GENERAL DESCRIPTION

The ML4871 is a continuous conduction boost regulator

designed for DC to DC conversion in multiple cell battery

powered systems. Continuous conduction allows the

regulator to maximize output current for a given inductor.

The maximum switching frequency can exceed 200kHz,

allowing the use of small, low cost inductors. The ML4871

is capable of start-up with input voltages as low as 1.8V

and is available in 5V and 3.3V output versions with an

output voltage accuracy of ±3%.

An integrated synchronous rectifier eliminates the need for

an external Schottky diode and provides a lower forward

voltage drop, resulting in higher conversion efficiency. In

addition, low quiescent battery current and variable

frequency operation result in high efficiency even at light

loads. The ML4871 requires only one inductor and two

capacitors to build a very small regulator circuit capable

of achieving conversion efficiencies approaching 90%.

The circuit also contains a RESET output which goes low

when the DETECT input drops below 1.25V.

BLOCK DIAGRAM

July 2000

ML4871

High Current Boost Regulator

1

FEATURES

s

Guaranteed full load start-up and operation

at 1.8V Input

s

Continuous conduction mode for high output current

s

Very low supply current (20µA output referenced) for

Micropower operation

s

Pulse Frequency Modulation and Internal Synchronous

Rectification for high efficiency

s

Maximum switching frequency > 200kHz

s

Minimum external components

s

Low ON resistance internal switching FETs

s

5V and 3.3V output versions

VL2

5

VOUT

6

+

≠

VIN

2

1.25V

START-UP

3

GND

VL1

1

DETECT

4

SYNCHRONOUS

RECTIFIER

CONTROL

BOOST

CONTROL

+

≠

+

≠

8

PWR GND

RESET

VREF

+

≠

COMP

7

FEATURING

Extended Commercial Temperature Range

