. 3-to-2 mode is chosen when V

IN

is

greater than 1.5 times V

OUT

but less than 2 times V

OUT

. 1-

to-1 mode is chosen when V

IN

falls below 1.5 times V

OUT

.

An internal load current sense circuit controls the switch

point of the step-down ratio as needed to maintain output

regulation over all load conditions.

Regulation is achieved by sensing the output voltage and

regulating the amount of charge transferred per cycle.

This method of regulation provides much lower input and

output ripple than that of conventional switched capacitor

charge pumps. The constant frequency charge transfer

also makes additional output or input filtering much less

demanding than conventional switched capacitor charge

pumps.

The LTC1911 also has a Burst Mode function that delivers

a minimum amount of charge for one cycle then goes into

a low current state until the output drops enough to require

another burst of charge. Burst Mode operation allows the

LTC1911 to achieve high efficiency even at light loads. The

part has shutdown capability as well as user-controlled

inrush current limiting. In addition, the part has short-

circuit and overtemperature protection.

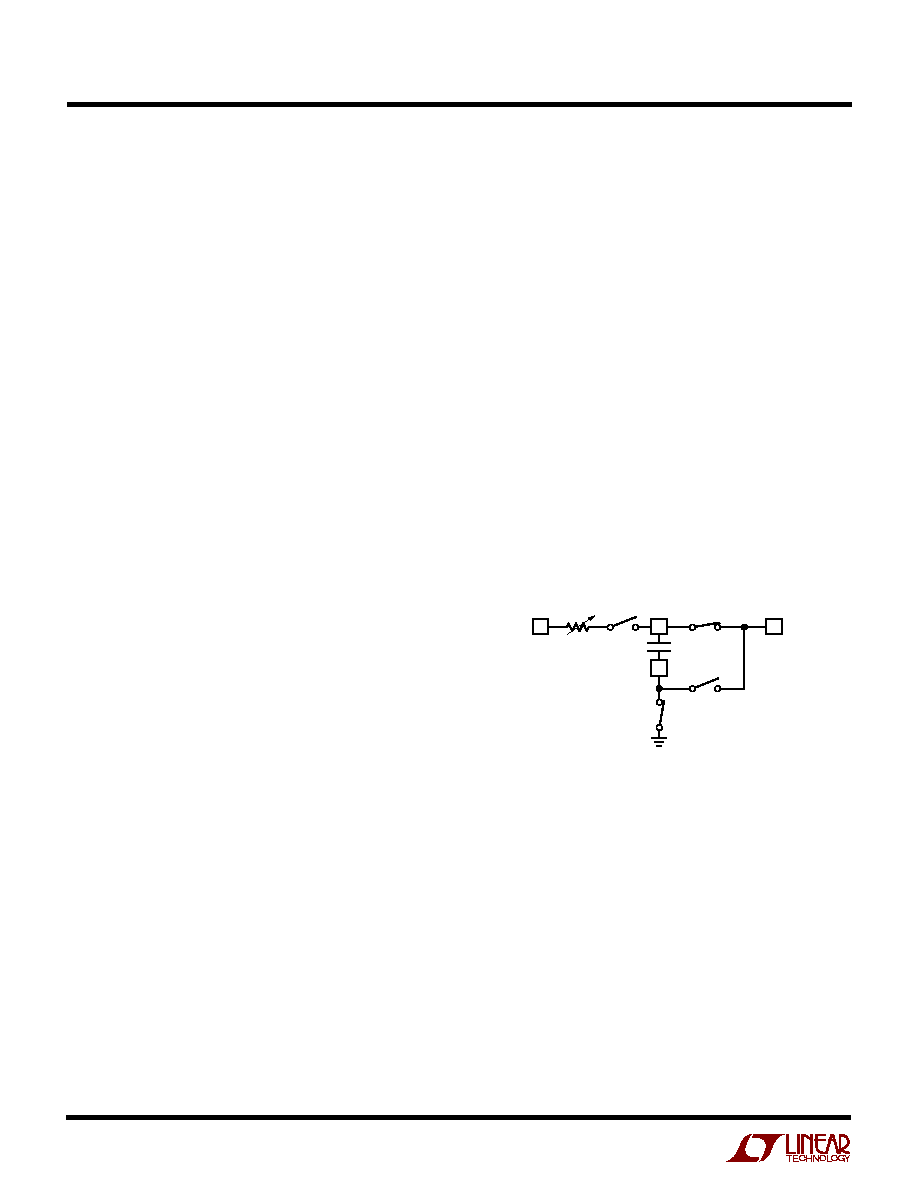

Step-Down Charge Transfer Operation

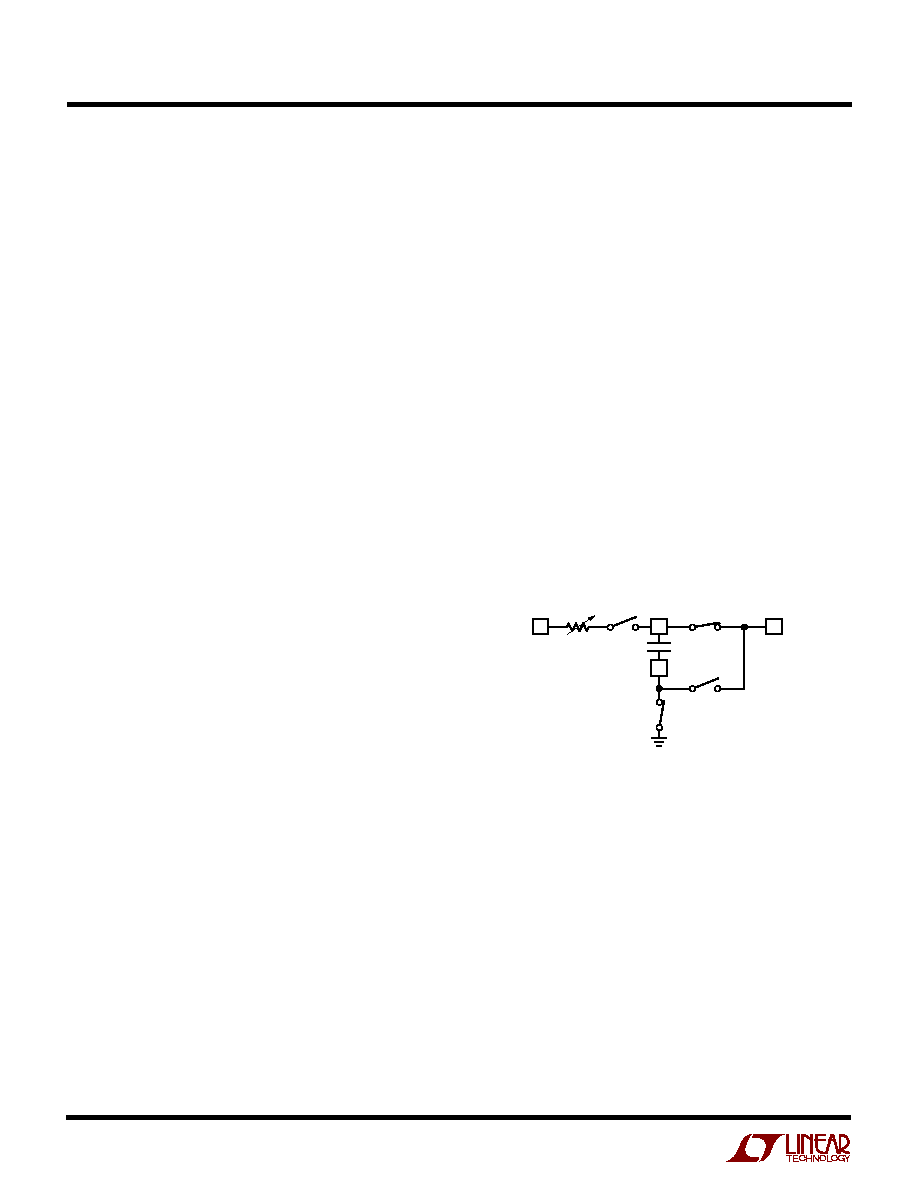

Figure 1a shows the switch configuration that is used for

2-to-1 step down mode. In this mode, a 2-phase clock

generates the switch control signals. On phase one of the

clock, the top plate of C1 is connected to V

IN

through R

A

and S4, the bottom plate is connected to V

OUT

through S3.

