The CLC730075 and CLC730074 evaluation boards

are designed to aid in the characterization of National

Semiconductor's 14-pin, triple monolithic amplifiers.

s

CLC730075 - DIP packages

Uses all through-hole components

s

CLC730074 - SOIC packages

Uses all surface-mount components

Both boards have identical circuit configurations and are

designed for non-inverting gains. Inverting gains

or other circuit configurations can be obtained with slight

modifications to the boards. Use the evaluation boards

as a:

s

Guide for high frequency layout

s

Tool to aid in device testing and characterization

Basic Operation

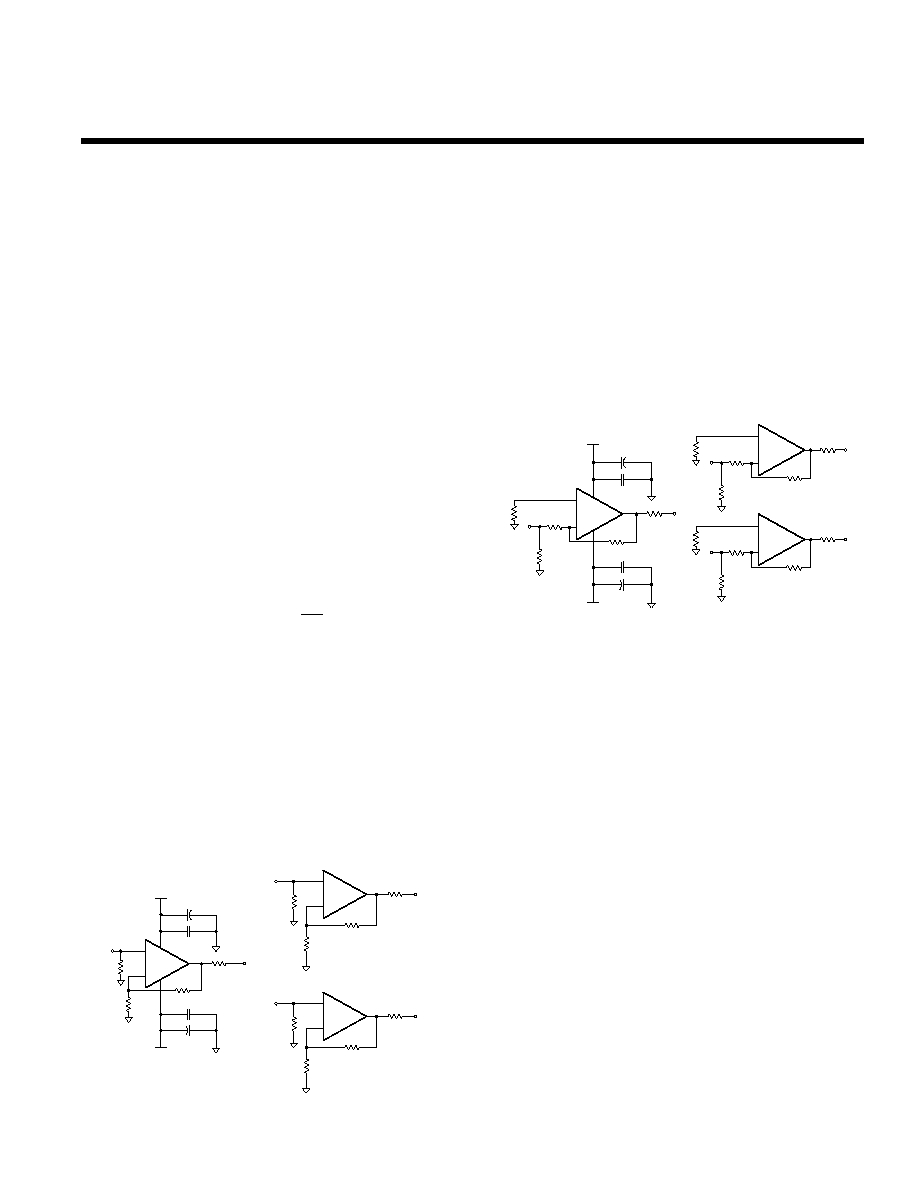

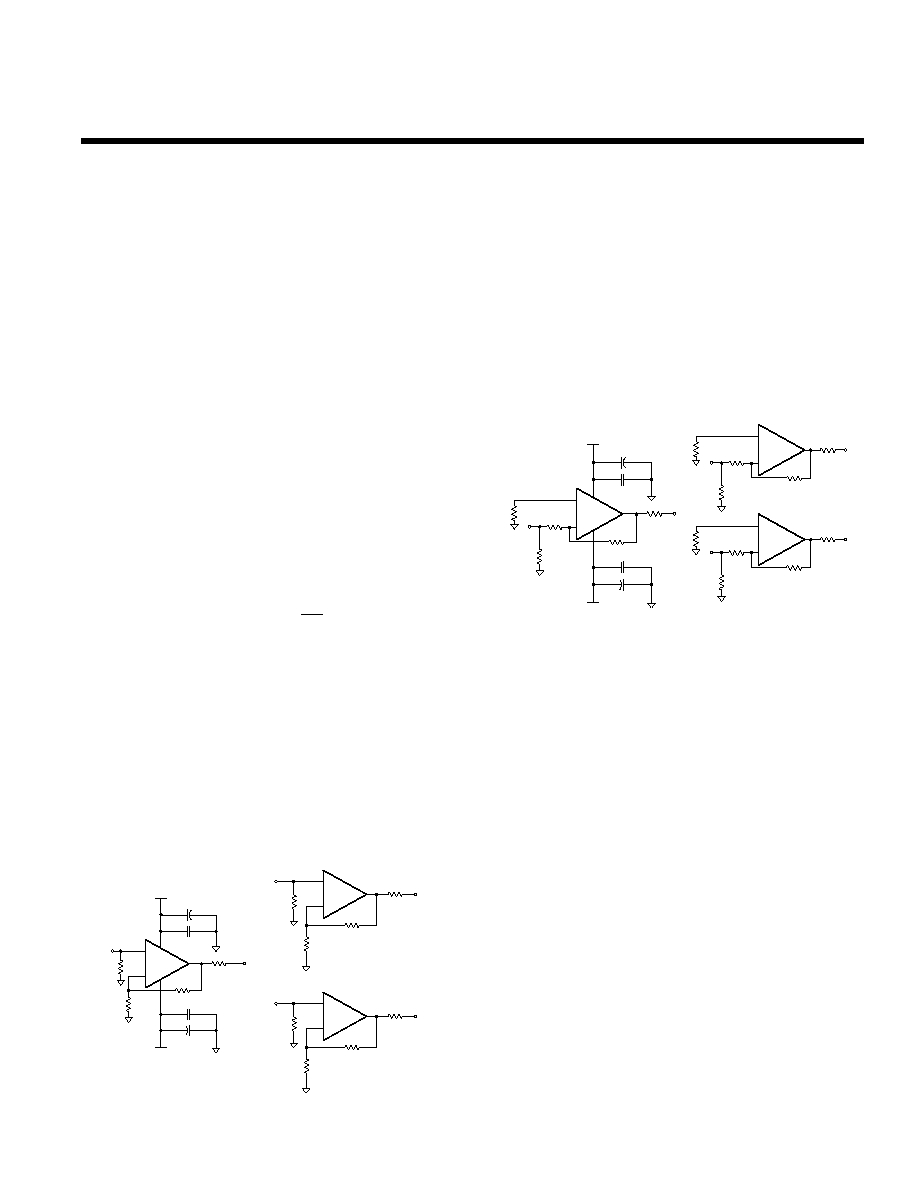

Figure 1 shows the non-inverting schematic for both

boards. The input signal is brought into the board

through SMA connectors to the non-inverting input

of the amplifier. The resistor R

in

is used to set the

input termination resistance to the op amp. The non-

inverting gain is set by the following equation:

Non-inverting Gain:

The value of the feedback resistor, R

f

, has a strong

influence on AC performance. Refer to the product data

sheet for feedback resistor selection. The output of the

op amp travels through a series resistance, R

out

, and

then leaves the board through an SMA connector. The

series resistance, R

out

, matches transmission lines or

isolates the output from capacitive loads. The 0.1

�

F

capacitor, C5, is placed between the power pins of the

amplifier to improve harmonic distortion performance. If

C5 is placed directly across pins 4 and 11, refer to the

CLC730074 board, then the capacitor provides the best

improvement in distortion performance.