-20∞C to 70∞C

for Portable Handheld Equipment

2

ML4871

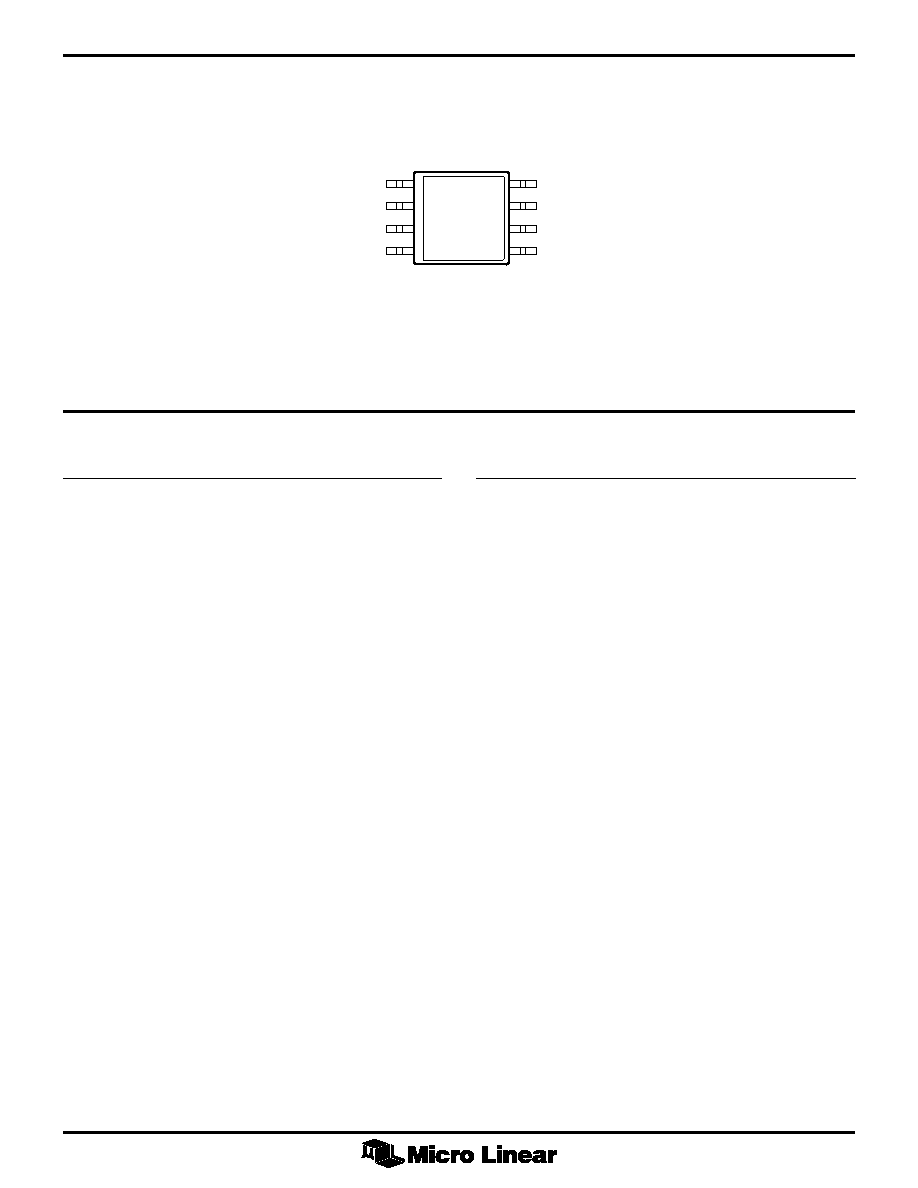

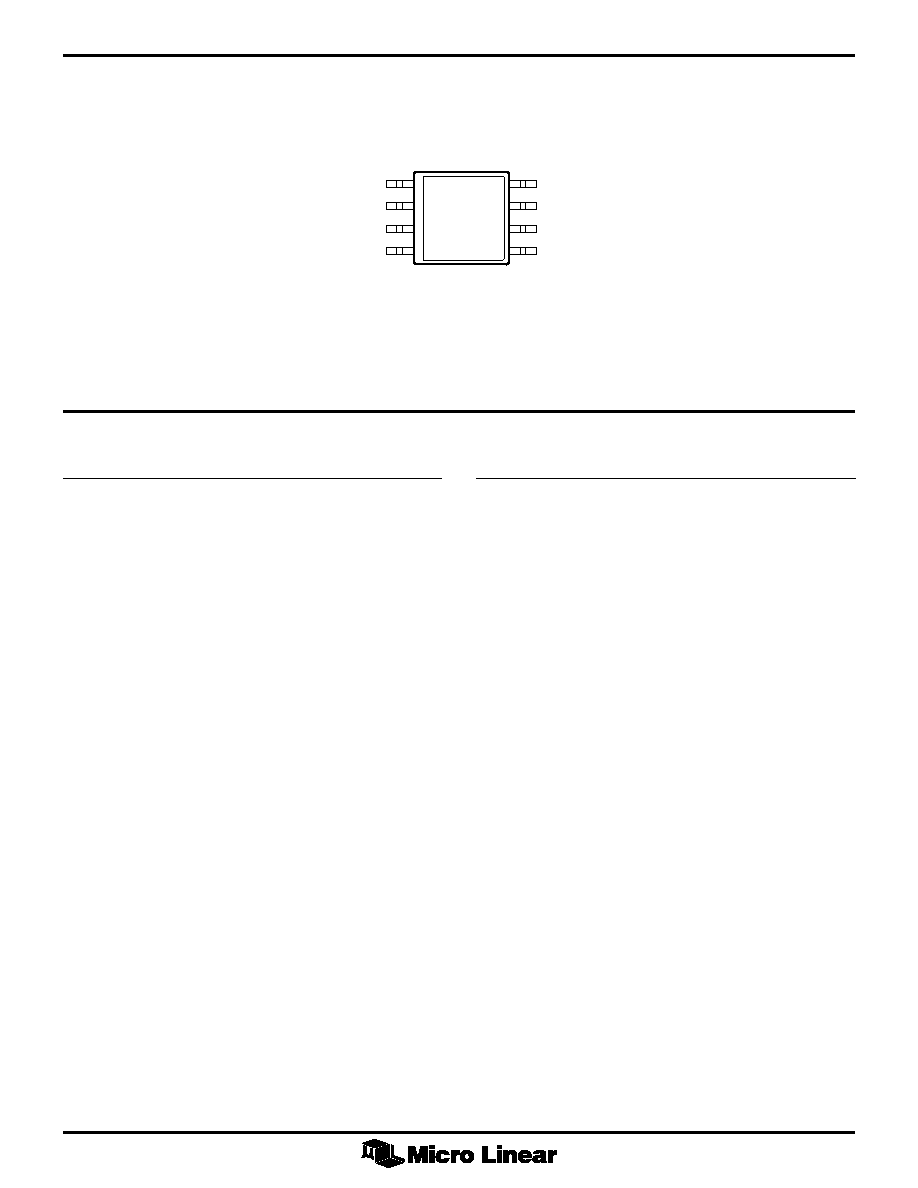

PIN CONFIGURATION

PIN DESCRIPTION

NO.

NAME

FUNCTION

1

V

L1

Boost inductor connection

2

V

IN

Battery input voltage

3

GND

Ground

4

DETECT

Pulling this pin below 1.25V causes

the RESET pin to go low

NO.

NAME

FUNCTION

5

V

OUT

Boost regulator output

6

V

L2

Boost inductor connection

7

RESET

Output goes low when DETECT goes

below 1.25V

8

PWR GND Return for the NMOS output transistor

ML4871

8-Pin SOIC (S08)

1

2

3

4

8

7

6

5

VL1

VIN

GND

DETECT

PWR GND

RESET

VL2

VOUT

TOP VIEW

3

ML4871

ABSOLUTE MAXIMUM RATINGS

Absolute maximum ratings are those values beyond which

the device could be permanently damaged. Absolute

maximum ratings are stress ratings only and functional

device operation is not implied.

