| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: MXR2999ML | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

MEMSIC MXR2999GL/ML

Page 1 of 6

2002.08.30.1

Improved

±1 g Dual Axis

Accelerometer with Ratiometric

Outputs

MXR2999GL/ML

FEATURES

Resolution better than 1 milli-g

Dual axis accelerometer fabricated on a monolithic CMOS IC

On chip mixed mode signal processing

No moving parts

50,000 g shock survival rating

17 Hz bandwidth expandable to >160 Hz

3.0V to 5.25V single supply continuous operation

Continuous self test

Independent axis programmability (special order)

Compensated for Sensitivity over temperature

Ultra low initial Zero-g Offset

APPLICATIONS

Automotive ≠ Vehicle Security/Vehicle Stability control/

Headlight Angle Control/Tilt Sensing

Security ≠ Gas Line/Elevator/Fatigue Sensing/Computer Security

Information Appliances ≠ Computer Peripherals/PDA's/Mouse

Smart Pens/Cell Phones

Internal

Oscillator

Sck

(optional)

CLK

Heater

Control

X axis

Y axis

Factory Adjust

Offset & Gain

Low Pass

Filter

Low Pass

Filter

Temperature

Sensor

Voltage

Reference

V

REF

A

OUTX

V

DD

V

DA

Gnd

2-AXIS

SENSOR

A

OUTY

T

OUT

Continous

Self Test

MXR2999GL/ML FUNCTIONAL BLOCK DIAGRAM

Gaming ≠ Joystick/RF Interface/Menu Selection/Tilt Sensing

GPS ≠ Electronic compass tilt correction

Consumer ≠ LCD projectors, pedometers, blood pressure

Monitor, digital cameras

GENERAL DESCRIPTION

The MXR2999GL/ML is a low cost, dual axis

accelerometer fabricated on a standard, submicron CMOS

process. It is a complete sensing system with on-chip

mixed mode signal processing. The MXR2999GL/ML

measures acceleration with a full-scale range of

±1 g and a

sensitivity of 1000mV/g. (The MEMSIC accelerometer

product line extends from

±.5 g to ±200 g with custom

versions available above

±10 g.) It can measure both

dynamic acceleration (e.g. vibration) and static acceleration

(e.g. gravity). The MXR2999GL/ML design is based on

heat convection and requires no solid proof mass. This

eliminates stiction and particle problems associated with

competitive devices and provides shock survival of 50,000

g, leading to significantly lower failure rate and lower loss

due to handling during assembly.

The MXR2999GL/ML provides a ratiometric analog output

that is proportional to 50% of the supply voltage at zero g

acceleration. The typical noise floor is 0.2 mg/ Hz

allowing signals below 1 milli-g to be resolved at 1 Hz

bandwidth. The 3dB rolloff of the device occurs at 17 Hz

but is expandable to >160 Hz (reference Application Note

AN-00MX-003). The MXR2999GL/ML is packaged in a

hermetically sealed LCC surface mount package (5 mm x 5

mm x 2 mm height) and is operational over a -40

∞C

to

105

∞C(ML) and 0∞C to 70∞C(GL) temperature range.

Information furnished by MEMSIC is believed to be accurate and reliable.

However, no responsibility is assumed by MEMSIC for its use, nor for any

infringements of patents or other rights of third parties which may result from

its use. No license is granted by implication or otherwise under any patent or

patent rights of MEMSIC.

MEMSIC, Inc.

800 Turnpike St., Suite 202, North Andover, MA 01845

Tel: 978.738.0900

Fax: 978.738.0196

www.memsic.com

MEMSIC MXR2999GL/ML

Page 2 of 6

2002.08.30.1

MXR2999GL/ML SPECIFICATIONS

(Measurements @ 25

∞C, Acceleration = 0 g unless otherwise noted; V

DD

, V

DA

= 5.0V unless

otherwise specified)

