| ÐлекÑÑоннÑй компоненÑ: LM1819 | СкаÑаÑÑ:  PDF PDF  ZIP ZIP |

Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

TL H 5263

LM1819

Air-Core

Meter

Driver

February 1995

LM1819 Air-Core Meter Driver

General Description

The LM1819 is a function generator driver for air-core

(moving-magnet) meter movements A Norton amplifier and

an NPN transistor are included on chip for signal condition-

ing as required Driver outputs are self-centering and devel-

op

g

4 5V swing at 20 mA Better than 2% linearity is guar-

anteed over a full 305-degree operating range

Features

Y

Self-centering 20 mA outputs

Y

12V operation

Y

Norton amplifier

Y

Function generator

Applications

Y

Air-core meter driver

Y

Tachometers

Y

Ruggedized instruments

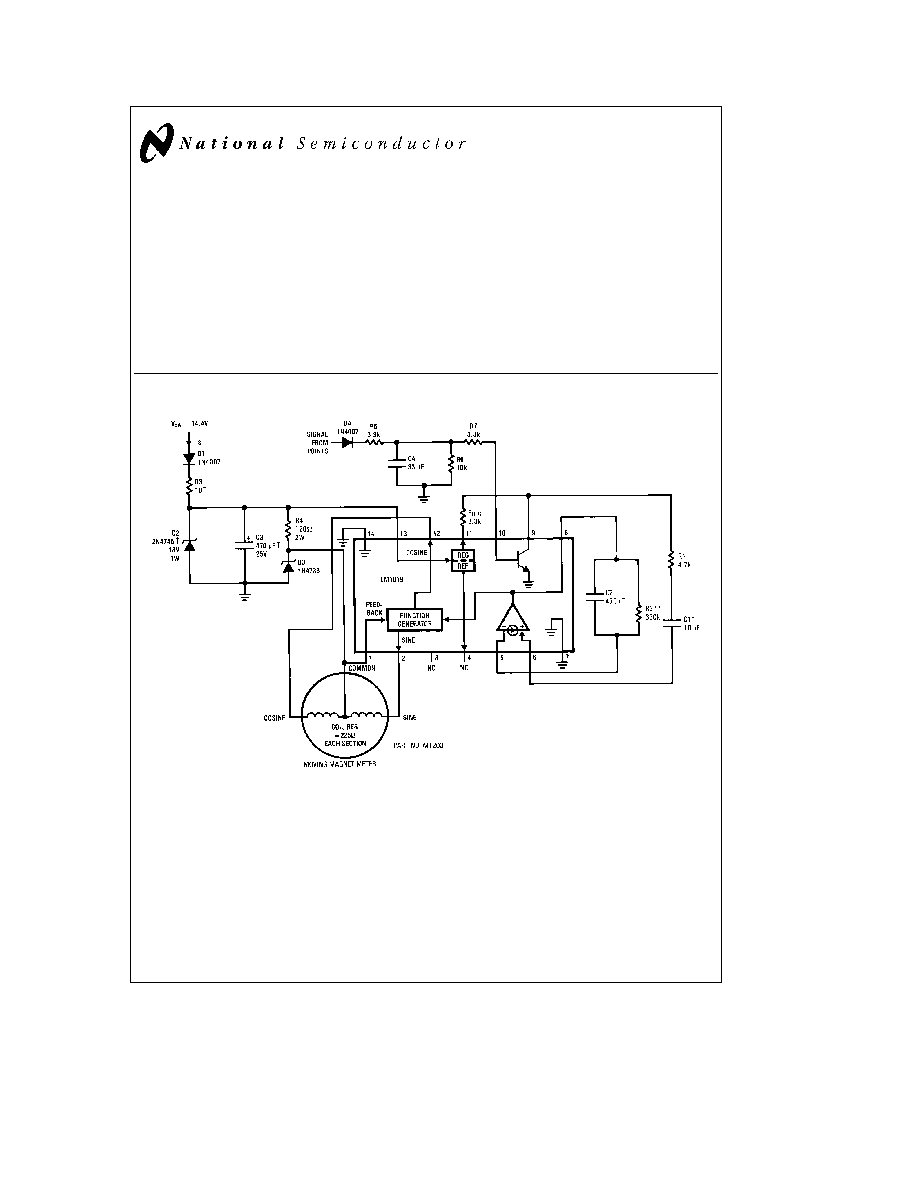

Typical Application

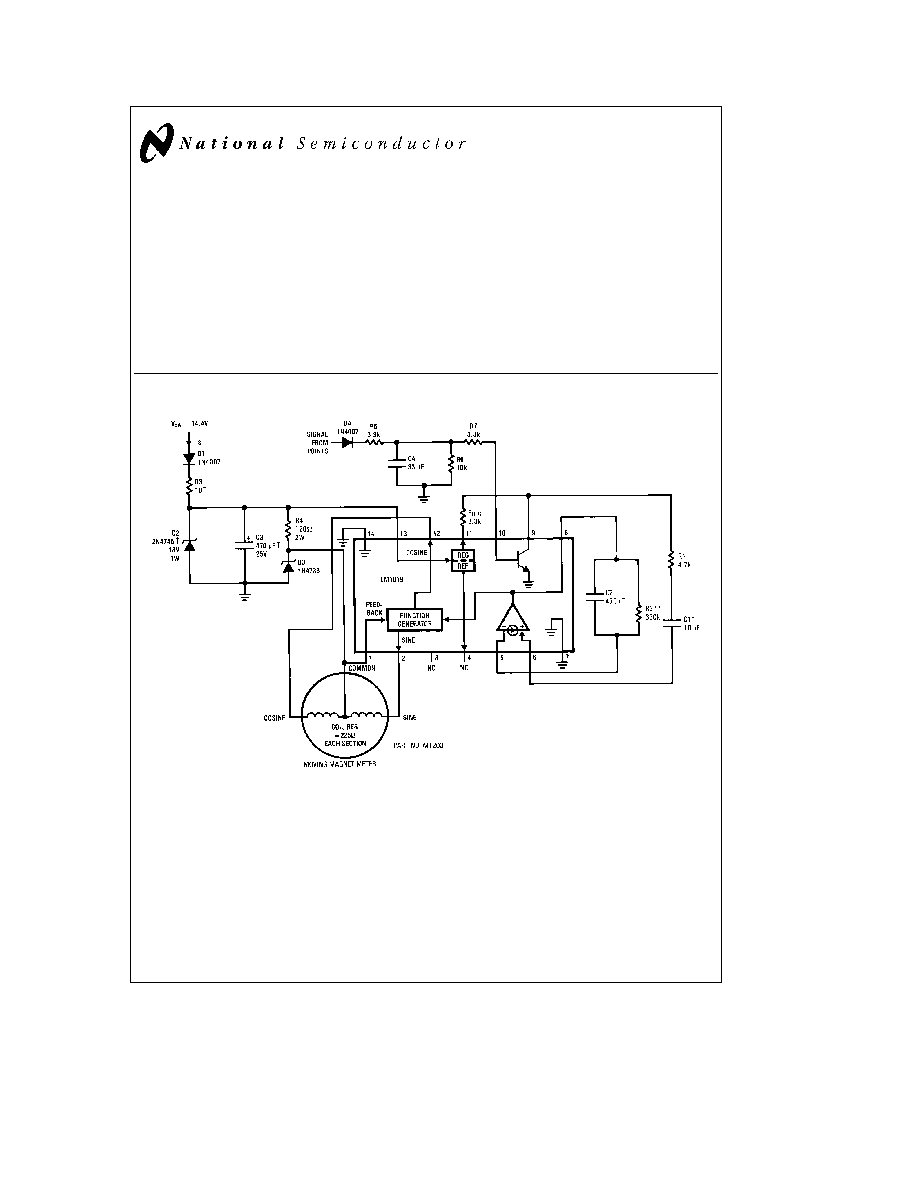

TL H 5263 1

FIGURE 1 Automotive Tachometer Application Circuit shown operates

with 4 cylinder engine and deflects meter pointer (270 ) at 6000 RPM

Order Number LM1819M or LM1819N

See NS Package Number M14A or N14A

TRW Type X463UW Polycarbonate Capacitor

RN60D Low TC Resistor (

g

100 ppm)

Components Required for Automotive Load Dump Protection

Available from FARIA Co

P O Box 983 Uncasville CT 06382

Tel 203-848-9271

C1995 National Semiconductor Corporation

RRD-B30M115 Printed in U S A

Absolute Maximum Ratings

If Military Aerospace specified devices are required

please contact the National Semiconductor Sales