The amount of charge transferred to C1 (and V

OUT

) is set

by the value of R

A

.

On phase two, flying capacitor C1 is connected to V

OUT

through S1 and to GND through S2. The charge that was

transferred onto C1 from the previous cycle is now trans-

ferred to the output. Thus, in 2-to-1 mode, charge is

transferred to V

OUT

on both phases of the clock. Since

charge current is sourced from GND on the second phase

of the clock, current multiplication is realized with respect

to V

IN

, i.e., I

OUT

equals approximately 2 ∑ I

IN

. This results

in significant efficiency improvement relative to a linear

regulator. The value of R

A

is set by the control loop of the

regulator.

V

IN

V

OUT

C1

R

A

C1

+

C1

≠

1911 F01a

S4

1

S1

2

S3

1

S2

2

Figure 1a. Step-Down Charge Transfer in 2-to-1 Mode

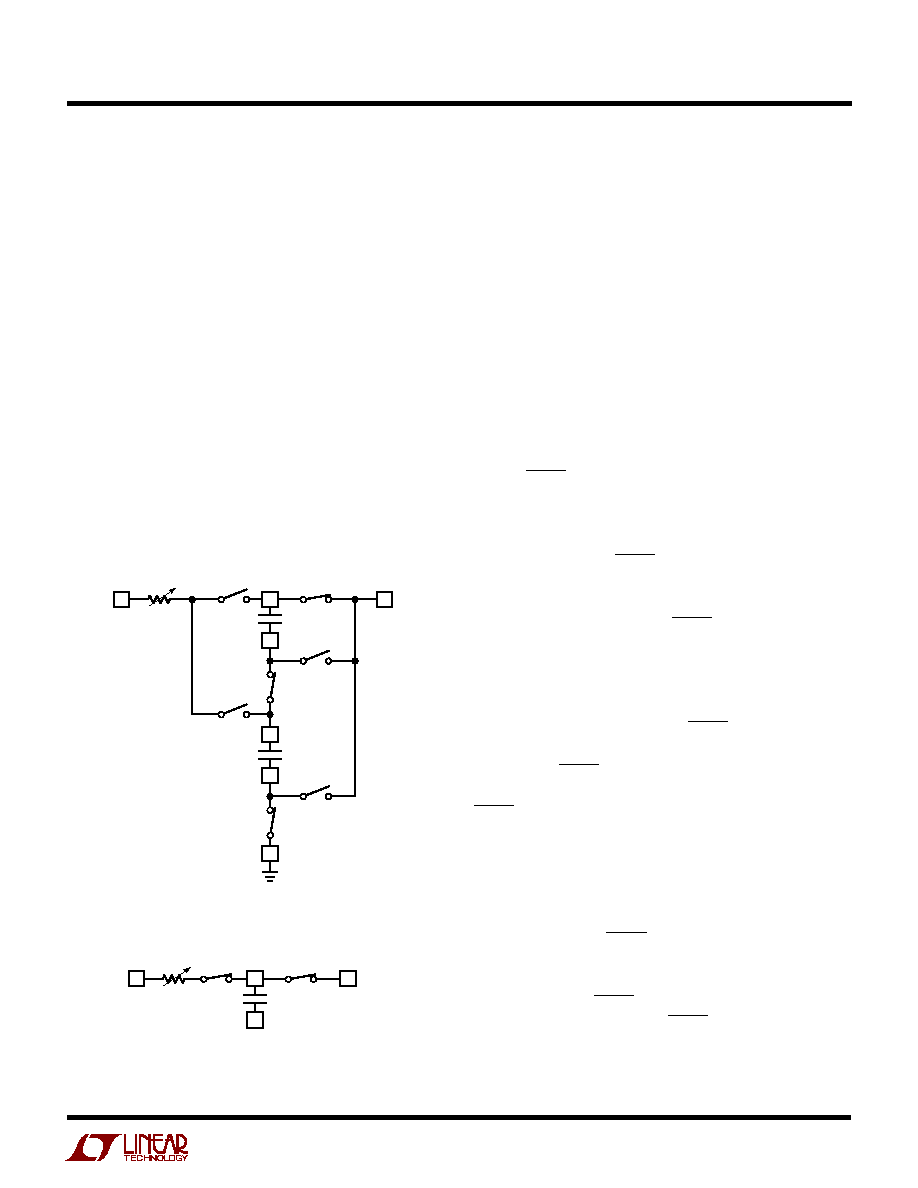

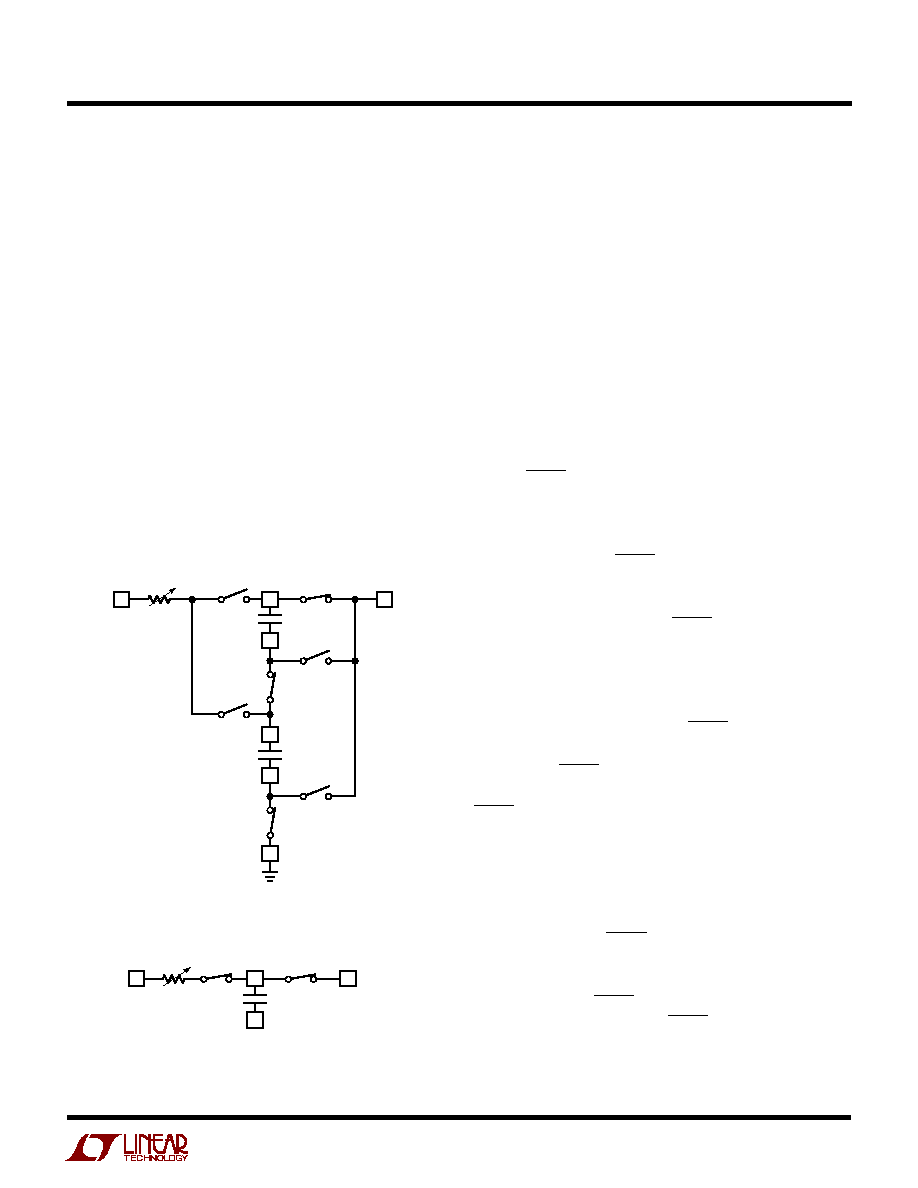

The 3-to-2 conversion mode also uses a nonoverlapping

clock for switch control but requires two flying capacitors

and a total of seven switches (see Figure 1b). On phase one

of the clock, the two capacitors are connected in parallel to

V

IN

through R

A

by switches S5 and S7, and to V

OUT

through S4 and S6. The amount of charge transferred to

C1|| C2 (and V

OUT

) is set by the regulator control loop

which determines the value of R

A

. On phase two, C1 and

C2 are connected in series from V

OUT

to GND through

switches S1, S2 and S3. On phase two, half of the charge

7

LTC1911-1.5/LTC1911-1.8

1911f

transferred to the parallel combination of C1 and C2 is

transferred to the V

OUT

. In this manner, charge is again

transferred from the flying capacitors to the output on

both phases of the clock. As in 2-to-1 mode, charge

current is sourced from GND on phase two of the clock

resulting in increased power efficiency. I

OUT

in 3-to-2

mode equals approximately (3/2)I

IN

.

In 1-to-1 mode (see Figure 1c), switch S1 is always closed

connecting the top plate of C1 to V

OUT

. Switch S2 remains

closed for almost the entire clock period, opening only

briefly at the end of clock phase one. In this manner, V

OUT

is connected to V

IN

through R

A

. The value of R

A

is set by

the regulator control loop which determines the amount of

current transferred to V

OUT

during the on period of S2. The

LTC1911 acts much like a linear regulator in this mode.

