| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: DAC8552 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Burr Brown Products

from Texas Instruments

DAC8552

FEATURES

DESCRIPTION

APPLICATIONS

DAC A

DAC B

V

REF

V

DD

V

A

OUT

V

B

OUT

Power-Down

Control Logic

Resistor

Network

2

Channel

Select

Load

Control

8

Control Logic

GND

SYNC

SCLK

D

IN

16

24-Bit,

Serial-to-

Parallel

Shift

Register

Data

Buffer A

Data

Buffer B

DAC

A

Register

DAC

Register B

DAC8552

SLAS430 ≠ JULY 2006

16-BIT, DUAL CHANNEL, ULTRA-LOW GLITCH VOLTAGE OUTPUT

DIGITAL-TO-ANALOG CONVERTER

∑

Relative Accuracy: 4LSB

The DAC8552 is a 16-bit, dual channel, voltage

output digital-to-analog converter (DAC) offering low

∑

Glitch Energy: 0.15nV-s

power operation and a flexible serial host interface.

∑

MicroPower Operation:

Each

on-chip

precision

output

amplifier

allows

155

µ

A per Channel at 2.7V

rail-to-rail output swing to be achieved over the

∑

Power-On Reset to Zero-Scale

supply range of 2.7V to 5.5V. The device supports a

standard 3-wire serial interface capable of operating

∑

Power Supply: 2.7V to 5.5V

with input data clock frequencies up to 30MHz for

∑

16-Bit Monotonic Over Temperature

V

DD

= 5V.

∑

Settling Time: 10

µ

s to

±

0.003% FSR

The DAC8552 requires an external reference voltage

∑

Ultra-Low AC Crosstalk: ≠100dB Typ

to set the output range of each DAC channel. Also

∑

Low-Power Serial Interface With

incorporated into the device is a power-on reset

Schmitt-Triggered Inputs

circuit which ensures that the DAC outputs power up

at zero-scale and remain there until a valid write

∑

On-Chip Output Buffer Amplifier With

takes place. The DAC8552 provides a flexible

Rail-to-Rail Operation

power-down

feature,

accessed

over

the

serial

∑

Double-Buffered Input Architecture

interface, that reduces the current consumption of

∑

Simultaneous or Sequential Output Update

the device to 700nA at 5V.

and Powerdown

The low-power consumption of this device in normal

∑

Available in a Tiny MSOP-8 Package

operation

makes

it

ideally

suited

for

portable

battery-operated equipment and other low-power

applications. The power consumption is 0.5mW per

channel at 2.7V, reducing to 1

µ

W in power-down

∑

Portable Instrumentation

mode.

∑

Closed-Loop Servo Control

The DAC8552 is available in a MSOP-8 package

∑

Process Control

with a specified operating temperature range of

∑

Data Acquisition Systems

≠40

∞

C to +105

∞

C.

∑

Programmable Attenuation

∑

PC Peripherals

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

SPI, QSP are trademarks of Motorola.

Microwire is a trademark of National Semiconductor.

PRODUCTION DATA information is current as of publication date.

Copyright © 2006, Texas Instruments Incorporated

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

www.ti.com

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

DAC8552

SLAS430 ≠ JULY 2006

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be

more susceptible to damage because very small parametric changes could cause the device not to meet its published

specifications.

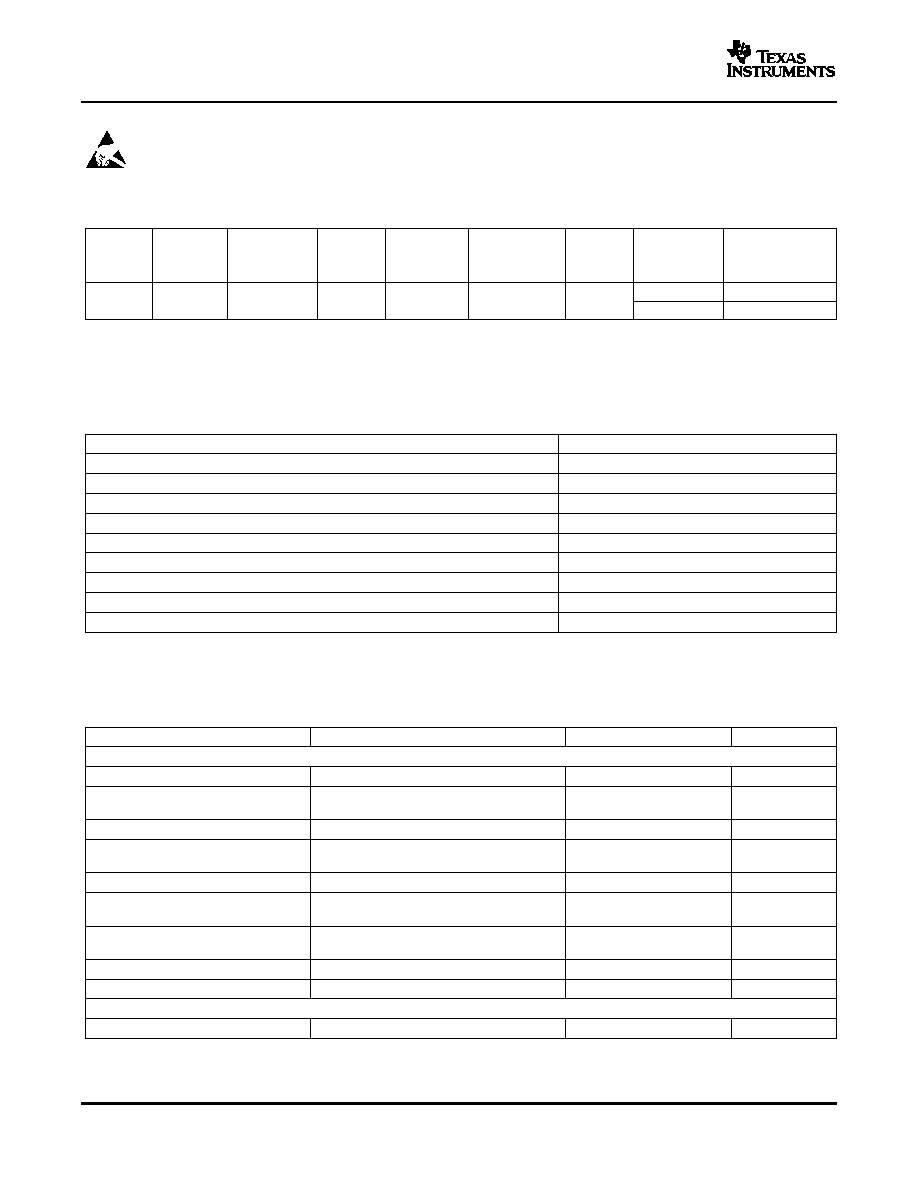

PACKAGING/ORDERING INFORMATION

(1)

MAXIMUM

MAXIMUM

RELATIVE

DIFFERENTIAL

SPECIFICATION

TRANSPORT

ACCURACY

NONLINEARITY

PACKAGE

PACKAGE

TEMPERATURE

PACKAGE

ORDERING

MEDIA,

PRODUCT

(LSB)

(LSB)

LEAD

DESIGNATOR

RANGE

MARKING

NUMBER

QUANTITY

DAC8552IDGKT

Tape and Reel, 250

DAC8552

±

12

±

1

MSOP-8

DGK

≠40

∞

C to +105

∞

C

D82

DAC8552IDGKR

Tape and Reel, 2500

(1)

For the most current package and ordering information, see the Package Option Addendum at the of this document, or see the TI

website at

www.ti.com

.

over operating free-air temperature range (unless otherwise noted)

(1)

UNIT

V

DD

to GND

≠0.3V to 6V

Digital input voltage to GND

≠0.3V to V

DD

+ 0.3V

V

OUTA

or V

OUTB

to GND

≠0.3V to V

DD

+ 0.3V

Operating temperature range

≠40

∞

C to +105

∞

C

Storage temperature range

≠65

∞

C to +150

∞

C

Junction temperature (T

J

max)

+150

∞

C

Power dissipation

(T

J

max ≠ T

A

)/

JA

JA

thermal impedance

206

∞

C/W

JC

thermal impedance

44

∞

C/W

(1)

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. Exposure to absolute

maximum conditions for extended periods may affect device reliability.

V

DD

= 2.7V to 5.5V, all specifications ≠40

∞

C to +105

∞

C (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

STATIC PERFORMANCE

(1)

Resolution

16

Bits

Relative accuracy

Measured by line passing through codes 513

±

4

±

12

LSB

and 64741

Differential nonlinearity

16-bit monotonic

±

0.35

±

1

LSB

Zero code error

Measured by line passing through codes 485

±

2.5

±

12

mV

and 64741

Zero code error drift

±

5

µ

V/

∞

C

Full-scale error

Measured by line passing through codes 485

±

0.1

±

0.5

% of FSR

and 64741

Gain error

Measured by line passing through codes 485

±

0.08

±

0.2

% of FSR

and 64741

Gain temperature coefficient

±

1

ppm of FSR/

∞

C

PSRR

Output unloaded

0.75

mV/V

OUTPUT CHARACTERISTICS

(2)

Output voltage range

0

V

REF

V

(1)

Linearity calculated using a reduced code range of 513 to 64741. Output unloaded.

(2)

Specified by design and characterization, not production tested.

2

Submit Documentation Feedback

www.ti.com

DAC8552

SLAS430 ≠ JULY 2006

ELECTRICAL CHARACTERISTICS (continued)

V

DD

= 2.7V to 5.5V, all specifications ≠40

∞

C to +105

∞

C (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

To

±

0.003% FSR 0200

H

to FD00

H

, R

L

= 2k

;

8

10

0pF < C

L

< 200pF

Output voltage settling time

µ

s

R

L

= 2k

; C

L

= 500pF

12

Slew rate

1.8

V/

µ

s

R

L

=

470

Capacitive load stability

pF

R

L

= 2k

1000

Code change glitch impulse

1LSB change around major carry

0.15

nV-s

Digital feedthrough

50k

series resistance on digital lines

0.15

nV-s

Full-scale swing on adjacent channel.

