OS-LM11A

LINEARlight flex

Data Sheet

Benefits

Linear separable LED strip on flexible

printed circuit board with self-adhesive

back

ÿ

Small height

ÿ

Available in various colors

ÿ

Applications

Illuminated signs

ÿ

Channel letters

ÿ

Path & contour marking

ÿ

Color

Voltage

[V DC]*

Power

[W]*

Radiance

Angle [∞]*

Wavelength [nm]

Color Temp [K]*

Lum. Flux

[lm]*

Current

[A]*

Product

Number of

LEDs

Technical Operating Data

white

10

30,0

120

5400 K

405

3

OS-LM11A-W1-854

300

white

10

30,0

120

4700 K

405

3

OS-LM11A-W1-847

300

red

10

15,0

120

615 nm

117

1,5

OS-LM11A-A

300

yellow

10

22,5

120

587 nm

405

2,25

OS-LM11A-Y1

300

green

10

30,0

120

528 nm

147

3

OS-LM11A-T

300

blue

10

30,0

120

470 nm

37

3

OS-LM11A-B

300

All Data are related to the entire module

Due to the special conditions of the manufacturing processes of LED the typical data of technical parameters can only reflect statistical figures and do not necessarily

correspond to the actual parameters of each single product which could differ from the typical data.

*)

Technical Features

Modules optimized for use with OSRAM

OPTOTRONIC power supplies.

ÿ

Dimmable by Pulse width modulation (PWM)

