| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: LM2485 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

LM2485

220V Triple Bias Clamp with G1 Blank Amplifier

General Description

The LM2485 is a triple channel clamp amplifier used to DC

restore the AC coupled outputs of a DTV CRT driver and for

cut-off adjustment. The LM2485 also has an integrated

blanking amplifier that can be used to drive the G1 grid of a

CRT negative for vertical retrace blanking. The blanking

output has a selectable pulse amplitude of either 20V

P-P

or

40V

P-P

via the Pin 13 option. The blanking input pulse can

be generated from a vertical flyback pulse or by a microcon-

troller.

The LM2485 can operate with a V

CC

supply of up to 220V

and a V

BB

supply of either 8V or 12V. This V

BB

option,

selectable via the Pin 12 option, ensures the LM2485 is

compatible with any National Semiconductor DTV CRT

driver sharing the same operating voltages in the applica-

tion.

The IC is packaged in an industry standard 24-lead molded

plastic dual-in-line package to meet high voltage spacing

requirements.

Features

n

V

CC

capable of up to 220V

n

V

BB

selectable to 8V or 12V via Pin 12 option

n

Wide bias output voltage range of over 100V

n

Inverted output pulse suitable for G1 blanking,

selectable to 20V

P-P

or 40V

P-P

via Pin 13 option

Applications

n

AC coupled CRT applications using DTV formats up to

1080i

n

Well-matched to the NSC LM12XX Family of

Preamplifiers and LM242X/3X/5X Family of DTV CRT

Drivers

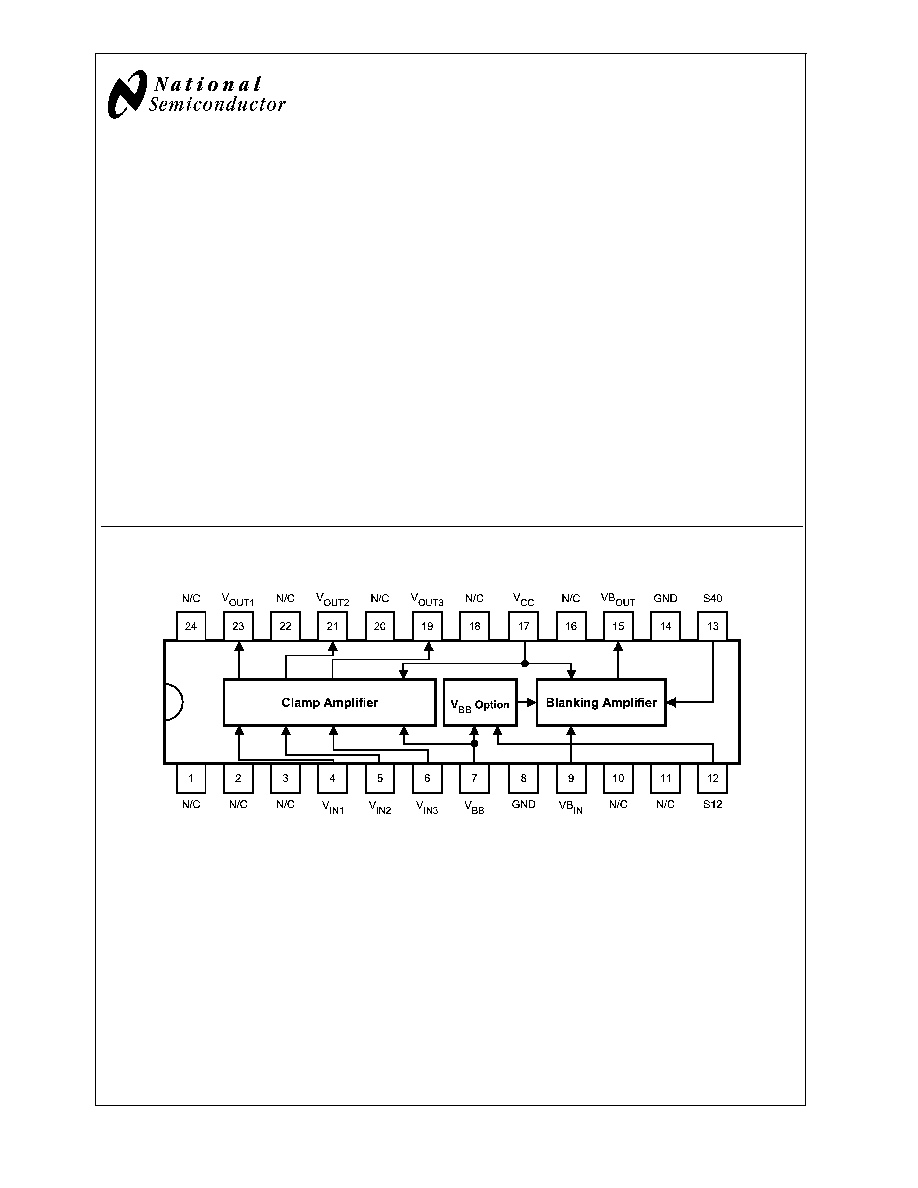

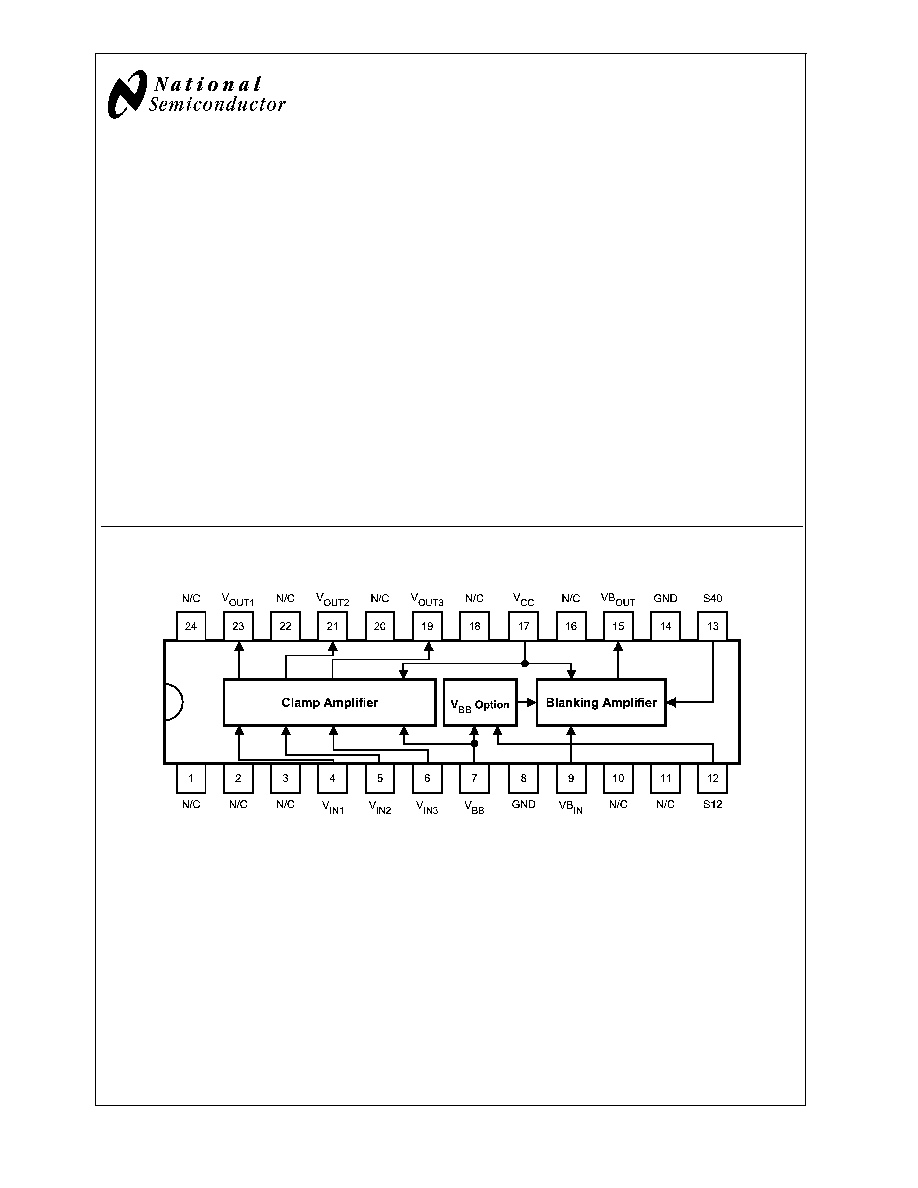

Pinout and Internal Block Diagram

20103433

FIGURE 1. Top View

Order Number LM2485NA

See NS Package Number N24C

December 2004

LM2485

220V

T

riple

Bias

Clamp

with

G1

Blank

Amplifier

© 2004 National Semiconductor Corporation

DS201034

www.national.com

Absolute Maximum Ratings

(Notes 1,

3)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage, V

CC

250V

Bias Voltage, V

BB

15V

Input Voltage, V

IN

-0.5V to +6.5V

Blanking Input Voltage, VB

IN

-0.5V to +6.5V

Storage Temperature Range, T

STG

-65∞C to +150∞C

Lead Temperature (Soldering,

<

10sec.)