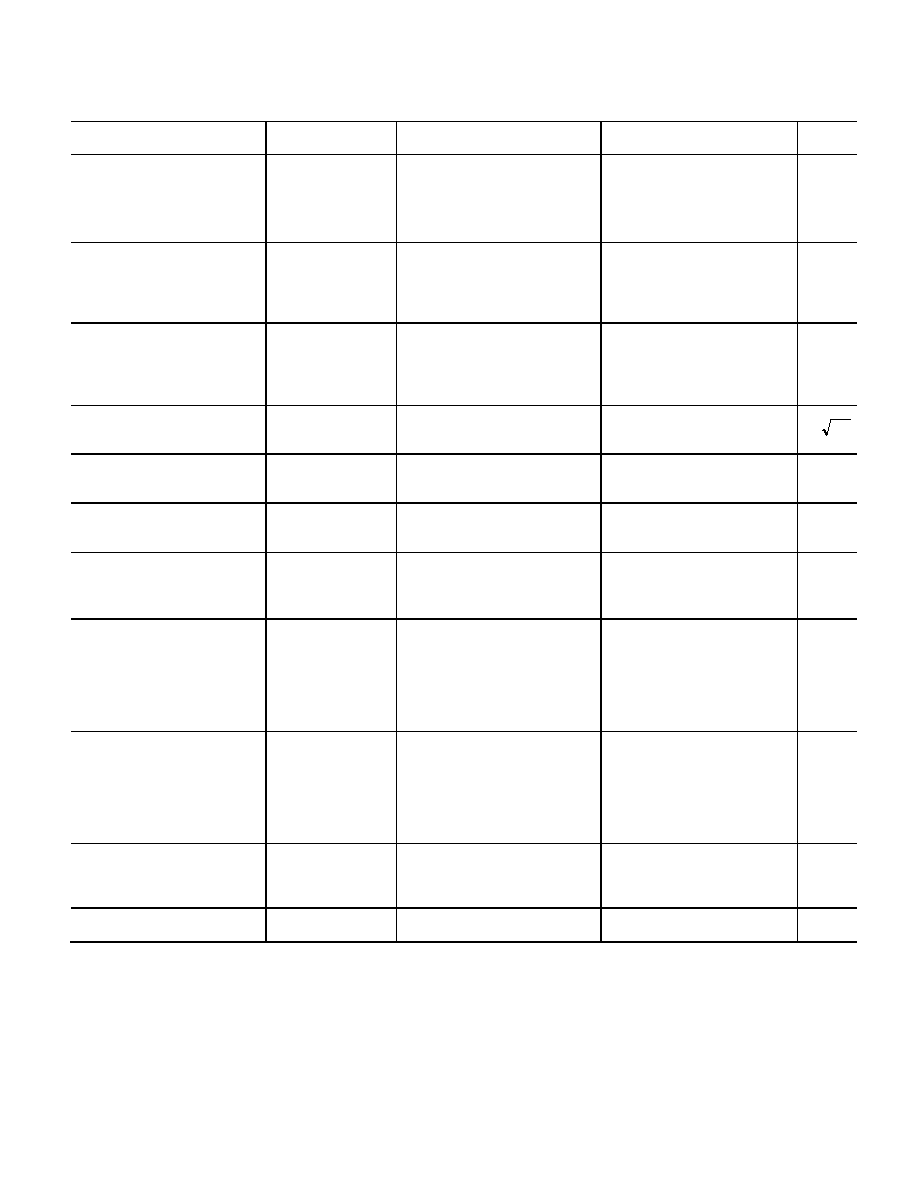

Parameter

Conditions

Min

MXR2999GL

Typ

Max

Min

MXR2999ML

Typ

Max

Units

SENSOR INPUT

Measurement Range

1

Each Axis

±1.0

±1.0

g

Nonlinearity

Best fit straight line

0.5

0.5

% of FS

Alignment Error

2

X Sensor to Y Sensor

±1.0

±1.0

degrees

Transverse Sensitivity

3

±2.0

±2.0

%

SENSITIVITY

Sensitivity, Analog Outputs at

pins

A

OUTX

and A

OUTY

5

Each Axis

950

1000

1050

950

1000

1050

mV/g

Change over Temperature

-10

+8

-25

+8

%

ZERO g BIAS LEVEL

0 g Offset

5

Each Axis

-0.1

0.0

+0.1

-0.1

0.0

+0.1

g

0 g Voltage

5

2.4

2.50

2.6

2.4

2.50

2.6

V

0 g Offset over Temperature

Based on 1000 mV/g

±1.5

±1.5

±1.5

±1.5

mg/

∞C

mV/

∞C

NOISE PERFORMANCE

Noise Density, rms

Without frequency

compensation

0.2

0.4

0.2

0.4

mg/

Hz

FREQUENCY RESPONSE

3dB Bandwidth - uncompensated

12

17

12

17

Hz

3dB Bandwidth ≠ compensated

4

>160

>160

Hz

TEMPERATURE OUTPUT

T

out

Voltage

1.21

1.25

1.29

1.21

1.25

1.29

V

Sensitivity

4.6

5.0

5.4

4.6

5.0

5.4

mV/

∞K

VOLTAGE REFERENCE

V

Ref

@3.0V-5.0V

supply

2.4

2.5 2.65

2.4 2.5 2.65

V

Change over Temperature

0.1

0.1

mV/

∞C

Current Drive Capability

Source

100

100

µA

SELF TEST

Continuous Voltage at A

OUTX

,

A

OUTY

under Failure

@5.0V Supply, output

rails to

supply voltage

5.0

5.0

V

Continuous Voltage at A

OUTX

,

A

OUTY

under Failure

@3.0V Supply, output

rails to

supply voltage

3.0

3.0

V

A

OUTX

and A

OUTY

OUTPUTS

Normal Output Range

@5.0V Supply

@3.0V Supply

0.1

0.1

4.9

2.9

0.1

0.1

4.9

2.9

V

V

Current

Source or sink, @

3.0V-5.0V supply

100

100

µA

Turn-On Time

@5.0V Supply

@3.0V Supply

100

40

100

40

mS

mS

POWER SUPPLY

Operating Voltage Range

3.0

5.25

3.0

5.25

V

Supply Current

@ 5.0V

2.7 3.8 4.4

2.7 3.8

4.4

mA

Supply Current

5

@

3.0V

3.2

4.7

5.4 3.2

4.7 5.4 mA

TEMPERATURE RANGE

Operating Range

0

+70

-40

+105

∞C

NOTES

1

Guaranteed by measurement of initial offset and sensitivity.

