| ÐлекÑÑоннÑй компоненÑ: LM2647 | СкаÑаÑÑ:  PDF PDF  ZIP ZIP |

Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

LM2647

Dual Synchronous Buck Regulator Controller

General Description

The LM2647 is an adjustable 200-500kHz dual channel

voltage-mode controlled high-speed synchronous buck

regulator controller ideally suited for battery powered appli-

cations such as laptop and notebook computers. The

LM2647 requires only N-channel FETs for both the upper

and lower positions of each synchronous stage. It features

line feedforward to improve the response to input transients.

At very light loads, the user can choose between the high-

efficiency Pulse-skip mode or the constant frequency

Forced-PWM mode. Lossless current limiting without the use

of external sense resistors is made possible by sensing the

voltage drop across the bottom FET. A unique adaptive duty

cycle clamping technique is incorporated to significantly re-

duce peak currents under abnormal load conditions. The two

independently programmable outputs switch 180° out of

phase (interleaved switching) to reduce the input capacitor

and filter requirements. The input voltage range is 5.5V to

28V while the output voltages are adjustable down to 0.6V.

Standard supervisory and control features include Soft-start,

Power Good, output Under-voltage and Over-voltage protec-

tion, Under-voltage Lockout, Soft-shutdown and Enable.

Features

n

Input voltage range from 5.5V to 28V

n

Synchronous dual-channel Interleaved switching

n

Forced-PWM or Pulse-skip modes

n

Lossless bottom-side FET current sensing

n

Adaptive duty cycle clamping

n

High current N-channel FET drivers

n

Low shutdown supply currents

n

Reference voltage accurate to within

±

1.5%

n

Output voltage adjustable down to 0.6V

n

Power Good flag and Chip Enable

n

Under-voltage lockout

n

Over-voltage/Under-voltage protection

n

Soft-start and Soft-shutdown

n

Switching frequency adjustable 200kHz-500kHz

Applications

n

Notebook Chipset Power Supplies

n

Low Output Voltage High-Efficiency Buck Regulators

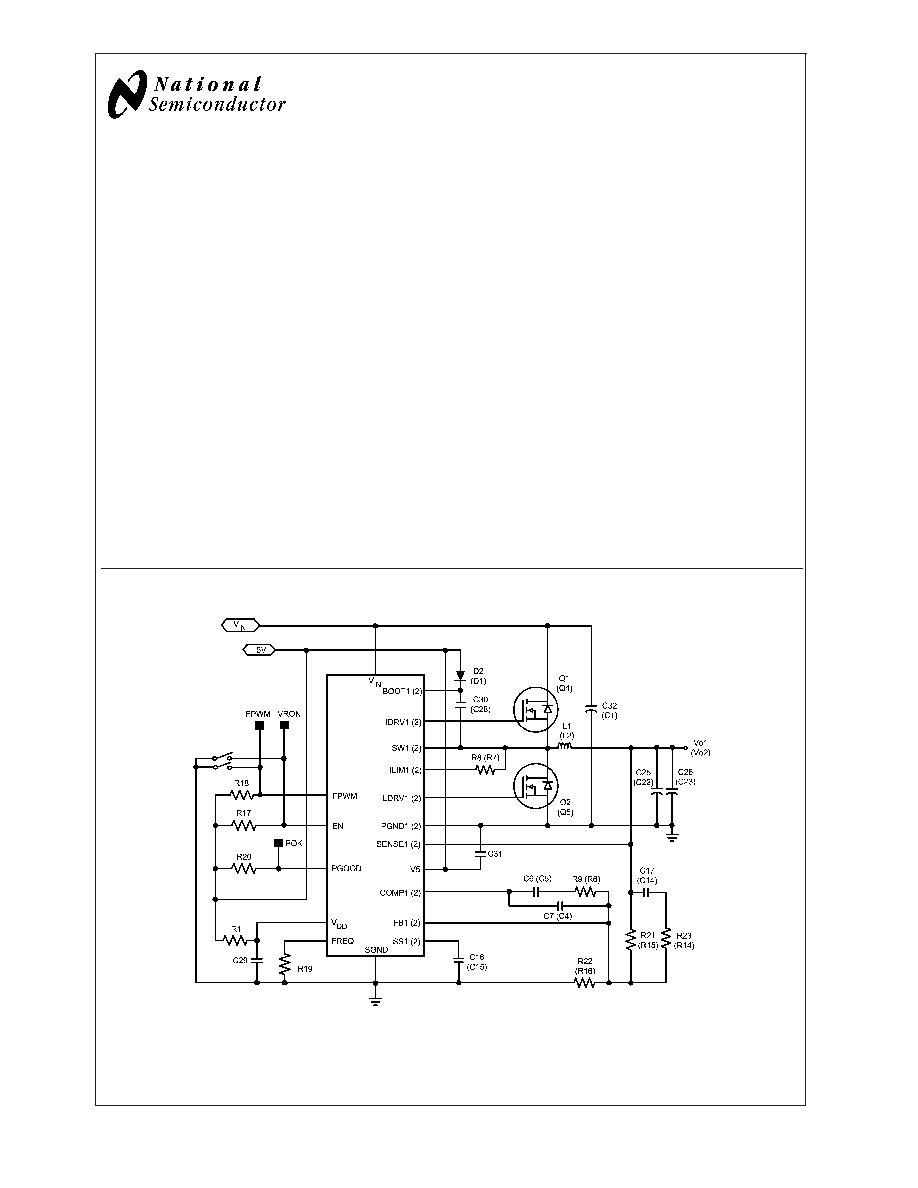

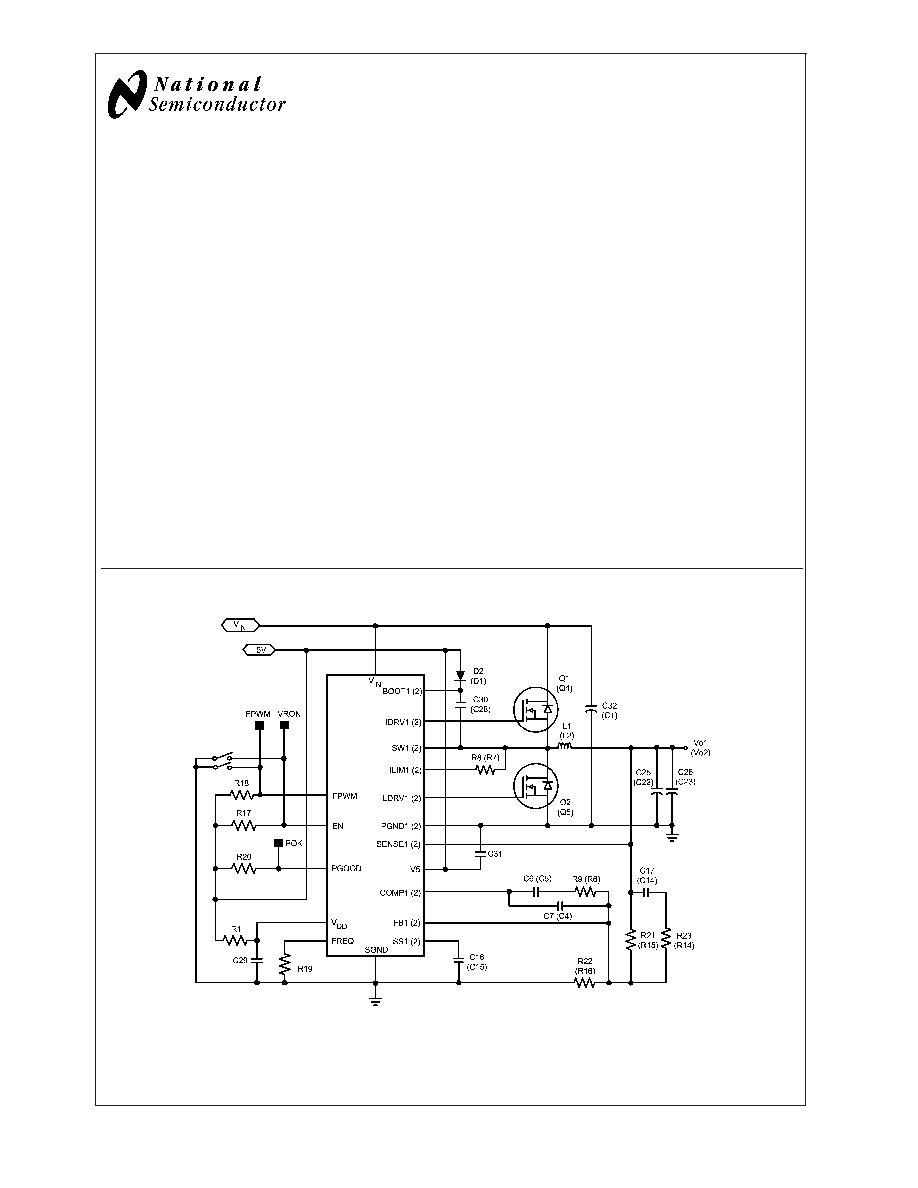

Typical Application (Channel 2 in parenthesis)

