| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: MSK105 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Output 1

-Vcc 1/2

+Vcc 1/2

Output 2

Output 3

-Vcc 3/4

+Vcc 3/4

Output 4

N/C

PIN-OUT INFORMATION

TYPICAL APPLICATIONS

4707 Dey Road Liverpool, N.Y. 13088

(315) 701-6751

FEATURES:

MIL-PRF-38534 CERTIFIED

105

ISO-9001 CERTIFIED BY DSCC

M.S.KENNEDY CORP.

Low Cost

Wide Supply Voltage Range: 5V to 40V

High Output Current: 3A Minimum

High Efficiency:

Vs-2.2V

at 2.5A

Internal Current Limit

Wide Common Mode Range

(Includes Negative Supply Voltage)

Low Distortion

Internal Output Snubbers for Ultra-Stable Operation

HIGH POWER QUAD

OPERATIONAL AMPLIFIER

EQUIVALENT SCHEMATIC

1

2

3

4

5

6

7

8

9

-Input 1

+Input 1

+Input 2

-Input 2

N/C

-Input 3

+Input 3

+Input 4

-Input 4

18

17

16

15

14

13

12

11

10

Half and Full Bridge Motor Drives

Audio Power Amplifiers

Bridge - 60W RMS Per Pair

Stereo - 30W RMS Per Channel

Ideal for Single Supply Systems

5V - Peripheral

12V - Automotive

28V - Avionic

DESCRIPTION:

The MSK 105 is a high power quad operational amplifier. Each amplifier is capable of delivering three amps of

current to the load. The MSK 105 is an excellent low cost alternative for bridge mode configurations since all

amplifiers are packaged together and will track thermally. The wide common mode range includes the negative rail,

facilitating single supply applications. It is possible to have a "ground based" input driving a single supply amplifier

with ground acting as the second or "bottom" supply of the amplifier. To maintain stability, output snubber networks

have been internally connected to each op amp output (see "amplifier stability" in the attached application notes).

The output stage is also current limit protected to approximately 3.0 amps. The MSK 105 is packaged in a space

efficient 18-pin ceramic dip. Consult factory for other packaging options if desired.

1

Rev. D 10/01

Storage Temperature

Lead Temperature

Case Operating Temperature

(MSK105B/E)

(MSK105)

Thermal Resistance (DC)

Junction to Case

(Per Amplifier)

(Per Die)

Input Bias Current

STATIC

Supply Voltage Range

INPUT

Offset Voltage

Offset Voltage Drift

Power Supply Rejection

Common Mode Rejection

Total Noise

OUTPUT

Output Voltage Swing

Output Current

Current Limit

Power Bandwidth

Crosstalk

Capacitive Load

TRANSFER CHARACTERISTICS

Slew Rate

Open Loop Voltage Gain

Total Supply Voltage

Output Current (within S.O.A.)

Input Voltage (Differential)

Input Voltage

(Common Mode)

Junction Temperature

-65∞C to +150∞C

300∞C

-55∞C to +125∞C

-40∞C to +85∞C

8.0∞C/W

5.0∞C/W

40V

4A

±V

CC

+V

CC

, -V

CC

-0.5V

150∞C

ABSOLUTE MAXIMUM RATINGS

T

ST

T

LD

T

C

R

TH

V

CC

±I

OUT

V

IND

V

IN

T

J

Unless otherwise noted ±VCC=±15VDC. Specification is for each of the four amplifiers unless otherwise noted.

Devices shall be capable of meeting the parameter, but need not be tested. Typical parameters are for reference only.

Industrial grade and 'E' suffix devices shall be tested to subgroups 1 and 4 unless otherwise requested.

Military grade devices ('B' suffix) shall be 100% tested to subgroups 1,2,3 and 4.

Subgroup 5 and 6 testing available upon request.

Subgroup 1,4 TC=+25∞C

Subgroup 2,5 TC=+125∞C

Subgroup 3,6 TA=-55∞C

Power Dissipation must be equal in both amplifiers of one dual die for this rating to apply.

Group A

Subgroup

-

1

2

3

1

-

-

-

-

-

-

4

4

-

-

-

-

4

-

Typ.

±15

±60

±120

±40

±0.5

±15

±35

±75

80

85

0.1

±14.2

±4.0

±4.0

13.6

68

0.022

1.5

100

Min.

±2.5

-

-

-

-

-

-

-

60

60

-

±14

±3.0

-

-

60

-

0.5

80

Min.

±2.5

-

-

-

-

-

-

-

60

60

-

±14

±3.0

-

-

-

-

0.5

80

Max.