Office Distributors for availability and specifications

Supply Voltage V

a

(pin 13)

20V

Power Dissipation (note 1)

1300 mW

Operating Temperature

b

40 C to

a

85 C

Storage Temperature

b

65 C to

b

150 C

Lead Temp (Soldering 10 seconds)

260 C

BV

CEO

20V

MIN

Electrical Characteristics

V

S

e

13 1V T

A

e

25 C unless otherwise specified

Symbol

Parameter

Pin(s)

Conditions

Min

Typ

Max

Units

I

S

Supply Current

13

Zero Input Frequency

65

mA

(See

Figure 1 )

V

REG

Regulator Voltage

11

I

REG

e

0 mA

8 1

8 5

8 9

V

Regulator Output Resistance

11

I

REG

e

0 mA to 3 mA

13 5

X

V

REF

Reference Voltage

4

I

REF

e

0 mA

1 9

2 1

2 3

V

Reference Output Resistance

4

I

REF

e

0 mA to 50 mA

5 3

kX

Norton Amplifier Mirror Gain

5 6

I

BIAS

j

20 mA

0 9

1 0

1 1

h

FE

NPN Transistor DC Gain

9 10

125

Function Generator Feedback

1

V

1

e

5 1V

1 0

mA

Bias Current

Drive Voltage Extremes

2 12

I

LOAD

e

20 mA

g

4

g

4 5

V

Sine and Cosine

Sine Output Voltage

2

V

8

e

V

REF

b

350

0

a

350

mV

with Zero Input

Function Generator Linearity

FSD

e

305

g

1 7

%FSD

k

Function Generator Gain

Meter Deflection DV

8

50 75

53 75

56 75

V

Note 1

For operation above 25 C the LM1819 must be derated based upon a 125 C maximum junction temperature and a thermal resistance of 76 C W which

applies for the device soldered in a printed circuit board and operating in a still-air ambient

