| ÐлекÑÑоннÑй компоненÑ: TC648BEOA | СкаÑаÑÑ:  PDF PDF  ZIP ZIP |

PWM Fan Speed Controllers With Auto-Shutdown, Fan Restart and FanSense Technology for Fault Detection

2003 Microchip Technology Inc.

DS21755B-page 1

M

TC646B/TC648B/TC649B

Features

· Temperature-Proportional Fan Speed for Acoustic

Noise Reduction and Longer Fan Life

· Efficient PWM Fan Drive

· 3.0V to 5.5V Supply Range:

- Fan Voltage Independent of TC646B/

TC648B/TC649B Supply Voltage

- Supports any Fan Voltage

· FanSense

TM

Fault Detection Circuit Protects

Against Fan Failure and Aids System Testing

(TC646B/TC649B)

· Automatic Shutdown Mode for "Green" Systems

· Supports Low Cost NTC/PTC Thermistors

· Over-Temperature Indication (TC646B/TC648B)

· Fan Auto-Restart

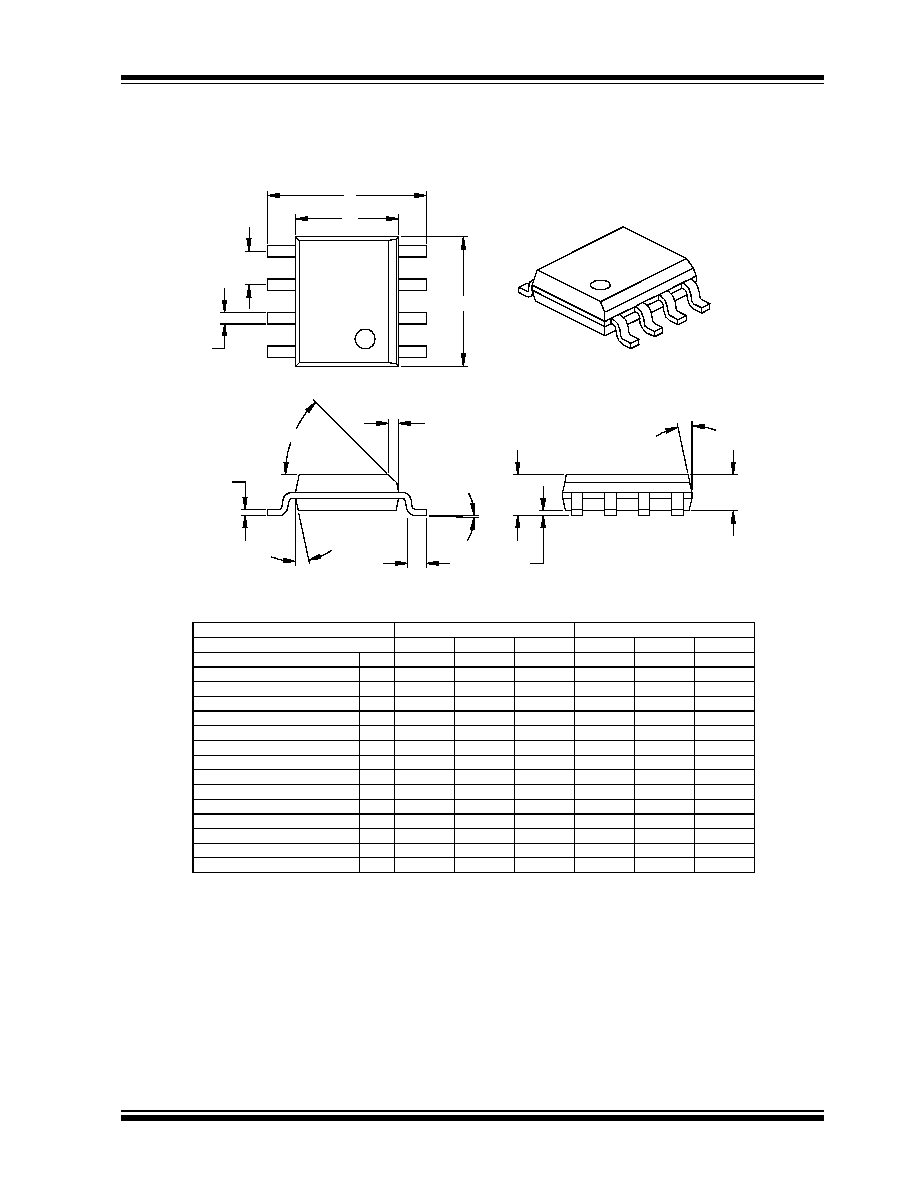

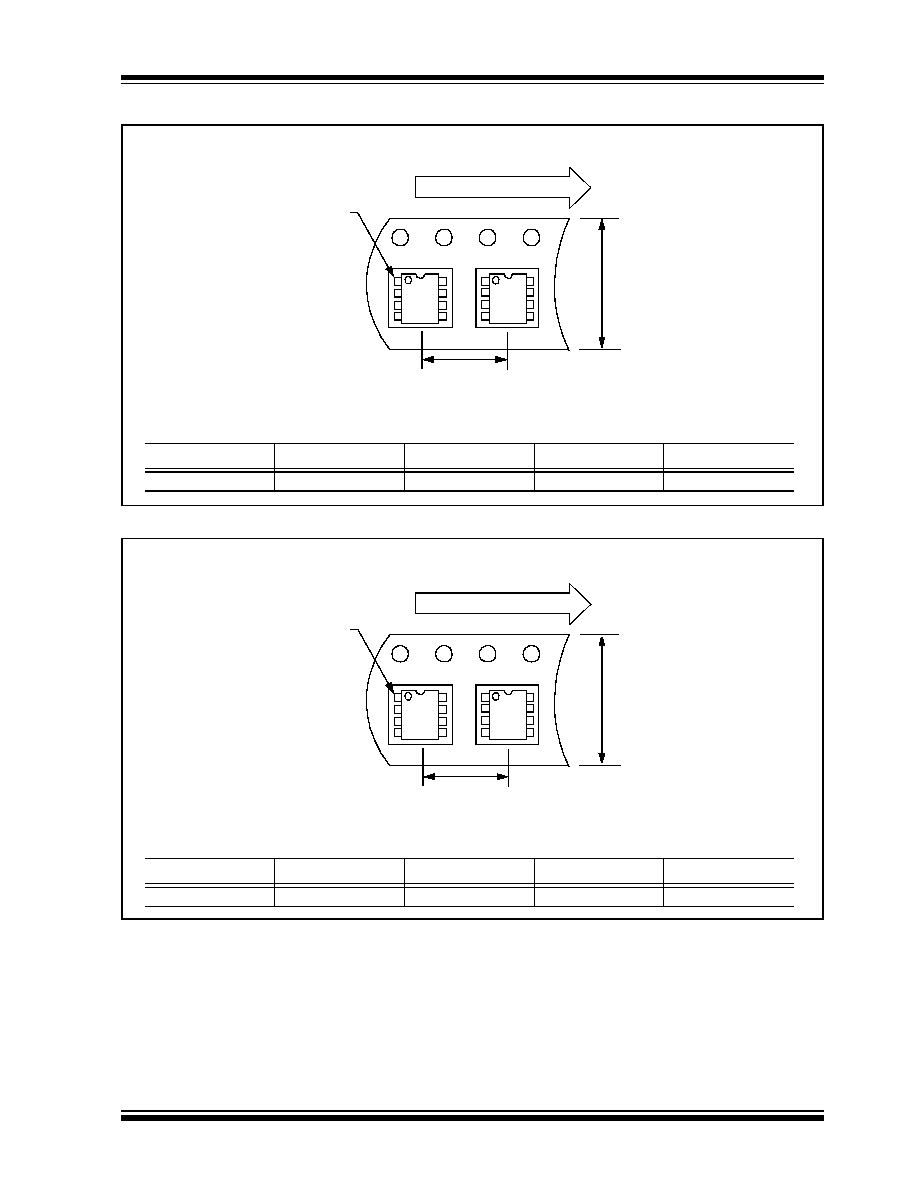

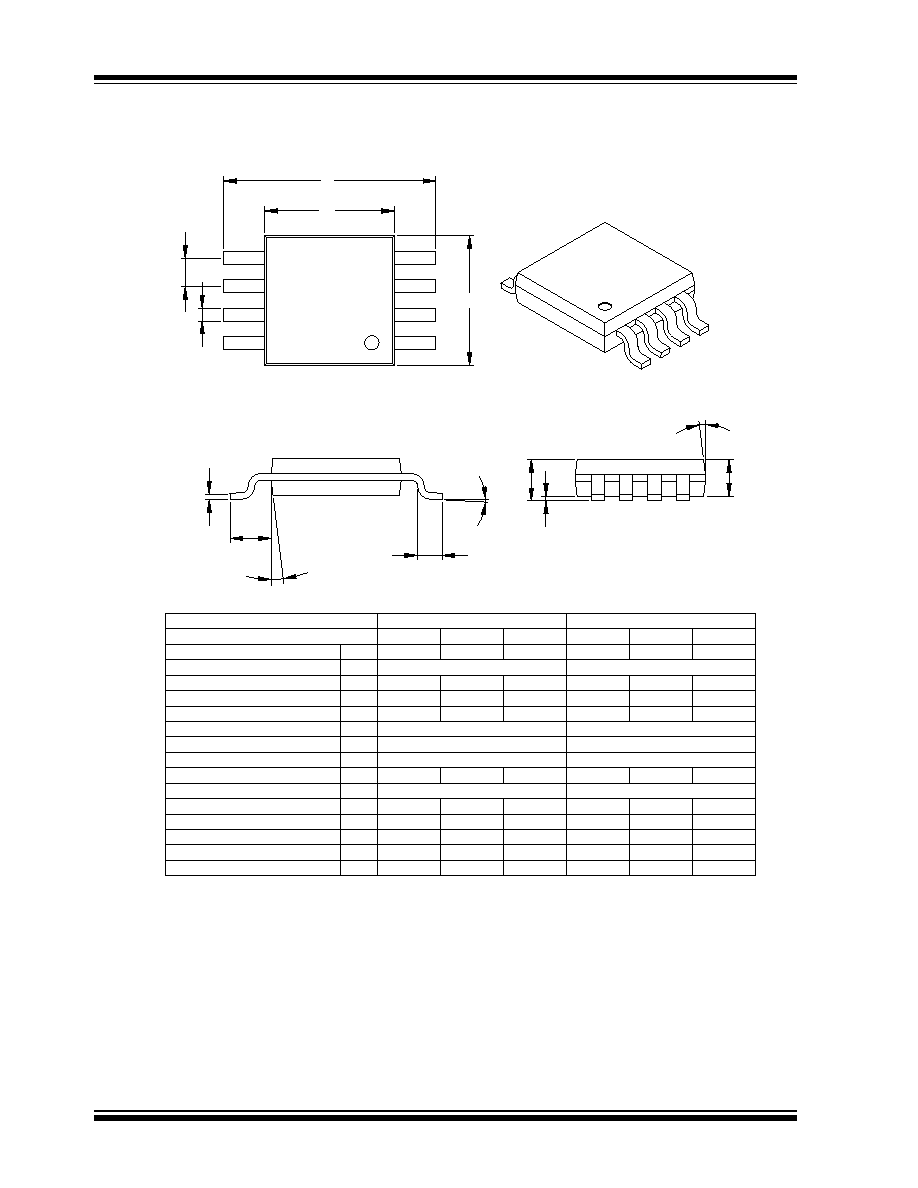

· Space-Saving 8-Pin MSOP Package

Applications

· Personal Computers & Servers

· LCD Projectors

· Datacom & Telecom Equipment

· Fan Trays

· File Servers

· General-Purpose Fan Speed Control

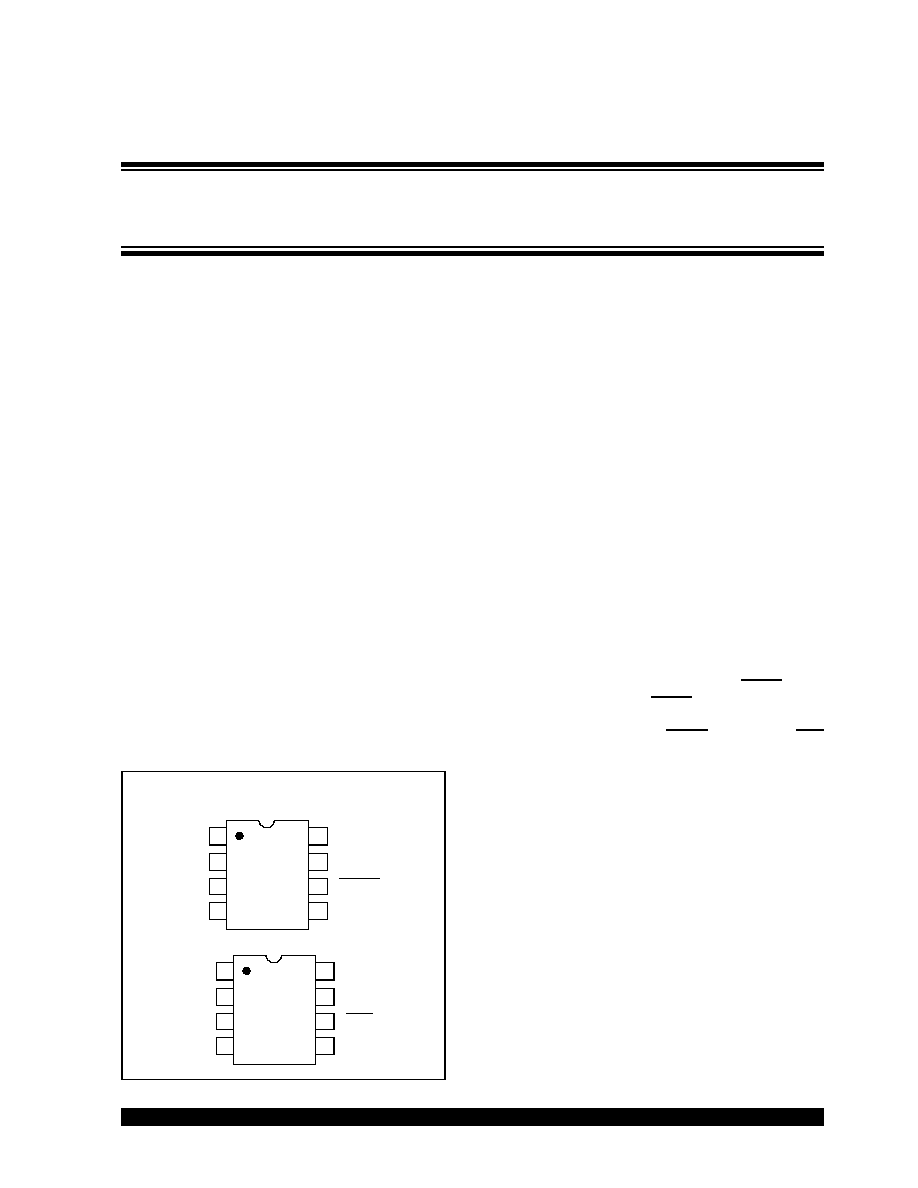

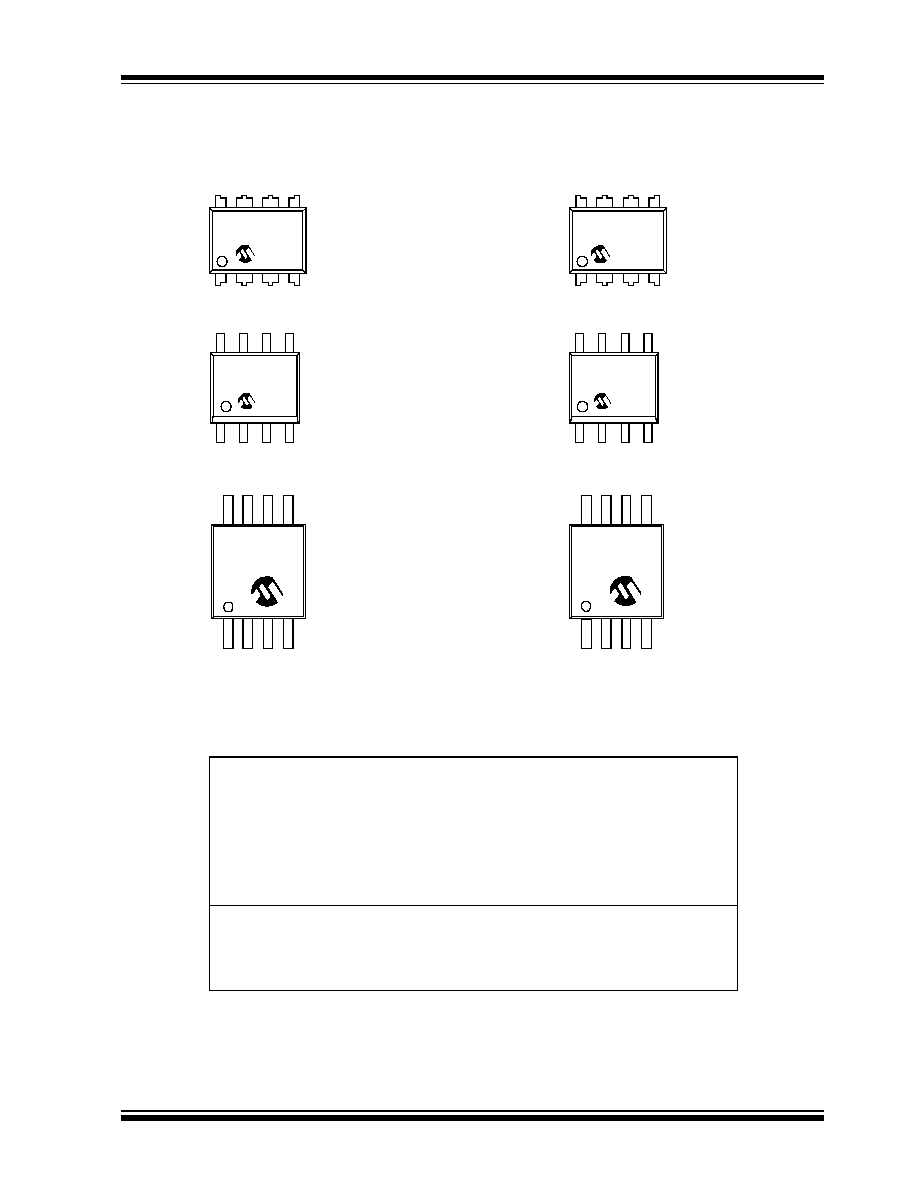

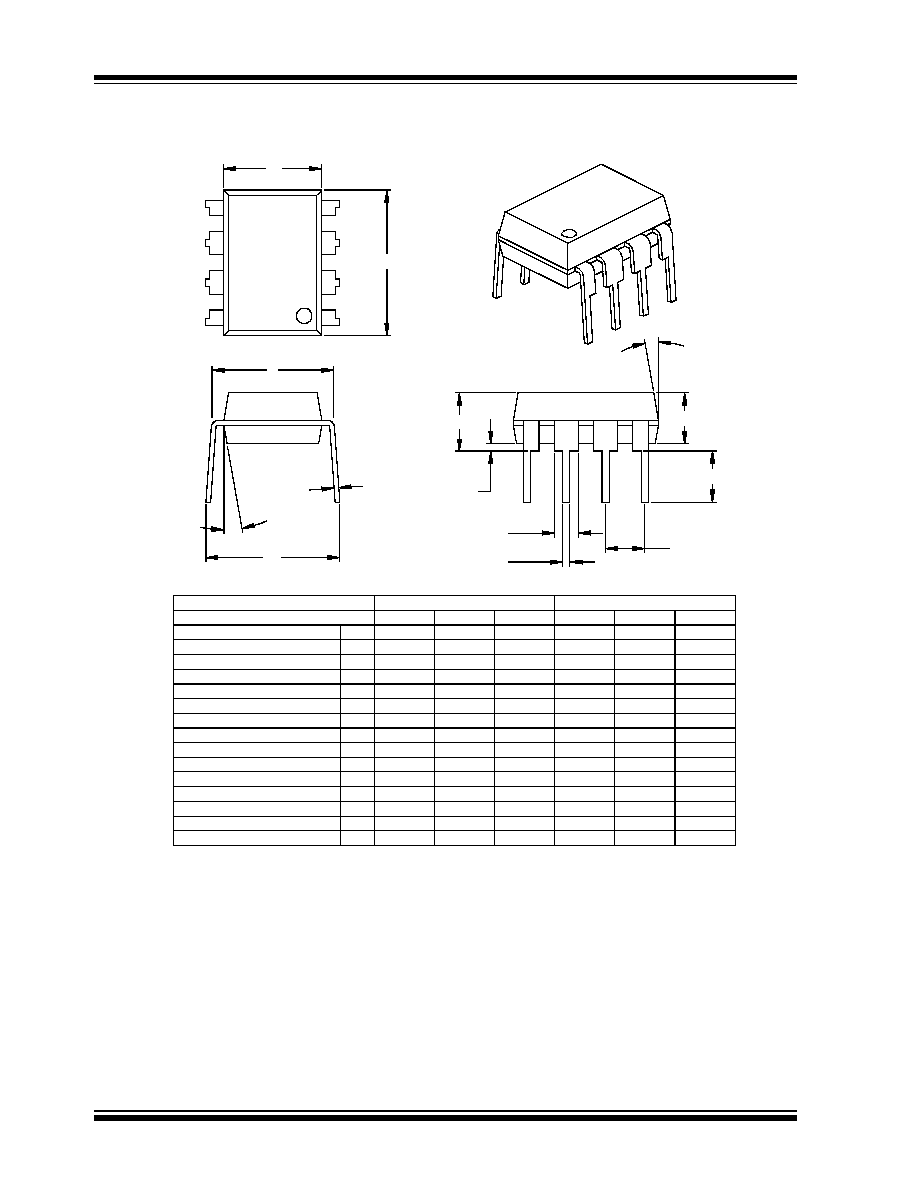

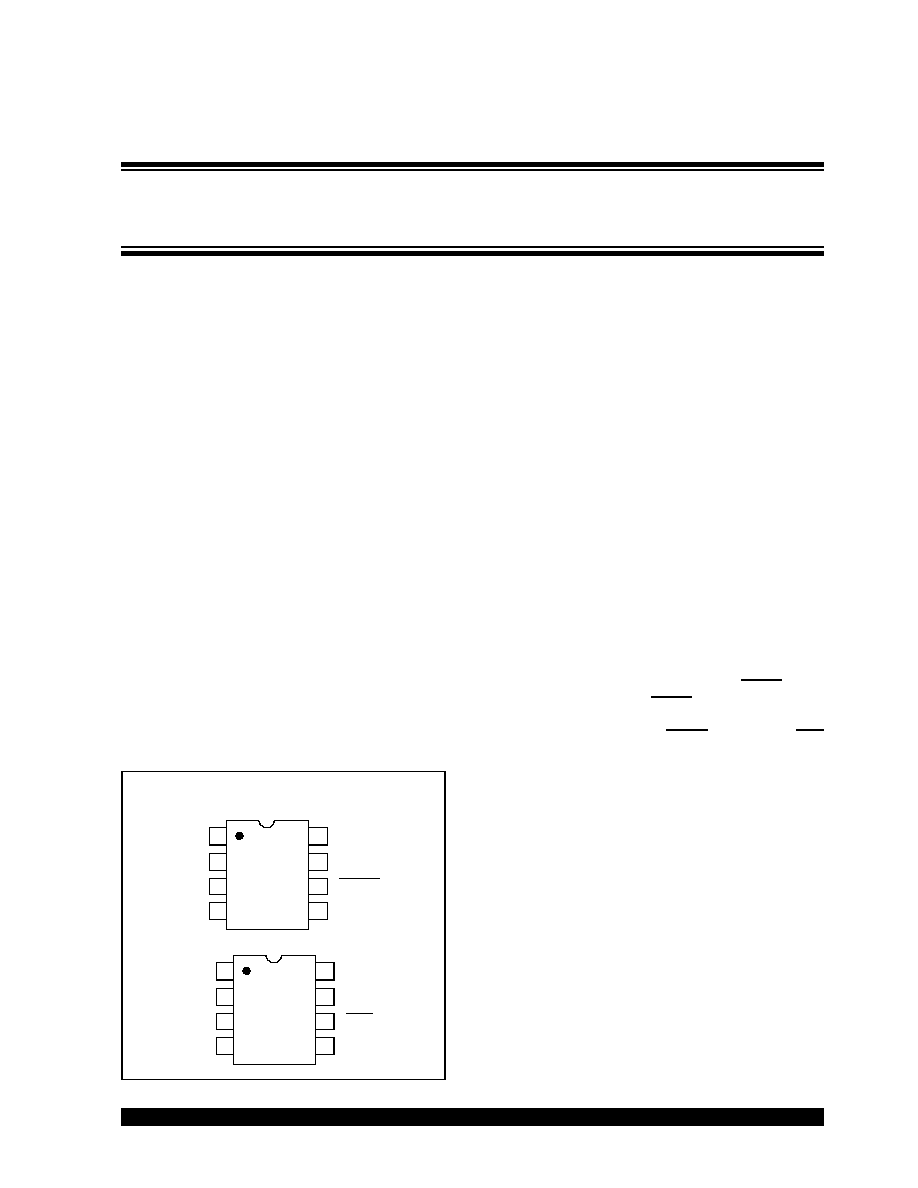

Package Types

Description

The TC646B/TC648B/TC649B devices are new ver-

sions of the existing TC646/TC648/TC649 fan speed

controllers. These devices are switch-mode fan speed

controllers that incorporate a new fan auto-restart func-

tion. Temperature-proportional speed control is accom-

plished using pulse width modulation. A thermistor (or

other voltage output temperature sensor) connected to

the V

IN

input supplies the required control voltage of

1.20V to 2.60V (typical) for 0% to 100% PWM duty

cycle. The auto-shutdown threshold/temperature is set

by a simple resistor divider on the V

AS

input. An inte-

grated Start-Up Timer ensures reliable fan motor start-

up at turn-on, coming out of shutdown mode, auto-

shutdown mode or following a transient fault. A logic

low applied to V

IN

(pin 1) causes fan shutdown.

The TC646B and TC649B also feature Microchip

Technology's proprietary FanSense technology for

increasing system reliability. In normal fan operation, a

pulse train is present at SENSE (pin 5). A missing-

pulse detector monitors this pin during fan operation. A

stalled, open or unconnected fan causes the TC646B/

TC649B device to turn the V

OUT

output on full (100%

duty cycle). If the fan fault persists (a fan current pulse

is not detected within a 32/f period), the FAULT output

goes low. Even with the FAULT output low, the V

OUT

output is on full during the fan fault condition in order to

attempt to restart the fan. FAULT (TC646B) or OTF

(TC648B) is also asserted if the PWM reaches 100%

duty cycle, indicating that maximum cooling capability

has been reached and a possible overheating condition

exists.

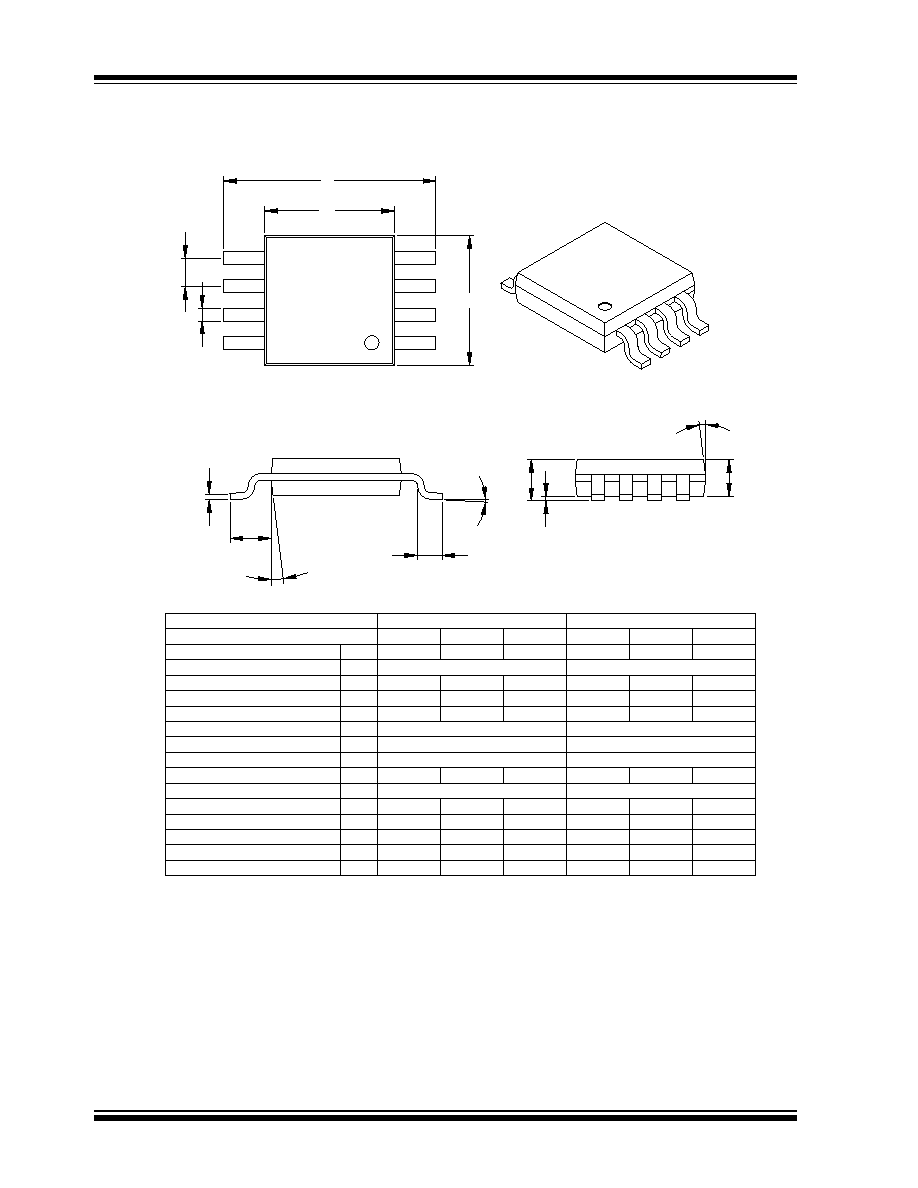

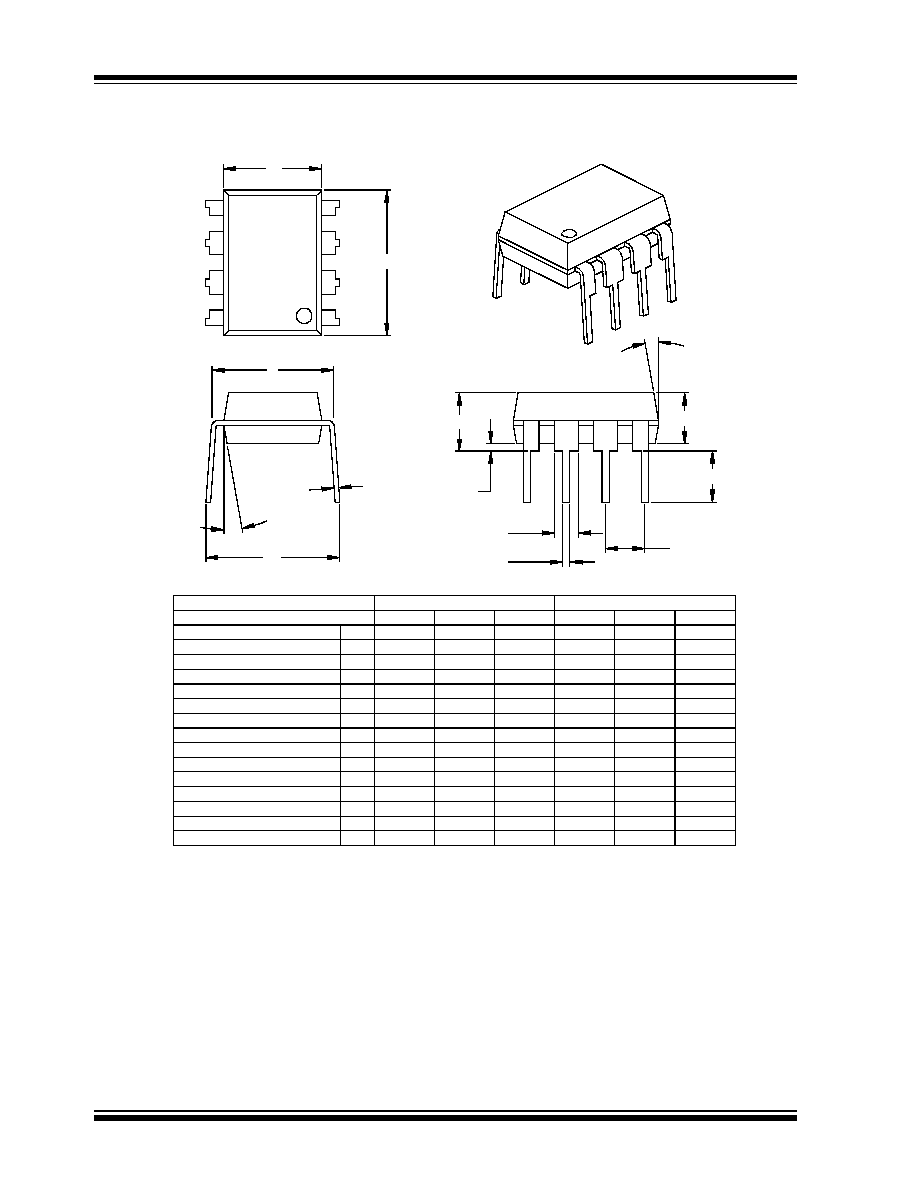

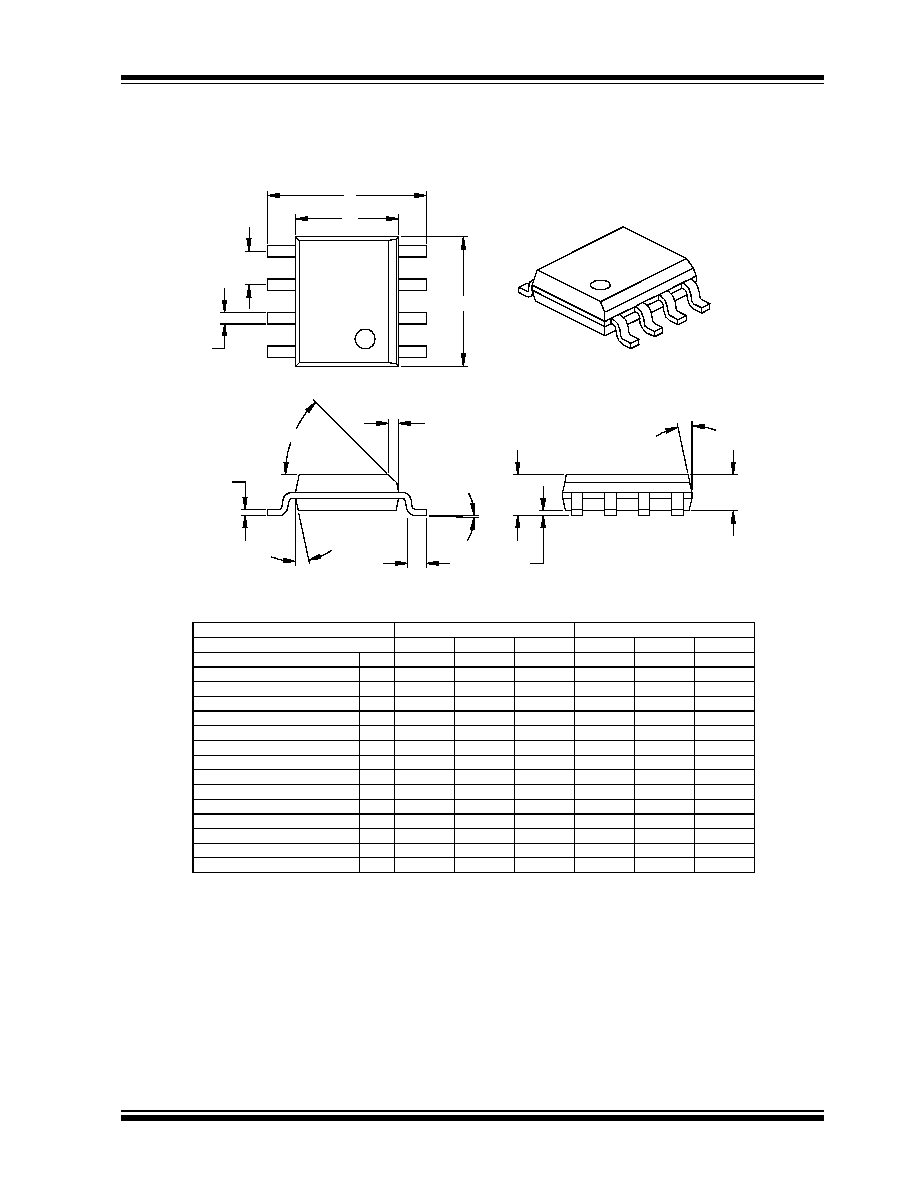

The TC646B, TC648B and TC649B devices are avail-

able in 8-pin plastic MSOP, SOIC and PDIP packages.