DC crosstalk

0.25

LSB

V

DD

= 5V, V

REF

= 4.096V

AC crosstalk

1kHz Sine wave

≠100

dB

DC output impedance

At mid-point input

1

V

DD

= 5V

50

Short circuit current

mA

V

DD

= 3V

20

Coming out of power-down mode V

DD

= 5V

2.5

µ

s

Power-up time

Coming out of power-down mode V

DD

= 3V

5

µ

s

AC PERFORMANCE

SNR

95

BW = 20kHz, V

DD

= 5V, f

OUT

= 1kHz,

THD

-85

1st 19 harmonics removed for SNR

dB

SFDR

87

calculation

SINAD

84

REFERENCE INPUT

V

REF

= V

DD

= 5.5V

90

120

Reference current

µ

A

V

REF

= V

DD

= 3.6V

60

100

Reference input range

0

V

DD

V

Reference input impedance

62

k

LOGIC INPUTS

(3)

Input current

±

1

µ

A

V

DD

= 5V

0.8

V

IN

L, Input LOW voltage

V

V

DD

= 3V

0.6

V

DD

= 5V

2.4

V

IN

H, Input HIGH voltage

V

V

DD

= 3V

2.1

Pin capacitance

3

pF

POWER REQUIREMENTS

V

DD

2.7

5.5

V

Input Code = 32768, no load, does not

I

DD

(normal mode)

include reference current

V

DD

= 3.6V to 5.5V

340

500

V

IH

= V

DD

and V

IL

= GND

µ

A

V

DD

= 2.7V to 3.6V

310

480

I

DD

(all power-down modes)

V

DD

= 3.6V to 5.5V

0.7

2

V

IH

= V

DD

and V

IL

= GND

µ

A

V

DD

= 2.7V to 3.6V

0.4

2

POWER EFFICIENCY

I

OUT

/I

DD

I

LOAD

= 2mA, V

DD

= 5V

89%

TEMPERATURE RANGE

Specified performance

≠40

+105

∞

C

(3)

Specified by design and characterization, not production tested.

3

Submit Documentation Feedback

www.ti.com

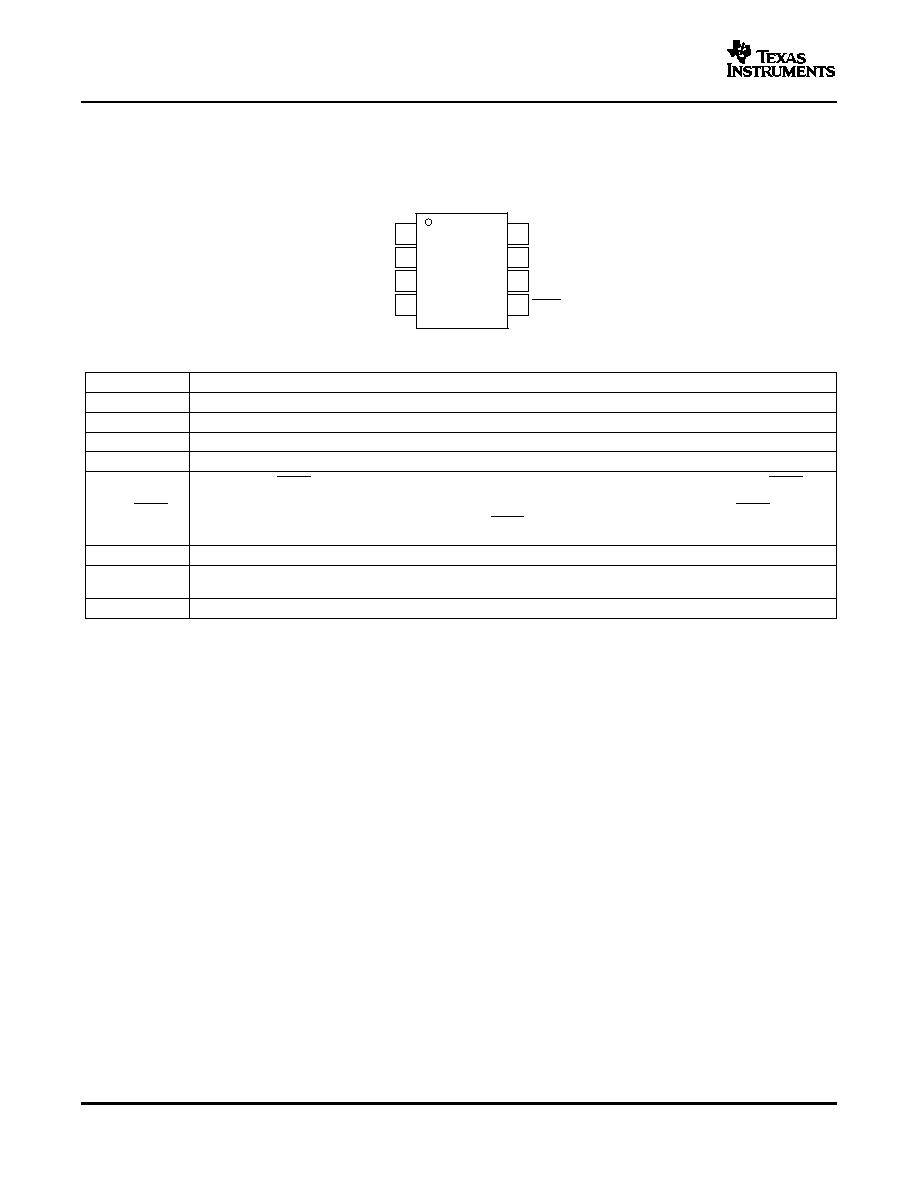

PIN CONFIGURATION

V

DD

V

REF

V

OUT

B

V

OUT

A

GND

D

IN

SCLK

SYNC

1

2

3

4

8

7

6

5

DAC8552

DAC8552

SLAS430 ≠ JULY 2006

DGK PACKAGE

MSOP-8

(Top View)

PIN DESCRIPTIONS

PIN

NAME

FUNCTION

1

V

DD

Power supply input, 2.7V to 5.5V

2

V

REF

Reference voltage input

3

V

OUT

B

Analog output voltage from DAC B

4

V

OUT

A

Analog output voltage from DAC A

Level triggered SYNC input (active LOW). This is the frame synchronization signal for the input data. When SYNC goes

LOW, it enables the input shift register and data is transferred on the falling edges of SCLK. The action specified by the

5

SYNC

8-bit control byte and 16-bit data word is executed following the 24th falling SCLK clock edge (unless SYNC is taken

HIGH before this edge in which case the rising edge of SYNC acts as an interrupt and the write sequence is ignored by

the DAC8552). Schmitt-Trigger logic input.

6

SCLK

Serial Clock Input. Data can be transferred at rates up to 30MHz at 5V. Schmitt-Trigger logic input.

Serial Data Input. Data is clocked into the 24-bit input shift register on the falling edge of the serial clock input.

7

D

IN

Schmitt-Trigger logic input.

8

GND

Ground reference point for all circuitry on the part.

4

Submit Documentation Feedback

www.ti.com

SERIAL WRITE OPERATION

SCLK

1

24

SYNC

D

IN

DB23

DB0

DB23

t

8

t

6

t

3

t

2

t

1

t

7

t

9

t

5

t

4

TIMING CHARACTERISTICS

(1) (2)

DAC8552

SLAS430 ≠ JULY 2006

V

DD

= 2.7V to 5.5V, all specifications ≠40

∞

C to +105

∞

C (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

V

DD

= 2.7V to 3.6V

50

t

1

(3)

SCLK cycle time

ns

V

DD

= 3.6V to 5.5V

33

V

DD

= 2.7V to 3.6V

13

t

2

SCLK HIGH time

ns

V

DD

= 3.6V to 5.5V

13

V

DD

= 2.7V to 3.6V

22.5

t

3

SCLK LOW time

ns

V

DD

= 3.6V to 5.5V

13

V

DD

= 2.7V to 3.6V

0

t

4

SYNC to SCLK rising edge setup time

ns

V

DD

= 3.6V to 5.5V

0

V

DD

= 2.7V to 3.6V

5

t

5

Data setup time

ns

V

DD

= 3.6V to 5.5V

5

V

DD

= 2.7V to 3.6V

4.5

t

6

Data hold time

ns

V

DD

= 3.6V to 5.5V

4.5

V

DD

= 2.7V to 3.6V

0

t

7

24th SCLK falling edge to SYNC rising edge

ns

V

DD

= 3.6V to 5.5V

0

V

DD

= 2.7V to 3.6V

50

t

8

Minimum SYNC HIGH time

ns

V

DD

= 3.6V to 5.5V

33

t

9

24th SCLK falling edge to SYNC falling edge

V

DD

= 2.7V to 5.5V

100

ns

(1)

All input signals are specified with t

R

= t

F

= 5ns (10% to 90% of V

DD

) and timed from a voltage level of (V

IL

+ V

IH

)/2.

(2)

See Serial Write Operation timing diagram.

(3)

Maximum SCLK frequency is 30MHz at V

DD

= 3.6V to 5.5V and 20MHz at V

DD

= 2.7V to 3.6V.