Application Hints

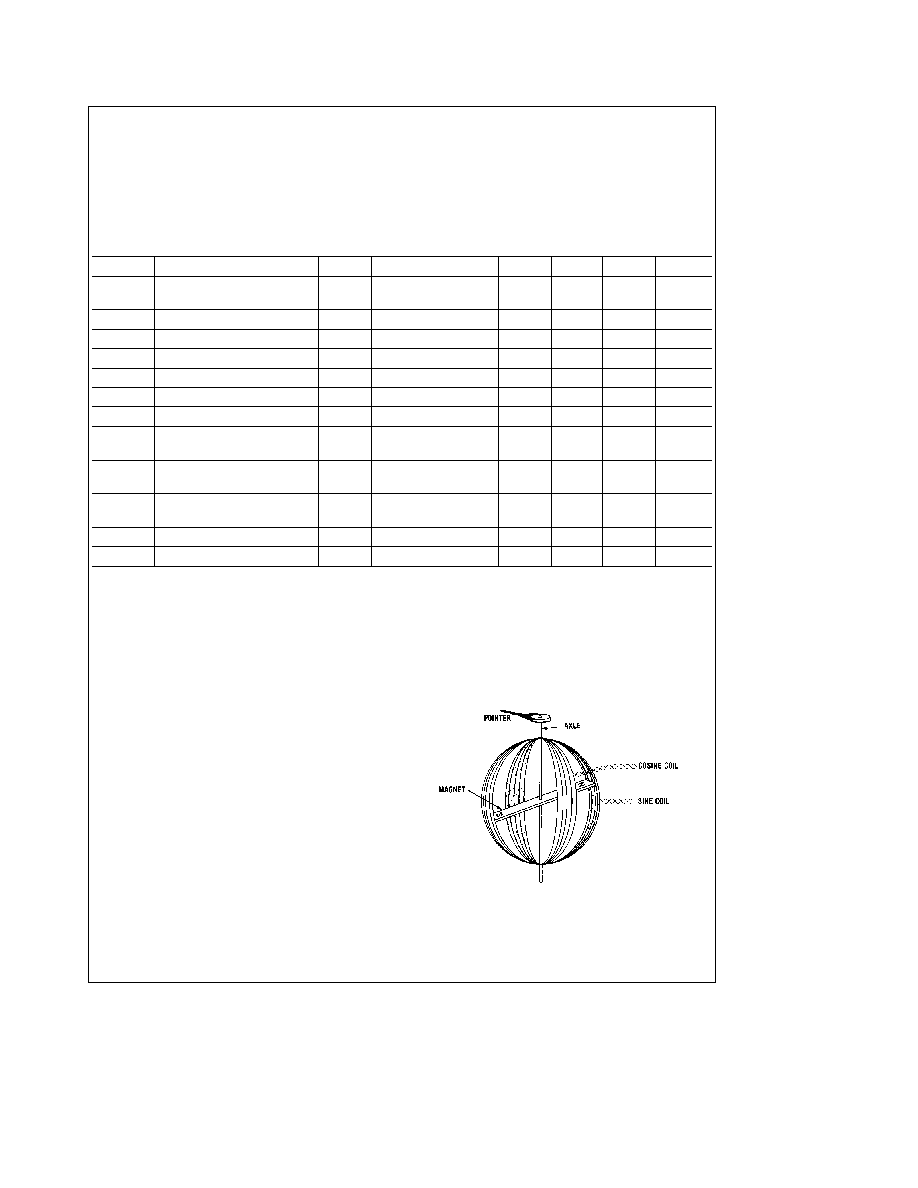

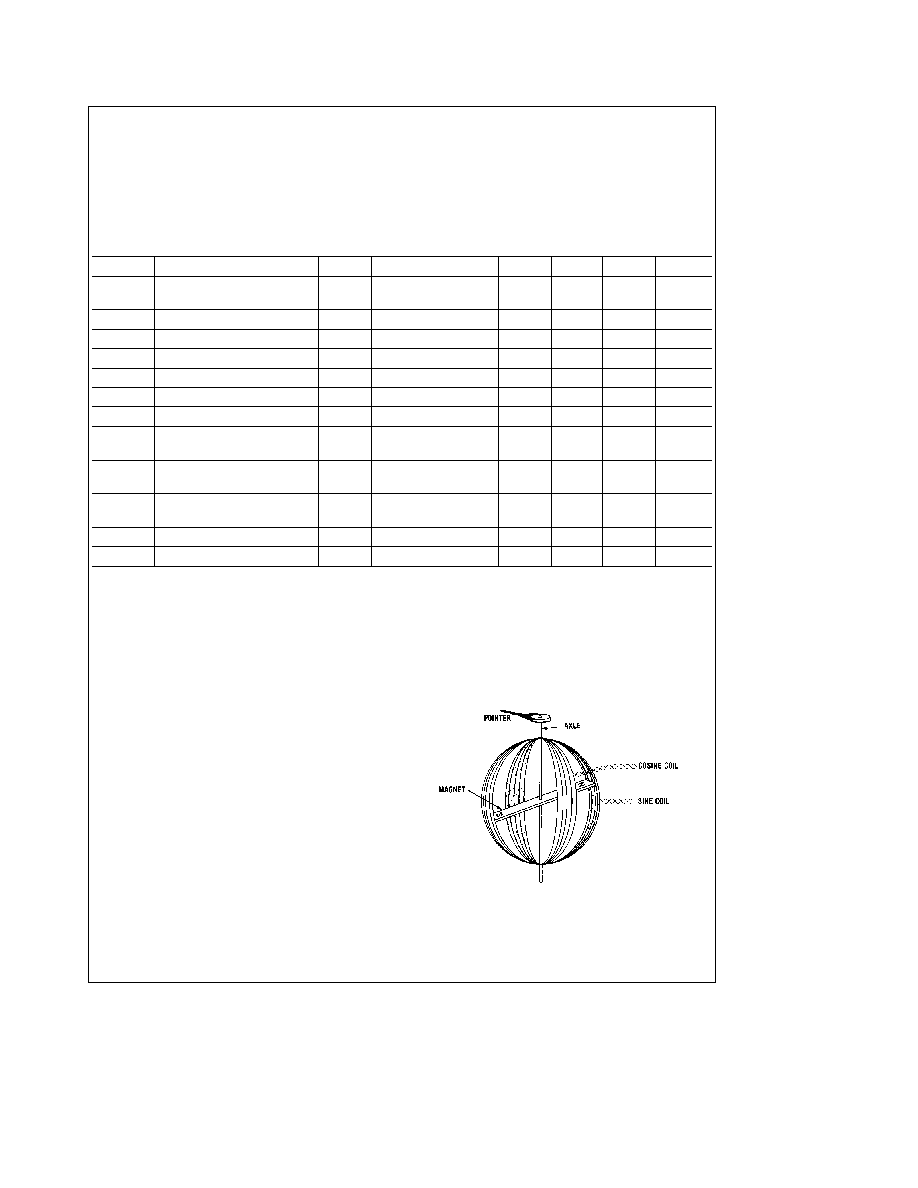

AIR-CORE METER MOVEMENTS

Air-core meters are often favored over other movements as

a result of their mechanical ruggedness and their indepen-

dence of calibration with age A simplified diagram of an air-

core meter is shown in

Figure 2 There are three basic

pieces a magnet and pointer attached to a freely rotating

axle and two coils each oriented at a right angle with re-

spect to the other The only moving part in this meter is the