Since all of the V

OUT

current is sourced from V

IN

, the

efficiency in 1-to-1 mode is approximately equal to that of

a linear regulator.

Mode Selection

The optimal step-down conversion mode is chosen based

on V

IN

and output load conditions. Two internal compara-

tors are used to select the default step-down mode based

on the input voltage. Each comparator has an adjustable

offset built in that increases (decreases) in proportion to

the increasing (decreasing) output load current. In this

manner, the mode switch point is optimized to provide

peak efficiency over all supply and load conditions. Each

comparator also has built-in hysteresis of about 300mV to

ensure that the LTC1911 does not oscillate between modes

when a transition point is reached.

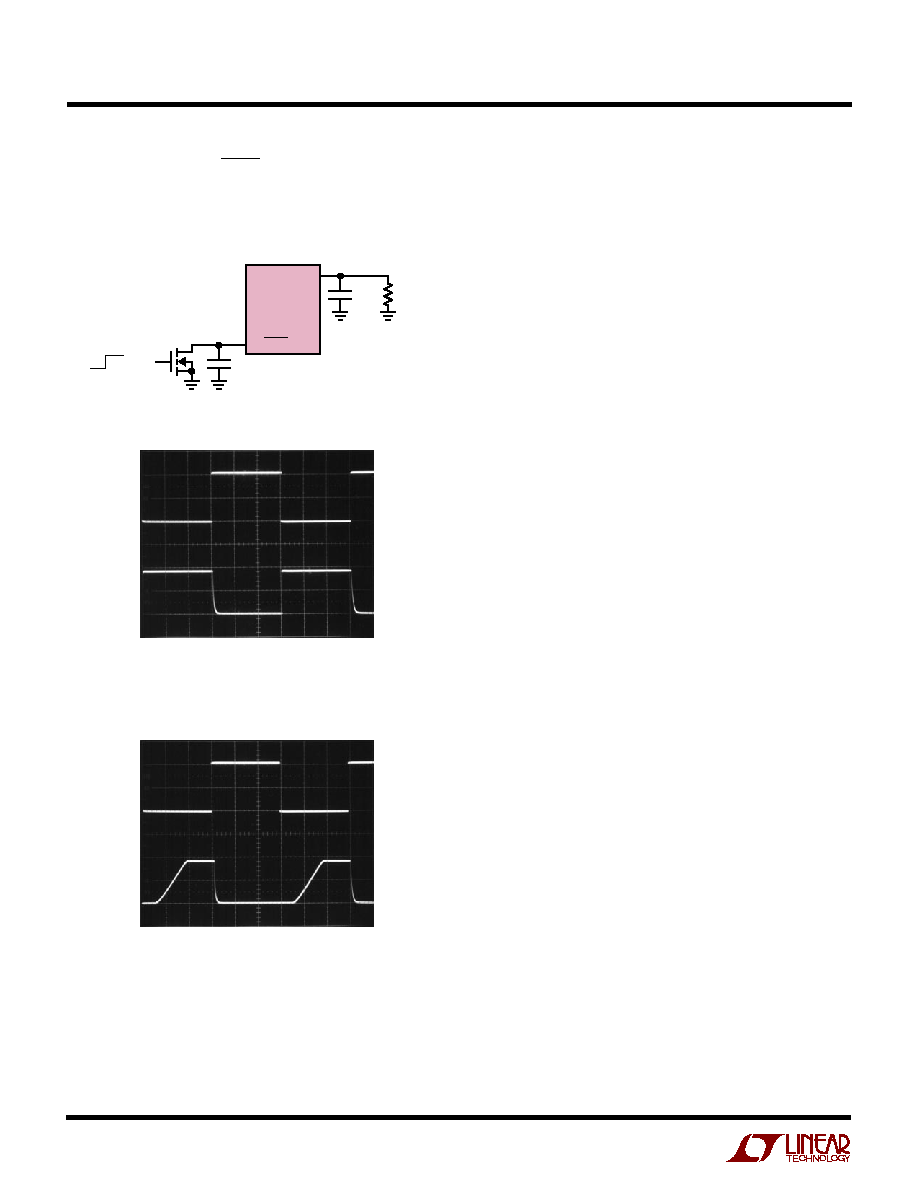

Soft-Start/Shutdown Operation

The SS/SHDN pin is used to implement both low current

shutdown and soft-start. The soft-start feature limits

inrush currents when the regulator is initially powered up

or taken out of shutdown. Forcing a voltage lower than

0.6V (typ) on the SS/SHDN pin will put the LTC1911 into

shutdown mode. Shutdown mode disables all control

circuitry and forces V

OUT

into a high impedance state. A

2

µ

A pull-up current on the SS/SHDN pin will force the part

into active mode if the pin is left floating or is driven with

an open-drain output that is in a high impedance state. If

the pin is not driven with an open-drain device, it must be

forced to a logic high voltage of 2.2V (min) to ensure

proper V

OUT

regulation. The SS/SHDN pin should not be

driven to a voltage higher than V

IN

. To implement soft-

start, the SS/SHDN pin must be driven with an open-drain

device and a capacitor must be connected from the SS/

SHDN pin to GND. Once the open-drain device is turned

off, the 2

µ

A pull-up current will begin charging the external

soft-start capacitor and force the voltage on the pin to

ramp towards V

IN

. As soon as the shutdown threshold is

reached (0.6V typ), the internal reference voltage that

controls the V

OUT

regulation point will follow the ramp

voltage on the SS/SHDN pin (minus a 0.6V offset to

account for the shutdown threshold) until the reference

reaches its final band gap voltage. This occurs when the

voltage on the SS/SHDN pin reaches approximately 1.9V.

