| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: HDSP2113S | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

2000 Infineon Technologies Corp. ∑ Optoelectronics Division ∑ San Jose, CA

www.infineon.com/opto ∑ 1-888-Infineon (1-888-463-4636)

OSRAM Opto Semiconductors GmbH & Co. OHG ∑ Regensburg, Germany

www.osram-os.com ∑ +49-941-202-7178

1

March 24, 2000-13

FEATURES

∑ Eight 0.200" Dot Matrix Characters in Red, Yellow,

High Efficiency Red, Green, High Efficiency Green,

or Soft Orange

∑ Built-in 128 Character ROM,

Mask Programmable for Custom Fonts

∑ Readable from 8 Feet (2.5 meters)

∑ Built-in Decoders, Multiplexers and Drivers

∑ Wide Viewing Angle, X Axis ±55

∞

, Y Axis ±65

∞

∑ Programmable Features:

≠ Individual Flashing Character

≠ Full Display Blinking

≠ Multi-Level Dimming and Blanking

≠ Clear Function

≠ Self Test

∑ Internal or External Clock

∑ End Stackable Dual-In-Line Plastic Package

∑ Read/Write Capability

∑ 16 User Definable Characters

DESCRIPTION

The HDSP2110S (Red), HDSP2111S (Yellow), HDSP2112S (High Effi-

ciency Red), HDSP2113S (Green), HDSP2114S (High Efficiency

Green), and HDSP2115S (Soft Orange) are eight digit, 5 x 7 dot matrix,

alphanumeric Intelligent Display devices. The 0.20 inch high digits are

packaged in a rugged, high quality, optically transparent, 0.6 inch lead

spacing, 28 pin plastic DIP.

The on-board CMOS has a built-in 128 character ROM. The

HDSP211XS also has a user definable character (UDC) feature, which

uses a RAM that permits storage of 16 arbitrary characters, symbols

or icons that are software-definable by the user. The character ROM

itself is mask programmable and easily modified by the manufacturer

to provide specified custom characters.

The HDSP211XS is designed for standard microprocessor interface

techniques, and is fully TTL compatible. The Clock I/O and Clock

Select pins allow the user to cascade multiple display modules.

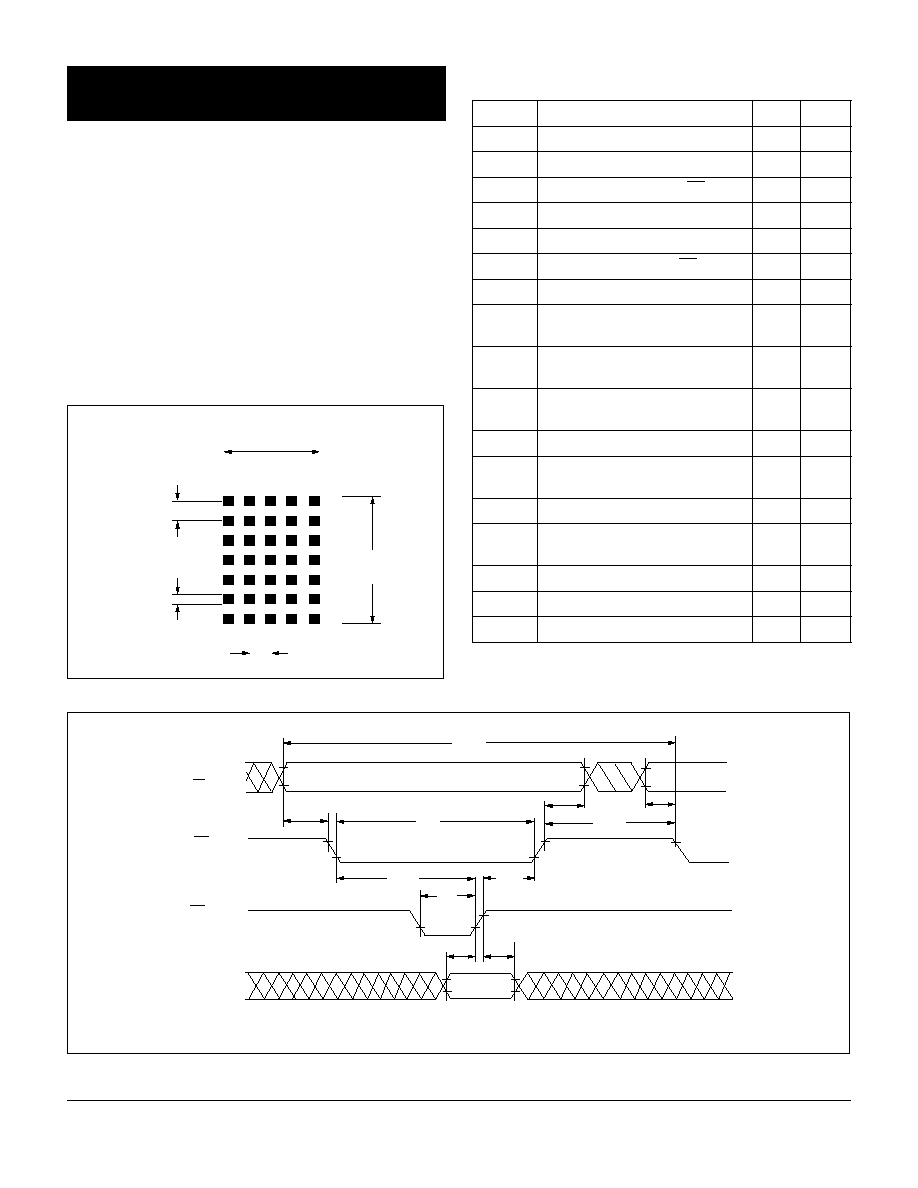

1.680 (42.67) max.

0.210

(5.34)

0.105

(2.67)

0.386

(9.8)

0.771

(19.58)

0.600

(15.24)

0.086

(2.19)

0.012 (0.30) typ.

0.100

(2.54) typ.

0.018 typ.

(.46)

0.160

±

.020

(4.06

±

.50)

0.209 (5.31)

HDSP211X

OSRAM

WW

Z

1

Part Number

Pin 1 Indicator

EIA Date

Code

Intensity Code

Color Bin

(For Yellow Only)

0.189

(4.81)

0.189

(4.79)

Dimensions in inches (mm)

RED

HDSP2110S

YELLOW

HDSP2111S

HIGH EFFICIENCY RED

HDSP2112S

GREEN

HDSP2113S

HIGH EFFICIENCY GREEN

HDSP2114S

SOFT ORANGE

HDSP2115S

0.200" 8-Character 5x7 Dot Matrix Parallel Input

Alphanumeric Intelligent Display

Æ

Devices

2000 Infineon Technologies Corp. ∑ Optoelectronics Division ∑ San Jose, CA

HDSP2110S/1S/2S/3S/4S/5S

www.infineon.com/opto ∑ 1-888-Infineon (1-888-463-4636)

OSRAM Opto Semiconductors GmbH & Co. OHG ∑ Regensburg, Germany

www.osram-os.com ∑ +49-941-202-7178

2

March 24, 2000-13

Maximum Ratings

(

T

A

=25

∞

C)

DC Supply Voltage,

V

CC

to GND

(max. voltage with no LEDs on) ...................≠0.3 to +7.0 VDC

Input Voltage Levels,

All Inputs ....................................................... ≠0.3 to

V

CC

+0.3

Operating Temperature ....................................... ≠40

∞

C to 85

∞

C

Storage Temperature ......................................... ≠40

∞

C to 100

∞

C

Relative Humidity (non-condensing) ....................................85%

Operating Voltage,

V

CC

to GND

(Max. voltage with 20 dots/digits on).............................. 5.5 V

Maximum Solder Temperature

(0.063" below seating plane, t<5.0 s)............................ 260

∞

C

ESD Protection at 1.5 k

,

100 pF .....................................................V

Z

=4.0 kV (each pin)

