| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: ML4803 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

February 1999

PRELIMINARY

ML4803

8-Pin PFC and PWM Controller Combo

1

BLOCK DIAGRAM

GENERAL DESCRIPTION

The ML4803 is a space-saving controller for power factor

corrected, switched mode power supplies that offers very

low start-up and operating currents.

Power Factor Correction (PFC) offers the use of smaller,

lower cost bulk capacitors, reduces power line loading

and stress on the switching FETs, and results in a power

supply fully compliant to IEC1000-3-2 specifications. The

ML4803 includes circuits for the implementation of a

leading edge, average current "boost" type PFC and a

trailing edge, PWM.

The ML4803-1's PFC and PWM operate at the same

frequency, 67kHz. The PFC frequency of the ML4803-2 is

automatically set at half that of the 134kHz PWM. This

higher frequency allows the user to design with smaller

PWM components while maintaining the optimum

operating frequency for the PFC. An overvoltage

comparator shuts down the PFC section in the event of a

sudden decrease in load. The PFC section also includes

peak current limiting for enhanced system reliability.

FEATURES

s

Internally synchronized PFC and PWM in one 8-pin IC

s

Patented one-pin voltage error amplifier with advanced

input current shaping technique

s

Peak or average current, continuous boost, leading

edge PFC (Input Current Shaping Technology)

s

High efficiency trailing-edge current mode PWM

s

Low supply currents; start-up: 150µA typ., operating:

2mA typ.

s

Synchronized leading and trailing edge modulation

s

Reduces ripple current in the storage capacitor

between the PFC and PWM sections

s

Overvoltage, UVLO, and brownout protection

s

PFC V

CC

OVP with PFC Soft Start

ISENSE

3

VEAO

4

VDC

5

ILIMIT

6

GND

2

PWM OUT

8

PFC OUT

1

≠

+

≠

+

COMP

COMP

35µA

16.2V

17.5V

VCC

+

≠

COMP

+

≠

≠1V

SOFT START

PFC/PWM UVLO

DUTY CYCLE

LIMIT

OSCILLATOR

PFC ≠ 67kHz

PWM ≠ 134kHz

VREF

VREF

1.2V

26k

40k

M1

R1

C1

30pF

M2

M7

M3

M4

M6

PWM

CONTROL

LOGIC

≠

+

1.5V

DC ILIMIT

PFC ILIMIT

PWM COMPARATOR

VCC OVP

PFC OFF

ONE PIN ERROR AMPLIFIER

LEADING

EDGE PFC

TRAILING

EDGE PWM

+

≠

COMP

7V

+

≠

COMP

≠1

≠4

REF

VCC

7

PFC

CONTROL

LOGIC

ML4803

2

February 1999

PIN CONFIGURATION

PIN DESCRIPTION

PIN

NAME

FUNCTION

1

PFC OUT

PFC driver output

2

GND

Ground

3

I

SENSE

Current sense input to the PFC current

limit comparator

4

VEAO

PFC one-pin error amplifier input

PIN

NAME

FUNCTION

5

V

DC

PWM voltage feedback input

6

I

LIMIT

PWM current limit comparator input

7

V

CC

Positive supply (may require an

external shunt regulator)

8

PWM OUT PWM driver output

1

2

3

4

8

7

6

5

PFC OUT

GND

ISENSE

VEAO

PWM OUT

VCC

ILIMIT

VDC

TOP VIEW

ML4803

8-Pin PDIP (P08)

8-Pin SOIC (S08)

ML4803

3

February 1999

ABSOLUTE MAXIMUM RATINGS

Absolute maximum ratings are those values beyond which

the device could be permanently damaged. Absolute

maximum ratings are stress ratings only and functional

device operation is not implied.

I

CC

Current (average) ............................................. 40mA

V

CC

MAX ............................................................... 18.3V

I

SENSE

Voltage .................................................. -5V to 1V

Voltage on Any Other Pin ...... GND - 0.3V to V

CC

+ 0.3V

Peak PFC OUT Current, Source or Sink ....................... 1A

Peak PWM OUT Current, Source or Sink ..................... 1A

PFC OUT, PWM OUT Energy Per Cycle .................. 1.5µJ

Junction Temperature .............................................. 150∞C

Storage Temperature Range ..................... ≠65∞C to 150∞C

Lead Temperature (Soldering, 10 sec) ..................... 260∞C

Thermal Resistance (

q

JA

)