5

Submit Documentation Feedback

www.ti.com

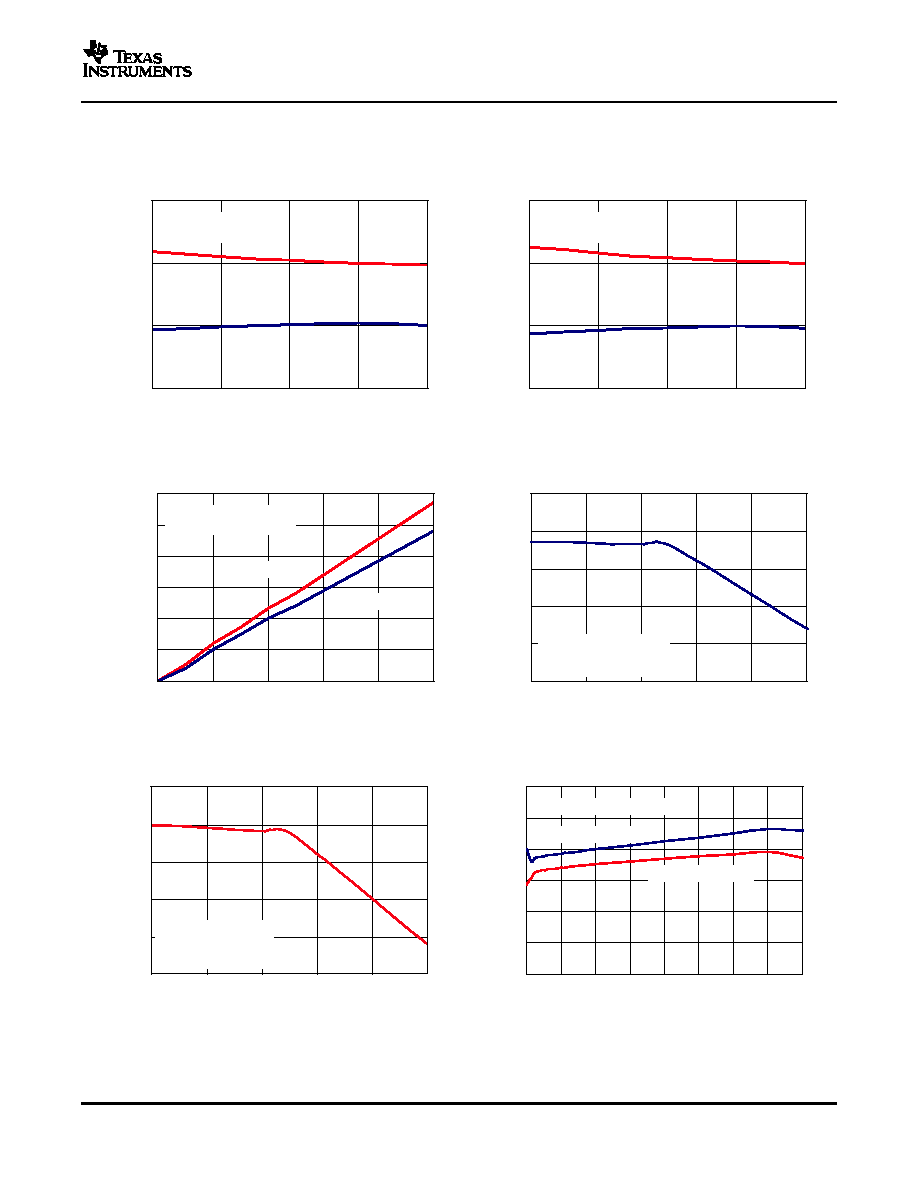

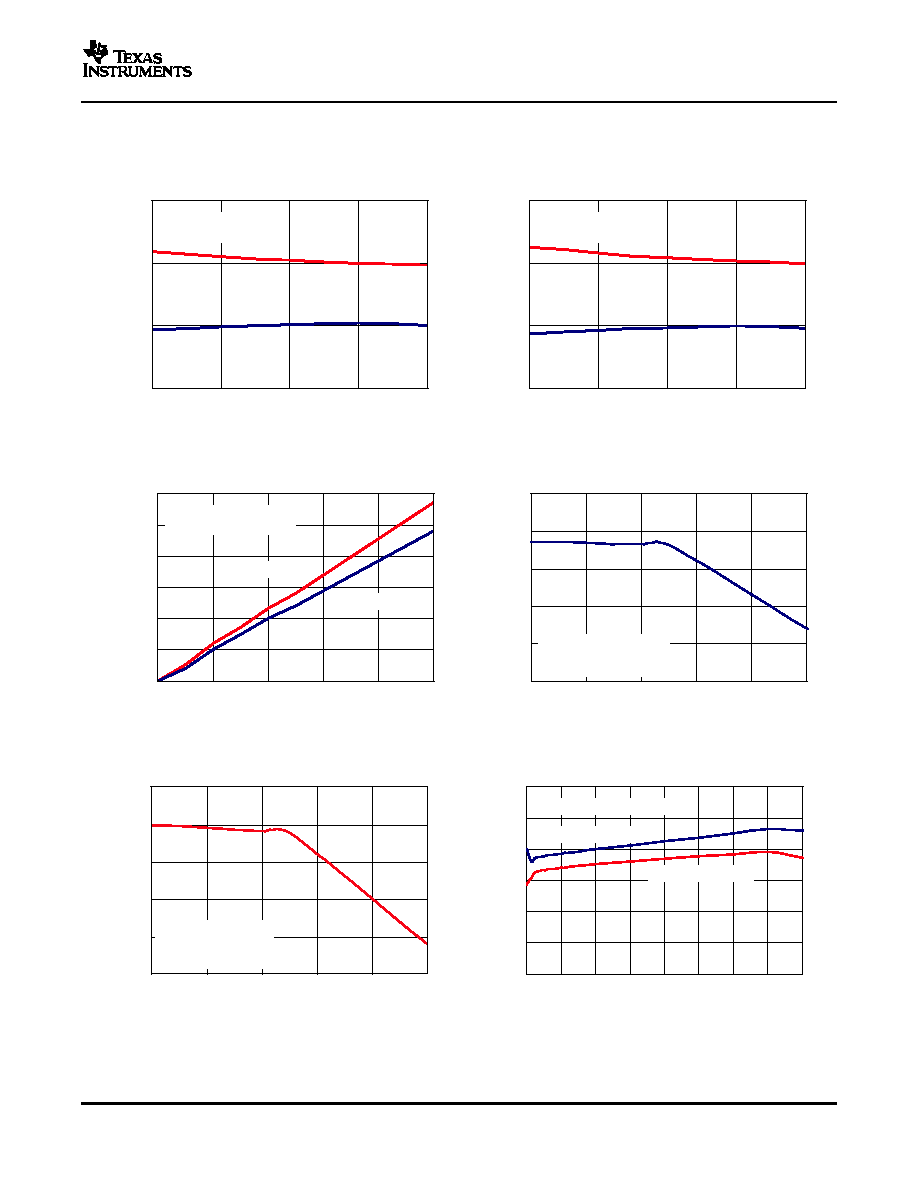

TYPICAL CHARACTERISTICS

8

6

4

2

0

-2

-4

-6

-8

LE(LSB)

0

8192

16384 24576 32768

Digital Input Code

40960 49152

57344 65536

1.0

0.5

0

-0.5

-1.0

DLE(LSB)

V

= 5V, V

= 4.9V, T = +25∞C

DD

REF

A

Channel A Output

8

6

4

2

0

-2

-4

-6

-8

LE(LSB)

0

8192

16384 24576 32768

Digital Input Code

40960 49152

57344 65536

1.0

0.5

0

-0.5

-1.0

DLE(LSB)

V

= 5V, V

= 4.9V, T = +25∞C

DD

REF

A

Channel B Output

8

6

4

2

0

-2

-4

-6

-8

LE(LSB)

0

8192

16384 24576 32768

Digital Input Code

40960 49152

57344 65536

1.0

0.5

0

-0.5

-1.0

DLE(LSB)

V

= 2.7V, V

= 2.5V, T = +25∞C

DD

REF

A

Channel A Output

8

6

4

2

0

-2

-4

-6

-8

LE(LSB)

0

8192

16384 24576 32768

Digital Input Code

40960 49152

57344 65536

1.0

0.5

0

-0.5

-1.0

DLE(LSB)

V

= 2.7V, V

= 2.5V, T = +25 C

∞

DD

REF

A

Channel B Output

T

A

- Free-Air Temperature -

∞

C

-7.5

-5.0

-2.5

0.0

2.5

5.0

7.5

-40

0

40

80

120

V

DD

= 5V

V

REF

= 4.99V

Zero-Scale Error - mV

CH B

CH A

T

A

- Free-Air Temperature -

∞

C

-7.5

-5.0

-2.5

0.0

2.5

5.0

7.5

-40

0

40

80

120

V

DD

= 2.7V

V

REF

= 2.69V

Zero-Scale Error - mV

CH B

CH A

DAC8552

SLAS430 ≠ JULY 2006

At T

A

= +25

∞

C, unless otherwise noted.

LINEARITY ERROR AND

LINEARITY ERROR AND

DIFFERENTIAL LINEARITY ERROR vs CODE

DIFFERENTIAL LINEARITY ERROR vs CODE

Figure 1.

Figure 2.

LINEARITY ERROR AND

LINEARITY ERROR AND

DIFFERENTIAL LINEARITY ERROR vs CODE

DIFFERENTIAL LINEARITY ERROR vs CODE

Figure 3.

Figure 4.

ZERO-SCALE ERROR vs TEMPERATURE

ZERO-SCALE ERROR vs TEMPERATURE

Figure 5.

Figure 6.