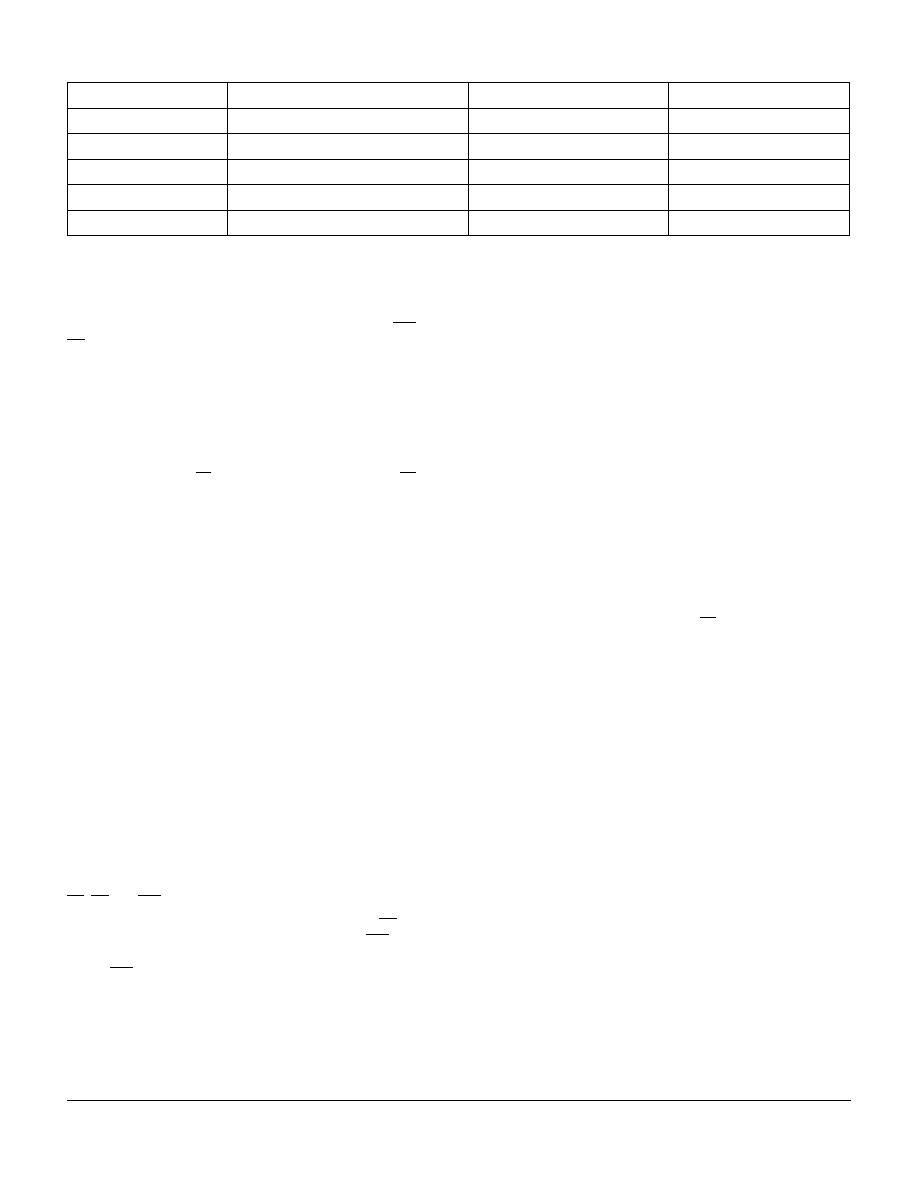

Figure 1. Enlarged Character Font

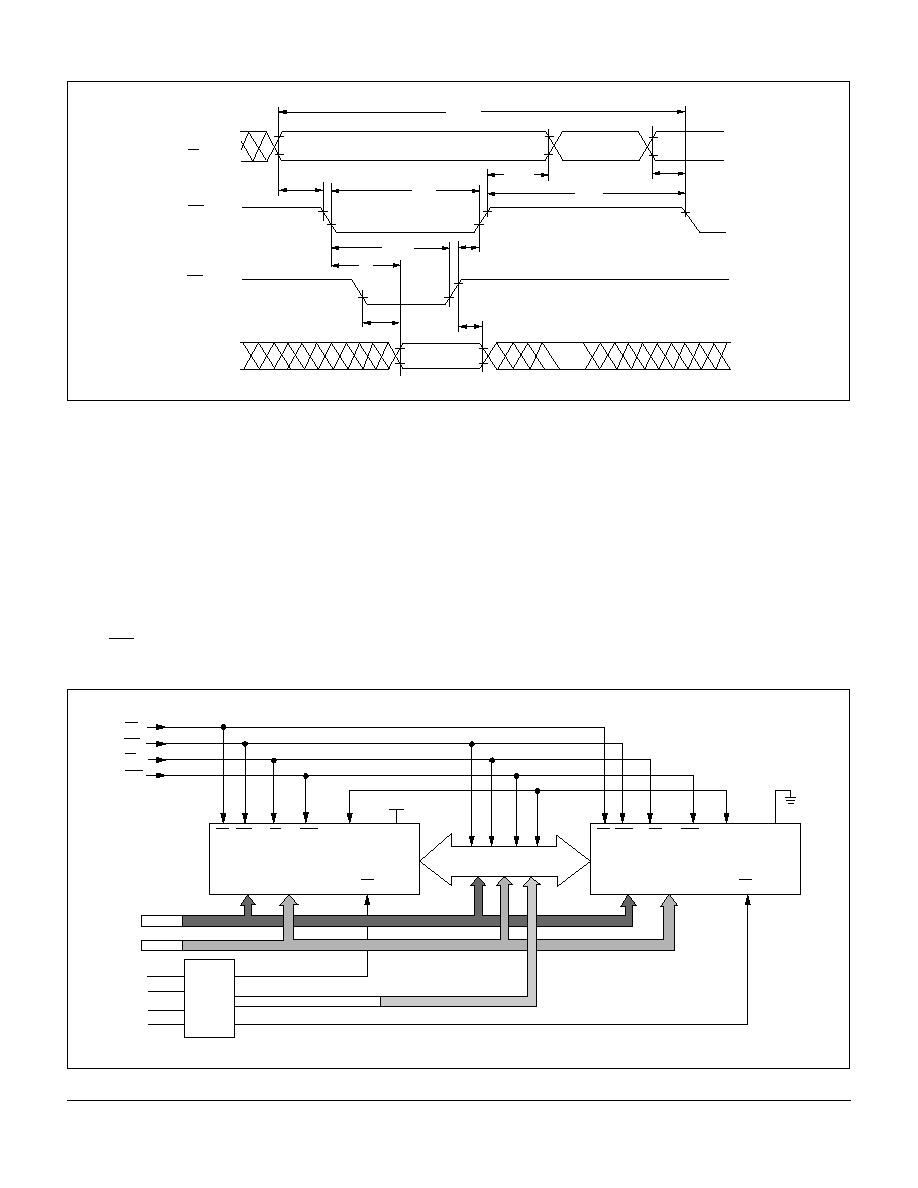

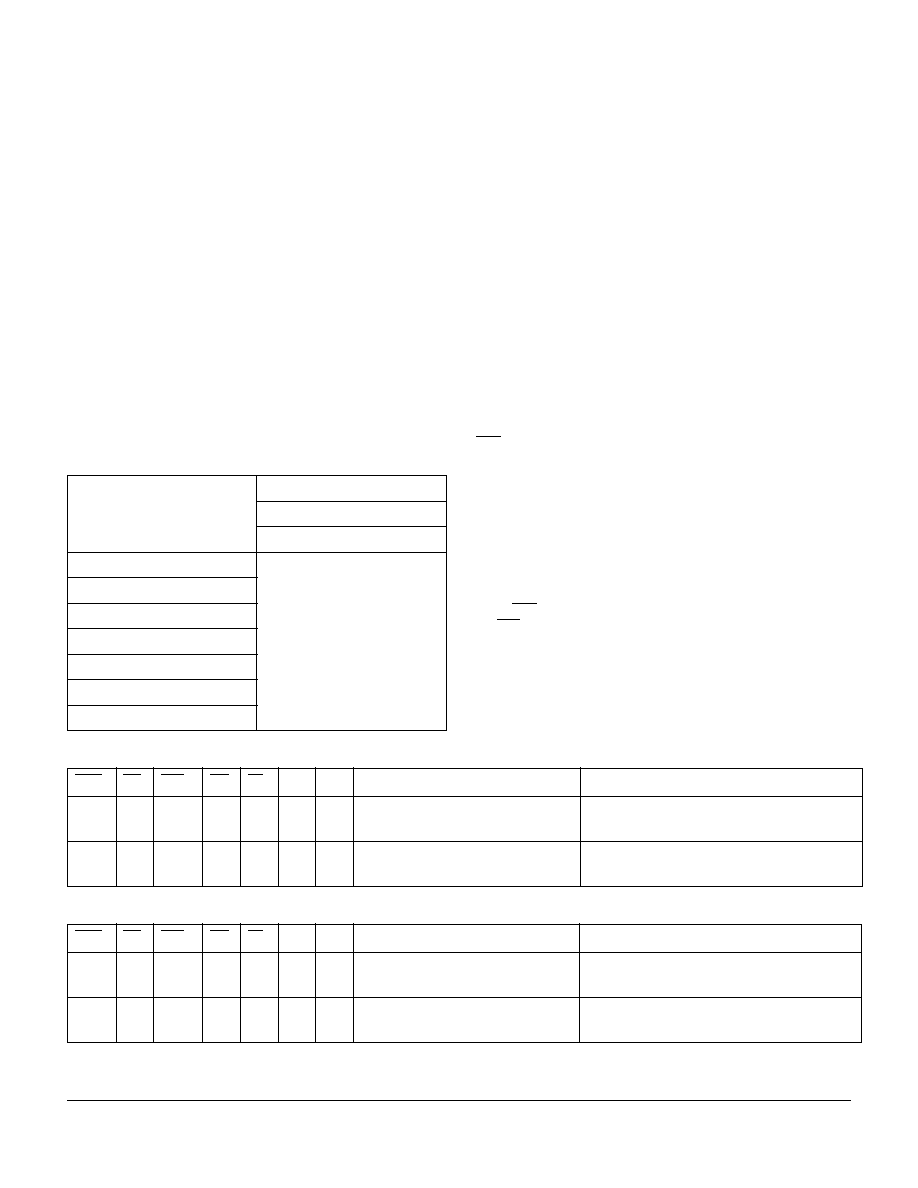

Figure 2. Write Cycle Timing Diagram

Input pulse levels ≠0.6 V to 2.4 V

ESD Warning:

Standard precautions for CMOS

handling should be observed.

0.112

(2.85)

0.030 (0.76) Typ.

0.01 (0.254)

0.026 (0.65) Typ.

0.189

(4.81)

R1

R2

R3

R4

R5

R6

R7

C1 C2 C3 C4 C5

Dimensions in inches (mm)

Tacc

Twd

Tdh

Tw

Tces

Tcer

Tceh

Tacs

Tach

Tacs

A0-A3

FL

Tce

CE

WR

D0-D7

Input pulse levels --0.6 V to 2.4 v

Switching Specifications

(over operating temperature range and

V

CC

=4.5 V)

Symbol

Description

Min.

Units

T

acc

Display Access Time--Write

210

ns

T

acc

Display Access Time--Read

230

ns

T

acs

Address Setup Time to CE

10

ns

T

ce

Chip Enable Active Time--Write

140

ns

T

ce

Chip Enable Active Time--Read

160

ns

T

ach

Address Hold Time to CE

20

ns

T

cer

Chip Enable Recovery Time

60

ns

T

ces

Chip Enable Active Prior to

Rising Edge--Write

140

ns

T

ces

Chip Enable Active Prior to

Rising Edge--Read

160

ns

T

ceh

Chip Enable Hold to Rising Edge

of Read/Write Signal

0

ns

T

w

Write Active Time

100

ns

T

wd

Data Valid Prior to

Rising Edge of Write Signal

50

ns

T

dh

Data Write Time

20

ns

T

r

Chip Enable Active Prior to Valid

Data

160

ns

T

rd

Read Active Prior to Valid Data

95

µ

s

T

df

Read Data Float Delay

10

ns

T

rc

Reset Active Time

300

ns

2000 Infineon Technologies Corp. ∑ Optoelectronics Division ∑ San Jose, CA

HDSP2110S/1S/2S/3S/4S/5S

www.infineon.com/opto ∑ 1-888-Infineon (1-888-463-4636)