Figure 1: Non-inverting Gain Configurations

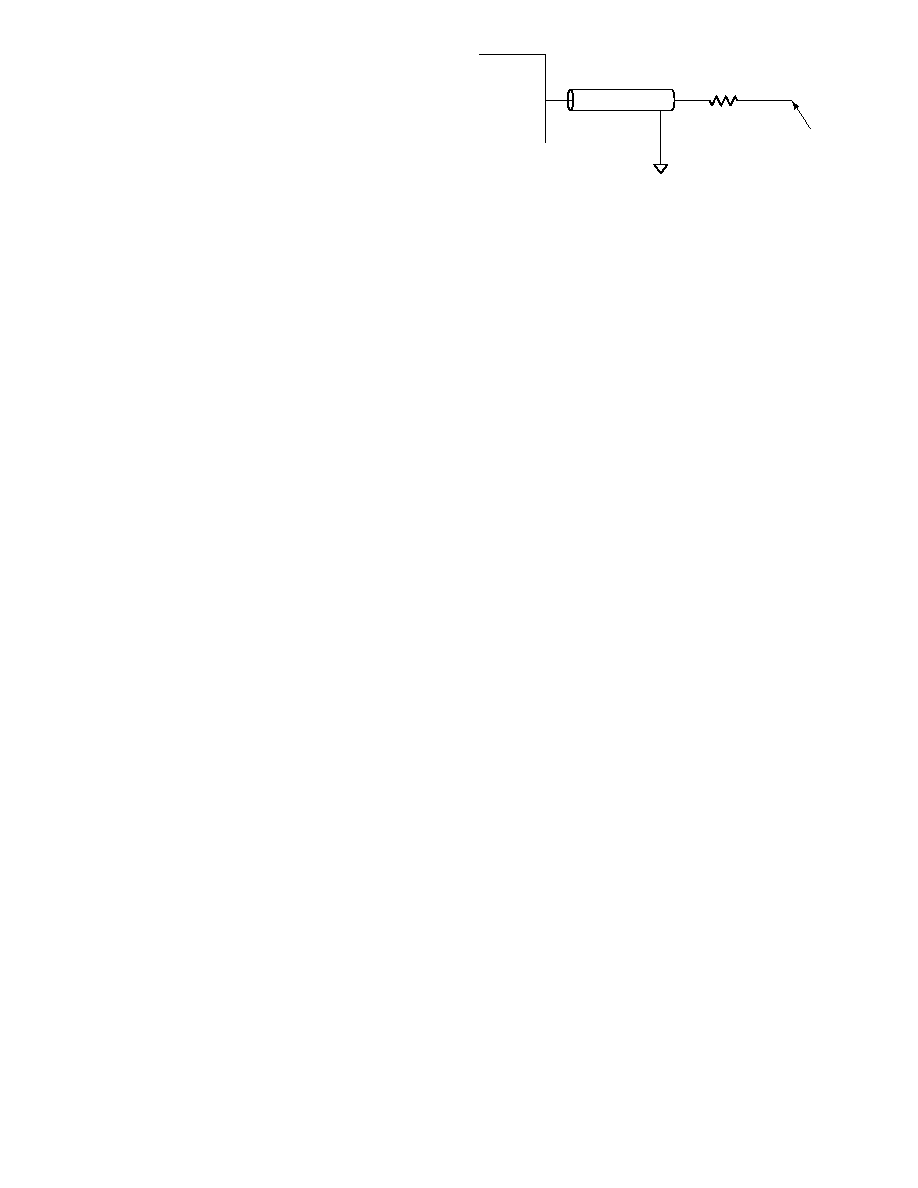

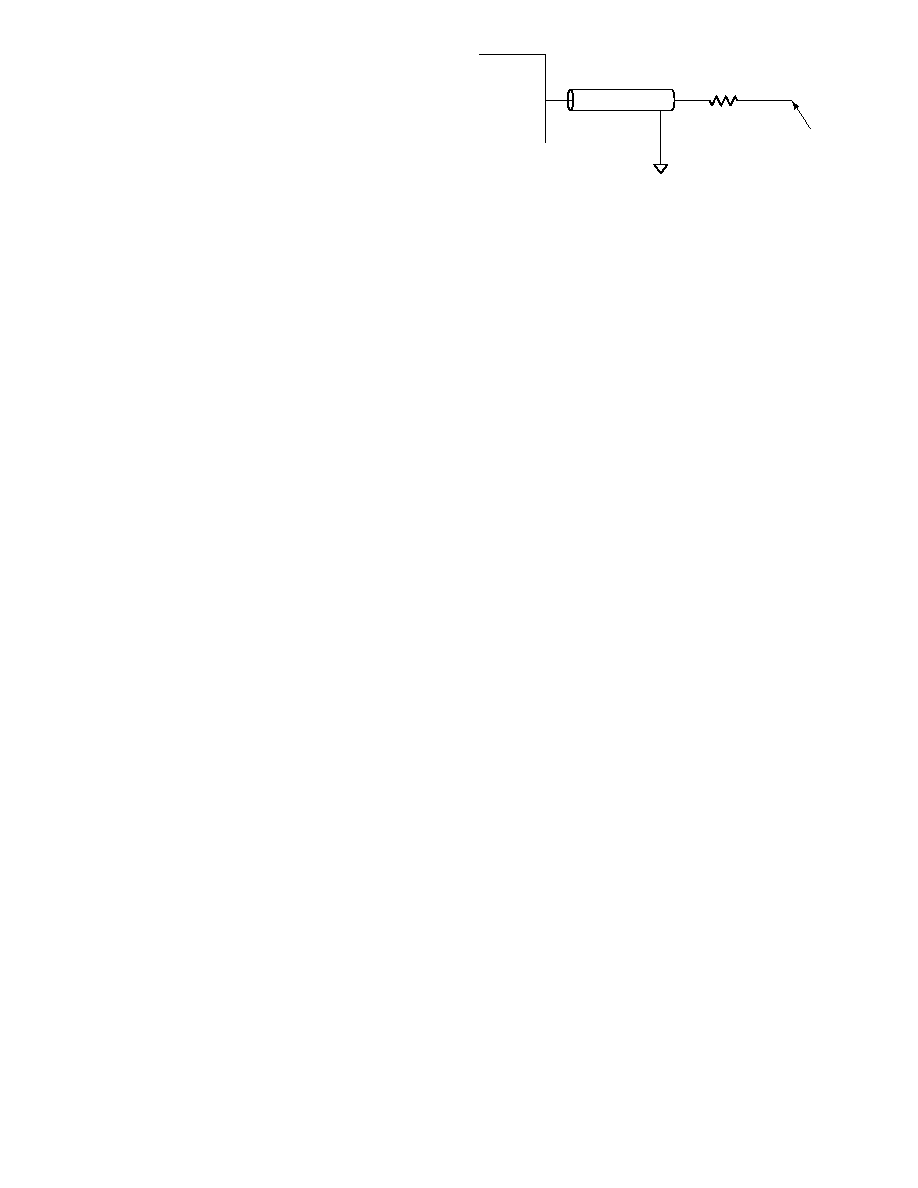

Inverting Gain Operation

The evaluation boards can be modified to provide an

inverting gain configuration. Complete these steps to

modify the board:

1. Cut the input trace

2. Use 25

for R

in

3. Terminate R

g

at the input trace instead of

ground

4. Add R

t

for desired input impedance (input

impedance = R

g

||R

t

)

Figure 2 illustrates the inverting schematic for both

boards.

Figure 2: Inverting Gain Configurations

Isolation and Channel Matching Performance

For maximum isolation between channels, proper power

supply decoupling is required. Always include the

bypass capacitors C1, C2, C3, and C4. The use of good

quality capacitors also helps to achieve better isolation

performance.

The evaluation boards have also been designed to mini-

mize channel-to-channel crosstalk. The input and output

pins of the amplifier are sensitive to the coupling of par-

asitic capacitances caused by power or ground planes

and traces. To reduce the influence of these parasitics,

the ground plane has been removed around these sen-

sitive nodes. In multilayer boards, remove both the