2

Alignment error is specified as the angle between the true and indicated axis of

sensitivity.

3

Transverse sensitivity is the algebraic sum of the alignment and the inherent

sensitivity errors.

4

External circuitry is required to extend the 3dB bandwidth (ref. Application Note:

AN-00MX-003)

5

The device operates over a 3.0V to 5.25V supply range. Please note that sensitivity

and zero g bias level will be slightly different at 3.0V operation. For devices to be

operated at 3.0V in production, they can be trimmed at the factory specifically for

this lower supply voltage operation, in which case the sensitivity and zero g bias

level specifications on this page will be met. Please contact the factory for specially

trimmed devices for low supply voltage operation.

MEMSIC MXR2999GL/ML

Page 3 of 6

2002.08.30.1

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage (V

DD

, V

DA

) .....................-0.5 to +7.0V

Storage Temperature ......................-65

∞C to +150∞C

Acceleration ............................................50,000 g

*Stresses above those listed under Absolute Maximum Ratings may cause permanent

damage to the device. This is a stress rating only; the functional operation of the

device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

Package Characteristics

Package

JA

JC

Device Weight

LCC-8

110

∞C/W 22∞C/W

< 1 gram

Pin Description: LCC-8 Package

Pin Name Description

1 T

OUT

Temperature (Analog Voltage)

2 A

OUTY

Y-Axis Acceleration Signal

3 Gnd Ground

4 V

DA

Analog Supply Voltage

5 A

OUTX

X-Axis Acceleration Signal

6 V

ref

2.5V

Reference

7

Sck

Optional External Clock

8 V

DD

Digital Supply Voltage

Ordering Guide

Model

Package Style

Temperature Range

MXR2999GL

LCC - 8

0 to 70

∞C

MXR2999ML

LCC - 8

-40 to 105

∞C

All parts are shipped in tape and reel packaging.

Caution:

ESD (electrostatic discharge) sensitive device.

8

4

1

2

3

7

6

5

Top View

ME

MS

I

C

X +g

Y +g

Note: The MEMSIC logo's arrow indicates the +X sensing

direction of the device. The +Y sensing direction is rotated 90∞

away from the +X direction following the right-hand rule.

THEORY OF OPERATION

The MEMSIC device is a complete dual-axis acceleration

measurement system fabricated on a monolithic CMOS IC

process. The device operation is based on heat transfer by

natural convection and operates like other accelerometers

having a proof mass. The stationary element, or `proof

mass', in the MEMSIC sensor is a gas.

A single heat source, centered in the silicon chip is

suspended across a cavity. Equally spaced

aluminum/polysilicon thermopiles (groups of

thermocouples) are located equidistantly on all four sides of

the heat source (dual axis). Under zero acceleration, a

temperature gradient is symmetrical about the heat source,

so that the temperature is the same at all four thermopiles,

causing them to output the same voltage.

Acceleration in any direction will disturb the temperature

profile, due to free convection heat transfer, causing it to be

asymmetrical. The temperature, and hence voltage output

of the four thermopiles will then be different. The

differential voltage at the thermopile outputs is directly

proportional to the acceleration. There are two identical

acceleration signal paths on the accelerometer, one to

measure acceleration in the x-axis and one to measure

acceleration in the y-axis. Please visit the MEMSIC

website at www.memsic.com for a picture/graphic

description of the free convection heat transfer principle.

MEMSIC MXR2999GL/ML

Page 4 of 6

2002.08.30.1

MXR2999GL/ML PIN DESCRIPTIONS

V

DD

≠ This is the supply input for the digital circuits and

the sensor heater in the accelerometer. The DC voltage

should be between 3.0 and 5.25 volts. Refer to the section

on PCB layout and fabrication suggestions for guidance on

external parts and connections recommended.

V

DA

≠ This is the power supply input for the analog

amplifiers in the accelerometer. Refer to the section on

PCB layout and fabrication suggestions for guidance on

external parts and connections recommended.

Gnd ≠ This is the ground pin for the accelerometer.

A

OUTX

≠ This pin is the output of the x-axis acceleration

sensor. The user should ensure the load impedance is

sufficiently high as to not source/sink >100

µA. While the

sensitivity of this axis has been programmed at the factory

to be the same as the sensitivity for the y-axis, the

accelerometer can be programmed for non-equal

sensitivities on the x- and y-axes. Contact the factory for

additional information on this feature.