OSRAM Opto Semiconductors GmbH & Co. OHG ∑ Regensburg, Germany

www.osram-os.com ∑ +49-941-202-7178

3

March 24, 2000-13

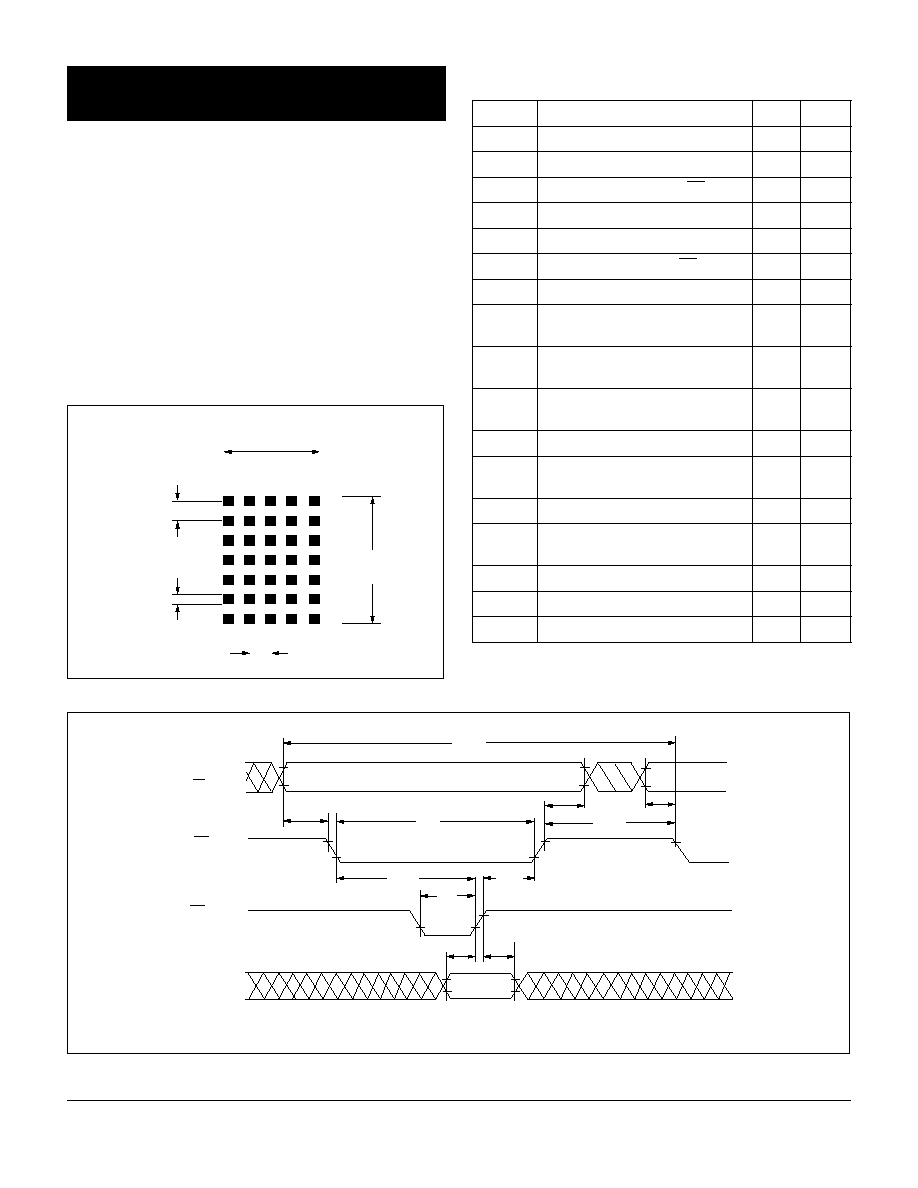

Figure 3. Read Cycle Timing Diagram

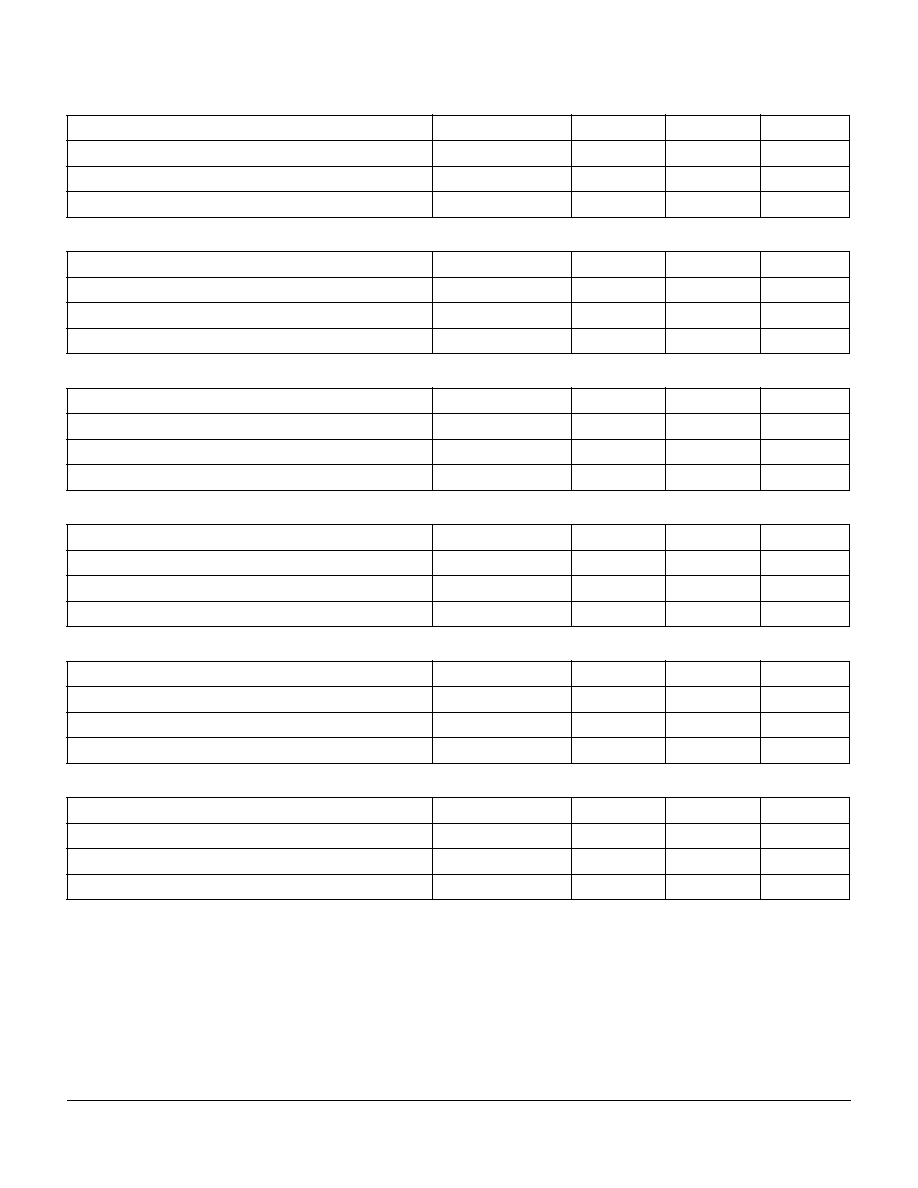

Cascading Displays

The HDSP211XS oscillator is designed to drive up to 16 other

HDSP211XSs with input loading of 15 pF each.

The following are the general requirements for cascading 16

displays together:

∑ Determine the correct address for each display.

∑ Use CE from an address decoder to select the correct

display.

∑ Select one of the Displays to provide the clock for the other

displays. Connect CLKSEL to

V

CC

for this display.

∑ Tie CLKSEL to ground on other displays.

∑ Use RTS to synchronize the blinking between the displays.

Figure 4. Cascading Diagram

Tacc

Trd

Tdf

Tr

Tces

Tcer

Tceh

Tacs

Tach

Tacs

A0-A3

FL

Tce

CE

RD

D0-D7

RD WR FL RST CLK I/O CLKSEL

D0-D7 A0-A4 CE

Display

D0-D7 A0-A4 CE

Up to14 More Displays

in between

Address Decode Chip 1 to 14

Address

Data I/O

RD

WR

FL

RST

V

CC

A6

A7

A8

A9

Address

Decoder

RD WR FL RST CLK I/O CLKSEL

0

15

Display

2000 Infineon Technologies Corp. ∑ Optoelectronics Division ∑ San Jose, CA

HDSP2110S/1S/2S/3S/4S/5S

www.infineon.com/opto ∑ 1-888-Infineon (1-888-463-4636)

OSRAM Opto Semiconductors GmbH & Co. OHG ∑ Regensburg, Germany

www.osram-os.com ∑ +49-941-202-7178

4

March 24, 2000-13

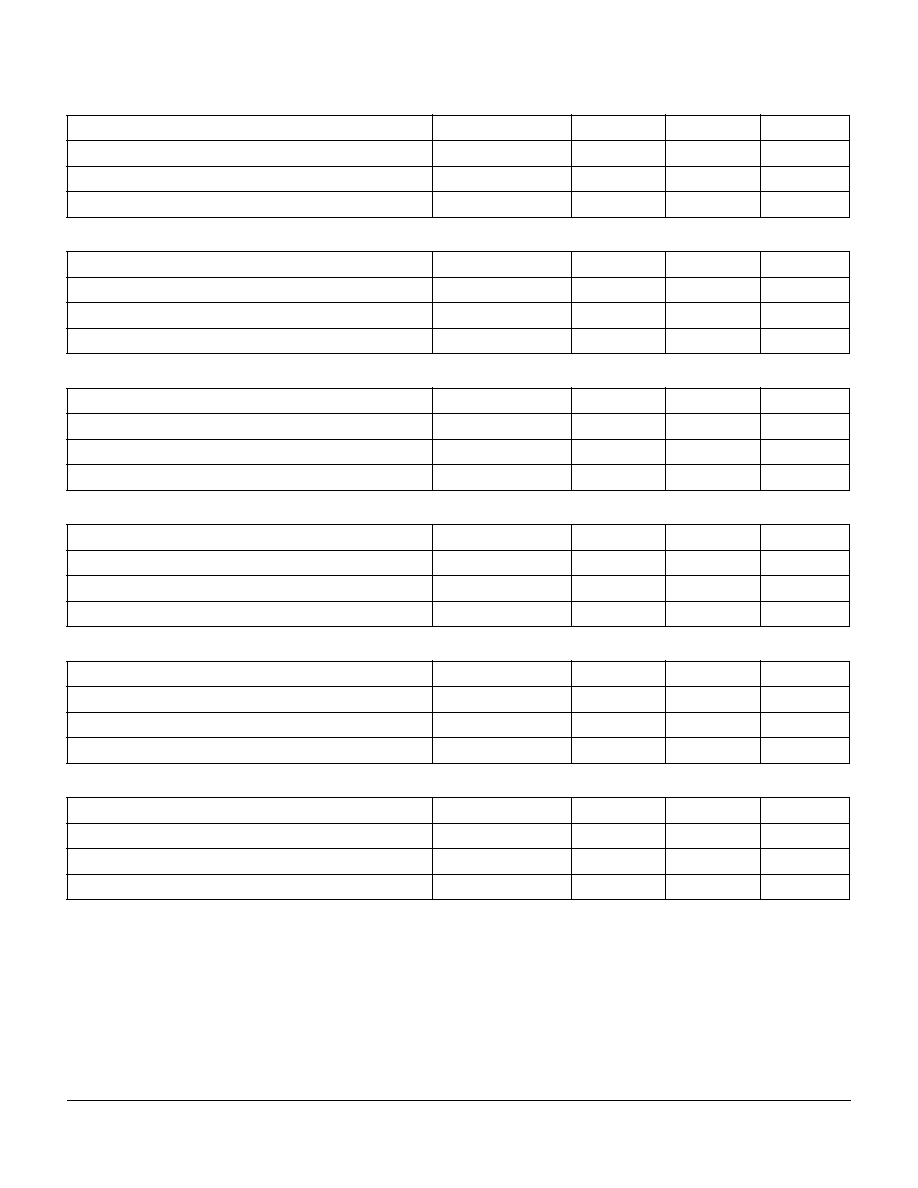

Optical Characteristics at 25

∞

C

(

V

CC

=5.0 V at full brightness)

Red HDSP2110S

Yellow HDSP2111S

High Efficiency Red HDSP2112S

Green HDSP2113S

High Efficiency Green HDSP2114S

Soft Orange HDSP2115S

Note:

1)

Peak luminous intensity is measured at

T

A

=

T

J

=25

∞

C. No time is allowed for the device to warm up prior to measurement.

Description

Symbol

Min.