Since the ramp rate on the SS/SHDN pin controls the ramp

rate on V

OUT

, the average inrush current can be controlled

through the selection of C

SS

and C

OUT

. For example, a

APPLICATIO S I FOR ATIO

W

U

U

U

V

IN

V

OUT

C1

R

A

C1

+

C1

≠

C2

+

C2

≠

S5

1

S7

1

S4

1

S1

2

S2

2

GND

C2

1911 F01b

S6

1

S3

2

Figure 1b. Step-Down Charge Transfer in 3-to-2 Mode

V

IN

V

OUT

C1

R

A

C1

+

C1

≠

1911 F01c

S2

S1

Figure 1c. Step-Down Charge Transfer in 1-to-1 Mode

8

LTC1911-1.5/LTC1911-1.8

1911f

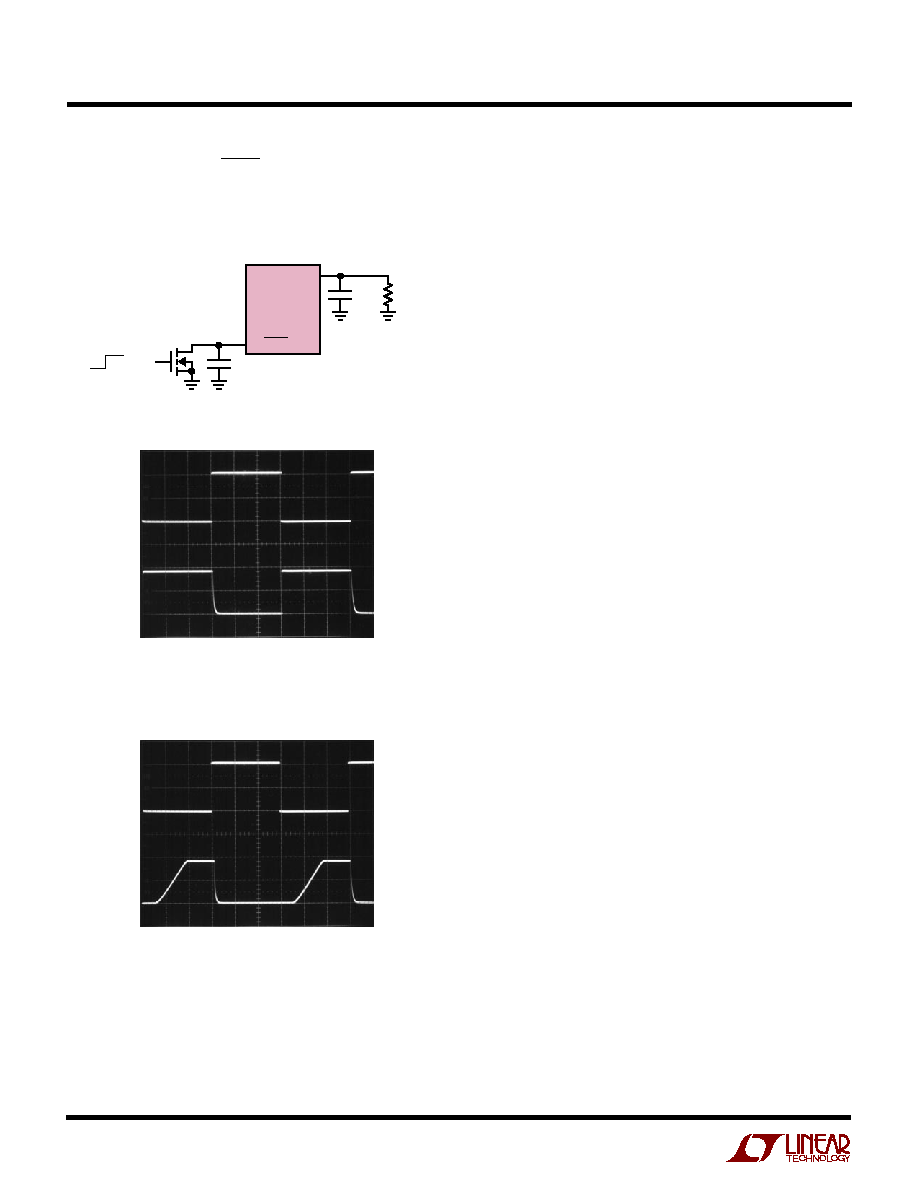

4.7nF capacitor on SS/SHDN results in a 3ms ramp time

from 0.6V to 1.9V on the pin. If C

OUT

is 10

µ

F, the 3ms V

REF

ramp time results in an average C

OUT

charge current of

only 6mA (see Figure 2).

Low Current Burst Mode Operation

To improve efficiency at low output currents, a Burst Mode

function was included in the design of the LTC1911. An

output current sense circuit is used to detect when the

required output current drops below 30mA typ. When this

occurs, the oscillator shuts down and the part goes into a

low current operating state. The LTC1911 will remain in

the low current operating state until V

OUT

has dropped

enough to require another burst of current. Unlike tradi-

tional charge pumps who's burst current is dependant on

many factors (i.e., supply, switch strength, capacitor

selection, etc.), the LTC1911 burst current is set by the

burst threshold. This means that the

output ripple voltage

during Burst Mode operaton will be fixed and is typically

5mV for C

OUT

= 10

µ

F.

Short-Circuit/Thermal Protection

The LTC1911 has built-in short-circuit current limiting as

well as overtemperature protection. During short-circuit

conditions it will automatically limit its output current to

approximately 600mA. The LTC1911 will shut down if the

junction temperature exceeds approximately 160

∞

C. Un-

der normal operating conditions, the LTC1911 should not

go into thermal shutdown but it is included to protect the

IC in cases of excessively high ambient temperatures, or

in cases of excessive power dissipation inside the IC (i.e.,

overcurrent or short circuit). The charge transfer will

reactivate once the junction temperature drops back to

approximately 150

∞

C. The LTC1911 can cycle in and out

of thermal shutdown indefinitely without latch-up or

damage until the fault condition is removed.

V

OUT

Ripple and Capacitor Selection

The type and value of capacitors used with the

LTC1911 determine several important parameters such

as regulator control loop stability, output ripple and

charge pump strength.

The value of C

OUT

directly controls the amount of output

ripple for a given load current. Increasing the size of C

OUT

will reduce the output ripple.

APPLICATIO S I FOR ATIO

W

U

U

U

Figure 2. Shutdown/Soft-Start Operation

SS/SHDN

C

SS

ON OFF V

CTRL

6

8

V

OUT

R

LOAD

LTC1911

C

OUT

(2a)

V

CTRL

2V/DIV

V

OUT

1V/DIV

C

SS

= 0nF

2ms/DIV

1911 F02b

C

OUT

= 10

µ

F

R

LOAD

= 10

(2b)

V

CTRL

2V/DIV

V

OUT

1V/DIV

C

SS

= 4.7nF

2ms/DIV

1911 F02c

C

OUT

= 10

µ

F

R

OUT

= 10

(2c)

9

LTC1911-1.5/LTC1911-1.8

1911f

To reduce output noise and ripple, it is suggested that a

low ESR (

0.1

) ceramic capacitor (10

µ

F

or greater) be

used for C

OUT

. Tantalum and Aluminum capacitors are not

recommended because of their high ESR (equivalent

series resistance).

Both the style and value of C

OUT

can significantly affect the

stability of the LTC1911. As shown in the Block Diagram,

the part uses a control loop to adjust the strength of the

charge pump to match the current required at the output.

The error signal of this loop is stored directly on the output

charge storage capacitor. The charge storage capacitor

also serves to form the dominant pole for the control loop.

To prevent ringing or instability it is important for the

output capacitor to maintain at least 4

µ

F of capacitance

over all conditions (See Ceramic Capacitor Selection

Guidelines).

Likewise excessive ESR on the output capacitor will tend

to degrade the loop stability of the LTC1911. The closed-

loop output resistance of the part is designed to be 0.13

.

For a 250mA load current change, the output voltage will

change by about 33mV. If the output capacitor has 0.13

or more of ESR, the closed-loop frequency response will

cease to roll-off in a simple 1-pole fashion and poor load

transient response or instability could result. Ceramic

capacitors typically have exceptional ESR performance,

and combined with a tight board layout, should yield

excellent stability and load transient performance.