20056304

June 2003

Dual

Synchronous

Buck

Regulator

Controller

© 2003 National Semiconductor Corporation

DS200563

www.national.com

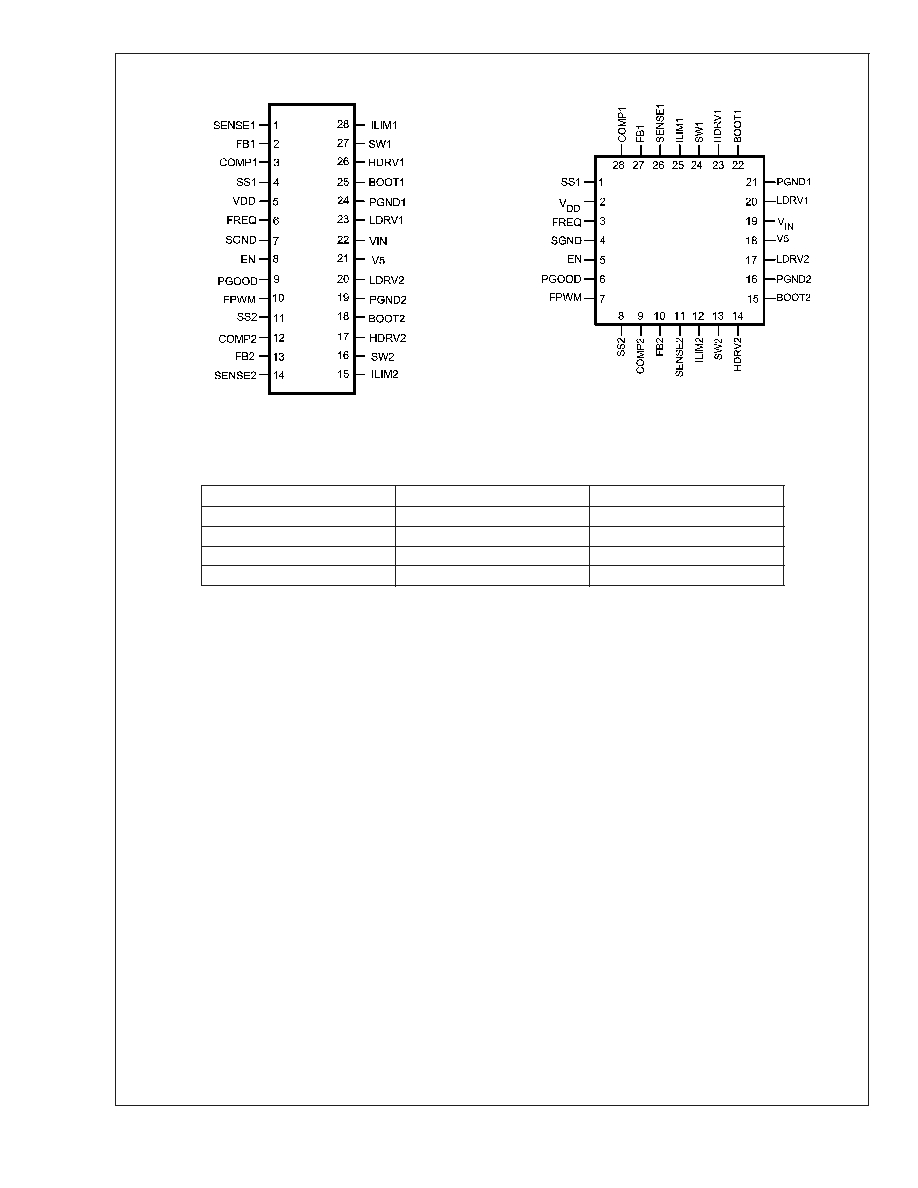