axle assembly The magnet will tend to align itself with the

vector sum of H fields of each coil where H is the magnetic

field strength vector If for instance a current passes

through the cosine coil (the reason for this nomenclature

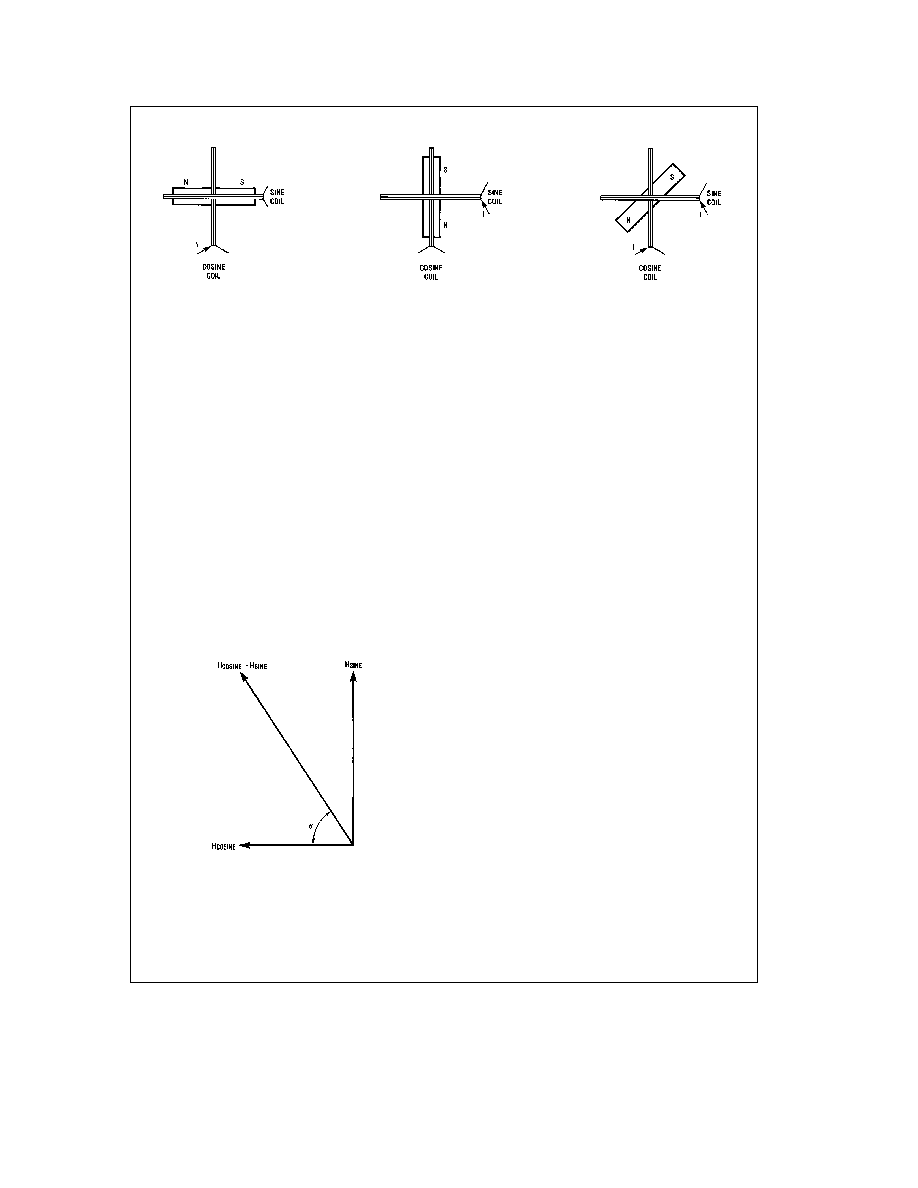

will become apparent later) as shown in

Figure 3(a) the

magnet will align its magnetic axis with the coil's H field

Similarly a current in the sine coil (

Figure 3(b) ) causes the

magnet to align itself with the sine H field If currents are