V

IN

Capacitor Selection

The constant frequency architecture used by the

LTC1911 makes input noise filtering much less demand-

ing than with conventional regulated charge pumps. De-

pending on the mode of operation the input current of the

LTC1911 can vary from I

OUT

to 0mA on a cycle-by-cycle

basis. Lower ESR will reduce the voltage steps caused by

changing input current, while the absolute capacitor value

will determine the level of ripple. For optimal input noise

and ripple reduction, it is recommended that a low ESR

ceramic capacitor be used for C

IN

. A tantalum capacitor

may be used for C

IN

but the higher ESR will lead to more

input noise. The LTC1911 will operate with capacitors

APPLICATIO S I FOR ATIO

W

U

U

U

less than 1

µ

F but the increasing input noise will feed

through to the output causing degraded performance.

For best performance a 1

µ

F

or greater capacitor is sug-

gested for C

IN

. Aluminum capacitors are not recom-

mended because of their high ESR.

Flying Capacitor Selection

Warning: A polarized capacitor such as tantalum or

aluminum should never be used for the flying capacitors

since their voltage can reverse upon start-up of the

LTC1911. Ceramic capacitors should always be used for

the flying capacitor.

The flying capacitor controls the strength of the charge

pump. In order to achieve the rated output current it is

necessary for the flying capacitor to have at least 0.4

µ

F of

capacitance over operating temperature with a 2V bias

(See Ceramic Capacitor Selection Guidelines). If only

100mA or less of output current is required the flying

capacitor minimum can be reduced to 0.15

µ

F.

Ceramic Capacitor Selection Guidelines

Capacitors of different materials lose their capacitance

with higher temperature and voltage at different rates. For

example, a ceramic capacitor made of X7R material will

retain most of its capacitance from ≠ 40

∞

C to 85

∞

C whereas

a Z5U or Y5V style capacitor will lose considerable capaci-

tance over that range (60% to 80% loss typ). Z5U and Y5V

capacitors may also have a very strong voltage coefficient

causing them to lose an additional 60% or more of their

capacitance when the rated voltage is applied. Therefore,

when comparing different capacitors it is often more

appropriate to compare the amount of achievable capaci-

tance for a given case size rather than discussing the

specified capacitance value. For example, over rated volt-

age and temperature conditions, a 4.7

µ

F, 10V, Y5V ce-

ramic capacitor in a 0805 case may not provide any more

capacitance than a 1

µ

F, 10V, X7R available in the same

0805 case. In fact, over bias and temperature range, the

1

µ

F, 10V, X7R will provide more capacitance than the

4.7

µ

F, 10V, Y5V. The capacitor manufacturer's data sheet

should be consulted to determine what value of capacitor

10

LTC1911-1.5/LTC1911-1.8

1911f

APPLICATIO S I FOR ATIO

W

U

U

U

is needed to ensure that minimum capacitance values are

met over operating temperature and bias voltage.

Table 1 is a list of ceramic capacitor manufacturers and

how to contact them.