The specified temperature range of these devices is

-40 to +85ºC.

MSOP, PDIP, SOIC

1

2

3

4

V

DD

5

6

7

8

V

OUT

SENSE

V

IN

C

F

V

AS

GND

FAULT

TC646B

TC649B

1

2

3

4

V

DD

5

6

7

8

V

OUT

NC

V

IN

C

F

V

AS

GND

OTF

TC648B

PWM Fan Speed Controllers With Auto-Shutdown, Fan

Restart and FanSenseTM Technology for Fault Detection

TC646B/TC648B/TC649B

DS21755B-page 2

2003 Microchip Technology Inc.

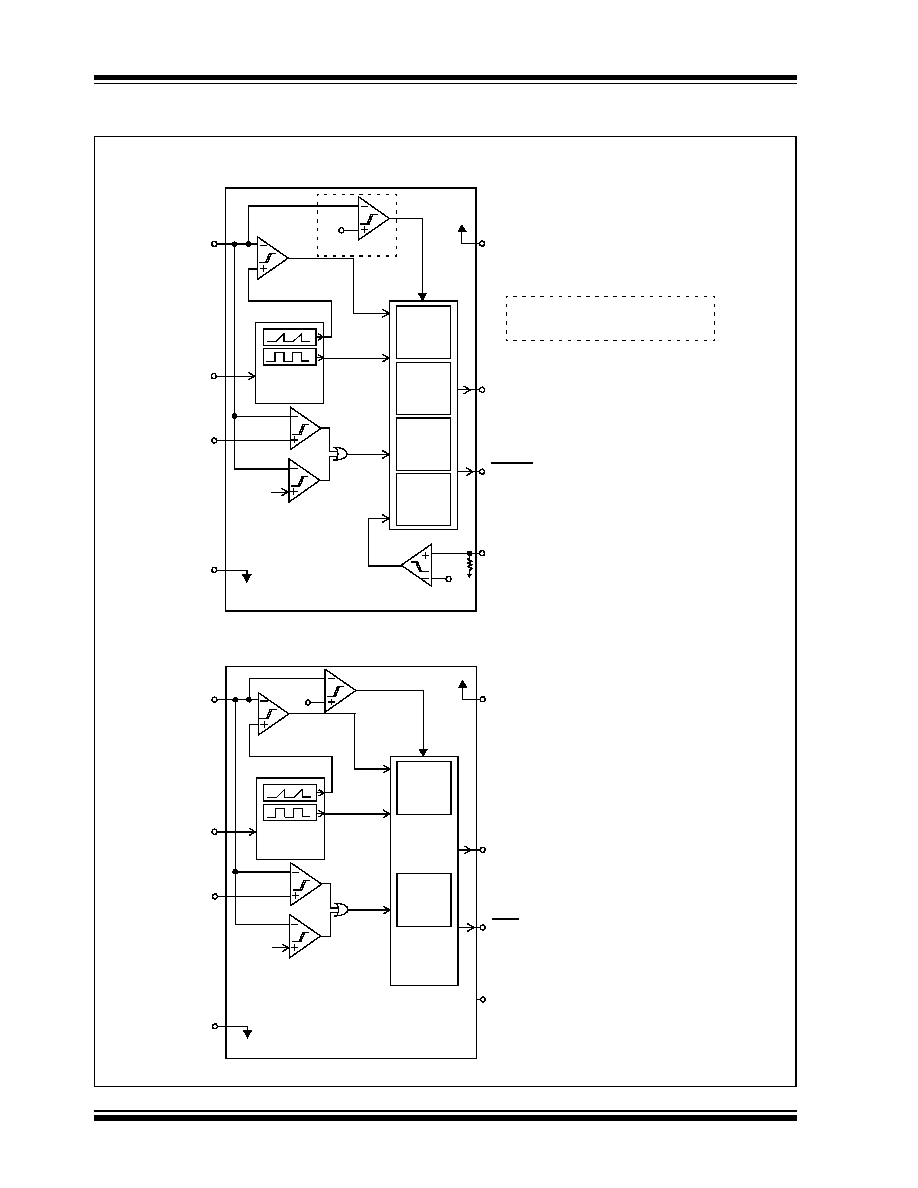

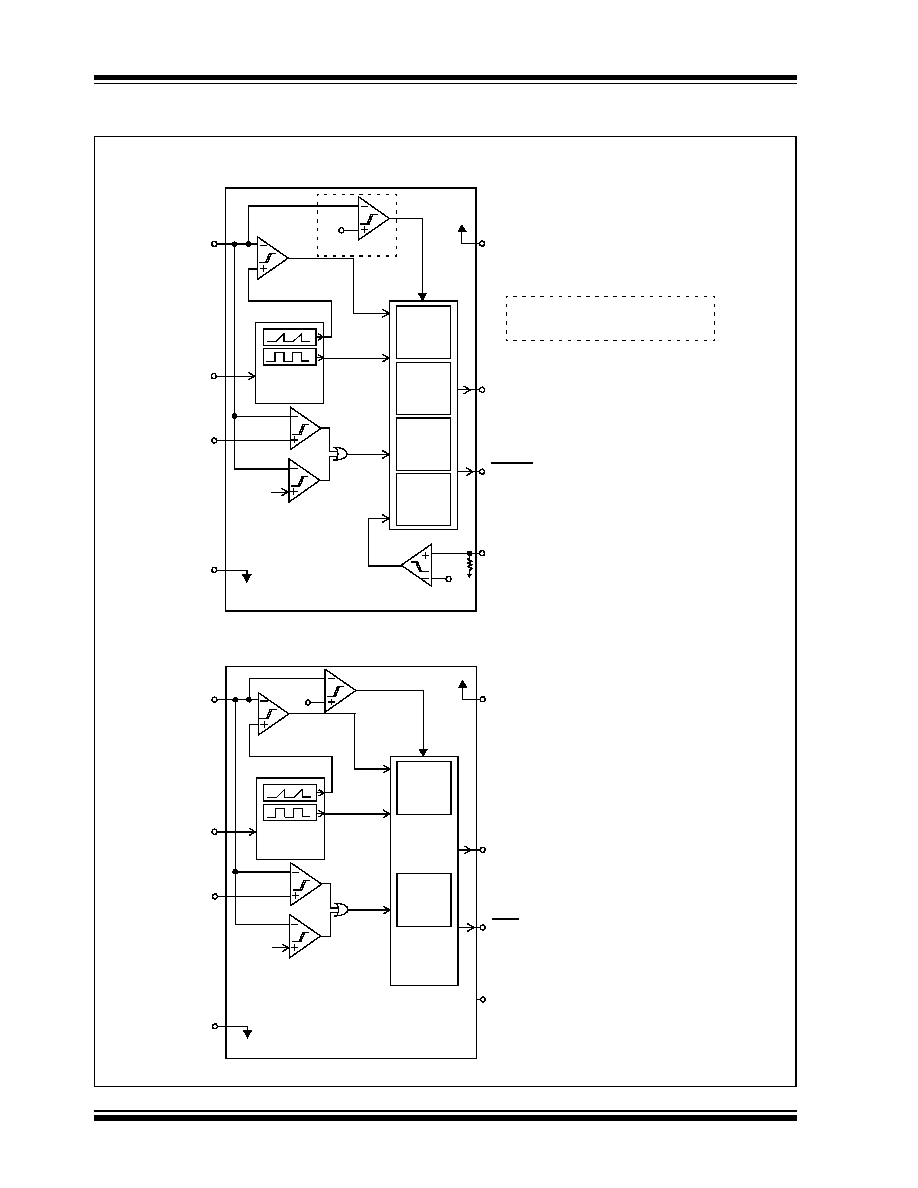

Functional Block Diagram

TC646B/TC649B

Note: The V

OTF

comparator

is for the TC646B device only.

70 mV

(typ)

V

OTF

10 k

V

SHDN

V

IN

C

F

V

AS

GND

V

DD

V

OUT

FAULT

SENSE

Clock

Generator

Control

Logic

3xT

PWM

Timer

Start-up

Timer

Missing

Pulse

Detect

TC648B

V

OTF

V

SHDN

V

IN

C

F

V

AS

GND

V

DD

V

OUT

OTF

NC

Clock

Generator

Control

Logic

Start-up

Timer

Note

2003 Microchip Technology Inc.

DS21755B-page 3

TC646B/TC648B/TC649B

1.0

ELECTRICAL

CHARACTERISTICS

Absolute Maximum Ratings

Supply Voltage (V

DD

) .......................................................6.0V

Input Voltage, Any Pin................(GND - 0.3V) to (V

DD

+0.3V)

Operating Temperature Range ....................- 40°C to +125°C

Maximum Junction Temperature, T

J

........................... +150°C

ESD Protection on all pins ........................................... > 3 kV

Notice: Stresses above those listed under "Maximum

Ratings" may cause permanent damage to the device. This is

a stress rating only and functional operation of the device at

those or any other conditions above those indicated in the

operational listings of this specification is not implied. Expo-

sure to maximum rating conditions for extended periods may

affect device reliability.

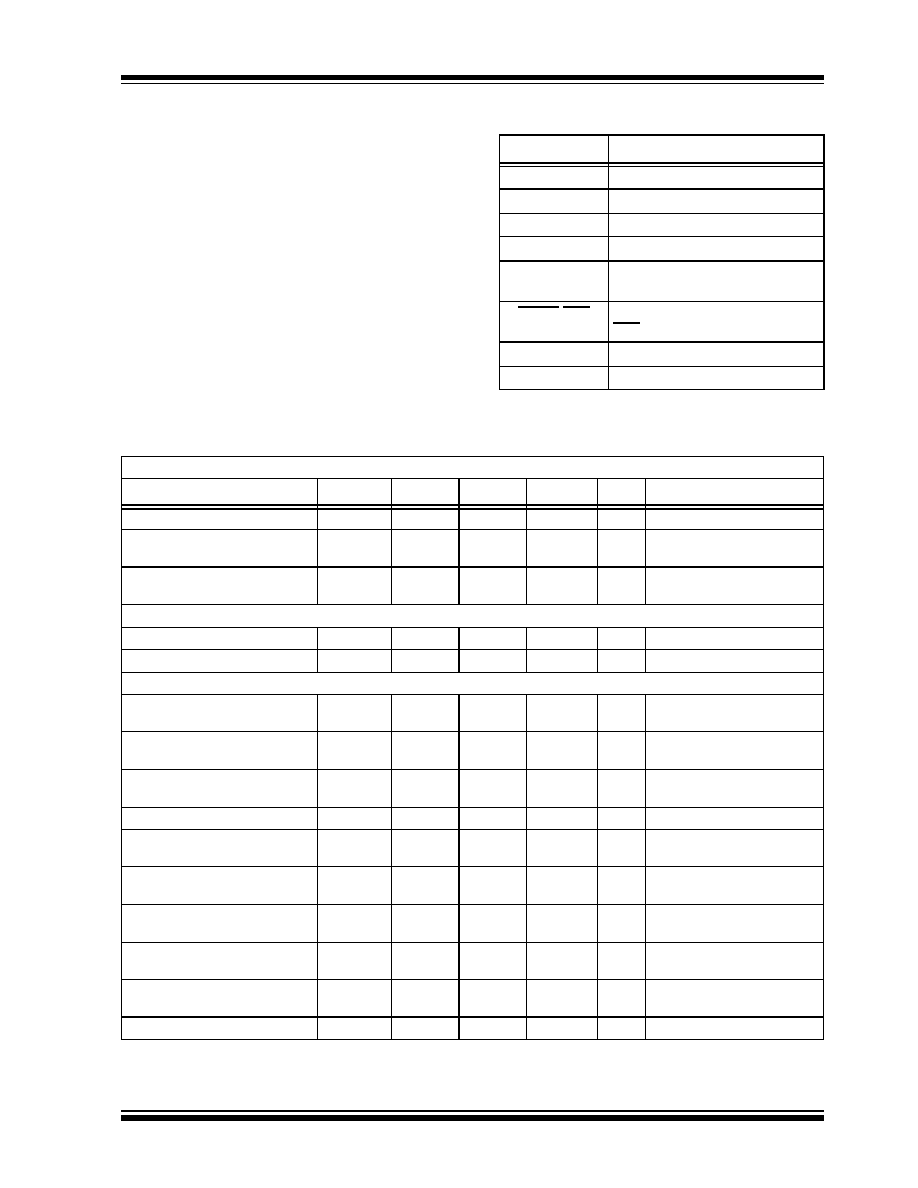

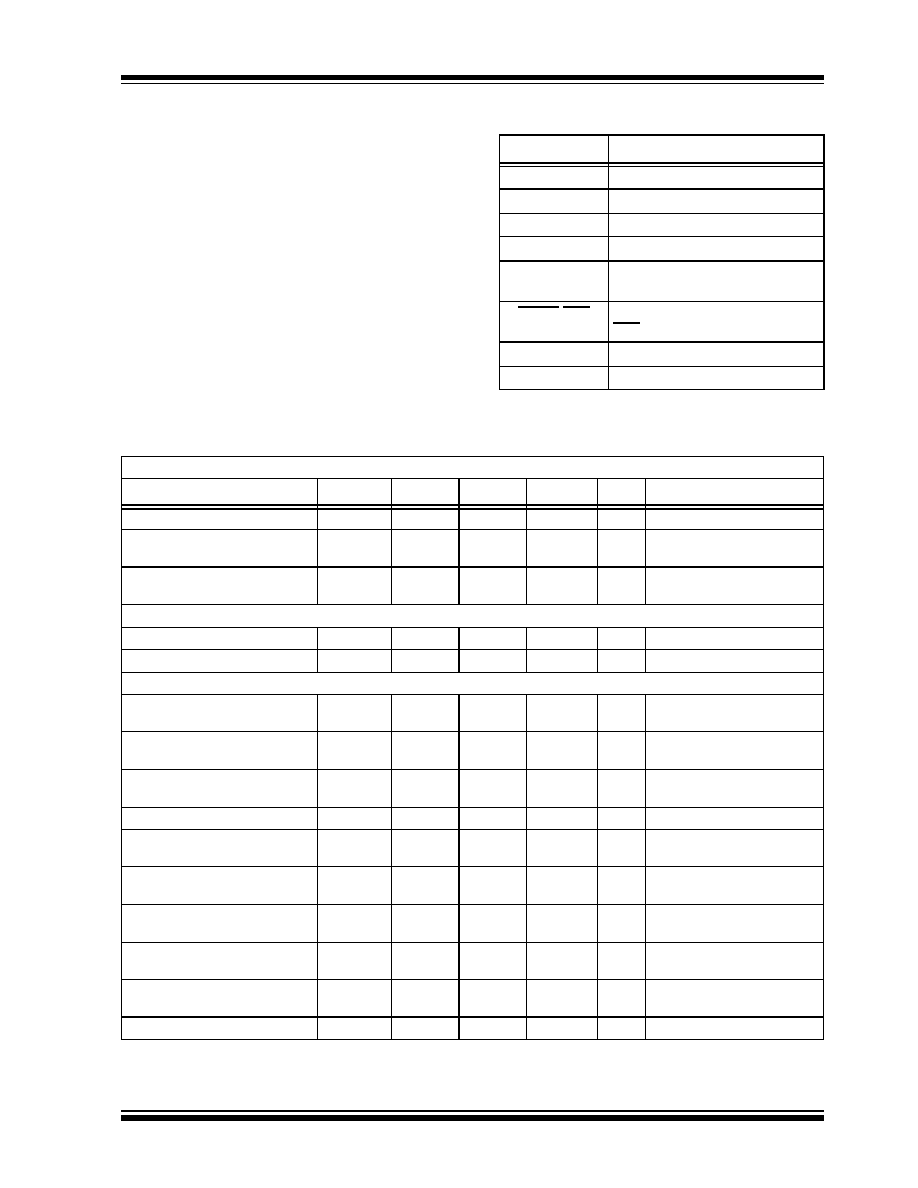

PIN FUNCTION TABLE

Name

Function

V

IN

Analog Input

C

F

Analog Output

V

AS

Analog Input

GND

Ground

SENSE/NC

Analog Input.

No Connect (NC) for TC648B

FAULT/OTF

Digital (Open-Drain) Output

OTF for TC648B

V

OUT

Digital Output

V

DD

Power Supply Input

ELECTRICAL CHARACTERISTICS

Electrical Specifications: Unless otherwise specified, all limits are specified for -40°C < T

A

< +85°C, V

DD

= 3.0V to 5.5V.

Parameters

Sym

Min

Typ

Max

Units

Conditions

Supply Voltage

V

DD

3.0

--

5.5

V

Supply Current, Operating

I

DD

--

200

400

µA

Pins 6, 7 Open,

C

F

= 1 µF, V

IN

= V

C(MAX)

Supply Current, Shutdown Mode

I

DD(SHDN)

--

30

--

µA

Pins 6, 7 Open,

C

F

= 1 µF, V

IN

= 0.35V

V

OUT

Output

Sink Current at V

OUT

Output

I

OL

1.0

--

--

mA

V

OL

= 10% of V

DD

Source Current at V

OUT

Output

I

OH

5.0

--

--

mA

V

OH

= 80% of V

DD

V

IN

, V

AS

Inputs

Input Voltage at V

IN

for 100% PWM

Duty Cycle

V

C(MAX)

2.45

2.60

2.75

V

Over-Temperature Indication

Threshold

V

OTF

V

C(MAX)

+

20 mV

V

For TC646B and TC648B

Over-Temperature Indication

Threshold Hysteresis

V

OTF-HYS

80

mV

For TC646B and TC648B

V

C(MAX)

- V

C(MIN)

V

C(SPAN)

1.3

1.4

1.5

V

Hysteresis on Auto-Shutdown

Comparator

V

HAS

--

70

--

mV

Auto-Shutdown Threshold

V

AS

V

C(MAX)

-

V

C(SPAN)

--

V

C(MAX)

V

Voltage Applied to V

IN

to Ensure

Shutdown Mode

V

SHDN

--

--

V

DD

x 0.13

V

Voltage Applied to V

IN

to Release

Shutdown Mode

V

REL

V

DD

x 0.19

--

--

V

V

DD

= 5V

Hysteresis on V

SHDN

, V

REL

V

HYST

--

0.03 X

V

DD

--

V

V

IN

,

V

AS

Input Leakage

I

IN

- 1.0

--

+1.0

µA

Note 1

Note 1:

Ensured by design, tested during characterization.

2:

For V

DD

< 3.7V, t

STARTUP

and t

MP

timers are typically 13/f.

TC646B/TC648B/TC649B

DS21755B-page 4

2003 Microchip Technology Inc.

TEMPERATURE SPECIFICATIONS

Pulse-Width Modulator

PWM Frequency

f

PWM

26

30

34

Hz

C

F

= 1.0 µF

SENSE Input (TC646B & TC649B)

SENSE Input Threshold Voltage

with Respect to GND

V

TH(SENSE)

50

70

90

mV

Blanking time to ignore pulse due

to V

OUT

turn-on

t

BLANK

--

3.0

--

µsec

FAULT / OTF Output

Output Low Voltage

V

OL

--

--

0.3

V

I

OL

= 2.5 mA

Missing Pulse Detector Timer

t

MP

--

32/f

--

sec

TC646B and TC649B, Note 2

Start-up Timer

t

STARTUP

--

32/f

--

sec

Note 2

Diagnostic Timer

t

DIAG

--

3/f

--

sec

TC646B and TC649B

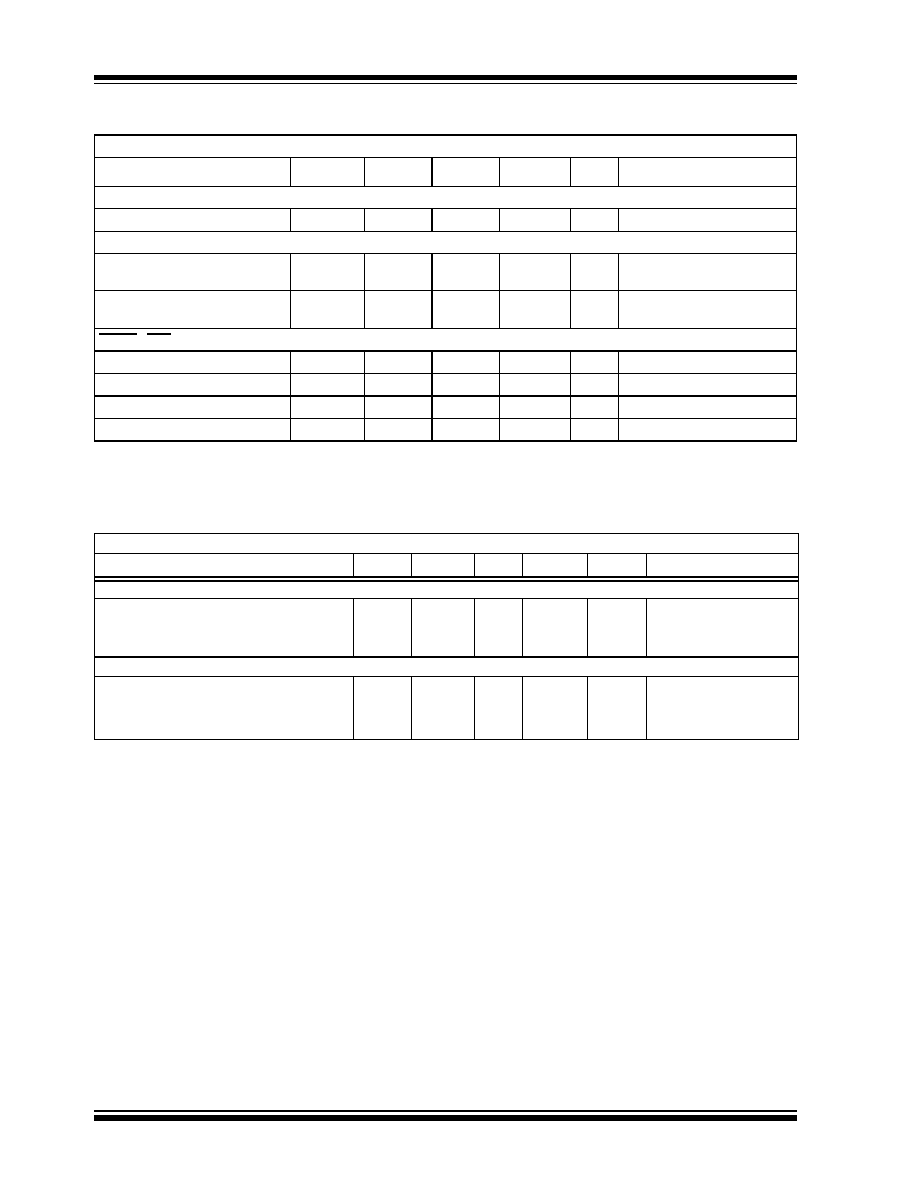

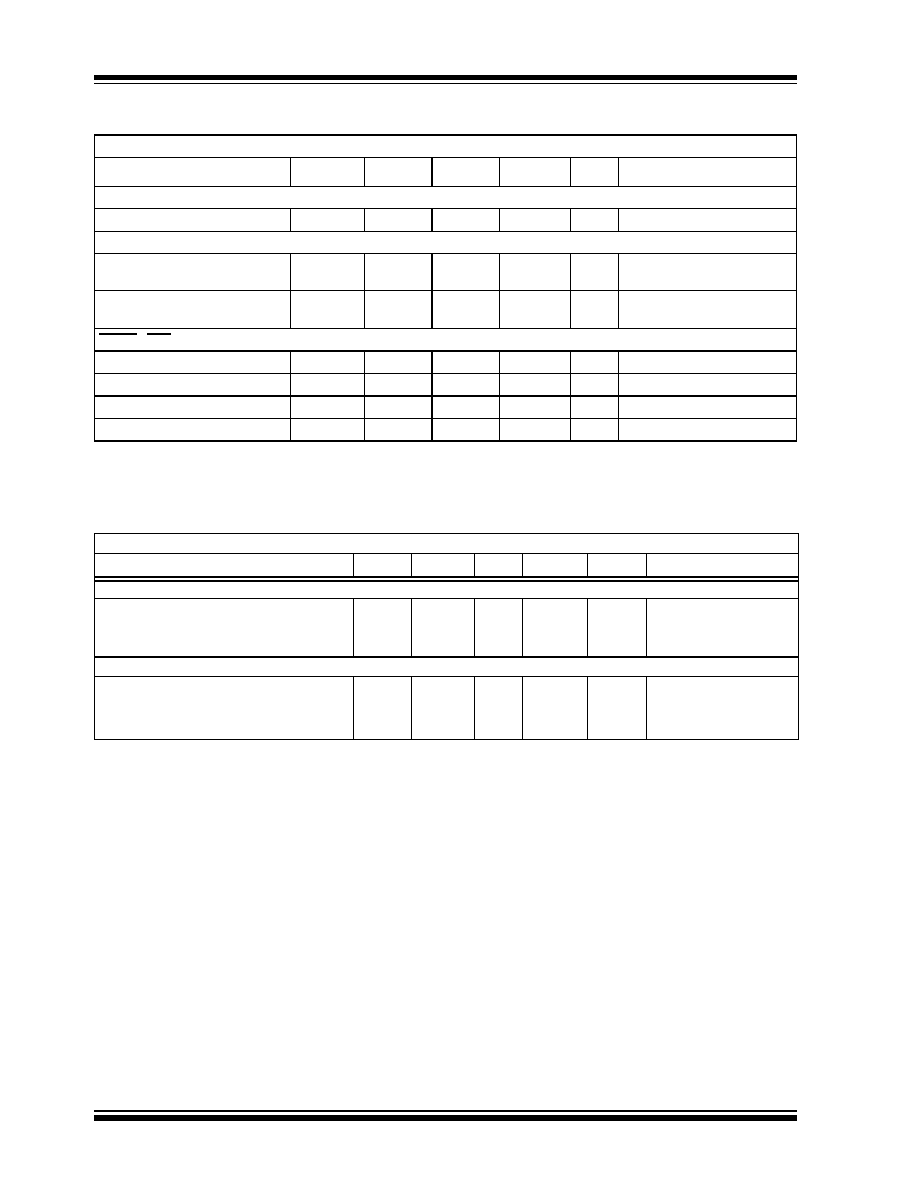

ELECTRICAL CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise specified, all limits are specified for -40°C < T

A

< +85°C, V

DD

= 3.0V to 5.5V.

Parameters

Sym

Min

Typ

Max

Units

Conditions

Note 1:

Ensured by design, tested during characterization.

2:

For V

DD

< 3.7V, t

STARTUP

and t

MP

timers are typically 13/f.

