| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: MIC502BM | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

May 1999

163

MIC502

MIC502

Micrel

MIC502

Fan Management IC

Advance Information

Features

∑ Temperature-proportional fan speed control

∑ Low-cost, efficient PWM fan drive

∑ 4.5V to 13.2V IC supply range

∑ Controls any voltage fan

∑ Overtemperature detection with fault output

∑ Integrated fan startup timer

∑ Automatic user-specified sleep mode

∑ Supports low-cost NTC/PTC thermistors

∑ 8-pin DIP and SOIC packages

Applications

∑ NLX and ATX power supplies

∑ Personal computers

∑ File servers

∑ Telecom and networking hardware

∑ Printers, copiers, and office equipment

∑ Instrumentation

∑ Uninterruptable power supplies

∑ Power amplifiers

Ordering Information

Part Number

Temperature Range

Package

MIC502BN

≠40

∞

C to +85

∞

C

8-pin Plastic DIP

MIC502BM

≠40

∞

C to +85

∞

C

8-pin SOIC

General Description

The MIC502 is a thermal and fan management IC which

supports the features for NLX/ATX power supplies and other

control applications.

Fan speed is determined by an external temperature sensor,

typically a thermistor-resistor divider, and (optionally) a sec-

ond signal, such as the NLX "FanC" signal. The MIC502

produces a low-frequency pulse-width modulated output for

driving an external motor drive transistor. Low-frequency

PWM speed control allows operation of standard brushless

dc fans at low duty cycle for reduced acoustic noise and

permits the use of a very small power transistor. The PWM

time base is determined by an external capacitor.

An open-collector overtemperature fault output is asserted if

the primary control input is driven above the normal control

range.

The MIC502 features a low-power sleep mode with a user-

determined threshold. Sleep mode completely turns off the

fan and occurs when the system is asleep or off (both control

inputs very low). A complete shutdown or reset can also be

initiated by external circuitry as desired.

The MIC502 is available as 8-pin plastic DIP and SOIC

packages in the ≠40

∞

C to +85

∞

C industrial temperature

range.

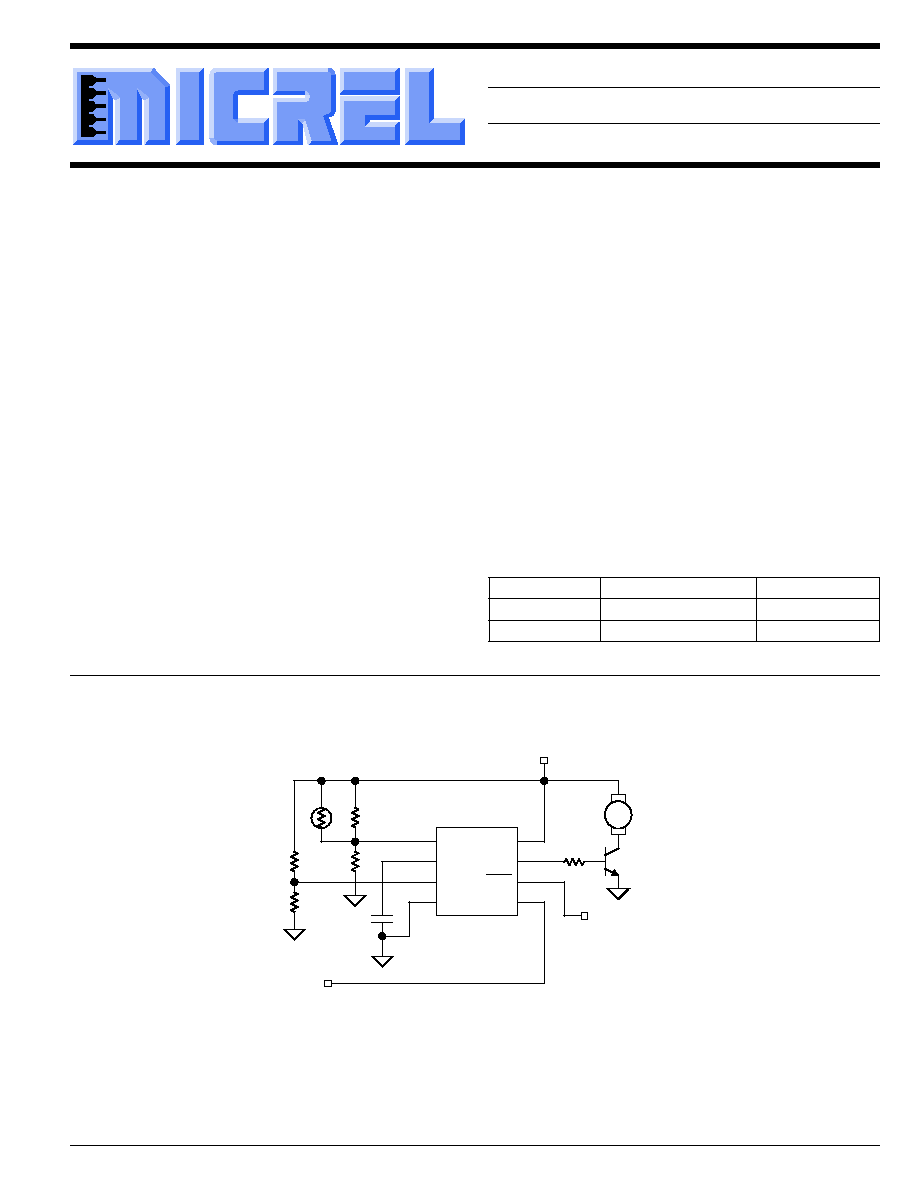

Typical Application

VT1

CF

VSLP

GND

VDD

OUT

OTF

VT2

1

2

3

4

8

7

6

5

R1

T1

R3

R4

C

F

R2

12V

R

BASE

Overtemperature

Fault Output

MIC502

Secondary

Fan-control

Input

Fan

Q1

MIC502

Micrel

MIC502

164

May 1999

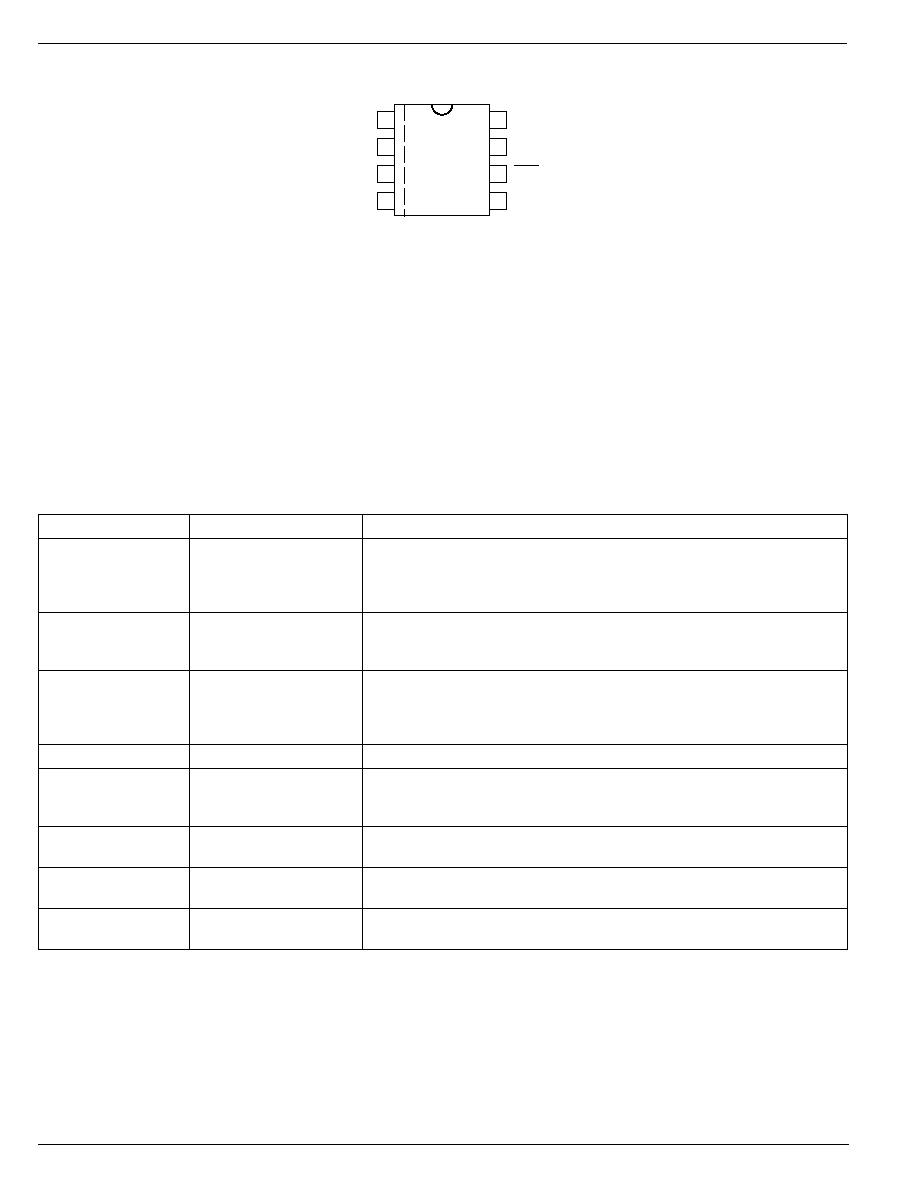

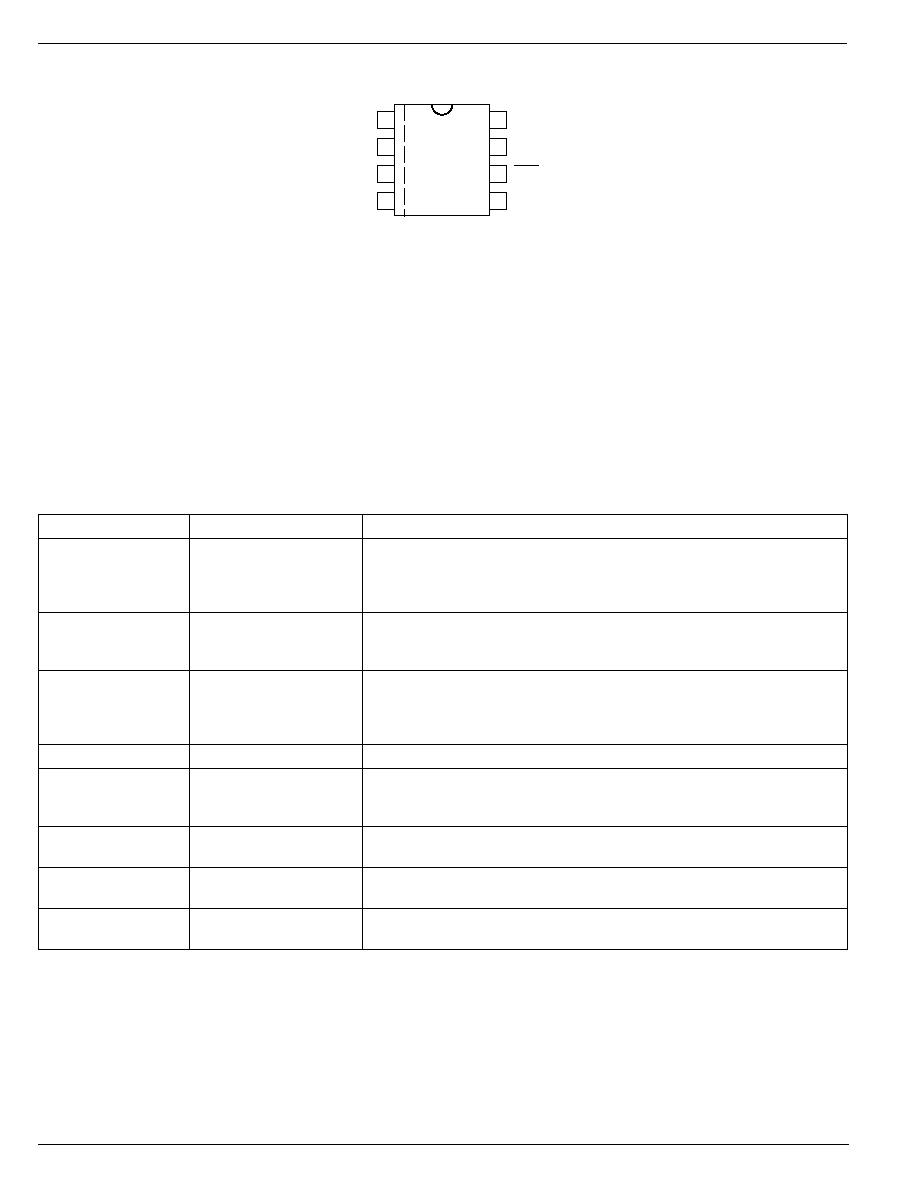

Pin Description

Pin Number

Pin Name

Pin Function

1

VT1

Thermistor 1 (Input): Analog input of approximately 30% to 70% of V

DD

produces active duty cycle of 0% to 100% at driver output (OUT). Connect to

external thermistor network (or other temperature sensor). Pull low for

shutdown.