Table 1. Ceramic Capacitor Manufacturers

AVX

1-(803)-448-1943

www.avxcorp.com

Kemet

1-(864) 963-6300

www.kemet.com

Murata

1-(800) 831-9172

www.murata.com

Taiyo Yuden

1-(800) 348-2496

www.t-yuden.com

Vishay

1-(800) 487-9437

www.vishay.com

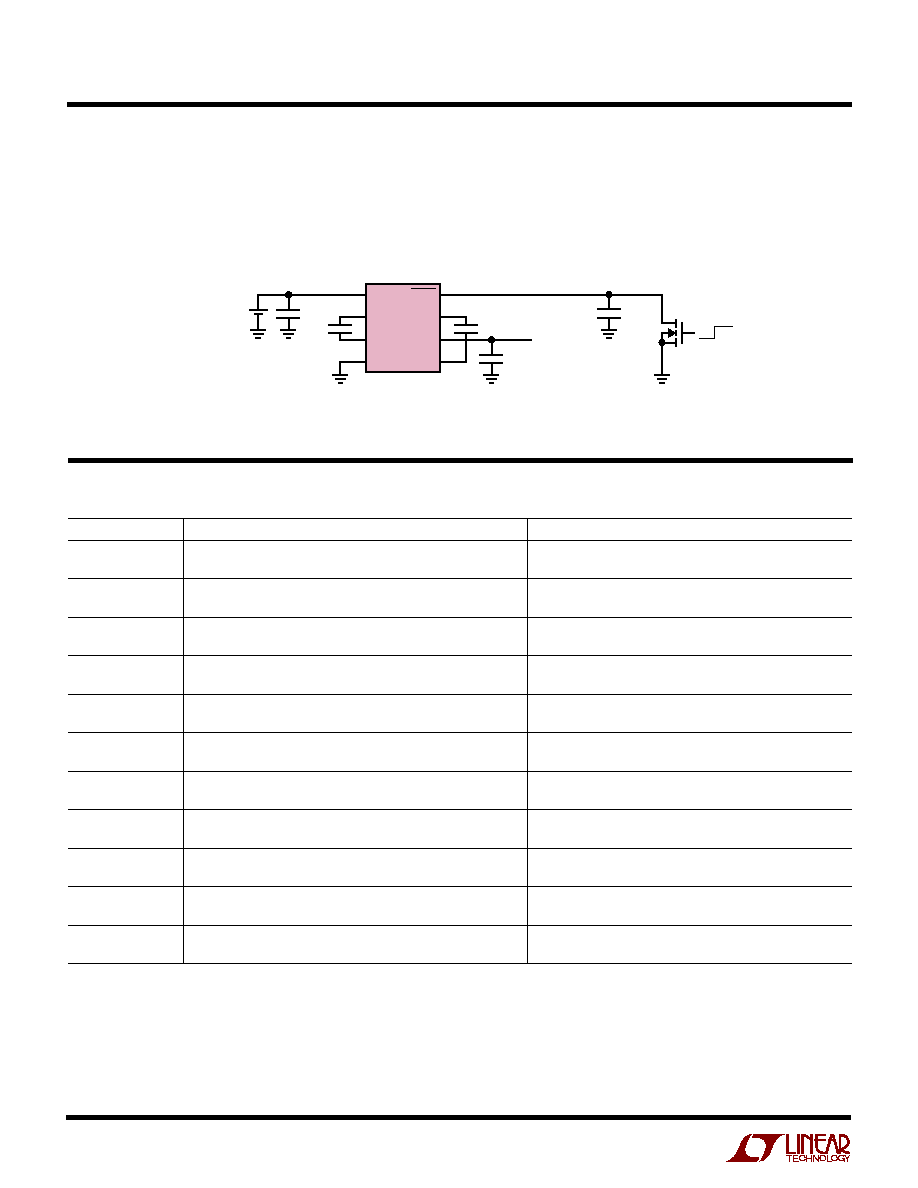

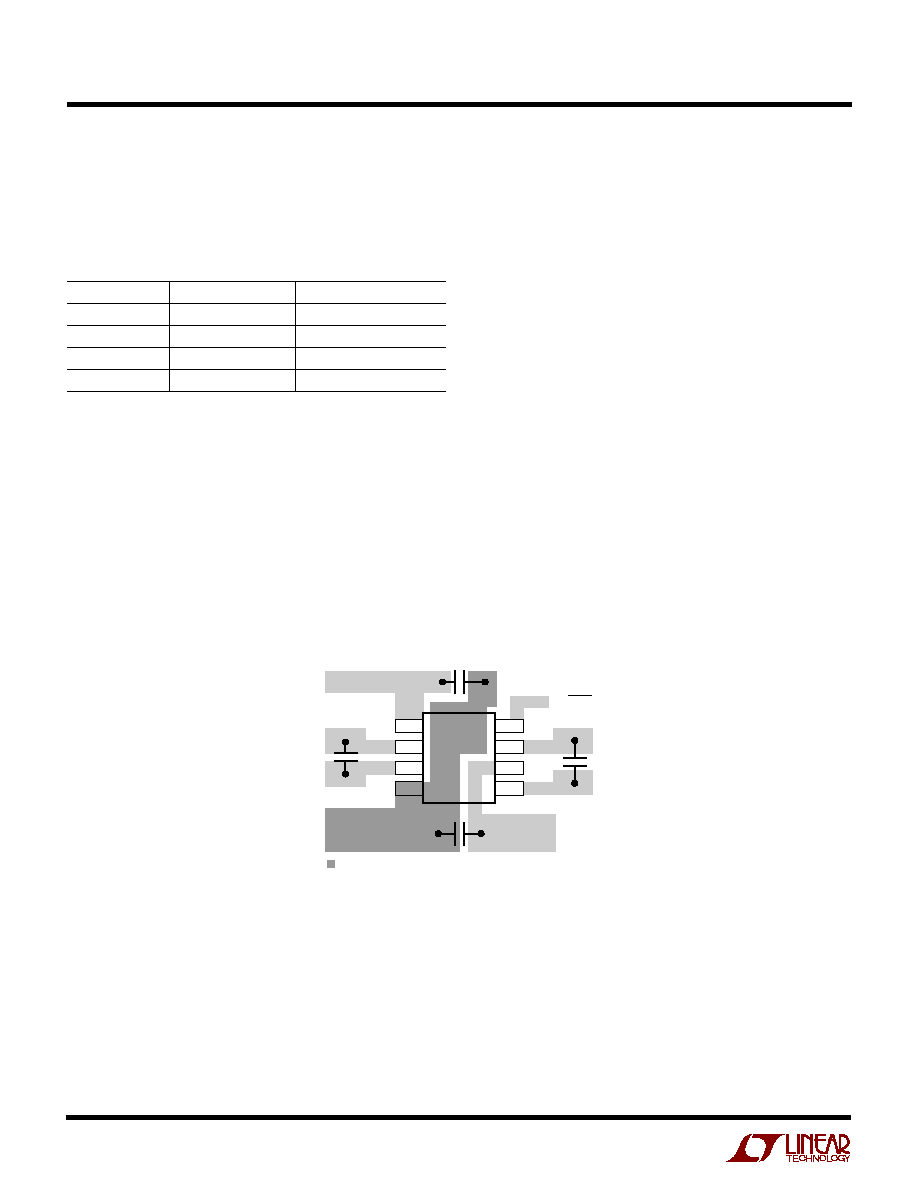

Layout Considerations

Due to the high switching frequency and transient cur-

rents produced by the LTC1911, careful board layout is

necessary for optimal performance. A true ground plane

and short connections to all capacitors will optimize

performance, reduce noise and ensure proper regulation

over all conditions. Figure 3 shows the recommended

layout configuration.

Additional output filtering can be achieved by placing a

second output capacitor, connected to the ground plane,

about 2cm or more from the LTC1911 output capacitor

(C4). The inductance of the trace running to the second

output capacitor will significantly attenuate the high speed

switching transients of the LTC1911. Even small capaci-

tors as low as 0.1

µ

F will provide excellent results.

Thermal Management

The power dissipation in the LTC1911 can cause the

junction temperature to rise at rates of up to 160

∞

C/W. If

the specified operating conditions are followed, the junc-

tion temperature should never exceed the 160

∞

C thermal

shutdown temperature. The junction temperature can

come very close and possibly exceed the specified 125

∞

C

operating junction temperature. To reduce the maximum

junction temperature, a good thermal connection to the PC

board is recommended. Connecting the GND pin (Pin 4) to

a ground plane, and maintaining a solid ground plane

under the device on two layers of the PC board, can reduce

the thermal resistance of the package and PC board

considerably.