Typ.

Units

Peak Luminous Intensity

(1)

I

V

peak

70

90

µ

cd/dot

Peak Wavelength

peak

--

660

nm

Dominant Wavelength

dom

--

639

nm

Description

Symbol

Min.

Typ.

Units

Peak Luminous Intensity

(1)

I

V

peak

130

210

µ

cd/dot

Peak Wavelength

peak

--

583

nm

Dominant Wavelength

dom

--

585

nm

Description

Symbol

Min.

Typ.

Units

Peak Luminous Intensity

(1)

I

V

peak

150

330

µ

cd/dot

Peak Wavelength

peak

--

630

nm

Dominant Wavelength

dom

--

620

nm

Description

Symbol

Min.

Typ.

Units

Peak Luminous Intensity

(1)

I

V

peak

150

260

µ

cd/dot

Peak Wavelength

peak

--

565

nm

Dominant Wavelength

dom

--

570

nm

Description

Symbol

Min.

Typ.

Units

Peak Luminous Intensity

(1)

I

V

peak

200

510

µ

cd/dot

Peak Wavelength

peak

--

568

nm

Dominant Wavelength

dom

--

574

nm

Description

Symbol

Min.

Typ.

Units

Peak Luminous Intensity

(1)

I

V

peak

150

270

µ

cd/dot

Peak Wavelength

peak

--

610

nm

Dominant Wavelength

dom

--

604

nm

2000 Infineon Technologies Corp. ∑ Optoelectronics Division ∑ San Jose, CA

HDSP2110S/1S/2S/3S/4S/5S

www.infineon.com/opto ∑ 1-888-Infineon (1-888-463-4636)

OSRAM Opto Semiconductors GmbH & Co. OHG ∑ Regensburg, Germany

www.osram-os.com ∑ +49-941-202-7178

5

March 24, 2000-13

Electrical Characteristics at 25

∞

C

Notes:

1)

I

CC

is an average value.

2)

I

CC

is measured with the display at full brightness. Peak

I

CC

=

28

/

15

I

CC

average (#displayed).

Recommended Operating Conditions

(

T

A

=≠40

∞

C to +85

∞

C)

Parameters

Limits

Conditions

Min.

Typ.

Max.

Units

V

CC

4.5

5.0

5.5

V

--

I

CC

Blank

--

0.65

1.0

mA

V

CC

=5.0 V,

V

IN

=5.0 V

I

CC

12 dots/digit on

(1) (2)

--

185

255

mA

V

CC

=5.0 V, "V" in all 8 digits

I

CC

20 dots/digit on

(1) (2)

--

284

370

mA

V

CC

=5.0 V, "#" in all 8 digits

I

ILP

(with pull-up)

Input Leakage

≠18

≠11

≠5.0

µ

A

V

CC

=5.0 V, V

IN

=0 V to V

CC

,

(WR, CE, FL, RST, RD, CLKSEL)

I

IL

(no pull-up)

Input Leakage

≠1.0

--

+1.0

µ

A

V

CC

=5.0 V, V

IN

=0≠5 V,

(CLK, A0≠A3, D0≠D7)

V

IH

Input Voltage High

2.0

--

V

CC

+0.3

V

V

CC

=4.5 V to 5.5 V

V

IL

Input Voltage Low

GND

≠0.3

--

--

V

V

CC

=4.5 V to 5.5 V

V

OL

(D0≠D7), Output Voltage Low

--

--

0.4

V

V

CC

=4.5 V, I

OL

=1.6 mA

V

OL

(CLK), Output Voltage Low

--

--

0.4

V

V

CC

=4.5 V, I

OL

=40

µ

A

V

OH

Output Voltage High

2.4

--

--

V

V

CC

=4.5 V, I

OH

=≠40

µ

A

JC

Thermal Resistance,

Junction to Case

--

25

--

∞

C/W

--

Clock I/O Frequency

28

57.34

81.14

kHz

V

CC

=4.5 to 5.5 V

FM, Digit Multiplex Frequency

125

256

362.5

Hz

V

CC

=4.5 to 5.5 V

Blinking Rate

0.98

2.0

2.83

Hz

--

Clock I/O Buss Loading

--

--

2.40

pF

--

Clock Out Rise Time

--

--

500

nsec

V

CC

=4.5 V, V

OH

=2.4 V

Clock Out Fall Time

--

--

500

nsec

V

CC

=4.5 V, V

OH

=0.4 V

Parameter

Symbol

Min.

Max.

Units

Supply Voltage

V

CC

4.5

5.5

V

Input Voltage Low

V

IL

--

0.8

V

Input Voltage High

V

IH

2.0

--

V

Output Voltage Low

V

OL

--

0.4

V

Output Voltage High

V

OH

2.4

--

V

2000 Infineon Technologies Corp. ∑ Optoelectronics Division ∑ San Jose, CA

HDSP2110S/1S/2S/3S/4S/5S

www.infineon.com/opto ∑ 1-888-Infineon (1-888-463-4636)

OSRAM Opto Semiconductors GmbH & Co. OHG ∑ Regensburg, Germany

www.osram-os.com ∑ +49-941-202-7178

6

March 24, 2000-13

Figure 5. Top View

Pin Assignment

Pin

Function

Definition

1

RST

Used to initialize a display and

sychronize blinking for multiple

displays

2

FL

Low input accesses the Flash RAM

3

A0

Address input LSB

4

A1

Address input

5

A2

Address input MSB

6

A3

Mode selector

7

V

CC

Optional connection to positive

power supply input.

8

V

CC

9

V

CC

10

A4

Mode Selector

11

CLKSEL

Selects internal/high clock source

28 Pins 15

1 Pins 14

Digit

0 1 2 3 4 5 6 7

Figure 6. Character Set

ASCII

CODE

D0

D1

D2

D3

L

L

L

L

0

H

L

L

L

1

L

H

L

L

2

H

H

L

L

3

L

L

H

L

4

H

L

H

L

5

L

H

H

L

6

H

H

H

L

7

L

L

L

H

8

H

L

L

H

9

L

H

L

H

A

H

H

L

H

B

L

L

H

H

C

H

L

H

H

D

L

H

H

H

E

H

H

H

H

F

L

L

L

L

H

H

H

H

X

L

L

L

L

L

L

L

L

H

L

L

H

H

L

L

H

H

X

L

H

L

H

L

H

L

H

X

0

1

2

3

4

5

6

7

8

D6

D7

D5 D4 HEX

UDC

0

UDC

1

UDC

2

UDC

3

UDC

4

UDC

5

UDC

6

UDC

7

UDC

8

UDC

9

UDC

10

UDC

11

UDC

12

UDC

13

UDC

14

UDC

15

Notes:

1. Upon power up, the device will

initialize in a random state.

2. X=don't care.

Pin Assignment (continued)

Pin

Function

Definition

12

CLK I/O

Outputs master clock or inputs

external clock

13

WR

A low will write data into the display

if CE is low

14

V

CC

Positive power supply input

15

GND supply

Analog Ground for LED drivers

16

GND logic

Digital Ground for internal drivers

17

CE

Enables access to the display

18

RD

A low will read data from the display if

CE is low. If read from display is not

required, then RD can be tied to V

CC

19

D0

Data input LSB

20

D1

Data input

21

No pin

--

22

No pin

--

23

D2

Data input

24

D3

Data input

25

D4

Data input

26

D5

Data input

27

D6

Data input

28

D7

Data input MSB, selects ROM,

page 1 or 2

2000 Infineon Technologies Corp. ∑ Optoelectronics Division ∑ San Jose, CA

HDSP2110S/1S/2S/3S/4S/5S

www.infineon.com/opto ∑ 1-888-Infineon (1-888-463-4636)