2

CF

PWM Timing Capacitor (External Component): Positive terminal for the

PWM triangle-wave generator timing capacitor. The recommended C

F

is

0.1

µ

F for 30Hz PWM operation.

3

VSLP

Sleep Threshold (Input): The voltage on this pin is compared to V

T1

and V

T2

.

When V

T1

< V

SLP

and V

T2

< V

SLP

the MIC502 enters sleep mode until V

T1

or

V

T2

rises above V

WAKE

. (V

WAKE

= V

SLP

+ V

HYST

.) Grounding VSLP

disables the sleep-mode function.

4

GND

Ground

5

VT2

Thermistor 2 (Input): Analog input of approximately 30% to 70% of V

DD

produces active duty cycle of 0% to 100% at driver output (OUT). Connect to

motherboard fan control signal or second temperature sensor.

6

/OTF

Overtemperature Fault (Output): Open-collector output (active low).

Indicates overtemperature fault condition (V

T1

> V

OT

) when active.

7

OUT

Driver Output: Asymmetical-drive active-high complimentary PWM output.

Typically connect to base of external NPN motor control transistor.

8

VDD

Power Supply (Input): IC supply input; may be independent of fan power

supply.

Pin Configuration

1

2

3

4

8

7

6

5

VDD

OUT

OTF

VT2

VT1

CF

VSLP

GND

8-Pin SOIC (M)

8-Pin DIP (N)

May 1999

165

MIC502

MIC502

Micrel

Absolute Maximum Ratings

(Note 1)

Supply Voltage (V

DD

) .................................................. +14V

Output Sink Current (I

OUT(sink)

) .................................. 10mA

Output Source Current (I

OUT(source)

) .......................... 25mA

Input Voltage (any pin) ......................... ≠0.3V to V

DD

+0.3V

Junction Temperature (T

J

) ...................................... +125

∞

C

Storage Temperature (T

A

) ....................... ≠65

∞

C to +150

∞

C

Lead Temperature (Soldering, 5 sec.) ...................... 260

∞

C

ESD, Note 3

Operating Ratings

(Note 2)

Supply Voltage (V

DD

) ................................ +4.5V to +13.2V

Sleep Voltage (V

SLP

) ........................................ GND to V

DD

Temperature Range (T

A

) ........................... ≠40

∞

C to +85

∞

C

Power Dissipation at 25

∞

C

SOIC ................................................................... 800mW

DIP ...................................................................... 740mW

Derating Factors

SOIC ............................................................... 8.3mW/

∞

C

Plastic DIP ....................................................... 7.7mW/

∞

C

Electrical Characteristics

4.5V

V

DD

13.2V, Note 4; T

A

= 25, bold values indicate ≠40

∞

C

T

A

+85

∞

C; unless noted

Symbol

Parameter

Condition

Min

Typ

Max

Units

I

DD

Supply Current, Operating

VSLP = grounded, OTF, OUT = open,

0.5

1.2

mA

C

F

= 0.1

µ

F, V

T1

= V

T2

= 0.7 V

DD

I

DD(slp)

Supply Current, Sleep

VT1 = grounded,

240

400

µ

A

VSLP, OTF, OUT = open, C

F

= 0.1

µ

F

Driver Output

t

R

Output Rise Time, Note 5

I

OH

= 10mA

TBD

50

µ

s

t

F

Output Fall Time, Note 5

I

OL

= 1mA

TBD

50

µ

s

I

OL

Output Sink Current

V

OL

= 0.5V

0.9

mA

I

OH

Output Source Current

4.5V

V

DD

5.5V, V

OH

= 2.4V

10

mA

10.8V

V

DD

13.2V, V

OH

= 3.2V

10

mA

I

OS

Sleep-Mode Output Leakage

V

OUT

= 0V

1

µ

A

Thermistor and Sleep Inputs

V

PWM(max)

100% PWM Duty Cycle

67

70

73

%V

DD

Input Voltage

V

PWM(span)

V

PWM(max)

≠ V

PWM(min)

37

40

43

%V

DD

V

HYST

Sleep Comparator Hysteresis

8

11

14

%V

DD

V

IL

VT1 Shutdown Threshold

0.7

V

V

IH

VT1 Startup Threshold

1.1

V

V

OT

VT1 Overtemperature Fault

Note 6

74

77

80

%V

DD

Threshold

I

VT

, I

VSLP

VT1, VT2, VSLP Input Current

≠2.5

1

µ

A

t

RESET

Reset Setup Time

minimum time V

T1

< V

IL

, to guarantee reset,

30

µ

s

Note 5

Oscillator

f

Oscillator Frequency, Note 7

4.5V

V

DD

5.5V, C

F

= 0.1

µ

F

24

27

30

Hz

10.8V

V

DD

13.2V, C

F

= 0.1

µ

F

27

30

33

Hz

f

MIN

, f

MAX

Oscillator Frequency Range

Note 7

15

90

Hz

t

STARTUP

Startup Interval

64/f

s

MIC502

Micrel

MIC502

166

May 1999

Symbol

Parameter

Condition

Min

Typ

Max

Units

Overtemperature Fault Output

V

OL

Active (Low) Output Voltage

I

OL

= 2mA

0.3

V

I

OH

Off-State Leakage

V

/OTF

= V

DD

1

µ

A

Note 1.

Exceeding the absolute maximum rating may damage the device.

Note 2.

The device is not guaranteed to function outside its operating rating.

Note 3.

Devices are ESD sensitive. Handling precautions recommended.

Note 4:

Part is functional over this V

DD

range; however, it is characterized for operation at 4.5V

V

DD

5.5V and 10.8V

V

DD

13.2V ranges. These

ranges correspond to nominal V

DD

of 5V and 12V, respectively.

Note 5.

Guaranteed by design.

Note 6.

V

OT

is guaranteed by design to always be higher than V

PWM(max)

.

Note 7.

Logic time base and PWM frequency. For other values of C

F

, f(Hz) = 30Hz

0.1 F

C

µ

, where C is in

µ

F.