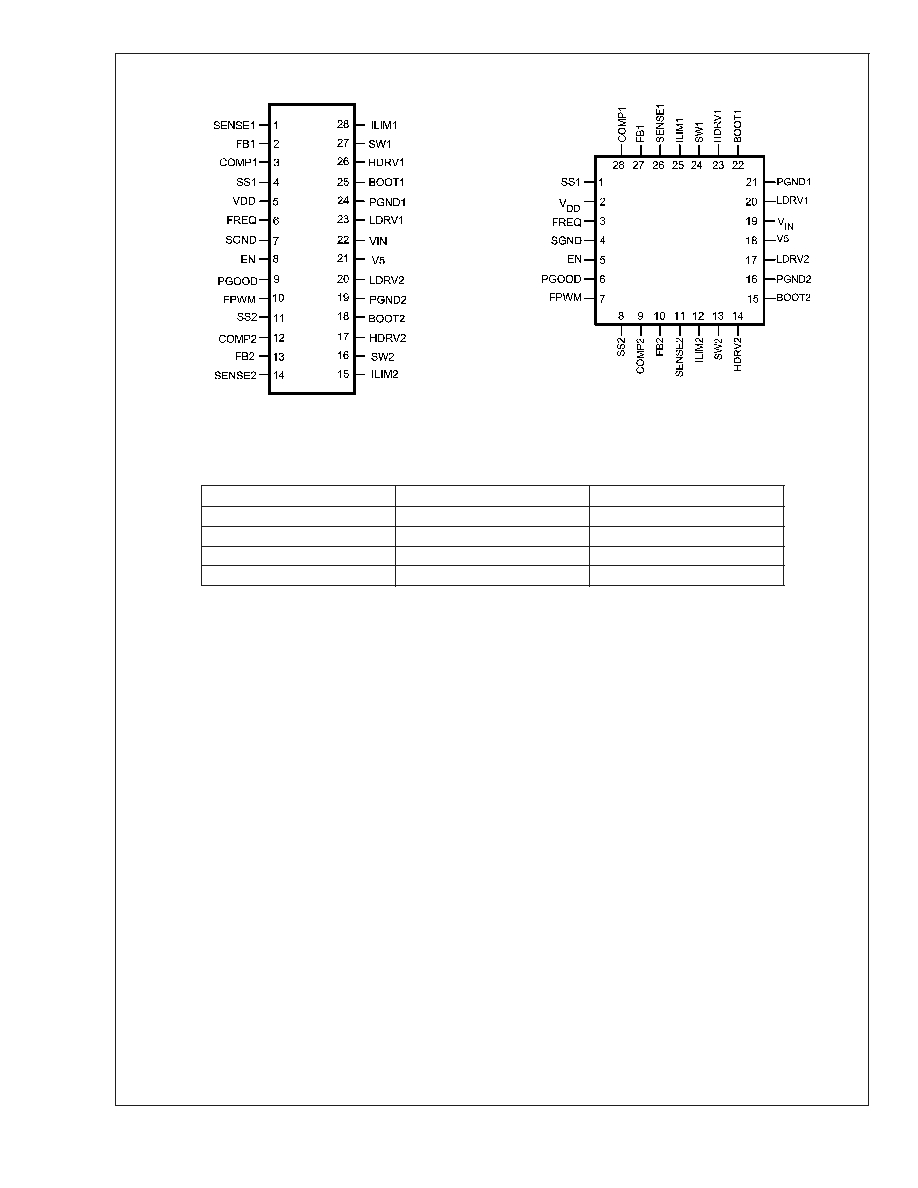

Connection Diagrams

20056302

Top View

28-Lead TSSOP (MTC)

20056303

Top View

28-Lead LLP (LQA)