Electrical Characteristics: Unless otherwise noted, all parameters apply at V

DD

= 3.0V to 5.5V

Parameters

Sym

Min

Typ

Max

Units

Conditions

Temperature Ranges

Specified Temperature Range

T

A

-40

--

+85

°C

Operating Temperature Range

T

A

-40

--

+125

°C

Storage Temperature Range

T

A

-65

--

+150

°C

Thermal Package Resistances

Thermal Package Resistance, 8-Pin MSOP

JA

--

200

--

°C/W

Thermal Package Resistance, 8-Pin SOIC

JA

--

155

--

°C/W

Thermal Package Resistance, 8-Pin PDIP

JA

--

125

--

°C/W

2003 Microchip Technology Inc.

DS21755B-page 5

TC646B/TC648B/TC649B

TIMING SPECIFICATIONS

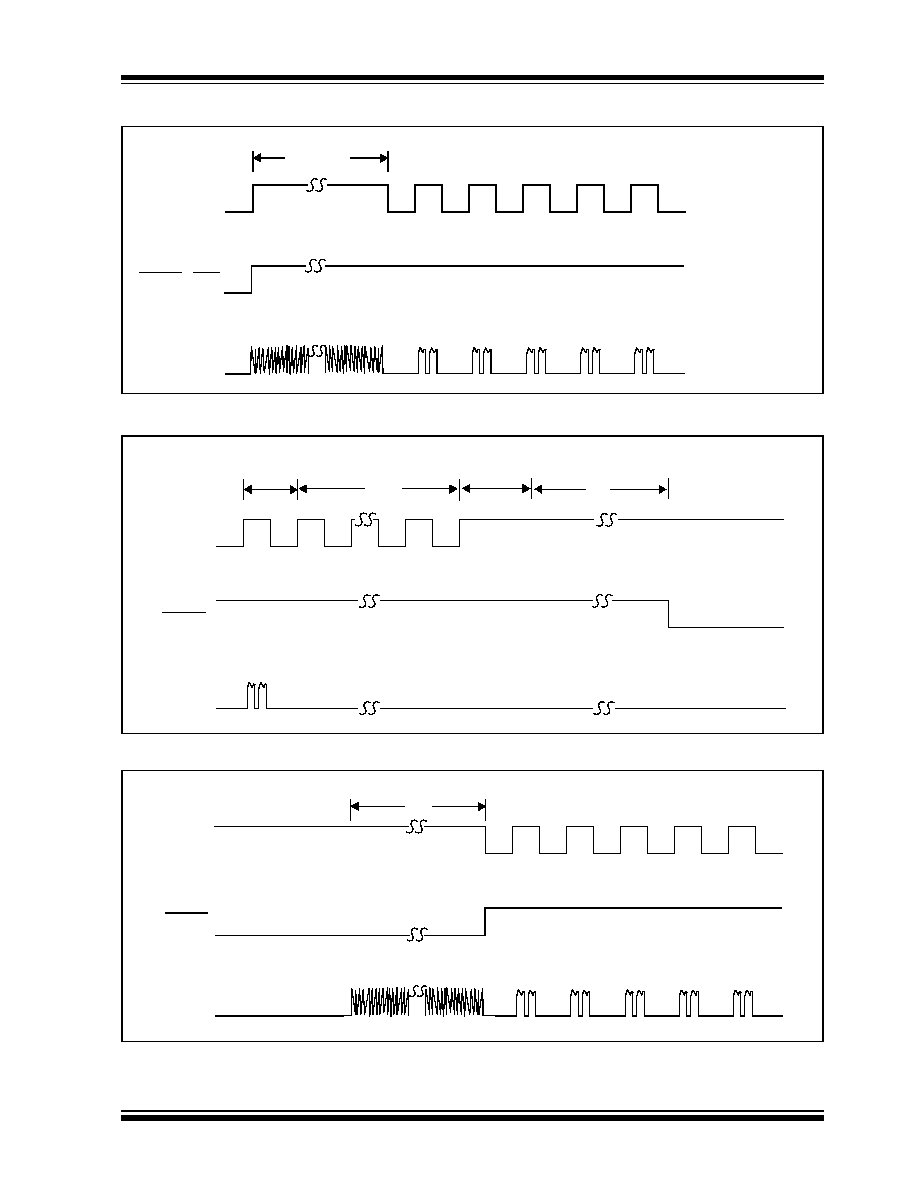

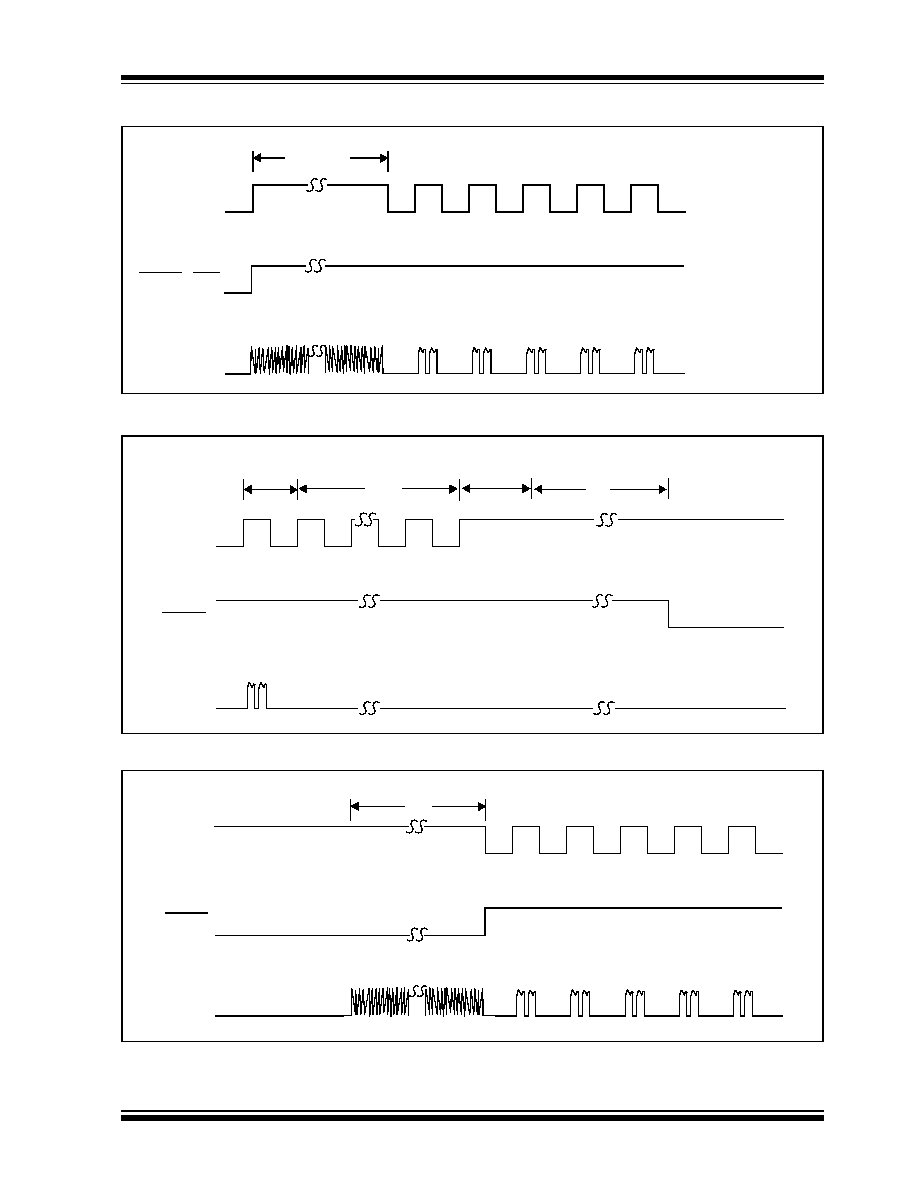

FIGURE 1-1:

TC646B/TC648B/TC649B Start-up Timing.

FIGURE 1-2:

Fan Fault Occurrence (TC646B and TC649B).

FIGURE 1-3:

Recovery From Fan Fault (TC646B and TC649B).

V

OUT

FAULT / OTF

SENSE

t

STARTUP

(TC646B and TC649B)

V

OUT

FAULT

SENSE

33.3 msec (C

F

= 1 µF)

t

MP

t

MP

t

DIAG

V

OUT

FAULT

SENSE

Minimum 16 pulses

t

MP

TC646B/TC648B/TC649B

DS21755B-page 6

2003 Microchip Technology Inc.

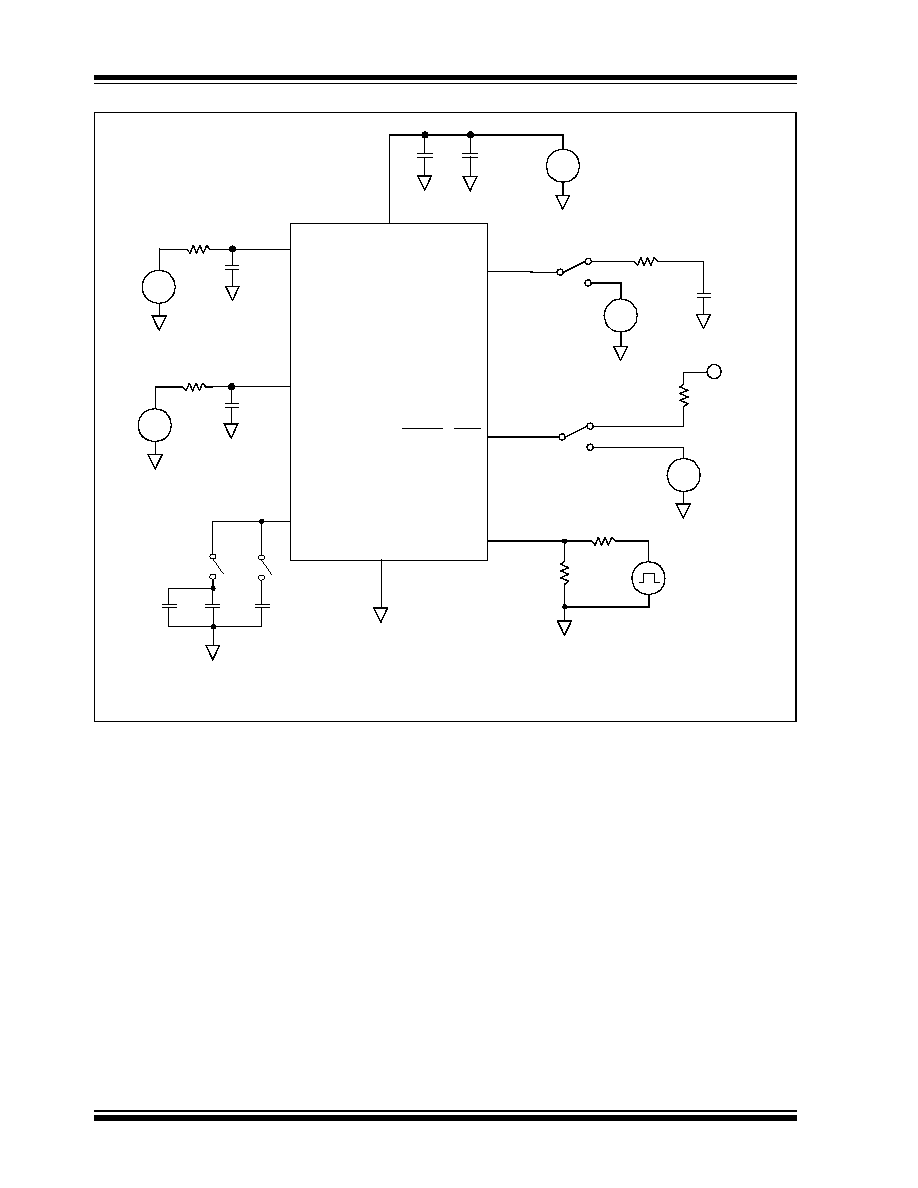

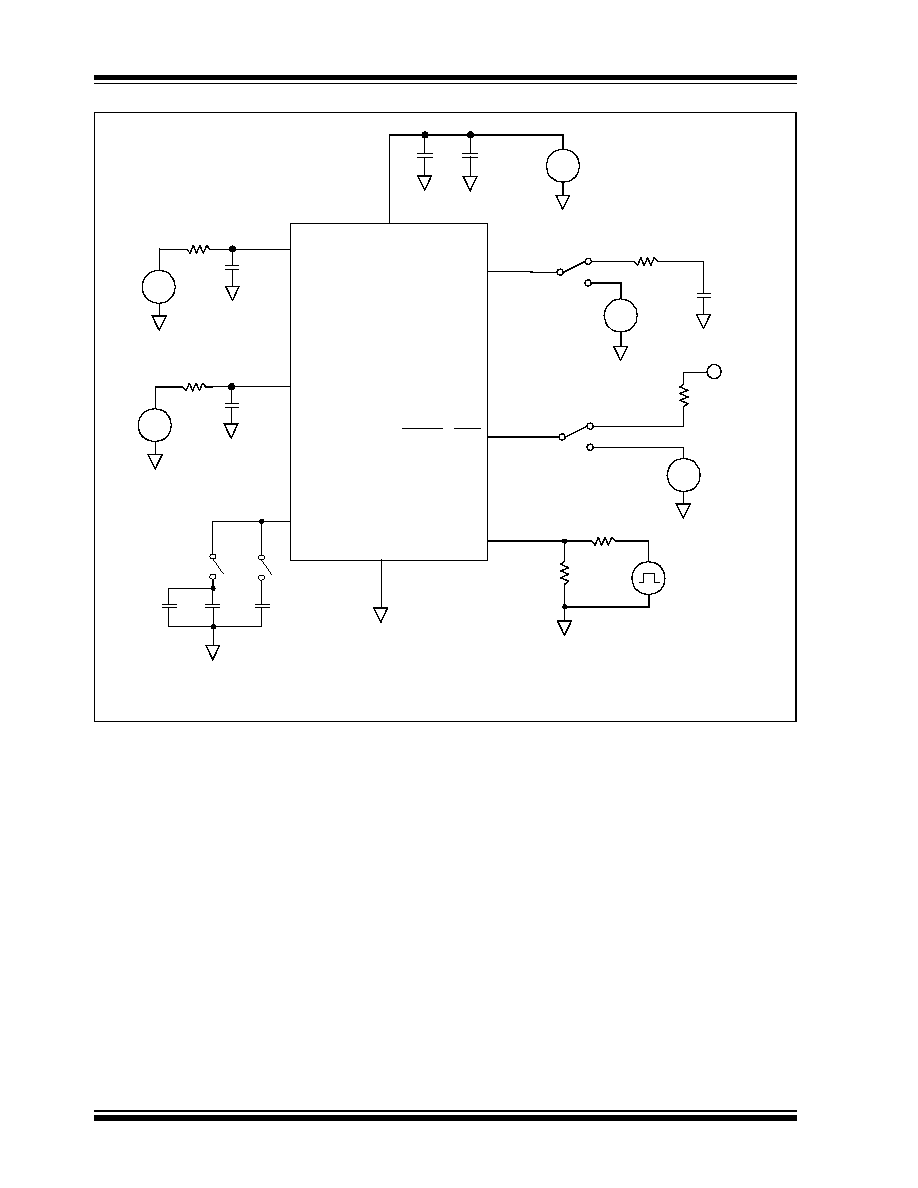

FIGURE 1-4:

TC646B/TC648B/TC649B Electrical Characteristics Test Circuit.

1

2

3

4

6

5

7

8

V

IN

C

F

V

AS

GND

FAULT / OTF

SENSE

V

OUT

V

DD

R

3

R

1

C

3

0.1 µF

C

2

1 µF

V

DD

C

1

0.1 µF

+

-

V

IN

+

-

C

4

0.1 µF

V

AS

+

-

R

2

K

1

K

2

0.1 µF

1 µF

.01 µF

C

7

C

6

C

5

R

4

V

SENSE

(pulse voltage source)

K

4

K

3

+

-

Current

limited

voltage

source

V

DD

R

5

Current

limited

voltage

source

C

8

0.1 µF

R

6

Note: C

5

and C

7

are adjusted to get the necessary 1 µF value.

TC646B and TC649B

TC646B

TC648B

TC649B

+

-

2003 Microchip Technology Inc.

DS21755B-page 7

TC646B/TC648B/TC649B

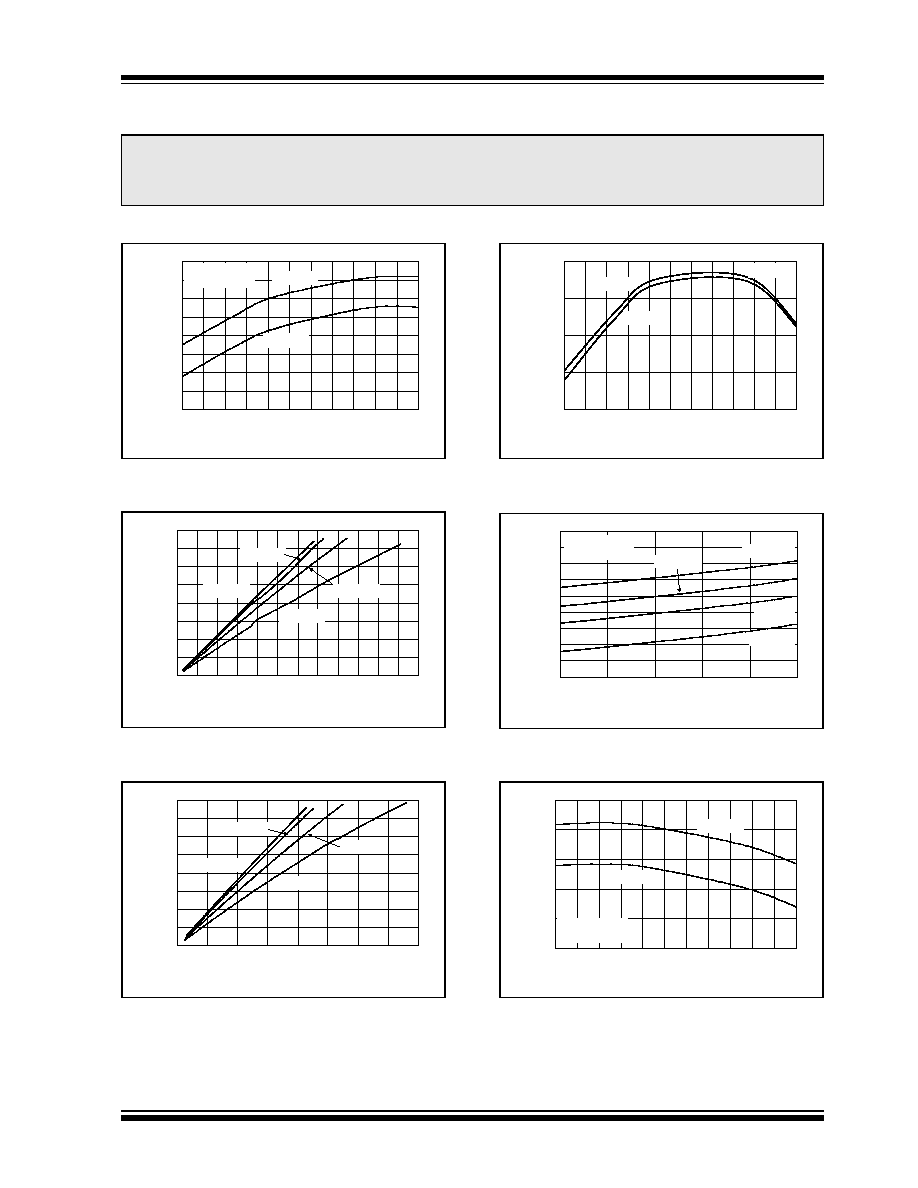

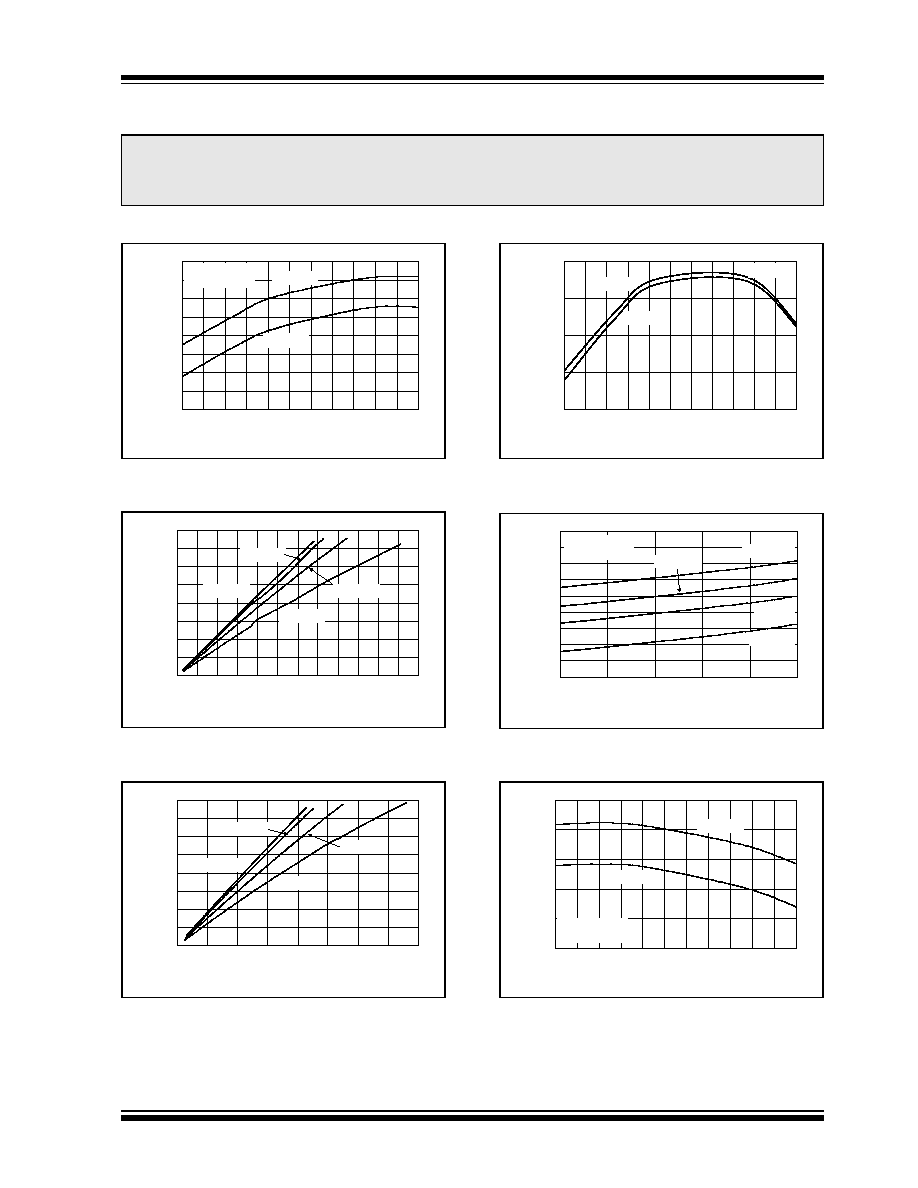

2.0

TYPICAL PERFORMANCE CURVES

Note: Unless otherwise indicated, V

DD

= 5V, T

A

= 25°C.

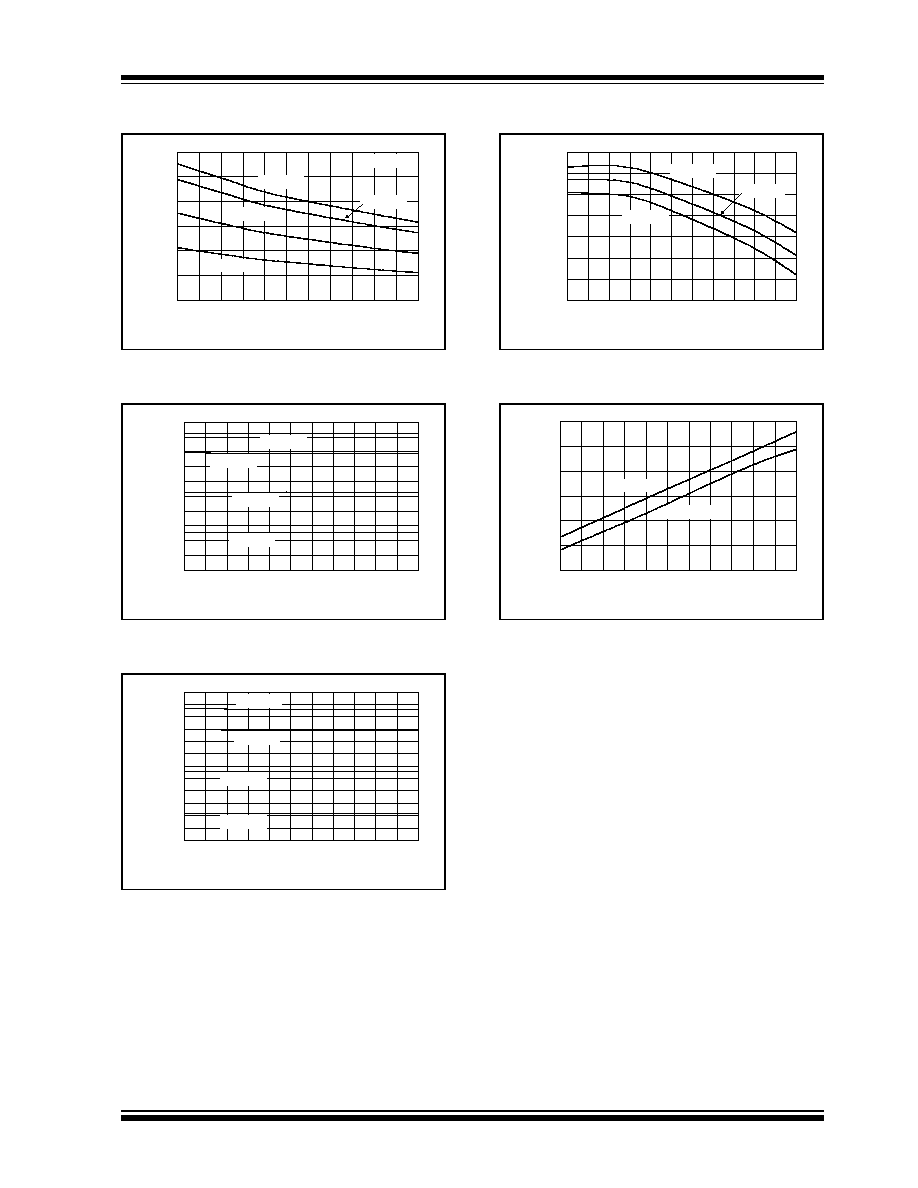

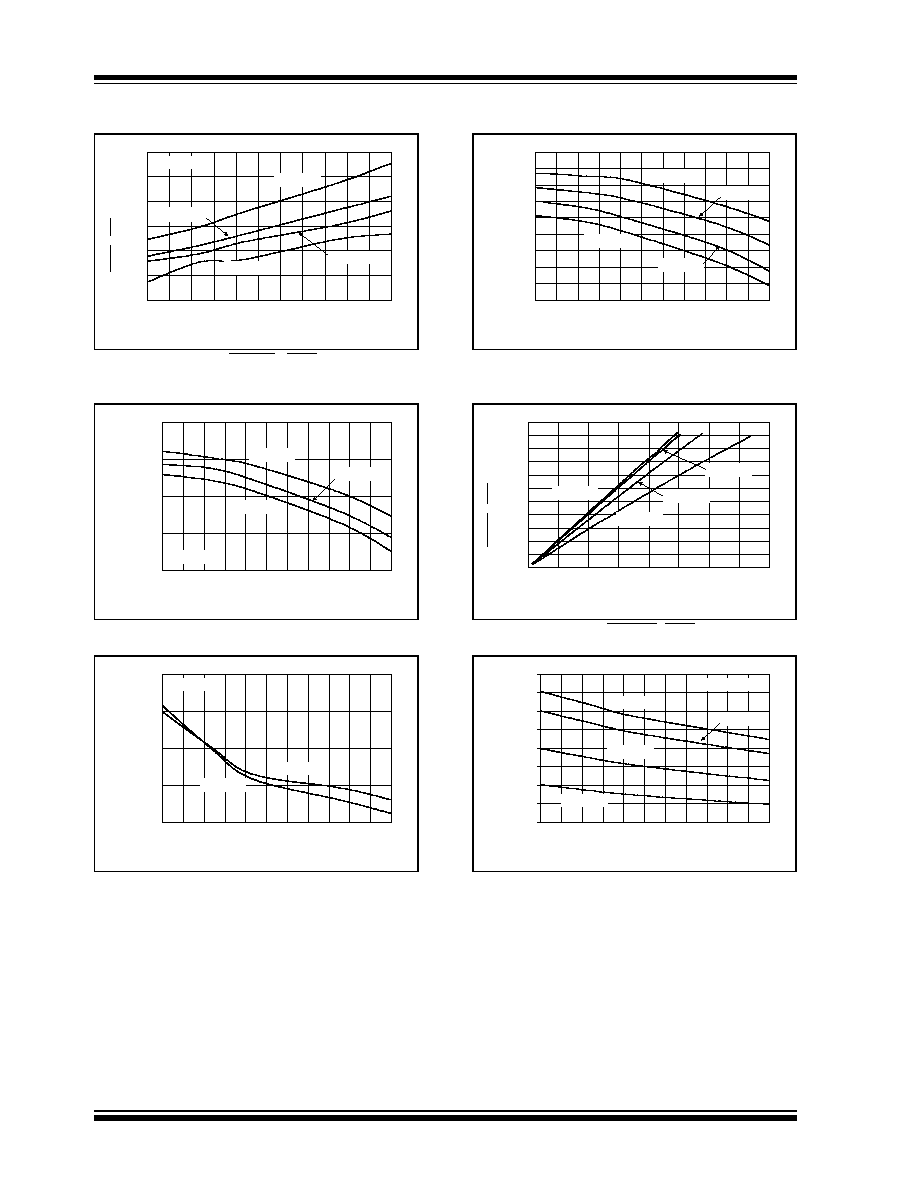

FIGURE 2-1:

I

DD

vs. Temperature.

FIGURE 2-2:

PWM Sink Current (I

OL

) vs.

V

OL

.

FIGURE 2-3:

PWM Source Current (I

OH

)

vs. V

DD

- V

OH

.

FIGURE 2-4:

PWM Frequency vs.

Temperature.

FIGURE 2-5:

I

DD

vs. V

DD

.

FIGURE 2-6:

I

DD

Shutdown vs.

Temperature.

Note:

The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

125

130

135

140

145

150

155

160

165

-40 -25 -10

5

20

35

50

65

80

95 110 125

Temperature (ºC)

I

DD

(µA)

V

DD

= 3.0V

V

DD

= 5.5V

Pins 6 & 7 Open

C

F

= 1 µF

0

2

4

6

8

10

12

14

16

0

50 100 150 200 250 300 350 400 450 500 550 600

V

OL

(mV)

I

OL

(mA)

V

DD

= 5.5V

V

DD

= 5.0V

V

DD

= 3.0V

V

DD

= 4.0V

0

2

4

6

8

10

12

14

16

0

100

200

300

400

500

600

700

800

V

DD

- V

OH

(mV)

I

OH

(mA)

V

DD

= 5.5V

V

DD

= 5.0V

V

DD

= 3.0V

V

DD

= 4.0V

28.50

29.00

29.50

30.00

30.50

-40 -25 -10

5

20

35

50

65

80

95 110 125

Temperature (ºC)

Oscillator Frequency (Hz)

V

DD

= 3.0V

V

DD

= 5.5V

C

F

= 1.0 F

125

130

135

140

145

150

155

160

165

170

3

3.5

4

4.5

5

5.5

V

DD

(V)

I

DD

(µA)

T

A

= -40ºC

T

A

= -5ºC

T

A

= +125ºC

T

A

= +90ºC

Pins 6 & 7 Open

C

F

= 1 µF

15

18

21

24

27

30

-40 -25 -10

5

20

35

50

65

80

95

110 125

Temperature (ºC)

I

DD

Shutdown (µA)

V

DD

= 5.5V

V

DD

= 3.0V

Pins 6 & 7 Open

V

IN

= 0V

TC646B/TC648B/TC649B

DS21755B-page 8

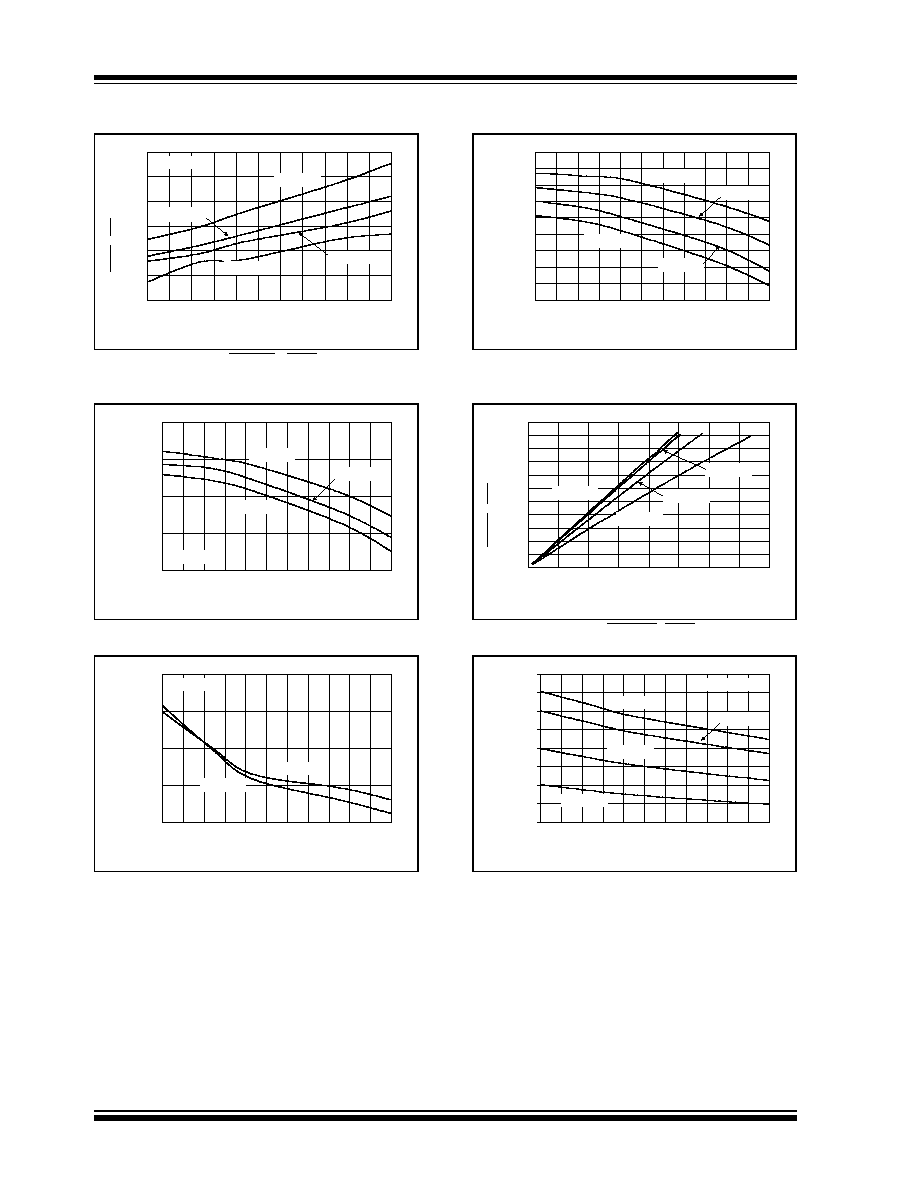

2003 Microchip Technology Inc.

Note: Unless otherwise indicated, V

DD

= 5V, T

A

= 25°C.