A

OUTY

≠

This pin is the output of the y-axis acceleration

sensor. The user should ensure the load impedance is

sufficiently high as to not source/sink >100

µA. While the

sensitivity of this axis has been programmed at the factory

to be the same as the sensitivity for the x-axis, the

accelerometer can be programmed for non-equal

sensitivities on the x- and y-axes. Contact the factory for

additional information on this feature.

T

OUT

≠ This pin is the buffered output of the temperature

sensor. The analog voltage at T

OUT

is an indication of the

die temperature. This voltage is useful as a differential

measurement of temperature from ambient and not as an

absolute measurement of temperature

Sck ≠ The standard product is delivered with an internal

clock option (800kHz). This pin should be grounded

when operating with the internal clock. An external

clock option can be special ordered from the factory

allowing the user to input a clock signal between 400kHz

and 1.6MHz.

V

ref

≠ A reference voltage is available from this pin. It is

set at 2.50V typical and has 100

µA of drive capability.

DISCUSSION OF TILT APPLICATIONS AND

RESOLUTION

Tilt Applications: One of the most popular applications of

the MEMSIC accelerometer product line is in

tilt/inclination measurement. An accelerometer uses the

force of gravity as an input to determine the inclination

angle of an object.

A MEMSIC accelerometer is most sensitive to changes in

position, or tilt, when the accelerometer's sensitive axis is

perpendicular to the force of gravity, or parallel to the

Earth's surface. Similarly, when the accelerometer's axis is

parallel to the force of gravity (perpendicular to the Earth's

surface), it is least sensitive to changes in tilt.

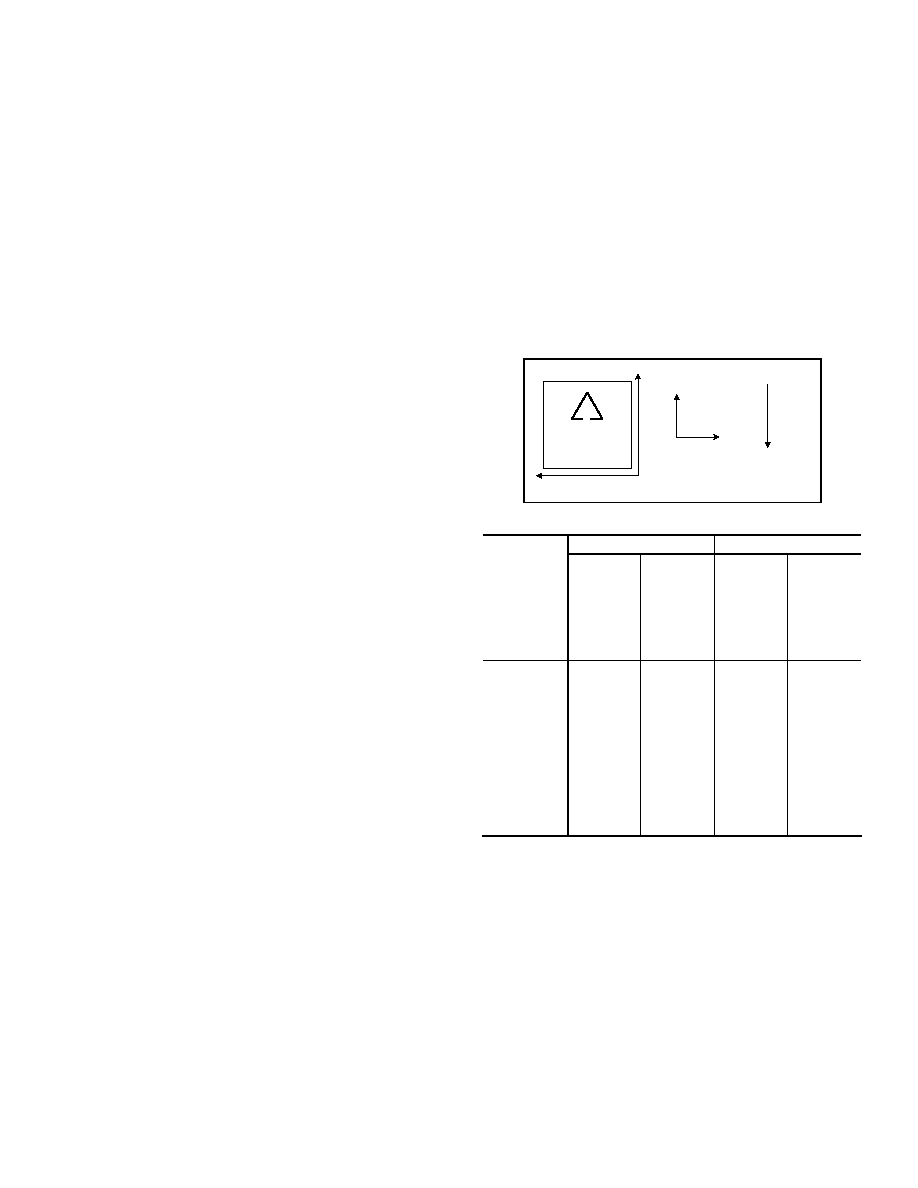

Table 1 and Figure 2 help illustrate the output changes in

the X- and Y-axes as the unit is tilted from +90

∞ to 0∞.