300∞C

ESD Tolerance

Human Body Model

2 kV

Machine Model

200V

Max Junction Temperature

150∞C

JA

(Max at 0 LFPM)

68∞C/W

Operating Ranges

(Note 3)

V

CC

170V to 230V

V

BB

(Pin 12 floated)

7.5V to 8.5V

V

BB

(Pin 12 grounded)

11.5V to 12.5V

V

IN

0V to 5V

V

OUT

105V to 215V

VB

IN

0V to 5V

VB

OUT

(V

CC

= 220V)

40V to 80V

VB

OUT

(V

CC

= 180V)

25V to 65V

Ambient Temperature Range, T

A

-20∞C to T

AMAX

(Note 5)

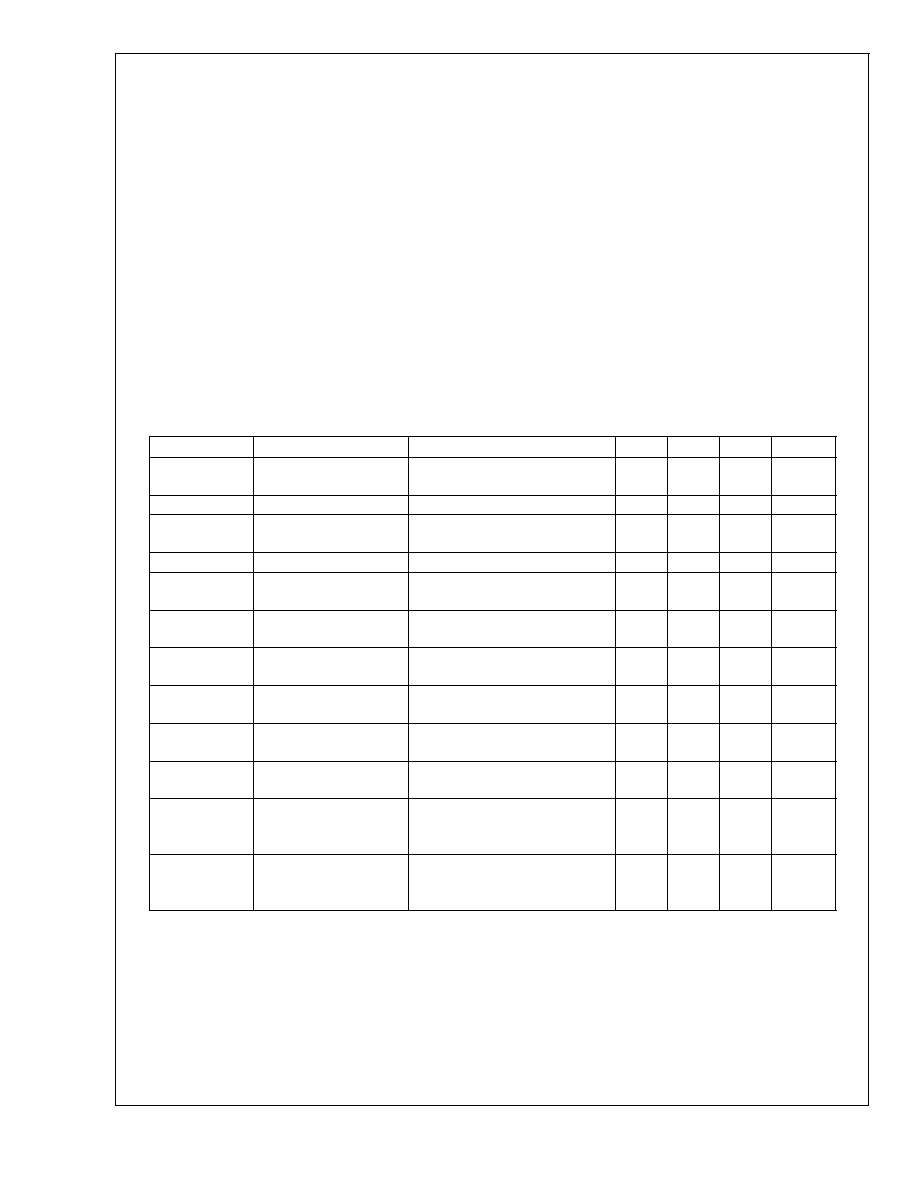

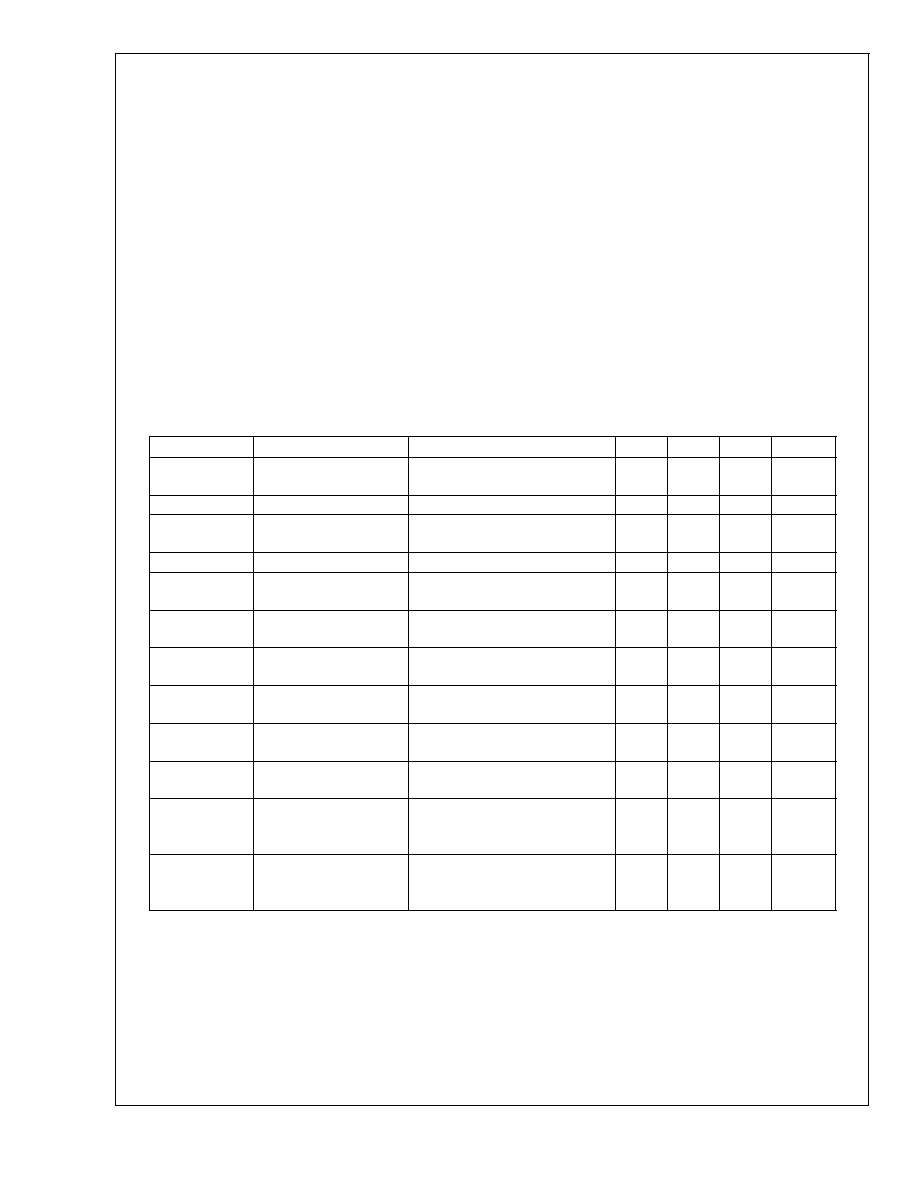

Electrical Characteristics

(See Figure 2 and Figure 3 for Test Circuits)

Unless otherwise noted: V

CC

= 220V, V

BB

= 8V, V

IN

= 2.5V

DC

, T

A

= 20∞C, Pin 12 floated, Pin 13 grounded.

Symbol

Parameter

Conditions

Min

Typ

Max

Units

I

CC

Supply Current

All channels, not including pull-up

resistor currents

3.1

4.2

mA

I

BB≠8

Bias Supply Current

All channels, V

BB

= 8V

6.0

10.0

mA

I

BB≠12

Bias Supply Current

All channels, Pin 12 grounded,

V

BB

= 12V

9.0

13.0

mA

V

OUT

Clamp Output Voltage

170

175

180

V

DC

V

OUT-Range

Clamp Output Voltage

Range

V

IN-Range