with the electronic controller OT DIM

ÿ

Smallest unit of 4 LEDs can be cut out at

regular intervals without damaging the rest of

the module

ÿ

Entire Module consists of 300 LEDs

ÿ

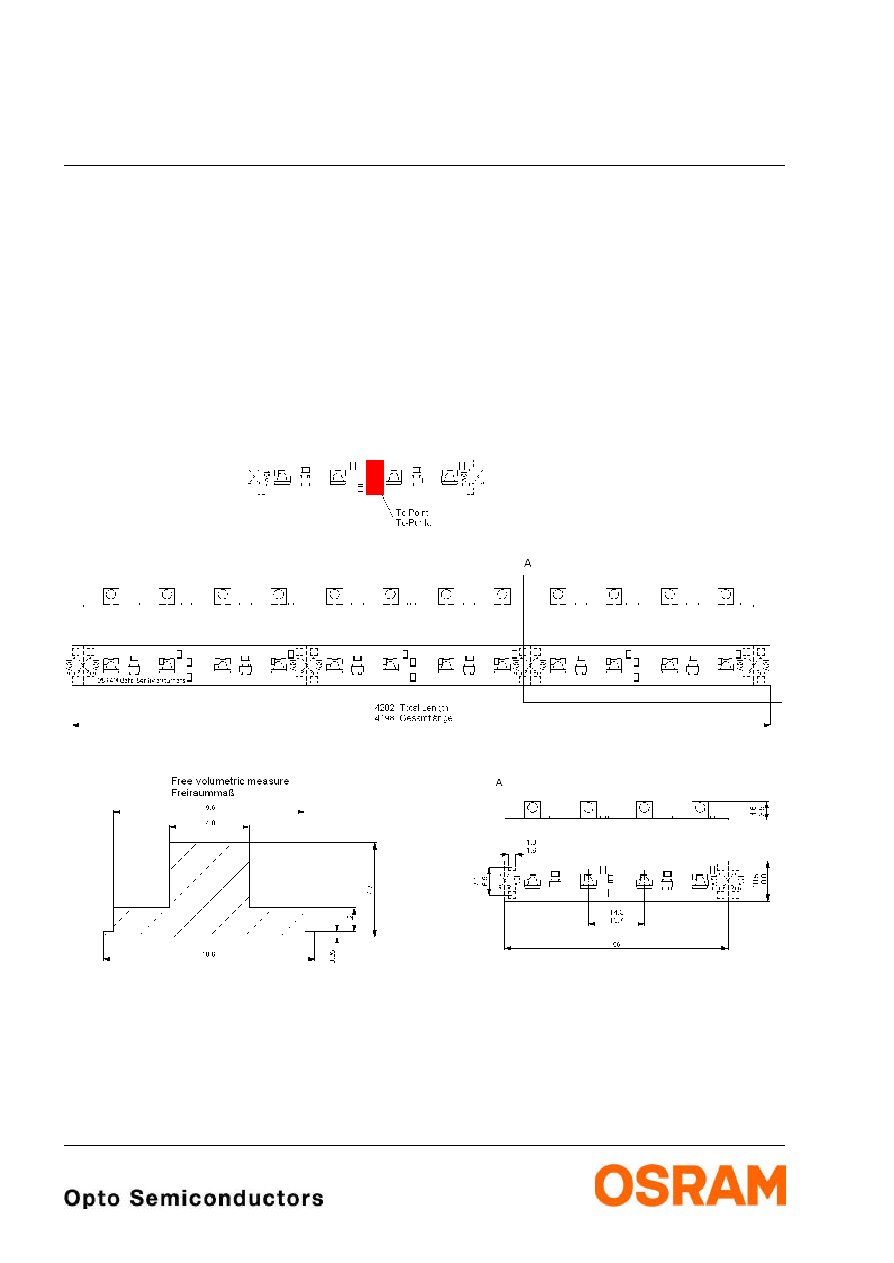

Size of PCB ( LxWxH): 4200 mm x 10 mm x 5

mm

ÿ

Size of smallest unit 4 LED

(LxW): 56 mm x 10 mm

ÿ

Wide viewing angle enables homogeneously

illuminated surfaces

ÿ

OS-LM11A -

Seite 1 von 4

Drawing

Operating Temperature

at Tc-Point [ ∞C ] *

Storage Temperature

[ ∞C ] *

Product

Voltage Range

[ V dc ] *

Reverse Voltage

[ V dc ] *

Minimum and Maximum Ratings

OS-LM11A-W1-854

10

11

11

...

-30

70

-40

85

...

...

OS-LM11A-W1-847

10

11

11

...

-30

70

-40

85

...

...

OS-LM11A-A

10

11

11

...

-30

80

-40

85

...

...

OS-LM11A-Y1

10

11

11

...

-30

80

-40

85

...

...

OS-LM11A-T

10

11

11

...

-30

70

-40

85

...

...

OS-LM11A-B

10

11

11

...

-30

70

-40

85

...

...

Exceeding maximum ratings for operation and storage temperature will reduce expected life time or destroy the LED Module.

Exceeding maximum ratings for operation voltage will cause hazardous overload and will likely destroy the LED Module.

The temperature of the LED module has to measured at the Tc-point according to EN60598-1 in a thermally constant status with a temperature sensor or a temperature

sensitive label (available e.g. at RS-Components). For exact location of the Tc-point see drawing below.

*)

OS-LM11A -

Seite 2 von 4

Safety Information

The LED module itself and all its components may not be mechanical stressed.

ÿ

Assembly must not damage or destroy conducting paths on the circuit board.

ÿ

The LED Module incorporates no protection against: Short circuits, Overload, Overheating. Therefore it is absolutely necessary to

operate the modules with a electronically stabilised power supply offering protection against the above mentioned safety risks.

For dimming applications attention should be paid to specific references in "OPTOTRONIC Technical Guide".

Parallel connection is highly recommended as safe electrical operation mode.

Serial connection is not recommended. Unbalanced voltage drop can cause hazardous overload and demage the LED module.

Installation of LED modules (with power supplies) needs to be made with regard to all applicable electrical and safety standards.

Only qualified personnel should be allowed to perform installations.

Correct electrical polarity needs to be observed. Wrong polarity will result in no light emission.

ÿ

ÿ

ÿ

OSRAM OPTOTRONIC power supplies are specifically designed with the necessary protection features for

safe operation.

When using other power supplies other than OPTOTRONIC the following basic safety features are required, in addition to any other

application specific concerns and local safety codes:

Short circuit protection

ÿ

Overload protection

Overheat protection

Correct output voltage

ÿ

ÿ

ÿ

ÿ

Please ensure that the power supply is of adequate power to operate the total load.

ÿ

At mounting on metallic surfaces there have to be a electrical isolation at soldering points between module and the mounting

surface.