Plastic DIP ..................................................... 110∞C/W

Plastic SOIC ................................................... 160∞C/W

OPERATING CONDITIONS

Temperature Range

ML4803CX-X ............................................. 0∞C to 70∞C

ML4803IX-X ............................................-40∞C to 85∞C

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, V

CC

= 15V, T

A

= Operating Temperature Range (Note 1)

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

ONE-PIN ERROR AMPLIFIER

VEAO Output Current

T

A

= 25∫C, V

EAO

= 6V

33.5

35.0

36.5

µA

Line Regulation

10V < V

CC

< 15V, V

EAO

= 6V

0.1

0.3

µA

V

CC

OVP COMPARATOR

Threshold Voltage

T

A

= 0∫C to 70∫C

15.5

16.0

16.5

V

PFC I

LIMIT

COMPARATOR

Threshold Voltage

-0.9

-1

-1.15

V

Delay to Output

150

300

ns

DC I

LIMIT

COMPARATOR

Threshold Voltage

1.4

1.5

1.6

V

Delay to Output

150

300

ns

OSCILLATOR

Initial Accuracy

T

A

= 25∞C

62

67

74

kHz

Voltage Stability

10V < V

CC

< 15V

1

%

Temperature Stability

2

%

Total Variation

Over Line and Temp

60

67

74.5

kHz

Dead Time

PFC Only

0.3

0.45

0.65

µs

PFC

Minimum Duty Cycle

V

EAO

> 7.0V,I

SENSE

= -0.2V

0

%

Maximum Duty Cycle

V

EAO

< 4.0V,I

SENSE

= 0V

90

95

%

Output Low Impedance

8

15

W

Output Low Voltage

I

OUT

= -100mA

0.8

1.5

V

I

OUT

= ≠10mA, V

CC

= 8V

0.7

1.5

V

ML4803

4

February 1999

ELECTRICAL CHARACTERISTICS

(Continued)

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

PFC (Continued)

Output High Impedance

8

15

W

Output High Voltage

I

OUT

= 100mA, V

CC

= 15V

13.5

14.2

V

Rise/Fall Time

C

L

= 1000pF

50

ns

PWM

Duty Cycle Range

TA = 0∫C to 70∫C, ML4803-2

0-43

0-47

0-50

%

TA = 0∫C to 70∫C, ML4803-1

0-49.5

0-50

%

Output Low Impedance

8

15

W

Output Low Voltage

I

OUT

= ≠100mA

0.8

1.5

V

I

OUT

= ≠10mA, V

CC

= 8V

0.7

1.5

V

Output High Impedance

8

15

W

Output High Voltage

I

OUT

= 100mA, V

CC

= 15V

13.5

14.2

V

Rise/Fall Time

C

L

= 1000pF

50

ns

SUPPLY

V

CC

Clamp Voltage (V

CCZ

)

I

CC

= 10mA

16.7

17.5

18.3

V

Start-up Current

V

CC

= 11V, C

L

= 0

0.2

0.4

mA

Operating Current

V

CC

= 15V, C

L

= 0

2.5

4

mA

Undervoltage Lockout Threshold

11.5

12

12.5

V

Undervoltage Lockout Hysteresis

2.4

2.9

3.4

V

Note 1:

Limits are guaranteed by 100% testing, sampling, or correlation with worst case test conditions.

ML4803

5

February 1999

FUNCTIONAL DESCRIPTION

The ML4803 consists of an average current mode boost

Power Factor Corrector (PFC) front end followed by a

synchronized Pulse Width Modulation (PWM) controller. It

is distinguished from earlier combo controllers by its low

pin count, innovative input current shaping technique, and

very low start-up and operating currents. The PWM section

is dedicated to peak current mode operation. It uses

conventional trailing-edge modulation, while the PFC uses

leading-edge modulation. This patented Leading Edge/

Trailing Edge (LETE) modulation technique helps to

minimize ripple current in the PFC DC buss capacitor.

The ML4803 is offered in two versions. The ML4803-1

operates both PFC and PWM sections at 67kHz, while the

ML4803-2 operates the PWM section at twice the

frequency (134kHz) of the PFC. This allows the use of

smaller PWM magnetics and output filter components,

while minimizing switching losses in the PFC stage.

In addition to power factor correction, several protection

features have been built into the ML4803. These include

soft start, redundant PFC over-voltage protection, peak

current limiting, duty cycle limit, and under voltage

lockout (UVLO). See Figure 12 for a typical application.

DETAILED PIN DESCRIPTIONS

V

EAO

This pin provides the feedback path which forces the PFC

output to regulate at the programmed value. It connects to

programming resistors tied to the PFC output voltage and

is shunted by the feedback compensation network.