applied simultaneously to both sine and cosine coils the

magnet will turn to the direction of the vector sum of the two

H

fields

(Figure 3(c)) H is proportional to the voltage applied

to a coil Therefore by varying both the polarity and magni-

tude of the coil voltages the axle assembly can be made to

rotate a full 360 The LM1819 is designed to drive the me-

ter through a minimum of 305

TL H 5263 2

FIGURE 2 Simplified Diagram of an Air Core Meter

2

Application Hints

(Continued)

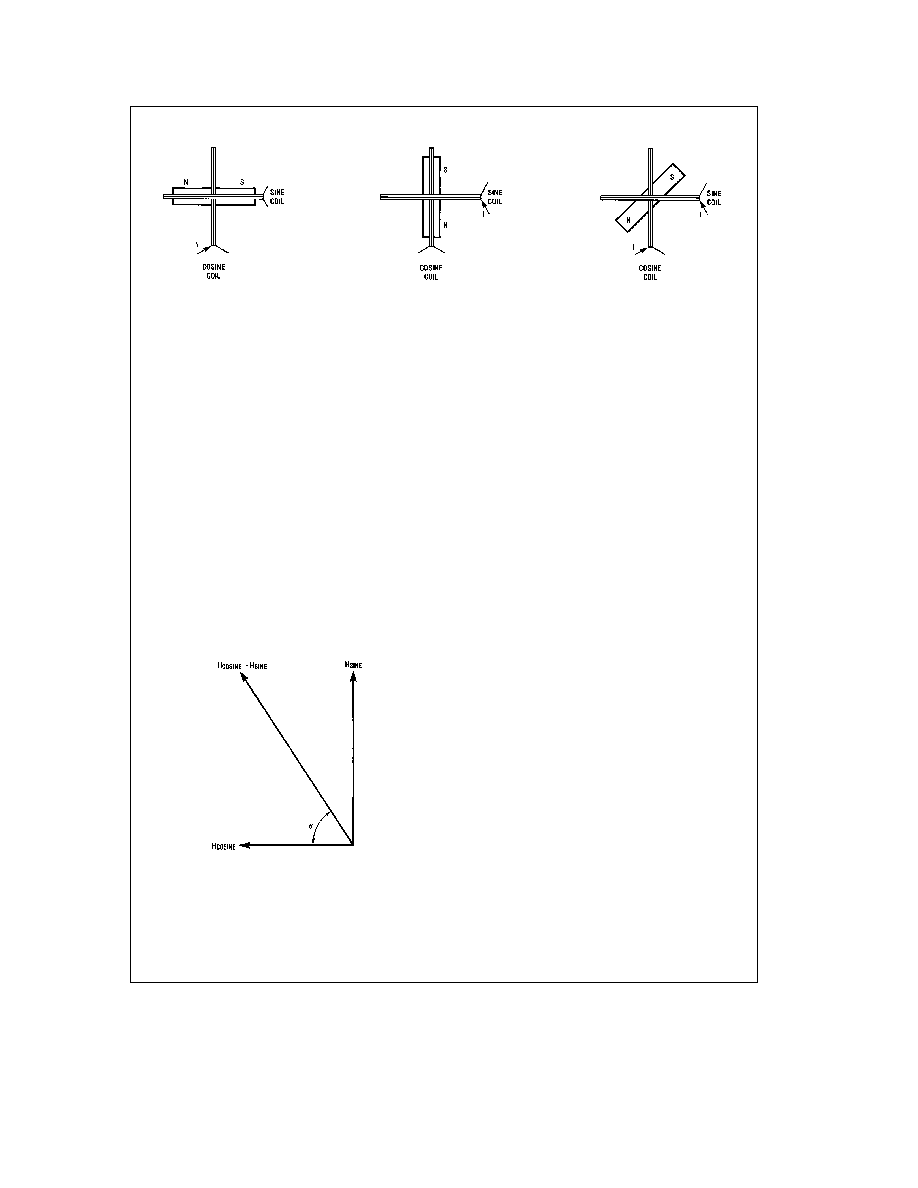

TL H 5263 3

(c)