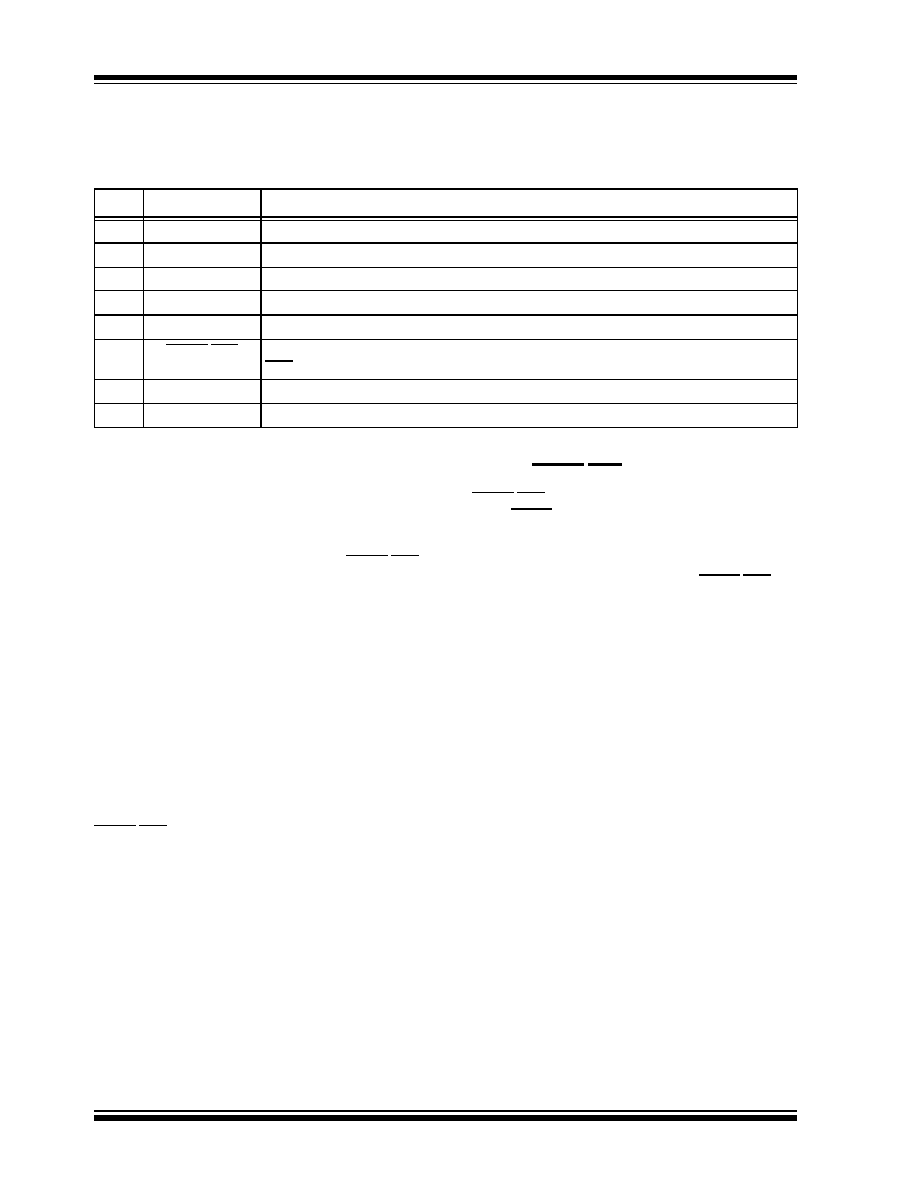

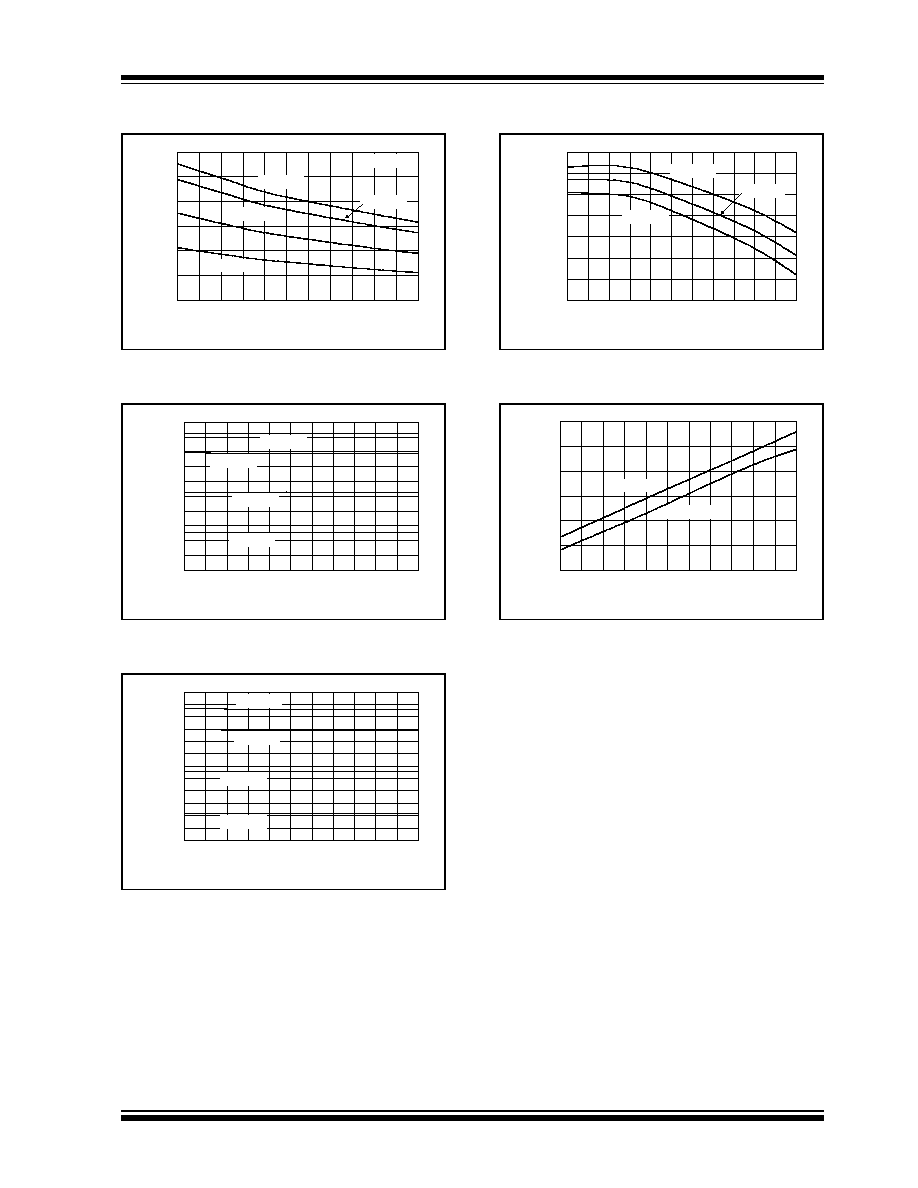

FIGURE 2-7:

FAULT / OTF V

OL

vs.

Temperature.

FIGURE 2-8:

V

C(MAX)

vs. Temperature.

FIGURE 2-9:

V

C(MIN)

vs. Temperature.

FIGURE 2-10:

Sense Threshold

(V

TH(SENSE)

) vs. Temperature.

FIGURE 2-11:

FAULT / OTF I

OL

vs. V

OL

.

FIGURE 2-12:

PWM Source Current (I

OH

)

vs. Temperature.

10

20

30

40

50

60

70

-40 -25 -10

5

20

35

50

65

80

95

110 125

Temperature (ºC)

FAULT / OTF V

OL

(mV)

I

OL

= 2.5 mA

V

DD

= 3.0V

V

DD

= 5.5V

V

DD

= 5.0V

V

DD

= 4.0V

2.570

2.580

2.590

2.600

2.610

-40 -25 -10

5

20

35

50

65

80

95 110 125

Temperature (ºC)

V

C(MAX)

(V)

V

DD

= 5.0V

V

DD

= 5.5V

V

DD

= 3.0V

C

F

= 1 µF

1.180

1.190

1.200

1.210

1.220

-40 -25 -10

5

20

35

50

65

80

95 110 125

Temperature (ºC)

V

C(MIN)

(V)

V

DD

= 5.0V

V

DD

= 3.0V

C

F

= 1 µF

69.5

70.0

70.5

71.0

71.5

72.0

72.5

73.0

73.5

74.0

-40 -25 -10

5

20

35

50

65

80

95 110 125

Temperature (ºC)

V

TH(SENSE)

(mV)

V

DD

= 3.0V

V

DD

= 4.0V

V

DD

= 5.5V

V

DD

= 5.0V

0

2

4

6

8

10

12

14

16

18

20

22

0

50

100

150

200

250

300

350

400

V

OL

(mV)

FAULT / OTF I

OL

(mA)

V

DD

= 5.5V

V

DD

= 3.0V

V

DD

= 4.0V

V

DD

= 5.0V

5.00

10.00

15.00

20.00

25.00

30.00

35.00

40.00

45.00

-40 -25 -10

5

20

35

50

65

80

95 110 125

Temperature (ºC)

V

OUT

I

OH

(mA)

V

DD

= 5.5V

V

DD

= 5.0V

V

DD

= 4.0V

V

DD

= 3.0V

V

OH

= 0.8V

DD

2003 Microchip Technology Inc.

DS21755B-page 9

TC646B/TC648B/TC649B

Note: Unless otherwise indicated, V

DD

= 5V, T

A

= 25°C.

FIGURE 2-13:

PWM Sink Current (I

OL

) vs.

Temperature.

FIGURE 2-14:

V

SHDN

Threshold vs.

Temperature.

FIGURE 2-15:

V

REL

Threshold vs.

Temperature.

FIGURE 2-16:

V

OTF

Threshold vs.

Temperature.

FIGURE 2-17:

Over-Temperature

Hysteresis (V

OTF-HYS

) vs. Temperature.

0

5

10

15

20

25

30

-40 -25 -10

5

20

35

50

65

80

95

110 125

Temperature (ºC)

V

OUT

I

OL

(mA)

V

DD

= 5.5V

V

DD

= 5.0V

V

DD

= 4.0V

V

DD

= 3.0V

V

OL

= 0.1V

DD

0.30

0.35

0.40

0.45

0.50

0.55

0.60

0.65

0.70

0.75

0.80

-40 -25 -10

5

20

35

50

65

80

95 110 125

Temperature (ºC)

V

SHDN

(V)

V

DD

= 3.0V

V

DD

= 4.0V

V

DD

= 5.0V

V

DD

= 5.5V

0.40

0.45

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

-40 -25 -10

5

20

35

50

65

80

95 110 125

Temperature (ºC)

V

REL

(V)

V

DD

= 3.0V

V

DD

= 4.0V

V

DD

= 5.0V

V

DD

= 5.5V

2.595

2.600

2.605

2.610

2.615

2.620

2.625

2.630

-40 -25 -10

5

20

35

50

65

80

95 110 125

Temperature (ºC)

V

OTF

(V)

V

DD

= 3.0V

V

DD

= 5.0V

V

DD

= 5.5V

70

75

80

85

90

95

100

-40 -25 -10

5

20

35

50

65

80

95 110 125

Temperature (ºC)

V

OTF

Hysteresis (mV)

V

DD

= 5.5V

V

DD

= 3.0V

TC646B/TC648B/TC649B

DS21755B-page 10

2003 Microchip Technology Inc.

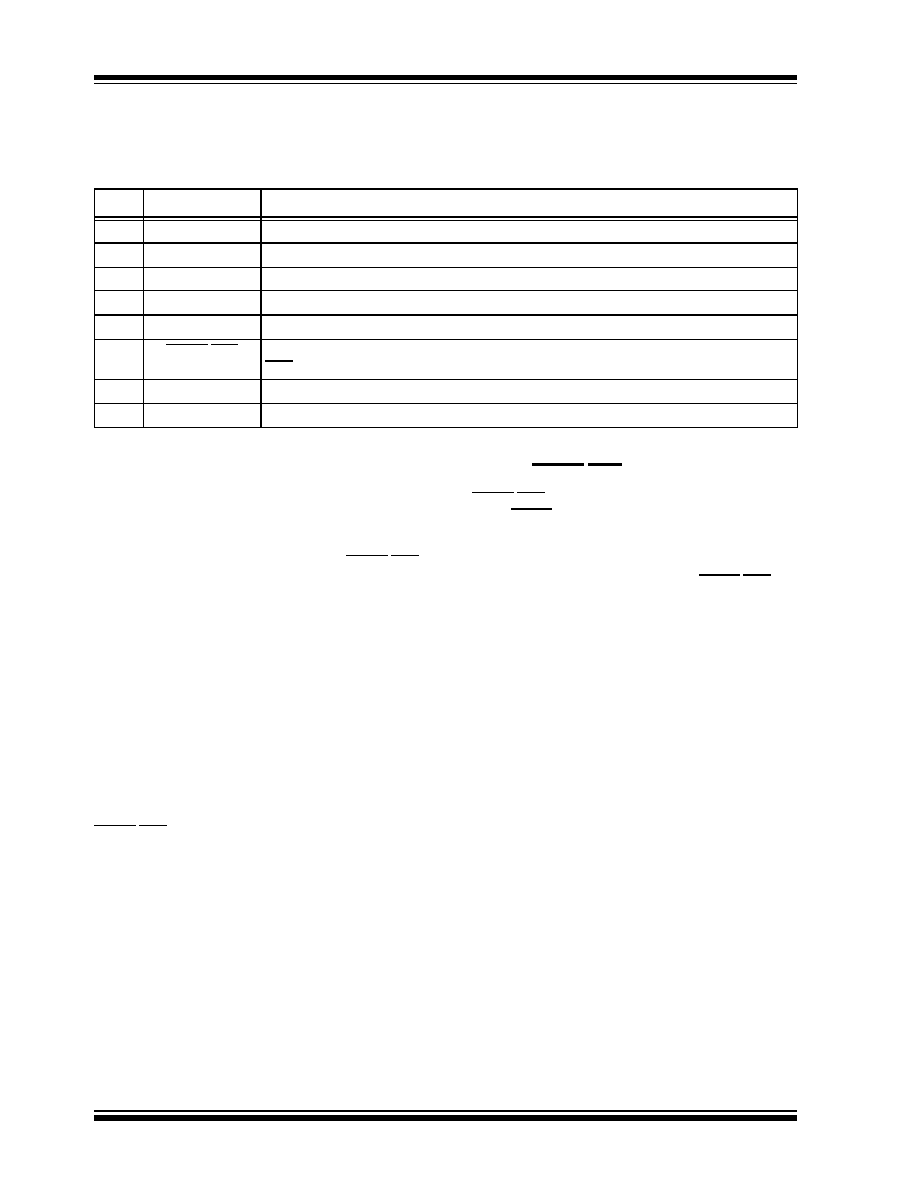

3.0

PIN FUNCTIONS

The descriptions of the pins are given in Table 3-1.

TABLE 3-1:

PIN FUNCTION TABLE

3.1

Analog Input (V

IN

)

The thermistor network (or other temperature sensor)

connects to V

IN

. A voltage range of 1.20V to 2.60V (typ-

ical) on this pin drives an active duty cycle of 0% to

100% on the V

OUT

pin. The TC646B, TC648B and

TC649B devices enter shutdown mode when

0

V

IN

V

SHDN

. During shutdown, the FAULT/OTF

output is inactive and supply current falls to 30 µA

(typical).

3.2

Analog Output (C

F

)

C

F

is the positive terminal for the PWM ramp generator

timing capacitor. The recommended value for the C

F

capacitor is 1.0 µF for 30 Hz PWM operation.

3.3

Analog Input (V

AS

)

An external resistor divider connected to V

AS

sets the

auto-shutdown threshold. Auto-shutdown occurs when

V

IN

< V

AS

. The fan is automatically restarted when

V

IN

> (V

AS

+ V

HAS

). During auto-shutdown, the

FAULT/OTF output is inactive and supply current falls

to 30 µA (typical).

3.4

Analog Input (SENSE)

Pulses are detected at SENSE as fan rotation chops

the current through a sense resistor. The absence of

pulses indicates a fan fault condition.

3.5

Digital (Open-Drain) Output

(FAULT/OTF)

FAULT/OTF goes low to indicate a fault condition.

When FAULT goes low due to a fan fault (TC646B and

TC649B devices), the output will remain low until the

fan fault condition has been removed (16 pulses have

been detected at the SENSE pin in a 32/f period). For

the TC646B and TC648B devices, the FAULT/OTF out-

put will also be asserted when the V

IN

voltage reaches

the V

OTF

threshold of 2.62V (typical). This gives an

over-temperature/100% fan speed indication

.

3.6

Digital Output (V

OUT

)

V

OUT

is an active-high complimentary output that

drives the base of an external NPN transistor (via an

appropriate base resistor) or the gate of an N-channel

MOSFET. This output has asymmetrical drive. During a

fan fault condition, the V

OUT

output is continuously on.

3.7

Power Supply Input (V

DD

)

The V

DD

pin with respect to GND provides power to the

device. This bias supply voltage may be independent of

the fan power supply.

3.8

Ground (GND)

Ground terminal.

3.9

No Connect (NC)

No internal connection.

Pin

Name

Function

1

V

IN

Analog Input

2

C

F

Analog Output

3

V

AS

Analog Input

4

GND

Ground

5

SENSE/NC

Analog Input/No Connect. NC for TC648B.

6

FAULT/OTF

Digital (Open-Drain) Output

OTF for TC648B

7

V

OUT

Digital Output

8

V

DD

Power Supply Input

2003 Microchip Technology Inc.

DS21755B-page 11

TC646B/TC648B/TC649B

4.0

DEVICE OPERATION

The TC646B/TC648B/TC649B devices are a family of

temperature-proportional, PWM mode, fan speed con-

trollers. Features of the family include minimum fan

speed, fan auto-shutdown, fan auto-restart, remote

shutdown, over-temperature indication and fan fault

detection.

The TC64XB family is slightly different from the original

TC64X family, which includes the TC642, TC646,

TC647, TC648 and TC649 devices. Changes have

been made to adjust the operation of the device during

a fan fault condition.

The key change to the TC64XB family of devices

(TC642B, TC647B, TC646B, TC648B, TC649B) is that

the FAULT and V

OUT

outputs no longer "latch" to a

state during a fan fault condition. The TC646B/

TC648B/TC649B family will continue to monitor the

operation of the fan so that when the fan returns to nor-

mal operation, the fan speed controller will also return

to normal operation (PWM mode). The operation and

features of these devices are discussed in the following

sections.

4.1

Fan Speed Control Methods

The speed of a DC brushless fan is proportional to the

voltage across it. This relationship will vary from fan-to-

fan and should be characterized on an individual basis.

The speed versus applied voltage relationship can then

be used to set up the fan speed control algorithm.

There are two main methods for fan speed control. The

first is pulse width modulation (PWM) and the second

is linear. Using either method, the total system power

requirement to run the fan is equal. The difference

between the two methods is where the power is

consumed.

The following example compares the two methods for

a 12V, 120 mA fan running at 50% speed. With 6V

applied across the fan, the fan draws an average

current of 68 mA.

Using a linear control method, there is 6V across the

fan and 6V across the drive element. With 6V and

68 mA, the drive element is dissipating 410 mW of

power.

Using the PWM approach, the fan voltage is modulated

at a 50% duty cycle, with most of the 12V being

dropped across the fan. With 50% duty cycle, the fan

draws a RMS current of 110 mA and an average cur-

rent of 72 mA. Using a MOSFET with a 1

R

DS(on)

(a

fairly typical value for this low current), the power dissi-

pation in the drive element would be: 12 mW (Irms

2

*

R

DS(on)

). Using a standard 2N2222A NPN transistor

(assuming a Vce-sat of 0.8V), the power dissipation

would be 58 mW (Iavg* Vce-sat).

The PWM approach to fan speed control results in

much less power dissipation in the drive element. This

allows smaller devices to be used and will not require

special heatsinking to remove the power being

dissipated in the package.

The other advantage of the PWM approach is that the

voltage being applied to the fan is always near 12V.

This eliminates any concern about not supplying a high

enough voltage to run the internal fan components,

which is very relevant in linear fan speed control.

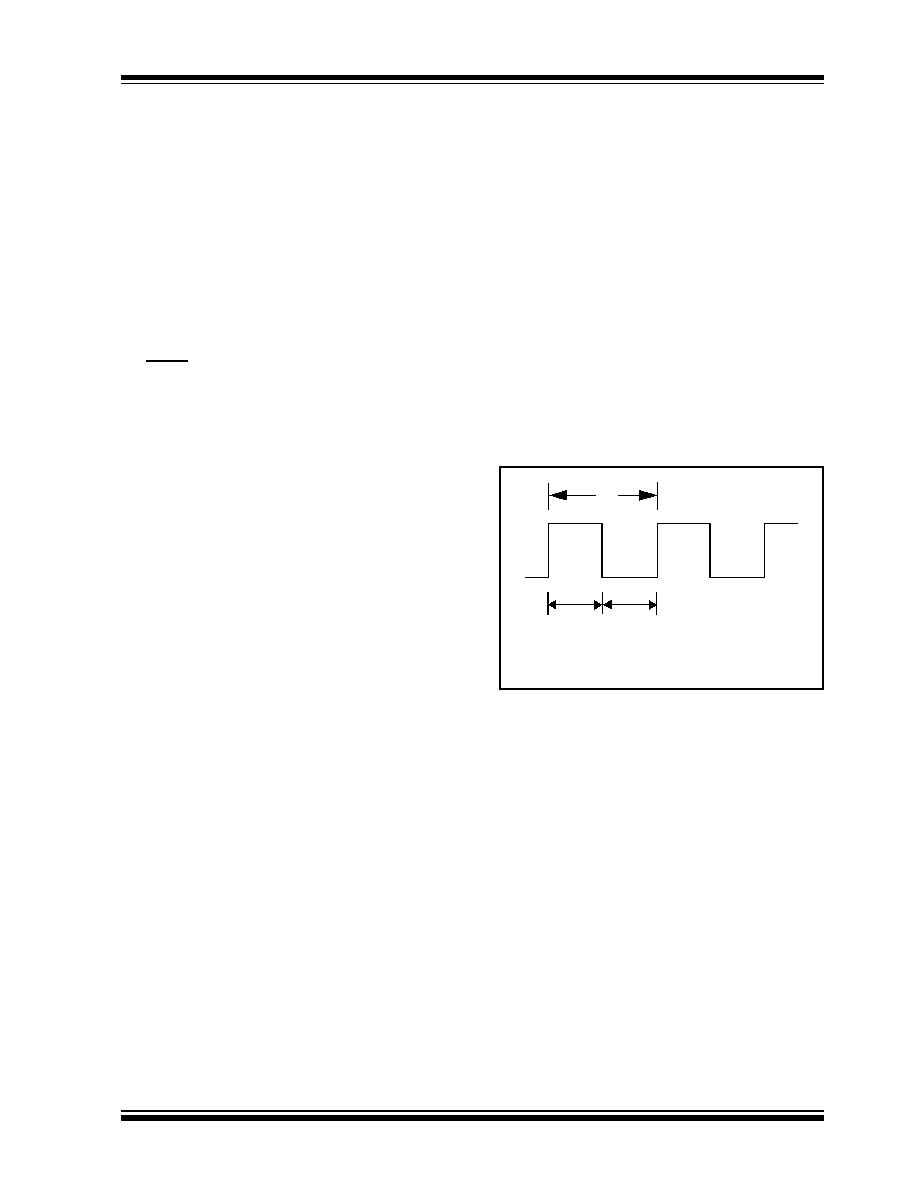

4.2

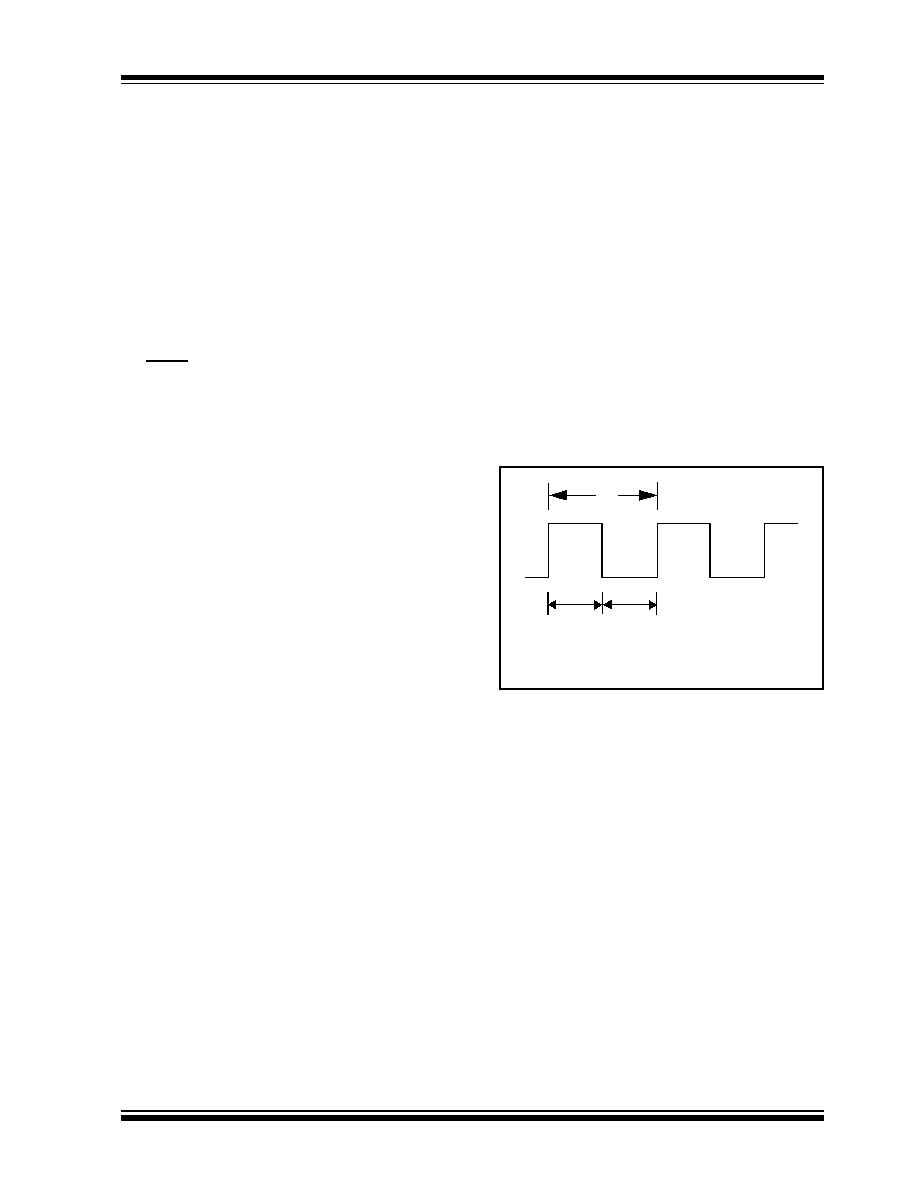

PWM Fan Speed Control

The TC646B, TC648B and TC649B devices implement

PWM fan speed control by varying the duty cycle of a

fixed-frequency pulse train. The duty cycle of a wave-

form is the on time divided by the total period of the

pulse. For example, if we take a 100 Hz waveform

(10 ms) with an on time of 5.0 ms, the duty cycle of this

waveform is 50% (5.0 ms / 10.0 ms). This example is

shown in Figure 4-1.

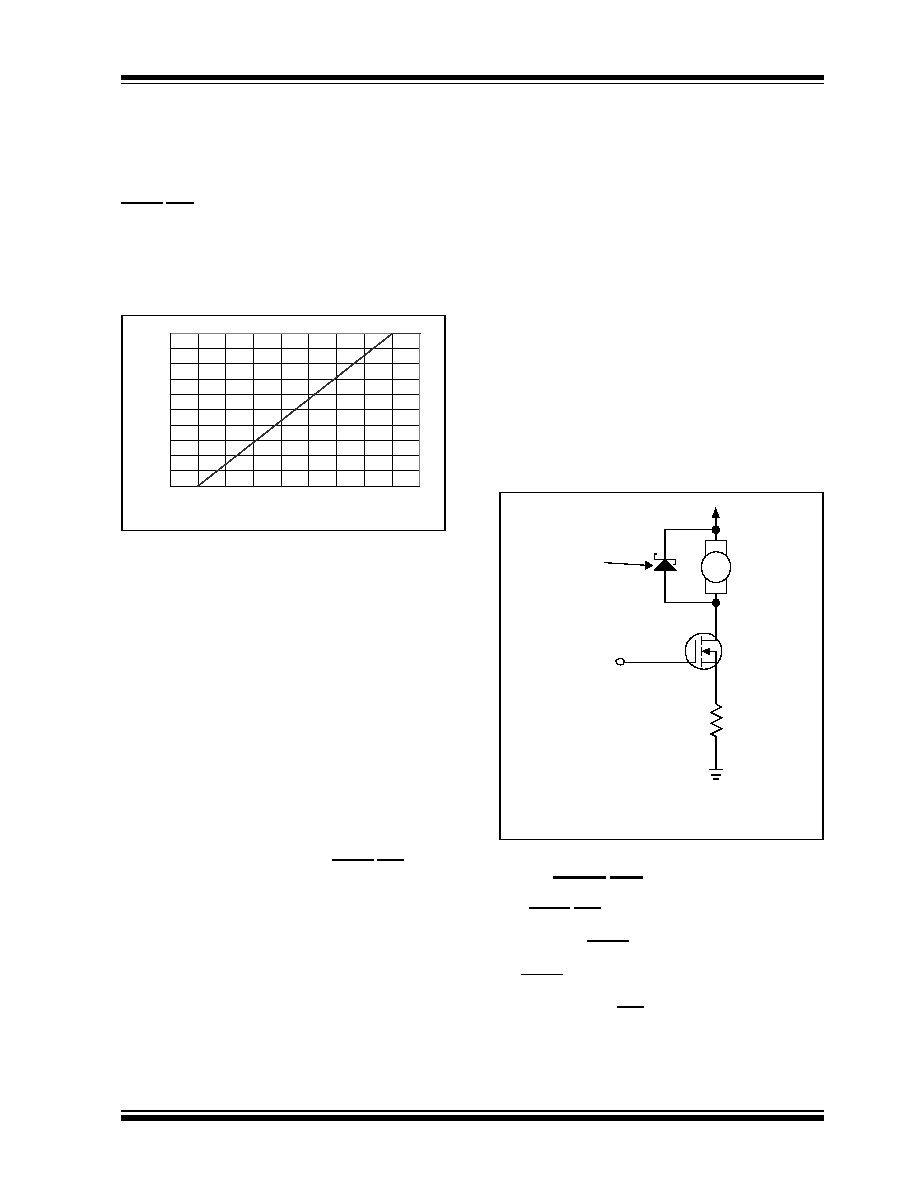

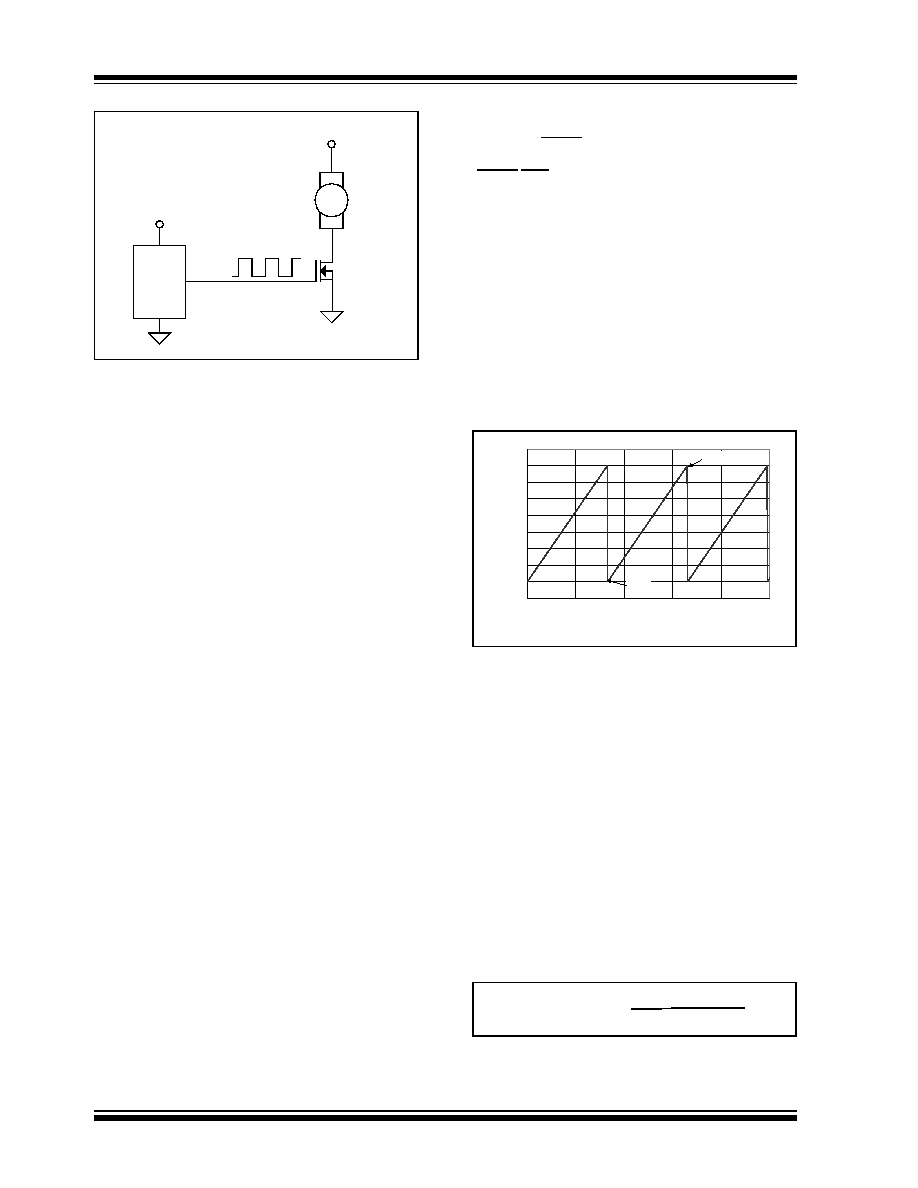

FIGURE 4-1:

Duty Cycle of a PWM

Waveform.

The TC646B/TC648B/TC649B devices generate a

pulse train with a typical frequency of 30 Hz

(C

F

= 1 µF). The duty cycle can be varied from 0% to

100%. The pulse train generated by the TC646B/

TC648B/TC649B device drives the gate of an external

N-channel MOSFET or the base of an NPN transistor.