6

Submit Documentation Feedback

www.ti.com

T

A

- Free-Air Temperature -

∞

C

-10

-5

0

5

-40

0

40

80

120

V

DD

= 5V

V

REF

= 4.99V

Full-Scale Error - mV

CH B

CH A

T

A

- Free-Air Temperature -

∞

C

-10

-5

0

5

-40

0

40

80

120

V

DD

= 2.7V

V

REF

= 2.69V

Full-Scale Error - mV

CH B

CH A

I

SINK

- Sink Current - mA

0.000

0.025

0.050

0.075

0.100

0.125

0.150

0

2

4

6

8

10

V

REF

= V

DD

- 10mV

DAC loaded with 0000

H

V

O

- Output V

oltage - V

V

DD

= 2.7V

V

DD

= 5.5V

I

SOURCE

- Source Current - mA

4.0

4.4

4.8

5.2

5.6

6.0

0

2

4

6

8

10

V

REF

= V

DD

- 10mV

DAC loaded with FFFF

H

V

DD

= 5.5V

V

O

- Output V

oltage - V

I

Source Current

mA

SOURCE

-

-

1.5

1.8

2.1

2.4

2.7

3.0

0

2

4

6

8

10

V

OutputV

oltage

V

O

-

-

V

= 2.7 V

V

= V

10mV

DAC loaded with FFFF

DD

REF

DD

H

-

Digital Input Code

0

100

200

300

400

500

600

0

8192 16384 24576 32768 40960 49152 57344 65536

Reference Current Included

I

D

D

- Supply Current -

µ

A

V

DD

= V

REF

= 3.6V

V

DD

= V

REF

= 5.5V

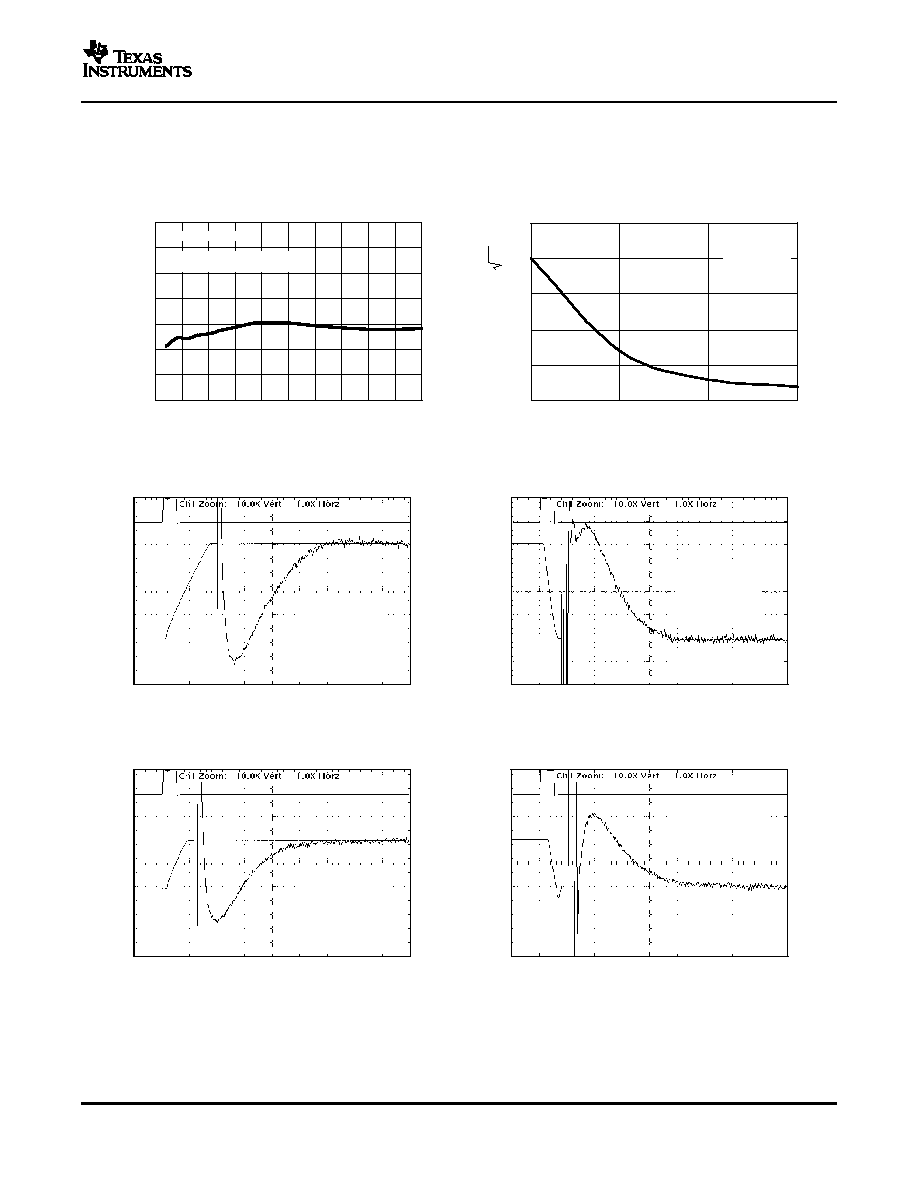

DAC8552

SLAS430 ≠ JULY 2006

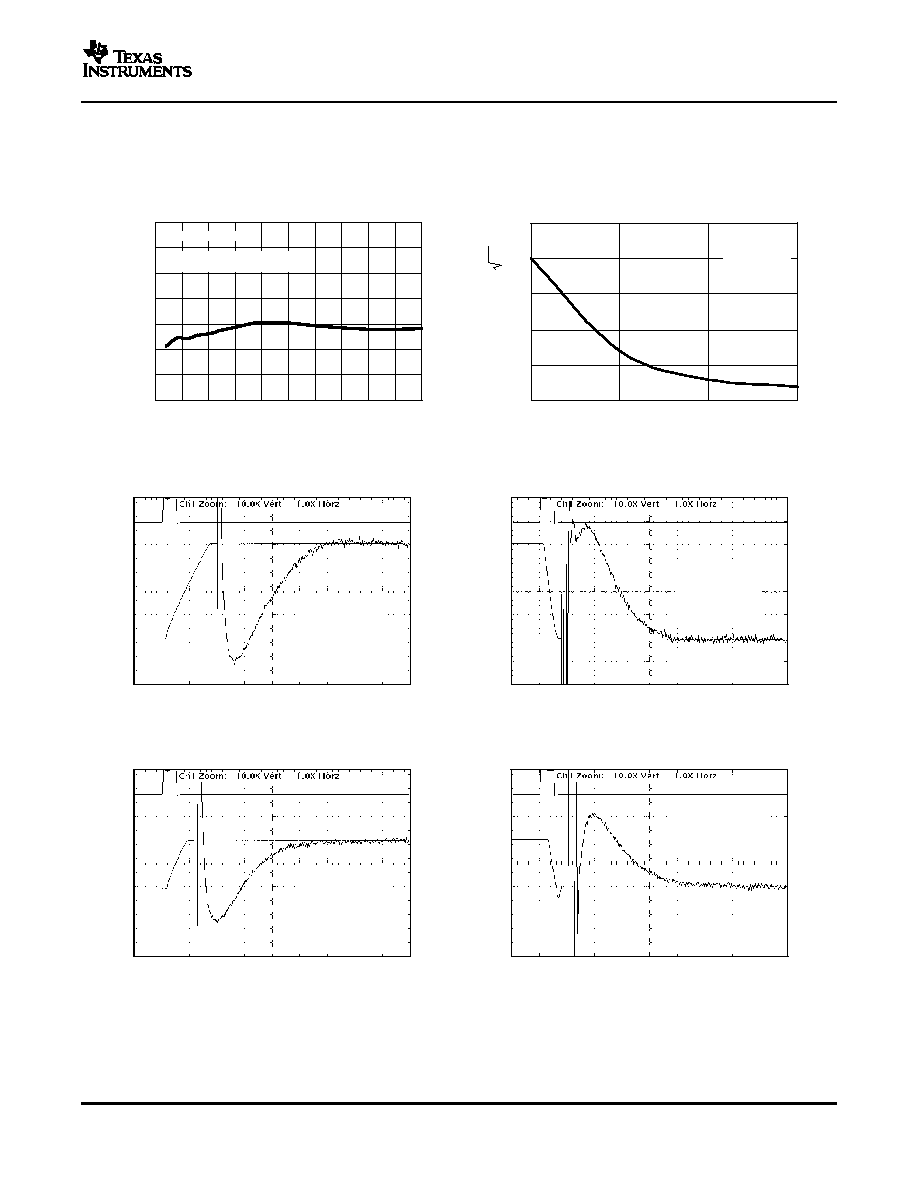

TYPICAL CHARACTERISTICS (continued)

At T

A

= +25

∞

C, unless otherwise noted.

FULL-SCALE ERROR vs TEMPERATURE

FULL-SCALE ERROR vs TEMPERATURE

Figure 7.

Figure 8.

SINK CURRENT CAPABILTY AT NEGATIVE RAIL

SOURCE CURRENT CAPABILITY AT POSITIVE RAIL

Figure 9.

Figure 10.

SOURCE CURRENT CAPABILITY AT POSITIVE RAIL

SUPPLY CURRENT vs DIGITAL INPUT CODE

Figure 11.

Figure 12.

7

Submit Documentation Feedback

www.ti.com

V

DD

- Supply Voltage - V

200

250

300

350

400

450

500

550

600

2.70

3.05

3.40

3.75

4.10

4.45

4.80

5.15

5.50

I

D

D

- Supply Current -

µ

A

V

REF

= V

DD

, All DAC's Powered,

Reference Current Included, No Load

T

A

- Free-Air Temperature -

∞

C

0

100

200

300

400

500

600

-40

0

40

80

120

I

D

D

- Supply Current -

µ

A

Reference Current Included

V

DD

= V

REF

= 3.6V

V

DD

= V

REF

= 5.5V

V

LOGIC

- Logic Input Voltage - V

0

100

200

300

400

500

600

700

800

0.0

0.5

1.0

1.5

2.0

2.5

I

D

D

- Supply Current -

µ

A

T

A

= 25

∞

C, SYNC Input (All other inputs = GND)

CH A powered up; All other channels in powerdown

V

DD

= V

REF

= 2.7V

V

LOGIC

- Logic Input Voltage - V

0

400

800

1200

1600

2000

2400

0.0

1.0

2.0

3.0

4.0

5.0

I

D

D

- Supply Current -

µ

A

T

A

= 25

∞

C, SYNC Input (All other inputs = GND)