I

SENSE

This pin ties to a resistor or current sense transformer

which senses the PFC input current. This signal should be

negative with respect to the IC ground. It internally feeds

the pulse-by-pulse current limit comparator and the

current sense feedback signal. The I

LIMIT

trip level is ≠1V.

The I

SENSE

feedback is internally multiplied by a gain of

four and compared against the internal programmed ramp

to set the PFC duty cycle. The intersection of the boost

inductor current downslope with the internal

programming ramp determines the boost off-time.

V

DC

This pin is typically tied to the feedback opto-collector. It

is tied to the internal 5V reference through a 26k

W resistor

and to GND through a 40k

W resistor.

I

LIMIT

This pin is tied to the primary side PWM current sense

resistor or transformer. It provides the internal pulse-by

pulse-current limit for the PWM stage (which occurs at

1.5V) and the peak current mode feedback path for the

current mode control of the PWM stage. The current ramp

is offset internally by 1.2V and then compared against the

opto feedback voltage to set the PWM duty cycle.

PFC OUT and PWM OUT

PFC OUT and PWM OUT are the high-current power

drivers capable of directly driving the gate of a power

MOSFET with peak currents up to ±1A. Both outputs are

actively held low when V

CC

is below the UVLO threshold

level.

V

CC

V

CC

is the power input connection to the IC. The V

CC

start-

up current is 150µA . The no-load I

CC

current is 2mA. V

CC

quiescent current will include both the IC biasing currents

and the PFC and PWM output currents. Given the

operating frequency and the MOSFET gate charge (Qg),

average PFC and PWM output currents can be calculated

as I

OUT

= Qg x F. The average magnetizing current

required for any gate drive transformers must also be

included. The V

CC

pin is also assumed to be proportional

to the PFC output voltage. Internally it is tied to the

V

CC

OVP comparator (16.2V) providing redundant high-

speed over-voltage protection (OVP) of the PFC stage.

V

CC

also ties internally to the UVLO circuitry, enabling

the IC at 12V and disabling it at 9.1V. V

CC

must be

bypassed with a high quality ceramic bypass capacitor

placed as close as possible to the IC.

Good bypassing is critical to the proper operation of the

ML4803.

V

CC

is typically produced by an additional winding off

the boost inductor or PFC Choke, providing a voltage that

is proportional to the PFC output voltage. Since the

V

CC

OVP max voltage is 16.2V, an internal shunt limits

V

CC

overvoltage to an acceptable value. An external

clamp, such as shown in Figure 1, is desirable but not

necessary.

V

CC

is internally clamped to 16.7V minimum, 18.3V

maximum. This limits the maximum V

CC

that can be

applied to the IC while allowing a V

CC

which is high

Figure 1. Optional V

CC

Clamp

VCC

GND

1N4148

1N4148

1N5246B

ML4803

6

February 1999

RAMP

VEAO

TIME

VSW1

TIME

REF

EA

≠

+

≠

+

OSC

DFF

R

D

Q

Q

CLK

U1

RAMP

CLK

U4

U3

C1

RL

I4

SW2

SW1

+

DC

I1

I2

I3

VIN

L1

U2

Figure 2. Typical Trailing Edge Control Scheme.

enough to trip the V

CC

OVP. The max current through this

zener is 10mA. External series resistance is required in

order to limit the current through this Zener in the case

where the V

CC

voltage exceeds the zener clamp level.

GND

GND is the return point for all circuits associated with

this part. Note: a high-quality, low impedance ground is

critical to the proper operation of the IC. High frequency

grounding techniques should be used.

POWER FACTOR CORRECTION

Power factor correction makes a nonlinear load look like a

resistive load to the AC line. For a resistor, the current

drawn from the line is in phase with, and proportional to,

the line voltage. This is defined as a unity power factor is

(one). A common class of nonlinear load is the input of a

most power supplies, which use a bridge rectifier and

capacitive input filter fed from the line. Peak-charging

effect, which occurs on the input filter capacitor in such a

supply, causes brief high-amplitude pulses of current to

flow from the power line, rather than a sinusoidal current

in phase with the line voltage. Such a supply presents a

power factor to the line of less than one (another way to

state this is that it causes significant current harmonics to

appear at its input). If the input current drawn by such a

supply (or any other nonlinear load) can be made to

follow the input voltage in instantaneous amplitude, it

will appear resistive to the AC line and a unity power

factor will be achieved.