(shown in Figure 4-2). See Section 5.5, "Output Drive

Device Selection", for more information on output drive

device selection.

t

ton

toff

t = Period

t = 1/f

f = Frequency

D = Duty Cycle

D = ton / t

TC646B/TC648B/TC649B

DS21755B-page 12

2003 Microchip Technology Inc.

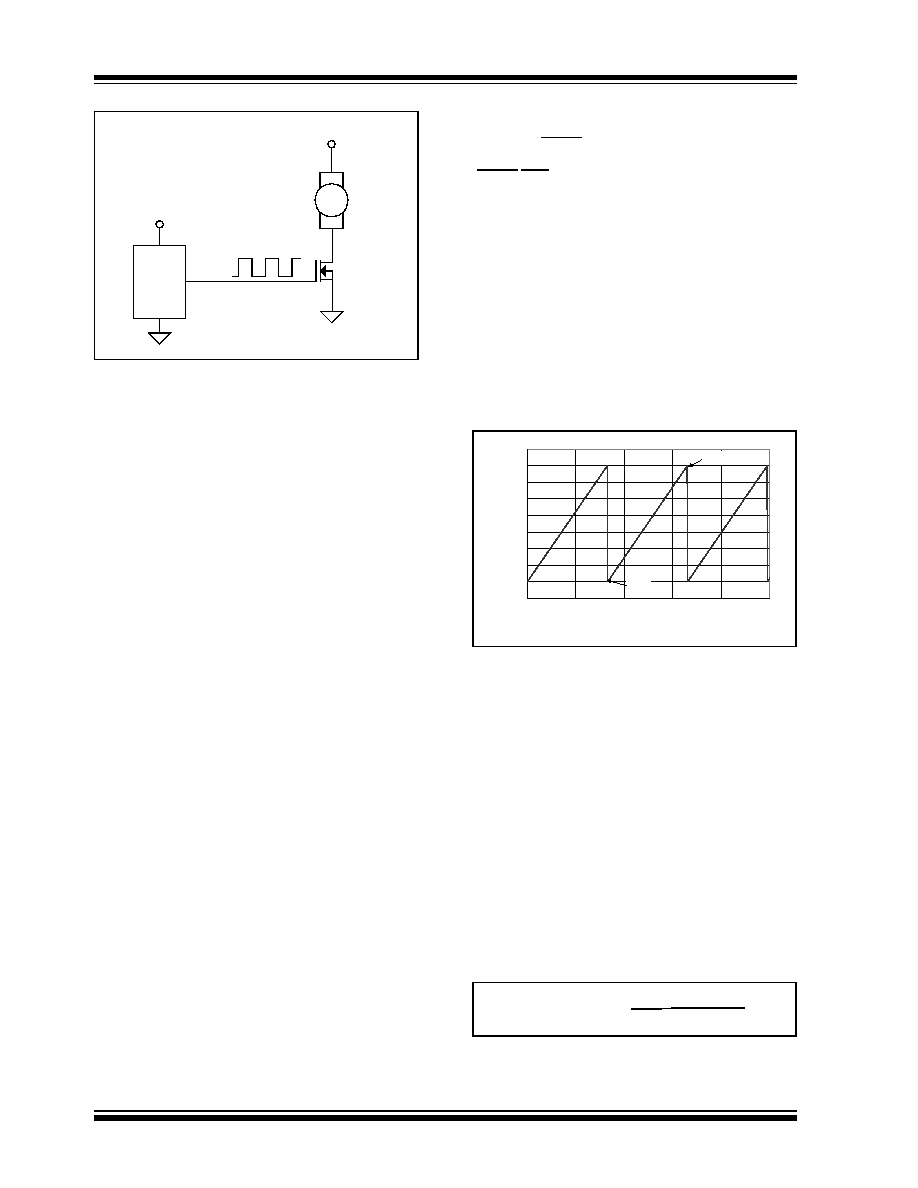

FIGURE 4-2:

PWM Fan Drive.

By modulating the voltage applied to the gate of the

MOSFET (Q

DRIVE

), the voltage that is applied to the

fan is also modulated. When the V

OUT

pulse is high, the

gate of the MOSFET is turned on, pulling the voltage at

the drain of Q

DRIVE

to zero volts. This places the full

12V across the fan for the t

on

period of the pulse. When

the duty cycle of the drive pulse is 100% (full on,

t

on

= t), the fan will run at full speed. As the duty cycle

is decreased (pulse on time "t

on

" is lowered), the fan

will slow down proportionally. With the TC646B,

TC648B and TC649B devices, the duty cycle is con-

trolled by the V

IN

input and can also be terminated by

the V

AS

input (auto-shutdown). This is described in

more detail in Section 5.5, "Output Drive Device

Selection".

4.3

Fan Start-up

Often overlooked in fan speed control is the actual

start-up control period. When starting a fan from a non-

operating condition (fan speed is zero revolutions per

minute (RPM)), the desired PWM duty cycle or average

fan voltage cannot be applied immediately. Since the

fan is at a rest position, the fan's inertia must be over-

come to get it started. The best way to accomplish this

is to apply the full rated voltage to the fan for a minimum

of one second. This will ensure that in all operating

environments, the fan will start and operate properly.

An example of the start-up timing is shown in

Figure 1-1.

A key feature of the TC646B/TC648B/TC649B devices

is the start-up timer. When power is first applied to the

device, or when the device is brought out of the shut-

down/auto-shutdown modes of operation, the V

OUT

output will go to a high state for 32 PWM cycles (one

second for C

F

= 1 µF). This will drive the fan to full

speed for this time frame.

During the start-up period for the TC646B and TC649B

devices, the SENSE pin is being monitored for fan

pulses. If pulses are detected during this period, the fan

speed controller will then move to PWM operation. If

pulses are not detected during the start-up period, the

start-up timer is activated again. If pulses are not

detected at the SENSE pin during this additional

period, the FAULT output will go low to indicate that a

fan fault condition has occurred. See Section 4.7,

"FAULT/OTF Output", for more details.

4.4

PWM Frequency & Duty Cycle

Control (C

F

& V

IN

Pins)

The frequency of the PWM pulse train is controlled by

the C

F

pin. By attaching a capacitor to the C

F

pin, the

frequency of the PWM pulse train can be set to the

desired value. The typical PWM frequency for a 1.0 µF

capacitor is 30 Hz. The frequency can be adjusted by

raising or lowering the value of the capacitor. The C

F

pin functions as a ramp generator. The voltage at this

pin will ramp from 1.20V to 2.60V (typically) as a saw-

tooth waveform. An example of this is shown in

Figure 4-3.

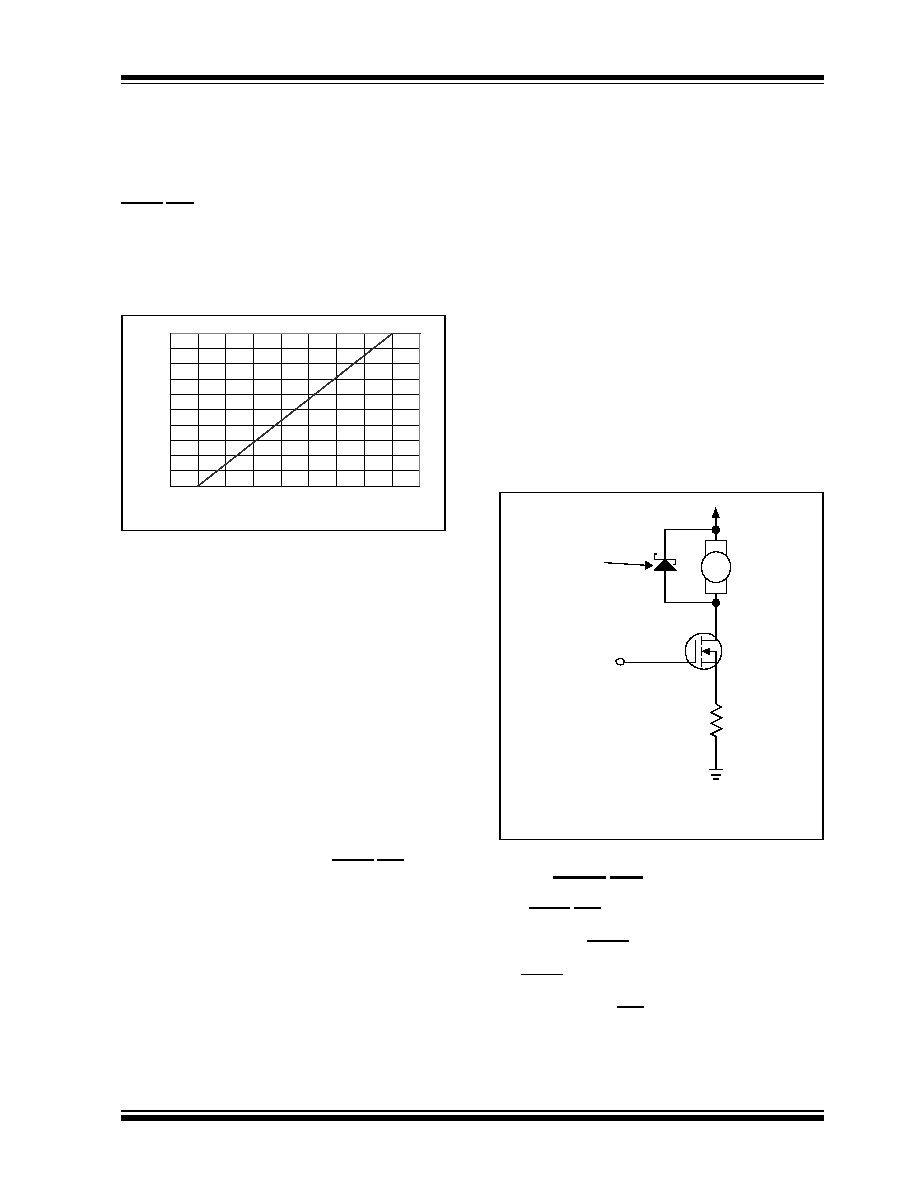

FIGURE 4-3:

C

F

Pin Voltage.

The duty cycle of the PWM output is controlled by the

voltage at the V

IN

input pin. The duty cycle of the PWM

output is produced by comparing the voltage at the V

IN

pin to the voltage ramp at the C

F

pin. When the voltage

at the V

IN

pin is 1.20V, the duty cycle will be 0%. When

the voltage at the V

IN

pin is 2.60V, the PWM duty cycle

will be 100% (these are both typical values). The

V

IN

-to-PWM duty cycle relationship is shown in

Figure 4-4.

The lower value of 1.20V is referred to as "V

CMIN

" and

the 2.60V threshold is referred to as "V

CMAX

". A calcu-

lation for duty cycle is shown in the equation below. The

voltage range between V

CMIN

and V

CMAX

is character-

ized as "V

CSPAN

" and has a typical value of 1.4V, with

minimum and maximum values of 1.3V and 1.5V,

respectively.

EQUATION

PWM DUTY CYCLE

FAN

12V

Q

DRIVE

TC646B

TC648B

TC649B

V

DD

GND

V

OUT

G

D

S

1.0

1.2

1.4

1.6

1.8

2.0

2.2

2.4

2.6

2.8

0

20

40

60

80

100

Time (msec)

C

F

Voltage (V)

C

F

= 1 µF

V

CMAX

V

CMIN

Duty Cycle (%) =

V

CMAX

- V

CMIN

(V

IN

- V

CMIN

) * 100

2003 Microchip Technology Inc.

DS21755B-page 13

TC646B/TC648B/TC649B

For the TC646B, TC648B and TC649B devices, the V

IN

pin is also used as the shutdown pin. The V

SHDN

and

V

REL

threshold voltages are characterized in the "Elec-

trical Characteristics Table" of Section 1.0. If the V

IN

pin

voltage is pulled below the V

SHDN

threshold, the device

will shut down (V

OUT

output goes to a low state, the

FAULT/OTF pin is inactive). If the voltage on the V

IN

pin

then rises above the release threshold (V

REL

), the

device will go through a power-up sequence (assuming

that the V

IN

voltage is also higher than the voltage at

the V

AS

pin). The power-up sequence is shown later in

the "Behavioral Algorithm Flowcharts" of Section 4.9.

FIGURE 4-4:

V

IN

Voltage vs. PWM Duty

Cycle (Typical).

4.5

Auto-Shutdown Mode (V

AS

)

For the TC646B, TC648B and TC649B devices, pin 3

is the V

AS

pin and is used for setting the auto-shutdown

threshold voltage.

The auto-shutdown function provides a way to set a

threshold voltage (temperature) at which the fan will be

shut off. This way, if the temperature in the system

reaches a threshold at which the fan(s) no longer needs

to operate, the fan can be shutdown automatically.

The voltage range for the V

AS

pin is the same as the

voltage range for the V

IN

pin (1.20V to 2.60V). The volt-

age at the V

AS

pin is set in this range so that when the

voltage at the V

IN

pin decreases below the voltage at

the V

AS

pin (signifying that the threshold temperature

has been reached), the V

OUT

output is shut off (goes to

a low state). In auto-shutdown, the FAULT/OTF output

is inactive (high-impedance). Auto-shutdown mode is

exited when the V

IN

voltage exceeds the V

AS

voltage

by the auto-shutdown hysteresis voltage (V

HAS

). Upon

exiting auto-shutdown mode, the start-up timer is

triggered and the device returns to normal operation.

4.6

V

OUT

Output (PWM Output)

The V

OUT

output is a digital output designed for driving

the base of a transistor or the gate of a MOSFET. The

V

OUT

output is designed to be able to quickly raise the

base current or the gate voltage of the external drive

device to its final value.

When the device is in shutdown/auto-shutdown mode,

the V

OUT

output is actively held low. The output can be

varied from 0% (full off) to 100% duty cycle (full on). As

previously discussed, the duty cycle of the V

OUT

output

is controlled via the V

IN

input voltage and can be termi-

nated based on the V

AS

voltage.

A base current-limiting resistor is required when using

a transistor as the external drive device in order to limit

the amount of drive current that is drawn from the V

OUT

output.

The V

OUT

output can be directly connected to the gate

of an external MOSFET. One concern when doing this,

though, is that the fast turn-off time of the fan drive

MOSFET can cause a problem because the fan motor

looks like an inductor. When the MOSFET is turned off

quickly, the current in the fan wants to continue to flow

in the same direction. This causes the voltage at the

drain of the MOSFET to rise. If there aren't any clamp

diodes internal to the fan, this voltage can rise above

the drain-to-source voltage rating of the MOSFET. For

this reason, an external clamp diode is suggested. This

is shown in Figure 4-5.

FIGURE 4-5:

Clamp Diode for Fan.

4.7

FAULT/OTF Output

The FAULT/OTF output is an open-drain, active-low

output. For the TC646B and TC649B devices, pin 6 is

labeled as the FAULT output and indicates when a fan

fault condition has occurred. For the TC646B device,

the FAULT output also indicates when an over-temper-

ature (OTF) condition has occurred. For the TC648B

device, pin 6 is the OTF output that indicates an over-

temperature (OTF) condition has occurred.

0

10

20

30

40

50

60

70

80

90

100

1

1.2

1.4

1.6

1.8

2

2.2

2.4

2.6

2.8

V

IN

(V)

Duty Cycle (%)

Q

1

GND

R

SENSE

V

OUT

Q

1

: N-Channel MOSFET

FAN

Clamp Diode

TC646B/TC648B/TC649B

DS21755B-page 14

2003 Microchip Technology Inc.

For the TC646B and TC648B devices, an over-temper-

ature condition is indicated when the V

IN

input reaches

the V

OTF

threshold voltage (the V

OTF

threshold voltage

is typically 20 mV higher than the V

CMAX

threshold and

has 80 mV of hysteresis). This indicates that maximum

cooling capacity has been reached (the fan is at full

speed) and that an overheating situation can occur.

When the voltage at the V

IN

input falls below the V

OTF

threshold voltage by the hysteresis value (V

OTF-HYS

),

the FAULT/OTF output will return to the high state (a

pull-up resistor is needed on the FAULT/OTF output).

For the TC646B/TC649B devices, a fan fault condition

is indicated when fan current pulses are no longer

detected at the SENSE pin. Pulses at the SENSE pin

indicate that the fan is spinning and conducting current.

If pulses are not detected at the SENSE pin for

32 PWM cycles, the 3-cycle diagnostic timer is fired.

This means that the V

OUT

output is high for 3 PWM

cycles. If pulses are detected in this 3-cycle period, nor-

mal PWM operation is resumed and no fan fault is indi-

cated. If no pulses are detected in the 3-cycle period,

the start-up timer is activated and the V

OUT

output is

driven high for 32 PWM cycles. If pulses are detected

during this time-frame, normal PWM operation is

resumed. If no pulses are detected during this time-

period, a fan fault condition exists and the FAULT

output is pulled low.

During a fan fault condition, the FAULT output will

remain low until the fault condition has been removed.

During this time, the V

OUT

output is driven high contin-

uously to attempt to restart the fan and the SENSE pin

is monitored for fan pulses. If a minimum of 16 pulses

are detected at the SENSE input over a 32 cycle time-

period (one second for C

F

= 1.0 µF), the fan fault con-

dition no longer exists. Therefore, The FAULT output is

released and the V

OUT

output returns to normal PWM

operation, as dictated by the V

IN

and V

AS

inputs.

If the V

IN

voltage is pulled below the V

SHDN

level during

a fan fault condition, the FAULT output will be released

and the V

OUT

output will be shutdown (V

OUT

= 0V). If

the V

IN

voltage then increases above the V

REL

thresh-

old and is above the V

AS

voltage, the device will go

through the normal start-up routine.

If, during a fan fault condition, the voltage at the V

IN

pin

drops below the V

AS

voltage level, the TC646B/

TC649B device will continue to hold the FAULT line low

and drive the V

OUT

output to 100% duty cycle. If the fan

fault condition is then removed, the FAULT output will

be released and the TC646B/TC649B device will enter

auto-shutdown mode until the V

IN

voltage is brought

above the V

AS

voltage by the auto-shutdown hysteresis

value (V

HAS

). The TC646B/TC649B device will then

resume normal PWM mode operation.

The sink current capability of the FAULT output is listed

in the "Electrical Characteristics Table" of Section 1.0.

4.8

Sensing Fan Operation (SENSE)

The SENSE input is an analog input used to monitor

the fan's operation (the TC648B device does not incor-

porate the fan sensing feature). It does this by sensing

fan current pulses that represent fan rotation. When a

fan rotates, commutation of the fan current occurs as

the fan poles pass the armatures of the motor. The

commutation of the fan current makes the current

waveshape appear as pulses. There are two typical

current waveforms of brushless DC fan motors,

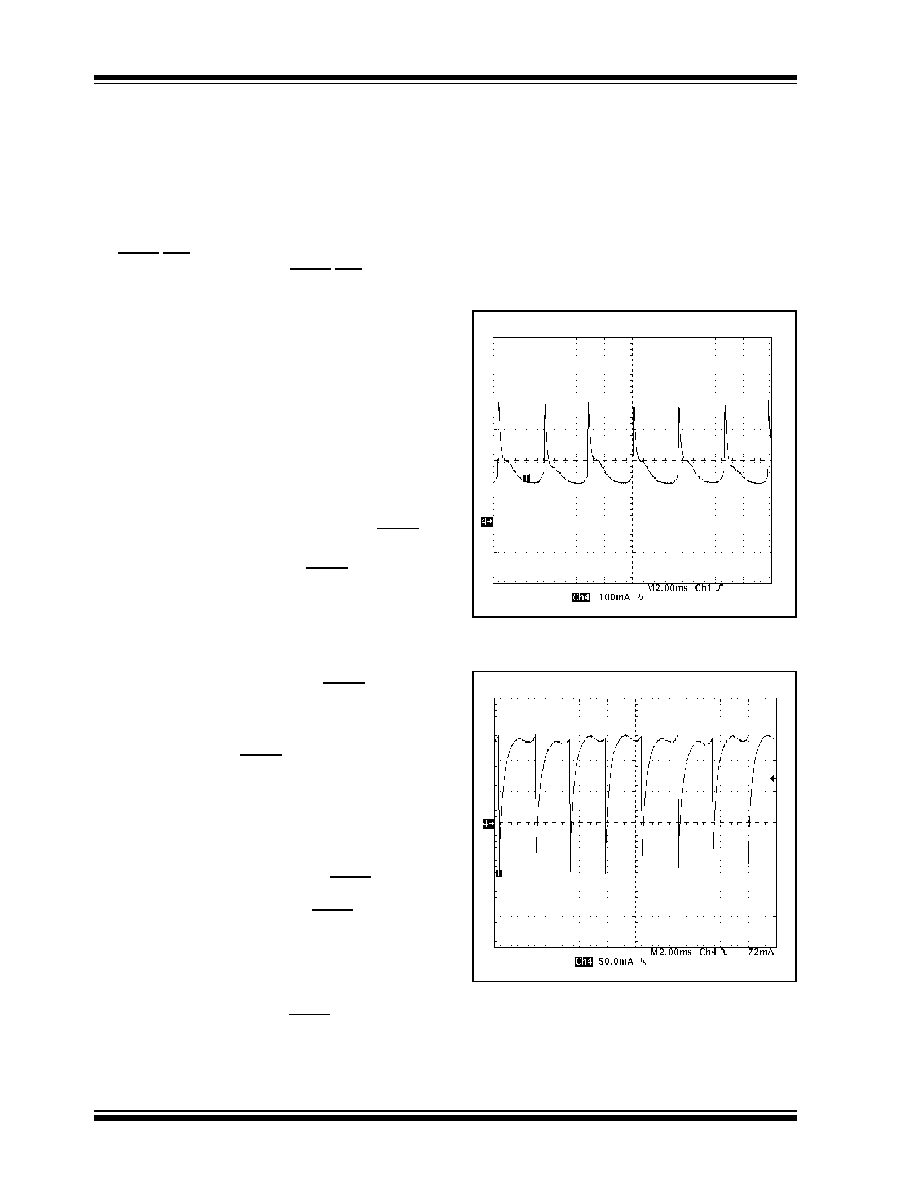

illustrated in Figures 4-6 and 4-7.

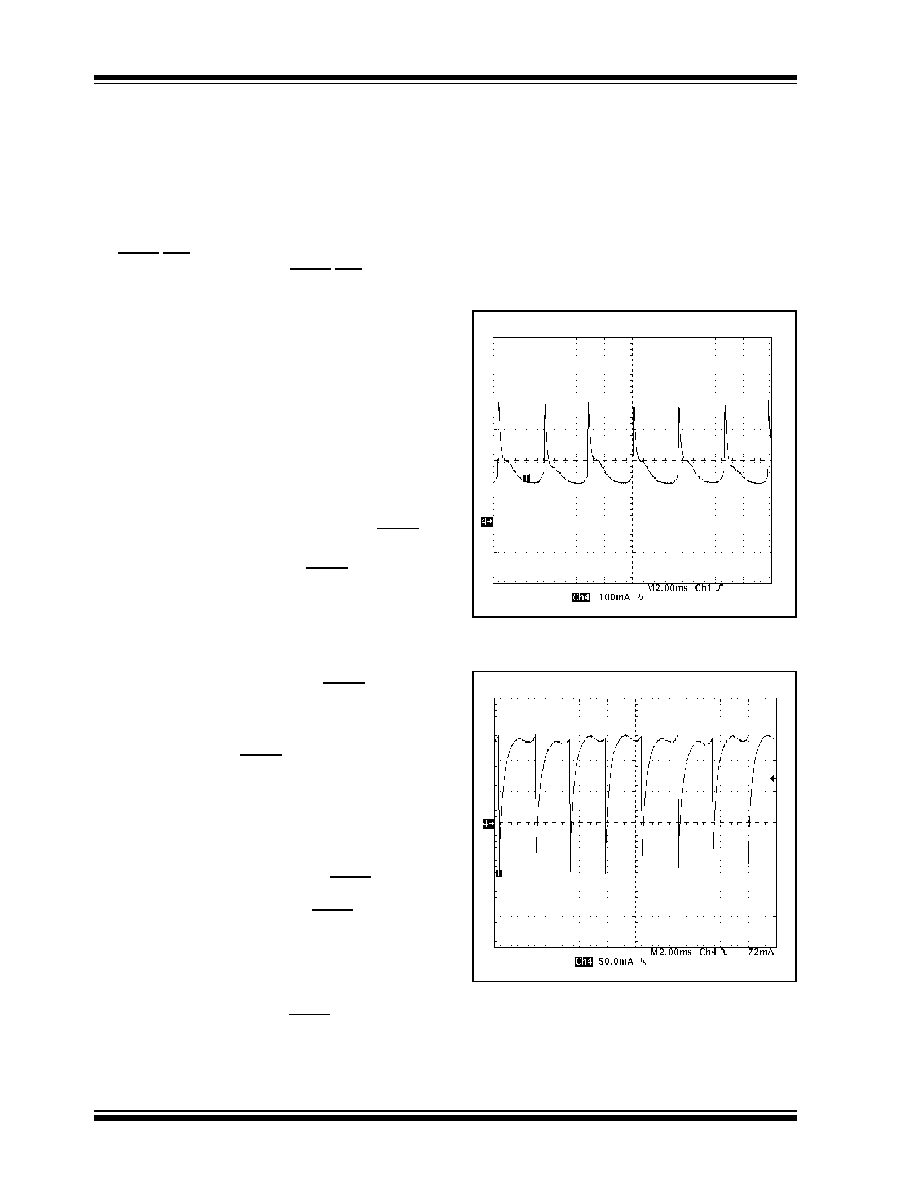

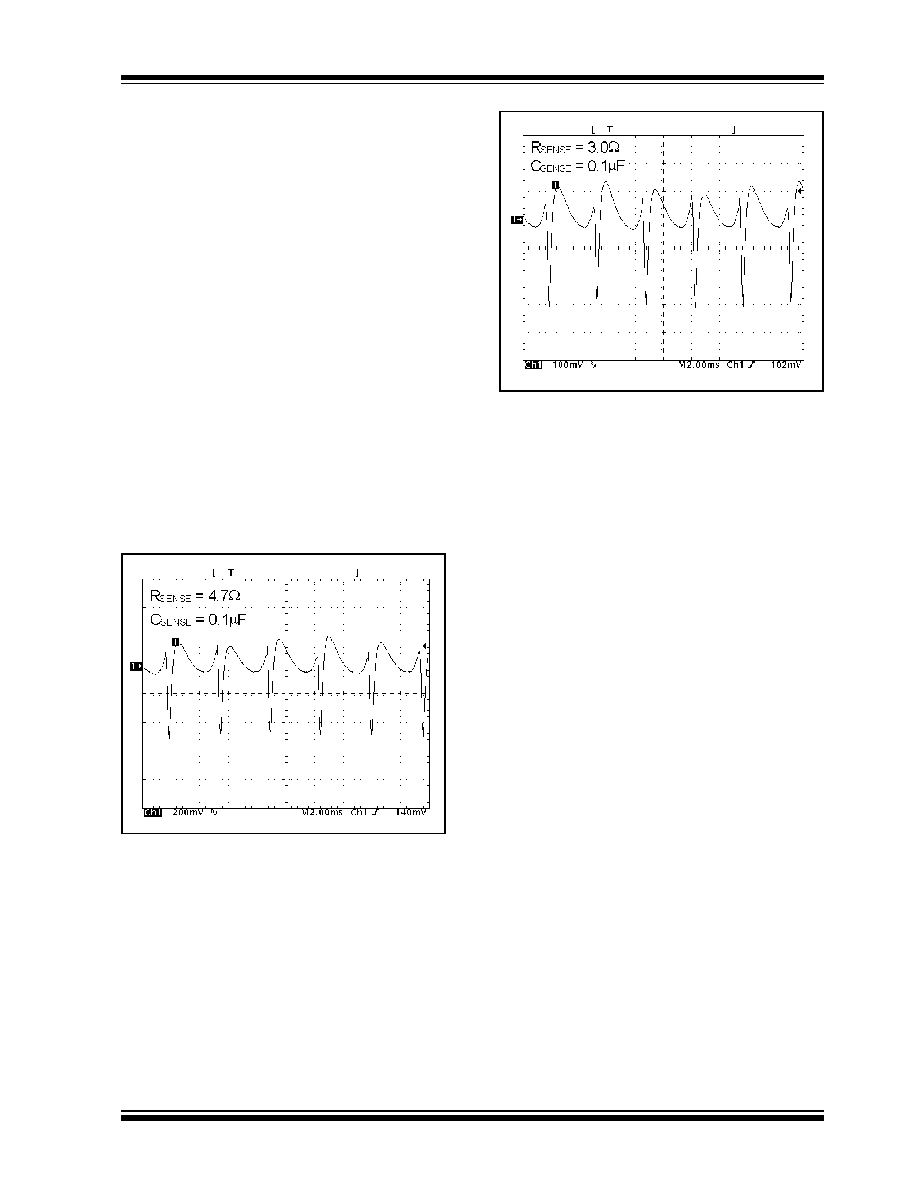

FIGURE 4-6:

Fan Current With DC Offset

And Positive Commutation Current.

FIGURE 4-7:

Fan Current With

Commutation Pulses To Zero.

2003 Microchip Technology Inc.

DS21755B-page 15

TC646B/TC648B/TC649B

The SENSE pin senses positive voltage pulses that

have an amplitude of 70 mV (typical value). Each time

a pulse is detected, the missing pulse detector timer

(t

MP

) is reset. As previously stated, if the missing pulse

detector timer reaches the time for 32 cycles, the loop

for diagnosing a fan fault is engaged (diagnostic timer,

then the start-up timer).

Both of the fan current waveshapes shown in Figures

4-6 and 4-7 can be sensed with the sensing scheme

shown in Figure 4-8.

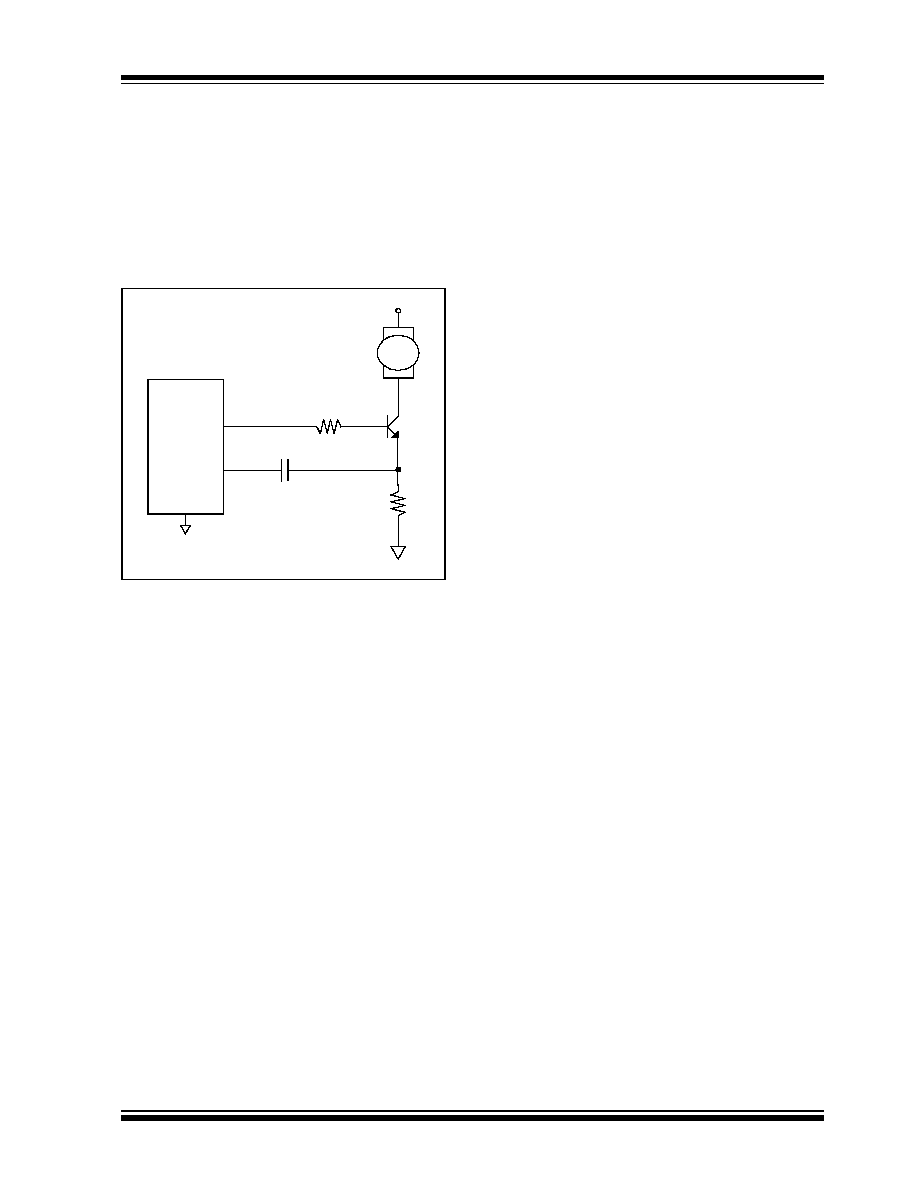

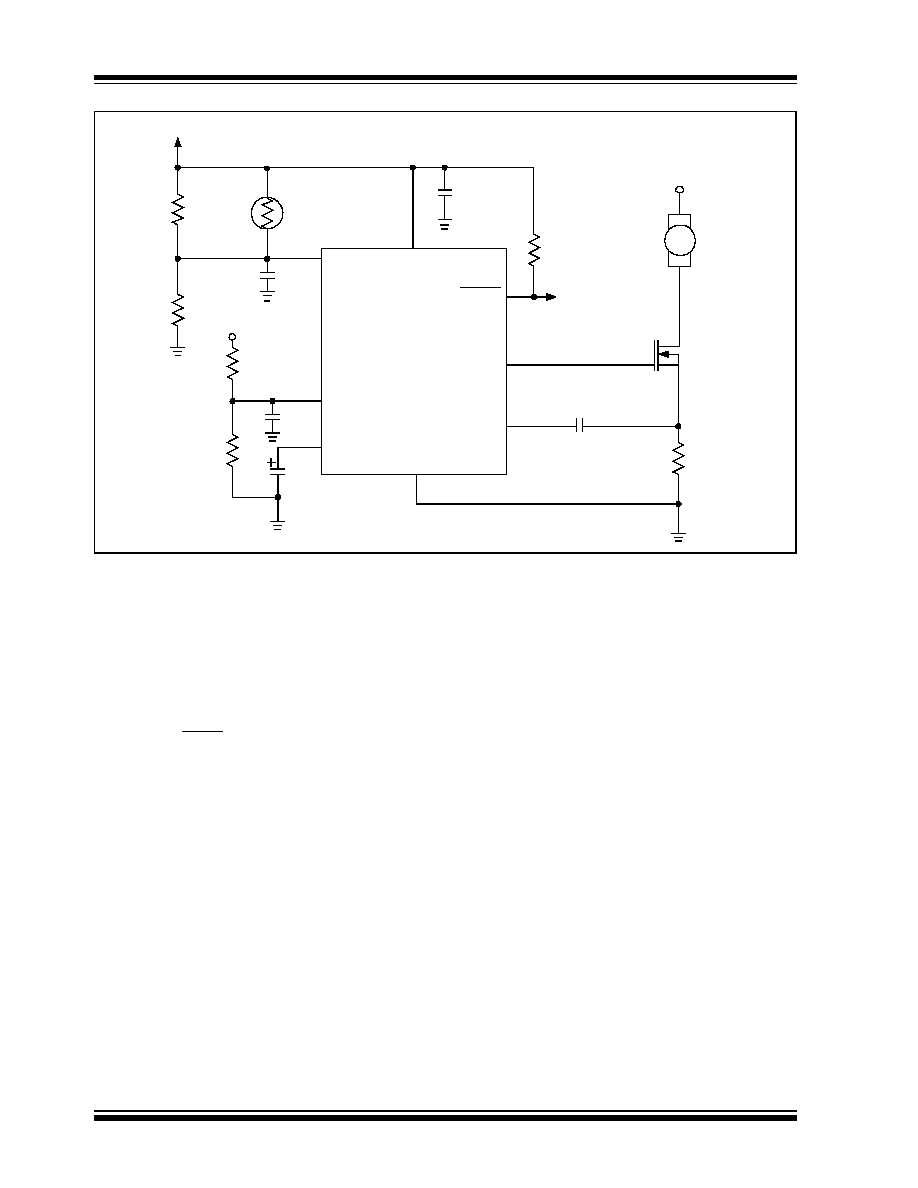

FIGURE 4-8:

Sensing Scheme For Fan

Current.