±20

±150

-

-

±15

-

±1500

-

-

-

1.0

-

-

-

-

-

-

-

-

Typ.

±15

±60

-

-

±2

±15

±35

±75

80

85

0.1

±14.2

±4.0

±4.0

13.6

68

0.022

1.5

100

Units

V

mA

mA

mA

mV

µV/∞C

nA

nA

dB

dB

mV

V

A

A

KHz

dB

µF

V/µS

dB

MSK105B/E

MSK105

2

Parameter

Max.

±20

±150

±210

±150

±12

-

±1000

±1000

-

-

1.0

-

-

-

-

-

-

-

-

Test Conditions

ELECTRICAL SPECIFICATIONS

1

2

NOTES:

Quiescent Current

2

2

2

2

2

2

2

(Split Supply)

Total; V

IN

=0V

V

IN

=0V

V

IN

=0V

V

CM

=0V

Full Temp.

V

CC

=±15V

V

CM

=±10VDC

R

L

=500

A

V

=1 C

L

=1500pF

(I

OUT

=±0.5A)

V

OUT

=MAX

V

OUT

=28V

PP

I

OUT

=1A f=1KHz

A

V

=+1V/V

f=10Hz R

L

=500

Rev. D 10/01

2

3

7

1

2

4

5

6

7

APPLICATION NOTES

SAFE OPERATING AREA (SOA)

AMPLIFIER STABILITY

Since both output transistors in this amplifier are NPN, con-

sideration must be taken when stabilizing the output. A one

ohm resistor, 0.047uF capacitor snubber network has been

added internally from the output to -Vcc on each amplifier. This

configuration minimizes local output stage oscillations. As al-

ways, adequate power supply bypassing is a necessity for

amplifier stability. A parallel combination of a 4.7uF electro-

lytic (for every amp of output current) and a 0.01uF ceramic

disc capacitor should be connected as close as possible to the

package power supply pins to ground. The R-C snubber net-

works shown on the outputs of the amplifiers in the typical

circuits are internal and should not be added externally.

If the inductive load is driven near steady state conditions al-

lowing the output to drop more than 6V below the supply rail

while the amplifier is current limiting, the inductor should be

capacitively coupled or the supply voltage must be lowered to

meet the SOA criteria. It is a good practice to also connect

reverse biased fast recovery diodes to the output for protection

against sustained high energy flyback.

BIDIRECTIONAL MOTOR DRIVE

PARALLEL CONNECTION

yields single 6A amplifier

±Vcc

20V

15V

10V

5V

Inductive Load

7.5mH

25mH

35mH

150mH

Capacitive Load

200uF

500uF

5mF

50mF

Safe operating area curves are a graphical representation of

all of the power limiting factors involved in the output stage of

an operational amplifier. Three major power limiting factors

are; output transistor wire bond carrying capability, output tran-

sistor junction temperature and secondary breakdown effects.

To see if your application is meeting or exceeding the limita-

tions of the safe operating area curves, perform the following

steps:

1.) Find the worst case output power dissipation. For a split

supply, purely resistive load application, this occurs when

V

OUT

=1/2 V

CC

.

2.) Take the values of (V

CC

-V

OUT

) and the corresponding out-

put current and find their intersection on the safe operating

area curves.

3.) Verify this point is below the safe operating area curves.

This is a simple task for purely resistive loads, for reactive loads

the following table will save extensive analysis. Under tran-

sient conditions, capacitive and inductive loads up to the fol-

lowing maximum are safe.