CH A powered up; All other channels in powerdown

V

DD

= V

REF

= 5.5V

-100

-90

-80

-70

-60

-50

-40

0

1

2

3

4

5

THD - T

otal Harmonic Distortion - dB

Output Tone - kHz

THD

2nd Harmonic

3rd Harmonic

-1dB FSR Digital Input, f

S

= 1MSPS

Measurement Bandwidth = 20kHz

V

DD

= 5V, V

REF

= 4.9V

-130

-110

-90

-70

-50

-30

-10

0

5000

10000

15000

20000

V

DD

= 5V, V

REF

= 4.096V

f

OUT

= 1kHz

f

CLK

= 1MSPS

f - Frequency - Hz

Gain - dB

DAC8552

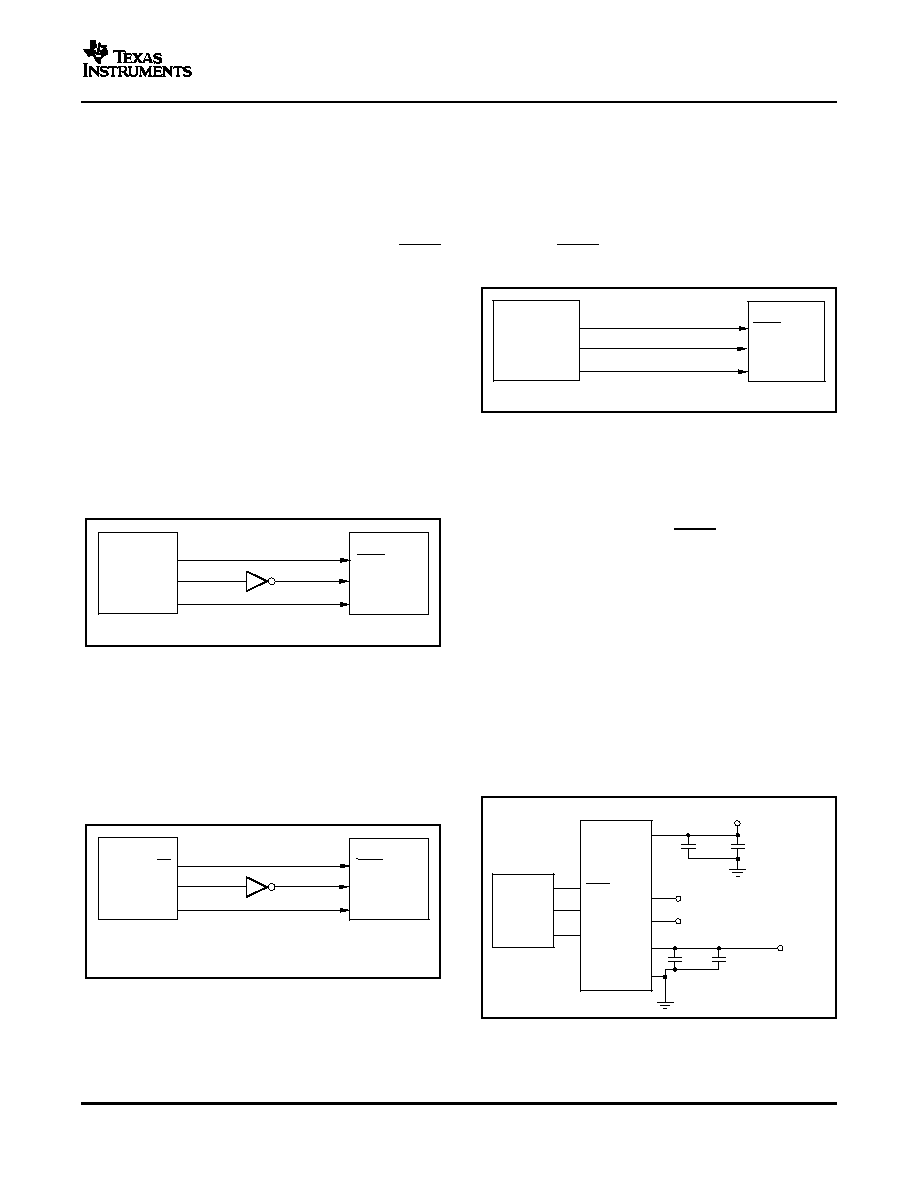

SLAS430 ≠ JULY 2006

TYPICAL CHARACTERISTICS (continued)

At T

A

= +25

∞

C, unless otherwise noted.

SUPPLY CURRENT vs SUPPLY VOLTAGE

SUPPLY CURRENT vs TEMPERATURE

Figure 13.

Figure 14.

SUPPLY CURRENT vs LOGIC INPUT VOLTAGE

SUPPLY CURRENT vs LOGIC INPUT VOLTAGE

Figure 15.

Figure 16.

TOTAL HARMONIC DISTORTION

vs

POWER SPECTRAL DENSITY

OUTPUT FREQUENCY

Figure 17.

Figure 18.

8

Submit Documentation Feedback

www.ti.com

84

86

88

90

92

94

96

98

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

SNR - Signal-to-Noise Ratio - dB

f - Output Frequency - kHz

V

DD

= V

REF

= 5V

-1dB FSR Digital Input, f

S

= 1MSPS

Measurement Bandwidth = 20kHz

100

150

200

250

300

350

100

1000

10000

100000

V

DD

= 5 V

V

REF

= 4.096

Code = 7FFF

No Load

nV/

Hz

- V

oltage Noise -

V

n

f - Frequency - Hz

Time (2 s/div)

m

V

= 5V

V

= 4.096V

From Code: D000

To Code: FFFF

DD

REF

Trigger Pulse 5V/div

Zoomed Rising Edge

1mV/div

Rising Edge

1V/div

Time (2 s/div)

m

V

= 5V

V

= 4.096V

From Code: FFFF

To Code: 0000

DD

REF

Trigger Pulse 5V/div

Zoomed Falling Edge

1mV/div

Falling

Edge

1V/div

Time (2 s/div)

m

V

= 5V

V

= 4.096V

From Code: 4000

To Code: CFFF

DD

REF

Trigger Pulse 5V/div

Zoomed Rising Edge

1mV/div

Rising

Edge

1V/div

Time (2 s/div)

m

V

= 5V

V

= 4.096V

From Code: CFFF

To Code: 4000

DD

REF

Trigger Pulse 5V/div

Zoomed Falling Edge

1mV/div

Falling

Edge

1V/div

DAC8552

SLAS430 ≠ JULY 2006

TYPICAL CHARACTERISTICS (continued)

At T

A

= +25

∞

C, unless otherwise noted.

SIGNAL-TO-NOISE RATIO

vs

OUTPUT FREQUENCY

OUTPUT NOISE DENSITY

Figure 19.

Figure 20.

FULL-SCALE SETTLING TIME: 5V RISING EDGE

FULL-SCALE SETTLING TIME: 5V FALLING EDGE

Figure 21.

Figure 22.

HALF-SCALE SETTLING TIME: 5V RISING EDGE

HALF-SCALE SETTLING TIME: 5V FALLING EDGE

Figure 23.

Figure 24.

9

Submit Documentation Feedback

www.ti.com

Time (2 s/div)

m

V

= 2.7V

V

= 2.5V

From Code: 0000

To Code: FFFF

DD

REF

Trigger Pulse 2.7V/div

Zoomed Rising Edge

1mV/div

Rising

Edge

0.5V/div

Time (2 s/div)

m

V

= 2.7V

V

= 2.5V

From Code: FFFF

To Code: 0000

DD

REF

Trigger Pulse 2.7V/div

Zoomed Falling Edge

1mV/div

Falling

Edge

0.5V/div

Time (2 s/div)

m

V

= 2.7V

V

= 2.5V

From Code: 4000

To Code: CFFF

DD

REF

Trigger Pulse 2.7V/div

Zoomed Rising Edge

1mV/div

Rising

Edge

0.5V/div

Time (2 s/div)

m

V

= 2.7V

V

= 2.5V

From Code: CFFF

To Code: 4000

DD

REF

Trigger Pulse 2.7V/div

Zoomed Falling Edge

1mV/div

Falling

Edge

0.5V/div

Time (400ns/div)

V

= 5V

V

= 4.096V

From Code: 7FFF

To Code: 8000

Glitch: 0.08nV-s

DD

REF

V

(500

V/div)

m

O

U

T

Time (400ns/div)

V

= 5V

V

= 4.096V

From Code: 8000

To Code: 7FFF

Glitch: 0.16nV-s

Measured Worst Case

DD

REF

V

(500

V/div)

m

O

U

T

DAC8552

SLAS430 ≠ JULY 2006

TYPICAL CHARACTERISTICS (continued)

At T

A

= +25

∞

C, unless otherwise noted.

FULL-SCALE SETTLING TIME: 2.7V RISING EDGE

FULL-SCALE SETTLING TIME: 2.7V FALLING EDGE

Figure 25.

Figure 26.

HALF-SCALE SETTLING TIME: 2.7V RISING EDGE

HALF-SCALE SETTLING TIME: 2.7V FALLING EDGE

Figure 27.

Figure 28.

GLITCH ENERGY: 5V, 1LSB STEP, RISING EDGE

GLITCH ENERGY: 5V, 1LSB STEP, FALLING EDGE

Figure 29.

Figure 30.

10

Submit Documentation Feedback

www.ti.com

Time (400ns/div)

V

= 5V

V

= 4.096V

From Code: 8000

To Code: 8010

Glitch: 0.04nV-s

DD

REF

V

(500

V/div)

m

O

U

T

Time (400ns/div)

V

= 5V

V

= 4.096V

From Code: 8010

To Code: 8000

Glitch: 0.08nV-s

DD

REF

V

(500

V/div)

m

O

U

T

Time (400ns/div)

V

= 5V

V

= 4.096V

From Code: 8000

To Code: 80FF

Glitch: Not Detected

Theoretical Worst Case

DD

REF

V

(5mV/div)

O

U

T

Time (400ns/div)

V

= 5V

V

= 4.096V

From Code: 80FF

To Code: 8000

Glitch: Not Detected

Theoretical Worst Case

DD

REF

V

(5mV/div)

O

U

T

Time (400ns/div)

V

= 2.7V

V

= 2.5V

From Code: 7FFF

To Code: 8000

Glitch: 0.08nV-s

DD

REF

V

(200

V/div)

m

O

U

T

Time (400ns/div)

V

= 2.7V

V

= 2.5V

From Code: 8000

To Code: 7FFF

Glitch: 0.16nV-s

Measured Worst Case

DD

REF

V

(200

V/div)

m

O

U

T

DAC8552

SLAS430 ≠ JULY 2006

TYPICAL CHARACTERISTICS (continued)

At T

A

= +25

∞

C, unless otherwise noted.

GLITCH ENERGY: 5V, 16LSB STEP, RISING EDGE

GLITCH ENERGY: 5V, 16LSB STEP, FALLING EDGE

Figure 31.

Figure 32.

GLITCH ENERGY: 5V, 256LSB STEP, RISING EDGE

GLITCH ENERGY: 5V, 256LSB STEP, FALLING EDGE

Figure 33.

Figure 34.

GLITCH ENERGY: 2.7V, 1LSB STEP, RISING EDGE

GLITCH ENERGY: 2.7V, 1LSB STEP, FALLING EDGE

Figure 35.

Figure 36.