The fan current flowing through R

SENSE

generates a

voltage that is proportional to the current. The C

SENSE

capacitor removes any DC portion of the voltage

across R

SENSE

and presents only the voltage pulse

portion to the SENSE pin of the TC646B/TC649B

devices.

The R

SENSE

and C

SENSE

values need to be selected so

that the voltage pulse provided to the SENSE pin is

70 mV (typical) in amplitude. Be sure to check the

sense pulse amplitude over all operating conditions

(duty cycles) as the current pulse amplitude will vary

with duty cycle. See Section 5.0, "Applications Informa-

tion", for more details on selecting values for R

SENSE

and C

SENSE

.

Key features of the SENSE pin circuitry are an initial

blanking period after every V

OUT

pulse and an initial

pulse blanker.

The TC646B/TC649B sense circuitry has a blanking

period that occurs at the turn-on of each V

OUT

pulse.

During this blanking period, the sense circuitry ignores

any pulse information that is seen at the SENSE pin

input. This stops the TC646B/TC649B device from

falsely sensing a current pulse that is due to the fan

drive device turn-on.

The initial pulse blanker is also implemented to stop

false sensing of fan current pulses. When a fan is in a

locked rotor condition, the fan current no longer com-

mutates, it simply flows through one fan winding and is

a DC current. When a fan is in a locked rotor condition

and the TC646B/TC649B device is in PWM mode, it

will see one current pulse each time the V

OUT

output is

turned on. The initial pulse blanker allows the

TC646B/TC649B device to ignore this pulse and

recognize that the fan is in a fault condition.

4.9

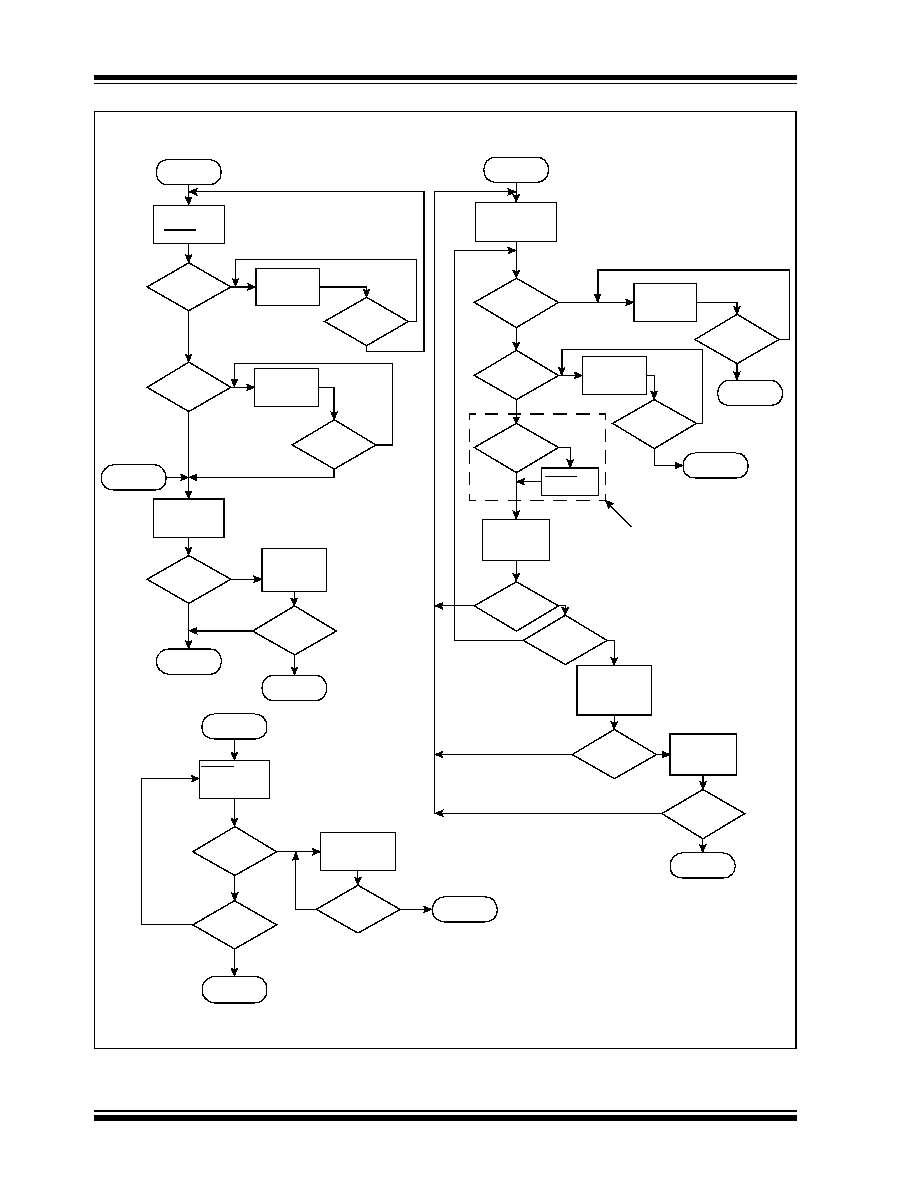

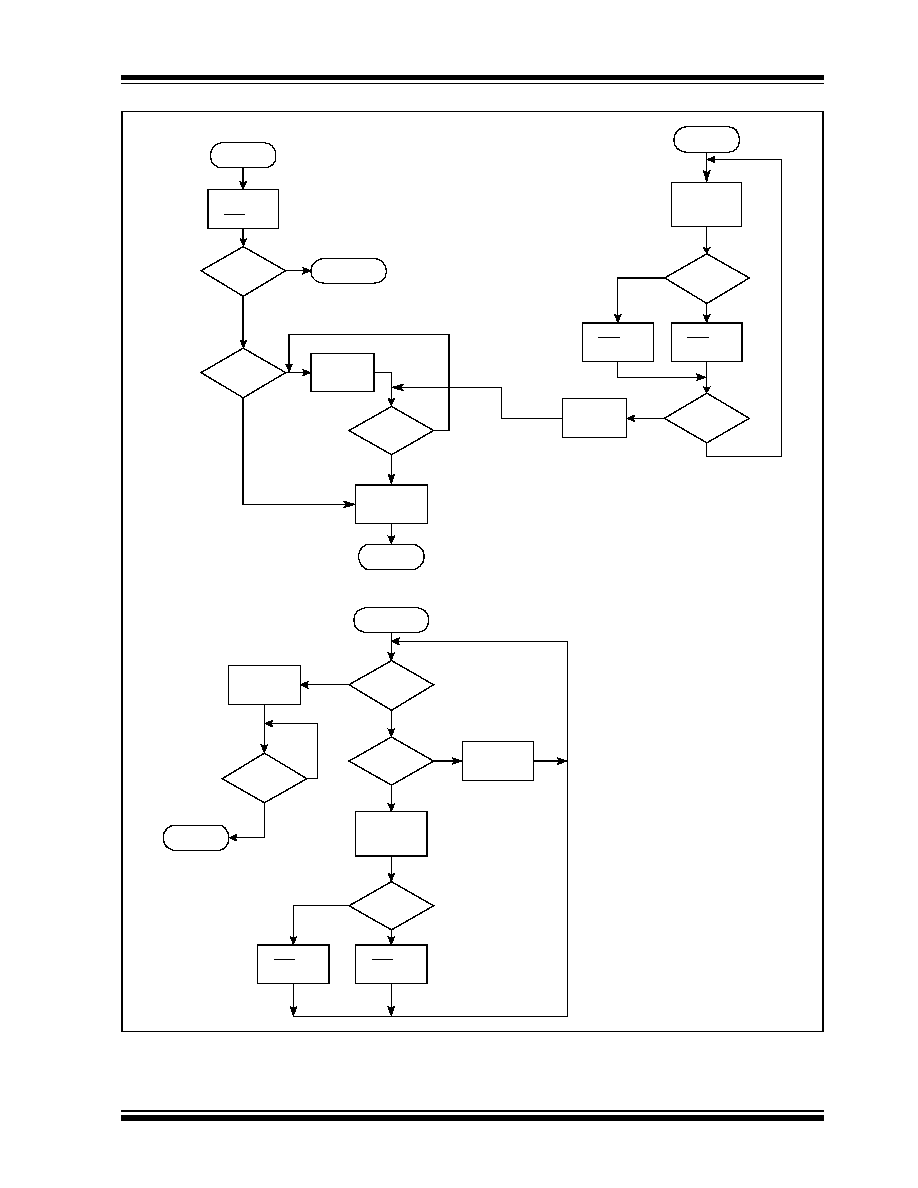

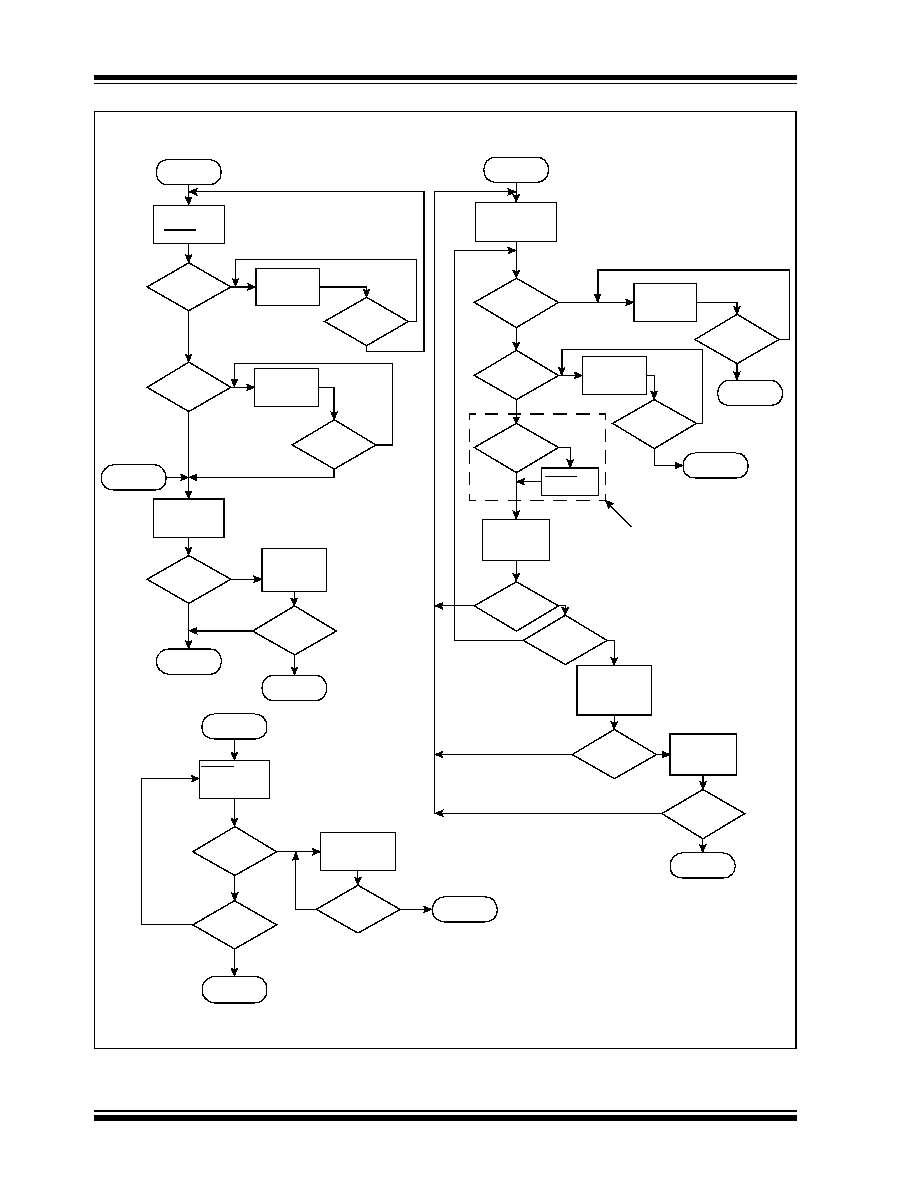

Behavioral Algorithms

The behavioral algorithms for the TC646B/TC649B

and TC648B devices are shown in Figure 4-9 and

Figure 4-10, respectively.

The behavioral algorithms show the step-by-step deci-

sion-making process for the fan speed controller oper-

ation. The TC646B and TC649B devices are very

similar with one exception: the TC649B device does

not implement the over-temperature portion of the

algorithm.

R

ISO

R

SENSE

C

SENSE

(0.1 µF typical)

SENSE

V

OUT

TC64XB

GND

FAN

TC646B/TC648B/TC649B

DS21755B-page 16

2003 Microchip Technology Inc.

FIGURE 4-9:

TC646B/TC649B Behavioral Algorithm.

Fire Start-up

Timer

(1 sec)

Fan Pulse

Detected?

Fan Pulse

Detected?

V

IN

< V

SHDN

?

V

IN

< V

AS

?

Shutdown

V

OUT

= 0

Auto-

Shutdown

V

OUT

= 0

Yes

No

No

No

No

Yes

Yes

Yes

Power-Up

Normal

Operation

Fan Fault

Power-on

Reset

FAULT = 1

V

IN

> V

REL

?

No

V

IN

>

(V

AS

+ V

HAS

)

Yes

Yes

No

Hot Start

Fire Start-up

Timer

(1 sec)

Fire Start-up

Timer

(1 sec)

V

IN

> V

REL?

Yes

Fan Fault

Clear Missing

Pulse Detector

V

OUT

Proportional

to V

IN

V

IN

< V

SHDN

?

V

IN

< V

AS

?

V

IN

> V

OTF

?

M.P.D.

Expired?

Fan Pulse

Detected?

Shutdown

V

OUT

= 0

Auto

Shutdown

V

OUT

= 0

No

No

No

No

No

No

Yes

Yes

Yes

Yes

Normal

Operation

Power-Up

V

IN

>

(V

AS

+ V

HAS

)

No

Yes

Hot Start

Yes

No

FAULT = 0

Yes

Fire

Diagnostic

Timer

(100 msec)

Fan Pulse

Detected?

Fan Pulse

Detected?

Yes

No

FAULT = Low,

V

OUT

= High

16 Pulses

Detected?

No

Yes

Power-Up

V

IN

< V

SHDN

?

V

IN

> V

REL

?

Fan Fault

Yes

Normal

Operation

Shutdown

V

OUT

= 0

Yes

No

No

TC646B Only

2003 Microchip Technology Inc.

DS21755B-page 17

TC646B/TC648B/TC649B

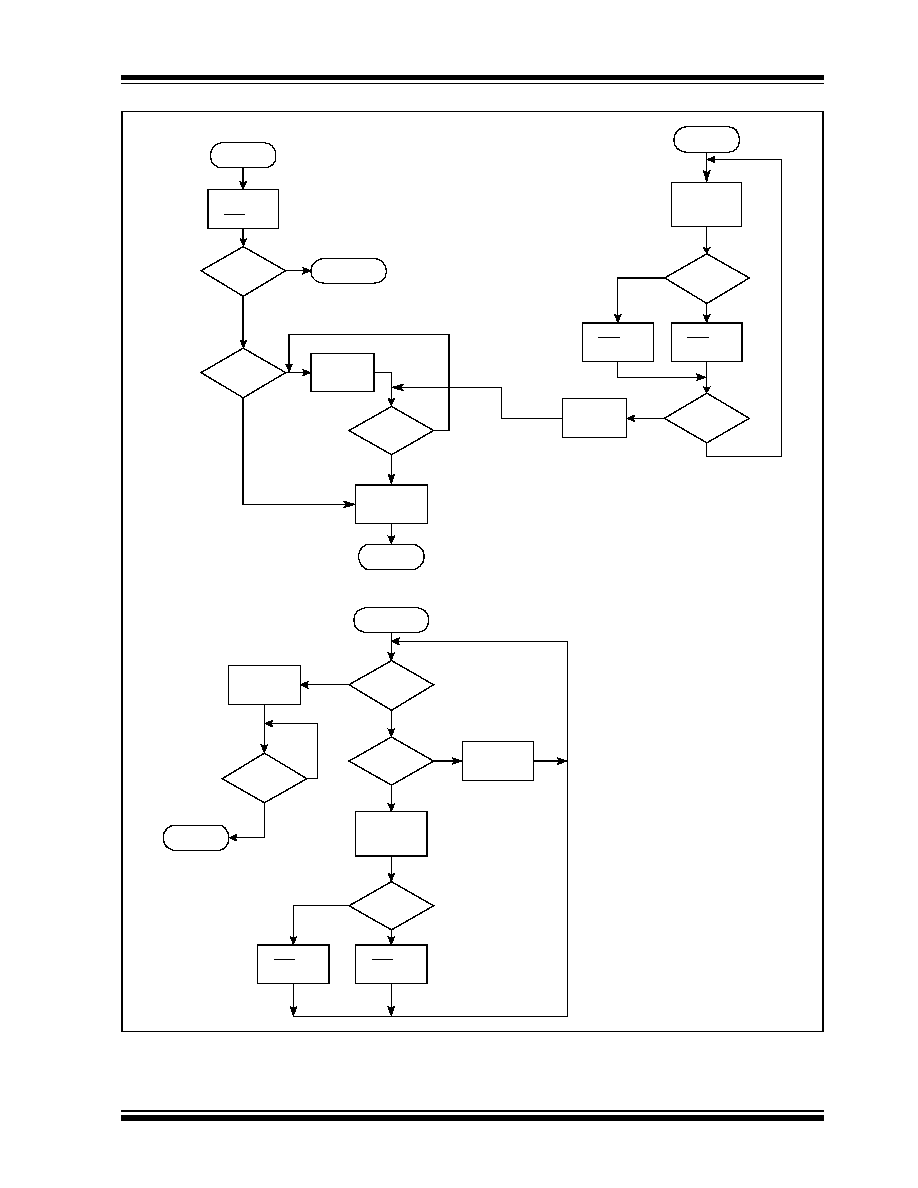

FIGURE 4-10:

TC648B Behavioral Algorithm.

V

AS

= 0V

V

IN

< V

AS

?

Auto-

Shutdown

V

OUT

= 0

Yes

No

No

Yes

Power-Up

Power-on

Reset

OTF = 1

V

IN

>

(V

AS

+ V

HAS

)

Yes

No

Fire Start-up

Timer

(1 sec)

V

IN

> 1.20V

V

OUT

Proportional

to V

IN

V

IN

> V

OTF

?

Auto

Shutdown

V

OUT

= 0

No

No

Yes

Normal

Operation

V

OUT

= 0

No

Yes

Yes

Minimum

Speed Mode

Normal

Operation

OTF = 1

OTF = 0

V

IN

< V

AS

?

Minimum

Speed Mode

V

IN

= 0V

Power-Up

V

IN

> 1.20V

V

OUT

Proportional

to V

IN

V

IN

> V

OTF

?

No

Yes

OTF = 1

OTF = 0

V

OUT

= 0

Yes

No

No

Yes

TC646B/TC648B/TC649B

DS21755B-page 18

2003 Microchip Technology Inc.

5.0

APPLICATIONS INFORMATION

5.1

Setting the PWM Frequency

The PWM frequency of the V

OUT

output is set by the

capacitor value attached to the C

F

pin. The PWM fre-

quency will be 30 Hz (typical) for a 1 µF capacitor. The

relationship between frequency and capacitor value is

linear, making alternate frequency selections easy.

As stated in previous sections, the PWM frequency

should be kept in the range of 15 Hz to 35 Hz. This will

eliminate the possibility of having audible frequencies

when varying the duty cycle of the fan drive.

A very important factor to consider when selecting the

PWM frequency for the TC646B/TC648B/TC649B

devices is the RPM rating of the selected fan and the

minimum duty cycle that you will be operating at. For

fans that have a full-speed rating of 3000 RPM or less,

it is desirable to use a lower PWM frequency. A lower

PWM frequency allows for a longer time-period to mon-

itor the fan current pulses. The goal is to be able to

monitor at least two fan current pulses during the on-

time of the V

OUT

output.

Example: The system design requirement is to operate

the fan at 50% duty cycle when ambient temperatures

are below 20°C. The fan full-speed RPM rating is

3000 RPM and has four current pulses per rotation. At

50% duty cycle, the fan will be operating at

approximately 1500 RPM.

EQUATION

If one fan revolution occurs in 40 msec, each fan pulse

occurs 10 msec apart. In order to detect two fan current

pulses, the on-time of the V

OUT

pulse must be at least

20 msec. With the duty cycle at 50%, the total period of

one cycle must be at least 40 msec, which makes the

PWM frequency 25 Hz. For this example, a PWM fre-

quency of 20 Hz is recommended. This would define a

C

F

capacitor value of 1.5 µF.

5.2

Temperature Sensor Design

As discussed in previous sections, the V

IN

analog input

has a range of 1.20V to 2.60V (typical), which repre-

sents a duty cycle range on the V

OUT

output of 0% to

100%, respectively. The V

IN

voltages can be thought of

as representing temperatures. The 1.20V level is the

low temperature at which the system requires very little

cooling. The 2.60V level is the high temperature, for

which the system needs maximum cooling capability

(100% fan speed).

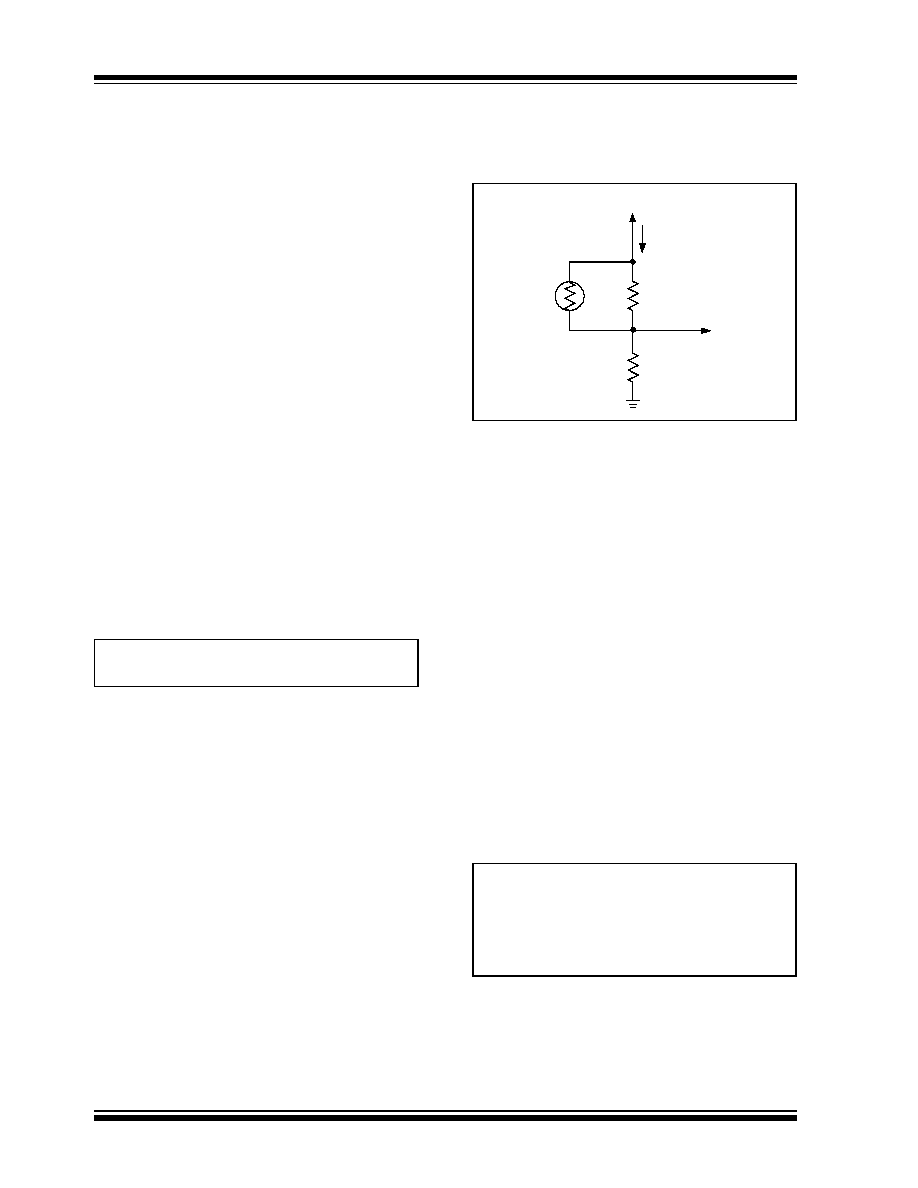

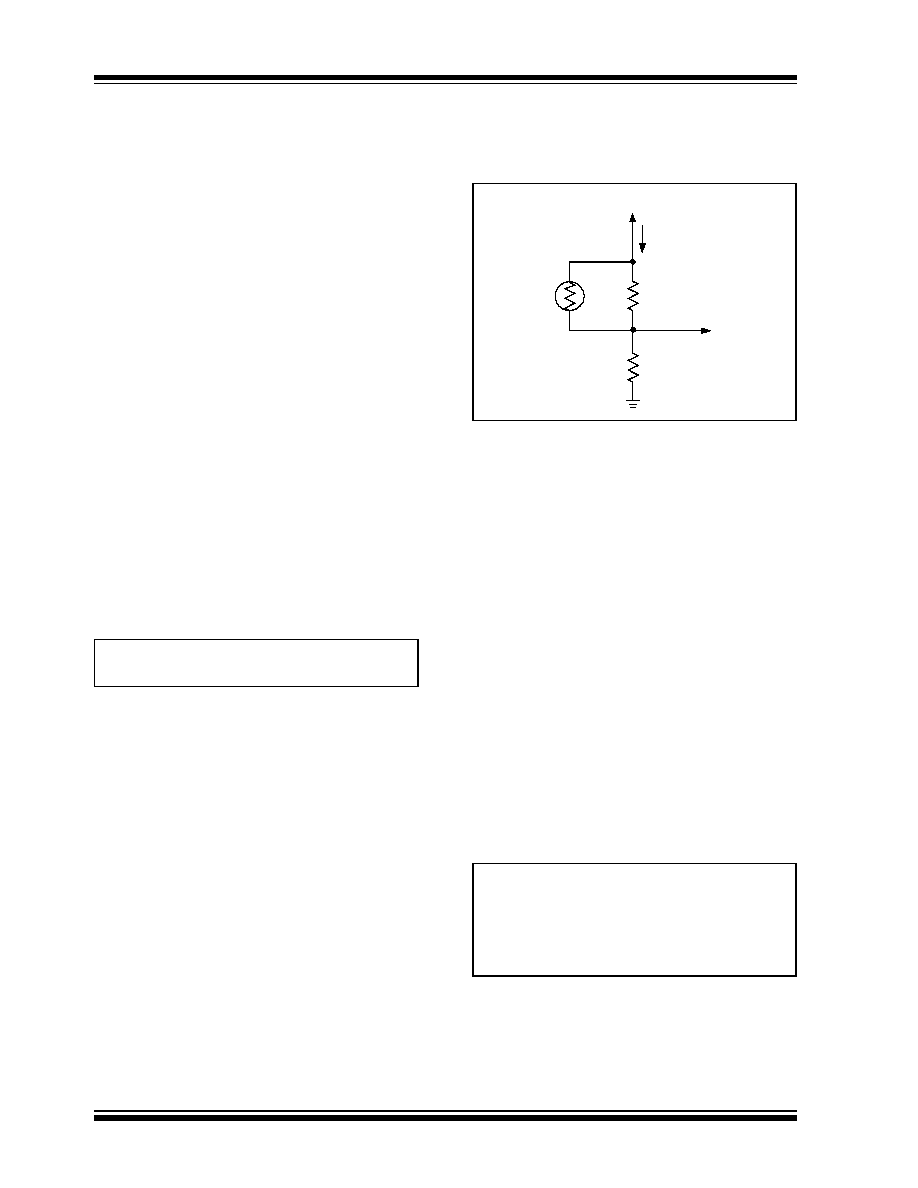

One of the simplest ways of sensing temperature over

a given range is to use a thermistor. By using a NTC

thermistor, as shown in Figure 5-1, a temperature-

variant voltage can be created.

FIGURE 5-1:

Temperature Sensing

Circuit.

Figure 5-1 represents a temperature-dependent, volt-

age divider circuit. R

T

is a conventional NTC thermistor,

R

1

and R

2

are standard resistors. R

1

and R

T

form a

parallel resistor combination that will be referred to as

R

TEMP

(R

TEMP

= R

1

* R

T

/ R

1

+ R

T

). As the temperature

increases, the value of R

T

decreases and the value of

R

TEMP

will decrease with it. Accordingly, the voltage at

V

IN

increases as temperature increases, giving the

desired relationship for the V

IN

input. R

1

helps to linear-

ize the response of the SENSE network and aids in

obtaining the proper V

IN

voltages over the desired tem-

perature range. An example of this is shown in

Figure 5-2.

If less current draw from V

DD

is desired, a larger value

thermistor should be chosen. The voltage at the V

IN

pin

can also be generated by a voltage output temperature

sensor device. The key is to get the desired V

IN

volt-

age-to-system (or component) temperature relation-

ship.

The following equations apply to the circuit in

Figure 5-1.

EQUATION

In order to solve for the values of R

1

, R

2

, V

IN

and the

temperatures at which they are to occur, need to be

selected. The variables T1 and T2 represent the

selected temperatures. The value of the thermistor at

these two temperatures can be found in the thermistor

Time for one revolution (msec.)

60 1000

×

1500

------------------------

40

=

=

R

2

R

1

R

T

I

DIV

V

IN

V

DD

V T1

( )

VDD R2

×

RTEMP T1

( ) R2

+

----------------------------------------------

=

V T2

( )

VDD R2

×

RTEMP T2

( ) R2

+

----------------------------------------------

=

2003 Microchip Technology Inc.

DS21755B-page 19

TC646B/TC648B/TC649B

data sheet. With the values for the thermistor and the

values for V

IN

, you now have two equations from which

the values for R

1

and R

2

can be found.

Example: The following design goals are desired:

· Duty Cycle = 50% (V

IN

= 1.90V) with Temperature

(T1) = 30°C

· Duty Cycle = 100% (V

IN

= 2.60V) with

Temperature (T2) = 60°C

Using a 100 k

thermistor (25°C value), we look up the

thermistor values at the desired temperatures:

· R

T

(T1) = 79428

@ 30°C

· R

T

(T2) = 22593

@ 60°C

Substituting these numbers into the given equations

produces the following numbers for R

1

and R

2

.