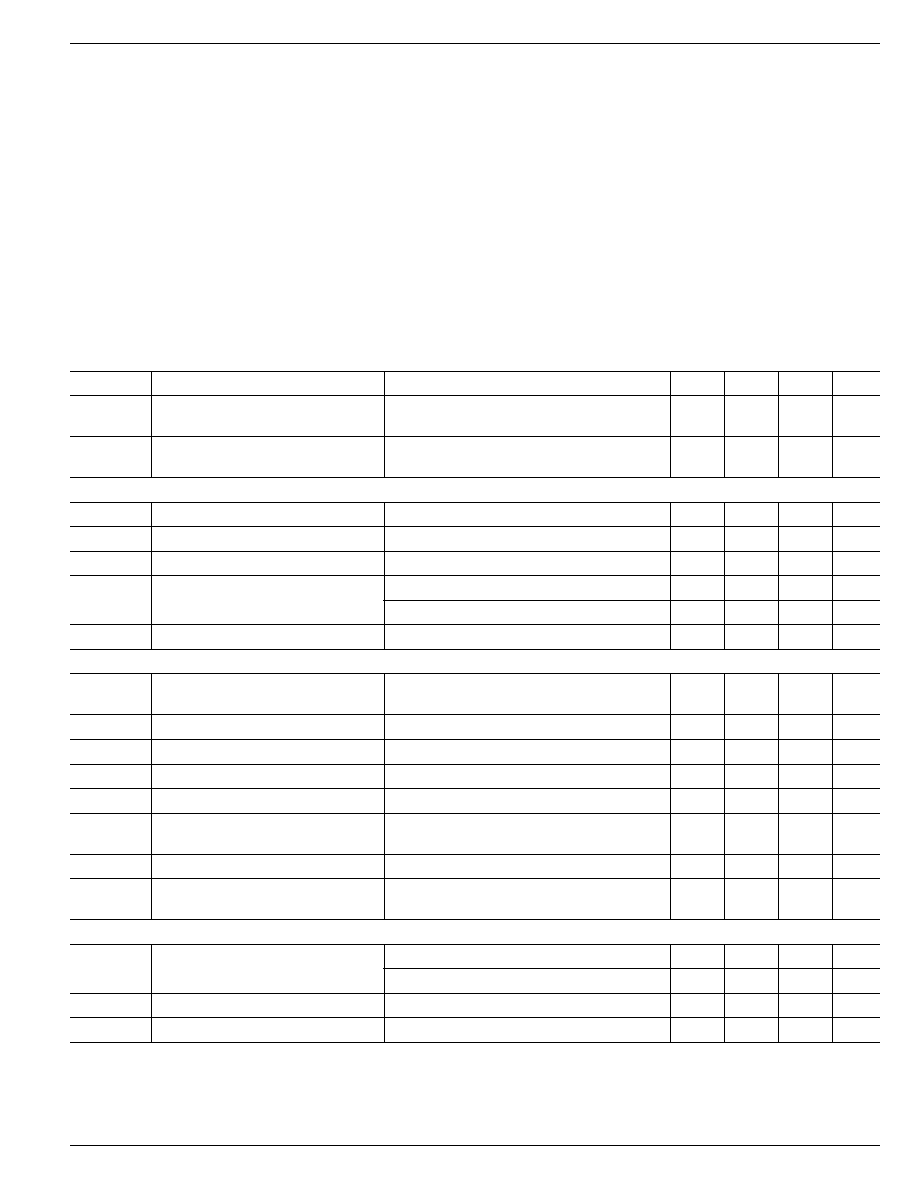

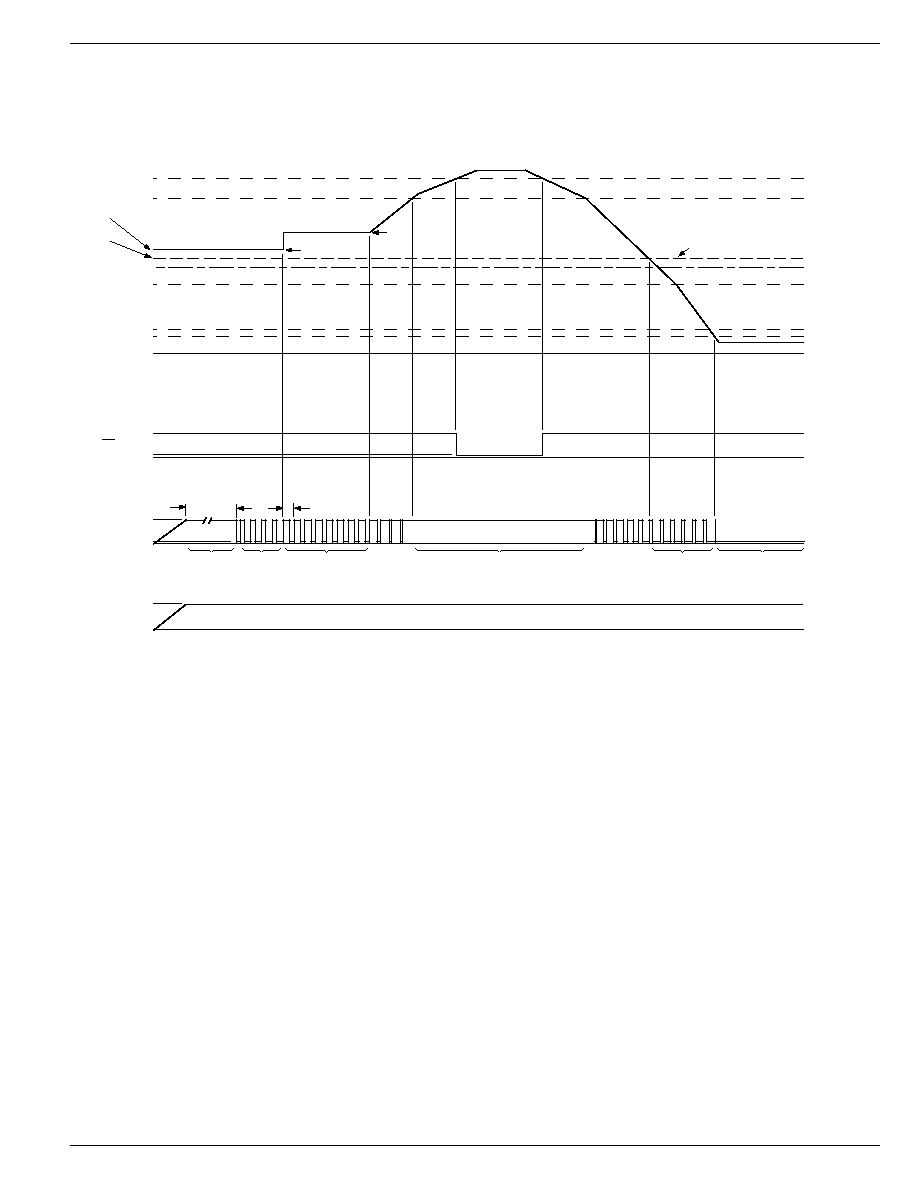

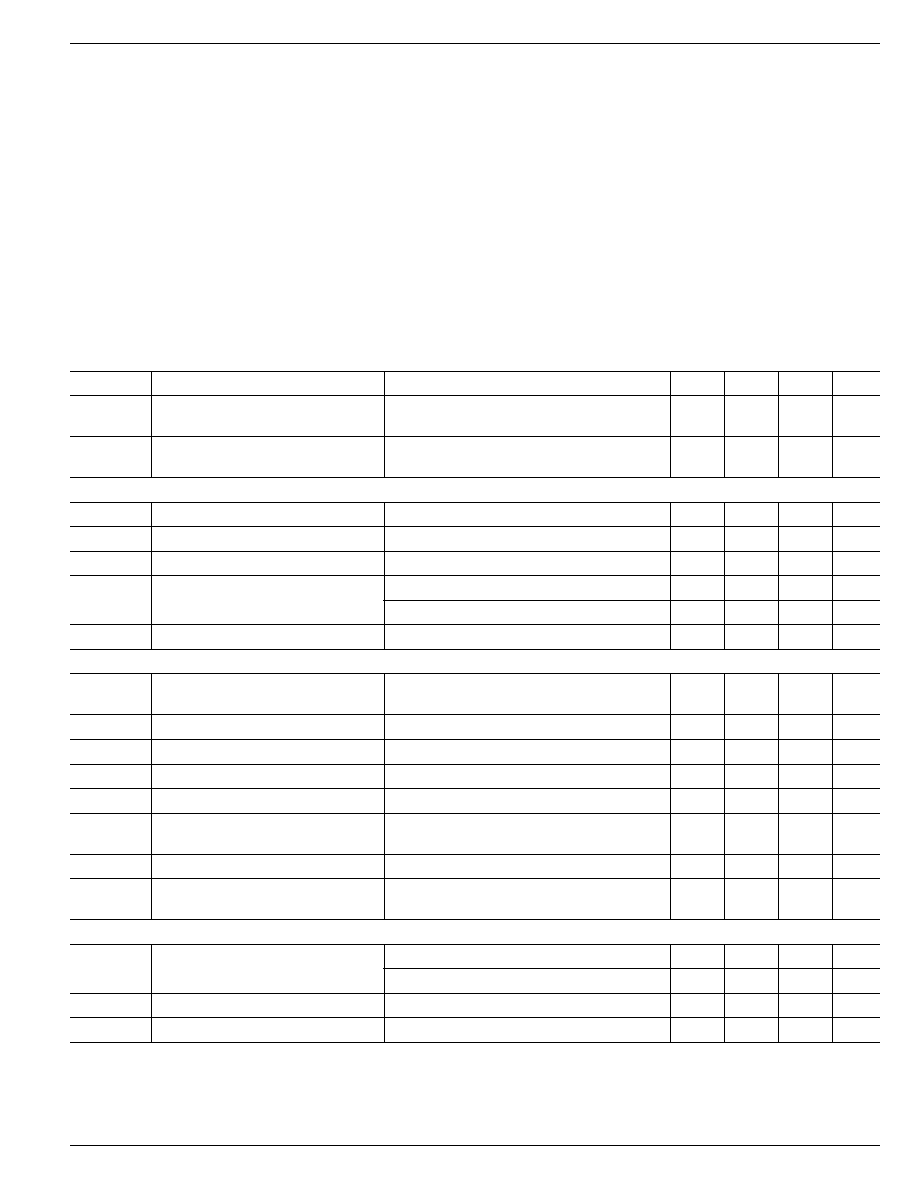

Timing Diagrams

V

OH

V

OL

50%

80%

40%

0%

100%

40%

70%

t

STARTUP

t

PWM

Output

Duty Cycle

A

B

C

D

E

F

G

0.7V

DD

0.3V

DD

0.3V

DD

V

T1

V

T2

V

SLP

100%

0%

30%

70%

80%

50%

40%

40%

Input

Signal

Range

V

OT

V

IH

V

IL

0V

V

OH

V

OL

V

OUT

V

OTF

0V

0V

Figure 1. Typical System Behavior

Note A.

Output duty-cycle is initially determined by V

T1

, as it is greater than V

T2

.

Note B.

PWM duty-cycle follows V

T1

as it increases.

Note C.

V

T1

drops below V

T2

. V

T2

now determines the output duty-cycle.

Note D.

The PWM duty-cycle follows V

T2

as it increases.

Note E.

Both V

T1

and V

T2

decrease below V

SLP

but above V

IL

. The device enters sleep mode.

Note F.

The PWM `wakes up' because one of the control inputs (V

T1

in this case) has risen above V

WAKE

. The startup timer is triggered, forcing OUT

high for 64 clock periods. (V

WAKE

= V

SLP

+ V

HYST

. See "Electrical Characteristics.")

Note G.

Following the startup interval, the PWM duty-cycle is the higher of V

T1

and V

T2

.

May 1999

167

MIC502

MIC502

Micrel

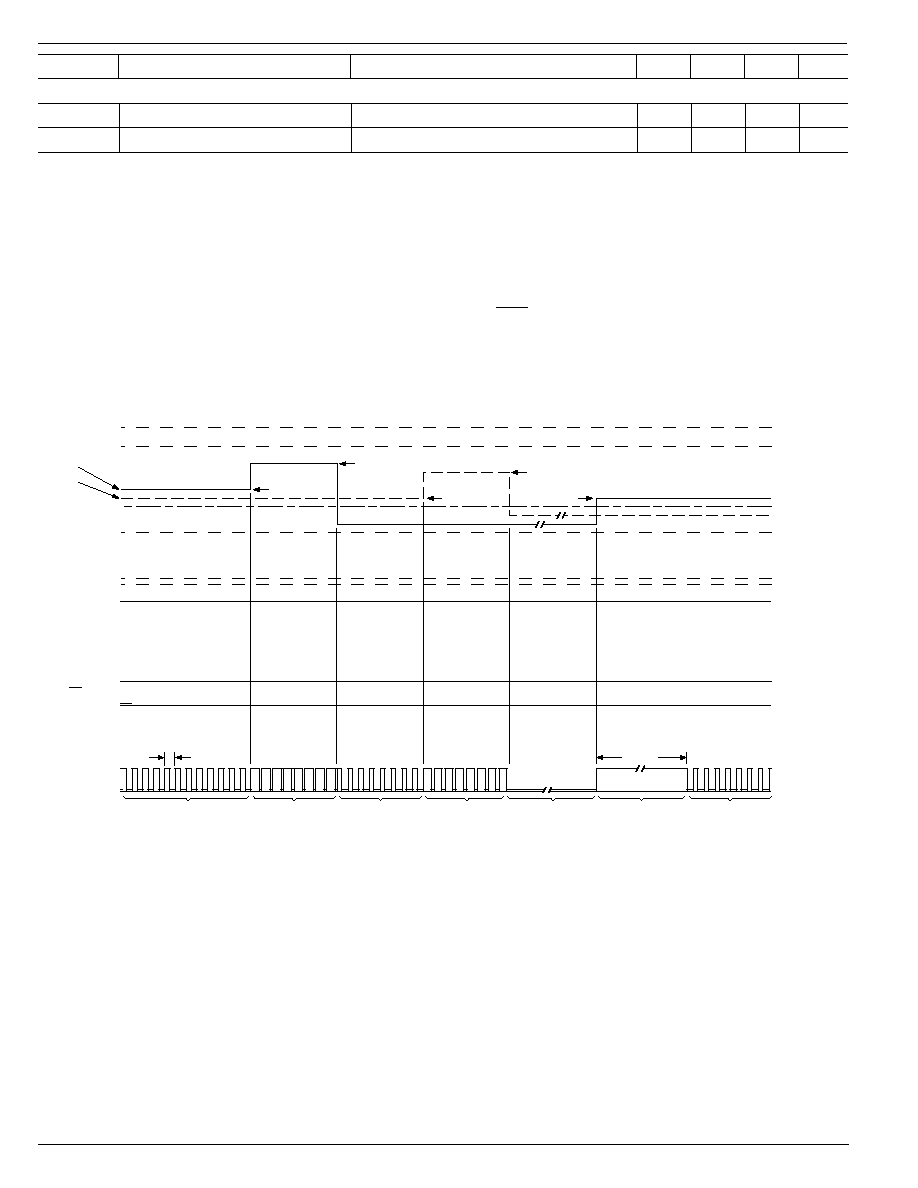

V

OH

V

OL

40%

60%

30%

0%

100%

t

STARTUP

t

PWM

Output

Duty Cycle

H

I

J

K

M

N

L

0.7V

DD

0.3V

DD

0.3V

DD

V

T1

V

T2

V

SLP

100%

0%

20%

60%

40%

30%

PWM

Range

V

OT

V

IH

V

IL

0V

V

OH

V

OL

V

OUT

V

OTF

O

100%

V

DD

0V

V

DD

0V

0V

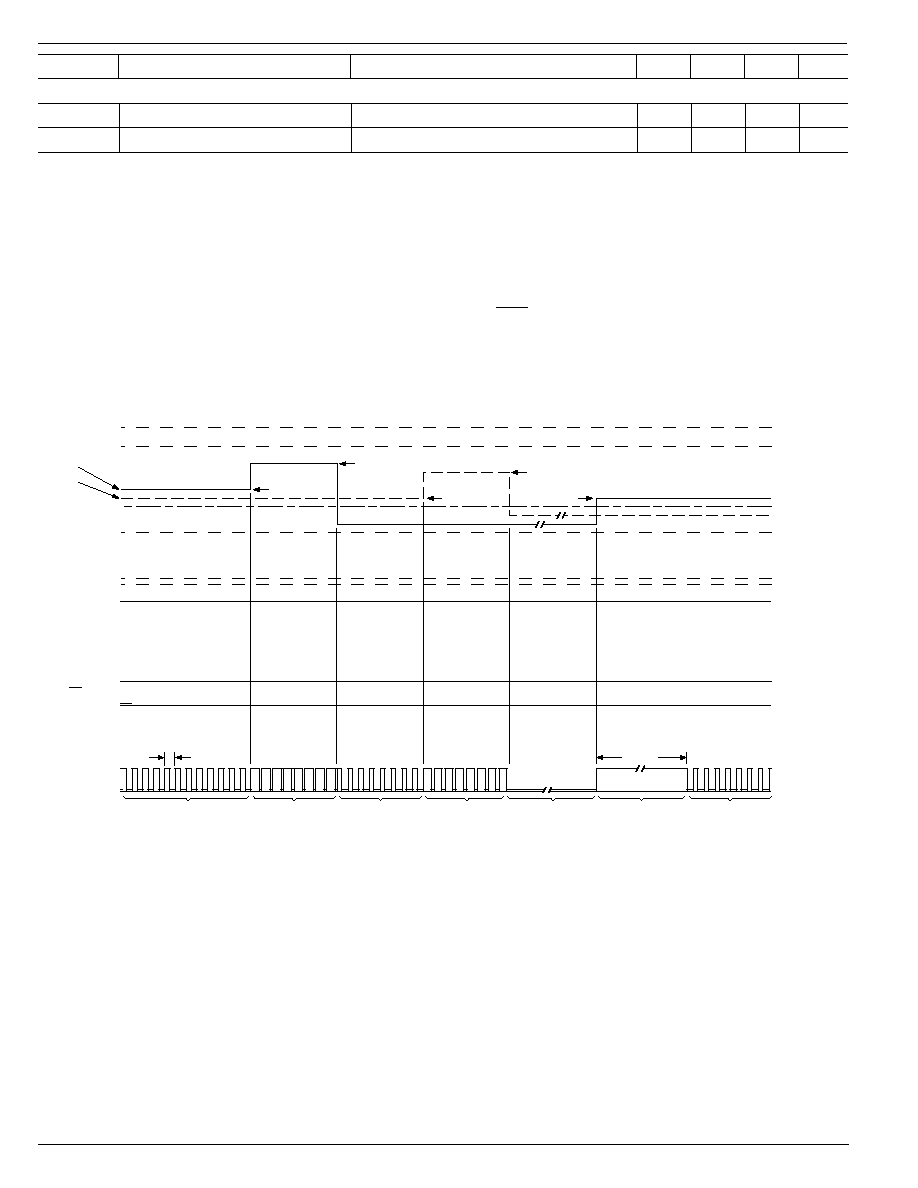

Figure 2. MIC502 Typical Power-Up System Behavior

Note H.