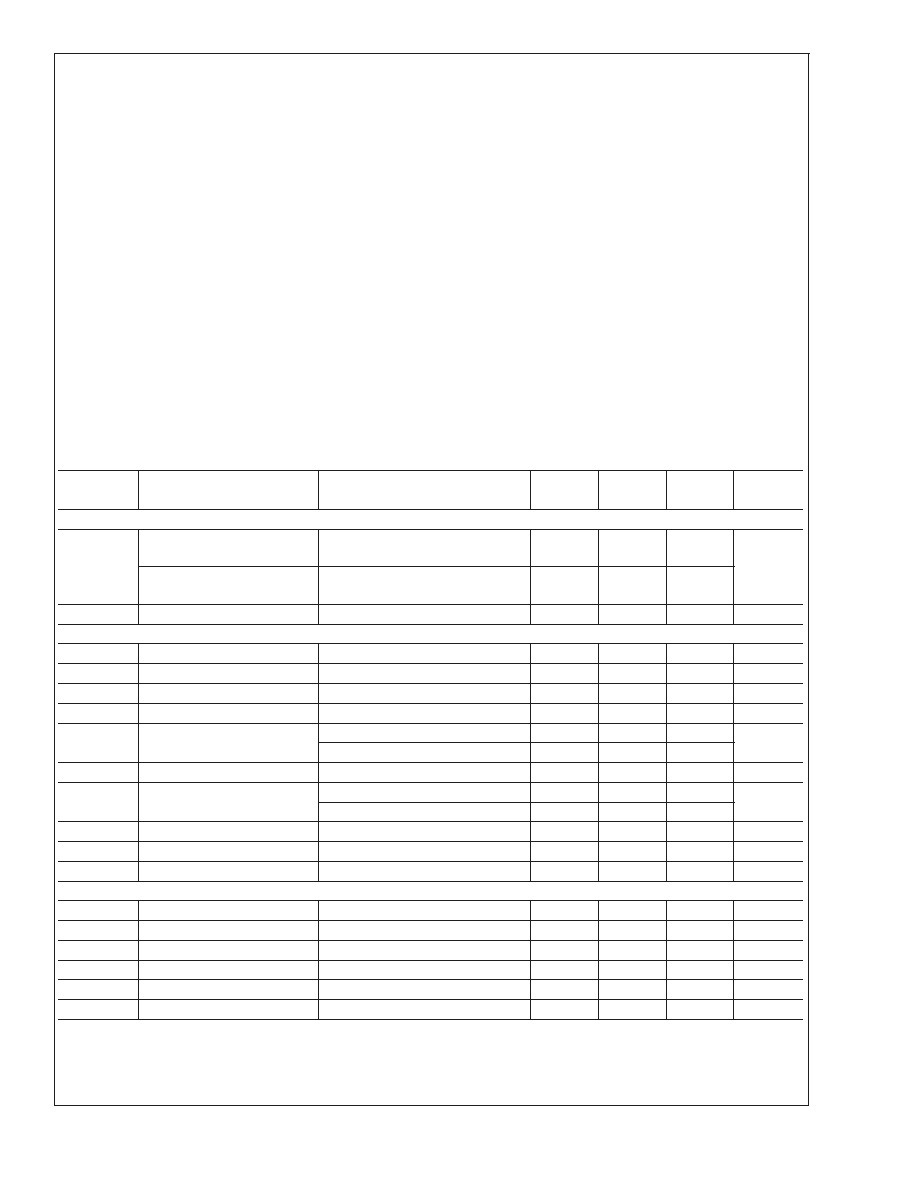

Ordering Information

Order Number

Package Drawing

Supplied As

LM2647MTC

MTC28

48 Units/Rail

LM2647MTCX

MTC28

2500 Units/13" Reel

LM2647LQ

LQA28A

1000 Units/7" Reel

LM2647LQX

LQA28A

4500 Units/13" Reel

Pin Description

(All pin numbers referred to here correspond to the TSSOP

package)

Pin 1, SENSE1: Output voltage sense pin for Channel 1. It is

tied directly to the output rail. The SENSE pin voltage is used

together with the VIN voltage (on Pin 22) to (internally)

calculate the CCM (continuous conduction mode) duty cycle.

This calculation is used by the IC to set the minimum duty

cycle in the SKIP mode to 85% of the CCM value. It is also

used to set the adaptive duty cycle clamp (see Pin 3). An

internal 20

resistor from the SENSE pin to ground dis-

charges the output capacitor gently (Soft-shutdown) when-

ever Power Not Good is signaled on Pin 9.

Pin 2, FB1: Feedback pin for Channel 1. This is the inverting

input of the error amplifier. The voltage on this pin under

regulation is nominally at 0.6V. A Power Good window on this

pin determines if the output voltage is within regulation limits

(

±

13%). If the voltage (on either channel) falls outside this

window for more than 7µs, Power Not Good is signaled on

the PGOOD pin (Pin 9). Output over-voltage and under-

voltage conditions are also detected by comparing the volt-

age on the Feedback pin with appropriate internal reference

voltage levels. If the voltage exceeds the safe window

(

±

30%) for longer than 7µs, a fault condition is asserted.

Then both the lower FETs are latched ON and the upper

FETs are latched OFF. When single channel operation is

desired, the Feedback pins of both channels should be

connected together, near the IC. All other pins specific to the

unused channel should be left floating (not connected to

each other either).

Pin 3, COMP1: Compensation pin for Channel 1. This is also

the output of the error amplifier of this channel. The voltage

level on this pin is compared with an internally generated

ramp signal to set the duty cycle for normal regulation. Since

the Feedback pin is the inverting input of the same error

amplifier, appropriate control loop compensation compo-

nents are placed between this pin and the Feedback pin.

The COMP pin is internally pulled low during Soft-start so as

to limit the duty cycle. Once Soft-start is completed, the

voltage on this pin can take up the value required to maintain

output regulation. But an internal voltage clamp does not

allow the pin to go much higher than the steady-state re-

quirement. This forms the adaptive duty cycle clamp feature

which serves to limit the maximum allowable duty cycle and

peak currents under sudden overloads. But at the same time

it has enough headroom to permit an adequate response to

step loads within the normal operating range.

Pin 4, SS1: Channel 1 Soft-start pin. A Soft-start capacitor is

placed between this pin and ground. A typical capacitance of

0.1µF is always recommended between this pin and ground.