V

OUT

........................................................................... 7V

Voltage on Any Other Pin .... GND ≠ 0.3V to V

OUT

+ 0.3V

Peak Switch Current (I

PEAK

) .......................................... 2A

Average Switch Current (I

AVG

) ..................................... 1A

Junction Temperature .............................................. 150∫C

Storage Temperature Range...................... ≠65∫C to 150∫C

Lead Temperature (Soldering 10 sec) ....................... 260∫C

Thermal Resistance (

q

JA

) .................................... 160∫C/W

OPERATING CONDITIONS

Temperature Range

ML4871CS-X ............................................. 0∫C to 70∫C

ML4871ES-X .......................................... ≠20∫C to 70∫C

V

IN

Operating Range

ML4871CS-X ................................ 1.8V to V

OUT

≠ 0.2V

ML4871ES-X ................................. 2.0V to V

OUT

≠ 0.2V

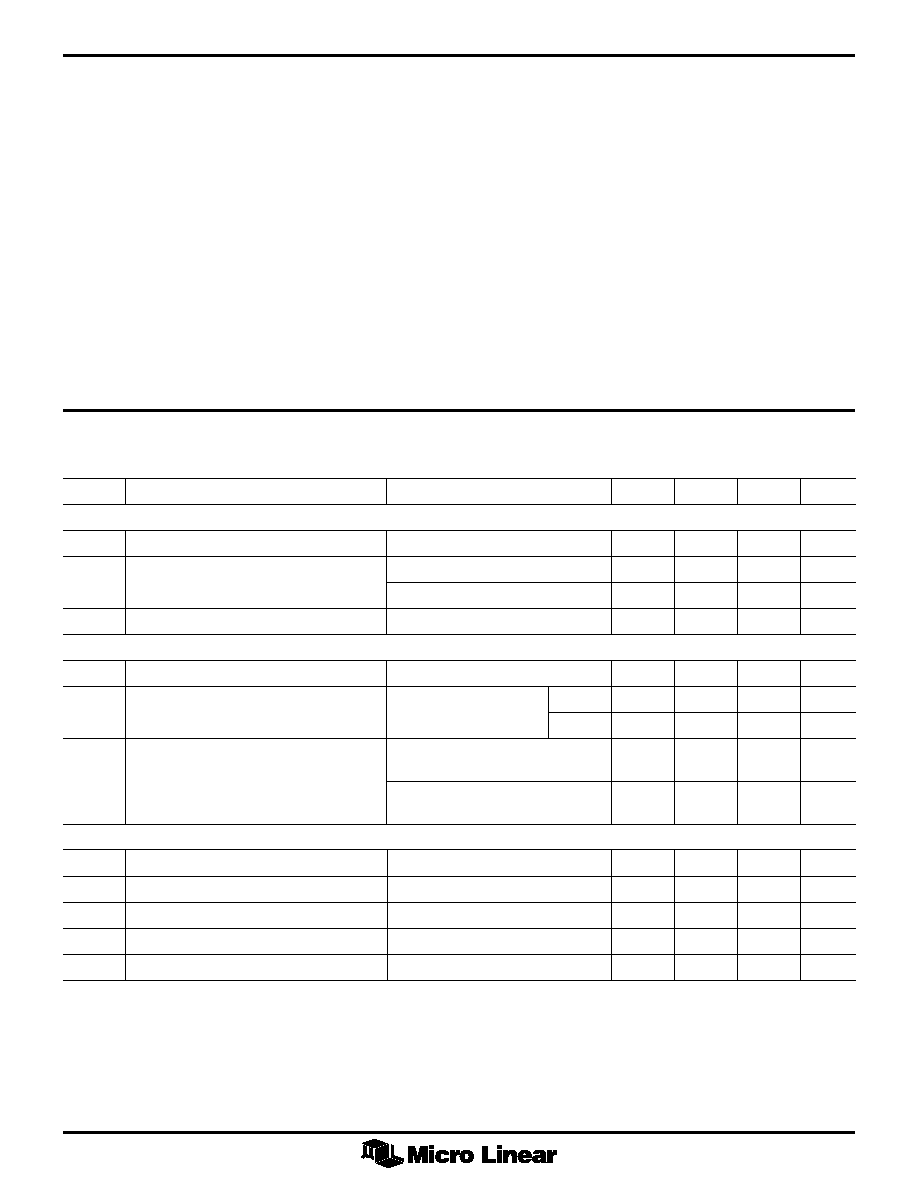

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, V

IN

= Operating Voltage Range, T

A

= Operating Temperature Range (Note 1).

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

SUPPLY

I

IN

V

IN

Current

V

IN

= V

OUT

≠ 0.2V

2

5

µA

I

OUT(Q)

V

OUT

Quiescent Current

DETECT = V

IN

30

40

µA

DETECT = 0V

25

35

µA

I

L(Q)

V

L

Quiescent Current

1

µA

PFM REGULATOR

I

L

Peak Current

1.2

1.4

1.7

A

V

OUT

Output Voltage

I

L(PEAK)

= 0

-3 Suffix

3.30

3.35

3.40

V

-5 Suffix

4.95

5.05

5.15

V

Load Regulation

See Figure 1, -3 Suffix

3.20

3.25

3.40

V

V

IN

= 2.4V, I

OUT

£ 400mA

See Figure 1, -5 Suffix

4.85

4.95

5.15

V

V

IN

= 2.4V, I

OUT

£ 220mA

RESET COMPARATOR

DETECT Threshold

1.18

1.25

1.28

V

DETECT Hysteresis

25

35

45

mV

DETECT Bias Current

≠100

100

nA

RESET Output High Voltage

I

RESET

= ≠200µA

V

OUT

≠ 0.2

V

RESET Output Low Voltage

I

RESET

= 500µA

0.2

V

Note 1:

Limits are guaranteed by 100% testing, sampling, or correlation with worst case test conditions.