At power-on, the startup timer forces OUT on for 64 PWM cycles of the internal timebase (t

PWM

). This insures that the fan will start from a

dead stop.

Note I.

The PWM duty-cycle follows the higher of V

T1

and V

T2,

in the case, V

T1

.

Note J.

The PWM duty-cycle follows V

T1

as it increases.

Note K.

PWM duty-cycle is 100% (OUT constantly on) anytime V

T1

> V

PWM(max)

.

Note L.

/OTF is asserted anytime V

T1

> V

OT

. (The fan continues to run at 100% duty-cycle.)

Note M. /OTF is deasserted when V

T1

falls below V

OT

; duty-cycle once again follows V

T1

.

Note N.

Duty-cycle follows V

T1

until V

T1

< V

T2

, at which time V

T2

becomes the controlling input signal. Note that V

T1

is below V

SLP

but above V

IH

; so

normal operation continues. (Both V

T1

and V

T2

must be below V

SLP

to active sleep mode.)

Note O.

All functions cease when V

T1

< V

IL

; this occurs regardless of the state of V

T2

.

MIC502

Micrel

MIC502

168

May 1999

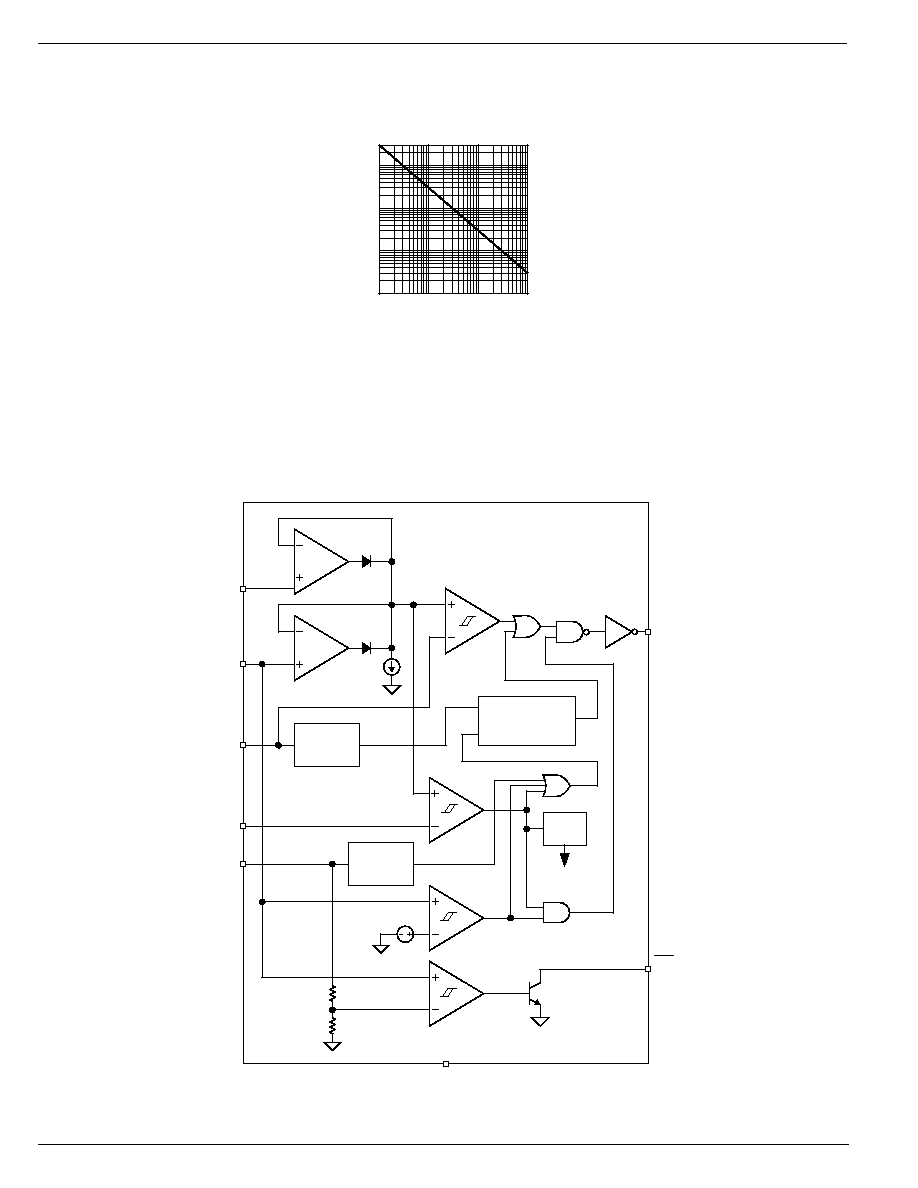

Functional Diagram

Oscillator

Start-Up

Timer

CLK

RESET

OUT

VT2

VT1

CF

OTF

OUT

Driver

GND

VSLP

Power-On

Reset

ENABLE

Sleep

Control

VDD

Overtemperature

Reset

Sleep

Bias

V

IL

PWM

8

3

5

6

7

4

2

1

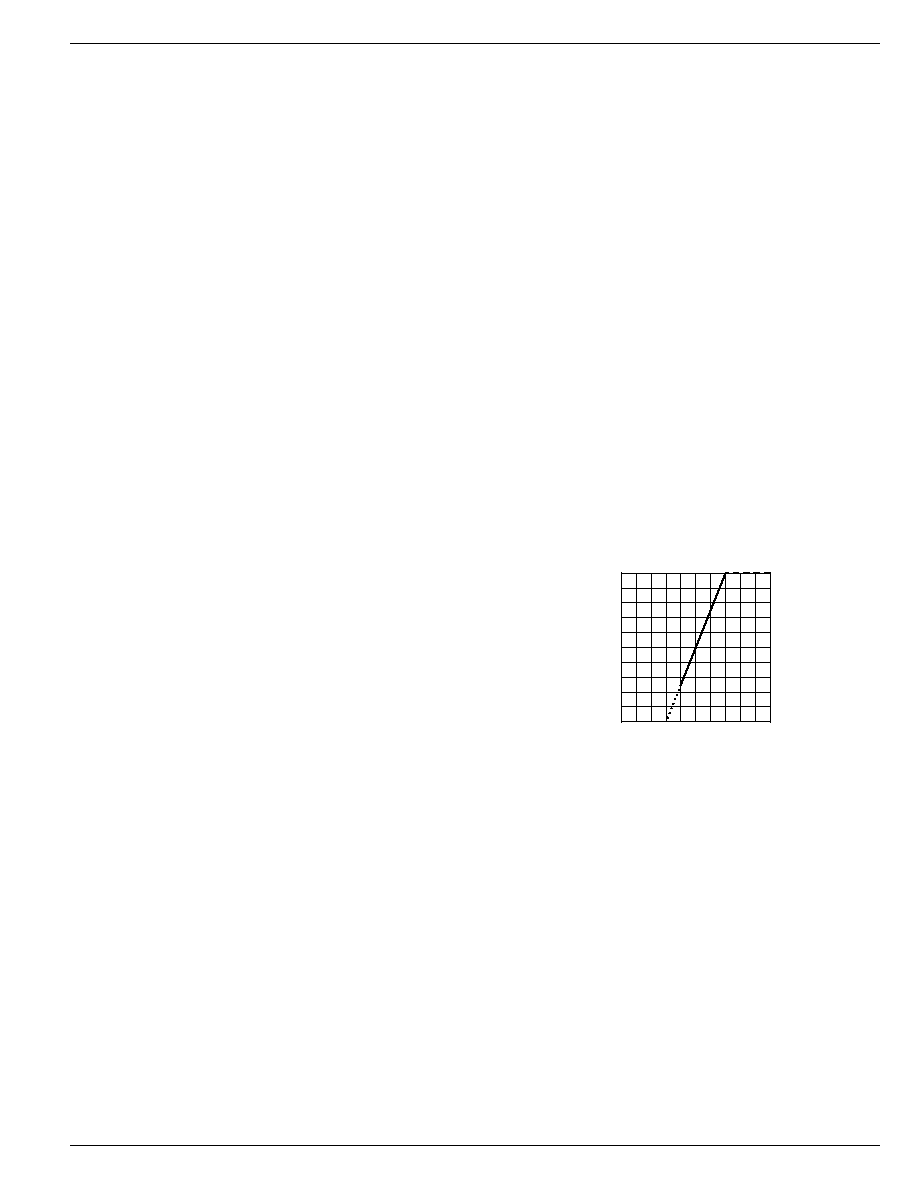

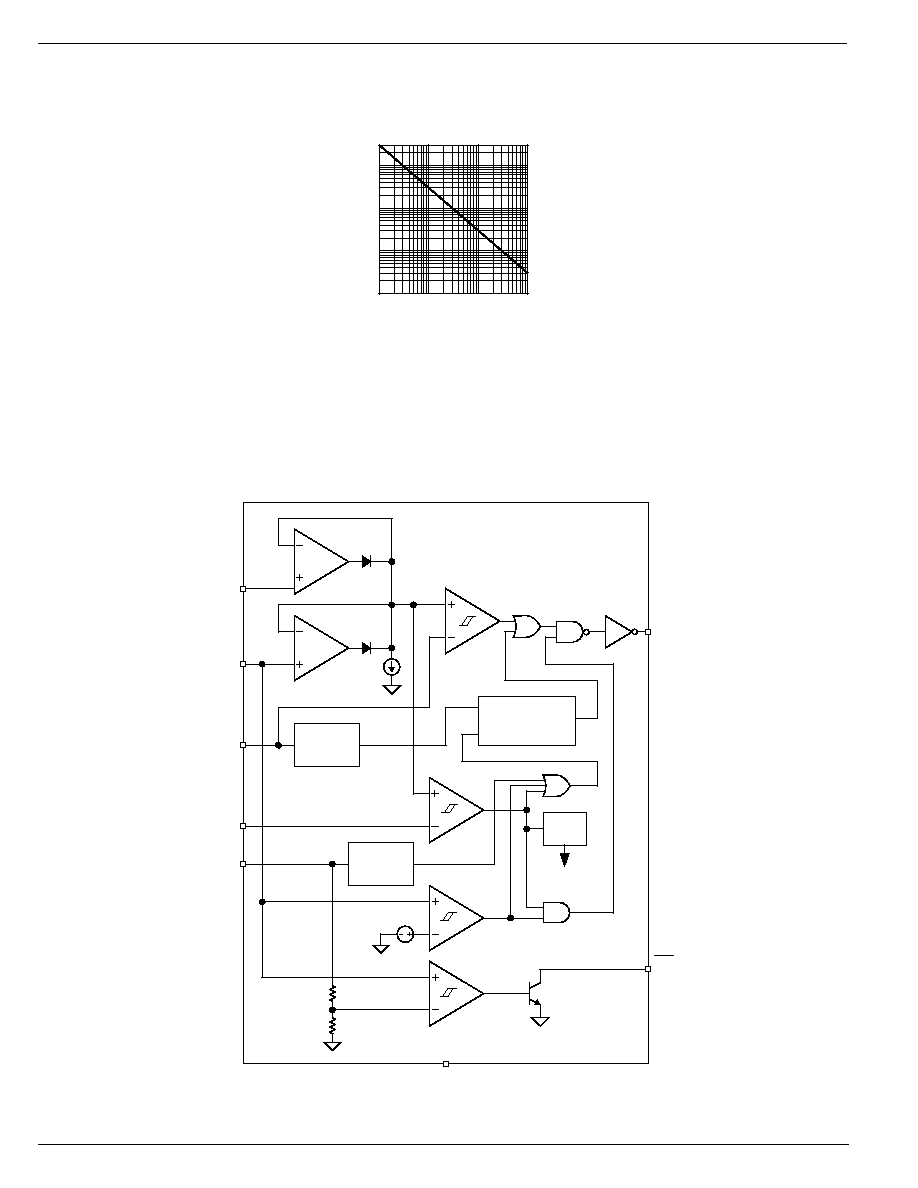

Typical Characteristics

1

10

100

1000

3000

0.001

0.01

0.1

1

FREQUENCY (Hz)

CAPACITANCE (

µ

F)

PWM Frequency vs.