OSRAM Opto Semiconductors GmbH & Co. OHG ∑ Regensburg, Germany

www.osram-os.com ∑ +49-941-202-7178

7

March 24, 2000-13

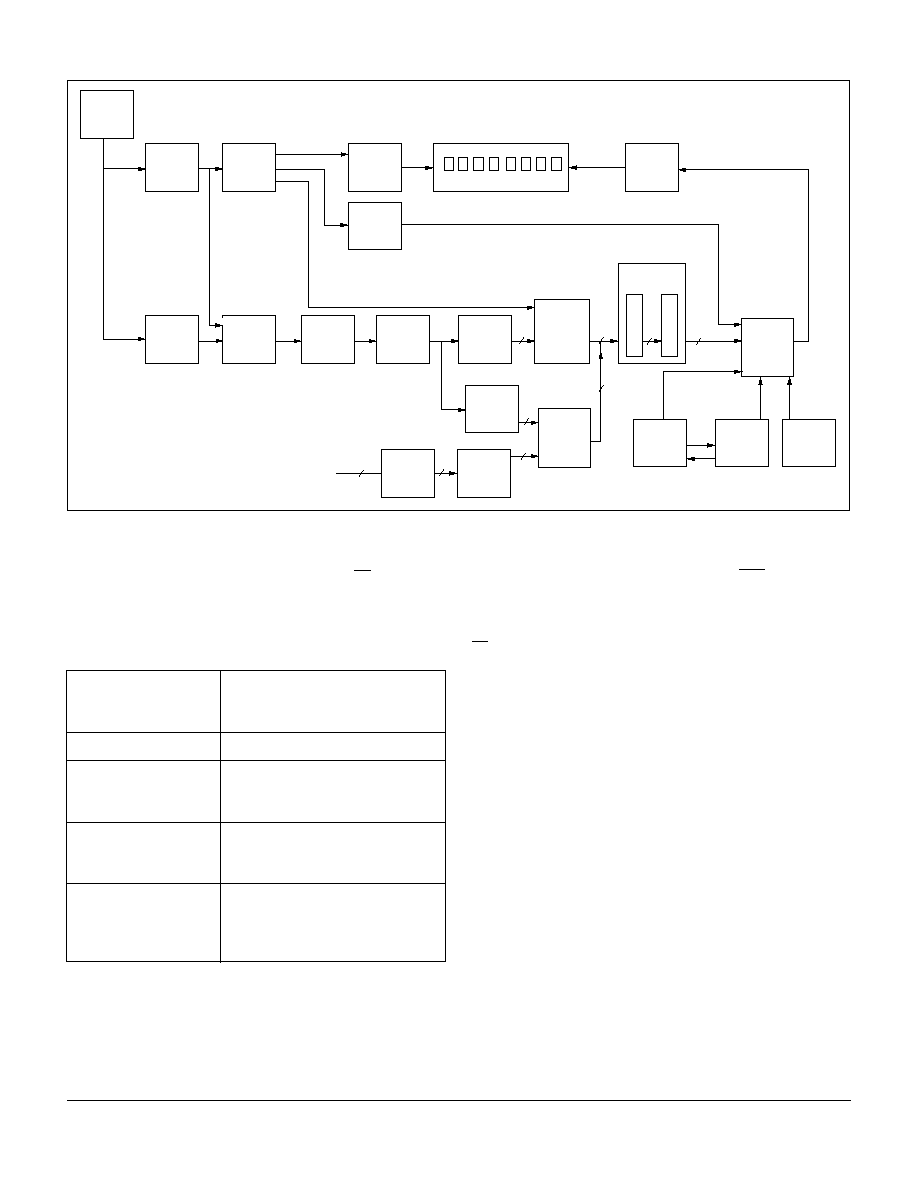

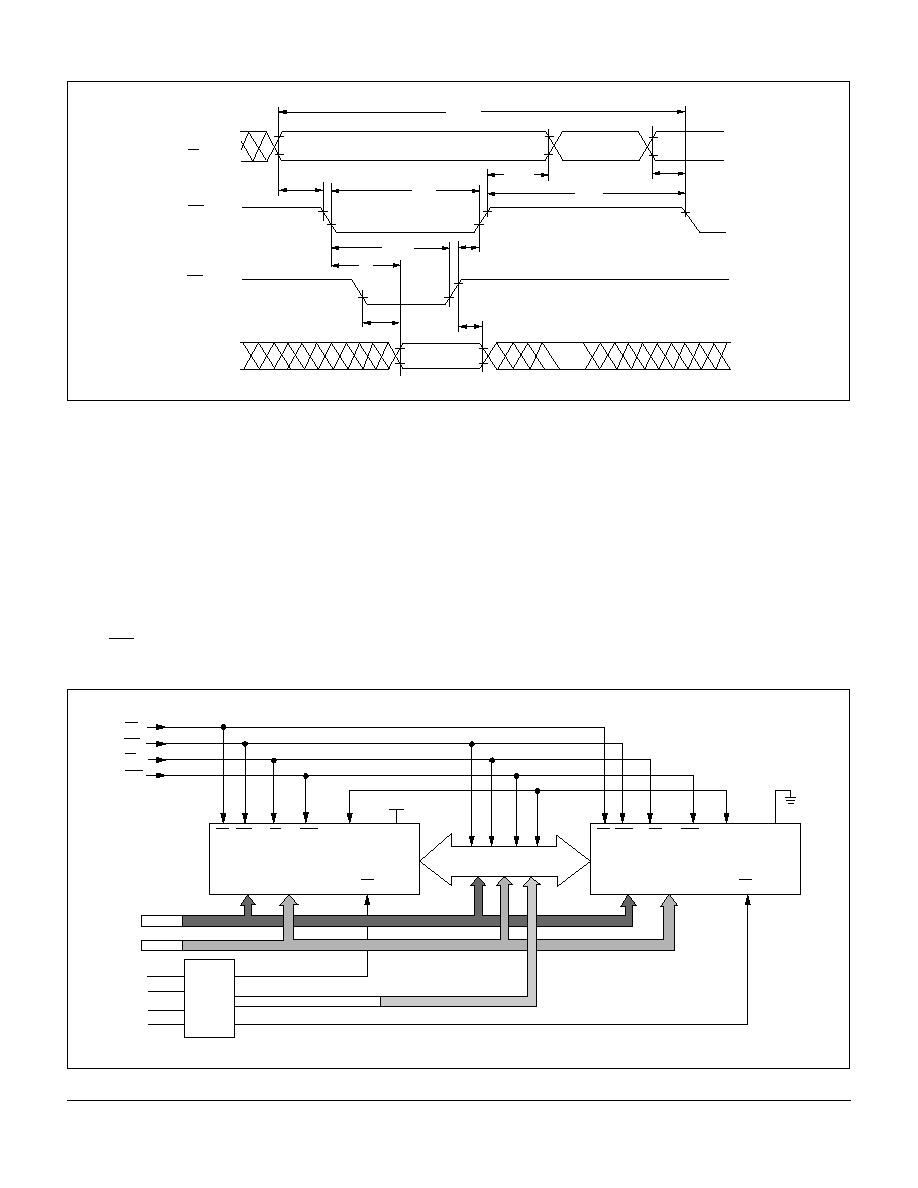

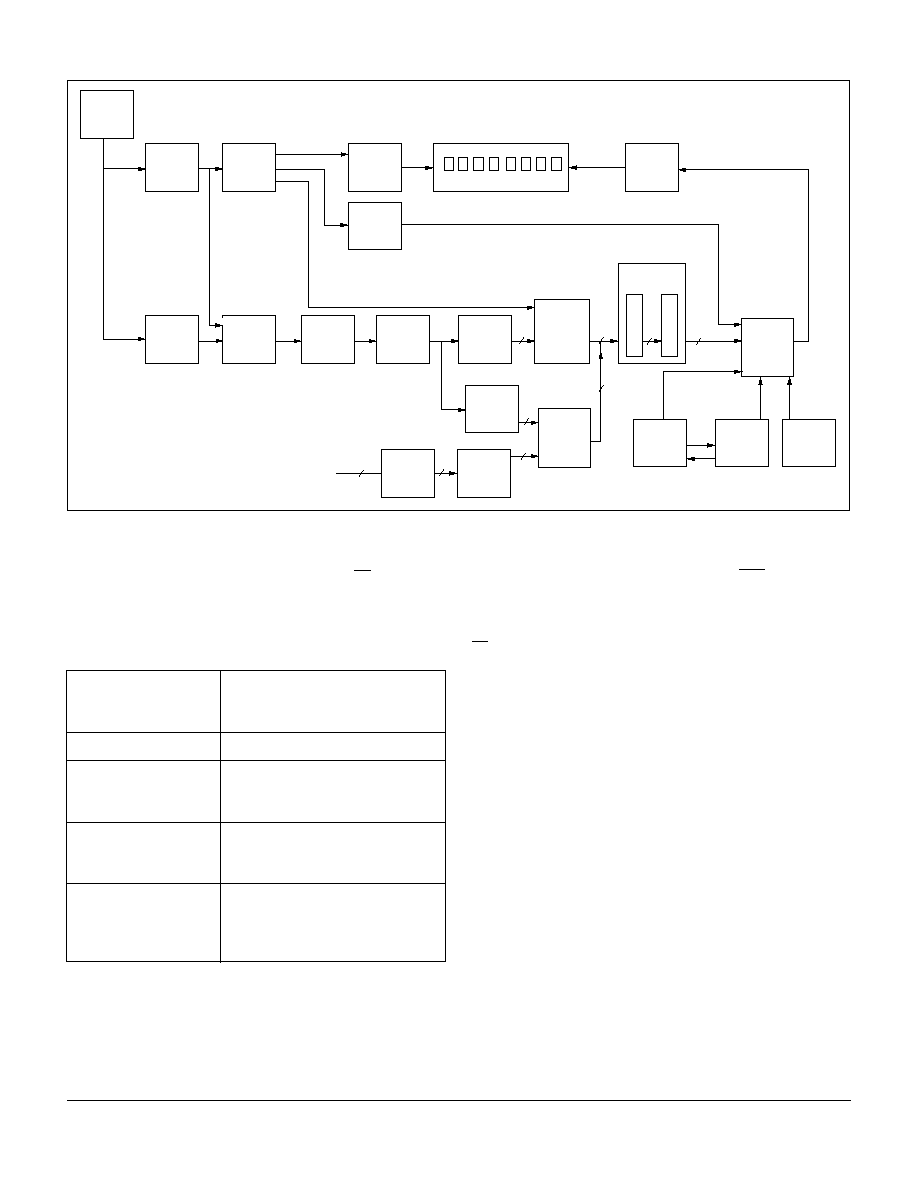

Figure 7. Block Diagram

˜

7

Counter

˜

128

Counter

˜

3

Counter

OSC

Row

Drivers

Column

Drivers

8 Digit Display

Cursor

Controls

and

Display

MUX

D Latch

Holding

Register

ROM

Word

Decode

ROM

Column

Latch

M

a

s

t

e

r

S

l

a

v

e

Character

RAM

Decode

˜

32

Counter

Character

RAM

UDC

Address

Register

Character

Decode

for Display

Character

Decode

(Read/Write)

UDC

RAM

Flash

RAM

Control

Word

Register

Self

Test

Data Bus

25

5

64

16

5

16

4

4

25

Functional Description

The display's user interface is organized into five memory

areas. They are accessed using the Flash Input, FL, and

address lines, A3 and A4. All the listed RAMs and Registers

may be read or written through the data bus. See Table 1. Each

input pin is described in Pin Definitions.

Five Basic Memory Areas

Character RAM

Stores either ASCII (Katakana)

character data or an UDC RAM

address

Flash RAM

1 x 8 RAM which stores Flash data

User-Defined

Character RAM

(UDC RAM)

Stores dot pattern for custom

characters

User-Defined Address

Register (UDC

Address Register)

Provides address to UDC RAM

when user is writing or reading

custom character

Control Word

Register

Enables adjustment of display

brightness, flash individual charac-

ters, blink, self test or clearing

the display

RST can be used to initialize display operation upon power up

or during normal operation. When activated, RST will clear the

Flash RAM and Control Word Register (00H) and reset the

internal counter. All eight display memory locations will be set

to 20H to show blanks in all digits.

FL pin enables access to the Flash RAM. The Flash RAM will

set (D0=1) or reset (D0=0) flashing of the character addressed

by A0≠A2.

The 1 x 8 bit Control Word Register is loaded with attribute

data if A3=0.

The Control Word Logic decodes attribute data for proper

implementation.

Character ROM is designed for 128 ASCII characters. The

ROM is Mask Programmable for custom fonts.