Rev. D 10/01

3

APPLICATION NOTES CONTINUED

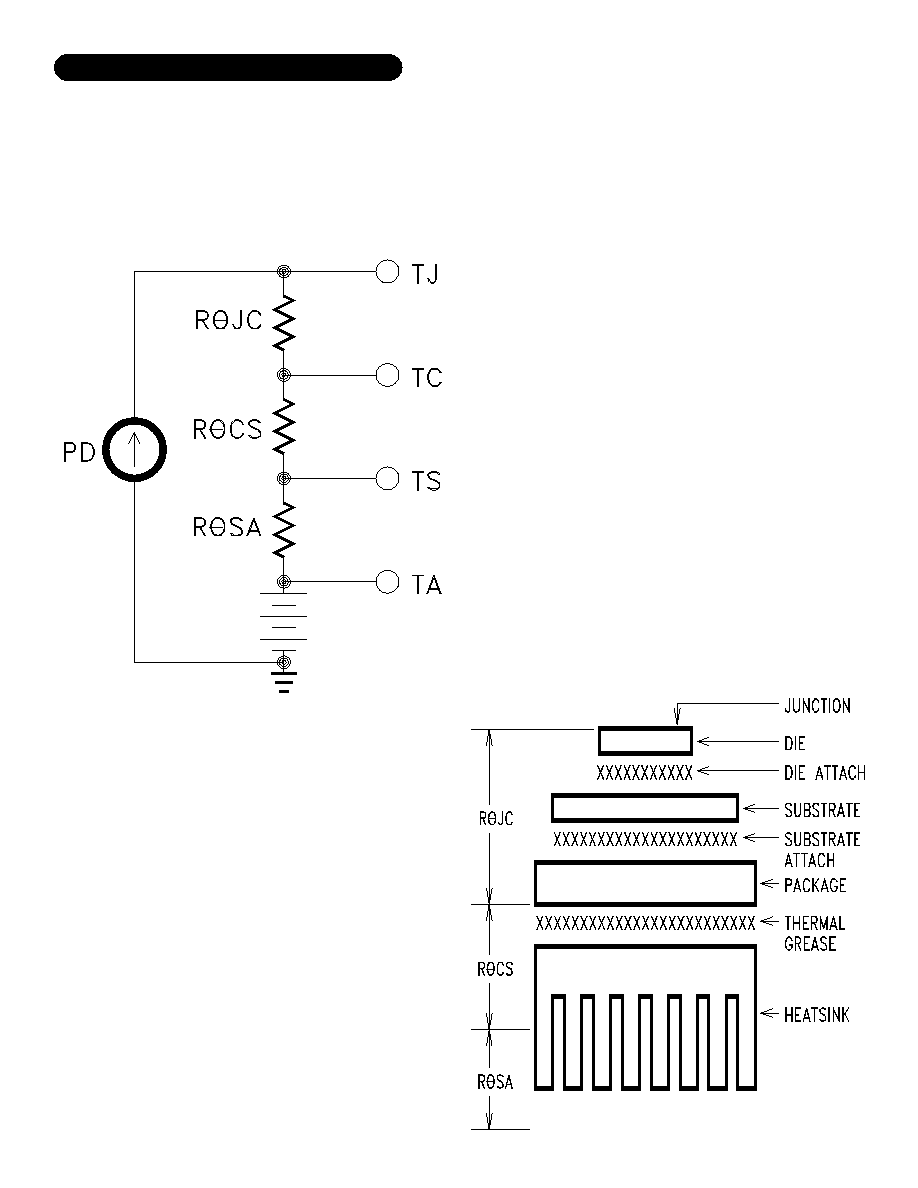

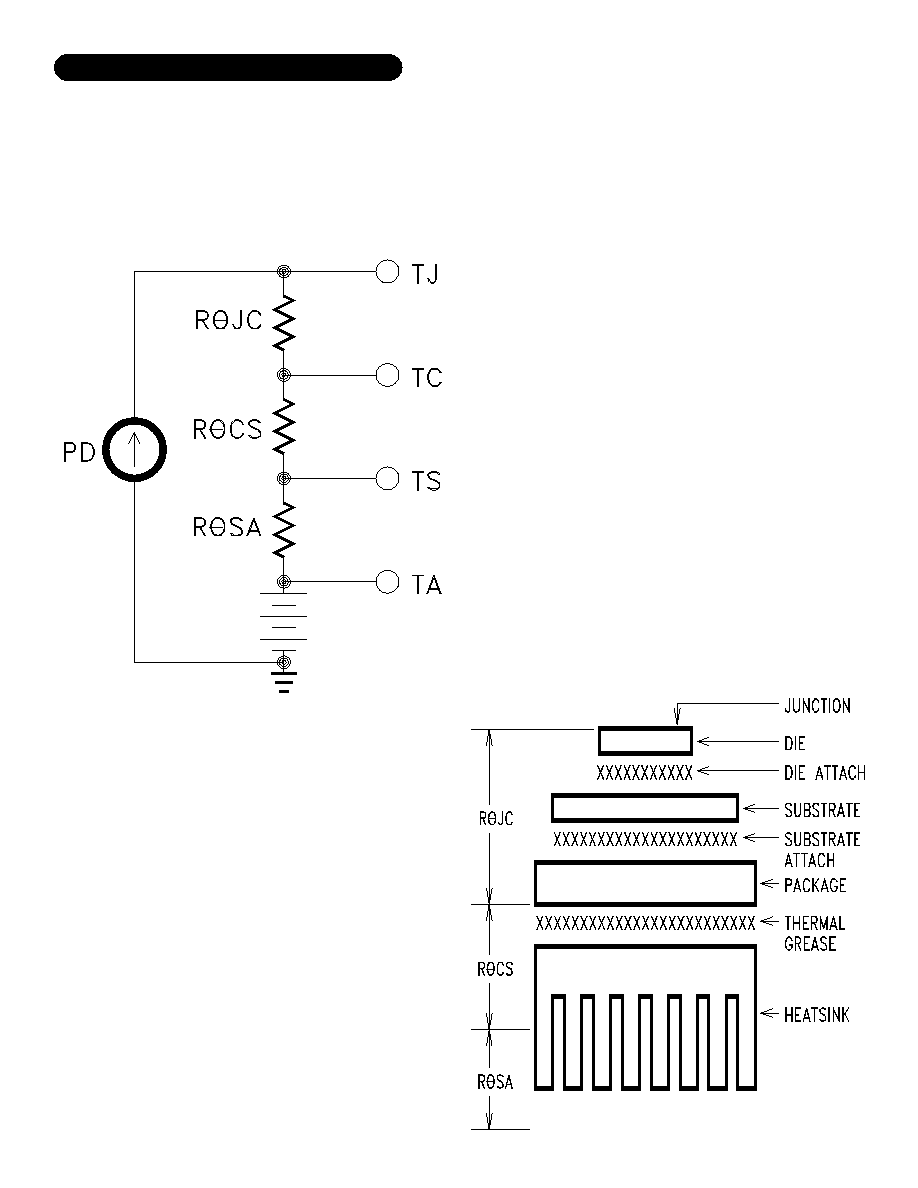

T

J

=P

D

x (R

JC

+ R

CS

+ R

SA

) + T

A

Where

T

J

= Junction Temperature

P

D

= Total Power Dissipation

R

JC

= Junction to Case Thermal Resistance

R

CS

= Case to Heat Sink Thermal Resistance

R

SA

= Heat Sink to Ambient Thermal Resistance

T

C

= Case Temperature

T

A

= Ambient Temperature

T

S

= Sink Temperature

Governing Equation:

Thermal Path:

HEAT SINKING

To determine if a heat sink is necessary for your appli-

cation and if so, what type, refer to the thermal model

and governing equation below.

Thermal

Model:

Example:

Inside the MSK 105 package are two monolithic dual amplifi-

ers that do not exhibit thermal crossover (die to die) at 45∞

spreading angle. Therefore, our example will focus on only one

of the two die. Further, consideration must be taken to calcu-

late power dissipation on each amplifier of the die to determine

worst case power dissipation. Only the worst case amplifier

will be used in this example. In our example, the amplifer is

required to drive 10 volts across a 20 ohm load. This calcu-

lates to 0.5 amps of output current. The power supplies are

±20 Vdc.

1.) To Find Power Dissipation

P

D

= [(quiescent current) x (+V

CC

- (-V

CC

))] + (V

CC

- V