Timing Capacitor Value

May 1999

169

MIC502

MIC502

Micrel

Functional Description

Oscillator

A capacitor connected to CF determines the frequency of the

internal time base which drives the state-machine logic and

determines the PWM frequency. This operating frequency

will be typically 30Hz to 60Hz. (C

F

= 0.1

µ

F for 30Hz.)

Pulse-Width Modulator

A triangle-wave generator and threshold detector comprise

the internal pulse-width modulator (PWM). The PWM's out-

put duty-cycle is determined by the higher of V

T1

or V

T2

. A

typical voltage range of 30% to 70% of V

DD

applied to the VT1

and VT2 pins corresponds to 0% to 100% duty-cycle. Since

at least one of the control voltage inputs is generally from a

thermistor-resistor divider connected to V

DD

, the PWM out-

put duty cycle will not be affected by changes in the supply

voltage.

Driver Output

OUT is a complementary push-pull digital output with asym-

metric drive (approximately 10mA source, 1mA sink--see

"Electrical Characteristics"). It is optimized for directly driving

an NPN transistor switch in the fan's ground-return. See

"Applications Information" for circuit details.

Shutdown/Reset

Internal circuitry automatically performs a reset of the MIC502

when power is applied. The MIC502 may be shut down at any

time by forcing V

T1

below its V

IL

threshold. This is typically

accomplished by connecting the VT1 pin to open-drain or

open-collector logic and results in an immediate and asyn-

chronous shutdown of the MIC502. The OUT and /OTF pins

will float while V

T1

is below V

IL

.

If V

T1

then rises above V

IH

, a device reset occurs. Reset is

equivalent to a power-up condition: the state of /OTF is

cleared, a startup interval is triggered, and normal fan opera-

tion begins.

Startup Interval

Any time the fan is started from the off state (power-on or

coming out of sleep mode or shutdown mode), the PWM

output is automatically forced high for a startup interval of 64

◊

t

PWM

. Once the startup interval is complete, PWM operation

will commence and the duty-cycle of the output will be

determined by the higher of V

T1

or V

T2

.

Overtemperature Fault Output

/OTF is an active-low, open-collector logic output. An over-

temperature condition will cause /OTF to be asserted. An

overtemperature condition is determined by V

T1

exceeding

the normal operating range of 30% to 70% of V

DD

by > 7% of

V

DD

. Note that V

OT

is guaranteed by design to always be

higher than V

PWM(max)

.

Sleep Mode

When V

T1

and V

T2

fall below V

SLP

, the system is deemed

capable of operating without fan cooling and the MIC502

enters sleep mode and discontinues fan operation. The

threshold where the MIC502 enters sleep mode is deter-

mined by V

SLP

. Connecting the VSLP pin to ground disables

sleep mode.

Once in sleep mode, all device functions cease (/OTF in-

active, PWM output off) unless V

T1

or V

T2

rise above V

WAKE

.

(V

WAKE

= V

SLP

+ V

HYST

.) V

HYST

is a fixed amount of hyster-

esis added to the sleep comparator which prevents erratic

operation around the V

SLP

operating point. The result is

stable and predictable thermostatic action: whenever pos-

sible the fan is shut down to reduce energy consumption and

acoustic noise, but will always be activated if the system

temperature rises.

If the device powers-up or exits its reset state, the fan will not

start unless V

T1

or V

T2

rises above V

WAKE

.

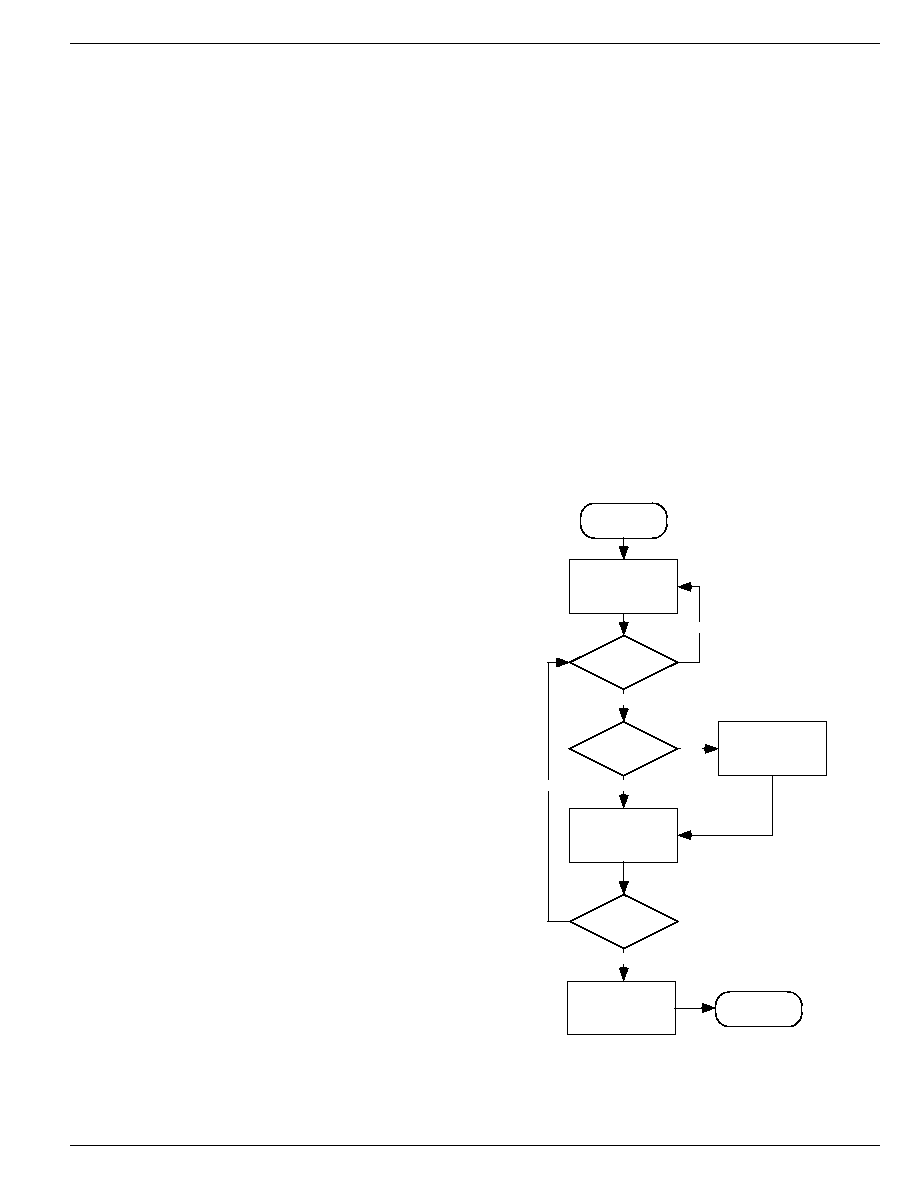

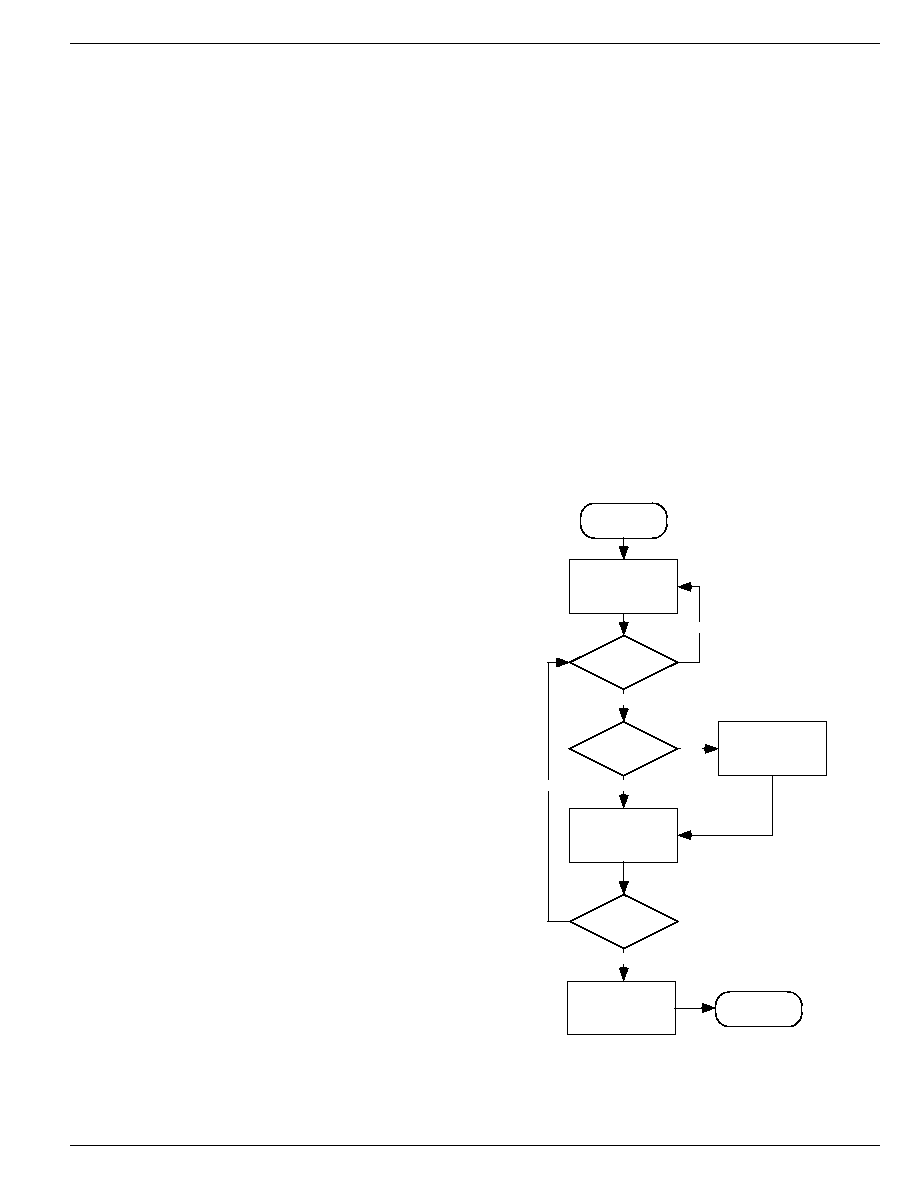

System Operation

Power Up

∑

A complete reset occurs when power is applied.

∑

OUT is off (low) and /OTF is inactive (high/floating).

∑

If V

T1

< V

IL

, the MIC502 remains in shutdown.

∑

The startup interval begins. OUT will be on (high) for 64

clock cycles (64

◊

t

PWM

).

∑

Following the startup interval, normal operation begins.

Reset Startup Timer;

Deassert /OTF;

OUT Off (Low).

V

T1

> V

OT

?

POWER ON

V

T1

< V

IL

?

NO

NO

OUT Held On (High)

During Startup

Interval.

Startup Interval

Finished

?