Notice that when one axis has a small change in output per

degree of tilt (in mg), the second axis has a large change in

output per degree of tilt. The complementary nature of

these two signals permits low cost accurate tilt sensing to

be achieved with the MEMSIC device (reference

application note AN-00MX-007).

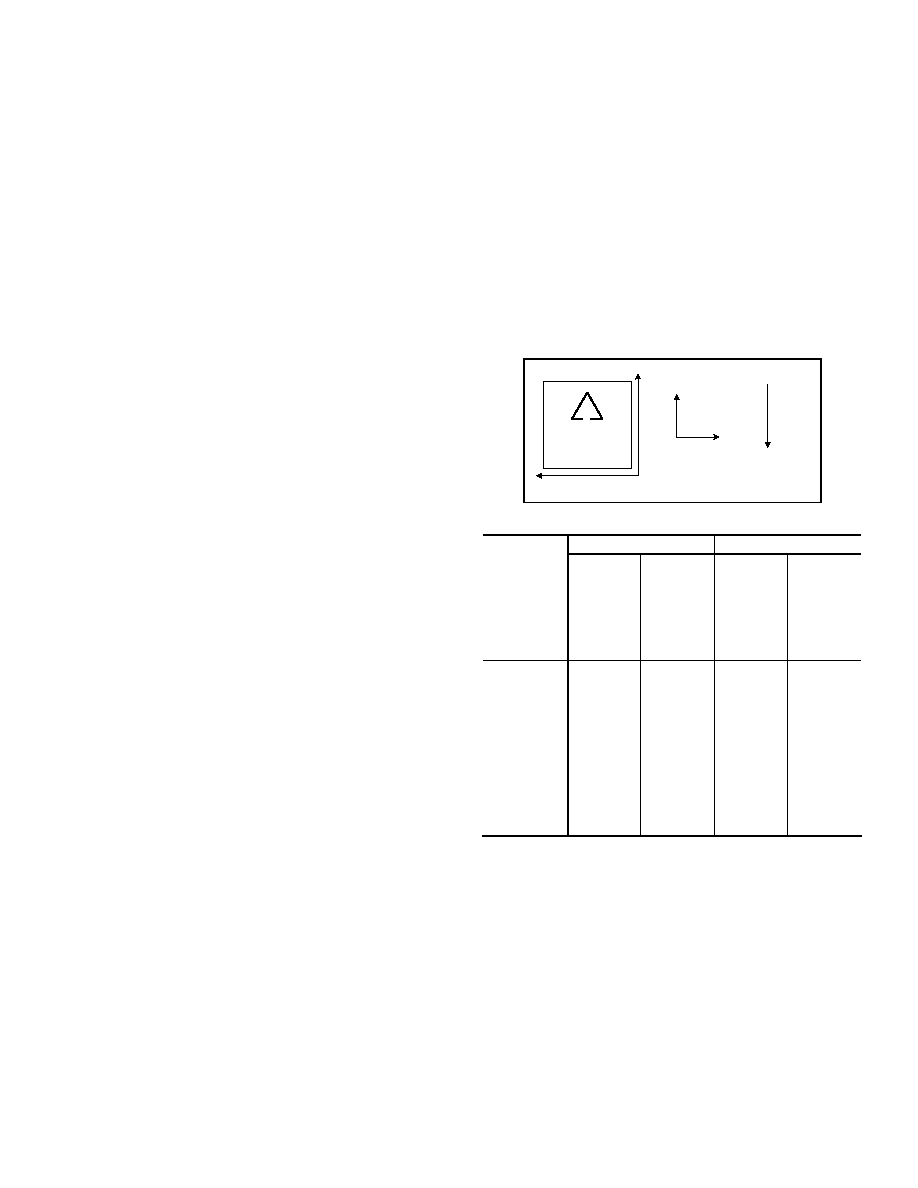

Top View

X

Y

+90

0

0

0

gravity

ME

M

S

I

C

Figure 2: Accelerometer Position Relative to Gravity

X-Axis

Y-Axis

X-Axis

Orientatio

n

To Earth's

Surface

(deg.)

X Output

(g)

Change

per deg.

of tilt

(mg)

Y Output

(g)

Change

per deg.

of tilt

(mg)

90

1.000

0.15 0.000

17.45

85

0.996

1.37 0.087

17.37

80

0.985

2.88 0.174

17.16

70

0.940

5.86 0.342

16.35

60

0.866

8.59 0.500

15.04

45

0.707

12.23 0.707

12.23

30

0.500

15.04 0.866

8.59

20

0.342

16.35 0.940

5.86

10

0.174

17.16 0.985

2.88

5

0.087

17.37 0.996

1.37

0

0.000

17.45 1.000

0.15

Table 1: Changes in Tilt for X- and Y-Axes

Resolution: The accelerometer resolution is limited by

noise. The output noise will vary with the measurement

bandwidth. With the reduction of the bandwidth, by

applying an external low pass filter, the output noise drops.