The Clock Source could either be the internal oscillator

(CLKSEL=1) of the device or an external clock (CLKSEL=0)

could be an input from another HDSP211X display for the syn-

chronization of blinking for multiple displays.

The Display Multiplexer controls the Row Drivers so no addi-

tional logic is required for a display system.

The Display has eight digits. Each digit has 35 LEDs clustered

into a 5 x 7 dot matrix.

2000 Infineon Technologies Corp. ∑ Optoelectronics Division ∑ San Jose, CA

HDSP2110S/1S/2S/3S/4S/5S

www.infineon.com/opto ∑ 1-888-Infineon (1-888-463-4636)

OSRAM Opto Semiconductors GmbH & Co. OHG ∑ Regensburg, Germany

www.osram-os.com ∑ +49-941-202-7178

8

March 24, 2000-13

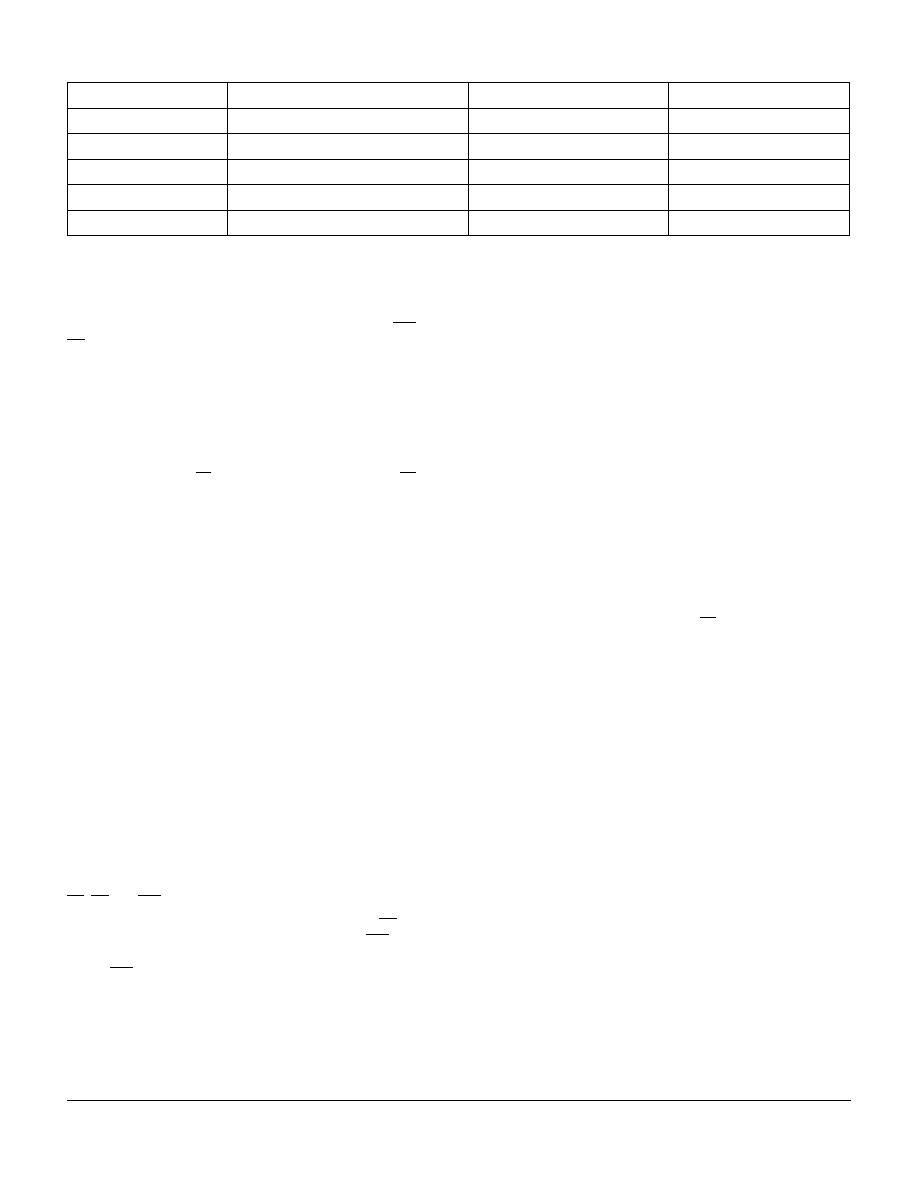

Table 1. Memory Selection

Theory of operation

The HDSP211XS Programmable Display is designed to work

with all major microprocessors. Data entry is via an eight bit

parallel bus. Three bits of address route the data to the proper

digit location in the RAM. Standard control signals like WR and

CE allow the data to be written into the display.

D0≠D7 data bits are used for both Character RAM and control

word data input. A3 acts as the mode selector.

If A3=1, character RAM is selected. Then input data bit D7 will

determine whether input data bits D0≠D6 is ASCII coded data

(D7=0) or UDC data (D7=1). See section on UDC Address Reg-

ister and RAM.

For normal operation FL pin should be held high. When FL is

held low, Flash RAM is accessed to set character blinking.

The seven bit ASCII code is decoded by the Character ROM to

generate Column data. Twenty columns worth of data is sent

out each display cycle, and it takes fourteen display cycles to

write into eight digits.

The rows are multiplexed in two sets of seven rows each.

The internal timing and control logic synchronizes the turning

on of rows and presentation of column data to assure proper

display operation.

Power Up Sequence

Upon power up display will come on at random. Thus the dis-

play should be reset on power-up. The reset will clear the

Flash RAM, Control Word Register and reset the internal

counter. All the digits will show blanks and display brightness

level will be 100%.

The display must not be accessed until three clock pulses

(110

µ

seconds minimum using the internal clock) after the ris-

ing edge of the reset line.

Microprocessor interface

The interface to a microprocessor is through the 8-bit data

bus (D0≠D7), the 4-bit address bus (A0≠A3) and control lines

FL, CE and WR.

To write data (ASCII/Control Word) into the display CE should

be held low, address and data signals stable and WR should

be brought low. The data is written on the low to high transi-

tion of WR.

The Control Word is decoded by the Control Word Decode

Logic. Each code has a different function. The code for display

brightness changes the duty cycle for the column drivers. The

peak LED current stays the same but the average LED current

diminishes depending on the intensity level.

FL

A4

A3

Section of Memory

A2≠A0

Data Bits Used

0

X

X

Flash RAM

Character Address

D0

1

0

0

UDC Address Register

Don't Care

D3≠D0

1

0

1

UDC RAM

Row Address

D4≠D0

1

1

1

Character RAM

Character Address

D7≠D0

1

1

0

Control Word Register

Don't Care

D7≠D0

The character Flash Enable causes 2.0 Hz coming out of the

counter to be ANDED with column drive signal and makes the

column driver to cycle at 2.0 Hz. Thus the character flashes at

2.0 Hz.

The display Blink works the same way as the Flash Enable but

causes all twenty column drivers to cycle at 2.0 Hz thereby

making all eight digits to blink at 2.0 Hz.

The Self Test function of the IC consists of two internal rou-

tines which exercise major portions of the IC and illuminates

all the LEDs.

Clear bit clears the character RAM and writes a blank into the

display memory. It however does not clear the control word.

ASCII Data or Control Word Data can be written into the display

at this point. For multiple display operation, CLK I/O must be

properly selected. CLK I/O will output the internal clock if

CLKSEL=1, or will allow input from an external clock if

CLKSEL=0.

Character RAM

The Character RAM is selected when FL, A4 and A3 are set to

1,1,1 during a read or write cycle. The Character RAM is a 8 by

8 bit RAM with each of the eight locations corresponding to a

digit on the display. Digit 0 is on the left side of the display and

digit 7 is on the right side of the display. Address lines, A2≠A0

select the digit address with A2 being the most significant bit

and A0 being the least significant bit. The two types of data

stored in the Character RAM are the ASCII coded data and the

UDC Address Data. The type of data stored in the Character

RAM is determined by data bit, D7. If D7 is low, then ASCII

coded data is stored in data bits D6≠D0. If D7 is high, then UDC

Address Data is stored in data bit D3≠D0.

The ASCII coded data is a 7 bit code used to select one of 128

ASCII characters permanently stored in the ASCII ROM.

The UDC Address data is a 4 bit code used to select one of the

UDC characters in the UDC RAM. There are up to 16 charac-

ters available. See Figure 8.

UDC Address Register and UDC RAM

The UDC Address Register and UDC RAM allows the user to

generate and store up to 16 custom characters. Each custom

character is defined in 5 x 7 dot matrix pattern. It takes 8 write

cycles to define a custom character, one cycle to load the UDC

Address Register and 7 cycles to define the character. The con-

tents of the UDC Address Register will store the 4 bit address

for one of the 16 UDC RAM locations. The UDC RAM is used

to store the custom character.

2000 Infineon Technologies Corp. ∑ Optoelectronics Division ∑ San Jose, CA

HDSP2110S/1S/2S/3S/4S/5S

www.infineon.com/opto ∑ 1-888-Infineon (1-888-463-4636)

OSRAM Opto Semiconductors GmbH & Co. OHG ∑ Regensburg, Germany

www.osram-os.com ∑ +49-941-202-7178

9

March 24, 2000-13

Control Word

The Control Word is used to set up the attributes required by

the user. It is addressed by setting FL=1, A4=1, A3=0. The

Control Word is an 8 bit register and is accessed using data

bits, D7≠D0. See Figures 12 and 13 for the logic and attributed

control. The Control Word has 5 functions. They are brightness

control, flashing character enable, blinking character enable,

self test, and clear (Flash and Character RAMS only).

Brightness Control

Control Word bits, D2≠D0, control the brightness of the display

with a binary code of 000 being 100% brightness and 111

being display blank. See Figure 13 for brightness level versus

binary code. The average I

CC

can be calculated by multiplying

the 100% brightness level I

CC

value by the display's brightness

level. For example, a display set to 80% brightness with a

100% average I

CC

value of 200 mA will have an average I

CC

value of 200 mA x 80%=160 mA.

Flash Function

Control Word bit, D3, enables or disables the Flash Function.

When D3 is 1, the Flash Function is enabled and any digit with

its corresponding bit set in the Flash RAM will flash at approxi-

mately 2.0 Hz. When using an external clock, the flash rate can

be determined by dividing the clock rate by 28,672. When D3 is

0, the Flash Function is disabled and the contents of the Flash

RAM is ignored. For synchronized flashing on multiple displays,

see the Reset Section.

UDC Address Register

The UDC Address Register is selected by setting FL=1, A4=0,

A3=0. It is a 4 bit register and uses data bits, D3≠D0 to store

the 4 bit address code (D7≠D4 are ignored). The address code

selects one of 16 UDC RAM locations for custom character

generation.