Deassert OUT

(OUT = Low)

YES

NO

Assert /OTF While

V

T1

> V

OT

NORMAL

OPERATION

YES

YES

Figure 3. Power-Up Behavior

MIC502

Micrel

MIC502

170

May 1999

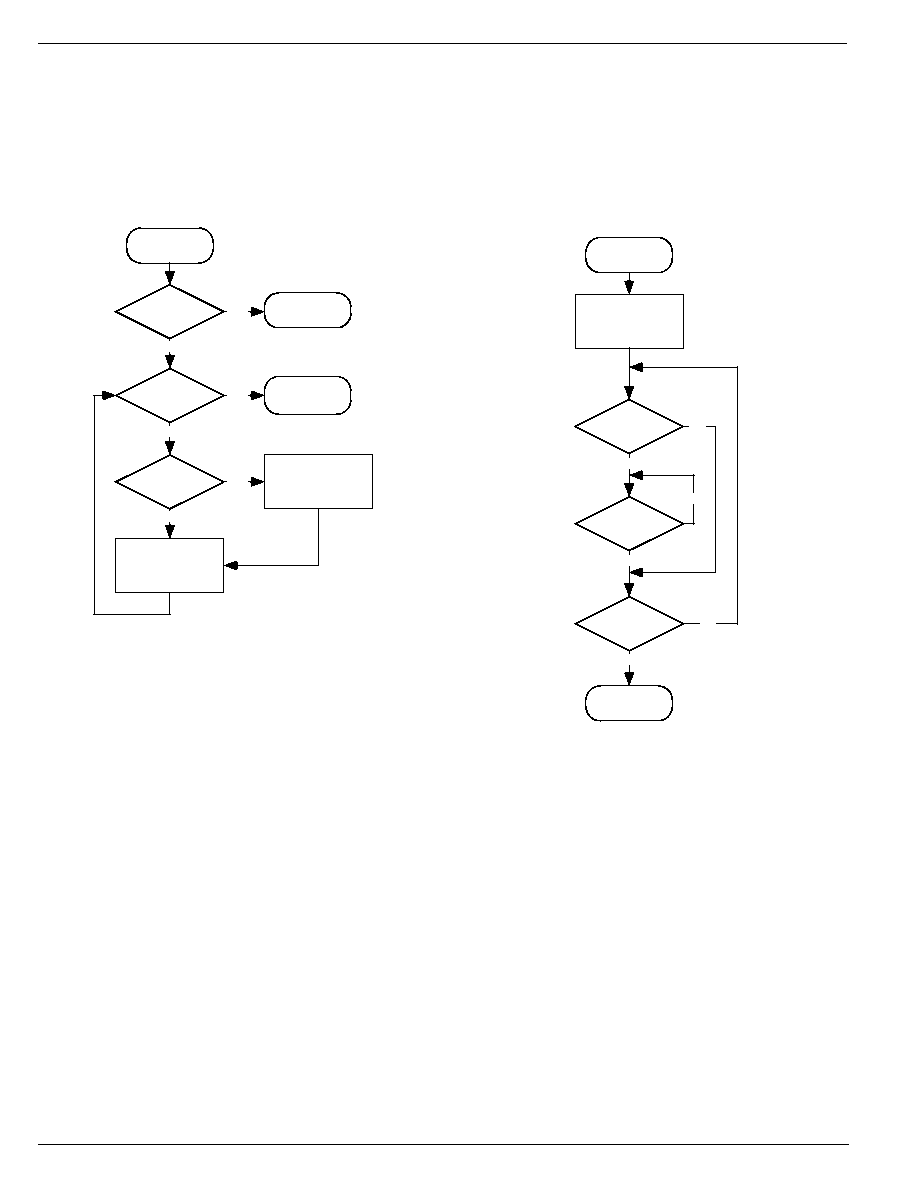

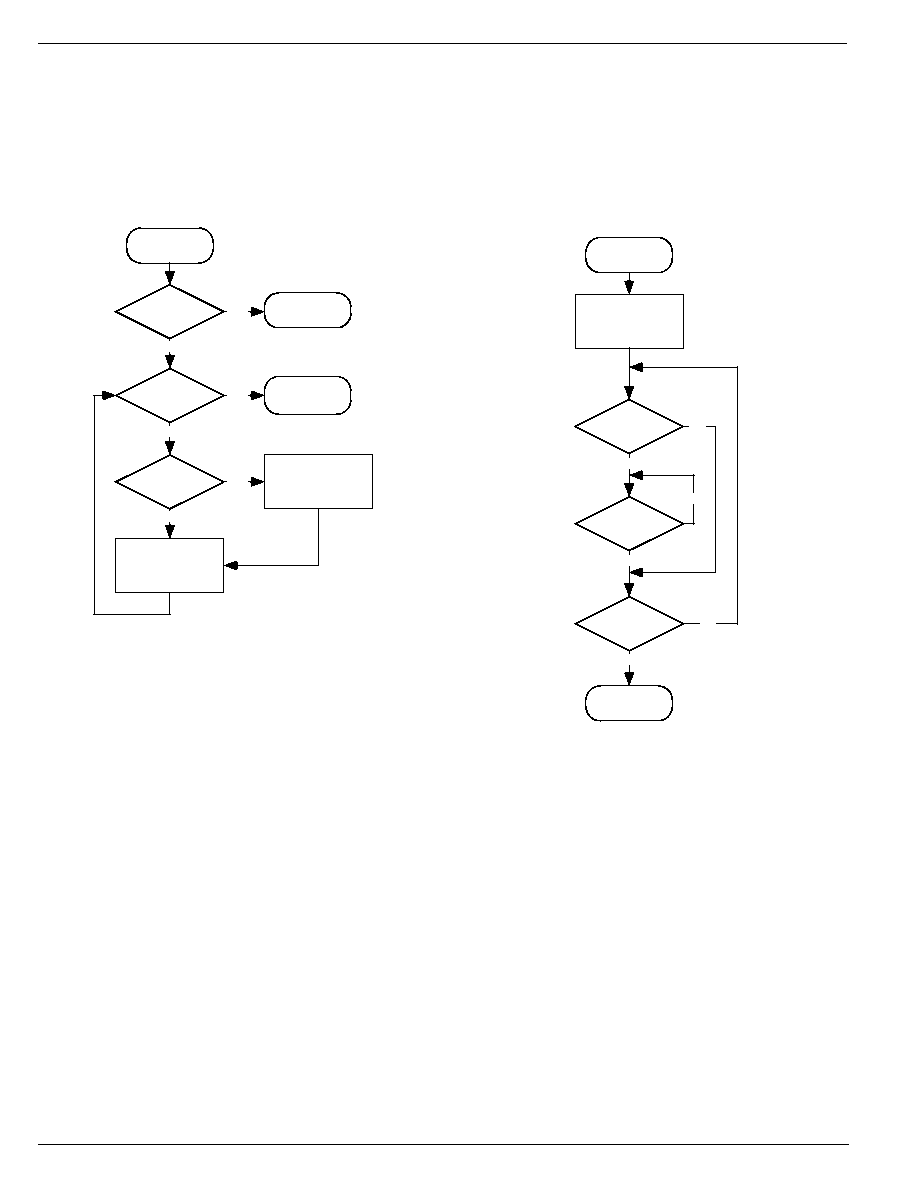

Normal Operation

Normal operation consists of the PWM operating to control

the speed of the fan according to V

T1

and V

T2

. Exceptions to

this otherwise indefinite behavior can be caused by any of

three conditions: V

T1

exceeding V

OT

, an overtemperature

condition; V

T1

being pulled below V

IL

initiating a device

shutdown and reset; or both V

T1

and V

T2

falling below V

SLP

,

activating sleep mode. Each of these exceptions is treated as

follows:

Overtemp?

V

T1

> V

OT

?

NORMAL

OPERATION

V

T1

and V

T2

< V

SLEEP

?

NO

OUT Duty Cycle

Proportional to

Greater of V

T1

, V

T2

YES

Assert /OTF while

V

T1

> V

OT

Reset?

V

T1

< V

IL

?

POWER ON

SLEEP

YES

NO

YES

NO

Figure 4. Normal System Behavior

∑

Overtemperature: If the system temperature rises

typically 7% above the 100% duty-cycle operating point,

/OTF will be activated to indicate an overtemperature

fault. (V

T1

> V

OT

) Overtemperature detection is essen-

tially independent of other operations--the PWM

continues its normal behavior; with V

T1

> V

PWM(max)

, the

output duty-cycle will be 100%. If V

T1

falls below V

OT

,

the overtemperature condition is cleared and /OTF is no

longer asserted. It is assumed that in most systems, the

/OTF output will initiate power supply shutdown.

∑

Shutdown/Reset: If V

T1

is driven below V

IL

an immedi-

ate, asynchronous shutdown occurs. While in shutdown

mode, OUT is off (low), and /OTF is unconditionally

inactive (high/floating). If V

T1

subsequently rises above

V

IH

, a device reset will occur. Reset is indistinguishable

from a power-up condition. The state of /OTF is cleared,

a startup interval is triggered, and normal fan operation

begins.

∑

Sleep: If V

T1

and V

T2

fall below V

SLP

, the device enters

sleep mode. All internal functions cease unless V

T1

or

V

T2

rise above V

WAKE

. (V

WAKE

= V

SLP

+ V

HYST

.) The

/OTF output is unconditionally inactive (high/floating)

and the PWM is disabled during sleep. (OUT will float.)

Sleep Mode

During normal operation, if V

T1

and V

T2

fall below V

SLP

, the

device will go into sleep mode and fan operation will stop. The

MIC502 will exit sleep mode when V

T1

or V

T2

rise above V

SLP

by the hysteresis voltage, V

HYST

. When this occurs, normal

operation will resume. The resumption of normal operation

upon exiting sleep is indistinguishable from a power-on reset.

(See "Sleep: Normal Operation," above.)

Disable PWM

Reset Released

V

T1

> V

IH

?

SLEEP

Reset Initiated

V

T1

< V

IL

?

YES

YES

Wake Up?

V

T1

or V

T2

>

V

SLP

+V

HYST

?

POWER ON

NO

NO

NO

YES

Figure 5. Sleep-Mode Behavior

May 1999

171

MIC502

MIC502

Micrel

Applications Information

The Typical Application drawing on page 1 illustrates a typical

application circuit for the MIC502. Interfacing the MIC502

with a system consists of the following steps:

1. Selecting a temperature sensor

2. Interfacing the temperature sensor to the VT1 input

3 Selecting a fan-drive transistor, and base-drive current

limit resistor

4. Deciding what to do with the Secondary

Fan-Control Input

5. Making use of the Overtemperature Fault Output.

Temperature Sensor Selection

Temperature sensor T1 is a negative temperature coefficient

(NTC) thermistor. The MIC502 can be interfaced with either

a negative or positive tempco thermistor; however, a nega-

tive temperature coefficient thermistor typically costs less

than its equivalent positive tempco counterpart. While a

variety of thermistors can be used in this application, the

following paragraphs reveal that those with an R25 rating

(resistance at 25

∞

C) of from about 50k

to 100k

lend

themselves nicely to an interface network that requires only

a modest current drain. Keeping the thermistor bias current

low not only indicates prudent design; it also prevents self-

heating of the sensor from becoming an additional design

consideration. It is assumed that the thermistor will be located

within the system power supply, which most likely also

houses the speed-controlled fan.

Temperature Sensor Interface

As shown by the Electrical Characteristics table, the working

voltage for input VT1 is specified as a percentage of V

DD

. This

conveniently frees the designer from having to be concerned

with interactions resulting from variations in the supply volt-

age. By design, the operating range of VT1 is from about 30%

of V

DD

to about 70% of V

DD

.

V

PWM(min)

= V

PWM(max)

≠ V

PWM(span)

When V

T1

= V

PWM(max)

0.7V

DD

, a 100% duty-cycle motor

drive signal is generated. Conversely, when V

T1

= V

PWM(min)

0.3V

DD

, the motor-drive signal has a 0% duty cycle.

Resistor voltage divider R1 || T1, R2 in the Typical Application

diagram is designed to preset V

T1

to a value of V

PWM

that

corresponds to the slowest desired fan speed when the

resistance of thermistor T1 is at its highest (cold) value. As

temperature rises the resistance of T1 decreases and V

T1

increases because of the parallel connection of R1 and T1.

Since V

T1

= V

PWM(min)

represents a stopped fan (0% duty-

cycle drive), and since it is foreseen that at least some cooling

will almost always be required, the lowest voltage applied to

the VT1 input will normally be somewhat higher than 0.3V

DD

(or >V

PWM(min)

). It is assumed that the system will be in sleep

mode rather than operate the fan at a very low duty cycle

(<< 25%). Operation at very low duty cycle results in relatively

little airflow. Sleep mode should be used to reduce acoustic

noise when the system is cool. For a given minimum desired

fan speed, a corresponding V

T1(min)

can be determined via

the following observation:

since

V

PWM(max)

= 70% of V

DD

100% RPM

and

V

PWM(min)

= 30% of V

DD

0% RPM

then

V

PWM(span)

= 40% of V

DD

100% RPM

range.