O

) x I

OUT

P

D

= 37.5 mA* x 40V + 10V x 0.5A

P

D

= 1.5W + 5W

P

D

= 6.5W

*

quiescent current for one amplifier is 1/4 of entire quiescent current.

Tj shall be 150∞C R

jc = 8.0∞C/W

Ta shall be 25∞C R

cs = 0.15∞C/W (

most thermal greases

)

2.) Rearrange the governing equation to solve for R

SA

(

heat sink to air

)

R

sa = ((Tj - TA)/PD) - R

jc - R

cs

= ((150∞C - 25∞C)/6.5W) - 8.0∞C/W - 0.15∞C/W

= 11.08∞C/W

Therefore, to maintain a junction temperature of no more than

150∞C for that amplifier, the heat sink must have a thermal

resistance of no more than 11.1∞C/W.

Rev. D 10/01

4

TYPICAL PERFORMANCE CURVES

Rev. D 10/01

5

MECHANICAL SPECIFICATIONS

ESD TRIANGLE INDICATES PIN 1.

ALL DIMENSIONS ARE ±0.010 INCHES UNLESS OTHERWISE LABELED.

The information contained herein is believed to be accurate at the time of printing. MSK reserves the right to make

changes to its products or specifications without notice, however, and assumes no liability for the use of its products.

Please visit our website for the most recent revision of this datasheet.

M.S. Kennedy Corp.

4707 Dey Road, Liverpool, New York 13088

Phone (315) 701-6751

FAX (315) 701-6752

www.mskennedy.com

MSK105

Screening Level

Part

Number

MSK105

MSK105E

MSK 105B

Industrial

Extended Reliability

Class H-Mil-PRF-38534

ORDERING INFORMATION

Rev. D 10/01

6