| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: ML4423CS | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

July 2000

ML4423

*

1, 2, or 3-Phase Variable Speed AC Motor Controller

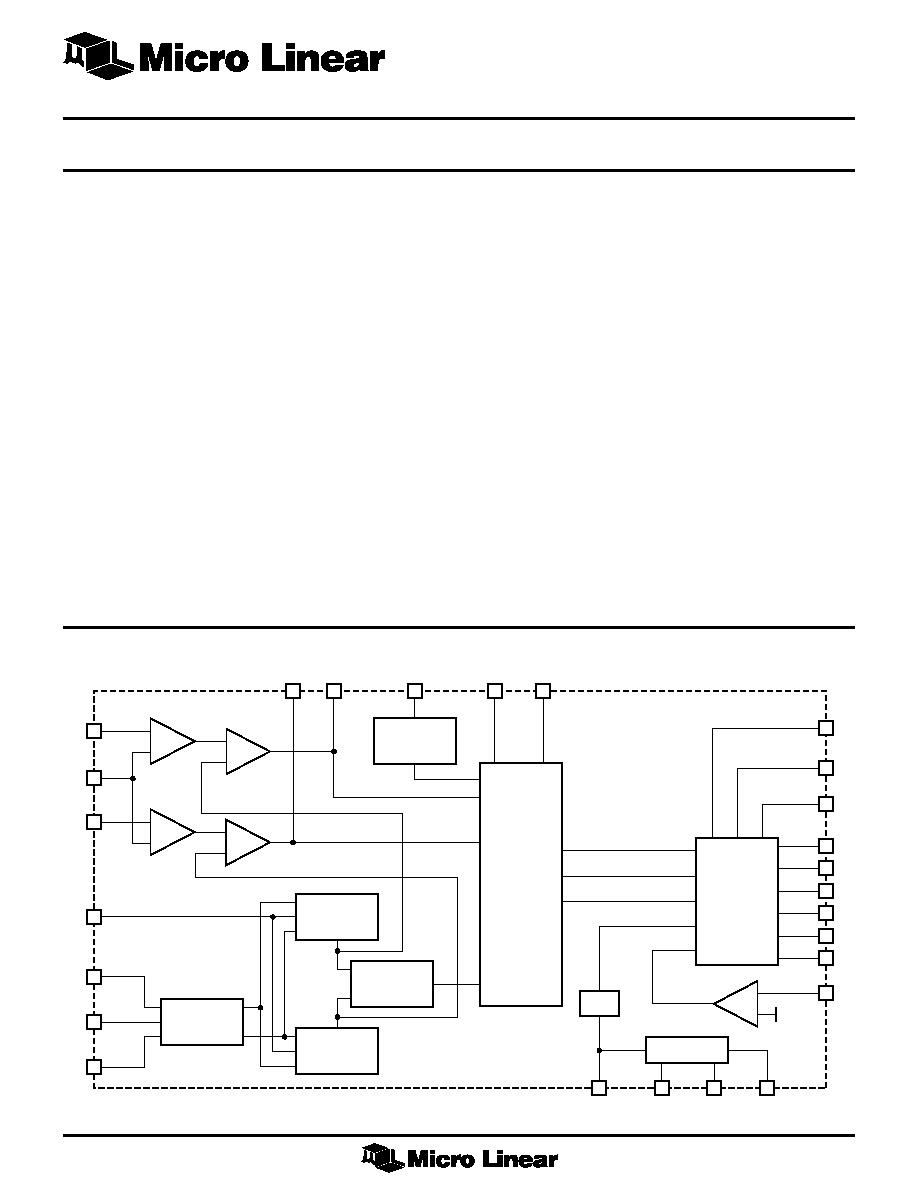

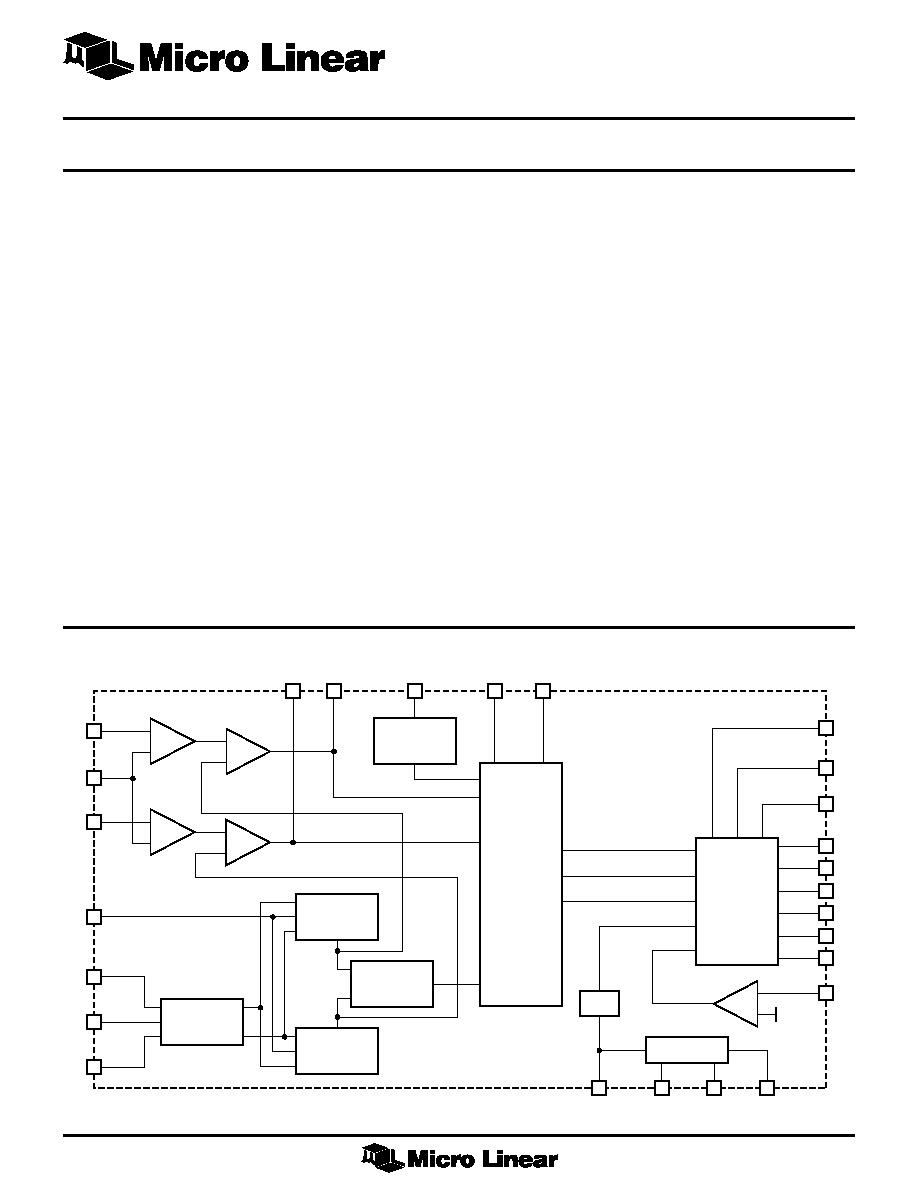

BLOCK DIAGRAM

1

GENERAL DESCRIPTION

The ML4423 provides the PWM sinewave drive signals

necessary for controlling three phase AC induction motors as

well as single and two phase split capacitor AC induction

motors.

A constant voltage/frequency ratio can be maintained

over a frequency range of greater than 10:1, providing

15Hz to 150Hz control. The output variable frequency AC

voltages are sensed and fed back to the controller to track the

sinewave frequency and amplitude set at the speed control

input. Direction, on two and three phase motors, is controlled

by changing the relative phase difference between the motor

windings: 90

◊ for two phase motors and 120◊ and 240◊ for three

phase motors.

To protect the motor, power devices, high voltage drivers

and control circuitry, the ML4423 includes fixed period,

pulse by pulse variable duty cycle current limit, deadtime

circuitry, and undervoltage lockout. The ML4423 has

selectable output voltage swing of 5V or 12V for

interfacing to different high side drivers and power devices.