Reduction of bandwidth will improve the signal to noise

ratio and the resolution. The output noise scales directly

with the square root of the measurement bandwidth. The

maximum amplitude of the noise, its peak- to- peak value,

approximately defines the worst case resolution of the

measurement. With a simple RC low pass filter, the rms

noise is calculated as follows:

MEMSIC MXR2999GL/ML

Page 5 of 6

2002.08.30.1

Noise (mg rms) = Noise(mg/ Hz ) *

)

6

.

1

*

)

(

(

Hz

Bandwidth

The peak-to-peak noise is approximately equal to 6.6 times

the rms value (for an average uncertainty of 0.1%).

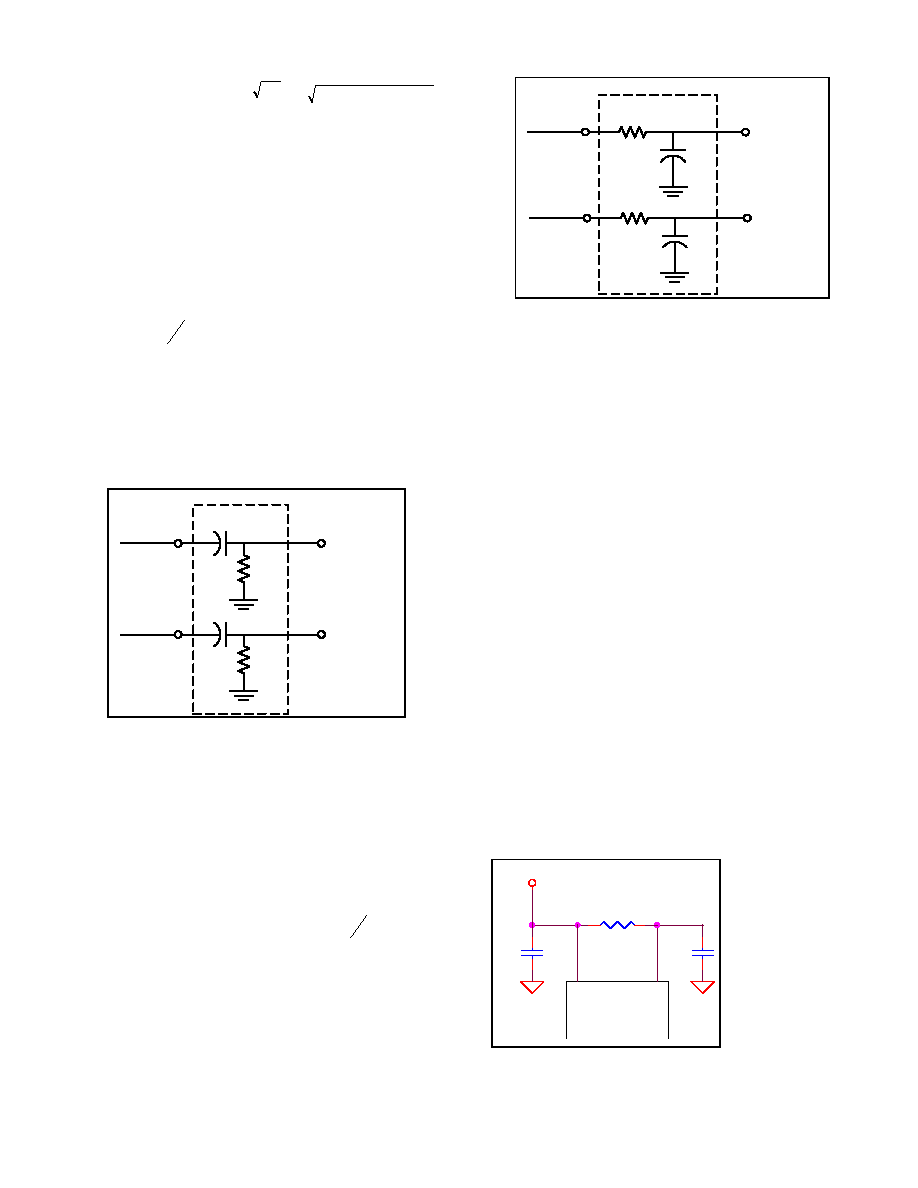

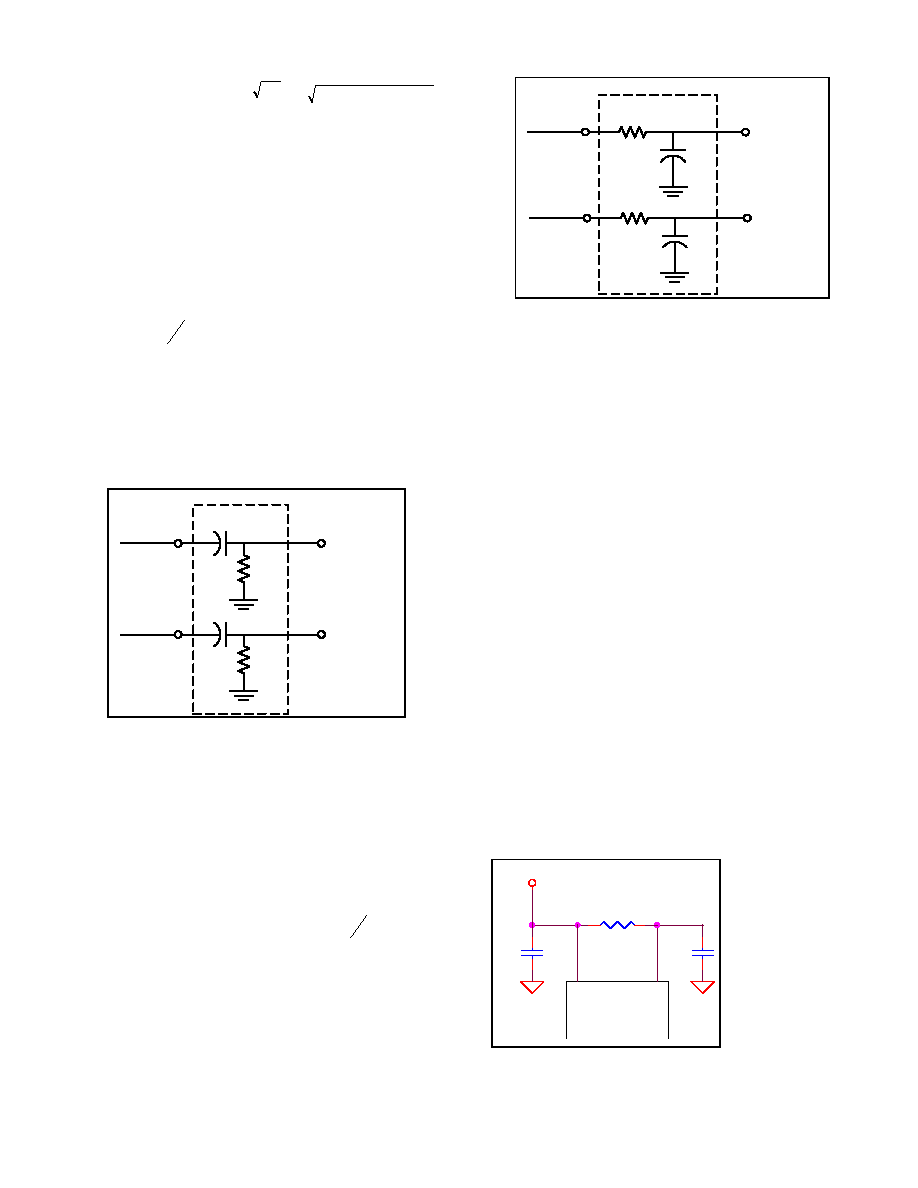

EXTERNAL FILTERS

AC Coupling: For applications where only dynamic

accelerations (vibration) are to be measured, it is

recommended to ac couple the accelerometer output as

shown in Figure 3. The advantage of ac coupling is that

variations from part to part of zero g offset and zero g

offset versus temperature can be eliminated. Figure 3 is a

HPF (high pass filter) with a ≠3dB breakpoint given by the

equation:

RC

f

2

1

=

. In many applications it may be

desirable to have the HPF ≠3dB point at a very low

frequency in order to detect very low frequency

accelerations. Sometimes the implementation of this HPF

may result in unreasonably large capacitors, and the

designer must turn to digital implementations of HPFs

where very low frequency ≠3dB breakpoints can be

achieved.

A

OUTX

R

C

A

OUTY

R

C

A

OUTX

Filtered

Output

A

OUTY

Filtered

Output

Figure 3: High Pass Filter

Low Pass Filter: An external low pass filter is useful in

low frequency applications such as tilt or inclination. The

low pass filter limits the noise floor and improves the

resolution of the accelerometer. When designing with

MEMSIC ratiometric output accelerometers (MXRxxxx

series), it is highly recommended that an external, 20 Hz

low pass filter be used to eliminate internally generated

periodic noise that is coupled to the output of the

accelerometer. The low pass filter shown in Figure 4 has a

≠3dB breakpoint given by the equation:

RC

f

2

1

=

. For

the 200 Hz ratiometric output device filter, C=0.2

µF and

R=39k

, ±5%, 1/8W.