ÿ

The maximum length of LINEARlight Flex OS-LM11 is 2072 mm for green, blue, white and yellow and 4200 mm for red with a two

pole power feed at one end. The complete module 4200 mm can be operated with a two pole power feed in the middle of the

module or from both ends.

ÿ

Pay attention to ESD steps when mounting the module

ÿ

The module, as manufactured, has no conformal coating and therefore offers no inherent protection against corrosion. The ability

to customize the length of the module by cutting at specifically marked points is a key feature of the product and hence the reason

for no factory installed conformal coating. For these reasons, it is recommended that the user complete all module modifications

first ( cutting, wiring) and then apply a conformal coating in the final stages of installation.

ÿ

Damage by corrosion will not be honored as a materials defect claim. It is the user¥s responsibility to provide suitable protection

against corrosive agents such as moisture and condensation and other harmful elements.

ÿ

For applications involving exposure to humidity and dust the module must be protected by a fixture or housing with a suitable

protection class. The module can be protected against condensation water by treatment with an appropriate circiut board garde

conformal cating. The conformal coating should have the following features:

- Optical transparency

- UV-resistance

- thermal expansion matching the thermal expansion of the module 15-30*10^-6 cm/cm/K

- low permeability of steam for all climatic conditions

- resistance against corrosive environment

The lacquer APL of the company Electrolube http://www.electrolube.com met the conditions for the LINEARlight Flex in our tests.

OS-LM11A -

Seite 3 von 4

Assembly Information

ÿ

Solder connections should only be performed on designated solder pads ( marked "10V +/-"). During soldering, do not exceed the

maximum soldering time of 10 seconds and the maximum soldering temperature of 260∞C.

ÿ

The smallest unit (56 mm- 4 LEDs) can be removed by cutting with scissors between the designated solder pads.

ÿ

The mounting of the module is facilitated by means of the double-sided adhesive on the back-surface of the module. Care must be

taken to provide a clean and dry mounting surface, free of oils or silicone coatings as well as dirt particle. The mounting substrate

must have sufficient structural integrity. Take care to completely remove the adhesive backing. Once the module is appropriately

positioned, press on the module with about 20N/cm≤ ( refer to application techniques of 3M adhesive transfer tapes).

ÿ

The minimum bending radius is 2 cm. The module may be bent over a smaller radius but only in regions of the circuit board

containing no electronic components and such bends should be made once and fixed in position to avoid cyclic fatigue.

ÿ

The thermal length expansion coefficent of the modul is 17*10^-6cm/cm/K. When installing in enviroments with large variations in

temperature ( e.g. outdoor applications) and operating length of more than 2 m, the use of metallic mounting surfaces is

necessary. Otherwise it is advisable to use an additional thicker adhesive tape to absorb the stress of any mismatch in expansion

coefficients.

Productgroup

Productname

EAN *

S-Unit *

Ordering Guide

LINEARlight flex

OS-LM11A-W1-854

4050300817217

8

LINEARlight flex

OS-LM11A-W1-847

4050300817194

8

LINEARlight flex

OS-LM11A-A

4050300938554

1

LINEARlight flex

OS-LM11A-Y1

4050300946016

8

LINEARlight flex

OS-LM11A-T

4050300938578

1

LINEARlight flex

OS-LM11A-B

4050300938561

1

EAN: Ordering number per single module

S-Unit: Modules per shipping unit

*)

Note: Typical performance data are subject to change without any further notice, particularly as LED technology evolves.

Related and Further Information

New creativity in lighting design

LED Modules for illuminated signs

ÿ

153 S07 E

The new dimension of light

ÿ

(in preparation)

OPTOTRONIC Technical Guide

ÿ

130 T08 E

OPTOTRONIC Data Sheets

ÿ

www.osram.com

Sales and Technical Support

OSRAM

Opto Semiconductors GmbH

Wernerwerkstrasse 2

D - 93049 Regensburg

Germany

www.osram-os.com

OSRAM GmbH

Hellabrunner Strasse 1

D - 81536 M¸nchen

Germany

www.osram.com

+49 (0)89 6213-0

See web-page for local phone numbers

OS-LM11A -

Seite 4 von 4