UDC RAM

The UDC RAM is selected by setting FL=1, A4=0, A3=1. The

RAM is comprised of a 7 x 5 bit RAM. As shown in Figure 11,

address lines, A2≠A0 select one of the 7 rows of the custom

character. Data bits, D4≠D0 determine the 5 bits of column

data in each row. Each data bit corresponds to a LED. If the

data bit is high, then the LED is on. If the data bit is low, the

LED is off. To create a character, each of the 7 rows of column

data need to be defined. See Figures 9 and 10 for logic.

Flash RAM

The Flash RAM allows the display to flash one or more of the

characters being displayed. The Flash Ram is accessed by set-

ting FL low. A4 and A3 are ignored. The Flash RAM is a 8 x 1 bit

RAM with each bit corresponding to a digit address. Digit 0 is

on the left side of the display and digit 7 is on the right side of

the display. Address lines, A2≠A0 select the digit address with

A2 being the most significant digit and A0 being the least sig-

nificant digit. Data bit, D0, sets and resets the flash bit for each

digit. When D0 is high, the flash bit is set and when D0 is low,

It is reset. See Figure 11.

Figure 8. Character RAM Access Logic

Figure 9. UDC Address Register and UDC Character RAM

RST

CE

WR

RD

FL

A4

A3

A2 A1 A0

D7 D6 D5 D4 D3 D2 D1 D0

1

0

0

1

1

1

1

Character Address for

Digits 0≠7

0

7 bit ASCII code for a Write Cycle

1

0

1

0

1

1

1

Character Address for

Digits 0≠7

0

7 bit ASCII code read during a Read Cycle

1

0

0

1

1

0

0

Character Address for

Digits 0≠7

1

D3≠D0=UDC address for a Write Cycle

1

0

1

0

1

0

0

Character Address for

Digits 0≠7

1

D3≠D0=UDC address for Read Data

RST

CE

WR

RD

FL

A4

A3

A2 A1 A0

D7 D6 D5 D4 D3 D2 D1 D0

1

0

0

1

1

0

0

Not used for UDC

Address Register

D3≠D0=UDC RAM Address Code for

Write Cycle

UDC

Address

Register

1

0

1

0

1

0

0

Not used for UDC

Address Register

D3≠D0=UDC RAM Address Code for

Read Cycle

1

0

0

1

1

0

1

A2≠A0=Character

Row Address

D4≠D0=Character Column Data for

Write Cycle

UDC

RAM

1

0

1

0

1

0

1

A2≠A0=Character

Row Address

D4≠D0=Character Column Data read

during a Read Cycle

2000 Infineon Technologies Corp. ∑ Optoelectronics Division ∑ San Jose, CA

HDSP2110S/1S/2S/3S/4S/5S

www.infineon.com/opto ∑ 1-888-Infineon (1-888-463-4636)

OSRAM Opto Semiconductors GmbH & Co. OHG ∑ Regensburg, Germany

www.osram-os.com ∑ +49-941-202-7178

10

March 24, 2000-13

Blink Function

Control Word bit, D4, enables or disables the Blink Function.

When D4 is 1, the Blink Function is enabled and all characters

on the display will blink at approximately 2.0 Hz. The Blink

Function will override the Flash Function if both functions are

enabled. When D4 is 0, the Blink Function is disabled. When

using an external clock, the blink rate can be determined by

dividing the clock rate by 28,672. For synchronized blinking on

multiple displays, see the Reset Section.

Self Test

Before starting Self Test, Reset must first be activated. Control

Word bits, D6 and D5, are used for the Self Test Function.

When D6 is 1, the Self Test is initiated. Results of the Self Test

are stored in bits D5. Control Word bit, D5, is a read only bit.

When D5 is 1, Self Test passed is indicated. When D5 is 0, Self

Test failed is indicated. The Self Test function of the IC consists

of two internal routines which exercise major portions of the IC

and illuminates all of the LEDs. The first routine cycles the

ASCII decoder ROM through all states and performs a check

sum on the output. If the check sum agrees with the correct

value, D5 is set to a 1.

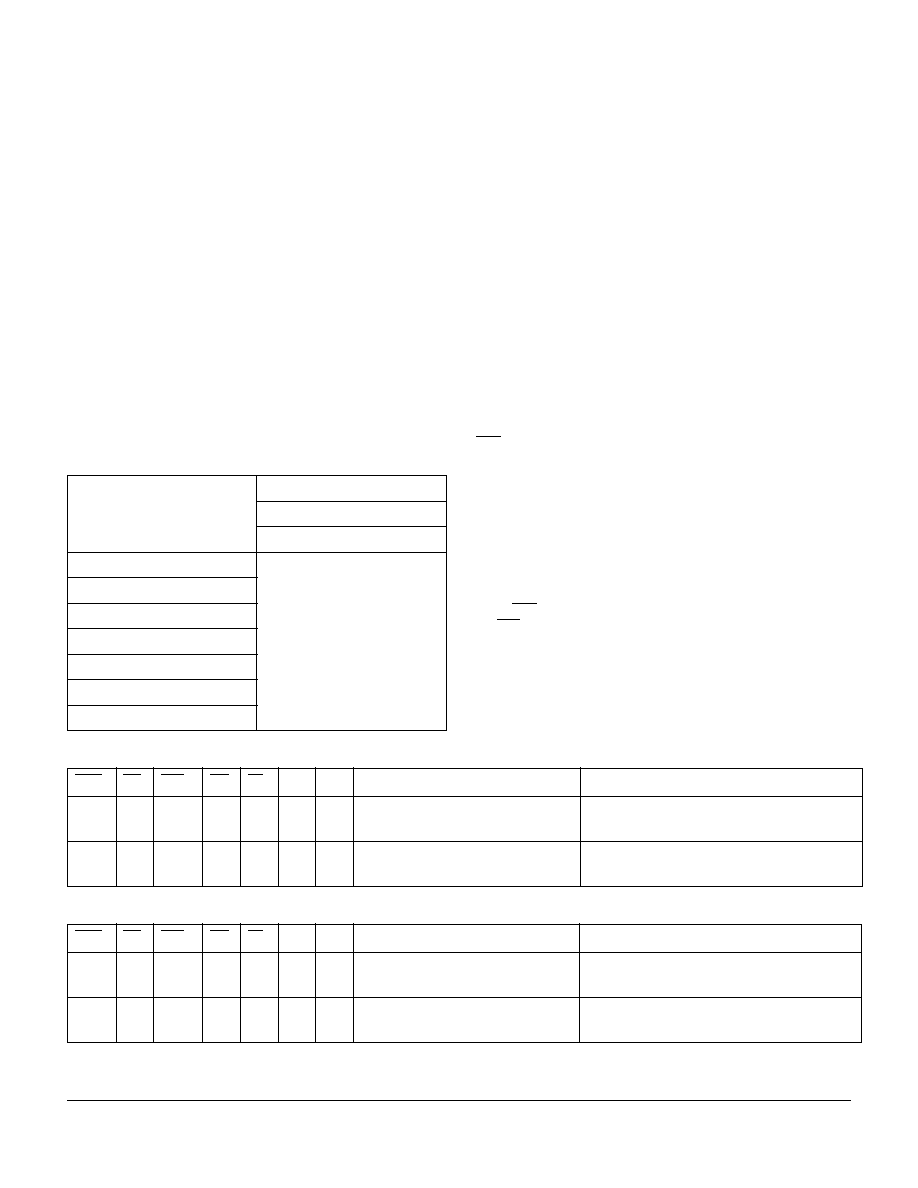

Figure 10. UDC Character Map

Figure 11. Flash RAM Access Logic

Figure 12. Control Word Access Logic

Row Data

A2

A1

A0

Row #

Column Data

C1

C2

C3

C4

C5

D4

D3

D2

D1

D0

0

0

0

1

5 x 7

Dot Matrix

Pattern

0

0

1

2

0

1

0

3

0

1

1

4

1

0

0

5

1

0

1

6

1

1

0

7

RST

CE

WR

RD

FL

A4

A3

A2 A1 A0

D7 D6 D5 D4 D3 D2 D1 D0

1

0

0

1

0

X

X

Flash RAM Address for Digits 0≠7

D0=Flash Data, 0-Flash Off and 1=Flash On

(Write Cycle)

1

0

1

0

0

X

X

Flash RAM Address for Digits 0≠7

D0=Flash Data, 0-Flash Off and 1=Flash On

(Read Cycle)

RST

CE

WR

RD

FL

A4

A3

A2 A1 A0

D7 D6 D5 D4 D3 D2 D1 D0

1

0

0

1

1

1

0

Not used for Control Word

Control Word data for a Write Cycle,

see Figure 13

1

0

1

0

1

1

0

Not used for Control Word

Control Word data for a Read during a

Read Cycle

The second routine provides a visual test of the LEDs using the

drive circuitry. This is accomplished by writing checkered and

inverse checkered patterns to the display. Each pattern is dis-

played for approximately 2.0 seconds. During the self test func-

tion the display must not be accessed. The time needed to

execute the self test function is calculated by multiplying the

clock time by 262,144 (typical time

4.6 sec.). At the end of the

self test function, the Character RAM is loaded with blanks; the

Control Word Register is set to zeroes except D5, and the

Flash RAM is cleared and the UDC Address Register is set to

all 1.0 s.

Clear Function (see Figures 13 and 14)

Control Word bit, D7 clears the character RAM to 20 hex and

the flash RAM to all zeroes. The RAMs are cleared within three

clock cycles (110

µ

s minimum, using the internal clock) when

D7 is set to 1. During the clear time the display must not be

accessed. When the clear function is finished, bit 7 of the

Control Word RAM will be reset to a "0".

Reset Function

The display should be reset on power up of the display

(RST=LOW). When the display is reset, the Character RAM,

Flash RAM, and Control Word Register are cleared.

The display's internal counters are reset. Reset cycle takes

three clock cycles (110

µ

seconds minimum using the internal

clock). The display must not be accessed during this time.

To synchronize the flashing and blinking of multiple displays, it

is necessary for the display to use a common clock source and

reset all the displays at the same time to start the internal

counters at the same place.

While RST is low, the display must not be accessed by RD

nor WR.

2000 Infineon Technologies Corp. ∑ Optoelectronics Division ∑ San Jose, CA

HDSP2110S/1S/2S/3S/4S/5S

www.infineon.com/opto ∑ 1-888-Infineon (1-888-463-4636)

OSRAM Opto Semiconductors GmbH & Co. OHG ∑ Regensburg, Germany

www.osram-os.com ∑ +49-941-202-7178

11

March 24, 2000-13

Figure 13. Control Word Data Definition

Figure 14. Clear Function

X=don't care

Figure 15. Display Cycle Using Built-in ROM Example

Display message "Showtime." Digit 0 is leftmost--closest to pin 1.