4

ML4871

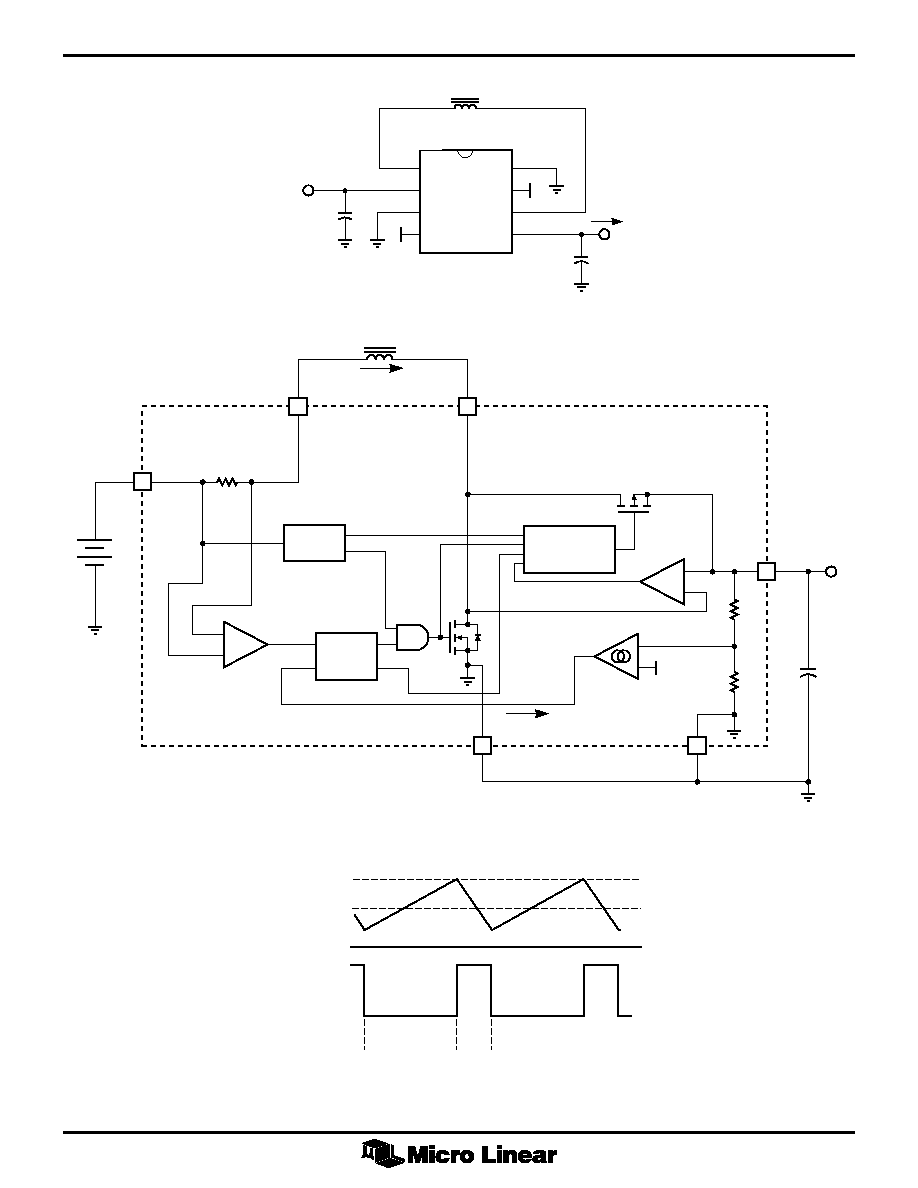

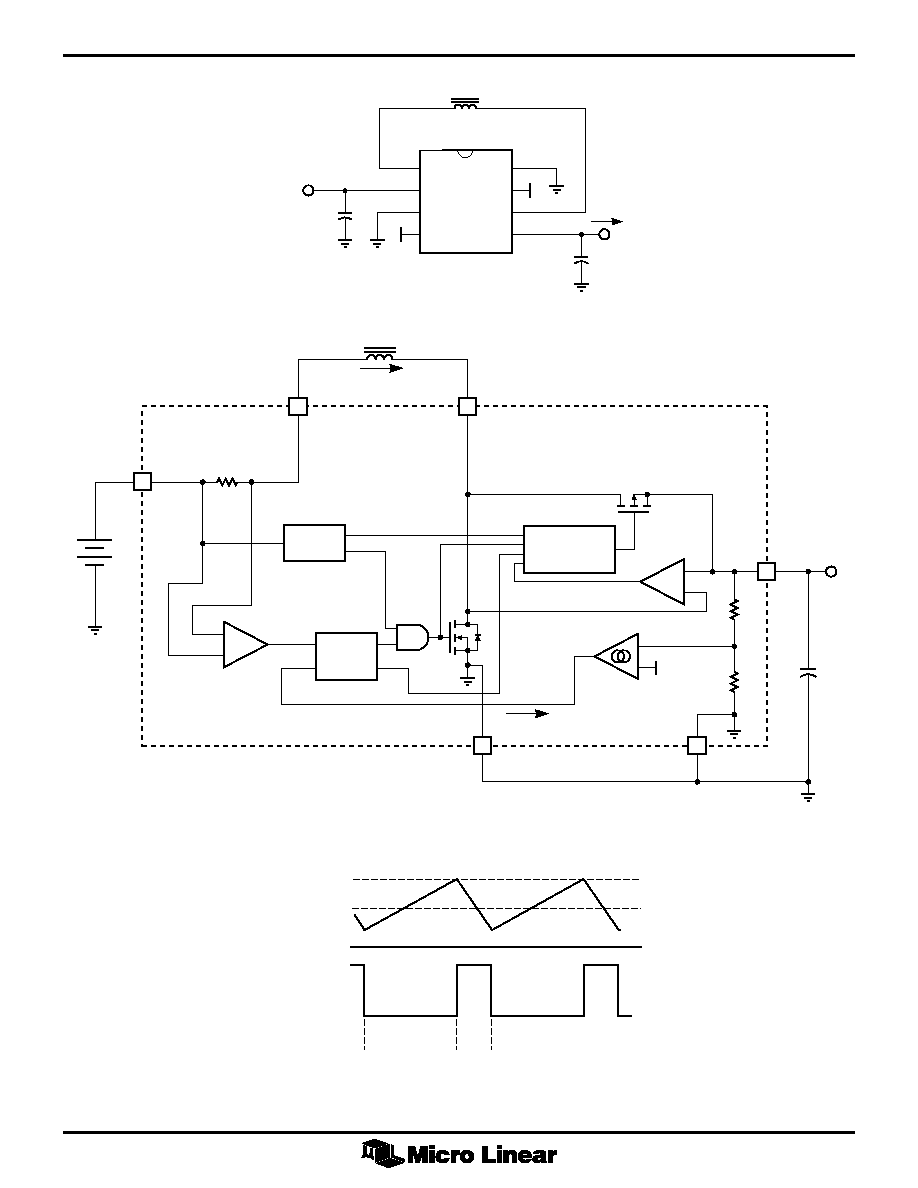

Figure 1. Application Test Circuit.

Figure 3. Inductor Current and Voltage Waveforms.

Figure 2. PFM Regulator Block Diagram.

ML4871

IOUT

200µF

100µF

VIN

20µH

(Sumida CD75)

VL1

VIN

GND

DETECT

PWR GND

RESET

VL2

VOUT

Q1 ON

Q2 OFF

Q1 OFF

Q2 ON

IL

VL2

IL(MAX)

ISET

VOUT

0

0

VL2

5

VOUT

6

+

≠

VIN

IL

2

1.25V

START-UP

3

GND

VL1

1

SYNCHRONOUS

RECTIFIER

CONTROL

BOOST

CONTROL

+

≠

+

≠

8

PWR GND

A1

A2

A3

Q1

Q2

VOUT

RSENSE

ISET

5

ML4871

FUNCTIONAL DESCRIPTION

The ML4871 combines a unique form of current mode

control with a synchronous rectifier to create a boost

converter that can deliver high currents while maintaining

high efficiency. Current mode control allows the use of a

very small, high frequency inductor and output capacitor.