To hold the input current draw of a device drawing power

from the AC line in phase with, and proportional to, the

input voltage, a way must be found to prevent that device

from loading the line except in proportion to the

instantaneous line voltage. The PFC section of the

ML4803 uses a boost-mode DC-DC converter to

accomplish this. The input to the converter is the full wave

rectified AC line voltage. No filtering is applied following

the bridge rectifier, so the input voltage to the boost

converter ranges, at twice line frequency, from zero volts

to the peak value of the AC input and back to zero. By

forcing the boost converter to meet two simultaneous

conditions, it is possible to ensure that the current that the

converter draws from the power line matches the

instantaneous line voltage. One of these conditions is that

the output voltage of the boost converter must be set

higher than the peak value of the line voltage. A

commonly used value is 385VDC, to allow for a high line

of 270VAC

RMS

. The other condition is that the current that

the converter is allowed to draw from the line at any given

instant must be proportional to the line voltage.

Since the boost converter topology in the ML4803 PFC is

of the current-averaging type, no slope compensation is

required.

LEADING/TRAILING MODULATION

Conventional Pulse Width Modulation (PWM) techniques

employ trailing edge modulation in which the switch will

turn ON right after the trailing edge of the system clock.

The error amplifier output voltage is then compared with

the modulating ramp. When the modulating ramp reaches

the level of the error amplifier output voltage, the switch

will be turned OFF. When the switch is ON, the inductor

FUNCTIONAL DESCRIPTION

(Continued)

ML4803

7

February 1999

REF

EA

≠

+

≠

+

OSC

DFF

R

D

Q

Q

CLK

U1

RAMP

CLK

U4

U3

C1

RL

I4

SW2

SW1

+

DC

I1

I2

I3

VIN

L1

VEAO

CMP

U2

RAMP

VEAO

TIME

VSW1

TIME

Figure 3. Typical Leading Edge Control Scheme.

current will ramp up. The effective duty cycle of the

trailing edge modulation is determined during the ON

time of the switch. Figure 2 shows a typical trailing edge

control scheme.

In the case of leading edge modulation, the switch is

turned OFF right at the leading edge of the system clock.

When the modulating ramp reaches the level of the error

amplifier output voltage, the switch will be turned ON.

The effective duty-cycle of the leading edge modulation is

determined during the OFF time of the switch. Figure 3

shows a leading edge control scheme.

One of the advantages of this control technique is that it

requires only one system clock. Switch 1 (SW1) turns OFF

and Switch 2 (SW2) turns ON at the same instant to

minimize the momentary "no-load" period, thus lowering

ripple voltage generated by the switching action. With

such synchronized switching, the ripple voltage of the first

stage is reduced. Calculation and evaluation have shown

that the 120Hz component of the PFC's output ripple

voltage can be reduced by as much as 30% using this

method, substantially reducing dissipation in the high-

voltage PFC capacitor.

TYPICAL APPLICATIONS

ONE PIN ERROR AMP

The ML4803 utilizes a one pin voltage error amplifier in

the PFC section (VEAO). The error amplifier is in reality a

current sink which forces 35µA through the output

programming resistor. The nominal voltage at the VEAO

pin is 5V. The VEAO voltage range is 4 to 6V. For a

11.3M

W resistor chain to the boost output voltage and 5V

steady state at the VEAO, the boost output voltage would

be 400V.

PROGRAMMING RESISTOR VALUE

Equation 1 calculates the required programming resistor

value.

Rp

V

V

I

V

V

A

M

BOOST

EAO

PGM

=

-

=

-

=

400

50

35

113

.

.

µ

(1)

PFC VOLTAGE LOOP COMPENSATION

The voltage-loop bandwidth must be set to less than

120Hz to limit the amount of line current harmonic

distortion. A typical crossover frequency is 30Hz.

Equation 1, for simplicity, assumes that the pole capacitor

dominates the error amplifier gain at the loop unity-gain

frequency. Equation 2 places a pole at the crossover

frequency, providing 45 degrees of phase margin.

Equation 3 places a zero one decade prior to the pole.

Bode plots showing the overall gain and phase are shown

in Figures 5 and 6. Figure 4 displays a simplified model of

the voltage loop.

C

Pin

R

V

VEAO C

f

COMP

p

BOOST

OUT

=

◊

◊

◊

◊ ◊ ◊

2

2

1

6

(2)

C

W

M

V

V

F

Hz

COMP

=

¥

¥

¥

¥ ¥ ¥

300

113

400

0 5

220

2

30

2

.

.