Logic levels: 0=Low, 1=High, X=Don't care.

CE

WR

FL

AL

A3

A2

A1

A0

D7

D6

D5

D4

D3

D2

D1

D0

Operation

0

0

0

0

1

1

1

1

0

0

X

X

X

X

X

X

0

1

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Clear disabled

Clear user RAM, page

RAM, flash RAM and dis-

play

RST

CE

WR RD

FL

A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0 Operation

Display

0

X

1

1

1

X

X

X

X

X

X

X

X

X

X

X

X

X

Reset. No Read/Write

Within 3 Clock Cycles

All Blank

1

0

0

1

1

1

0

X

X

X

0

0

X

0

0

0

1

1

53% Brightness

Selected

All Blank

1

0

0

1

1

1

1

0

0

0

0

1

0

1

0

0

1

1

Write "S" to Digit 0

S

1

0

0

1

1

1

1

0

0

1

0

1

0

0

1

0

0

0

Write "H" to Digit 1

SH

1

0

0

1

1

1

1

0

1

0

0

1

0

0

1

1

1

1

Write "O" to Digit 2

SHO

1

0

0

1

1

1

1

0

1

1

0

1

0

1

0

1

1

1

Write "W" to Digit 3

SHOW

1

0

0

1

1

1

1

1

0

0

0

1

0

1

0

1

0

0

Write "T" to Digit 4

SHOWT

1

0

0

1

1

1

1

1

0

1

0

1

0

0

1

0

0

1

Write "I" to Digit 5

SHOWTI

1

0

0

1

1

1

1

1

1

0

0

1

0

0

1

1

0

1

Write "M" to Digit 6

SHOWTIM

1

0

0

1

1

1

1

1

1

1

0

1

0

0

0

1

0

1

Write "E" to Digit 7

SHOWTIME

D7 D6 D5 D4 D3 D2 D1 D0

C ST ST BL FL Br Br Br

0 0 0 100% Brightness

0 0 1 80% Brightness

0 1 0 53% Brightness

0 1 1 40% Brightness

1 0 0 27% Brightness

1 0 0 20% Brightness

1 1 0 13% Brightness

1 1 1 Blank Display

0 Flash Function Disabled

1 Flash Function Enabled

0 Blink Function Disabled

1 Blink Function Enabled (overrides Flash Function)

X Normal Operation X=bit ignored

R Run Self Test, R=Test Result, R=1/pass, 0=fail

0

1

0 Normal Operation

1 Clear Flash RAM & Character RAM (Character RAM=20 Hex)

Key

C

Clear Function

ST

Self test

BL

Blink function

FL

Flash function

Br

Brightness control

2000 Infineon Technologies Corp. ∑ Optoelectronics Division ∑ San Jose, CA

HDSP2110S/1S/2S/3S/4S/5S

www.infineon.com/opto ∑ 1-888-Infineon (1-888-463-4636)

OSRAM Opto Semiconductors GmbH & Co. OHG ∑ Regensburg, Germany

www.osram-os.com ∑ +49-941-202-7178

12

March 24, 2000-13

Figure 16. Displaying User Defined Character Example

Load character "A" into UDC-5 and then display it in digit 2

Logic levels: 0=Low, 1=High, X=Don`t care

Electrical and Mechanical Considerations

Voltage Transient Suppression

For best results power the display and the components that

interface with the display to avoid logic inputs higher than V

CC

.

Additionally, the LEDs may cause transients in the power sup-

ply line while they change display states. The common practice

is to place a parallel combination of a .01

µ

F and a 22

µ

F capac-

itor between V

CC

and GND for all display packages.

ESD Protection

The input protection structure of the HDSP211XS provides sig-

nificant protection against ESD damage. It is capable of with-

standing discharges greater than 2.0 kV. Take all the standard

precautions, normal for CMOS components. These include

properly grounding personnel, tools, tables, and transport carri-

ers that come in contact with unshielded parts. If these condi-

tions are not, or cannot be met, keep the leads of the device

shorted together or the parts in antistatic packaging.

Soldering

Considerations

The HDSP211XS can be hand soldered with SN63 solder using

a grounded iron set to 260

∞

C.

Wave soldering is also possible following these conditions:

Preheat that does not exceed 93

∞

C on the solder side of the PC

board or a package surface temperature of 85

∞

C. Water soluble

organic acid flux (except carboxylic acid) or rosin-based RMA

flux without alcohol can be used.

Direct contact with alcohol or alcohol vapor will cause degrada-

tion of the package.

Wave temperature of 245

∞

C

±

5

∞

C with a dwell between 1.5

sec. to 3.0 sec. Exposure to the wave should not exceed

temperatures above 260∞C for five seconds at 0.063" below

the seating plane. The packages should not be immersed in

the wave.

RST CE

WR RD

FL

A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0 Operation

Display

0

X

1

1

1

X

X

X

X

X

X

X

X

X

X

X

X

X

Reset. No Read/Write

Within 3 Clock Cycles

All Blank

1

0

0

1

1

0

0

X

X

X

X

X

X

X

0

1

0

1

Select UDC-5

All Blank

1

0

0

1

1

0

1

0

0

0

X

X

X

0

1

1

1

0

Write into Row 1 of UDC-5

All Blank

1

0

0

1

1

0

1

0

0

1

X

X

X

1

0

0

0

1

Write into Row 2 of UDC-5

All Blank

1

0

0

1

1

0

1

0

1

0

X

X

X

1

0

0

0

1

Write into Row 3 of UDC-5

All Blank

1

0

0

1

1

0

1

0

1

1

X

X

X

1

1

1

1

1

Write into Row 4 of UDC-5

All Blank

1

0

0

1

1

0

1

1

0

0

X

X

X

1

0

0

0

1

Write into Row 5 of UDC-5

All Blank

1

0

0

1

1

0

1

1

0

1

X

X

X

1

0

0

0

1

Write into Row 6 of UDC-5

All Blank

1

0

0

1

1

0

1

1

1

0

X

X

X

1

0

0

0

1

Write into Row 7 of UDC-5

All Blank

1

0

0

1

1

1

1

0

1

0

1

X

X

X

0

1

0

1

Write UDC-5 into Digit 2

(Digit 2) A

Post Solder Cleaning Procedures

The least offensive cleaning solution is hot D.I. water (60∞C) for

less than 15 minutes. Addition of mild saponifiers is accept-

able. Do not use commercial dishwasher detergents.

For faster cleaning, solvents may be used. Exercise care in

choosing solvents as some may chemically attack the nylon

package. Maximum exposure should not exceed two minutes

at elevated temperatures. Acceptable solvents are TF (trichorot-

rifluorethane), TA, 111 Trichloroethane, and unheated ace-

tone.

(1)

Note:

1)

Acceptable commercial solvents are: Basic TF, Arklone, P.

Genesolv, D. Genesolv DA, Blaco-Tron TF, Blaco-Tron TA, and

Freon TA.

Unacceptable solvents contain alcohol, methanol, methylene

chloride, ethanol, TP35, TCM, TMC, TMS+, TE, or TES.

Since many commercial mixtures exist, contact a solvent

vendor for chemical composition information. Some major

solvent manufacturers are: Allied Chemical Corporation,

Specialty Chemical Division, Morristown, NJ; Baron-

Blakeslee, Chicago, IL; Dow Chemical, Midland, MI; E.I.

DuPont de Nemours & Co., Wilmington, DE.

For further information refer to Appnotes 18 and 19 at

www.infineon.com/opto.

An alternative to soldering and cleaning the display modules is

to use sockets. Naturally, 28 pin DIP sockets .600" wide with

.100" centers work well for single displays. Multiple display

assemblies are best handled by longer SIP sockets or DIP sock-

ets when available for uniform package alignment. Socket man-

ufacturers are Aries Electronics, Inc., Frenchtown, NJ; Garry

Manufacturing, New Brunswick, NJ; Robinson-Nugent, New

Albany, IN; and Samtec Electronic Hardward, New Albany, IN.

For further information refer to Appnote 22 at www.infin-

eon.com/opto.

2000 Infineon Technologies Corp. ∑ Optoelectronics Division ∑ San Jose, CA

HDSP2110S/1S/2S/3S/4S/5S

www.infineon.com/opto ∑ 1-888-Infineon (1-888-463-4636)

OSRAM Opto Semiconductors GmbH & Co. OHG ∑ Regensburg, Germany

www.osram-os.com ∑ +49-941-202-7178

13

March 24, 2000-13

Optical Considerations

The .200" high character of the HDSP211XS gives readability up

to eight feet. Proper filter selection enhances readability over

this distance.

Using filters emphasizes the contrast ratio between a lit LED

and the character background. This will increase the discrimina-

tion of different characters. The only limitation is cost. Take into

consideration the ambient lighting environment for the best

cost/benefit ratio for filters.

Incandescent (with almost no green) or fluorescent (with

almost no red) lights do not have the flat spectral response of

sunlight. Plastic band-pass filters are an inexpensive and effec-

tive way to strengthen contrast ratios. The HDSP2110/2112S

are red/high efficiency red displays and should be matched

with long wavelength pass filter in the 570 nm to 590 nm

range. The HDSP2113S should be matched with a yellow-

green band-pass filter that peaks at 565 nm. For displays of

multiple colors, neutral density grey filters offer the best com-

promise.

Additional contrast enhancement is gained by shading the dis-

plays. Plastic band-pass filters with built-in louvers offer the

next step up in contrast improvement. Plastic filters can be

improved further with anti-reflective coatings to reduce glare.

The trade-off is fuzzy characters. Mounting the filters close to

the display reduces this effect. Take care not to overheat the

plastic filter by allowing for proper air flow.

Optimal filter enhancements are gained by using circular

polarized, anti-reflective, band-pass filters. The circular polar-

izing further enhances contrast by reducing the light that

travels through the filter and reflects back off the display to

less than 1%.

Several filter manufacturers supply quality filter materials.

Some of them are: Panelgraphic Corporation, W. Caldwell, NJ;

SGL Homalite, Wilmington, DE; 3M Company, Visual Products

Division, St. Paul, MN; Polaroid Corporation, Polarizer Division,

Cambridge, MA; Marks Polarized Corporation, Deer Park, NY,

Hoya Optics, Inc., Fremont, CA.

One last note on mounting filters: recessing displays and bezel

assemblies is an inexpensive way to provide a shading effect in

overhead lighting situations. Several bezel manufacturers are:

R.M.F. Products, Baklava, IL; Nobody Components, Griffith

Plastic Corp., Burningly, CA; Photo Chemical Products of Cali-

fornia, Santa Monica, CA; I.E.E.-Atlas, Van Nuys, CA.