Synchronous rectification replaces the conventional

external Schottky diode with an on-chip PMOS FET to

reduce losses and eliminate an external component. Also

included on-chip are an NMOS switch and current sense

resistor, further reducing the number of external

components, which makes the ML4871 very easy to use.

REGULATOR OPERATION

The ML4871 is a variable frequency, current mode

switching regulator. Its unique control scheme converts

efficiently over more than three decades of load current.

A block diagram of the boost converter is shown in Figure 2.

Error amp A3 converts deviations in the desired output

voltage to a small current, I

SET

. The inductor current is

measured through a 50m

W resistor which is amplified by

A1. The boost control block matches the average inductor

current to a multiple of the I

SET

current by switching Q1

on and off. The peak inductor current is limited by the

controller to about 1.5A.

At light loads, I

SET

will momentarily reach zero after an

inductor discharge cycle , causing Q1 to stop switching.

Depending on the load, this idle time can extend to tenths

of seconds. While the circuit is not switching, only 20µA

of supply current is drawn from the output. This allows the

part to remain efficient even when the load current drops

below 200µA.

Amplifier A2 and the PMOS transistor Q2 work together to

form a low drop diode. When transistor Q1 turns off, the

current flowing in the inductor causes pin 6 to go high. As

the voltage on V

L2

rises above V

OUT

, amplifier A2 allows

the PMOS transistor Q2 to turn on. In discontinuous

operation, (where I

L

always returns to zero), A2 uses the

resistive drop across the PMOS switch Q2 to sense zero

inductor current and turns the PMOS switch off. In

continuous operation, the PMOS turn off is independent of

A2, and is determined by the boost control circuitry.

Typical inductor current and voltage waveforms are shown

in Figure 3.

RESET COMPARATOR

An additional comparator is provided to detect low V

IN

,

low V

OUT

, or any other error condition that the user may

want to sense. The inverting input of the comparator is

connected to the 1.25V reference, and the non-inverting

input is connected to the DETECT pin. The output of this

comparator is connected to the RESET pin of the device

and can swing from V

OUT

to ground.

DESIGN CONSIDERATIONS

OUTPUT CURRENT CAPABILITY

The maximum current available at the output of the

regulator is related to the maximum inductor current by

the ratio of the input to output voltage and the full load

efficiency. The maximum inductor current is

approximately 1.25A and the full load efficiency may be

as low as 70%. The maximum output current can be

determined by using the typical performance curves

shown in Figures 4 and 5, or by calculation using the

following equation:

I

V

V

A

OUT MAX

IN MIN

OUT

(

)

(

)

.

.

=

125

0 7

(1)

INDUCTOR SELECTION

The ML4871 is able to operate over a wide range of

inductor values. A value of 10µH is a good choice, but any

value between 5µH and 33µH is acceptable. As the

inductor value is changed the control circuitry will

automatically adjust to keep the inductor current under

control. Choosing an inductance value of less than 10µH

will reduce the component's footprint, but the efficiency

and maximum output current may drop.

It is important to use an inductor that is rated to handle 1.5A

peak currents without saturating. Also look for an inductor

with low winding resistance. A good rule of thumb is to

allow 5 to 10m

W of resistance for each µH of inductance.

The final selection of the inductor will be based on trade-

offs between size, cost and efficiency. Inductor tolerance,

core and copper loss will vary with the type of inductor

selected and should be evaluated with a ML4871 under

worst case conditions to determine its suitability.

Several manufacturers supply standard inductance values

in surface mount packages:

Coilcraft

(847) 639-6400

Coiltronics

(561) 241-7876

Dale

(605) 665-9301

Sumida

(847) 956-0666