= 1.5V to 4.5V

75

V

A

V

Clamp Output DC Voltage

Gain

1.0V

V

IN

5.0V

≠23

≠25

≠27

V/V

LE

Clamp Output Linearity

Error

(Note 4)

5

%

VB

OUT-High

Blanking Output High

Level

VB

IN

0.5V

80

V

DC

VB

OUT-Low1

Blanking Output Low

Level 1

VB

IN

4.5V, Pin 13 floated

60

V

DC

VB

OUT-Low2

Blanking Output Low

Level 2

VB

IN

4.5V

40

V

DC

t

R

Blanking Output Rise

Time

VB

IN

= 0V≠5V Logic Pulse at 8.6%

duty cycle (480p), VB

OUT

= 40V

P-P

(40V-80V)

2.0

us

t

F

Blanking Output Fall Time VB

IN

= 0V≠5V Logic Pulse at 8.6%

duty cycle (480p), VB

OUT

= 40V

P-P

(40V-80V)

4.5

us

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.

Note 2: Operating Ratings indicate conditions for which the device is functional, but do not guarantee specific performance limits. For guaranteed specifications and

the test conditions, see the Electrical Characteristics. Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis. The guaranteed

specifications apply only for the test conditions listed. Some performance characteristics may change when the device is not operated under the listed test

conditions.