The IC connects an internal 1.8 k

resistor (R

SS_DCHG

, see

Electrical Characteristics table) between this pin and ground

to discharge any remaining charge on the Soft-start capaci-

tor under several conditions. These conditions include the

initial power-up sequence, start-up by toggling the EN pin,

and also recovery from a fault condition. The purpose is to

bring down the voltage on both the Soft-start pins to below

100mV for obtaining reset. Reset having thus been obtained,

an 11µA current source at this pin charges up the Soft-start

capacitor. The voltage on this pin controls the maximum duty

cycle, and this produces a gradual ramp-up of the output

voltage, thereby preventing large inrush currents into the

LM2647

www.national.com

2

Pin Description

(Continued)

output capacitors. The voltage on this pin finally clamps

close to 5V. This pin is again connected to the internal 115µA

current sink whenever a current limit event is in progress.

This sink current discharges the Soft-start capacitor and

forces the duty cycle low to protect the power components.

When a fault condition is asserted (See Pin 2) the SS pin is

internally connected to ground via the 1.8 k

resistor.

Pin 5, VDD: 5V supply rail for the control and logic sections

of both channels. For normal operation to start, the voltage

on this pin must be brought above 4.5V. Subsequently, the

voltage on this pin (including any ripple component) should

not allowed to fall below 4V for a duration longer than 7µs.

Since this pin is also the supply rail for the internal control

sections, it should be well-decoupled particularly at high

frequencies. A minimum 0.1µF-0.47µF (ceramic) capacitor

should be placed on the component side very close to the IC

with no intervening vias between this capacitor and the

VDD/SGND pins. If the voltage on Pin 5 falls below the lower

UVLO threshold, both upper FETs are latched OFF and

lower FETs latched ON. Power Not Good is then also sig-

naled immediately (on Pin 9). To effect recovery, the EN pin

must be taken below 0.8V and then back above 2V (with

VDD held above 4.5V). Or the voltage on the VDD pin must

be taken below 1.0V and then back again above 4.5V (with

EN pin held above 2V). Normal operation will then resume

assuming that the fault condition has cleared.

Pin 6, FREQ: Frequency adjust pin. The switching frequency

(for both channels) is set by a resistor connected between

this pin and ground. A value of 22.1k

sets the frequency to

300kHz (nominal). If the resistance is increased, the switch-

ing frequency falls. An approximate relationship is that for

every 7.3k

increase (or decrease) in the value of the fre-

quency adjust resistance, the time period (1/f) increases (or

decreases) by about 1µs.

Pin 7, SGND: Signal Ground pin. This is the lower rail for the

control and logic sections of both channels. SGND should be

connected on the PCB to the system ground, which in turn is

connected to PGND1 and PGND2. The layout is important

and the recommendations in the section Layout Guidelines

should be followed.

Pin 8, EN: IC Enable pin. When EN is taken high, both

channels are enabled by means of a Soft-start power-up

sequence (see Pin 4). When EN is brought low, Power Not

Good is signaled within 100ns. This causes Soft-shutdown to

occur (see Pins 1 and 9). The Soft-start capacitor is then

discharged by an internal 1.8k

resistor (R

SS_DCHG

, see

Electrical Characteristics table). But note that when the En-

able pin is toggled, a fault condition is not asserted. There-

fore in this case, the lower FETs are not latched ON, even as

the output voltage ramps down, eventually falling below the

under-voltage threshold. In fact, in this situation, both the

upper and the lower FETs of the two channels are latched

OFF, until the Enable pin is taken high again. If a fault

shutdown has occurred, taking the Enable pin low and then

high again (toggling), resets the internal latches, and the IC

will resume normal switching operation.

Pin 9, PGOOD: Power Good output pin. An open-Drain logic

output that is pulled high with an external pull-up resistor,

indicating that both output voltages are within a pre-defined

Power Good window. Outside this window, the pin is inter-

nally pulled low (Power Not Good signaled) provided the

output error lasts for more than 7µs. But the pin is also pulled

low within 100ns of the Enable pin being taken low, irrespec-

tive of the output voltage level. Note that PGOOD must

always be high before it can respond by going low. So

regulation on both channels must be achieved first. Further,

for fault monitoring to be in place, PGOOD must have been

high prior to occurrence of the fault condition. Note that since

under a fault assertion, the lower FETs are always latched

ON, this will not happen if regulation has not been already

been achieved first. For correct signaling on this pin under

single-channel operation, see description of Pin 2.

Pin 10, FPWM: Logic input for selecting either the Forced

PWM (FPWM) Mode or Pulse-skip Mode (SKIP) for both

channels (together). When the pin is driven high, the IC

operates in the FPWM mode, and when pulled low or left

floating, the SKIP mode is enabled. In FPWM mode, the

lower FET of a given channel is always ON whenever the

upper FET is OFF (except for a narrow shoot-through pro-

tection deadband). This leads to continuous conduction

mode of operation, which has a fixed frequency and (almost)

fixed duty cycle down to very light loads. But this does

reduce efficiency at light loads. The alternative is the SKIP

mode, where the lower FET remains ON only until the volt-

age on the Switch pin (see Pin 27 or Pin 16) is more negative

than 2.2mV (typical). So for example, for a 21m

FET, this

translates to a current threshold of 2.2mV/21m

= 0.1A.