11

Submit Documentation Feedback

www.ti.com

Time (400ns/div)

V

= 2.7V

V

= 2.5V

From Code: 8000

To Code: 8010

Glitch: 0.04nV-s

DD

REF

V

(200

V/div)

m

O

U

T

Time (400ns/div)

V

= 2.7V

V

= 2.5V

From Code: 8010

To Code: 8000

Glitch: 0.12nV-s

DD

REF

V

(200

V/div)

m

O

U

T

Time (400ns/div)

V

= 2.7V

V

= 2.5V

From Code: 8000

To Code: 80FF

Glitch: Not Detected

Theoretical Worst Case

DD

REF

V

(5mV/div)

O

U

T

Time (400ns/div)

V

= 2.7V

V

= 2.5V

From Code: 80FF

To Code: 8000

Glitch: Not Detected

Theoretical Worst Case

DD

REF

V

(5mV/div)

O

U

T

DAC8552

SLAS430 ≠ JULY 2006

TYPICAL CHARACTERISTICS (continued)

At T

A

= +25

∞

C, unless otherwise noted.

GLITCH ENERGY: 2.7V, 16LSB STEP, RISING EDGE

GLITCH ENERGY: 2.7V, 16LSB STEP, FALLING EDGE

Figure 37.

Figure 38.

GLITCH ENERGY: 2.7V, 256LSB STEP, RISING EDGE

GLITCH ENERGY: 2.7V, 256LSB STEP, FALLING EDGE

Figure 39.

Figure 40.

12

Submit Documentation Feedback

www.ti.com

THEORY OF OPERATION

DAC SECTION

62k

GND

DAC Register

REF (+)

Register String

REF (-)

V

OUT

REF

V

50k

50k

V

OUT

A, B

+

V

REF

D

65536

(1)

RESISTOR STRING

To Output

Amplifier

(2x Gain)

R

DIVIDER

R

R

R

R

V

REF

V

REF

2

OUTPUT AMPLIFIER

SERIAL INTERFACE

DAC8552

SLAS430 ≠ JULY 2006

The architecture of each channel of the DAC8552

consists of a resistor-string DAC followed by an

output buffer amplifier.

Figure 41

shows a simplified

block diagram of the DAC architecture.

Figure 41. DAC8552 Architecture

The input coding for each device is unipolar straight

binary, so the ideal output voltage is given by:

where D = decimal equivalent of the binary code that

is loaded to the DAC register; it can range from 0 to

65535. V

OUT

A,B refers to channel A or B.

The resistor string section is shown in

Figure 42

. It is

simply a divide-by-2 resistor followed by a string of

resistors, each of value R. The code loaded into the

Figure 42. Resistor String

DAC register determines at which node on the string

the voltage is tapped off. This voltage is then applied

The write sequence begins by bringing the SYNC

to the output amplifier by closing one of the switches

line LOW. Data from the D

IN

line is clocked into the

connecting the string to the amplifier.

24-bit shift register on each falling edge of SCLK.

The serial clock frequency can be as high as 30MHz,

making the DAC8552 compatible with high speed

DSPs. On the 24th falling edge of the serial clock,

Each output buffer amplifier is capable of generating

the last data bit is clocked into the shift register and

rail-to-rail voltages on its output which approaches

the shift register is locked. Further clocking does not

an output range of 0V to V

DD

(gain and offset errors

change the shift register data. Once 24 bits are

must be taken into account). Each buffer is capable

locked into the shift register, the 8 MSBs are used as

of driving a load of 2k

in parallel with 1000pF to

control bits and the 16 LSBs are used as data. After

GND. The source and sink capabilities of the output

receiving the 24th falling clock edge, the DAC8552

amplifier can be seen in the typical characteristics.

decodes the 8 control bits and 16 data bits to

perform the required function, without waiting for a

SYNC rising edge. A new SPI sequence starts at the

The DAC8552 uses a 3-wire serial interface (SYNC,

next falling edge of SYNC. A rising edge of SYNC

SCLK, and D

IN

), which is compatible with SPITM and

before the 24-bit sequence is complete resets the

QSPTM, and MicrowireTM interface standards, as well

SPI interface; no data transfer occurs.

as most DSPs. See the Serial Write Operation timing

After the 24th falling edge of SCLK is received, the

diagram for an example of a typical write sequence.

SYNC line may be kept LOW or brought HIGH. In

either case, the minimum delay time from the 24th

falling SCLK edge to the next falling SYNC edge

must be met in order to properly begin the next

13

Submit Documentation Feedback

www.ti.com

POWER-ON RESET

INPUT SHIFT REGISTER

POWER-DOWN MODES

V

A,B

OUT

Amplifier

Resistor

String

DAC

Power-Down

Circuitry

Resistor

Network

SYNC INTERRUPT

DAC8552

SLAS430 ≠ JULY 2006

cycle. To assure the lowest power consumption of

the device, care should be taken that the levels are

The DAC8552 contains a power-on reset circuit that

as close to each rail as possible. (See the Typical

controls the output voltage during power-up. On

Characteristics section for the Supply Current vs

power-up, the DAC registers are filled with zeros and

Logic Input Voltage transfer characteristic curve).

the output voltages are set to zero-scale; they

remain there until a valid write sequence and load

command is made to the respective DAC channel.

This is useful in applications where it is important to

The input shift register of the DAC8552 is 24 bits

know the state of the output of each DAC output

wide (see

Figure 45

) and is made up of 8 control bits

while the device is in the process of powering up.

(DB16≠DB23) and 16 data bits (DB0≠DB15). The

first two control bits (DB22 and DB23) are reserved

No device pin should be brought high before power

and must be '0' for proper operation. LDA (DB20)

is applied to the device.

and LD B (DB21) control the updating of each analog

output with the specified 16-bit data value or power-

down command. Bit DB19 is a Don't Care bit, which

does not affect the operation of the DAC8552 and

The DAC8552 utilizes four modes of operation.

can be '1' or '0'. The following control bit, Buffer

These modes are accessed by setting two bits (PD1

Select (DB18), controls the destination of the data

and PD0) in the control Load action to one or both

(or power-down command) between DAC A and

DACs.

Table 1

shows how the state of the bits

DAC B. The final two control bits, PD0 (DB16) and

correspond to the register and performing a mode of

PD1 (DB17), select the power-down mode of one or

operation of each channel of the device. (Each DAC

both of the DAC channels. The four modes are

channel can be powered down simultaneously or

normal mode or any one of three power-down

independently of each other. Power-down occurs

modes.

A

more

complete

description

of

the

after proper data is written into PD0 and PD1 and a

operational modes of the DAC8552 can be found in

Load

command

occurs.)

See

the

Operation

the Power-Down Modes section. The remaining

Examples section for additional information.

sixteen bits of the 24-bit input word make up the data

bits. These are transferred to the specified Data

Table 1. Modes of Operation for the DAC8552

Buffer or DAC Register, depending on the command

PD1 (DB17)

PD0 (DB16)

OPERATING MODE

issued by the control byte, on the 24th falling edge of

0

0

Normal Operation

SCLK.

See

Table

2

and

Table

3

for

more

--

--

Power-down modes

information.

0

1

Output typically 1k

to GND

1

0

Output typically 100k

to GND

1

1

High impedance

When both bits are set to 0, the device works

normally with a typical power consumption of 450

µ

A

at 5V. For the three power-down modes, however,

the supply current falls to 700nA at 5V (400nA at

3V). Not only does the supply current fall but the

output stage is also internally switched from the

output of the amplifier to a resistor network of known

values. This has the advantage that the output

Figure 43. Output Stage During Power-Down

impedance of the device is known while it is in

(High Impedance)

power-down mode. There are three different options

for power-down: The output is connected internally to

GND through a 1k

resistor, a 100k

resistor, or it is

left open-circuited (High-Impedance). The output

In a normal write sequence, the SYNC line is kept

stage is illustrated in

Figure 43

.

LOW for at least 24 falling edges of SCLK and the

addressed DAC register is updated on the 24th

All

analog

circuitry

is

shut

down

when

the

falling edge. However, if SYNC is brought HIGH

power-down mode is activated. Each DAC will exit

before the 24th falling edge, it acts as an interrupt to

power-down when PD0 and PD1 are set to 0, new

the write sequence; the shift register is reset and the

data is written to the Data Buffer, and the DAC

write sequence is discarded. Neither an update of

channel receives a Load command. The time to exit

the data buffer contents, DAC register contents or a

power-down is typically 2.5

µ

s for V

DD

= 5V and 5

µ

s

change

in

the

operating

mode

occurs

(see

for V

DD

= 3V (see the Typical Characteristics).

Figure 44

).

14

Submit Documentation Feedback

www.ti.com

SCLK

SYNC

D

IN

Invalid Write - Sync Interrupt:

SYNC HIGH before 24th Falling Edge

Valid Write - Buffer/DAC Update:

SYNC HIGH after 24th Falling Edge

DB23 DB22

DB0

DB23 DB22

DB1 DB0

24th

Falling

Edge

24th

Falling

Edge

1

2

1

2

DAC8552

SLAS430 ≠ JULY 2006

Figure 44. Interrupt and Valid SYNC Timing

DB23

DB12

0

0

LDB

LDA

X

Buffer Select

PD1

PD0

D15

D14

D13

D12

DB11

DB0

D11

D10

D9

D8

D7

D6

D5

D5

D3

D2

D1

D0

Figure 45. DAC8552 Data Input Register Format

Table 2. Control Matrix

D23

D22

D21

D20

D19

D18

D17

D16

D15

D14

D13≠D0

Don't

Buffer

MSB-2...