· R

1

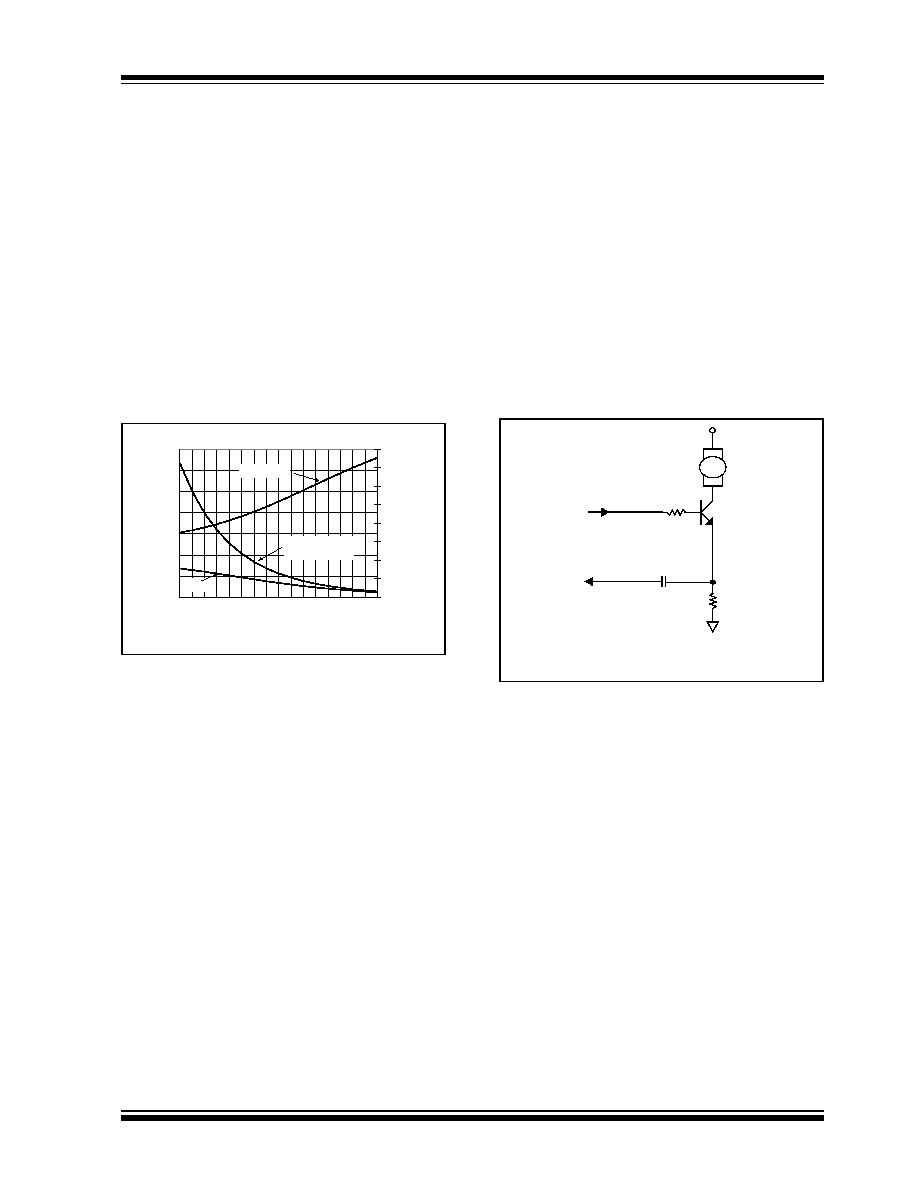

= 34.8 k

· R

2

= 14.7 k

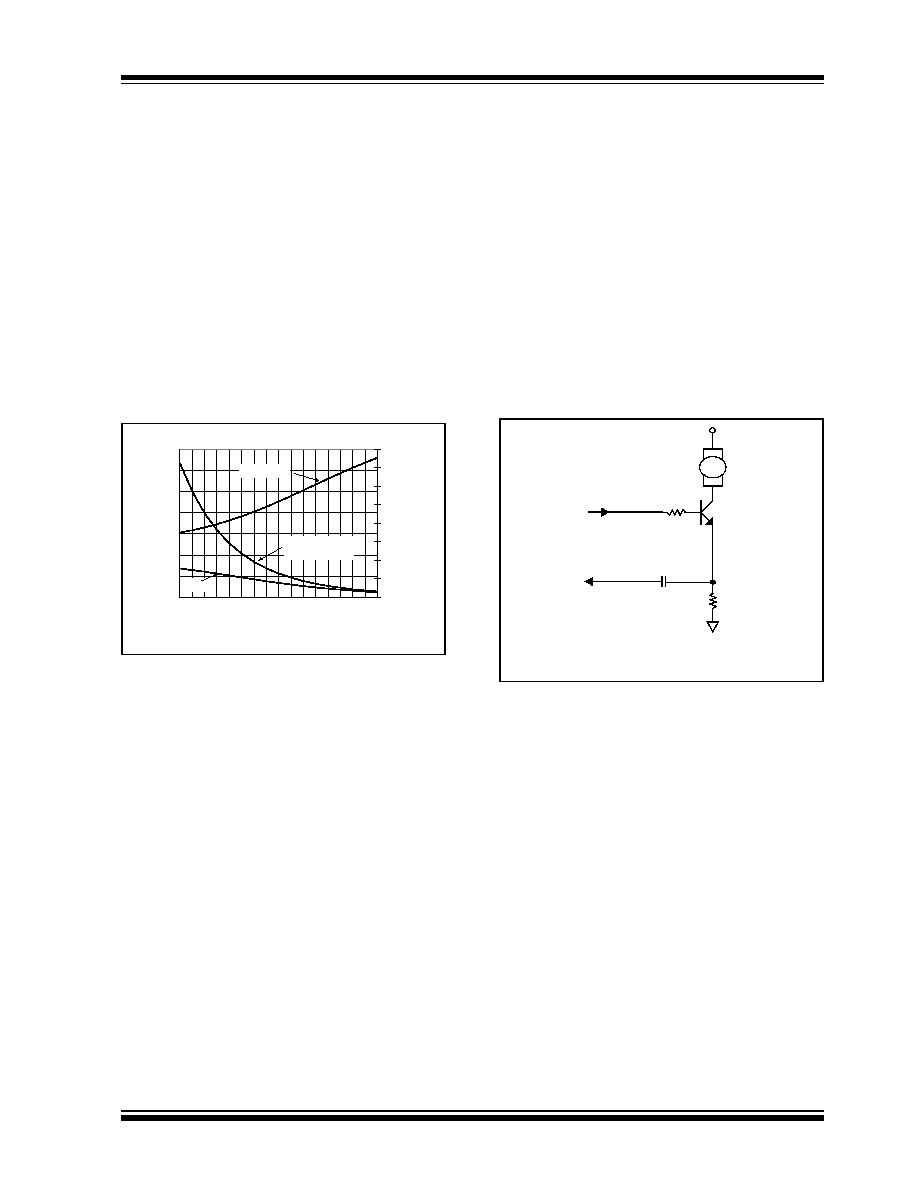

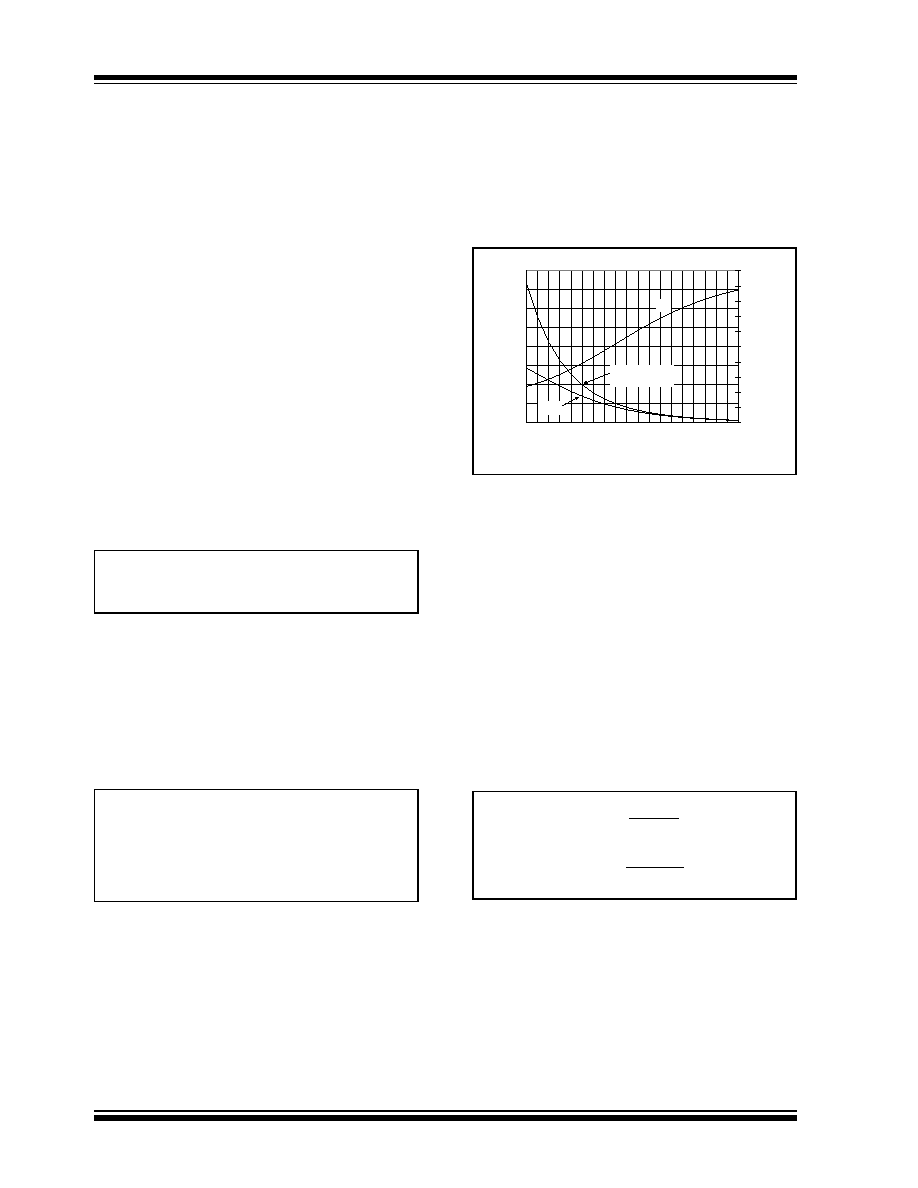

FIGURE 5-2:

How Thermistor Resistance,

V

IN

, and R

TEMP

Vary With Temperature.

Figure 5-2 graphs R

T

, R

TEMP

(R

1

in parallel with R

T

)

and V

IN

, versus temperature for the example shown

above.

5.3

Thermistor Selection

As with any component, there are a number of sources

for thermistors. A listing of companies that manufacture

thermistors can be found at www.temperatures.com/

thermivendors.html. This website lists over forty

suppliers of thermistor products. A brief list is shown

here:

5.4

FanSense Network

(R

SENSE

and C

SENSE

)

The SENSE network (comprised of R

SENSE

and

C

SENSE

) allows the TC646B and TC649B devices to

detect commutation of the fan motor. R

SENSE

converts

the fan current into a voltage. C

SENSE

AC couples this

voltage signal to the SENSE pin. The goal of the

SENSE network is to provide a voltage pulse to the

SENSE pin that has a minimum amplitude of 90 mV.

This will ensure that the current pulse caused by the

fan commutation is recognized by the TC646B/

TC649B device.

A 0.1 µF ceramic capacitor is recommended for

C

SENSE

. Smaller values will require that larger sense

resistors be used. Using a 0.1 µF capacitor results in

reasonable values for R

SENSE

. Figure 5-3 illustrates a

typical SENSE network.

FIGURE 5-3:

Typical Sense Network.

The required value of R

SENSE

will change with the cur-

rent rating of the fan and the fan current waveshape. A

key point is that the current rating of the fan specified

by the manufacturer may be a worst-case rating, with

the actual current drawn by the fan being lower than

this rating. For the purposes of setting the value for

R

SENSE

, the operating fan current should be measured

to get the nominal value. This can be done by using an

oscilloscope current probe or using a voltage probe

with a low-value resistor (0.5

). Another good tool for

this exercise is the TC642 Evaluation Board. This

board allows the R

SENSE

and C

SENSE

values to be eas-

ily changed while allowing the voltage waveforms to be

monitored to ensure the proper levels are being

reached.

Table 5-1 shows values of R

SENSE

according to the

nominal operating current of the fan. The fan currents

are average values. If the fan current falls between two

of the values listed, use the higher resistor value.

-

Thermometrics

®

-

Quality Thermistor

TM

-

Ametherm

®

-

Sensor Scientific

TM

-

U.S. Sensor

TM

-

Vishay

®

-

Advanced Thermal

Products

TM

-

muRata

®

0

20

40

60

80

100

120

140

20

30

40

50

60

70

80

90

100

Temperature (ºC)

Network Resistance (k

)

0.000

0.500

1.000

1.500

2.000

2.500

3.000

3.500

4.000

V

IN

(V)

NTC Thermistor

100 k @ 25ºC

V

IN

Voltage

R

TEMP

FAN

R

ISO

R

SENSE

C

SENSE

SENSE

V

OUT

(0.1 µF typical)

715

Note:

See Table 5-1 for R

SENSE

values.

TC646B/TC648B/TC649B

DS21755B-page 20

2003 Microchip Technology Inc.

TABLE 5-1:

FAN CURRENT VS. R

SENSE

The values listed in Table 5-1 are for fans that have the

fan current waveshape shown in Figure 4-7. With this

waveshape, the average fan current is closer to the

peak value, which requires the resistor value to be

higher. When using a fan that has the fan current wave-

shape shown in Figure 4-6, the resistor value can often

be decreased since the current peaks are higher than

the average and it is the AC portion of the voltage that

gets coupled to the SENSE pin.

The key point when selecting an R

SENSE

value is to try

to minimize the value in order to minimize the power

dissipation in the resistor. In order to do this, it is critical

to know the waveshape of the fan current and not just

the average value.

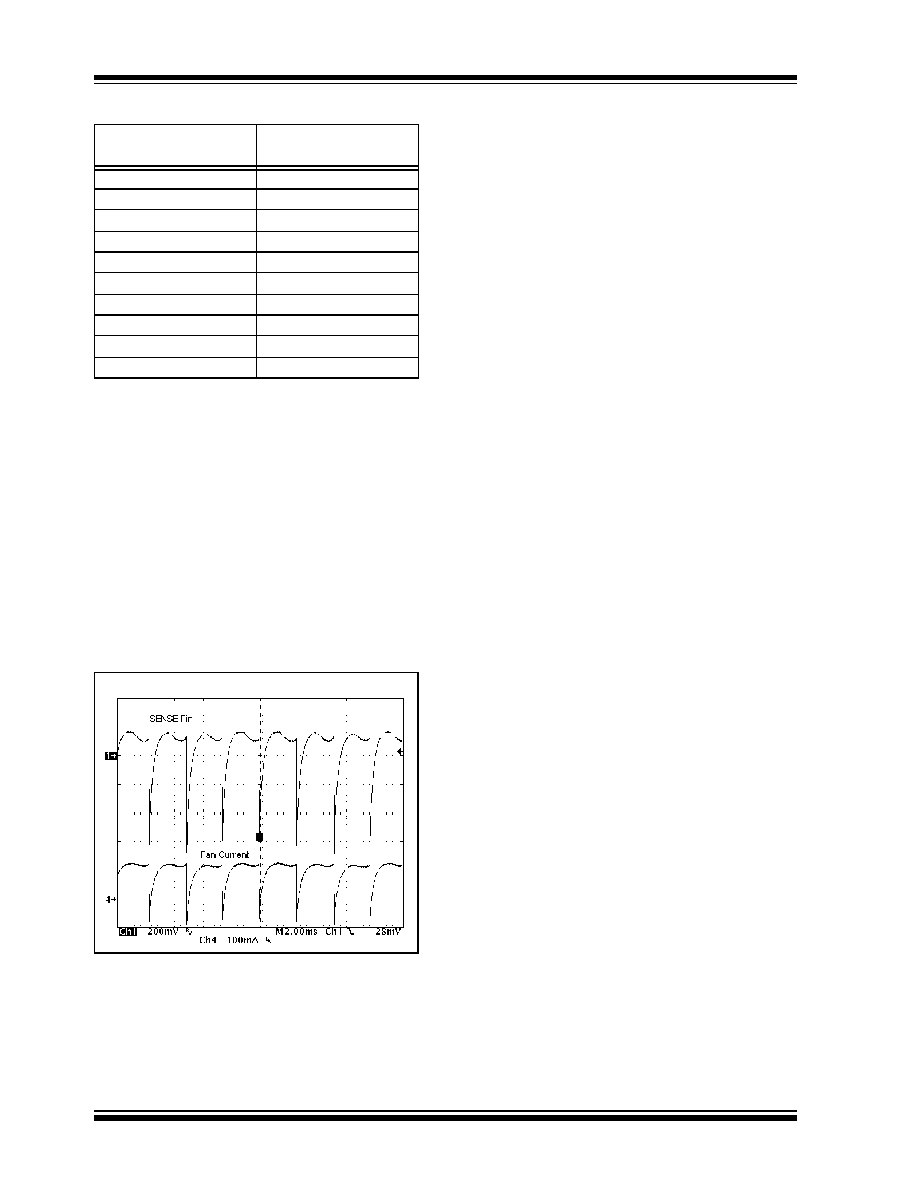

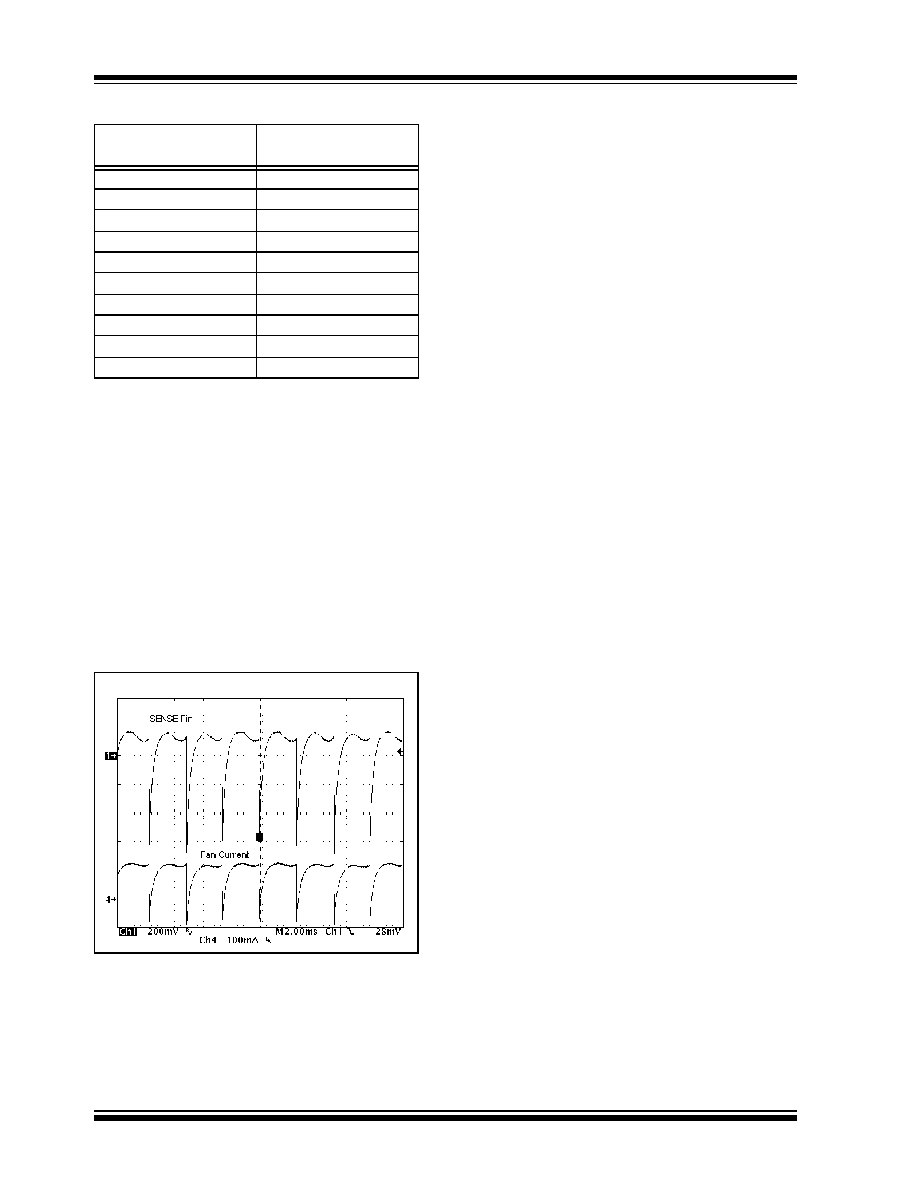

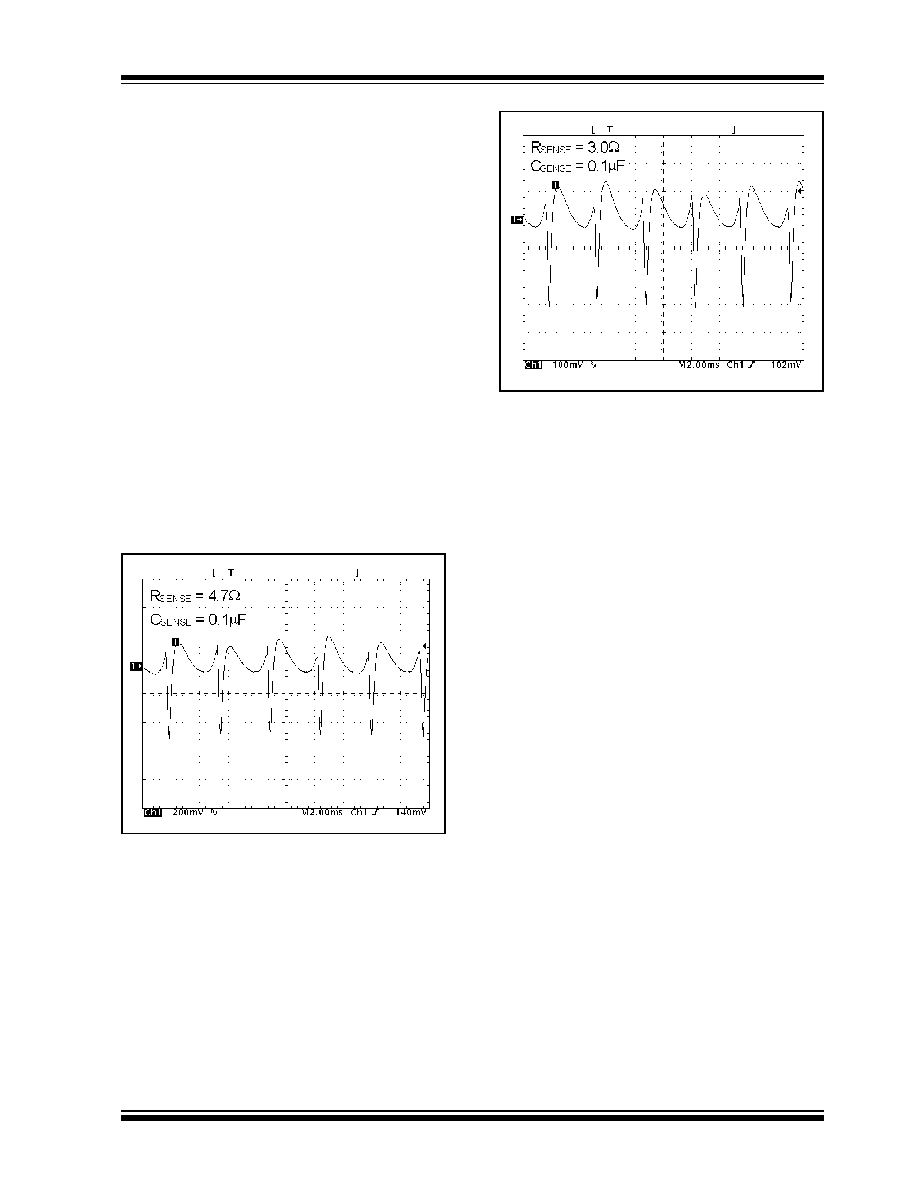

Figure 5-4 shows some typical waveforms for the fan

current and the voltage at the SENSE pin.

FIGURE 5-4:

Typical Fan Current and

SENSE Pin Waveforms.

Another important factor to consider when selecting the

R

SENSE

value is the fan current value during a locked-

rotor condition. When a fan is in a locked-rotor condi-

tion (fan blades are stopped even though power is

being applied to the fan), the fan current can increase

dramatically (often 2.5 to 3.0 times the normal operat-

ing fan current). This will effect the power rating of the

R

SENSE

resistor selected.

When selecting the fan for the application, the current

draw of the fan during a locked-rotor condition should

be considered. Especially if multiple fans are being

used in the application.

There are two main types of fan designs when looking

at fan current draw during a locked-rotor condition.

The first is a fan that will simply draw high DC currents

when put into a locked-rotor condition. Many older fans

were designed this way. An example of this is a fan that

draws an average current of 100 mA during normal

operation. In a locked-rotor condition, this fan will draw

250 mA of average current. For this design, the

R

SENSE

power rating must be sized to handle the

250 mA condition. The fan bias supply must also take

this into account.

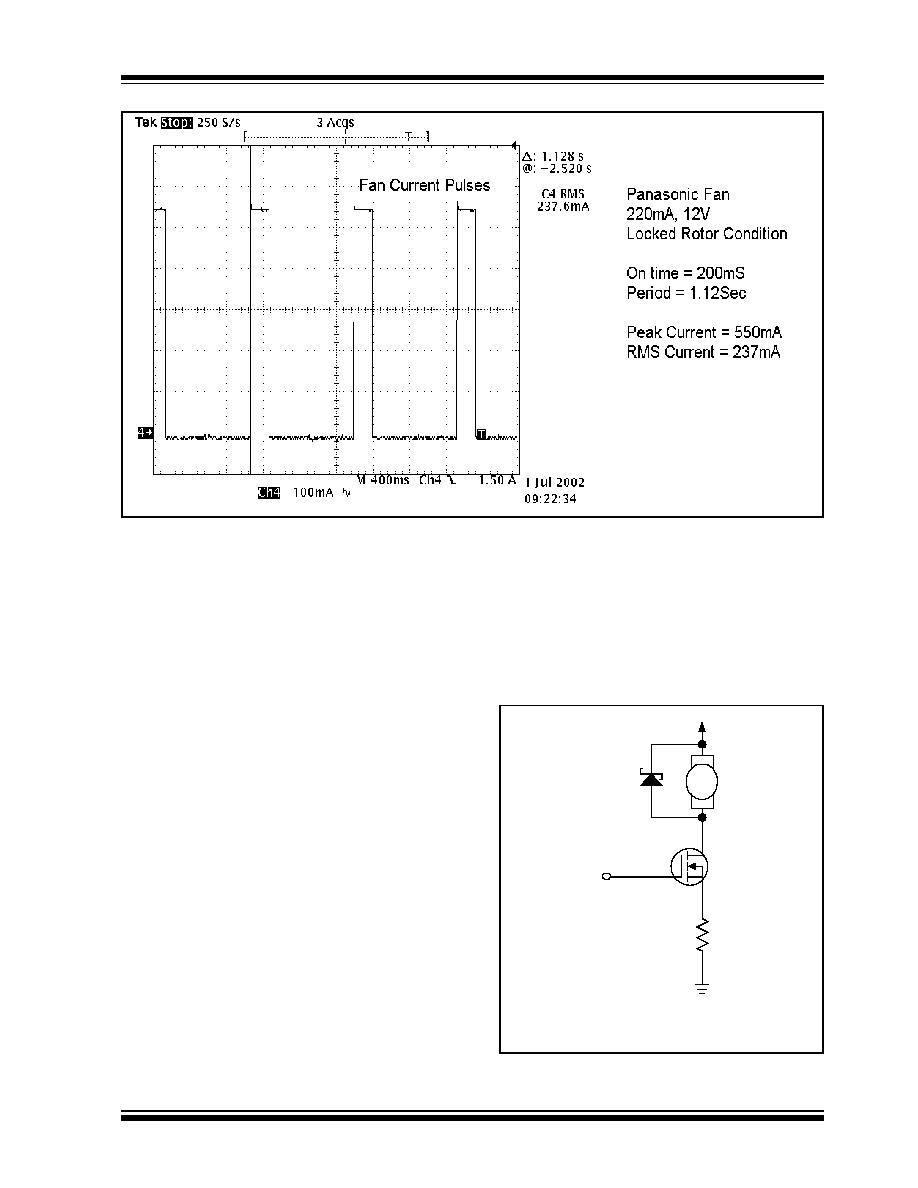

The second style design, which represents many of the

newer fan designs today, acts to limit the current in a

locked-rotor condition by going into a pulse mode of

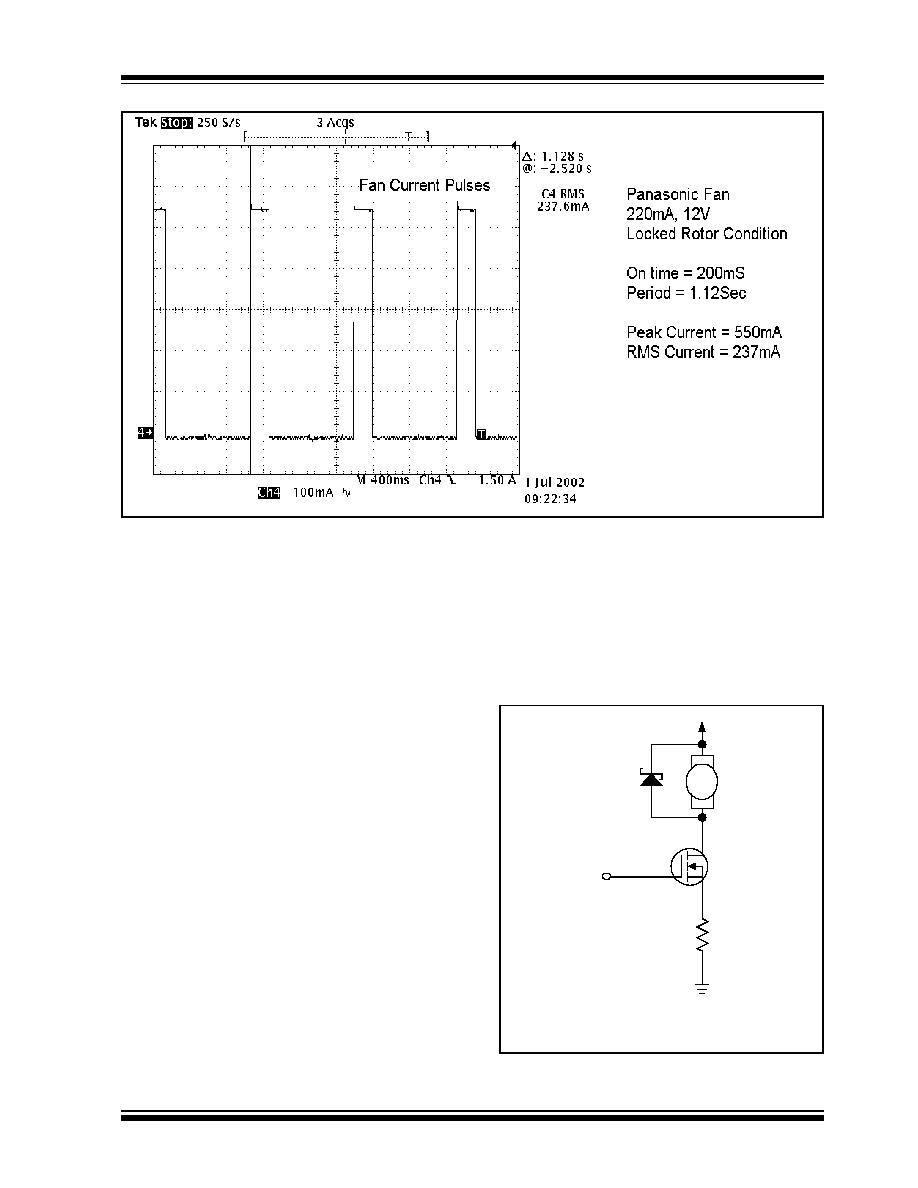

operation. An example of the fan current waveshape

for this style fan is shown in Figure 5-5. The fan repre-

sented in Figure 5-5 is a Panasonic

®

, 12V, 220 mA fan.

During the on-time of the waveform, the fan current is

peaking up to 550 mA. Due to the pulse mode opera-

tion, the actual RMS current of the fan is very near the

220 mA rating. Because of this, the power rating for the

R

SENSE

resistor does not have to be oversized for this

application.

Nominal Fan Current

(mA)

R

SENSE

(

)

50

9.1

100

4.7

150

3.0

200

2.4

250

2.0

300

1.8

350

1.5

400

1.3

450

1.2

500

1.0

2003 Microchip Technology Inc.

DS21755B-page 21

TC646B/TC648B/TC649B

FIGURE 5-5:

Fan Current During a Locked Rotor Condition.