W

m

p

0

5

C

nF

COMP

= 16

LEADING/TRAILING MODULATION

(Continued)

ML4803

8

February 1999

Figure 4. Voltage Control Loop

60

40

20

0

≠20

≠40

≠60

GAIN (dB)

FREQUENCY (Hz)

0.1

10

1000

1

100

Power Stage

Overall Gain

Compensation

Network Gain

0

50

100

150

200

PHASE (

∫

)

FREQUENCY (Hz)

0.1

1

10

1000

100

Power Stage

Overall

Compensation

Network

Figure 5. Voltage Loop Gain

Figure 6. Voltage Loop Phase

50

40

30

20

10

0

I RAMP

(µA)

VEAO (V)

0

2

7

5

1

3

6

4

FF @ ≠55∫C

TYP @ ≠55∫C

TYP @ 155∫C

SS @ 155∫C

TYP @ ROOM TEMP

Figure 7. Internal Ramp Current vs. V

EAO

R

f

C

COMP

COMP

=

¥ ¥ ¥

1

2

p

(3)

R

Hz

nF

k

COMP

=

¥

¥

=

1

6 28 30

16

330

.

W

C

f

R

ZERO

COMP

=

¥ ¥

¥

1

2

10

p

(4)

C

Hz

k

F

ZERO

=

¥

¥

=

1

6 28 3

330

0 16

.

.

W

m

INTERNAL VOLTAGE RAMP

The internal ramp current source is programmed by way of

the VEAO pin voltage. Figure 7 displays the internal ramp

current vs. the VEAO voltage. This current source is used

to develop the internal ramp by charging the internal

30pF +12/≠10% capacitor. See Figures 10 and 11. The

frequency of the internal programming ramp is set

internally to 67kHz.

PFC CURRENT SENSE FILTERING

In DCM, the input current wave shaping technique used

by the ML4803 could cause the input current to run away.

In order for this technique to be able to operate properly

under DCM, the programming ramp must meet the boost

inductor current down-slope at zero amps. Assuming the

programming ramp is zero under light load, the OFF-time

will be terminated once the inductor current reaches zero.

Subsequently the PFC gate drive is initiated, eliminating

the necessary dead time needed for the DCM mode. This

forces the output to run away until the V

CC

OVP shuts

down the PFC. This situation is corrected by adding an

TYPICAL APPLICATIONS

(Continued)

ML4803

ML4803

IVEAO

35µA

IOUT

VO

220µF

RLOAD

667

330k

11.3M

0.15µF

15nF

POWER

STAGE

COMPENSATION

VEAO

VEAO +

≠

ML4803

9

February 1999

TYPICAL APPLICATIONS

(Continued)

Figure 8. PFC Soft Start

Figure 9. I

SENSE

Offset for Light Load Conditions

offset voltage to the current sense signal, which forces the

duty cycle to zero at light loads. This offset prevents the

PFC from operating in the DCM and forces pulse-skipping

from CCM to no-duty, avoiding DMC operation. External

filtering to the current sense signal helps to smooth out

the sense signal, expanding the operating range slightly

into the DCM range, but this should be done carefully, as

this filtering also reduces the bandwidth of the signal

feeding the pulse-by-pulse current limit signal. Figure 9

displays a typical circuit for adding offset to I

SENSE

at

light loads.

PFC Start-Up and Soft Start

During steady state operation VEAO draws 35µA. At start-

up the internal current mirror which sinks this current is

defeated until V

CC

reaches 12V. This forces the PFC error

voltage to V

CC

at the time that the IC is enabled. With

leading edge modulation V

CC

on the VEAO pin forces

zero duty on the PFC output. When selecting external

compensation components and V

CC

supply circuits VEAO

must not be prevented from reaching 6V prior to V

CC

reaching 12V in the turn-on sequence. This will guarantee

that the PFC stage will enter soft-start. Once V

CC

reaches

12V the 35µA VEAO current sink is enabled. VEAO

compensation components are then discharged by way of

the 35µA current sink until the steady state operating point

is reached. See Figure 8.

PFC SOFT RECOVERY FOLLOWING V

CC

OVP

The ML4803 assumes that V

CC

is generated from a source

that is proportional to the PFC output voltage. Once that

source reaches 16.2V the internal current sink tied to the

VEAO pin is disabled just as in the soft start turn-on

sequence. Once disabled, the VEAO pin charges HIGH

by way of the external components until the PFC duty

cycle goes to zero, disabling the PFC. The V

CC

OVP resets

once the VCC discharges below 16.2V, enabling the

VEAO current sink and discharging the VEAO

compensation components until the steady state operating

point is reached. It should be noted that, as shown in

Figure 8, once the VEAO pin exceeds 6.5V, the internal

ramp is defeated. Because of this, an external Zener can

be installed to reduce the maximum voltage to which the

VEAO pin may rise in a shutdown condition. Clamping

the VEAO pin externally to 7.4V will reduce the time

required for the VEAO pin to recover to its steady state

value.