Note 3: All voltages are measured with respect to GND, unless otherwise specified.

Note 4: Linearity Error is the variation in DC gain from V

IN

= 1.0V to 5.0V measured at the points 1.0V, 1.5V, 4.5V, and 5.0V.

Note 5: See Section THERMAL CONSIDERATIONS to calculate T

AMAX

.

LM2485

www.national.com

2

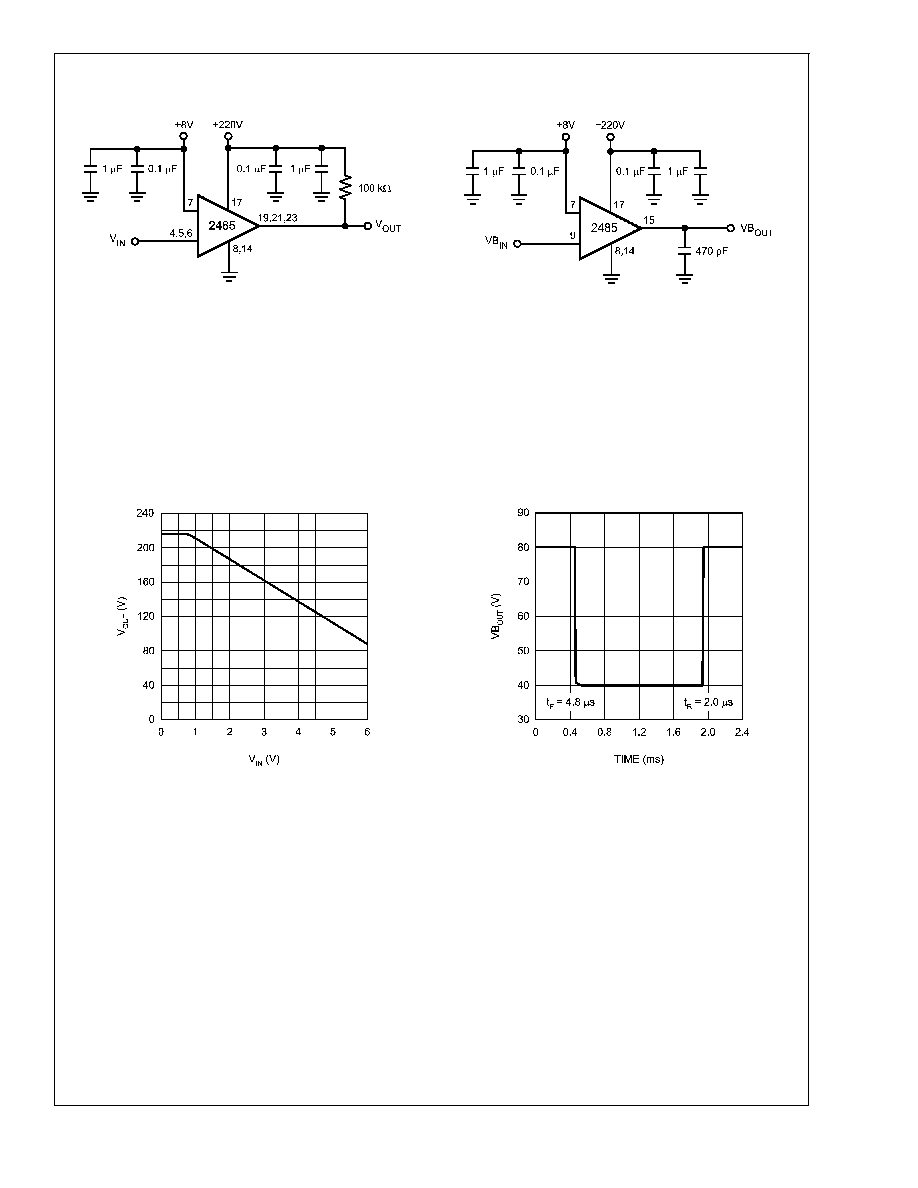

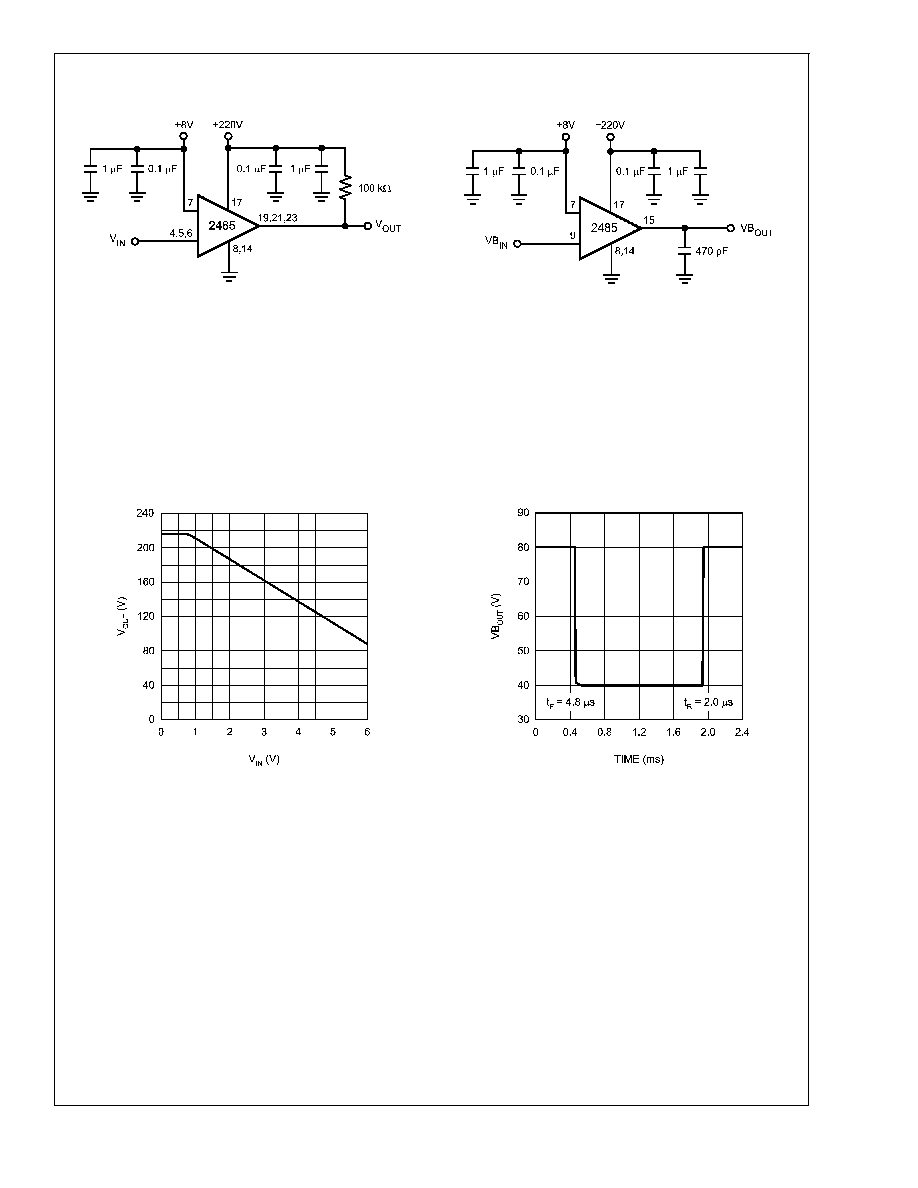

Test Circuits

Figure 2 shows the test circuit used to evaluate the LM2485 clamp amplifier. A high impedance voltmeter (

>

10M

) is used to

measure the DC voltages at the V

OUT

output pins. Figure 3 shows the test circuit used to evaluate the LM2485 blanking amplifier.

An oscilloscope and a scope probe are used to measure the pulse amplitude at the VB

OUT

output pin.

Typical Performance Characteristics

(V

CC

= 220V, V

BB

= 8V, VB

IN

= 0V≠5V Logic Pulse at 8.6% duty cycle, Pin 12 floated, Pin 13 grounded, Test Circuits - Figure 2

and Figure 3)

20103434

FIGURE 2. Clamp Amplifier Test Circuit

20103437

FIGURE 3. Blanking Amplifier Test Circuit

20103435

FIGURE 4. V

OUT

vs. V

IN

20103438

FIGURE 5. VB

OUT

(40V

P-P

)

LM2485

www.national.com

3

Theory of Operation

The pinout and internal block diagram of the LM2485 is

shown in Figure 1.

The LM2485 is a triple channel bias clamp amplifier used to

DC restore the AC coupled outputs of a DTV CRT driver and

for cut-off adjustment. The clamp circuit amplifies the DC

inputs, V

IN

, by the internally fixed gain of ≠25. Each DC

clamp output, V

OUT

, will require a pull-up resistor to V

CC

.

The clamp DC transfer function is shown in Figure 4.

The LM2485 also has an integrated blanking amplifier that

takes a positive-going 5V input pulse, VB

IN

, and outputs a

negative-going pulse, VB

OUT

, with a selectable amplitude of

either 20V

P-P

or 40V

P-P

via the Pin 13 (S40) option. If Pin 13

is floated, the VB

OUT

pulse amplitude is 20V

P-P

; if Pin 13 is

grounded, the amplitude is 40V

P-P

(see Figure 5). With a

simple clamp circuit, this inverted pulse can be used to drive

the G1 grid of a CRT negative to blank the horizontal retrace

lines during the vertical flyback period. The input pulse can

be generated from a vertical flyback pulse or by a microcon-

troller.