(b)

(a)

FIGURE 3 Magnet and pointer position are controlled by the H field generated by the two drive coils

In an air-core meter the axle assembly is supported by two

nylon bushings The torque exerted on the pointer is much

greater than that found in a typical d'Arsonval movement In

contrast to a d'Arsonval movement where calibration is a

function of spring and magnet characteristics air-core me-

ter calibration is only affected by the mechanical alignment

of the drive coils Mechanical calibration once set at manu-

facture can not change

Making pointer position a linear function of some input is a

matter of properly ratioing the drive to each coil The H field

contributed by each coil is a function of the applied current

and the current is a function of the coil voltage Our desired

result is to have i (pointer deflection measured in degrees)

proportional to an input voltage

i

e

kV

IN

1

where k is a constant of proportionality with units of de-

grees volt The vector sum of each coils' H field must follow

the deflection angle i We know that the axle assembly

always points in the direction of the vector sum of H

SINE

and H

COSINE

This direction (see

Figure 4 ) is found from the

formula

(i)

e

arctan

l

H

SINE

l l

H

COSINE

l

2

Recalling some basic trigonometry

(i)

e

arctan(sin (i)

cos(i ))

3

TL H 5263 4

FIGURE 4 The vector sum of H

COSINE

and H

SINE

points

in a direction i measured in a clockwise direction from

H

COSINE

Comparing 3 to 2 we see that if H

SINE

varies as the sine

of i and H

COSINE

varies as the cosine of i we will gener-

ate a net H field whose direction is the same as i And since

the axle assembly aligns itself with the net H field the point-

er will always point in the direction of i

THE LM1819

Included in the LM1819 is a function generator whose two

outputs are designed to vary approximately as the sine and

cosine of an input A minimum drive of

g

20 mA at

g

4V is

available at pins 2 (sine) and 12 (cosine) The common side

of each coil is returned to a 5 1V zener diode reference and

fed back to pin 1

For the function generator kj54 V (in equation 1) The

input (pin 8) is internally connected to the Norton amplifier's

output V

IN

as considered in equation 1 is actually the dif-

ference of the voltages at pins 8 (Norton output function

generator input) and 4 Typically the reference voltage at pin

4 is 2 1V Therefore

i

e

k(V

8

b

V

REF

)

e

54 (V

8

b

2 1)

4

As V

8

varies from 2 1V to 7 75V the function generator will

drive the meter through the chip's rated 305 range

Air-core meters are mechanically zeroed during manufac-

ture such that when only the cosine coil is driven the point-

er indicates zero degrees deflection However in some ap-

plications a slight trim or offset may be required This is

accomplished by sourcing or sinking a DC current of a few

microamperes at pin 4

A Norton amplifier is available for conditioning various input

signals and driving the function generator A Norton amplifi-

er was chosen since it makes a simple frequency to voltage

converter While the non-inverting input (pin 6) bias is at one

diode drop above ground the inverting input (5) is at 2 1V

equal to the pin 4 reference Mirror gain remains essentially

flat to I

MIRROR

e

5 mA The Norton amplifier's output (8) is

designed to source current into its load To bypass the Nor-

ton amplifier simply ground the non-inverting input tie the

inverting input to the reference and drive pin 8 (Norton out-

put function generator input) directly

An NPN transistor is included on chip for buffering and

squaring input signals Its usefulness is exemplified in

Fig-

ures 1

6 where an ignition pulse is converted to a rectan-

gular waveform by an RC network and the transistor The

emitter is internally connected to ground It is important not

to allow the base to drop below

b

5V

dc

as damage may

occur The 2 1V reference previously described is derived

from an 8 5V regulator at pin 11 Pin 11 is used as a stable

supply for collector loads and currents of up to 5 mA are

easily accommodated

3

Application Hints

(Continued)

TACHOMETER APPLICATION

A measure of the operating level of any motor or engine is

the rotational velocity of its output shaft In the case of an

automotive engine the crankshaft speed is measured using

the units ``revolutions per minute'' (RPM) It is possible to

indirectly measure the speed of the crankshaft by using the

signal present on the engine's ignition coil The fundamental

frequency of this signal is a function of engine speed and

the number of cylinders and is calculated (for a four-stroke

engine) from the formula

f e

n

0

120

(Hz)