C1

1911 F03

C4

OUT

GND

C2

V

IN

SS/SHDN

: CONNECT TO GND PLANE ON BACK OF BOARD

C3

U1

Figure 3. Recommended Component Placement and Grounding

11

LTC1911-1.5/LTC1911-1.8

1911f

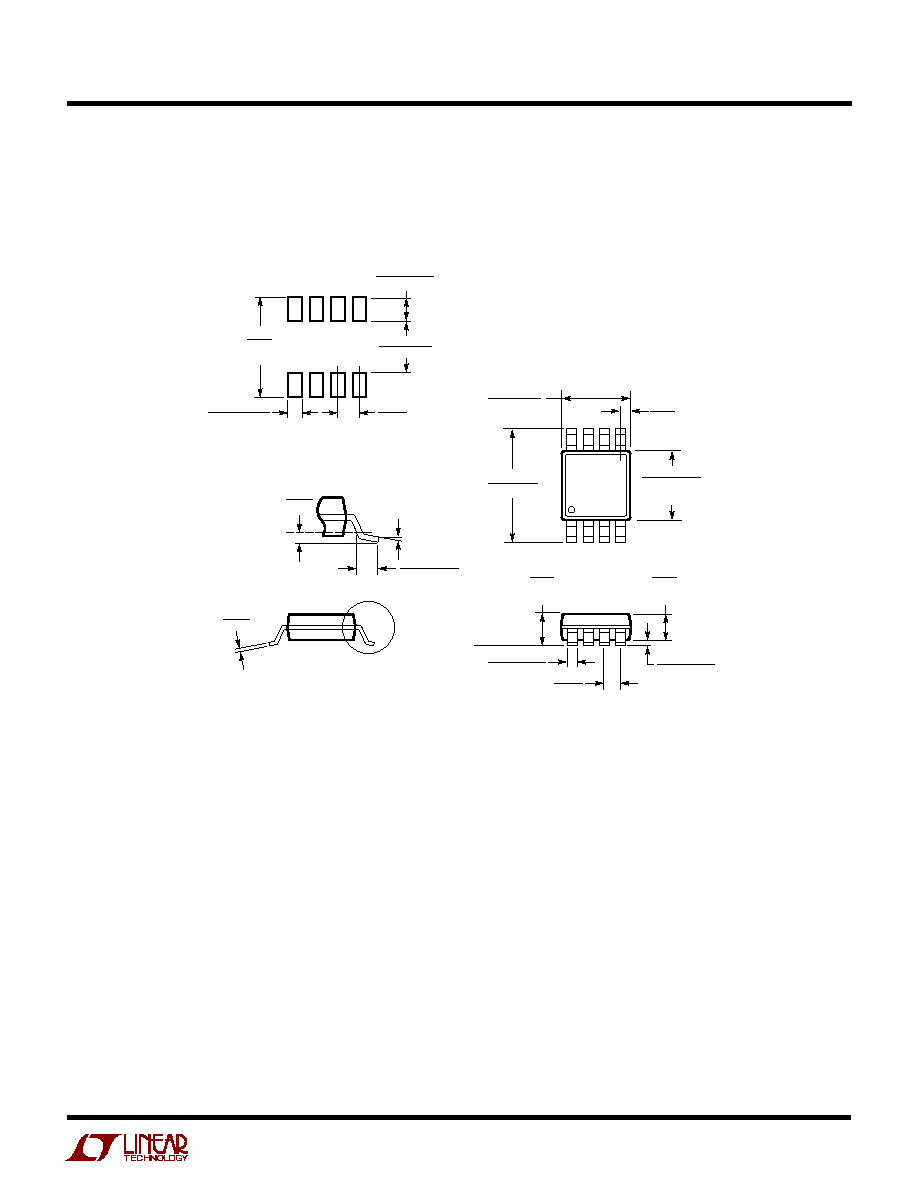

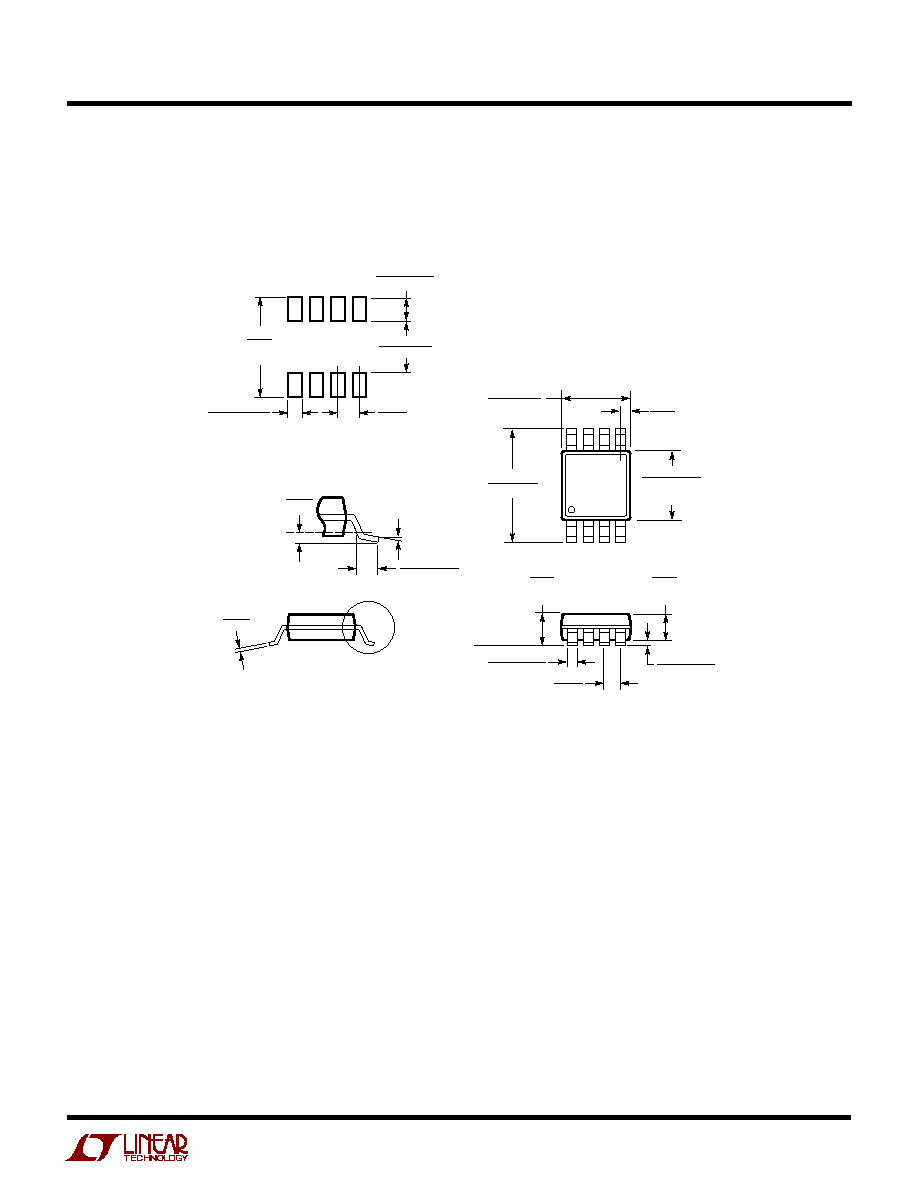

U

PACKAGE DESCRIPTIO

MS8 Package

8-Lead Plastic MSOP

(Reference LTC DWG # 05-08-1660)

MSOP (MS8) 0102

0.53

±

0.015

(.021

±

.006)

SEATING

PLANE

NOTE:

1. DIMENSIONS IN MILLIMETER/(INCH)

2. DRAWING NOT TO SCALE

3. DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH, PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

4. DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

5. LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING) SHALL BE 0.102mm (.004") MAX

0.18

(.077)

0.254

(.010)

1.10

(.043)

MAX

0.22 ≠ 0.38

(.009 ≠ .015)

0.13

±

0.05

(.005

±

.002)

0.86

(.034)

REF

0.65

(.0256)

BCS

0

∞

≠ 6

∞

TYP

DETAIL "A"

DETAIL "A"

GAUGE PLANE

1

2

3

4

4.88

±

0.1

(.192

±

.004)

8

7 6 5

3.00

±

0.102

(.118

±

.004)

(NOTE 3)

3.00

±

0.102

(.118

±

.004)

NOTE 4

0.52

(.206)

REF

5.23

(.206)

MIN

3.2 ≠ 3.45

(.126 ≠ .136)

0.889

±

0.127

(.035

±

.005)

RECOMMENDED SOLDER PAD LAYOUT

0.42

±

0.04

(.0165

±

.0015)

TYP

0.65

(.0256)

BSC

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no represen-

tation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

12

LTC1911-1.5/LTC1911-1.8

1911f

©

LINEAR TECHNOLOGY CORPORATION 2001

LT/TP 1102 2K ∑ PRINTED IN USA

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

q

FAX: (408) 434-0507

q

www.linear.com

PART NUMBER

DESCRIPTION

COMMENTS

LTC1514

50mA, 650kHz, Step-Up/Down Charge Pump

V

IN

= 2.7V to 10V, V

OUT

= 3V to 5V, I

Q

= 60

µ

A, I

SD

= 10

µ

A,

with Low Battery Comparator

S8 Package

LTC1515

50mA, 650kHz, Step-Up/Down Charge Pump

V

IN

= 2.7V to 10V, V

OUT

= 3.3V or 5V, I

Q

= 60

µ

A, I

SD

= <1

µ

A,

with Power On Reset

S8 Package

LT1776

500mA (I

OUT

), 200kHz, High Efficiency Step-Down

90% Efficiency, V

IN

= 7.4V to 40V, V

OUT

= 1.24V, I

Q

= 3.2mA,

DC/DC Converter

I

SD

= 30

µ

A, N8,S8 Packages

LTC3250-1.5

250mA, 1.5MHz, High Efficiency, Step-Down Charge Pump

85% Efficiency, V

IN

= 3.1V to 5.5V, V

OUT

= 1.5V, I

Q

= 35

µ

A,

I

SD

= <1

µ

A, ThinSOT Package

LTC3251

500mA, 1MHz to 1.6MHz, Spread Spectrum,

85% Efficiency, V

IN

= 3.1V to 5.5V, V

OUT

= 0.9V to 1.6V,

Step-Down Charge Pump

I

Q

= 9

µ

A, I

SD

= <1

µ

A, MS Package

LTC3404

600mA (I

OUT

), 1.4MHz, Synchronous Step-Down

95% Efficiency, V

IN

= 2.7V to 6V, V

OUT

= 0.8V, I

Q

= 10

µ

A,

DC/DC Converter

I

SD

= <1

µ

A, MS8 Package

LTC3405A

300mA (I

OUT

), 1.5MHz, Synchronous Step-Down

95% Efficiency, V

IN

= 2.7V to 6V, V

OUT

= 0.8V, I

Q

= 20

µ

A,

DC/DC Converter

I

SD

= <1

µ

A, ThinSOT Package

LTC3406B

600mA (I

OUT

), 1.5MHz, Synchronous Step-Down

95% Efficiency, V

IN

= 2.5V to 5.5V, V

OUT

= 0.6V, I

Q

= 20

µ

A,

DC/DC Converter

I

SD

= <1

µ

A, ThinSOT Package

LTC3411

1.25A (I

OUT

), 4MHz, Synchronous Step-Down

95% Efficiency, V

IN

= 2.5V to 5.5V, V

OUT

= 0.8V, I

Q

= 60

µ

A,

DC/DC Converter

I

SD

= <1

µ

A, MS Package

LTC3412

2.5A (I

OUT

), 4MHz, Synchronous Step-Down

95% Efficiency, V

IN

= 2.5V to 5.5V, V

OUT

= 0.8V, I

Q

= 60

µ

A,

DC/DC Converter

I

SD

= <1

µ

A, TSSOP16E Package

LTC3440

600mA (I

OUT

), 2MHz, Synchronous Buck-Boost

95% Efficiency, V

IN

= 2.5V to 5.5V, V

OUT

= 2.5V, I

Q

= 25

µ

A,

DC/DC Converter

I

SD

= <1

µ

A, MS Package

ThinSOT is a trademark of Linear Technology Corporation.