A

OUTX

R

C

A

OUTY

R

C

A

OUTX

Filtered

Output

A

OUTY

Filtered

Output

Figure 4: Low Pass Filter

USING THE ACCELEROMETER IN VERY LOW

POWER APPLICATIONS (BATTERY OPERATION)

In applications with power limitations, power cycling can

be used to extend the battery operating life. One important

consideration when power cycling is that the accelerometer

turn on time limits the frequency bandwidth of the

accelerations to be measured. For example, operating at

3.0V the turn on time is 40mS. To double the operating

time, a particular application may cycle power ON for

40mS, then OFF for 40mS, resulting in a measurement

period of 80mS, or a frequency of 12.5Hz. With a

frequency of measurements of 12.5Hz, accelerations

changes as high as 6.25Hz can be detected. Power cycling

can be used effectively in many inclinometry applications,

where inclination changes can be slow and infrequent.

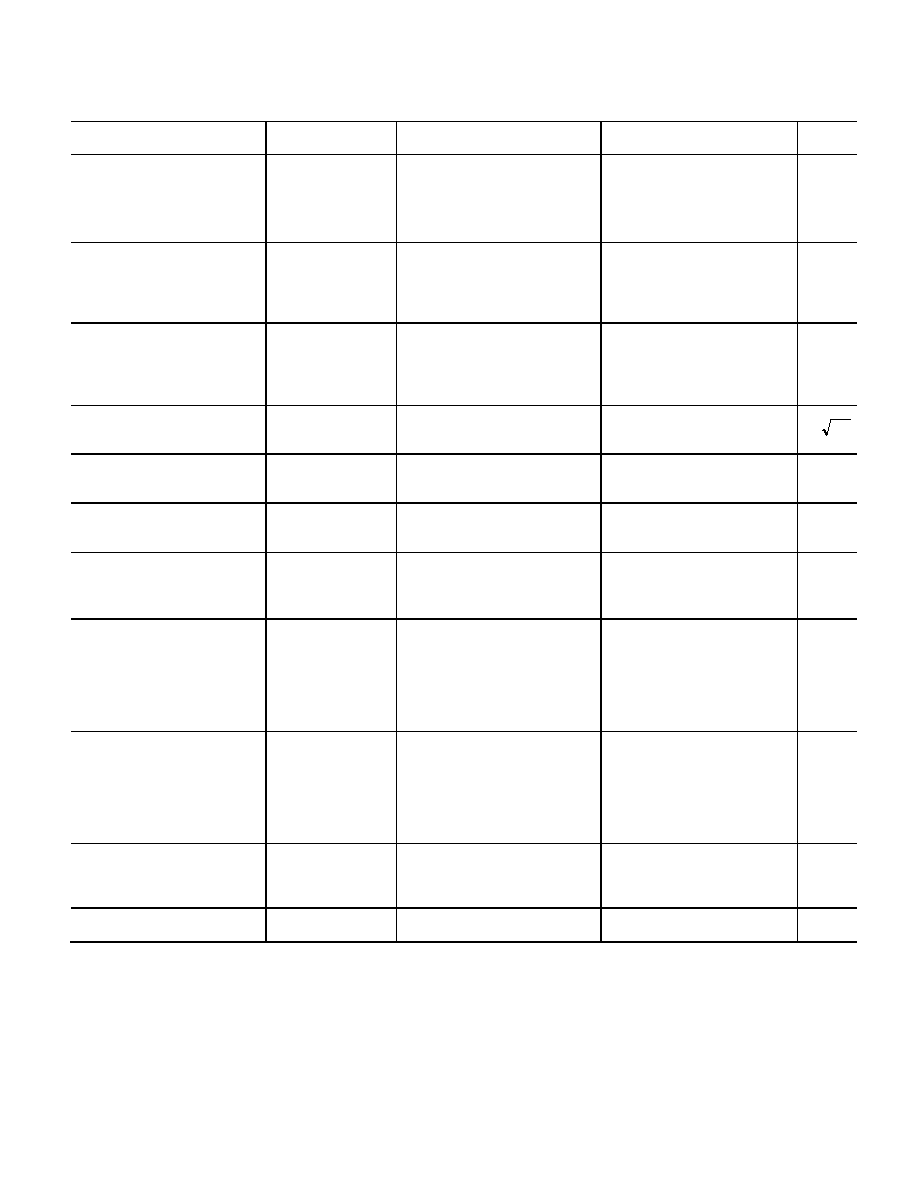

POWER SUPPLY NOISE REJECTION

Two capacitors and a resistor are recommended for best

rejection of power supply noise (reference Figure 5 below).

The capacitors should be located as close as possible to the

device supply pins (V

DA

, V

DD

). The capacitor lead length

should be as short as possible, and surface mount capacitors

are preferred. For typical applications, capacitors C1 and

C2 can be ceramic 0.1 µF, and the resistor R can be 10 .

In 5V applications where power consumption is not a

concern, maximum supply noise rejection can be obtained

by significantly increasing the values of C1, C2 and R. For

example, C1 = C2 = 0.47 µF and R = 270 will virtually

eliminate power supply noise effects.

R

MEMSIC

Accelerometer

VDA

C1

C2

VDD

V SUPPLY

Figure 5: Power Supply Noise Rejection