FEATURES

s

Drives single, two, and three phase AC motors

s

Greater than 10:1 variable speed control range

s

Constant V/F ratio with programmable end points

s

Reverse capability for two and three phase motors

s

Low distortion PWM sinewave drive

s

Eliminates run capacitors in PSC motors

s

Coast function for quick power disable

s

Low cost interface for various gate drivers

s

PWM current limit, undervoltage lockout, and

programmable deadtime

s

12V

±20% operation with onboard 8V reference

(* Indicates Part Is End Of Life As Of July 1, 2000)

VSPEED

5

CO

12

FB A

1

RSPEED

6

VMIN

4

VDD

GND

RREF

REFERENCE

VREF

26

CT

17

8

7

HA

HB

HC

LA

LB

GATING

LOGIC

&

OUTPUT

DRIVERS

PWM

SINE

WAVE

CONTROL

PWM

OSCILLATOR

SINE A

GENERATOR

SINE C

GENERATOR

SPEED

CONTROL

SINE B

GENERATOR

UVLO

LC

20

ISENSE

16

19

21

23

22

24

5V/12 SELECT

25

RDT

9

COAST

14

13

SINE A-C

27

SINE B-C

28

3PH/2PH

18

F/

R

15

+

≠

COMP

0.5V

+

≠

+

≠

FB B

3

FB C

2

+

≠

+

≠

ML4423

2

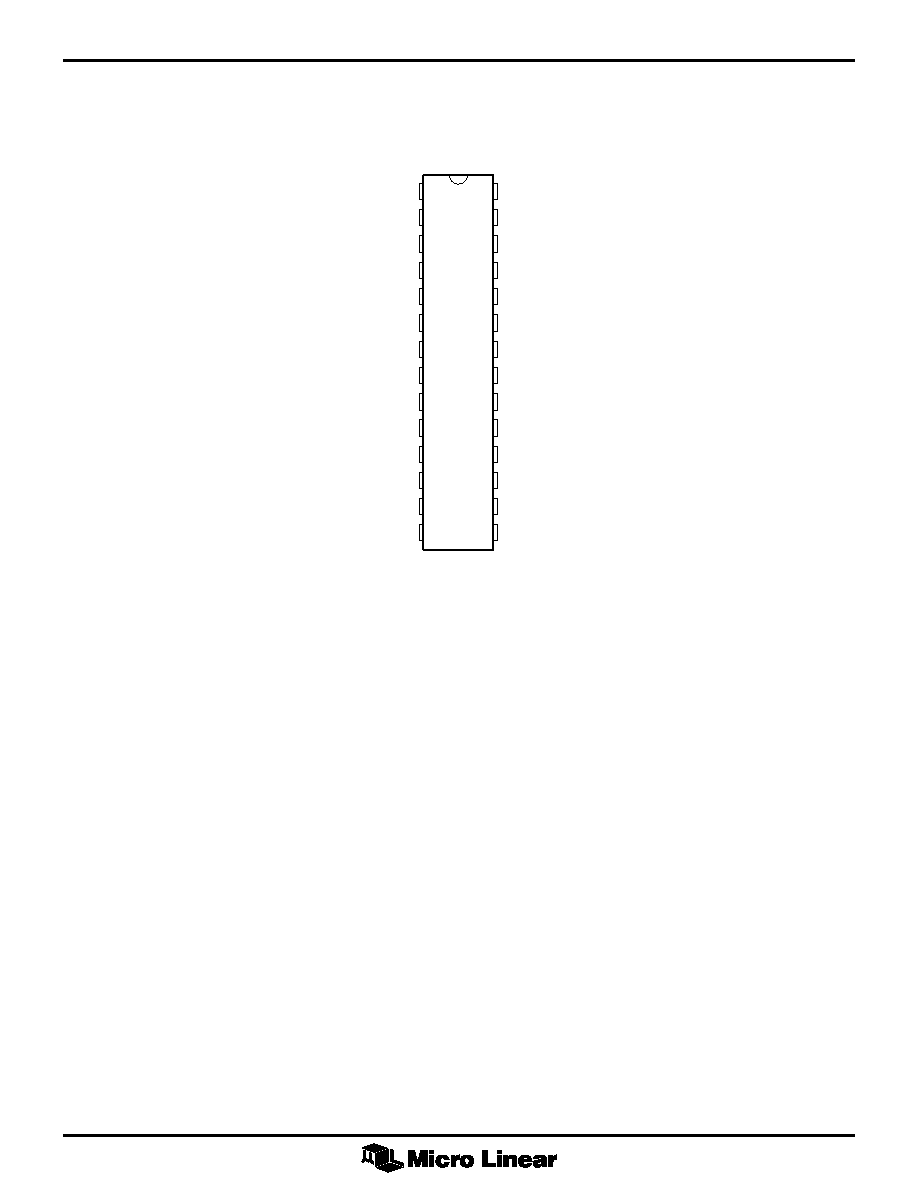

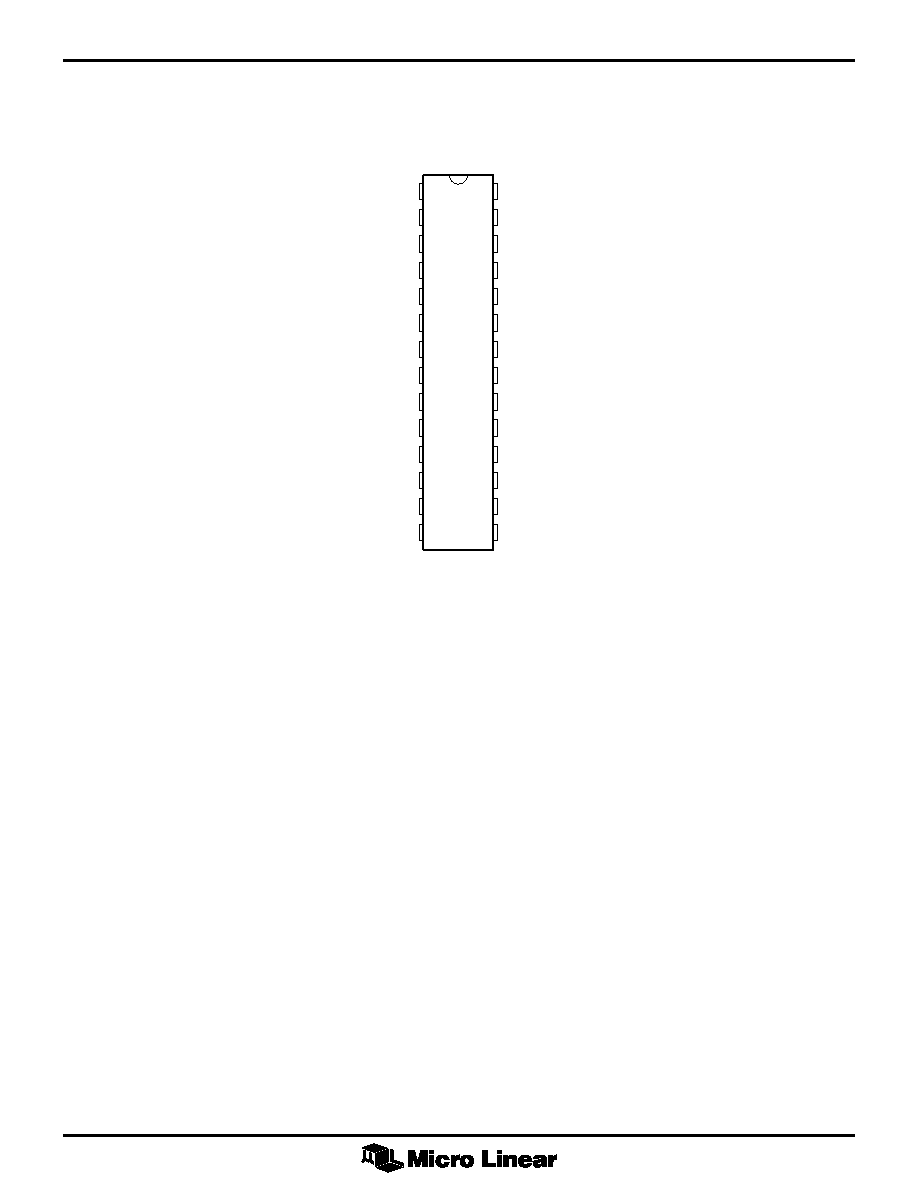

PIN CONFIGURATION

1

2

3

4

5

6

7

8

9

10

11

12

03

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

SENSE A

SENSE C

SENSE B

VMIN

VSPEED

RSPEED

VREF

RREF

RDT

SINE A-C

SINE B-C

CO

CT

COAST

CGM2

CGM1

VDD

5V/12V SELECT

HA

HC

HB

LA

LC

LB

3PH/2PH

GND

ISENSE

F/

R

TOP VIEW

ML4423

28-Pin Narrow PDIP (P28N)

28-Pin SOIC (S28)

ML4423

3

PIN DESCRIPTION

PIN

NAME

FUNCTION

1

FB A

Differential input which, in

conjunction with FB C, feeds back the

voltage applied across motor winding

A-C.