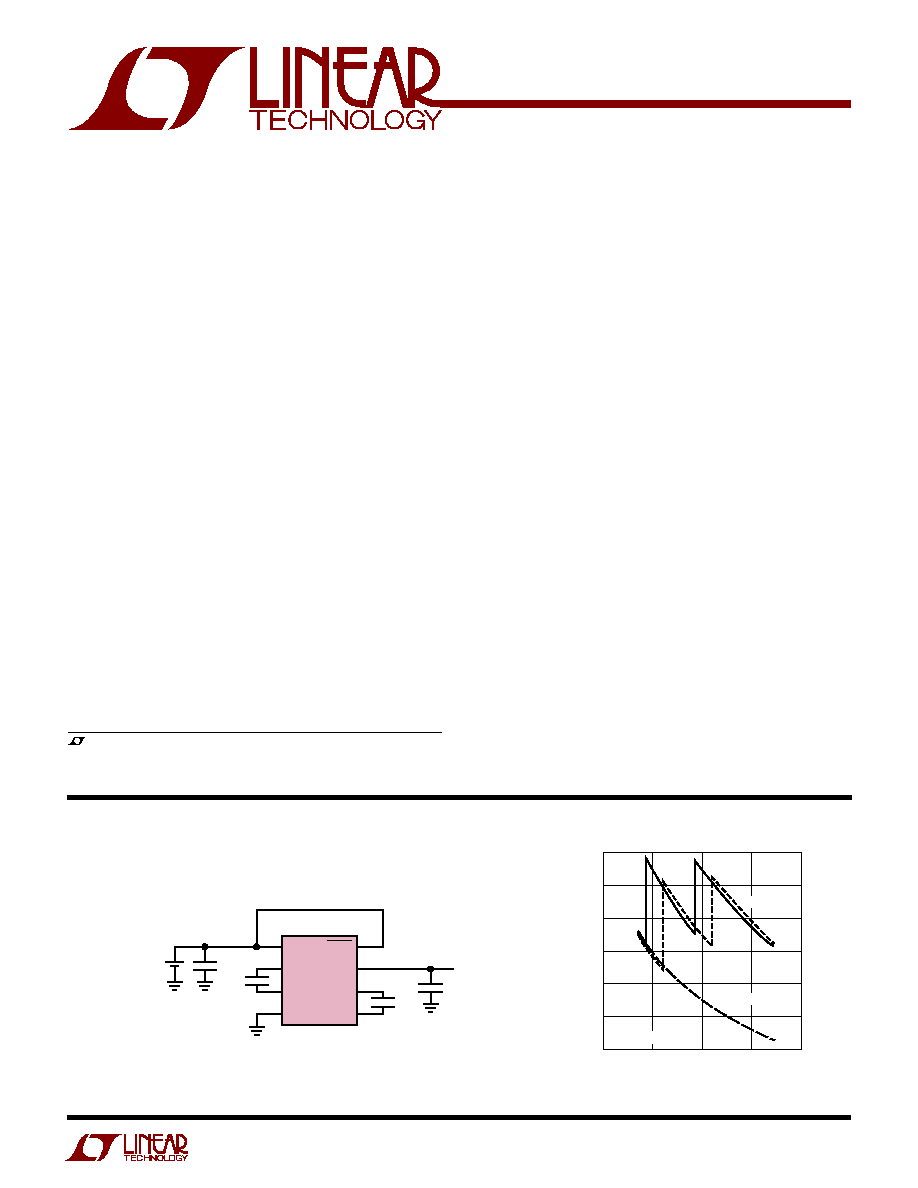

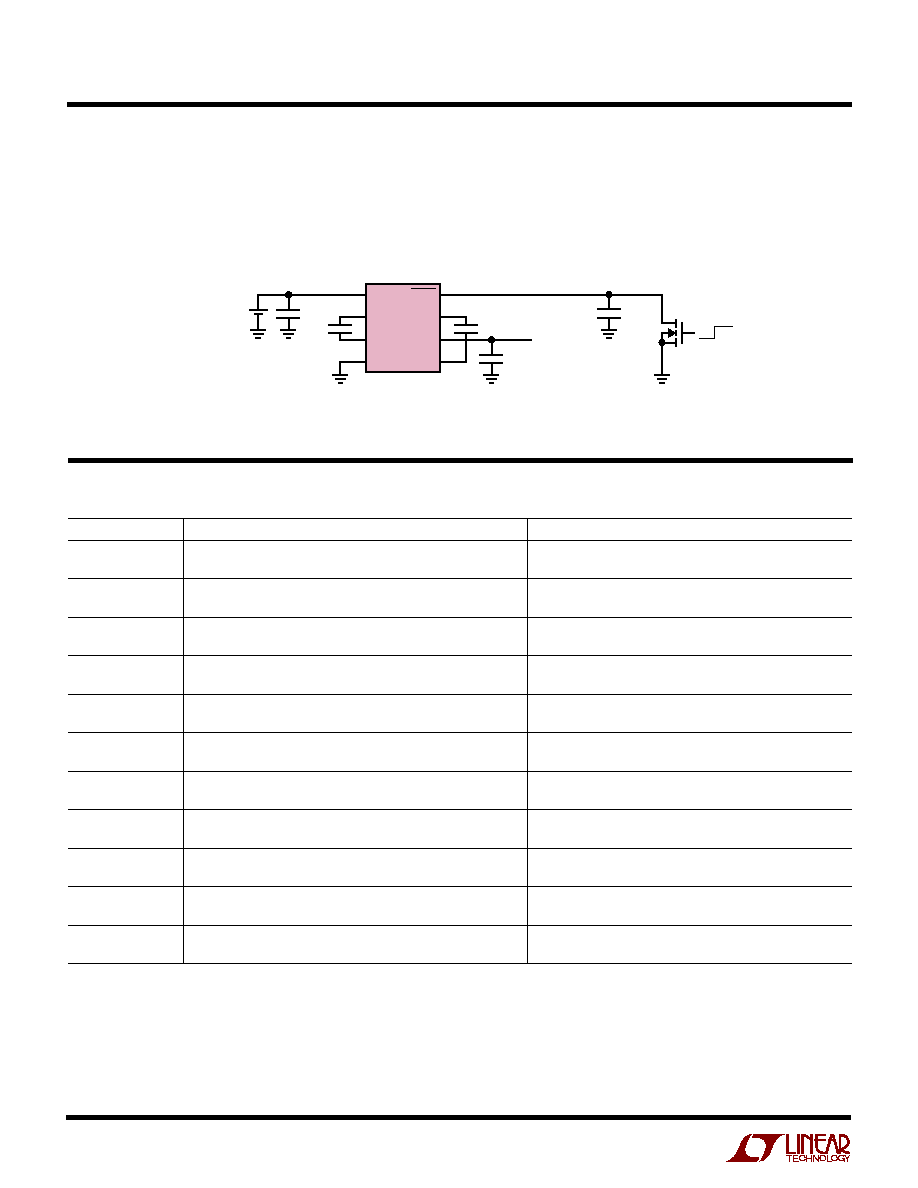

TYPICAL APPLICATIO

U

DC/DC Converter with Shutdown and Soft-Start

V

IN

C2

+

C2

≠

GND

8

7

6

5

1

2

3

4

SS/SHDN

C1

+

V

OUT

C1

≠

LTC1911-1.5

1

µ

F*

1-CELL Li-Ion

OR

3-CELL NiMH

10

µ

F*

10

µ

F*

2N7002

ON OFF

10nF

1911 TA03

V

OUT

= 1.5V

I

OUT

= 250mA

1

µ

F*

*CERAMIC CAPACITOR

2.7V TO 5.5V INPUT

RELATED PARTS