Therefore, if the (instantaneous) inductor current falls below

this value, the lower FET will turn OFF every cycle at this

point (when operated in SKIP mode). This threshold is set by

the zero-cross Comparator in the Block Diagram. Note that if

the inductor current waveform is high enough to be always

above this zero-cross threshold (V

SW_ZERO

, see Table of

Electrical Characteristics), there will be no observable differ-

ence between FPWM and SKIP mode settings (in steady-

state). SKIP mode, when it actually occurs, is clearly a

discontinuous mode of operation. However, note that in con-

ventional discontinuous mode, the duty cycle keeps falling

(towards zero) as the load decreases. But the LM2647 does

not allow the duty cycle to fall by more than 15% of its

original value (at the CCM-DCM boundary). This forces

pulse-skipping, and the average frequency is effectively de-

creased as the load decreases. This mode of operation

improves efficiency at light loads, but the frequency is effec-

tively no longer a constant. Note that a minimum pre-load of

0.1mA should be maintained on the output of each channel

to ensure regulation in SKIP mode. The resistive divider from

output to ground used to set the output voltage could be

designed to serve as part or all of this required pre-load.

Pin 11, SS2: Soft-start pin for Channel 2. See Pin 4.

Pin 12, COMP2: Soft-start pin for Channel 2. See Pin 3.

Pin 13, FB2: Feedback pin for Channel 2. See Pin 2.

Pin 14, SENSE2: Output voltage sense pin for Channel 2.

See Pin 1.

Pin 15, ILIM2: Channel 2 Current Limit pin. When the bottom

FET is ON, a 62µA (typical) current flows out of this pin into

an external current limit setting resistor connected to the

Drain of the lower FET. This is a current source, therefore the

drop across this resistor serves to push the voltage on this

pin to a more positive value. However, the Drain of the lower

FET which is connected to the other side of the same

resistor is trying to go more negative as the load current

increases. At some value of instantaneous current, the volt-

age on this pin will transit from positive to negative. The point

where it is zero is the current limiting condition and is de-

tected by the Current Limit Comparator in the Block Dia-

gram. When current limit condition has been detected, the

next ON-pulse of the upper FET will be omitted. The lower

FET will again be monitored to determine if the current has

fallen below the threshold. If it has, the next ON-pulse will be

LM2647

www.national.com

3

Pin Description

(Continued)

permitted. If not, the upper FET will be turned OFF and will

stay so for several cycles if necessary, until the current

returns to normal. Eventually, if the overcurrent condition

persists, and the upper FET has not been turned ON, the

output will clearly start to fall. Ultimately the output will fall

below the under-voltage threshold, and a fault condition will

be asserted by the IC.

Pin 16, SW2: The Switching node of the buck regulator of

Channel 2. Also serves as the lower rail of the floating driver

of the upper FET.

Pin 17, HDRV2: Gate drive pin for the upper FET of Channel

2 (High-side drive). The top gate driver is interlocked with the

bottom

gate

driver

to

prevent

shoot-through/cross-

conduction.

Pin 18, BOOT2: Bootstrap pin for Channel 2. This is the

upper supply rail for the floating driver of the upper FET. It is

bootstrapped by means of a ceramic capacitor connected to

the channel Switching node. This capacitor is charged up by

the IC to a value of about 5V as derived from the V5 pin (Pin

21).

Pin 19, PGND2: Power Ground pin of Channel 2. This is the

return path for the bottom FET gate drive. Both the PGND's

are to be connected on the PCB to the system ground and

also to the Signal ground (Pin 7) in accordance with the

recommended Layout Guidelines .

Pin 20, LDRV2: Gate drive pin for the Channel 2 bottom FET

(Low-side drive). The bottom gate driver is interlocked with

the

top

gate

driver

to

prevent

shoot-through/cross-

conduction. It is always latched high when a fault condition is

asserted by the IC.

Pin 21, V5: Upper rail of the lower FET drivers of both

channels. Also used to charge up the bootstrap capacitors of

the upper FET drivers. This is connected to an external 5V

supply. The 5V rail may be the same as the rail used to

provide power to the VDD pin (Pin 5), but the VDD pin will

then require to be well-decoupled so that it does not interact

with the V5 pin. A low-pass RC filter consisting of a ceramic

0.1µF capacitor (preferably 0.22µF) and a 10

resistor will

suffice as shown in the Typical Applications circuit.