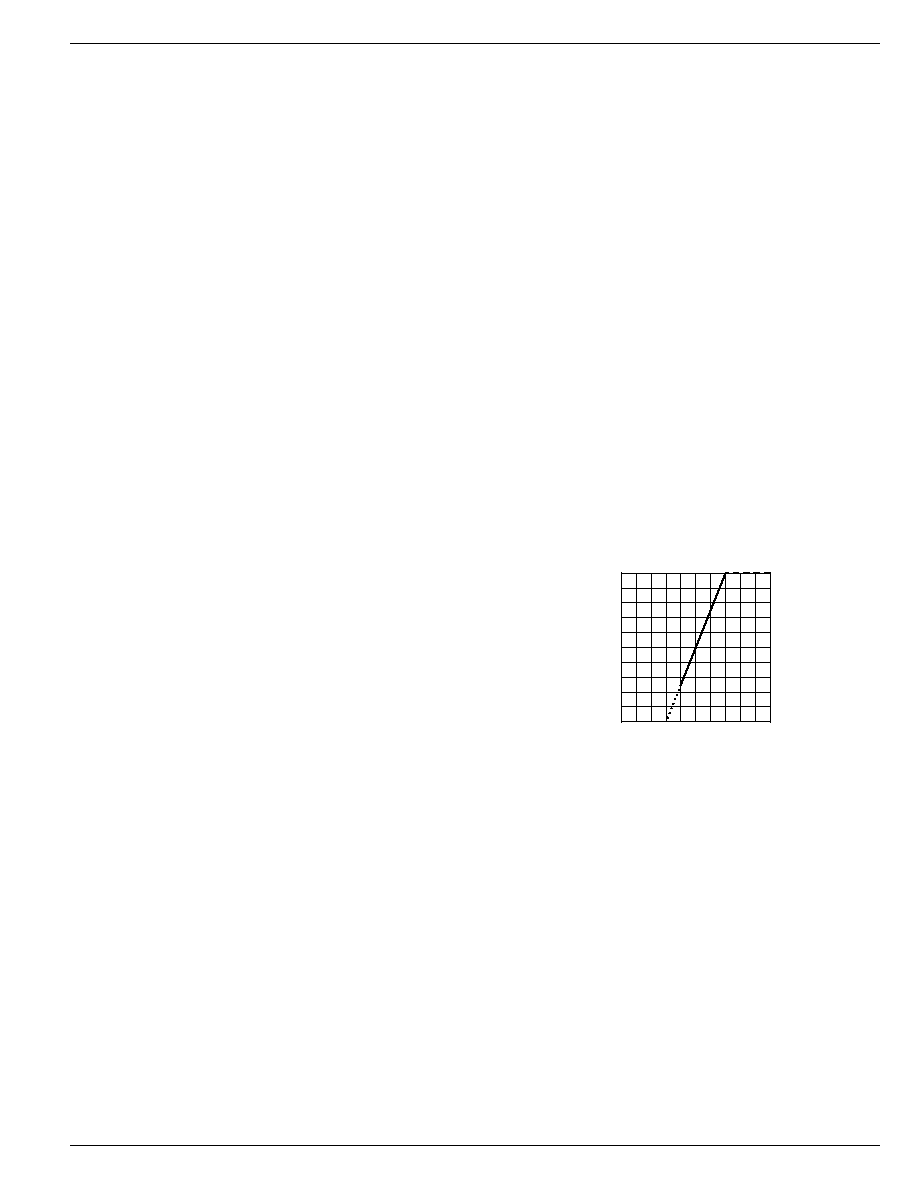

Figure 6 shows the following linear relationship between the

voltage applied to the VT1 input, motor drive duty cycle, and

approximate motor speed.

since

V

T1

= 0.7V

DD

100% PWM

then

V

T1

= 0.6V

DD

75% PWM

and

V

T1

= 0.5V

DD

50% PWM

and

V

T1

= 0.4V

DD

25% PWM.

In addition to the R25 thermistor rating, sometimes a data

sheet will provide the ratio of R25/R50 (resistance at 25

∞

C

divided by resistance at 50

∞

C) is given. Sometimes this is

given as an R0/R50 ratio. Other data sheet contents either

specify or help the user determine device resistance at

arbitrary temperatures. The thermistor interface to the MIC502

usually consists of the thermistor and two resistors.

0

20

40

60

80

100

0

20

40

60

80

100

DUTY CYCLE (%)

V

T1

/SUPPLY VOLTAGE (%)

Figure 6. Control Voltage vs. Fan Speed

Design Example

The thermistor-resistor interface network is shown in the

Typical Application drawing. The following example describes

the design process: A thermistor data sheet specifies a

thermistor that is a candidate for this design as having an R25

resistance of 100k

. The data sheet also supports calcula-

tion of resistance at arbitrary temperatures, and it was discov-

ered the candidate thermistor has a resistance of 13.6k at

70

∞

C (R70). Accuracy is more important at the higher tem-

perature end of the operating range (70

∞

C) than the lower end

because we wish the overtemperature fault output (/OTF) to

be reasonably accurate--it may be critical to operating a

power supply crowbar or other shutdown mechanism, for

example. The lower temperature end of the range is less

important because it simply establishes minimum fan speed,

which is when less cooling is required.

MIC502

Micrel

MIC502

172

May 1999

Referring to the "Typical Application," the following approach

can be used to design the required thermistor interface

network:

Let

R1 =

R

T1

= 13.6k

(at 70

∞

C)

and

V

T

= 0.7V

DD

(70% of V

DD

)

Since

V =

V

R2

R

|| R1+ R2

T

DD

T1

◊

(

)

0.7 =

R2

R

+ R2

T1

(

)

0.7R

T1

+ 0.7R2 = R2

0.7R

T1

= 0.3R2

and

R2 = 2.33R

T1

= 2.33

◊

13.6k = 31.7k

33k

Let's continue by determining what the temperature-propor-

tional voltage is at 25

∞

C.

Let

R1 =

and

R

T1

= 100k

(at 25

∞

C).

From

V =

V

R2

R

+ R2

T

DD

T1

◊

(

)

V =

V

33k

100k + 33k

T

DD

◊

(

)

V

T

= 0.248V

DD

Recalling from above discussion that the desired V

T

for 25

∞

C

should be about 40% of V

DD

, the above value of 24.8% is far

too low. This would produce a voltage that would stop the fan

(recall from the above that this occurs when V

T

is about 30%

of V

DD

. To choose an appropriate value for R1 we need to

learn what the parallel combination of R

T1

and R1 should be

at 25

∞

C:

Again

V =

V

R2

R

|| R1+ R2

T

DD

T1

◊

(

)

0.4 =

R2

R

|| R1+ R2

T1

(

)

0.4(R

T1

|| R1) + 0.4R2 = R2

0.4(R

T1

|| R1) = 0.6R2

and

R

T1

|| R1 = 1.5R2 = 1.5

◊

33k = 49.5k

Since

R

T1

= 100k

and

RT1 || R1 = 49.5k

50k

let

R1 = 100k

While that solves the low temperature end of the range, there

is a small effect on the other end of the scale. The new value

of V

T

for 70

∞

C is 0.734, or about 73% of V

DD

. This represents

only a 3% shift from the design goal of 70% of V

DD

. In

summary, R1 = 100k, and R2 = 33k. The candidate thermistor

used in this design example is the RL2010-54.1K-138-D1,

manufactured by Keystone Thermometrics.

The R25 resistance (100k

) of the chosen thermistor is

probably on the high side of the range of potential thermistor

resistances. The result is a moderately high-impedance

network for connecting to the V

T1

and/or V

T2

input(s). Be-

cause these inputs can have up to 1

µ

A of leakage current,

care must be taken if the input network impedance becomes

higher than the example. Leakage current and resistor accu-

racy could require consideration in such designs. Note that

the V

SLP

input has this same leakage current specification.

Secondary Fan-Control Input

The above discussions also apply to the secondary fan-

control input, VT2, pin 5. It is possible that a second ther-

mistor, mounted at another temperature-critical location out-

side the power supply, may be appropriate. There is also the

possibility of accommodating the NLX "FanC" signal via this

input. If a second thermistor is the desired solution, the VT2

input may be treated exactly like the VT1 input. The above

discussions then apply directly. If, however, the NLX FanC

signal is to be incorporated into the design then the operating

voltage (V

DD

= 5V vs. V

DD

= 12V) becomes a concern. The

FanC signal is derived from a 12V supply and is specified to

swing at least to 10.5V. A minimum implementation of the

FanC signal would provide the capability of asserting full-

speed operation of the fan; this is the case when 10.5V

FanC

12V. This FanC signal can be applied directly to the

VT2 input of the MIC502, but only when its V

DD

is 12V. If this

signal is required when the MIC502 V

DD

= 5V a resistor

divider is necessary to reduce this input voltage so it does not

exceed the MIC502 V

DD

voltage. A good number is 4V

(80%V

DD

).

Because of input leakage considerations, the impedance of

the resistive divider should be kept at

100k

. A series

resistor of 120k

driven by the Fan C signal and a 100k

shunt resistor to ground make a good divider for driving the

V

T2

input.

Transistor and Base-Drive Resistor Selection

The OUT motor-drive output, pin 7, is intended for driving a

medium-power device, such as an NPN transistor. A rather

ubiquitous transistor, the 2N2222A, is capable of switching

up to about 400mA. It is also available as the PN2222A in a

plastic TO-92 package. Since 400mA is about the maximum

current for most popular computer power supply fans (with

many drawing substantially less current) and since the MIC502

provides a minimum of 10mA output current, the PN2222A,

with its minimum

of 40, is the chosen motor-drive transistor.

May 1999

173

MIC502

MIC502

Micrel

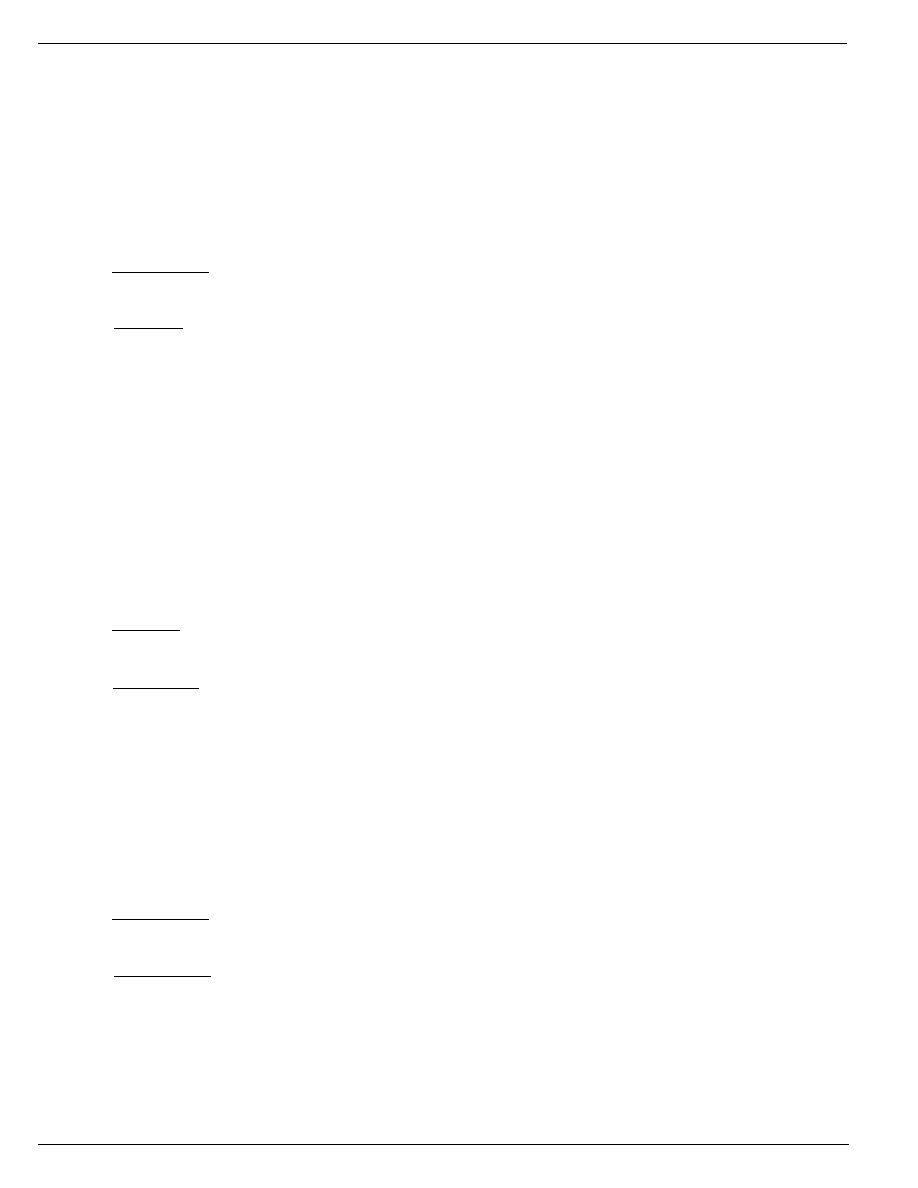

The design consists soley of choosing the value R

BASE

in

Figures 7 and 8. To minimize on-chip power dissipation in the

MIC502, the value of R

BASE

should be determined by the

power supply voltage. The Electrical Characteristics table

specifies a minimum output current of 10mA. However,

different output voltage drops (V

DD

≠ V

OUT

) exist for 5V vs.

12V operation. The value R

BASE

should be as high as

possible for a given required transistor base-drive current in

order to reduce on-chip power dissipation.

Referring to the "Typical Application" and to the "Electrical

Characteristics" table, the value for R

BASE

is calculated as

follows. For V

DD

= 5V systems, I

OH

of OUT (pin 7) is

guaranteed to be a minimum of 10mA with a V

OH

of 2.4V.

R

BASE

then equals (2.4V ≠ V

BE

)

˜

10mA = 170

.