Reserved

Reserved

Load B

Load A

PD1

PD0

MSB

MSB-1

Care

Select

LSB

DESCRIPTION

0 = A,

(Always Write 0)

1 = B

0

0

0

0

X

#

0

0

Data

WR Buffer # w/Data

0

0

0

0

X

#

See

Table 3

X

WR Buffer # w/Power-down Command

0

0

0

1

X

#

0

0

Data

WR Buffer # w/Data and Load DAC A

0

0

0

1

X

0

See

Table 3

X

WR Buffer A w/Power-Down Command and LOAD DAC A

(DAC A Powered Down)

0

0

0

1

X

1

See

Table 3

X

WR Buffer B w/Power-Down Command and LOAD DAC A

0

0

1

0

X

#

0

0

Data

WR Buffer # w/Data and Load DAC B

0

0

1

0

X

0

See

Table 3

X

WR Buffer A w/Power-Down Command and LOAD DAC B

0

0

1

0

X

1

See

Table 3

X

WR Buffer B w/Power-Down Command and LOAD DAC B

(DAC B Powered Down)

0

0

1

1

X

#

0

0

Data

WR Buffer # w/Data and Load DACs A and B

0

0

1

1

X

0

See

Table 3

X

WR Buffer A w/Power-Down Command and Load DACs A and

B (DAC A Powered Down)

0

0

1

1

X

1

See

Table 3

X

WR Buffer B w/Power-Down Command and Load DACs A and

B (DAC B Powered Down)

Table 3. Power-Down Commands

D17

D16

OUTPUT IMPEDANCE POWER DOWN COMMANDS

PD1

PD0

0

1

1k

1

0

100k

1

1

High Impedance

15

Submit Documentation Feedback

www.ti.com

OPERATION EXAMPLES

DAC8552

SLAS430 ≠ JULY 2006

Example 1: Write to Data Buffer A; Through Buffer B; Load DACA Through DACB Simultaneously

∑

1st -- Write to DataBuffer A:

Reserved

Reserved

LDB

LDA

DC

Buffer Select

PD1

PD0

DB15

--

DB1

DB0

0

0

0

0

X

0

0

0

D15

--

D1

D0

∑

2nd -- Write to Data Buffer B and Load DAC A and DAC B simultaneously:

Reserved

Reserved

LDB

LDA

DC

Buffer Select

PD1

PD0

DB15

--

DB1

DB0

0

0

1

1

X

1

0

0

D15

--

D1

D0

The DACA and DACB analog outputs simultaneously settle to the specified values upon completion of the 2nd

write sequence. (The Load command moves the digital data from the data buffer to the DAC register at which

time the conversion takes place and the analog output is updated. Completion occurs on the 24th falling SCLK

edge after SYNC LOW.)

Example 2: Load New Data to DACA and DACB Sequentially

∑

1st -- Write to Data Buffer A and Load DAC A: DACA output settles to specified value upon completion:

Reserved

Reserved

LDB

LDA

DC

Buffer Select

PD1

PD0

DB15

--

DB1

DB0

0

0

0

1

X

0

0

0

D15

--

D1

D0

∑

2nd -- Write to Data Buffer B and Load DAC B: DACB output settles to specified value upon completion:

Reserved

Reserved

LDB

LDA

DC

Buffer Select

PD1

PD0

DB15

--

DB1

DB0

0

0

1

0

X

1

0

0

D15

--

D1

D0

After completion of the 1st write cycle, the DACA analog output settles to the voltage specified; upon completion

of write cycle 2, the DACB analog output settles.

Example 3: Power-Down DACA to 1k

and Power-Down DACB to 100k

Simultaneously

∑

1st -- Write power-down command to Data Buffer A:

Reserved

Reserved

LDB

LDA

DC

Buffer Select

PD1

PD0

DB15

--

DB1

DB0

0

0

0

0

X

0

0

1

Don't Care

∑

2nd -- Write power-down command to Data Buffer B and Load DACA and DACB simultaneously:

Reserved

Reserved

LDB

LDA

DC

Buffer Select

PD1

PD0

DB15

--

DB1

DB0

0

0

1

1

X

1

1

0

Don't Care

The DACA and DACB analog outputs simultaneously power-down to each respective specified mode upon

completion of the 2nd write sequence.

Example 4: Power-Down DACA and DACB to High-Impedance Sequentially:

∑

1st -- Write power-down command to Data Buffer A and Load DAC A: DAC A output = Hi-Z:

Reserved

Reserved

LDB

LDA

DC

Buffer Select

PD1

PD0

DB15

--

DB1

DB0

0

0

0

1

X

0

1

1

Don't Care

∑

2nd -- Write power-down command to Data Buffer B and Load DAC B: DAC B output = Hi-Z:

Reserved

Reserved

LDB

LDA

DC

Buffer Select

PD1

PD0

DB15

--

DB1

DB0

0

0

1

0

X

1

1

1

Don't Care

The DACA and DACB analog outputs sequentially power-down to high-impedance upon completion of the 1st

and 2nd write sequences, respectively.

16

Submit Documentation Feedback

www.ti.com

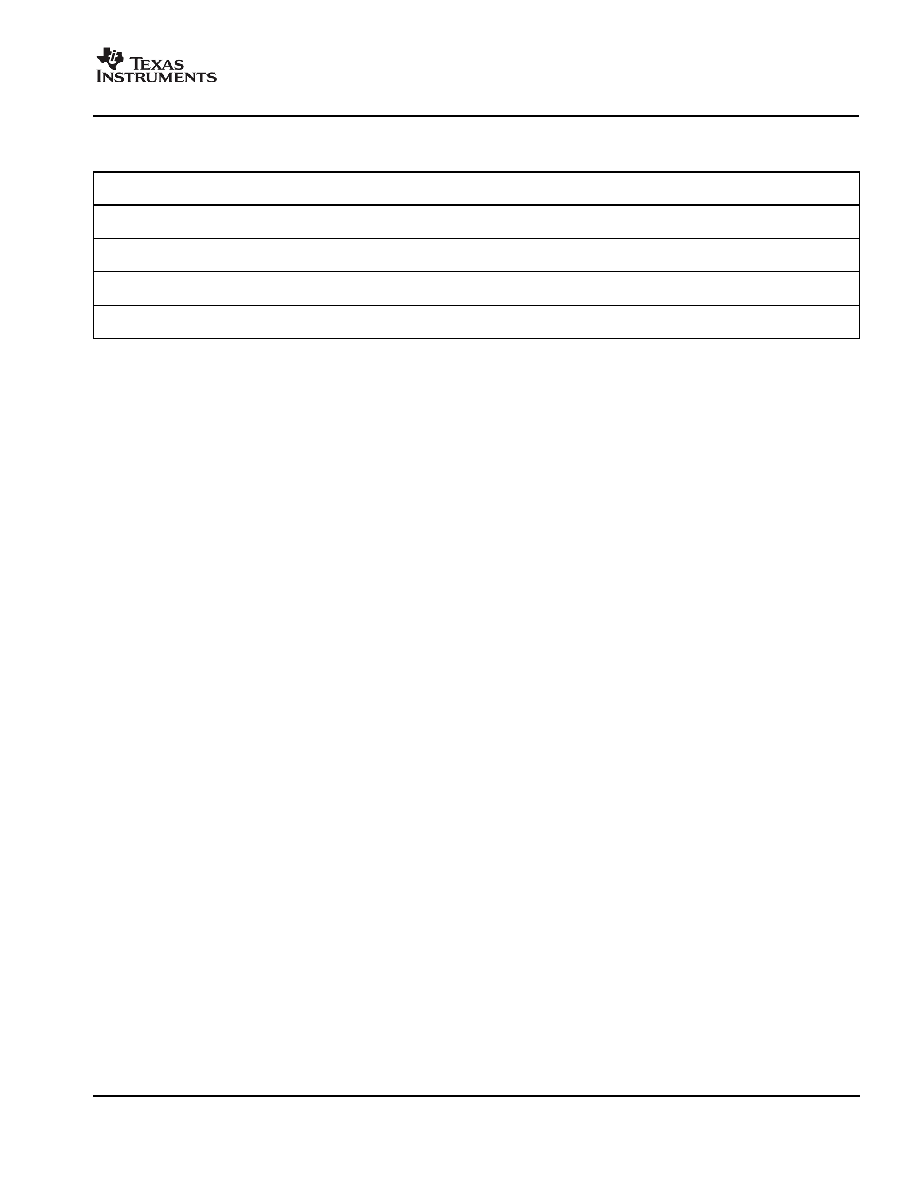

MICROPROCESSOR INTERFACING

DAC8552 to 8051 INTERFACE

DAC8552 to 68HC11 INTERFACE

68HC11

(1)

PC7

SCK

MOSI

SYNC

SCLK

D

IN

(1)

DAC8552

(1)Additional pins omitted for clarity.

80C51/80L51

(1)

P3.3

TXD

RXD

(1)

SYNC

SCLK

D

IN

(1)Additional pins omitted for clarity.

DAC8552

DAC8552 to TMS320 DSP INTERFACE

DAC8552 to Microwire INTERFACE

SYNC

SCLK

D

IN

Microwire

TM

CS

SK

SO

(1)

(1) Additional pins omitted for clarity.

Microwire is a registered trademark of National Semiconductor.

DAC8552

TMS320 DSP

SYNC

D

IN

SCLK

FSX

DX

CLKX

V

DD

V

OUT

A

V

OUT

B

Output A

Output B

Reference

Input

V

REF

GND

0.1

µ

F

1

µ

F to 10

µ

F

Positive Supply

0.1

µ

F

10

µ

F

DAC8552

DAC8552

SLAS430 ≠ JULY 2006

Figure 46

shows a serial interface between the

Figure 48

shows a serial interface between the

DAC8552 and a typical 8051-type microcontroller.

DAC8552 and the 68HC11 microcontroller. SCK of

The setup for the interface is as follows: TXD of the

the 68HC11 drives the SCLK of the DAC8552, while

8051 drives SCLK of the DAC8552, while RXD

the MOSI output drives the serial data line of the

drives the serial data line of the device. The SYNC

DAC. The SYNC signal is derived from a port line

signal is derived from a bit-programmable pin on the

(PC7), similar to the 8051 diagram.

port of the 8051. In this case, port line P3.3 is used.

When data is to be transmitted to the DAC8552,

P3.3 is taken LOW. The 8051 transmits data in 8-bit

bytes; thus only eight falling clock edges occur in the

transmit cycle. To load data to the DAC, P3.3 is left

LOW after the first eight bits are transmitted, then a

second and third write cycle is initiated to transmit

the remaining data. P3.3 is taken HIGH following the

completion of the third write cycle. The 8051 outputs

Figure 48. DAC8552 to 68HC11 Interface

the serial data in a format which presents the LSB

first, while the DAC8552 requires its data with the

MSB as the first bit received. The 8051 transmit

The 68HC11 should be configured so that its CPOL

routine must therefore take this into account, and

bit is 0 and its CPHA bit is 1. This configuration

mirror the data as needed

causes data appearing on the MOSI output to be

valid on the falling edge of SCK. When data is being

transmitted to the DAC, the SYNC line is held LOW

(PC7). Serial data from the 68HC11 is transmitted in

8-bit bytes with only eight falling clock edges

occurring in the transmit cycle. (Data is transmitted

MSB first.) In order to load data to the DAC8552,

PC7 is left LOW after the first eight bits are

transferred, then a second and third serial write

operation is performed to the DAC. PC7 is taken

Figure 46. DAC8552 to 80C51/80L51 Interface

HIGH at the end of this procedure.