ground and power traces and planes around the input

and output pins.

Layout Considerations

General layout and supply bypassing play major roles in

high frequency performance. When designing your own

board, use the evaluation board as a guide and follow

these steps as a basis for high frequency layout:

1. Use a ground plane.

2. Include 6.8

�

F tantalum and 0.1

�

F ceramic

capacitors on both supplies.

14-Pin Triple Op Amp Eval. Boards

Part Numbers CLC730075, CLC730074

September 1997

+

-

Channel 1

R

f1

C

1

C

3

OUT

1

IN

1

+V

CC

C

2

C

4

-V

CC

5

6

11

4

7

+

+

R

g1

R

in1

R

out1

+

-

Channel 2

R

f2

R

g2

R

in2

12

13

14

R

out2

OUT

2

IN

2

+

-

Channel 3

R

f3

R

g3

R

in3

10

9

8

R

out3

OUT

3

IN

3

+

-

Channel 1

R

f1

C

1

C

3

OUT

1

IN

1

+V

CC

C

2

C

4

-V

CC

5

6

11

4

7

+

+

R

t1

25

R

in1

R

out1

R

g1

Select R

t

to yield desired

input impedance = R

g

||R

t

R

g2

+

-

Channel 2

R

f2

OUT

2

IN

2

12

13

14

R

t2

25

R

in2

R

out2

R

g3

+

-

Channel 3

R

f3

OUT

3

IN

3

10

9

8

R

t3

25

R

in3

R

out3

1

R

R

f

g

+

� 1997 National Semiconductor Corporation

http://www.national.com

Printed in the U.S.A.