UVLO

Once V

CC

reaches 12V both the PFC and PWM are

enabled. The UVLO threshold is 9.1V providing 2.9V of

hysteresis.

GENERATING V

CC

An internal clamp limits overvoltage to V

CC

. This clamp

circuit ensures that the V

CC

OVP circuitry of the ML4803

will function properly over tolerance and temperature

while protecting the part from voltage transients. This

circuit allows the ML4803 to deliver 15V nominal gate

drive at PWM OUT and PFC OUT, sufficient to drive low-

cost IGBTs.

It is important to limit the current through the Zener to

avoid overheating or destroying it. This can be done with

a single resistor in series with the V

CC

pin, returned to a

bias supply of typically 14V to 18V. The resistor value

must be chosen to meet the operating current requirement

of the ML4803 itself (4.0mA max) plus the current

required by the two gate driver outputs.

V

CC

OVP

V

CC

is assumed to be a voltage proportional to the PFC

output voltage, typically a bootstrap winding off the boost

0

0

200ms/Div.

VBOOST

0

VOUT

VEAO

VCC

10V/div.

10V/div.

10V/div.

200V/div.

0

PFC

GATE

C23

0.01µF

CR16

1N4148

R29

20k

VCC

RTN

R28

20k

R4

1k

C16

1µF

C5

0.0082µF

R19

10k

ISENSE

R3

0.015

3W

ML4803

10

February 1999

inductor. The V

CC

OVP comparator senses when this

voltage exceeds 16V, and terminates the PFC output drive

while disabling the VEAO current sink. Once the VEAO

current sink is disabled, the VEAO voltage will charge

unabated, except for a diode clamp to V

CC

, reducing the

PFC pulse width. Once the V

CC

rail has decreased to

below 16.2V the VEAO sink will be enabled, discharging

external VEAO compensation components until the steady

state voltage is reached. Given that 15V on V

CC

corresponds to 400V on the PFC output, 16V on V

CC

corresponds to an OVP level of 426V.

COMPONENT REDUCTION

Components associated with the V

RMS

and I

RMS

pins of a

typical PFC controller such as the ML4824 have been

eliminated. The PFC power limit and bandwidth does vary

with line voltage. Double the power can be delivered from

a 220 V AC line versus a 110 V AC line. Since this is a

combination PFC/PWM, the power to the load is limited

by the PWM stage.