(5)

where n

e

number of cylinders and

0

e

rotational velocity of

the crankshaft in RPM From this formula the maximum fre-

quency normally expected (for an 8 cylinder engine turning

4500RPM) is 300 Hz In certain specialized ignition systems

(motorcycles and some automobiles) where the coil wave-

form is operated at twice this frequency (

f e

0

60) These

systems are identified by the fact that multiple coils are used

in lieu of a single coil and distributor Also the coils have

two outputs instead of one

A typical automotive tachometer application is shown in

Fig-

ure 1 The coil waveform is filtered squared and limited by

the RC network and NPN transistor The frequency of the

pulse train at pin 9 is converted to a proportional voltage by

the Norton amplifier's charge pump configuration The igni-

tion circuit shown in

Figure 5 is typical of automotive sys-

tems The switching element ``S'' is opened and closed in

synchronism with engine rotation When ``S'' is closed en-

ergy is stored in Lp When opened the current in Lp diverts

from ``S'' into C The high voltage produced in Ls when ``S''

is opened is responsible for the arcing at the spark plug

The coil voltage (see

Figure 6 ) can be used as an input to

the LM1819 tachometer circuit This waveform is essentially

constant

duty cycle D4 rectifies this waveform thereby pre-

venting negative voltages from reaching the chip C4 and

R5 form a low pass filter which attenuates the high frequen-

cy ringing and R7 limits the input current to about 2 5mA

R6 acts as a base bleed to shut the transistor OFF when

``S'' is closed The collector is pulled up to the internal regu-

lator by R

REG

The output at pin 9 is a clean rectangular

pulse

Many ignition systems use magnetic hall effect or optical

sensors to trigger a solid state switching element at ``S ''

These systems (see the LM1815) typically generate pulses

of constant

width and amplitude suitable for driving the

charge pump directly

The charge pump circuit in

Figure 7 can be operated in two

modes constant input pulse width (C1 acts as a coupling

capacitor) and constant input duty cycle (C1 acts as a differ-

entiating capacitor) The transfer functions for these two

modes are quite diverse However deflection is always di-

rectly proportional to R2 and ripple is proportional to C2

The following variables are used in the calculation of meter

deflection

symbol

description

n

number of cylinders

0 0

IDLE

engine speed at redline and idle RPM

i

pointer deflection at redline degrees

e

charge pump input pulse width seconds

V

IN

peak to peak input voltages volts

Di

maximum desired ripple degrees

k

function generator gain degrees volt

f f

IDLE

input frequency at redline and idle Hz

Where the NPN transistor and regulator are used to create a

pulse V

IN

e

8 5V Acceptable ripple ranges from 3 to 10 de-

grees (a typical pointer is about 3 degrees wide) depending

on meter damping and the input frequency

The constant pulse width circuit is designed using the fol-

lowing equations

(1)

100 mA

k

V

IN

R1

k

3 mA

(2)

C

1

t

10e

R

1

(3)

R

2

e

R

1

i

V

IN

e

k

f

e

120R

1

i

V

IN

n

0

e

k

(4)

C

2

e

1

R

2

Di

f

IDLE

e

1

R

2

Di

n

0

IDLE

The constant duty cycle equations are as follows

R

REG

t

3 kX

R

1

s

V

IN

x10

4

b

R

REG

C

1

s

e

10(R

REG

a

R

1

)