N

3. Place the 6.8

�

F capacitors within 0.75 inches

of the power pins.

4. Place the 0.1

�

F capacitors less than 0.1

inches from the power pins.

5. Remove the ground plane under and around

the part, especially near the input and output

pins to reduce parasitic capacitance.

6. Minimize all trace lengths to reduce series

inductances.

7. Use individual flush-mount sockets, for prototyping.

Measurement Hints

If 50

coax and 50

R

in

/R

out

resistors are used, many of

the typical performance plots found in the product data

sheets can be reproduced.

When SMA connectors and cables are not available to

evaluate the amplifier, do not use normal oscilloscope

probes. Use low impedance resistive divider probes of

100 to 500

. If a low impedance probe is not available,

then a section of 50

coaxial cable and a low impedance

resistor (10

to 50

) may be used. Follow these 3 steps

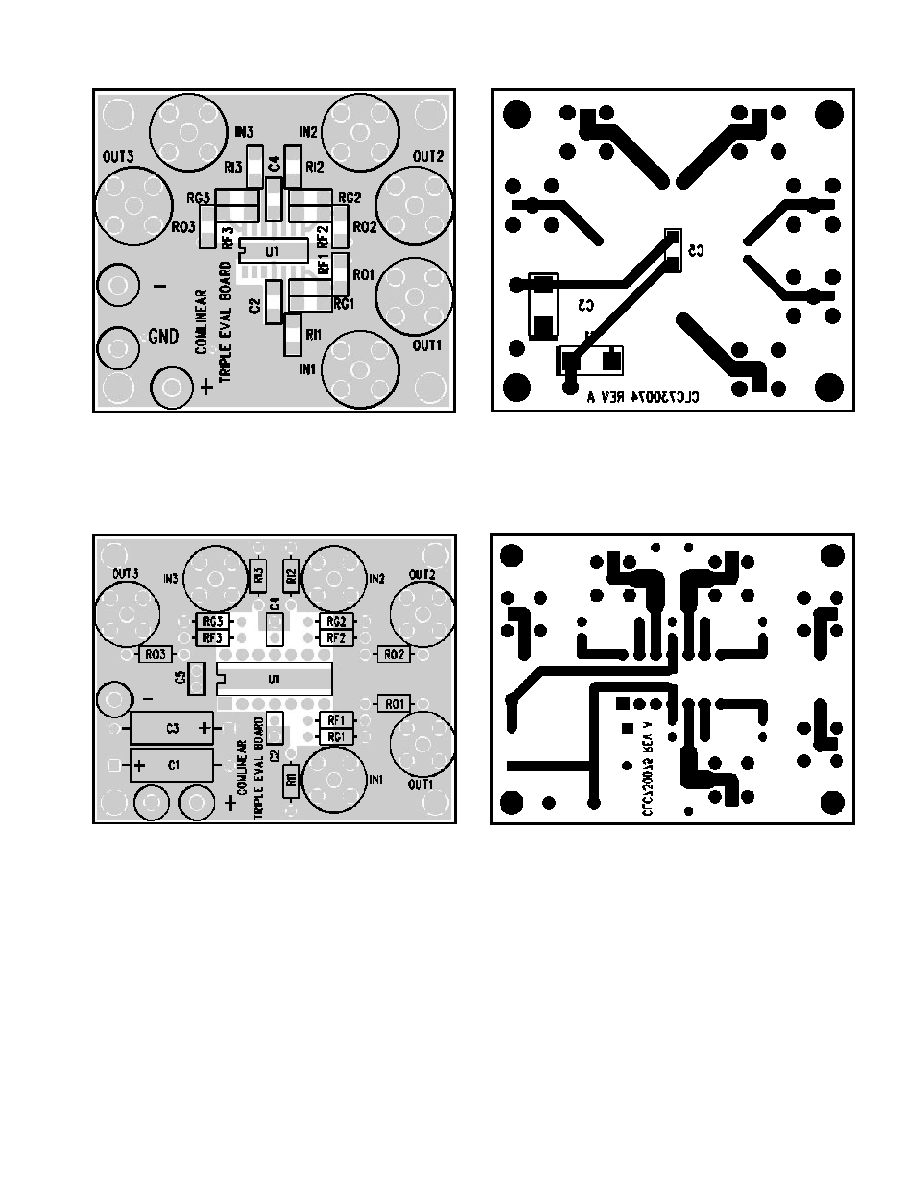

to create a "cable/resistor" probe:

1. Connect one end of the coax's center to a test

measurement box terminated in 50

.

2. Connect the other end of the cable's center

conductor to the low impedance resistor. (The

open side of the resistor is now a probe.)