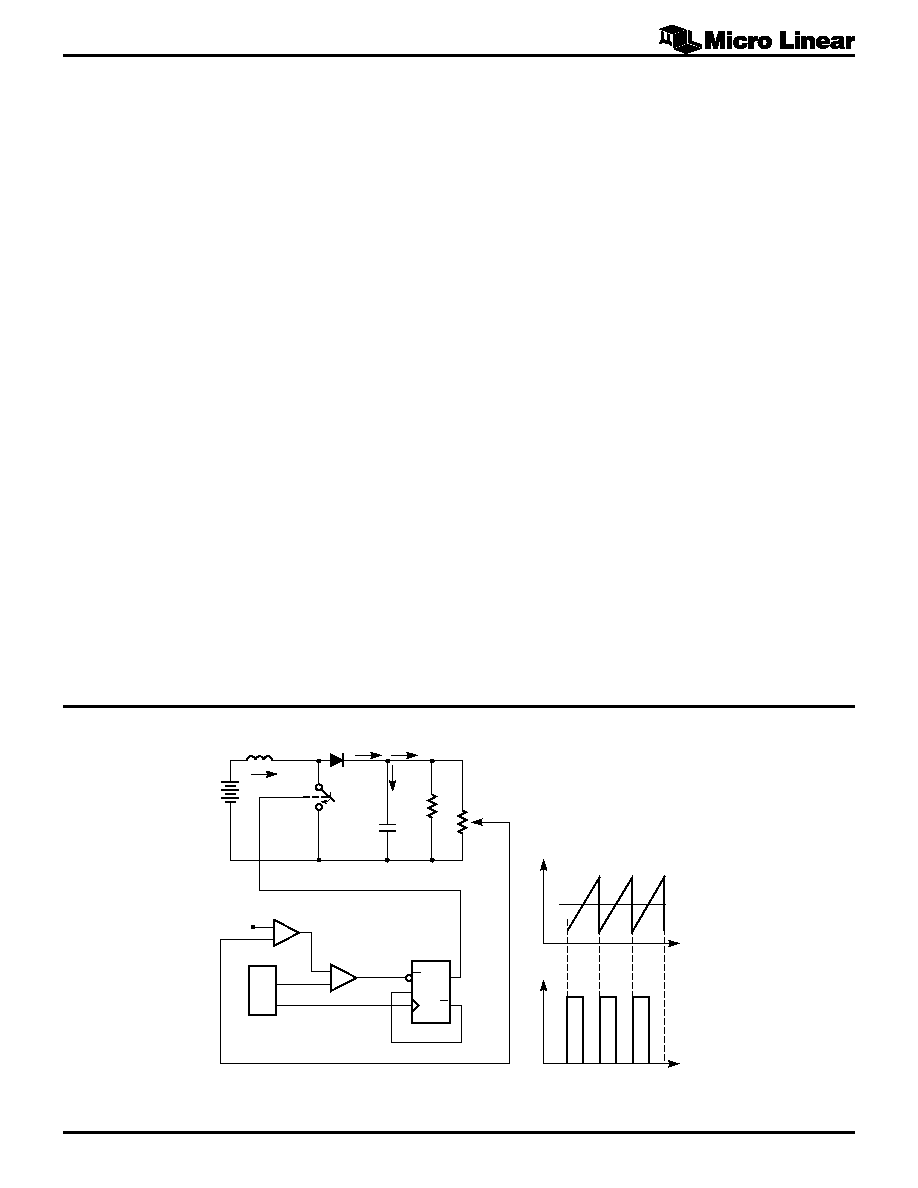

Figure 11. ML4803 PFC Control

Figure 10. Typical Peak Current Mode Waveforms

TYPICAL APPLICATIONS

(Continued)

VISENSE

VC1 RAMP

GATE

DRIVE

OUTPUT

CZERO

ISENSE

VC1

5V

VI SENSE

GATE

OUTPUT

RCOMP

RP

VOUT = 400V

VEAO

35µA

R1

4

+

≠

COMP

≠4

3

CCOMP

C1

30pF

ML4803

11

February 1999

Figure 12. Typical Application Circuit. Universal Input 240W 12V DC Output

BR1

600V

4A

LINE

NEUTRAL

F1 5A 250V

J1-1

J1-2

C19

4.7nF

250VAC

C20

4.7nF

250VAC

R24

470k

0.5W

TH1

10

5A

R3 0.15

3W

102T

L2

Q5

Q2

Q4

Q1

1000µH

R1

36

CR1 8A, 600V

CR7

CR3

CR18 51V

C26

0.01µF

500V

C18 4.7nF

CR2

30A, 60V

R36 220

L1 25µH

C29 0.01µF

CR2

30A

60V

C2

2200µF

C3

1µF

C1

220µF

450V

R2

L3

36

CR5

16V

0.5W

R22

10k

R8 36

R23

10k

R38 22

R30 200

C7

0.1µF

R27

20k

3W

R26

20k

3W

R10

0.75

3W

T2

T1

C23

0.01µF

CR4

CR11

CR10

CR12

CR9

R5 36

R11 150

Q3

R4 1k

ML4803

1

2

3

4

8

7

6

5

C15

0.015µF

C6

1µF

C5

8.2nF

C28

1µF

C9

1µF

C10

2.2nF

U2

4

5

1

2

2

3

1

R17 3.3k

R6 1.2k

C12 0.1µF

C25

0.01µF

500V

12V

J2-1

12VRET

J2-2

R18 1k

U3

CR8

L2

4T

CR15

1

10

3

4

R32 100

C27

0.01µF

R15

9.09k

7.0V

R21

10k

C14

4.7µF

C17

0.1µF

R16

2.37k

R13

5.62M

R7

10

CR16

IN4148

R12

5.62M

C4

0.47µF

250VAC

R14

150

2W

R37

330

R9

1.5k

C13 1nF

R31

10

C11

1000µF

C21

1µF

C22

1µF

R29 20k

R28

20k

R19

10k

PFC

GND

ISENSE

VEAO

PWM

VCC

ILIMIT

VDC

R20

510

R25

390k

C8

0.15µF

C16

0.01µF

ML4803

12

February 1999

PHYSICAL DIMENSIONS

inches (millimeters)