Figure 49

shows the connections between the

Figure 47

shows an interface between the DAC8552

DAC8552 and a TMS320 digital signal processor. By

and any Microwire compatible device. Serial data is

decoding the FSX signal, multiple DAC8552s can be

shifted out on the falling edge of the serial clock and

connected to a single serial port of the DSP.

is clocked into the DAC8552 on the rising edge of

the SK signal.

Figure 47. DAC8552 to Microwire Interface

Figure 49. DAC8552 to TMS320 DSP

17

Submit Documentation Feedback

www.ti.com

APPLICATION INFORMATION

CURRENT CONSUMPTION

OUTPUT VOLTAGE STABILITY

DRIVING RESISTIVE AND CAPACITIVE

SETTLING TIME AND OUTPUT GLITCH

DIFFERENTIAL AND INTERGRAL

CROSSTALK AND AC PERFORMANCE

USING REF02 AS A POWER SUPPLY FOR

DAC8552

SLAS430 ≠ JULY 2006

The DAC8552 typically consumes 170

µ

A at V

DD

=

The DAC8552 exhibits excellent temperature stability

5 V and 155

µ

A at V

DD

= 2.7V for each active

of 5ppm/

∞

C typical output voltage drift over the

channel, excluding reference current consumption.

specified temperature range of the device. This

Additional current consumption can occur at the

enables the output voltage of each channel to stay

digital inputs if V

IH

<< V

DD

. For most efficient power

within

a

±

25

µ

V

window

for

a

±

1

∞

C

ambient

operation, CMOS logic levels are recommended at

temperature change.

the digital input to the DAC.

Good

power-supply

rejection

ratio

(PSRR)

In power-down mode, typical current consumption is

performance reduces supply noise present on V

DD

700nA. A delay time of 10ms to 20ms after a

from appearing at the outputs. Combined with good

power-down command is issued to the DAC is

DC noise performance and true 16-bit differential

typically sufficient for the power-down current to drop

linearity, the DAC8552 becomes an ideal choice for

below 10

µ

A.

closed-loop control applications.

LOADS

PERFORMANCE

The DAC8552 output stage is capable of driving

The DAC8552 settles to

±

0.003% of its full-scale

loads of up to 1000 pF while remaining stable. Within

range within 10

µ

s, driving a 200pF, 2k

load. For

the offset and gain error margins, the DAC8552 can

good settling performance the outputs should not

operate rail-to-rail when driving a capacitive load.

approach the top and bottom rails. Small signal

Resistive loads of 2k

can be driven by the

settling time is under 1

µ

s, enabling data update rates

DAC8552 while achieving good load regulation.

exceeding 1MSPS for small code changes.

When the outputs of the DAC are driven to the

Many

applications

are

sensitive

to

undesired

positive rail under resistive loading, the PMOS

transient signals such as glitch. The DAC8552 has a

transistor of each Class-AB output stage can enter

proprietary, ultra-low glitch architecture addressing

into the linear region. When this occurs, the added

such

applications.

Code-to-code

glitches

rarely

IR

voltage

drop

deteriorates

the

linearity

exceed 1mV and they last under 0.3

µ

s. Typical glitch

performance of the DAC. This only occurs within

energy is an outstanding 0.15nV-s. Theoretical worst

approximately the top 100mV of the DACs output

cast glitch should occur during a 256LSB step, but it

voltage

characteristic.

Under

resistive

loading

is so low, it cannot be detected.

conditions, good linearity is preserved as long as the

output voltage is at least 100 mV below the VDD

voltage.

NONLINEARITY

The DAC8552 uses precision, thin-film resistors to

achieve monotonicity and good linearity. Typical

The DAC8552 architecture uses separate resistor

linearity error is

±

4LSBs;

±

0.3mV error for a 5V

strings for each DAC channel in order to achieve

range. Differential linearity is typically

±

0.35LSBs,

ultra-low crosstalk performance. DC crosstalk seen

±

27

µ

V error for a consecutive code change.

at one channel during a full-scale change on the

neighboring channel is typically less than 0.5 LSBs.

The AC crosstalk measured (for a full-scale, 1kHz

DAC8552

sine wave output generated at one channel, and

measured at the remaining output channel) is

Due to the extremely low supply current required by

typically under ≠100dB.

the DAC8552, a possible configuration is to use a

REF02 +5V precision voltage reference to supply the

In addition, the DAC8552 can achieve typical AC

required voltage to the DAC8552s supply input as

performance of 96dB signal-to-noise ratio (SNR) and

well as the reference input, as shown in

Figure 50

.

-85dB total harmonic distortion (THD), making the

This is especially useful if the power supply is quite

DAC8552 a solid choice for applications requiring

noisy or if the system supply voltages are at some

high SNR at output frequencies at or below 10kHz.

value other than 5V. The REF02 will output a steady

supply voltage for the DAC8552. If the REF02 is

18

Submit Documentation Feedback

www.ti.com

V

OUT

A, B

+

V

REF

D

65536

R1

)

R2

R1

*

V

REF

R2

R1

V

OUT

A, B

+

10

D

65536

*

5 V

(3)

LAYOUT

REF02

3-Wire

Serial

Interface

+5V

1.34mA

V

DD

, V

REF

V

OUT

= 0V to 5V

SYNC

SCLK

D

IN

+15

DAC8552

BIPOLAR OPERATION USING THE DAC8552

V

DD

, V

REF

V

OUT

A,B

R

1

10k

R

2

10k

+5V

10

µ

F

0.1

µ

F

±

5V

OPA703

DAC8552

-

6V

+6V

NOTE: Other pins omitted for clarity.

DAC8552

SLAS430 ≠ JULY 2006

used, the current it needs to supply to the DAC8552

is 340

µ

A typical and 500

µ

A max for V

DD

= 5V. When

a DAC output is loaded, the REF02 also needs to

where D represents the input code in decimal

supply the current to the load. The typical current

(0≠65535).

required (with a 5k

load on a given DAC output) is:

340

µ

A + (5V/5k

) = 1.34mA

With V

REF

= 5 V, R1 ≠ R2 = 10k

.

This is an output voltage range of

±

5V with 0000

H

corresponding

to

a

≠5V

output

and

FFFF

H

corresponding to a 5V output. Similarly, using V

REF

=

2.5V, a

±

2.5V output voltage range can be achieved.

A precision analog component requires careful

layout,

adequate

bypassing,

and

clean,

well-regulated power supplies.

The DAC8552 offers single-supply operation, and it

will often be used in close proximity with digital logic,

microcontrollers, microprocessors, and digital signal

processors. The more digital logic present in the

design and the higher the switching speed, the more

Figure 50. REF02 as a Power Supply to the

difficult it will be to keep digital noise from appearing

DAC8552

at the output.

Due to the single ground pin of the DAC8552, all

return currents, including digital and analog return

currents for the DAC, must flow through a single

The DAC8552 has been designed for single-supply

point. Ideally, GND would be connected directly to an

operation but a bipolar output range is also possible

analog ground plane. This plane would be separate

using the circuit in

Figure 51

. The circuit shown will

from

the

ground

connection

for

the

digital

give an output voltage range of

±

V

REF

. Rail-to-rail

components until they were connected at the power

operation at the amplifier output is achievable using

entry point of the system.

an amplifier such as the OPA703, see

Figure 51

.

The power applied to V

DD

should be well regulated

and low noise. Switching power supplies and DC/DC

converters will often have high-frequency glitches or

spikes riding on the output voltage. In addition, digital

components can create similar high-frequency spikes

as their internal logic switches states. This noise can

easily couple into the DAC output voltage through

various paths between the power connections and

analog output.

As with the GND connection, V

DD

should be

connected to a positive power-supply plane or trace

that is separate from the connection for digital logic

Figure 51. Bipolar Operation with the DAC8552

until they are connected at the power entry point. In

addition, a 1

µ

F to 10

µ

F capacitor in parallel with a

The output voltage for any input code can be

0.1

µ

F bypass capacitor is strongly recommended. In

calculated as follows:

some

situations,

additional

bypassing

may

be

required, such as a 100

µ

F electrolytic capacitor or

even

a

Pi

filter

made

up

of

inductors

and

capacitors≠all designed to essentially low-pass filter

the supply, removing the high-frequency noise.

19

Submit Documentation Feedback

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish

MSL Peak Temp

(3)

DAC8552IDGKR

ACTIVE

MSOP

DGK

8

2500 Green (RoHS &

no Sb/Br)

CU NIPDAU

Level-1-260C-UNLIM

DAC8552IDGKRG4

ACTIVE

MSOP

DGK

8

2500 Green (RoHS &

no Sb/Br)

CU NIPDAU

Level-1-260C-UNLIM

DAC8552IDGKT

ACTIVE

MSOP

DGK

8

250

Green (RoHS &

no Sb/Br)

CU NIPDAU

Level-1-260C-UNLIM

DAC8552IDGKTG4

ACTIVE

MSOP

DGK

8

250

Green (RoHS &

no Sb/Br)

CU NIPDAU

Level-1-260C-UNLIM

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent

for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

PACKAGE OPTION ADDENDUM

www.ti.com

31-Jul-2006

Addendum-Page 1

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI's terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI's standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty. Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products

Applications

Amplifiers

amplifier.ti.com

Audio

www.ti.com/audio

Data Converters

dataconverter.ti.com

Automotive

www.ti.com/automotive

DSP

dsp.ti.com

Broadband

www.ti.com/broadband

Interface

interface.ti.com

Digital Control

www.ti.com/digitalcontrol

Logic

logic.ti.com

Military

www.ti.com/military

Power Mgmt

power.ti.com

Optical Networking

www.ti.com/opticalnetwork

Microcontrollers

microcontroller.ti.com

Security

www.ti.com/security

Low Power Wireless www.ti.com/lpw

Telephony

www.ti.com/telephony

Video & Imaging

www.ti.com/video

Wireless

www.ti.com/wireless

Mailing Address:

Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright

2006, Texas Instruments Incorporated