3. Connect the ground shield of the cable to

evaluation board ground and test box ground.

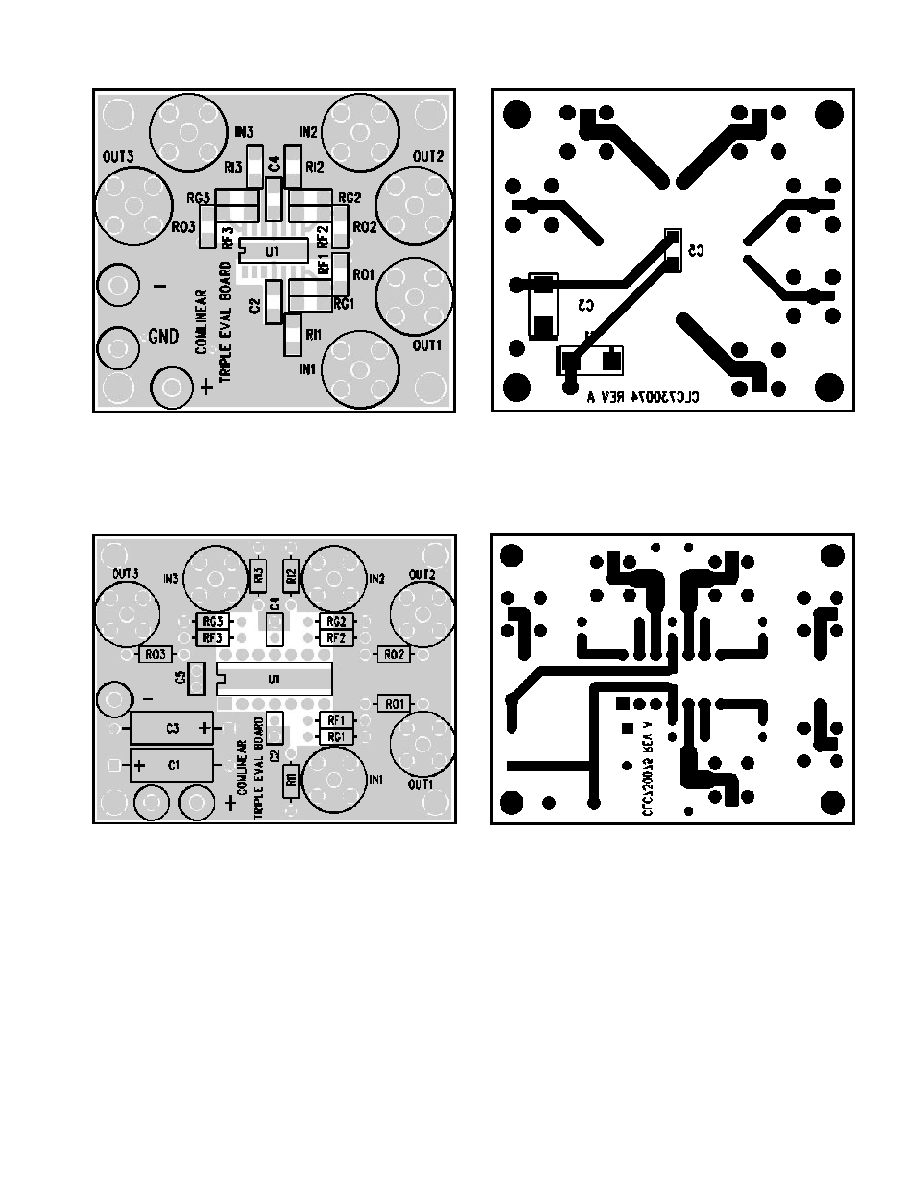

Figure 3: "Cable/Resistor" Probe Configuration

This "cable/resistor" probe, shown in Figure 3, forms a

voltage attenuator between the resistor and the 50

termination resistance of the test box. This method

allows measurements to be performed directly on the

output pin of the amplifier.

When evaluating only one channel on the board,

complete the following on the unused channel:

1. Included R

f

and R

g

as shown in Figure 1

2. Ground the input

3. Load the output with 50

to ground

Power Supplies

Refer to the product data sheet for the recommended

supply voltages.