The LM2485 can operate with a V

CC

supply of up to 220V

and a selectable V

BB

supply of either 8V or 12V via the Pin

12 (S12) option. If Pin 12 is floated, then 8V is expected at

the V

BB

pin; if Pin 12 is grounded, then 12V is expected. This

V

BB

option ensures the LM2485 is compatible with any

National Semiconductor DTV CRT driver sharing the same

operating voltages in the application. Note that using a V

BB

supply of 12V will increase the input offset of the clamp

circuit, which would have the effect of shifting the DC trans-

fer function slightly to the right. Also, if the V

BB

option is

incorrectly matched to the actual V

BB

supply voltage, an

incorrect VB

OUT

amplitude will be produced. Therefore, it is

important to ensure that the appropriate V

BB

option is used

and the V

BB

supply is within the range stated in the Section

Operating Ranges .

Application Information

INTRODUCTION

National Semiconductor (NSC) is committed to provide ap-

plication information that assists our customers in obtaining

the best performance possible from our products. The fol-

lowing information is provided in order to support this com-

mitment. The reader should be aware that the optimization of

performance was done using a specific printed circuit board

designed at NSC. Variations in performance can be realized

due to physical changes in the printed circuit board and the

application. Therefore, the designer should know that com-

ponent value changes may be required in order to optimize

performance in a given application. The values shown in this

document can be used as a starting point for evaluation

purposes.

POWER SUPPLY BYPASS

The LM2485 should have proper power supply bypassing for

optimal arc protection and performance. A 0.1 µF capacitor

should be connected from each of the supply pins, V

CC

and

V

BB

, to ground, as close to the supply and ground pins as

possible. Additionally, a 1 µF electrolytic capacitor should be

connected from each supply to the LM2485 ground and

placed reasonably close to both supply pins.

ARC PROTECTION

During normal CRT operation, internal arcing may occasion-

ally occur. To protect the LM2485 against arcing, it is impor-

tant that the recommended applications circuit is used and

good layout practices are followed. Please refer to the Sec-

tion NSC Demonstration Board for a detailed example on arc

protection and PCB layout considerations.

THERMAL CONSIDERATIONS

Determining Maximum Power Dissipation and Ambient

Temperature

Power dissipation within an integrated circuit package is a

very important parameter. An incorrect maximum power dis-

sipation calculation may result in excessive thermal stress to

the device, affecting its reliability and performance. To esti-

mate the maximum power dissipation of the LM2485, the

following system parameters should be determined first.

∑

Maximum V

CC

and V

BB

supply voltages

∑

Average CRT cut-off voltages

∑

Maximum average beam currents

∑

Highest duty cycle

Once these parameters are known, the system designer can

then calculate the maximum ambient temperature surround-

ing the LM2485 without a heat sink. A small, low-cost heat

sink may be used if the calculated maximum ambient tem-

perature does not satisfy the worst-case operating tempera-

ture inside the TV.

The following example shows how to determine the maxi-

mum power dissipation and maximum ambient temperature

and assumes the recommended application circuit is used

(see Figure 6).

Example

The LM2485 uses 1.0W of static power from the 220V and

8V supplies, assuming the worst-case supply currents. If the

average CRT cut-off voltage of all channels is 180V and

each LM2485 output sinks a maximum average beam cur-

rent of 1.0 mA at 77% duty cycle (480p format) at the highest

brightness setting, the LM2485 will dissipate:

P

DISS

= P

STATIC

+ 3 x (V

CUT-OFF

x I

AVGMAX

) x

, or

P

DISS

= 1.0W + 3 x (180V x 1.0 mA) x 0.77 = 1.42W.

The maximum thermal resistance from junction-to-air,

JA

,

and maximum junction temperature, T

JMAX

, are stated in the

Section Absolute Maximum Ratings . Therefore, the maxi-

mum ambient temperature surrounding the LM2485 can be

calculated:

T

AMAX

= T

JMAX

- (P

DISS

x

JA

), or

T

AMAX

= 150∞C - (1.42W x 68∞C/W) = 53∞C.

TYPICAL APPLICATION

Used in conjunction with NSC's LM12XX Preamplifier and

LM24XX CRT Driver, a complete analog video solution from

the preamplifier input to the CRT cathode can be achieved.

The LM2485 can support any AC coupled DTV application

using formats up to 1080i with proper selection of a pream-

plifier and CRT drivers.