2

FB C

Input which feeds back the voltage

applied to motor winding C. Reference

voltage for windings A and B.

3

FB B

Differential input which, in

conjunction with FB C, feeds back the

voltage applied across motor winding

B-C.

4

V

MIN

The voltage on this pin sets the

minimum sinewave amplitude at low

speeds.

5

V

SPEED

The voltage on this pin sets the

frequency and amplitude of the

sinewaves generated at SINE

A

and

SINE

B

.

6

R

SPEED

An external resistor to ground provides

a variable current to the sinewave

generator. The current is proportional

to V

SPEED

.

7

V

REF

8V reference output which can be

used for setting V

SPEED

and V

MIN

.

8

R

REF

An external resistor to ground provides

a constant current used for setting the

PWM frequency in conjunction with

C

T

.

9

R

DT

An external resistor to ground sets the

deadtime in the output stage to

prevent cross-conduction in the power

devices.

10

SINE A-C

A test output for observing the

internally generated sinewave used for

motor winding A-C.

11

SINE B-C

A test output for observing the

internally generated sinewave used for

motor winding B-C.

12

C

O

An external capacitor to ground sets

the sinewave frequency in conjunction

with V

SPEED

and R

SPEED

.

PIN

NAME

FUNCTION

13

C

T

An external capacitor to ground sets

the PWM triangle frequency in

conjunction with the external resistor

R

REF

.

14

COAST

A logic low input causes all output

drive transistors to turn OFF. An

internal pull-up drives COAST to V

DD

if left unconnected.

15

F/R

A logic high input causes phase A to

lead phase B, while a logic low input

causes phase A to lag phase B. An

internal pull-up drives F/R to V

DD

if

left unconnected.

16

I

SENSE

Motor current sense input.

17

GND

Signal and power ground.

18

3PH/2PH

Leaving this pin unconnected selects

3-phase drive. Connecting this pin to

V

DD

selects single/2-phase drive.

19

LB

Low side drive output for phase B.

20

LC

Low side drive output for phase C.

21

LA

Low side drive output for phase A.

22

HB

High side drive output for phase B.

23

HC

High side drive output for phase C.

24

HA

High side drive output for phase A.

25

5V/12V

Input to select 5V or 12V output drive.

SELECT

Leaving this pin unconnected selects

5V output drive levels at the driver

outputs. Connecting this pin to V

CC

selects 12V output drive levels at the

driver outputs.

26

V

DD

12V power supply input.

27

C

GM1

An external capacitor to ground sets a

pole in the feedback loop.

28

C

GM2

An external capacitor to ground sets a

pole in the feedback loop.

ML4423

4

ABSOLUTE MAXIMUM RATINGS

Absolute maximum ratings are those values beyond which

the device could be permanently damaged. Absolute

maximum ratings are stress ratings only and functional

device operation is not implied.

V

DD ..............................................................................................

15V

Output Drive Current ...........................................

±50mA

Logic Inputs (F/R, COAST) .............................. ≠0.3 to 7V

Junction Temperature .............................................. 150∫C

Storage Temperature Range ...................... ≠65∫C to 150∫C

Lead Temperature (Soldering 10 sec) ...................... 260∫C

Thermal Resistance (

q

JA

)

Plastic DIP ....................................................... 52∫C/W

Plastic SOIC .................................................... 75∫C/W

OPERATING CONDITIONS

Temperature Range

C Suffix ...................................................... 0∫C to 70∫C

I Suffix .................................................... ≠40∫C to 85∫C

V

DD

........................................................... 9.6V to 14.4V

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, V

DD

= 12V

± 20%, R

SPEED

= 160k

W, R

SENSE

= 250m

W, R

REF

= 200k

W,

C

0

= 0.47

mF, C

PWM

= 220pF, R

DT

= 166k

W, T

A

= Operating Temperature Range (Note 1).