For V

DD

= 12V systems, R

BASE

= (3.4 ≠ 0.7)

˜

0.01 = 250

.

Overtemperature Fault Output

The /OTF output, pin 6, is an open-collector NPN output. It is

compatible with CMOS and TTL logic and is intended for

alerting a system about an overtemperature condition or

triggering a power supply crowbar circuit. If V

DD

for the

MIC502 is 5V the output should not be pulled to a higher

voltage. This output can sink up to 2mA and remain compat-

ible with the TTL logic-low level.

Timing Capacitors vs. PWM Frequency

The recommended C

F

(see first page) is 0.1

µ

F for opertaion

at a PWM frequency of 30Hz. This frequency is factory

trimmed within

±

3Hz using a 0.1% accurate capacitor. If it is

desired to operate at a different frequency, the new value for

C

F

is calculated as follows:

C =

3

f

, where C is in

µ

F and f is in Hz.

The composition, voltage rating, ESR, etc., parameters of the

capacitor are not critical. However, if tight control of frequency

vs. temperature is an issue, the temperature coefficient may

become a consideration.

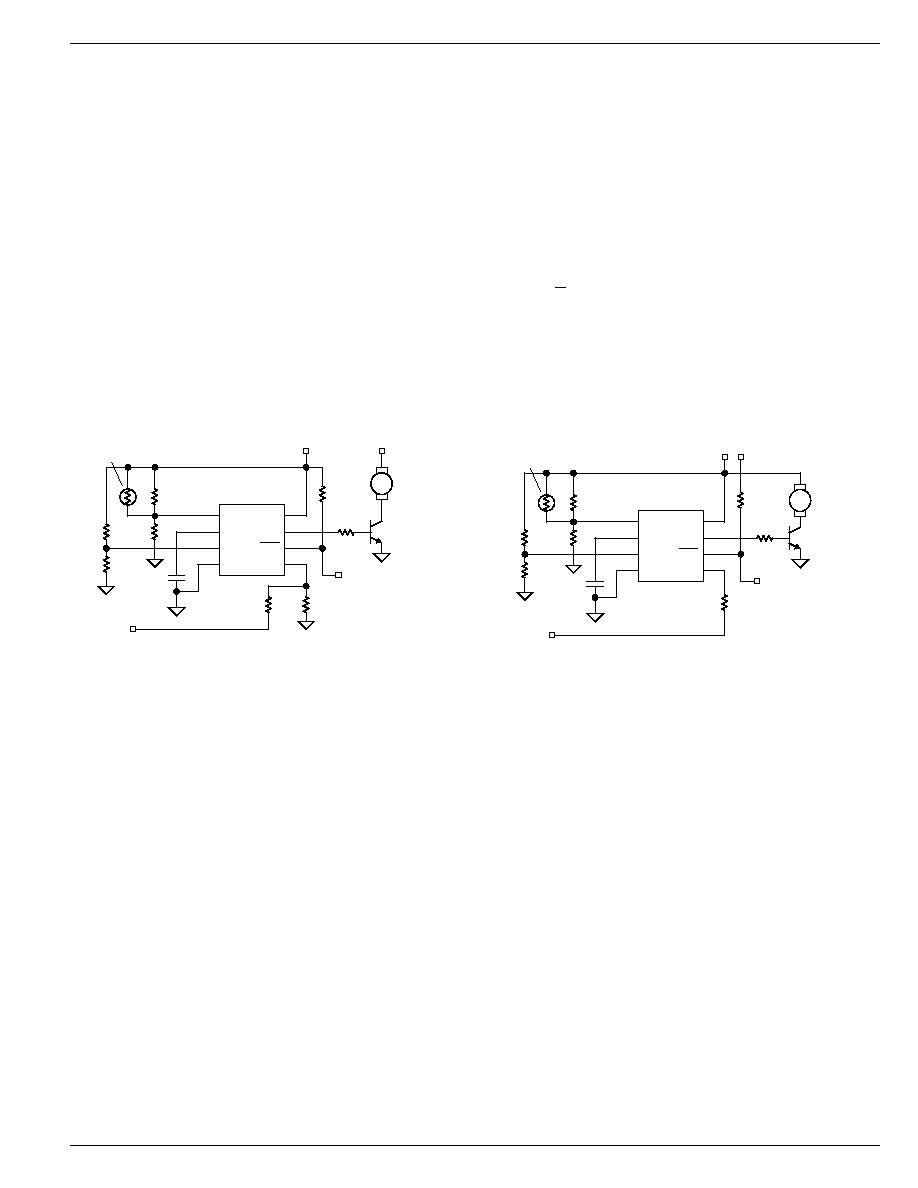

VT1

CF

VSLP

GND

VDD

OUT

OTF

VT2

1

2

3

4

8

7

6

5

R1

100k

T1

R3

56k

R4

56k

C

F

R2

33k

5V

R

BASE

Overtemperature

Fault Output

MIC502

NLX FanC

Signal Input

Yate Loon

YD80SM-12

or similar fan

Q1

0.1µF

180

100k

47k

Keystone Thermonics

RL2010-54.1K-138-D1

or similar

120k

12V

Figure 7. Typical 5V V

DD

Application Circuit

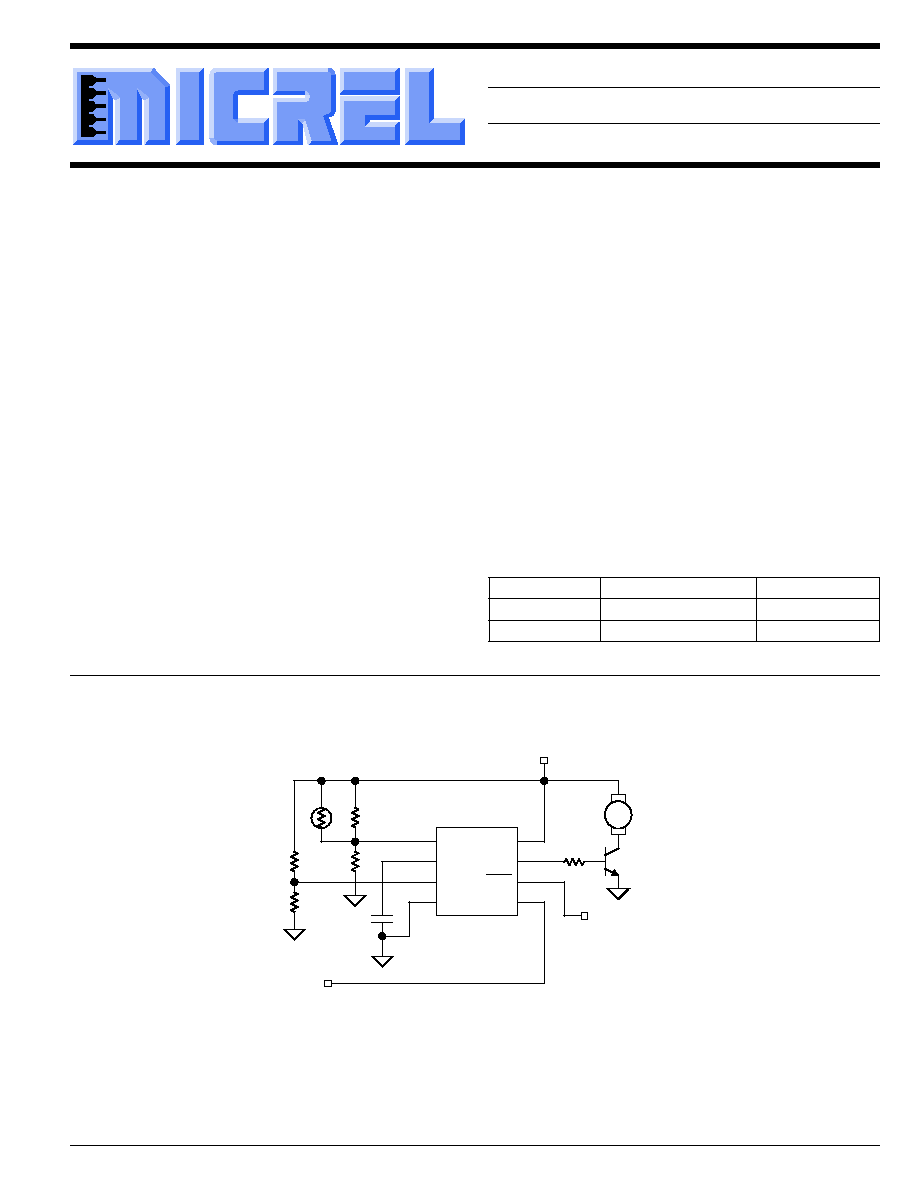

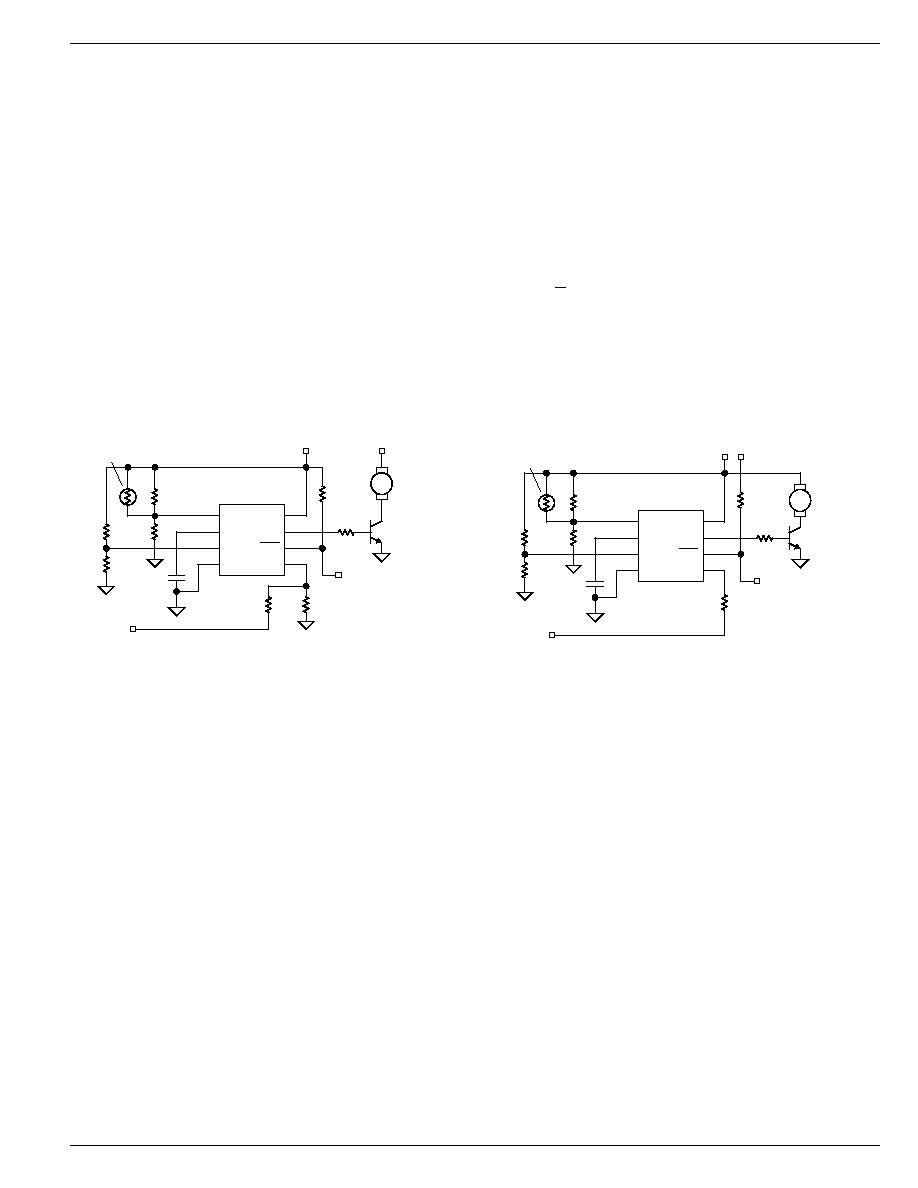

VT1

CF

VSLP

GND

VDD

OUT

OTF

VT2

1

2

3

4

8

7

6

5

R1

100k

T1

R3

56k

R4

56k

C

F

R2

33k

12V

R

BASE

Overtemperature

Fault Output

MIC502

NLX FanC

Signal Input

Yate Loon

YD80SM-12

or similar fan

Q1

0.1µF

280

5V

4.7k

47k

Keystone Thermonics

RL2010-54.1K-138-D1

or similar

Figure 8. Typical 12V V

DD

Application Circuit