LM2485

www.national.com

4

NSC Demonstration Board

Figure 6 shows the recommended application schematic for

the NSC Demonstration Board that can be used to evaluate

the LM2423/LM2485 AC coupled solution in a Direct-View

CRT Digital TV application. Figure 7 shows the routing and

component placement on the NSC LM2423/LM2485 Dem-

onstration Board. This board provides a good example of a

PCB layout that was designed for robust arc protection and

optimal video performance.

PCB LAYOUT CONSIDERATIONS

Note that the NSC Demonstration Board complies with the

layout guidelines outlined below. For convenience, the com-

ponent names are shown in parenthesis to cross-reference

with the schematic and layout images provided.

Power Supplies and Grounds

∑

0.1uF bypass capacitors (C3 and C6) should be placed

very close to V

BB

and V

CC

of the LM2485. These capaci-

tors should have a short, direct return to the LM2485

ground.

∑

1uF electrolytic capacitors (C1 and C2) should also be

placed reasonably close to both supply pins.

∑

GND Pins 8 and 14 should connect to a solid ground

plane under the LM2485. The LM2485 ground plane

should connect directly to the CRT Driver ground at one

point (above C21). Do not connect the LM2485 ground

plane directly to CRT ground to protect the LM2485 from

arcing.

Inputs

∑

The LM2485 input traces should be routed away from all

output traces of the CRT Driver. This will help protect the

video preamplifier and LM2485 from high frequency,

large amplitude video coupling and potential damage

from arcing at the cathodes.

∑

If the LM2485 inputs are coming from the main board,

0.1uF capacitors (C4, C5, C7) should be placed at the

V

IN

pins of the input connector. If a LM12XX preamplifier

is placed on the neck board, these 0.1uF capacitors

should be placed very close to its DAC output pins to

protect it during arcing. In both cases, these capacitors

should be connected to the LM2485 ground and should

not be connected directly to CRT ground.

∑

1k

series resistors (R1, R3, R4) should be placed close

to the V

IN

pins and a small resistor may also be placed

close to the VB

IN

pin. These resistors will protect the

preamplifier in the event that the LM2485 fails.

Outputs

∑

1.5k

resistors (R6, R7, R8) and 0.1uF capacitors (C21,

C24, C25) should be placed near the V

OUT

pins to limit

the current and voltage surges on the outputs during an

arc event. These bypass capacitors should have a short,

direct return to the LM2485 ground.

∑

Because the clamp outputs carry DC, the clamp output

traces routed to each AC coupled video output can be

long. Avoid cutting a ground trace(s) simply to route

clamp output traces and use wire jumpers, if necessary.

∑

Clamp diodes (D3, D5, D6) and pull-up resistors (R20,

R23, R24) should be placed closest to the video output

traces to minimize the size of the video nodes and reduce

parasitic capacitance on the video outputs. The clamp

diodes must be 1SS83 or equivalent diodes; do not use

1N4148 type diodes. These diodes must have a fast

transient response, low shunt capacitance, low series

impedance, and a high peak current rating to clamp the

video output voltage to the V

CC

supply during an arc

event.

∑

0.1uF bypass capacitors (C46, C48, C9) should be

placed very close to the 1SS83 type arc protection diodes

(D1/D2, D4/D7, D8/D9) between V

CC

and ground. The

ground connection should have a short, direct path to

CRT ground. Therefore, arc currents shunted by the pro-

tection diodes can return to the CRT DAG (J6).

∑

300V spark gaps (S1, S2, S3, S4) are strongly recom-

mended and should be placed very close to the cathode

and G1 pins and grounded directly to the CRT ground

plane, so arc current can return to the nearby CRT DAG.

Spark gaps help to minimize voltage stress on the CRT

Driver and LM2485.

∑

If the G1 blanking feature is used, all G1 circuit compo-

nents should be placed as close as possible to the G1 pin

of the CRT connector, with the exception of a small

resistor (R2) placed close to the VB

OUT

pin to limit any

current toward the LM2485. The sequence of circuit com-

ponents from the VB

OUT

pin to the G1 pin is recom-

mended to protect the LM2485 against arcing. All these

components must be grounded directly to the CRT

ground plane. Therefore, arc currents can easily return to

the CRT DAG. Do not omit any of the components in the

G1 circuit as they are required to protect the LM2485

against arcing and for correct G1 blank operation.

∑

If the G1 blanking feature is not used, simply place a

470pF capacitor from the VB

OUT

pin to LM2485 ground

and do not connect the output to the G1 circuitry.

Pin Options and No Connects

∑

Depending on the pin options required, Pin 12 and Pin 13

can be connected to ground via a ground plane, trace, or

jumper wire. See the Section Theory of Operation to

determine the appropriate pin option for the application.

∑

The "No Connect" or N/C pins (pins 16, 18, 20, 22, 24)

are not connected to the die internally in order to achieve

larger spacing between the high voltage V

CC

and V

OUT

pins. These N/C pins should not be used to route other

traces through.

LM2485

www.national.com

5