Component Values

s

R

f

, R

g

- Use the product data sheet to

select values

s

R

in

, R

out

- 50

(Refer to

Basic Operation

section for details)

s

R

t

- Optional resistor for inverting gain

configurations (Refer

Inverting Gain

Operation section for details)

s

C3, C4 - 6.8

�

F tantalum capacitors

s

C1, C2, C5 - 0.1

�

F ceramic capacitors

http://www.national.com

2

Test Box and

Evaluation Board

Ground

50

Coaxial

Cable

Low Impedance

Resistor

Probe

Test Box

(terminated

in 50

)

3

http://www.national.com

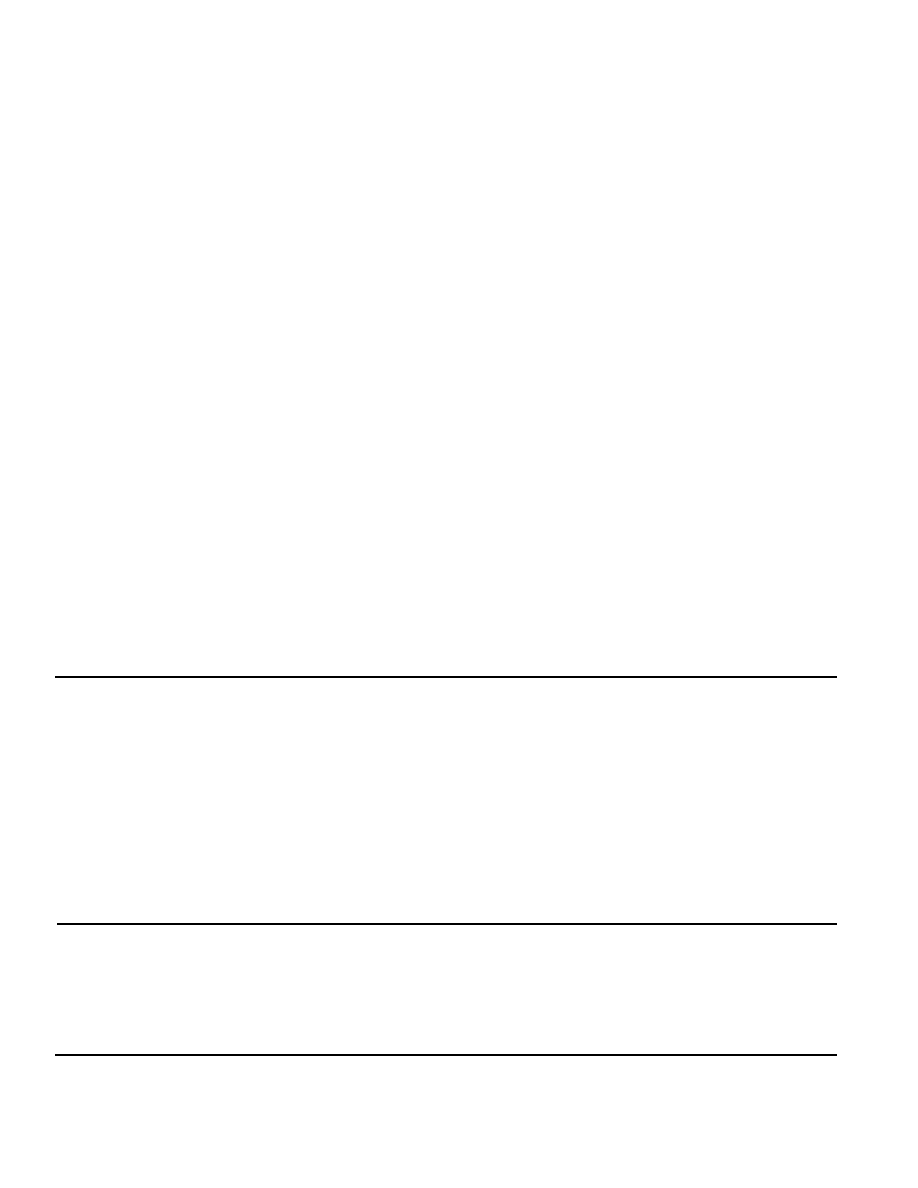

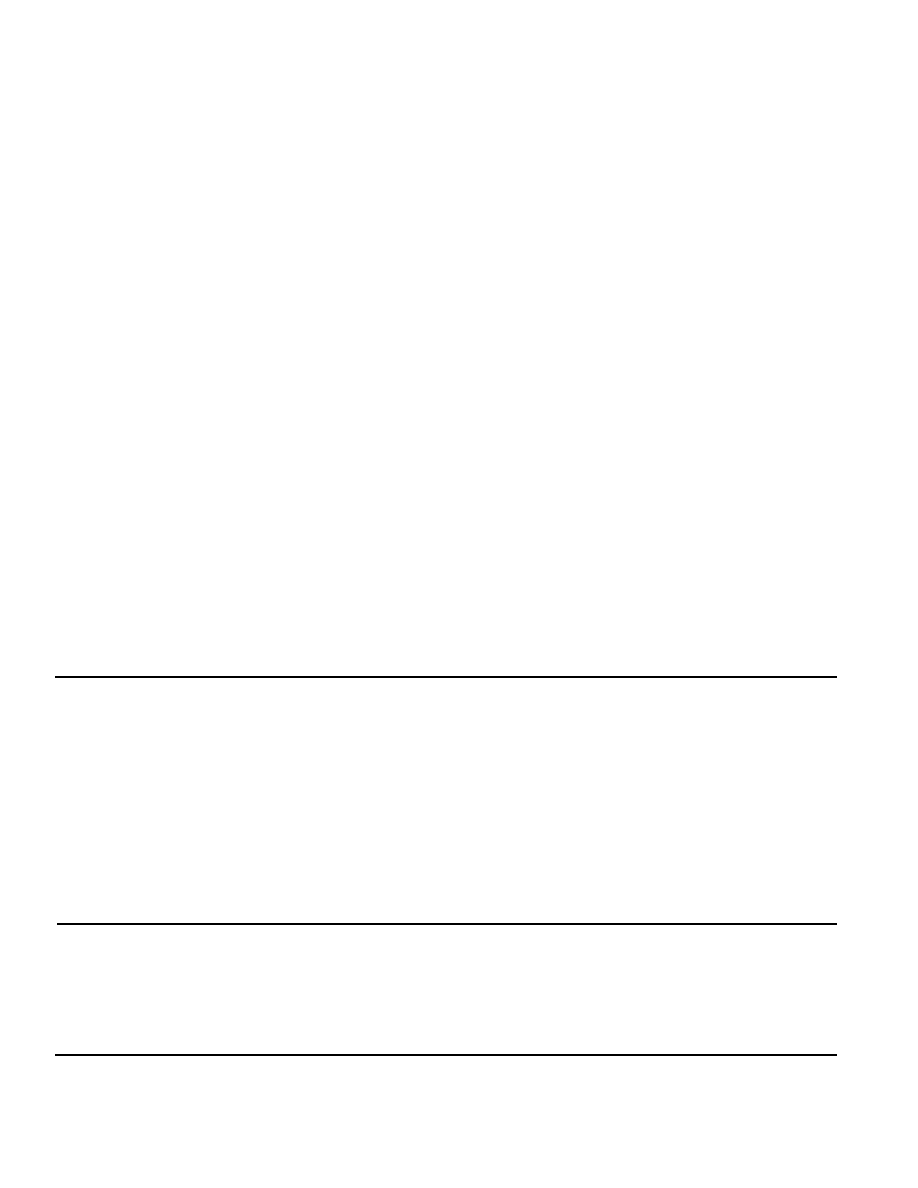

DIP � Top Side

DIP � Bottom Side

SOIC � Top Side

SOIC � Bottom Side

http://www.national.com

4

Lit #660904-001

Customer Design Applications Support

National Semiconductor is committed to design excellence. For sales, literature and technical support, call the

National Semiconductor Customer Response Group at 1-800-272-9959 or fax 1-800-737-7018.

Life Support Policy

National's products are not authorized for use as critical components in life support devices or systems without the express written approval of the

president of National Semiconductor Corporation. As used herein:

1. Life support devices or systems are devices or systems which, a) are intended for surgical implant into the body, or b) support or

sustain life, and whose failure to perform, when properly used in accordance with instructions for use provided in the labeling, can

be reasonably expected to result in a significant injury to the user.

2. A critical component is any component of a life support device or system whose failure to perform can be reasonably expected to

cause the failure of the life support device or system, or to affect its safety or effectiveness.

National Semiconductor

National Semiconductor

National Semiconductor

National Semiconductor

Corporation

Europe

Hong Kong Ltd.

Japan Ltd.

1111 West Bardin Road

Fax: (+49) 0-180-530 85 86

13th Floor, Straight Block

Tel: 81-043-299-2309

Arlington, TX 76017

E-mail: europe.support.nsc.com

Ocean Centre, 5 Canton Road

Fax: 81-043-299-2408

Tel: 1(800) 272-9959

Deutsch Tel: (+49) 0-180-530 85 85

Tsimshatsui, Kowloon

Fax: 1(800) 737-7018

English Tel: (+49) 0-180-532 78 32

Hong Kong

Francais Tel: (+49) 0-180-532 93 58

Tel: (852) 2737-1600

Italiano Tel: (+49) 0-180-534 16 80

Fax: (852) 2736-9960

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said

circuitry and specifications.

N