R

Z

e

i

3 54n

0

C

1

e

i

425

f

C

1

C

2

e

425C

1

Di

The values in

Figure 1 were calculated with n

e

4

0

e

6000RPM

i

e

270

degrees

e

e

1

ms

V

IN

is

V

REG

b

0 7V and Di

e

3 degrees in the constant duty cycle

mode For distributorless ignitions these same equations will

apply if

0

60 is substituted for

f

4

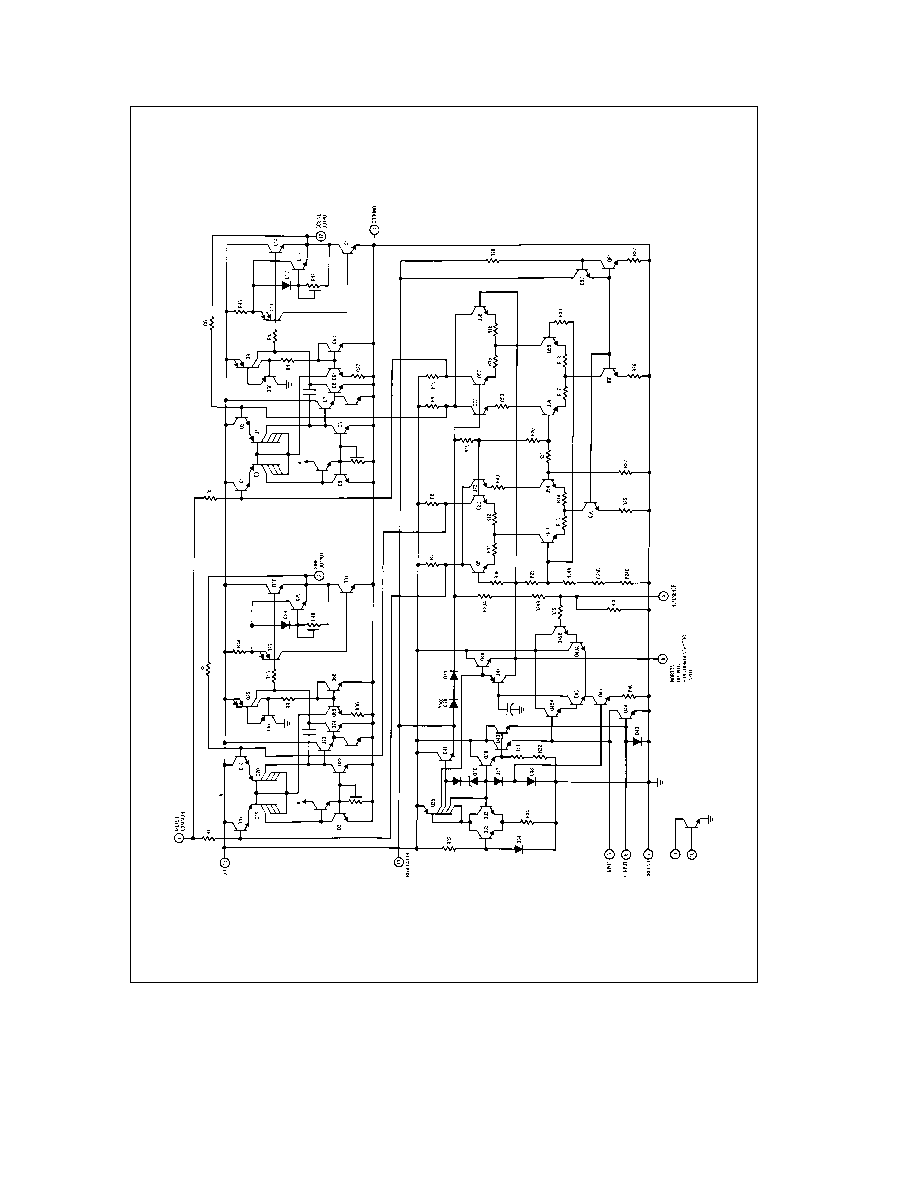

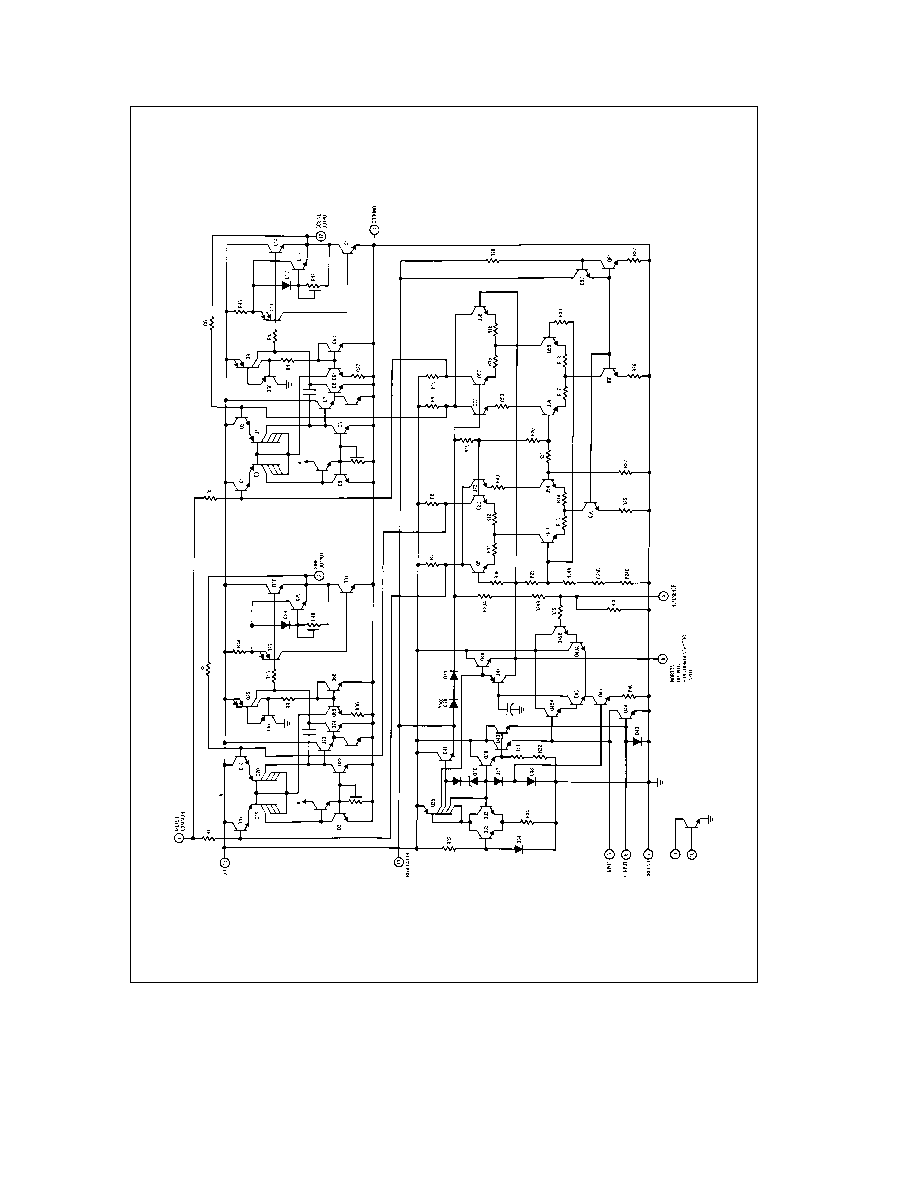

Equivalent Schematic

TLH5263

1

2

5