Pin 22, VIN: The input to both the Buck regulator power

stages. It also is used by the internal ramp generator to

implement the line feedforward feature. The VIN pin is also

used with the SENSE pin voltage to predict the CCM (con-

tinuous conduction mode) duty cycle and to thereby set the

minimum allowed DCM duty cycle to 85% of the CCM value

(in SKIP mode, see Pin 10). This is a high input impedance

pin, drawing only about 100µA (typical) from the input rail.

Pin 23, LDRV1: LDRV pin of Channel 1. See Pin 20.

Pin 24, PGND1: PGND pin for Channel 1.See Pin 19.

Pin 25, BOOT1: Boot pin of Channel 1. See Pin 18.

Pin 26, HDRV1: HDRV pin of Channel 1. See Pin 17.

Pin 27, SW1: SW pin of Channel 1. See Pin 16.

Pin 28, ILIM1: Channel 2 Current Limit pin. See Pin 15.

LM2647

www.national.com

4

Absolute Maximum Ratings

(Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Voltages from the indicated pins to SGND/PGND unless

otherwise indicated (Note 2):

VIN

30V

V5

7V

VDD

7V

BOOT1, BOOT2

36V

BOOT1 to SW1, BOOT2 to

SW2

7V

SW1, SW2

30V

ILIM1, ILIM2

30V

SENSE1, SENSE2, FB1, FB2

7V

PGOOD

7V

EN

7V

Power Dissipation (T

A

= 25°C)

(Note 3)

1.0W

Junction Temperature

+150°C

ESD Rating (Note 4)

2kV

Ambient Storage Temperature

Range

-65°C to +150°C

Soldering Dwell Time,

Temperature

Wave

Infrared

Vapor Phase

4 sec, 260°C

10 sec, 240°C

75 sec, 219°C

Operating Ratings

(Note 1)

VIN

5.5V to 28V

VDD, V5

4.5V to 5.5V

Junction Temperature

-5°C to +125°C

Electrical Characteristics

Specifications with standard typeface are for T

J

= 25°C, and those with boldface apply over full Operating Junction Tempera-

ture range. VDD = V5 = 5V, V

SGND

= V

PGND

= 0V, VIN = 15V, V

EN

= 3V, R

FADJ

= 22.1K unless otherwise stated. (Note 5)

Symbol

Parameter

Conditions

Min

(Note 6)

Typical

(Note 7)

Max

(Note 6)

Units

Reference

V

FB_REG

FB Pin Voltage at Regualtion

(either FB Pin)

VDD = 4.5V to 5.5V,

VIN = 5.5V to 28V

591

600

609

mV

V

FB

Line Regulation

VDD = 4.5V to 5.5V,

VIN = 5.5V to 28V

0.5

I

FB

FB Pin Current (sourcing)

V

FB

at regulation

20

100

nA

Chip Supply

I

Q_VIN

VIN Quiescent Current

V

FB1

= V

FB2

= 0.7V

100

200

µA

I

SD_VN

VIN Shutdown Current

V

EN

= 0V

0

5

µA

I

Q_VDD

VDD Quiescent Current

V

FB1

= V

FB2

= 0.7V

2.5

4

mA

I

SD_VDD

VDD Shutdown Current

V

EN

= 0V

8

15

µA

I

Q_V5

V5 Normal Operating Current

V

FB1

= V

FB2

= 0.7V

0.3

0.5

mA

V

FB1

= V

FB2

= 0.5V

1

1.5

I

SD_V5

V5 Shutdown Current

V

EN

= 0V

0

5

µA

I

Q_BOOT

BOOT Quiescent Current

V

FB1

= V

FB2

= 0.7V

2

5

µA

V

FB1

= V

FB2

= 0.5V

300

500

I

SD_BOOT

BOOT Shutdown Current

V

EN

= 0V

1

5

µA

V

UVLO

VDD UVLO Threshold

VDD rising from 0V

3.9

4.2

4.5

V

VDD UVLO Hysteresis

VDD = V5 falling from V

UVLO

0.5

0.7

0.9

V

Logic

I

EN

EN Input Current

V

EN

= 0 to 5V

0

µA

V

EN_HI

EN Input Logic High

2

1.8

V

V

EN_LO

EN Input Logic Low

1.3

0.8

V

FPWM Pull-down

V

FPWM

= 2V

100

200

1000

k

V

FPWM_HI

FPWM Input Logic High

2

1.8

V

VFPWM_LO

FPWM Input Logic Low

1.3

0.8

V

LM2647

www.national.com

5

Document Outline