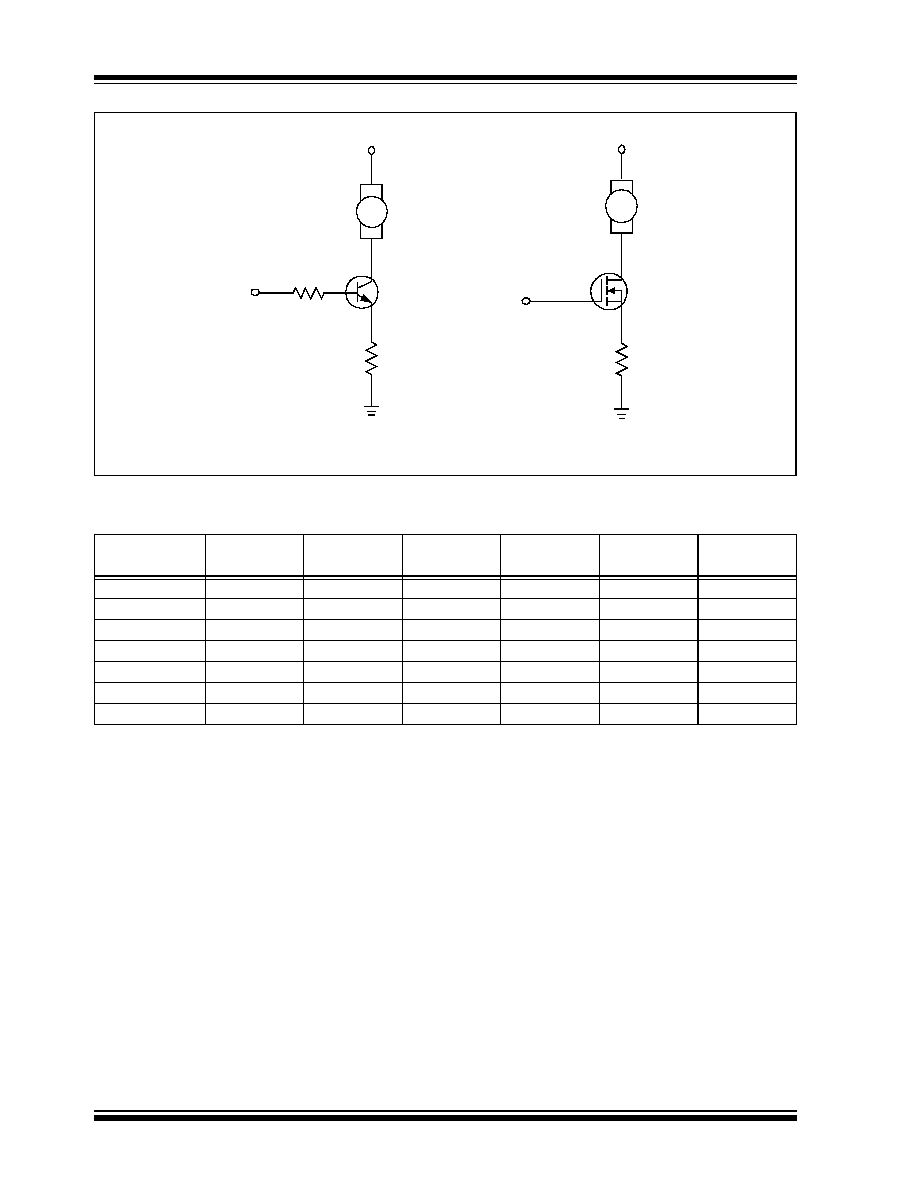

5.5

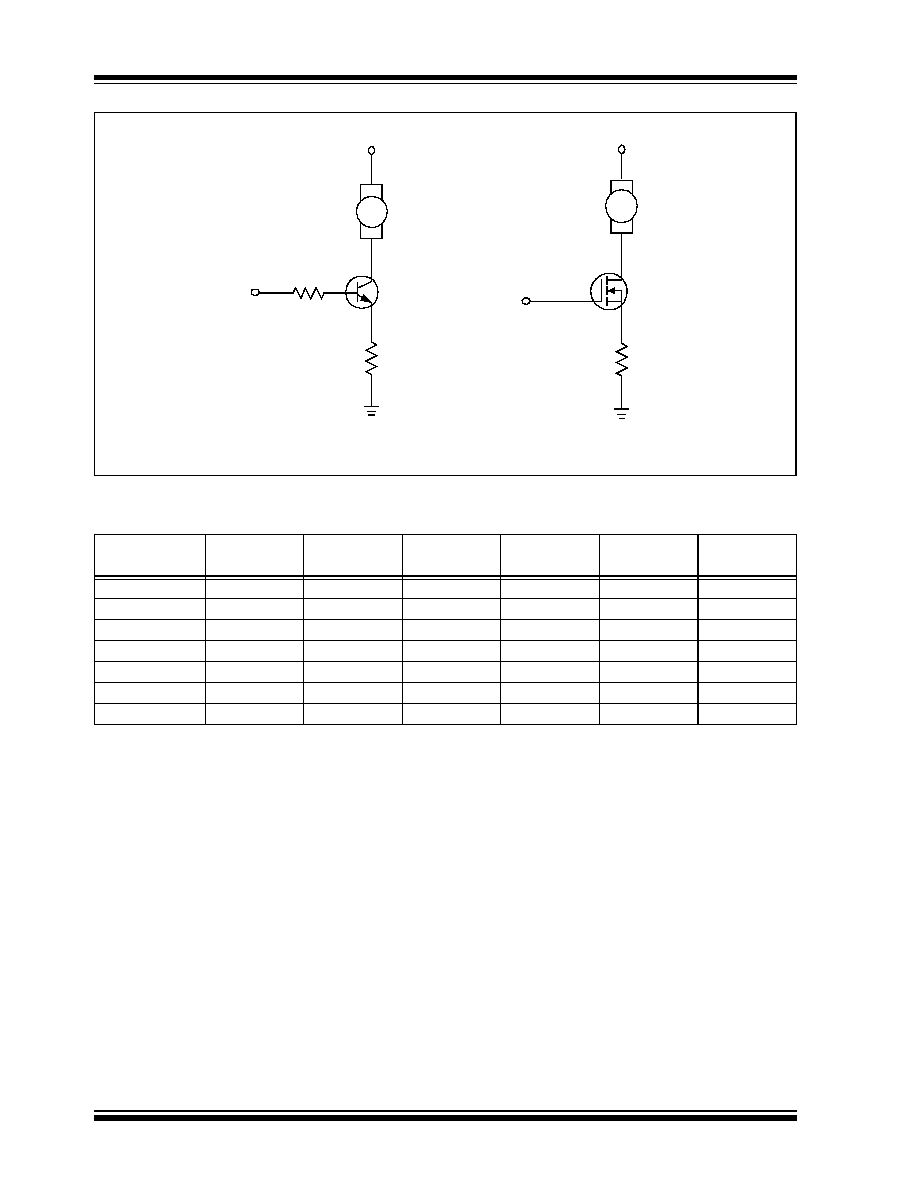

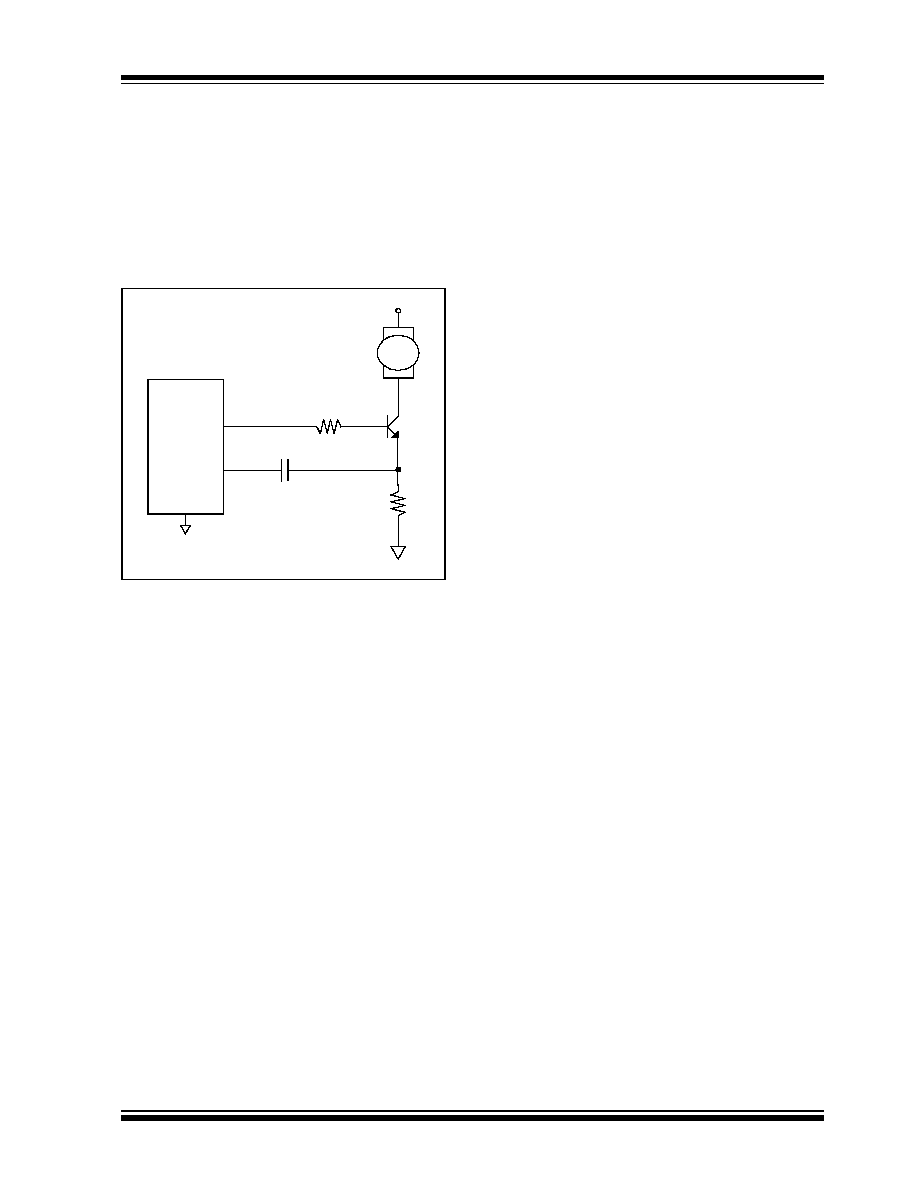

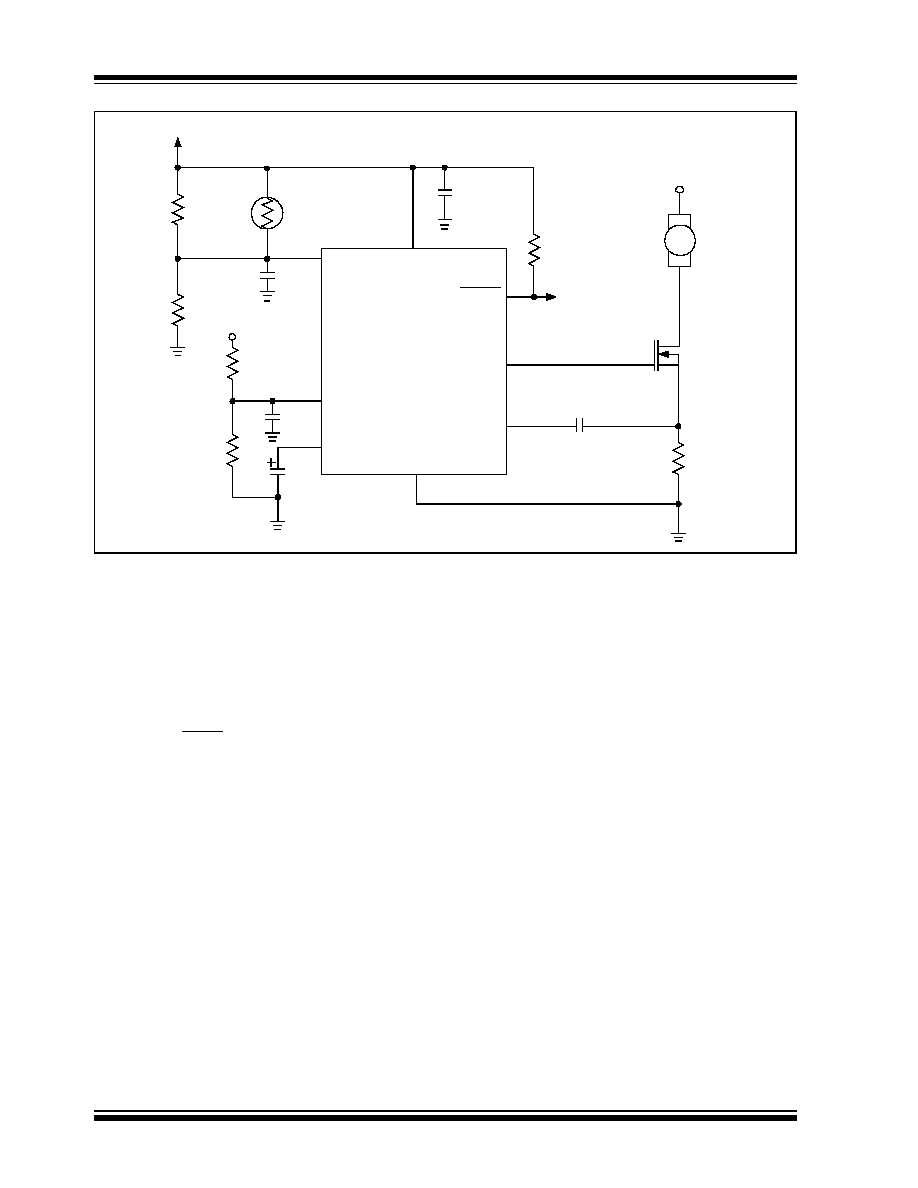

Output Drive Device Selection

The TC646B/TC648B/TC649B is designed to drive an

external NPN transistor or N-channel MOSFET as the

fan speed modulating element. These two arrange-

ments are shown in Figure 5-7. For lower-current fans,

NPN transistors are a very economical choice for the

fan drive device. It is recommended that, for higher cur-

rent fans (300 mA and above), MOSFETs be used as

the fan drive device. Table 5-2 provides some possible

part numbers for use as the fan drive element.

When using a NPN transistor as the fan drive element,

a base current-limiting resistor must be used. This is

shown in Figure 5-7.

When using MOSFETs as the fan drive element, it is

very easy to turn the MOSFETs on and off at very high

rates. Because the gate capacitances of these small

MOSFETs are very low, the TC646B/TC648B/TC649B

can charge and discharge them very quickly, leading to

very fast edges. Of key concern is the turn-off edge of

the MOSFET. Since the fan motor winding is essentially

an inductor, once the MOSFET is turned off the current

that was flowing through the motor wants to continue to

flow. If the fan does not have internal clamp diodes

around the windings of the motor, there is no path for

this current to flow through and the voltage at the drain

of the MOSFET may rise until the drain-to-source rating

of the MOSFET is exceeded. This will most likely cause

the MOSFET to go into avalanche mode. Since there is

very little energy in this occurrence, it will probably not

fail the device, but it would be a long-term reliability

issue.

The following is recommended:

· Ask how the fan is designed. If the fan has clamp

diodes internally, this problem will not be seen. If

the fan does not have internal clamp diodes, it is a

good idea to install one externally (Figure 5-6).

Putting a resistor between V

OUT

and the gate of

the MOSFET will also help slow down the turn-off

and limit this condition.

FIGURE 5-6:

Clamp Diode For Fan Turn-

Off.

Q

1

GND

R

SENSE

V

OUT

Q

1

: N-Channel MOSFET

FAN

TC646B/TC648B/TC649B

DS21755B-page 22

2003 Microchip Technology Inc.

FIGURE 5-7:

Output Drive Device Configurations.

TABLE 5-2:

FAN DRIVE DEVICE SELECTION TABLE (NOTE 2)

5.6

Bias Supply Bypassing and Noise

Filtering

The bias supply (V

DD

) for the TC646B/TC648B/

TC649B devices should be bypassed with a 1.0 µF

ceramic capacitor. This capacitor will help supply the

peak currents that are required to drive the base/gate

of the external fan drive devices.

As the V

IN

pin controls the duty cycle in a linear fashion,

any noise on this pin can cause duty cycle jittering. For

this reason, the V

IN

pin should be bypassed with a

0.01 µF capacitor.

In order to keep fan noise off of the TC646B/TC648B/

TC649B device ground, individual ground returns for

the TC646B/TC648B/TC649B and the low side of the

fan current sense resistor should be used.

5.7

Design Example/Typical

Application

The system has been designed with the following

components and criteria:

System inlet air ambient temperature ranges from 0ºC

to 50ºC. At 20ºC, system cooling is no longer required,

so the fan is to be turned off. Prior to turn-off, the fan

should be run at 40% of its full fan speed. Full fan

speed should be reached when the ambient air is 40ºC.

The system has a surface mount, NTC-style thermistor

in a 1206 package. The thermistor is mounted on a

daughtercard that is directly in the inlet air stream. The

thermistor is a NTC, 100 k

@ 25ºC, Thermometrics

®

part number NHQ104B425R5. The given Beta for the

thermistor is 4250. The system bias voltage to run the

fan controller is 5V, while the fan voltage is 12V.

Device

Package

Max Vbe sat /

Vgs(V)

Min hfe

V

CE

/V

DS

(V)

Fan Current

(mA)

Suggested

Rbase (

)

MMBT2222A

SOT-23

1.2

50

40

150

800

MPS2222A

TO-92

1.2

50

40

150

800

MPS6602

TO-92

1.2

50

40

500

301

SI2302

SOT-23

2.5

NA

20

500

Note 1

MGSF1N02E

SOT-23

2.5

NA

20

500

Note 1

SI4410

SO-8

4.5

NA

30

1000

Note 1

SI2308

SOT-23

4.5

NA

60

500

Note 1

Note 1:

A series gate resistor may be used in order to control the MOSFET turn-on and turn-off times.

2:

These drive devices are suggestions only. Fan currents listed are for individual fans.

Q

1

GND

Fan Bias

R

SENSE

R

BASE

V

OUT

FAN

a) Single Bipolar Transistor

Q

1

GND

Fan Bias

R

SENSE

V

OUT

b) N-Channel MOSFET

FAN

2003 Microchip Technology Inc.

DS21755B-page 23

TC646B/TC648B/TC649B

The fan used in the system is a Panasonic

®

, Panaflo

®

-

series fan, model number FBA06T12H.

A fault indication is desired when the fan is in a locked-

rotor condition. This signal is used to indicate to the

system that cooling is not available and a warning

should be issued to the user. No fault indication from

the fan controller is necessary for an over-temperature

condition as this is being reported elsewhere.

Step 1: Gathering Information.

The first step in the design process is to gather the

needed data on the fan and thermistor. For the fan, it is

also a good idea to look at the fan current waveform, as

indicated earlier in the data sheet.

Fan Information: Panasonic number: FBA06T12H

- Voltage = 12V

- Current = 145 mA (data sheet number)

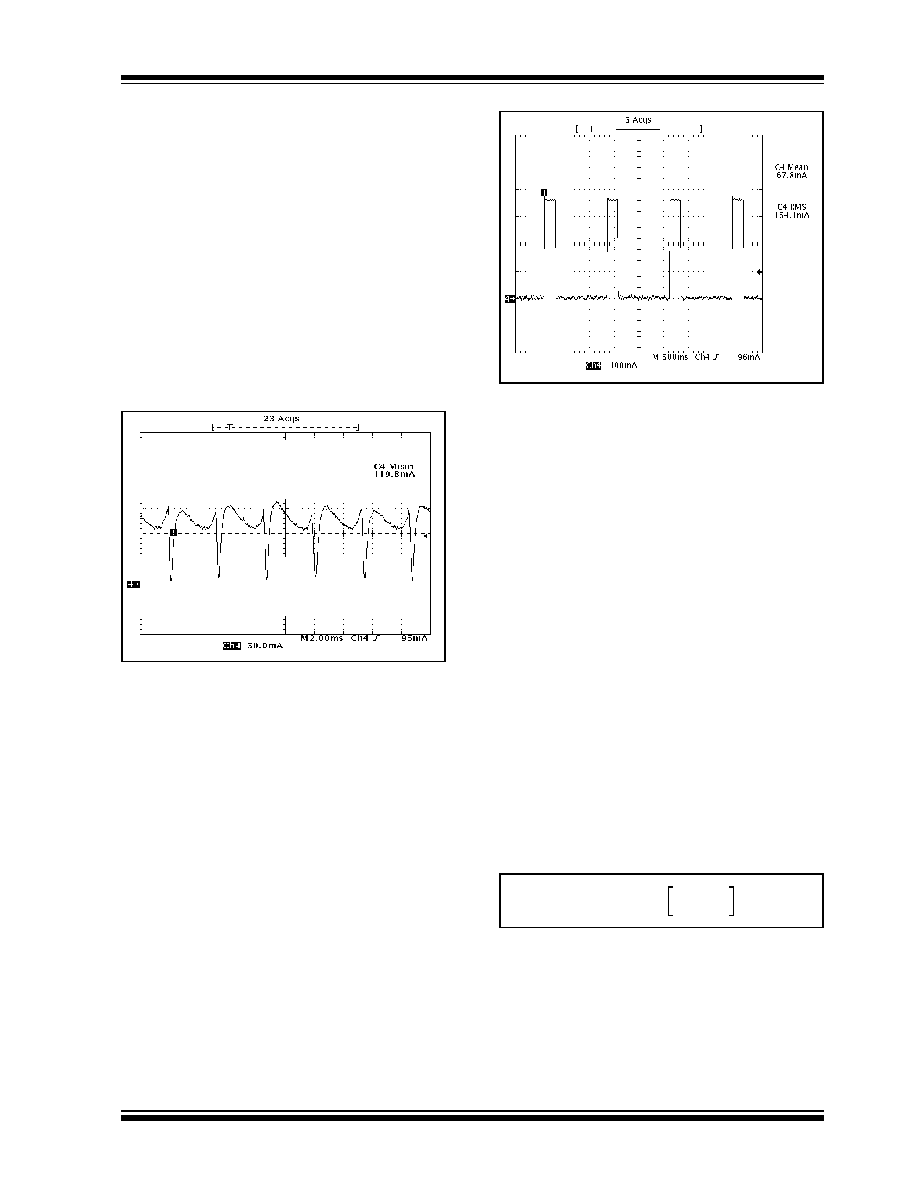

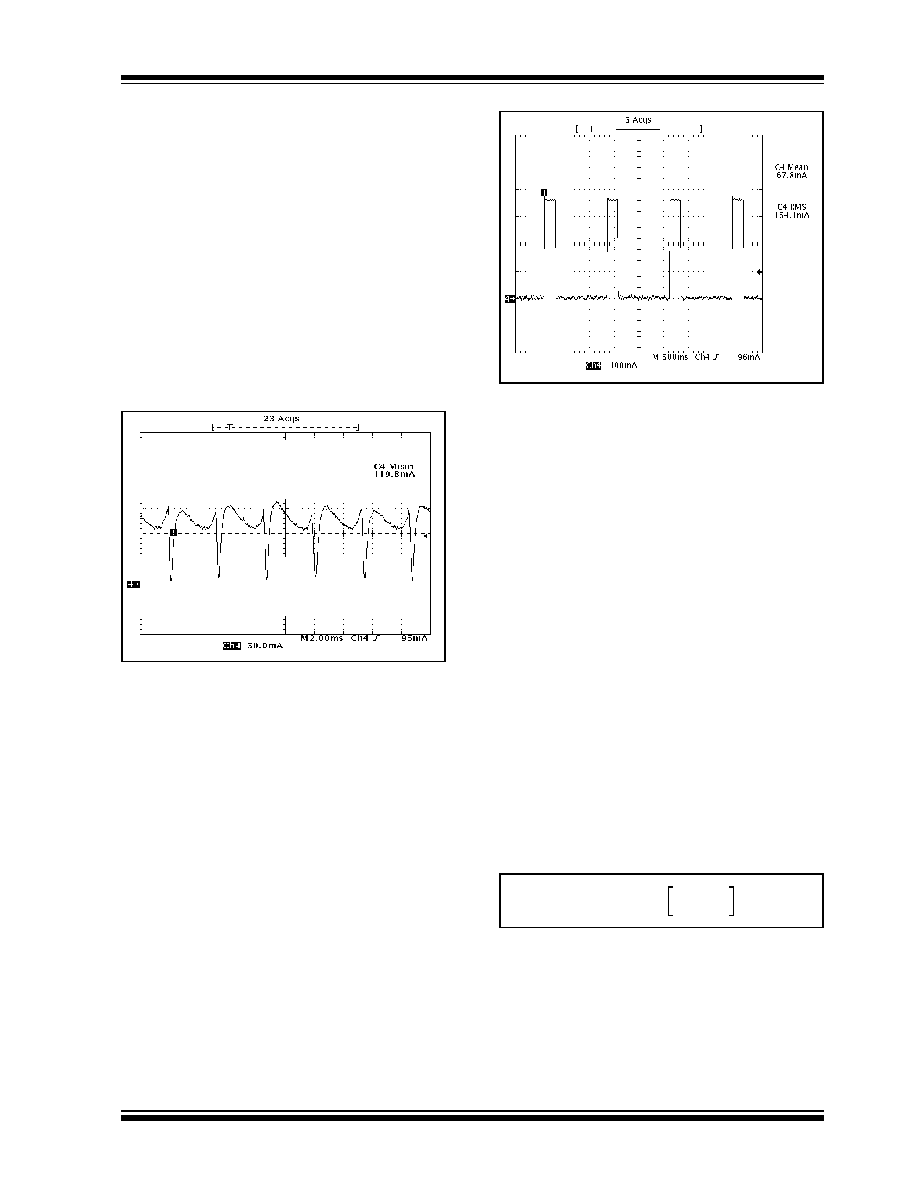

FIGURE 5-8:

FBA06T12H Fan Current

Waveform.

From the waveform in Figure 5-8, the fan current has

an average value of 120 mA, with peaks up to 150 mA.

This information will help in the selection of the R

SENSE

and C

SENSE

values later on. Also of interest for the

R

SENSE

selection value is what the fan current does in

a locked-rotor condition.

FIGURE 5-9:

FBA06T12H Locked-Rotor

Fan Current.

From Figure 5-9, it is seen that in a locked-rotor fault

condition, the fan goes into a pulsed current mode of

operation. During this mode, when the fan is conduct-

ing current, the peak current value is 360 mA for peri-

ods of 200 msec. This is significantly higher than the

average full fan speed current shown in Figure 5-8.

However, because of the pulse mode, the average fan

current in a locked-rotor condition is lower and was

measured at 68 mA. The RMS current during this

mode, which is necessary for current sense resistor

(R

SENSE

) value selection, was measured at 154 mA.

This is slightly higher than the RMS value during full fan

speed operation.

Thermistor Information: Thermometrics part number:

NHQ104B425R5

- Resistance Value: 100 k

@ 25ºC

- Beta Value (

): 4250

From this information, the thermistor values at 20ºC

and 40ºC must be found. This information is needed in

order to select the proper resistor values for R

1

and R

2

(see Figure 5-13), which sets the V

IN

voltage.

The equation for determining the thermistor values is

shown below:

EQUATION

R

T0

is the thermistor value at 25ºC. T

0

is 298.15 and T

is the temperature of interest. All temperatures are in

degrees kelvin.

Using this equation, the values for the thermistor are

found to be:

- R

T

(20ºC) = 127,462

- R

T

(40ºC) = 50,520

R

T

R

TO

T

O

T

(

)

T T

O

·

------------------------

exp

=

TC646B/TC648B/TC649B

DS21755B-page 24

2003 Microchip Technology Inc.

Step 2: Selecting the Fan Controller.

The requirements for the fan controller are that it have

auto-shutdown capability at 20ºC and also indicate a

fan fault condition. No over-temperature indication is

necessary. From these specifications, the proper

selection is the TC649B device.

Step 3: Setting the PWM Frequency.

The fan is rated at 4200 RPM with a 12V input. The

goal is to run to a 40% duty cycle (roughly 40% fan

speed), which equates to approximately 1700 RPM. At

1700 RPM, one full fan revolution occurs every

35 msec. The fan being used is a four-pole fan that

gives four current pulses per revolution. With this infor-

mation, and viewing test results at 40% duty cycle, two

fan current pulses were always seen during the PWM

on time with a PWM frequency of 30 Hz. For this rea-

son, the C

F

value is selected to be 1.0 µF.

Step 4: Setting the V

IN

Voltage.

From the design criteria, the desired duty cycle at 20ºC

is 40% and full fan speed should be reached at 40ºC.

Based on a V

IN

voltage range of 1.20V to 2.60V, which

represents 0% to 100% duty cycle, the 40% duty cycle

voltage can be found using the following equation:

EQUATION

Using the above equation, the V

IN

values are

calculated to be:

- V

IN

(40%) = 1.76V

- V

IN

(100%) = 2.60V

Using these values along with the thermistor resistance

values calculated earlier, the R

1

and R

2

resistor values

can now be calculated using the following equation:

EQUATION

R

TEMP

is the parallel combination of R

1

and the ther-

mistor. V(T1) represents the V

IN

voltage at 20ºC and

V(T2) represents the V

IN

voltage at 40ºC. Solving the

equations simultaneously yields the following values

(V

DD

= 5V):

- R

1

= 238,455

- R

2

= 45,161

Using standard 1% resistor values, the selected R

1

and

R

2

values are:

- R

1

= 237 k

- R

2

= 45.3 k

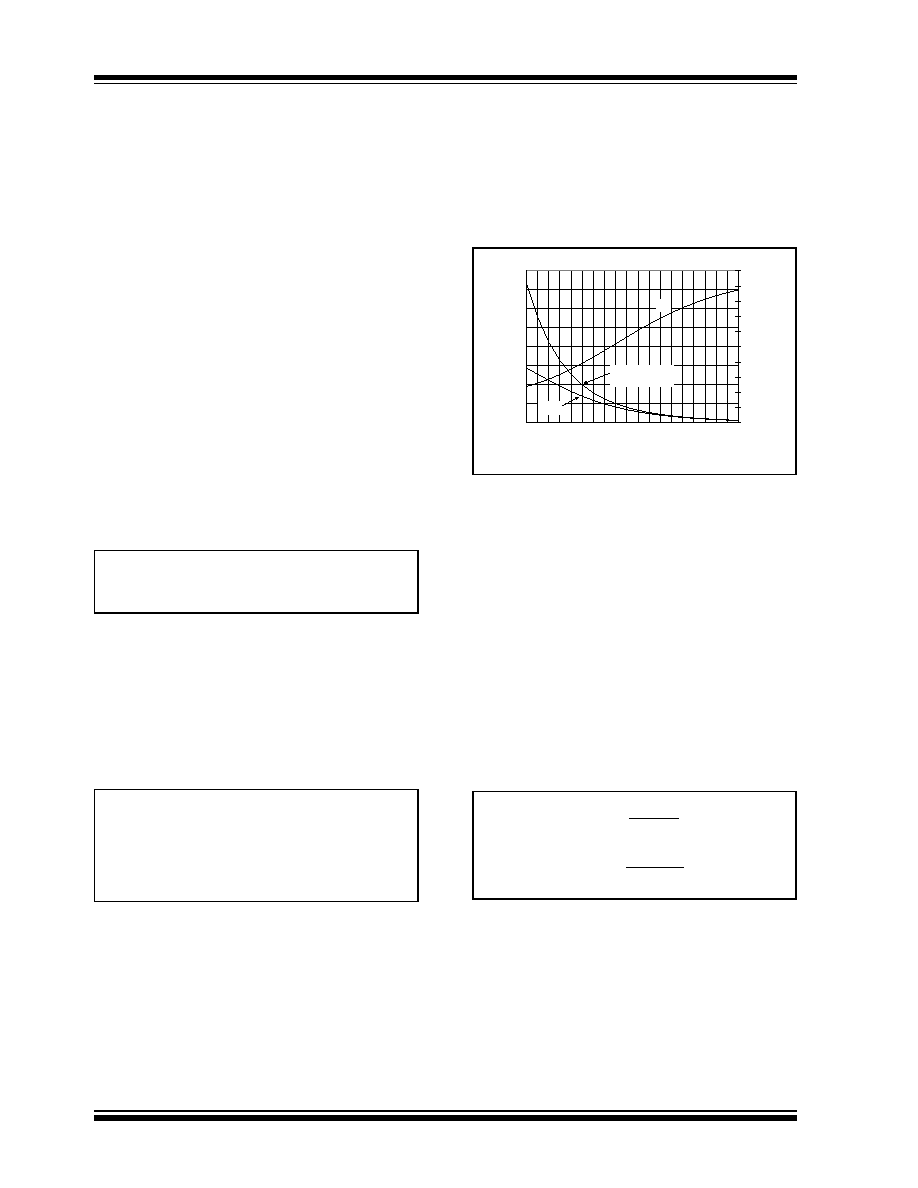

A graph of the V

IN

voltage, thermistor resistance and

R

TEMP

resistance versus temperature for this

configuration is shown in Figure 5-10.

FIGURE 5-10:

Thermistor Resistance, V

IN

and R

TEMP

vs. Temperature

Step 5: Setting the Auto-Shutdown Voltage (V

AS

).

Setting the voltage for the auto-shutdown is done using

a simple resistor voltage divider. The criteria for the

voltage divider in this design is that it draw no more

than 100 µA of current. The required auto-shutdown

voltage was determined earlier in the selection of the

V

IN

voltage at 40% duty cycle, since this was also set

at the temperature that auto-shutdown is to occur

(20ºC).

- V

AS

= 1.76V

Given this desired setpoint and knowing the desired

divider current, the following equations can be used to

solve for the resistor values for R

3

and R

4

:

EQUATION

Using the equations above, the resistor values for R

3

and R

4

are found to be:

- R

3

= 32.4 k

- R

4

= 17.6 k

Using standard 1% resistor values yields the following

values:

- R

3

= 32.4 k

- R

4

= 17.8 k

V

IN

= (DC * 1.4V) + 1.20V

DC = Desired Duty Cycle

V T1

( )

V

DD

R

2

×

R

TEMP

T1

( ) R

2

+

------------------------------------------

=

V T2

( )

V

DD

R

2

×

R

TEMP

T2

( ) R

2

+

------------------------------------------

=

0

50

100

150

200

250

300

350

400

0

10

20

30

40

50

60

70

80

90

Temperature (ºC)

Network Resistance (k

)

0.00

0.50

1.00

1.50

2.00

2.50

3.00

3.50

4.00

4.50

5.00

V

IN

(V)

V

IN

NTC Thermistor

100 k @ 25ºC

R

TEMP

I

DIV

=

5V

R

3

+ R

4

V

AS

=

5V * R

4

R

3

+ R

4

2003 Microchip Technology Inc.

DS21755B-page 25

TC646B/TC648B/TC649B

Step 6: Selecting the Fan Drive Device (Q

1

).

Since the fan operating current is below 200 mA, a

transistor or MOSFET can be used as the fan drive

device. In order to reduce component count and cur-

rent draw, the drive device for this design is chosen to

be a N-channel MOSFET. Selecting from Table 5-2,

there are two MOSFETs that are good choices, the

MGSF1N02E and the SI2302. These devices have the