SEATING PLANE

0.240 - 0.260

(6.09 - 6.60)

PIN 1 ID

0.299 - 0.335

(7.59 - 8.50)

0.365 - 0.385

(9.27 - 9.77)

0.016 - 0.020

(0.40 - 0.51)

0.100 BSC

(2.54 BSC)

0.008 - 0.012

(0.20 - 0.31)

0.015 MIN

(0.38 MIN)

8

0∫ - 15∫

1

0.055 - 0.065

(1.39 - 1.65)

0.170 MAX

(4.32 MAX)

0.125 MIN

(3.18 MIN)

0.020 MIN

(0.51 MIN)

(4 PLACES)

Package: P08

8-Pin PDIP

SEATING PLANE

0.148 - 0.158

(3.76 - 4.01)

PIN 1 ID

0.228 - 0.244

(5.79 - 6.20)

0.189 - 0.199

(4.80 - 5.06)

0.012 - 0.020

(0.30 - 0.51)

0.050 BSC

(1.27 BSC)

0.015 - 0.035

(0.38 - 0.89)

0.059 - 0.069

(1.49 - 1.75)

0.004 - 0.010

(0.10 - 0.26)

0.055 - 0.061

(1.40 - 1.55)

8

0.006 - 0.010

(0.15 - 0.26)

0∫ - 8∫

1

0.017 - 0.027

(0.43 - 0.69)

(4 PLACES)

Package: S08

8-Pin SOIC

ML4803

13

February 1999

Micro Linear Corporation

2092 Concourse Drive

San Jose, CA 95131

Tel: (408) 433-5200

Fax: (408) 432-0295

www.microlinear.com

ORDERING INFORMATION

PART NUMBER

PFC/PWM FREQUENCY

TEMPERATURE RANGE

PACKAGE

ML4803CP-1

67kHz / 67kHz

0∞C to 70∞C

8-Pin PDIP (P08)

ML4803CS-1

67kHz / 67kHz

0∞C to 70∞C

8-Pin SOIC (S08)

ML4803IP-1

67kHz / 67kHz

-40∞C to 85∞C

8-Pin PDIP (P08)

ML4803IS-1

67kHz / 67kHz

-40∞C to 85∞C

8-Pin SOIC (S08)

ML4803CP-2

67kHz / 134kHz

0∞C to 70∞C

8-Pin PDIP (P08)

ML4803CS-2

67kHz / 134kHz

0∞C to 70∞C

8-Pin SOIC (S08)

ML4803IP-2

67kHz / 134kHz

-40∞C to 85∞C

8-Pin PDIP (P08)

ML4803IS-2

67kHz / 134kHz

-40∞C to 85∞C

8-Pin SOIC (S08)

© Micro Linear 1999.

is a registered trademark of Micro Linear Corporation. All other trademarks are the

property of their respective owners.

Products described herein may be covered by one or more of the following U.S. patents: 4,897,611; 4,964,026; 5,027,116;

5,281,862; 5,283,483; 5,418,502; 5,508,570; 5,510,727; 5,523,940; 5,546,017; 5,559,470; 5,565,761; 5,592,128; 5,594,376;

5,652,479; 5,661,427; 5,663,874; 5,672,959; 5,689,167; 5,714,897; 5,717,798; 5,742,151; 5,747,977; 5,754,012; 5,757,174;

5,767,653; 5,777,514; 5,793,168; 5,798,635; 5,804,950; 5,808,455; 5,811,999; 5,818,207; 5,818,669; 5,825,165; 5,825,223;

5,838,723; 5.844,378; 5,844,941. Japan: 2,598,946; 2,619,299; 2,704,176; 2,821,714. Other patents are pending.

Micro Linear makes no representations or warranties with respect to the accuracy, utility, or completeness of the contents

of this publication and reserves the right to make changes to specifications and product descriptions at any time without

notice. No license, express or implied, by estoppel or otherwise, to any patents or other intellectual property rights is granted

by this document. The circuits contained in this document are offered as possible applications only. Particular uses or

applications may invalidate some of the specifications and/or product descriptions contained herein. The customer is urged

to perform its own engineering review before deciding on a particular application. Micro Linear assumes no liability

whatsoever, and disclaims any express or implied warranty, relating to sale and/or use of Micro Linear products including

liability or warranties relating to merchantability, fitness for a particular purpose, or infringement of any intellectual property

right. Micro Linear products are not designed for use in medical, life saving, or life sustaining applications.

DS4803-01