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

REFERENCE

V

REF

Output Voltage

7.6

7.8

8.2

V

Line Regulation

Total Variation

Line, Temperature

DIGITAL INPUTS

V

IL

Input Low Voltage

0.8

V

V

IH

Input High Voltage

2

V

OUTPUT DRIVERS

V

OL

Output Low Voltage

I

OL

= 20mA, 5V/12V SELECT = V

DD

1

V

I

OL

= 2mA, 5V/12V SELECT = open

0.1

V

V

OH

Output High Voltage

I

OL

= ≠20mA, 5V/12V SELECT = V

DD

V

DD

≠ 1

V

I

OL

= ≠2mA, 5V/12V SELECT = open

5

V

SINE WAVE GENERATOR

V

PP

Peak Voltage

V

SPEED

= 4.4V

3.4

V

Frequency

V

SPEED

= 4.4V

60

Hz

Distortion

5

%

PWM GENERATOR

Ramp Frequency

25

kHz

CURRENT LIMIT

Threshold Voltage

0.4

0.5

0.6

V

UNDERVOLTAGE LOCKOUT

Threshold Voltage

7.8

8.4

9.2

V

Hysteresis

0.5

V

SUPPLY

I

CC

V

CC

Operating Current

10

14

20

mA

Note 1: Limits are guaranteed by 100% testing, sampling, or correlation with worst-case test conditions.

ML4423

5

FUNCTIONAL DESCRIPTION

The ML4423 generates 2 reference sinewaves separated

by 90∫ or 60∫ in a closed loop feedback system. These

sinewaves can be varied in amplitude and frequency by

the speed input. Signals across the motor windings are fed

back and the ML4423 drives the external power output

stage with the PWM sinewave signal necessary to cause

the measured (feedback) output waveform to match the

internal reference sinewaves. The ML4423 provides fixed

period, variable duty cycle current limit protection, and

a programmable dead time circuit to prevent cross

conduction in the power output stage. An undervoltage

lockout circuit turns off the external power transistors if

V

DD

falls below 9V.

CIRCUIT BLOCKS AND COMPONENT SELECTION

R

REF

R

REF

should be set to 200k

W. This current along with

C

PWM

set the PWM frequency.

Speed Control

The voltage on V

SPEED

(pin 5) controls the sinewave

frequency and amplitude. A 160k

W resistor to ground on

R

SPEED

(pin 6) converts the voltage on V

SPEED

to a current

which is used to control the frequency of the output PWM

sinewaves. The amplitude of the sinewaves increases

linearly with V

SPEED

until it reahces 4.4V. Above this

voltage the amplitude remains constant and only the

frequency changes as shown in Figures 1 and 2.

SINE

A

and SINE

B

Generators

The capacitor to ground on C

0

sets the frequency of the

sinewave according to the following relationship. C

0

should be a low temperature coefficient capacitor for

stable output frequency.

f

V

R

C

V

SINE

SPEED

SPEED

=

◊

4

0 170

0

.

(1)

For R

SPEED

= 160k

W

f

V

C

SINE

SPEED

=

◊

108 800

0

,

(2)

With V

SPEED

= 3V and C

0

= 0.47

mF, f

SINE

= 58.7Hz and

can be observed at test points SINE

A

(pin 10) and SINE

B

(pin 11).

PWM Generator

A triangular PWM frequency will be generated on a

capacitor to ground on C

PWM

(pin 13). The frequency is

set by the following equation:

f

C

PWM

PWM

=

◊

1

200 000

,

(3)

For C

PWM

= 220pF, f

PWM

= 22.7kHz. It is recommended

150

120

90

60

30

0

2

4

6

8

V

SPEED

(V)

FREQ

UENCY (Hz)

RSPEED = 160

C0 = 0.47

µ

F

1.25

1.00

0.75

0.50

0.25

0

2

4

4.4V

6

8

NORMALIZED OUPTUT (V)

V

SPEED

(V)

Figure 1. Frequency vs V

SPEED

Figure 2. Normalized Output Voltage vs V

SPEED