| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: OV7411P | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Version 1.4, March 21, 2003

Proprietary to OmniVision Technologies

1

Advanced Information

Preliminary Datasheet

OV7910 Color CMOS NTSC/PAL C

AMERA

C

HIPTM

OV7411 B&W CMOS NTSC/PAL C

AMERA

C

HIPTM

O

mni

TM

ision

General Description

The OV7910 (color) and OV7411 (black and white) single

chip CMOS C

AMERA

C

HIPSTM

are designed to provide a

high level of functionality in a small footprint package.

Both devices support NTSC/PAL composite video and

S-Video. The OV7910 imager also provides RGB and

YCbCr video signals, and each device directly interfaces

with a VCR TV monitor or other 75 ohm terminated input.

A minimal number of external components are required to

complete a fully functional camera subsystem. The

OV7910/OV7411 video cameras require only a single

5-volt DC supply and have been designed for very low

power operation. These products are ideal for all

applications requiring a small footprint, low voltage, low

power and low cost color or black and white video camera.

Features

∑

Single chip 1/3" format video camera

∑

PAL with 628 x 582 pixels or NTSC with

510 x 492 pixels.

∑

Composite video:

≠

NTSC

≠

S-Video

∑

Component video RGB or YUV

∑

Sensitivity boost (+18 dB)/AGC ON/OFF

∑

Automatic exposure/gain/white balance

∑

External frame sync capability

∑

Aperture correction

∑

SCCB programmable controls:

≠

Color saturation

≠

Brightness

≠

Contrast

≠

White balance

≠

Exposure time

≠

Gain

∑

Gamma correction (0.45) ON/OFF

∑

Low power consumption

∑

+5 volt only power supply

Ordering Information

Product

Package

OV7910 (Color, NTSC/PAL)

CLCC-48

OV7411 (B&W, NTSC/PAL)

CLCC-48

Applications

∑

Automotive

∑

PC Multimedia

∑

Toys

∑

Security

∑

Surveillance

∑

Video phones

∑

Video conference equipment

Key Specifications

Figure 1 OV7910/OV7411 Pin Diagram

Array Size

PAL 628 x 582

NTSC 510 x 492

Power Supply 5 VDC + 5%

Power Requirements 200 mW

Image Area

PAL 5.78 mm x 4.19 mm

NTSC 4.69 mm x 3.54 mm

Auto Electronic Exposure Time 1/60s to 1/2000s

Lens Size 1/3"

Min. Illumination

(3000K)

OV7910 < 5 Lux

OV7411 < 1 Lux

S/N Ratio 40 dB

Pixel Size 9.2 µm x 7.2 µm

Fixed Pattern Noise < 0.03% V

PP

Package Dimensions .560 in. x .560 in.

36

FSI

37

PWDN

38

AMOD0

39

AMOD1

40

HSHP

41

DEVDD

42

DEGND

31

VAXPXO

32

VHSYNC/MIR

33

FSO/VSFR

34

FODD/I2CEN

35

PALSW

13 EVDD

12 SMTAWB

11 RSVD11

10 HSAT

9

CEXP

8

RGSW

7

AVDD

18 OVDD

17 RVCVO

16 GYYO

15 BVCO

14 EGND

48

VR

EF

4

1

SG

N

D

2

SV

D

D

3

Vc

B

R

T

4

BP

AV

E

5

RS

V

D

5

6

AG

ND

43

SC

L

44

SD

A

45

VR

EF

1

46

V

R

EF

2

47

VR

EF

3

OV7910/OV7411

25

DV

DD

24

PA

L

23

XC

L

K

2

22

XC

L

K

1

21

BK

L

T

20

HG

AI

N

19

G2

X

30

AW

B

T

M

29

AW

B

E

N

28

AG

CE

N

27

GA

M

M

A

26

DG

ND

2

Proprietary to OmniVision Technologies

Version 1.4, March 21, 2003

OV7910/OV7411

CMOS NTSC/PAL C

AMERA

C

HIP

TM

O

mni

ision

Functional Description

This section describes the various functions of the OV7910/OV7411. Refer to

Figure 2

for the functional block diagram of the

OV7910/OV7411.

Figure 2 Functional Block Diagram

Clock/Timing Generator and Control Logic

Image Array

(628 X 582)

Row

Select

I

2

C

Interface

Gain

Control

I2

C

E

N

SD

A

SC

L

ASP

Control

CVO

Analog Signal

Processor

(ASP)

XC

L

K

1

XC

L

K

2

PW

D

N

FS

I

BK

L

T

V

c

BRT

G

A

MMA

VH

S

Y

N

C

VA

X

P

X

O

FO

D

D

AMP

Control

Register

Bank

Column Sample/Hold

Functional Description

Version 1.4, March 21, 2003

Proprietary to OmniVision Technologies

3

O

mni

ision

Video Standards

Two TV standards are implemented and available as

output in the OV7910/OV7411 imaging devices,

NTSC (M) and PAL (B).

Table 1

shows how to configure

the standard of choice. Note that the accuracy and

stability of the crystal clock frequency is important to avoid

unwanted color shift in TV video system.

Video Formats

The OV7910/OV7411 image sensors support a variety of

formats including Composite (CVBS), S-Video (YO/CO),

RGB components, and YUV components. Composite and

S-Video signals are generated from the internal TV

encoder and RGB/YUV outputs are generated form the

color matrix prior to entering the encoder. The image

sensor utilizes the RG/BG Bayer pattern, sending raw

pixel data through the color matrix, creating RGB or YUV

component signals. At the same time, YUV signals are

also processed to generate both composite and S-video

signals. Note that color format configuration is valid only

for the OV7910 image sensor.

Composite and S-Video

The Composite/S-Video format is the power-up default

configuration for the OV7910/OV7411 image sensors.

AMOD0

(pin 38) and

AMOD1

(pin 39) select composite

and S-video formats. In this configuration,

RVCVO

(pin 17) outputs the YO component of the S-video signal

and

BVCO

(pin 15) outputs the CO component.

Table 2

summarizes the available formats and the settings

required on the appropriate pins.

RGB Format

Setting AMOD0 = 1 (with AMOD1 = x) selects the RGB

format. In this configuration,

RVCVO

outputs the RED

component,

GYYO

outputs the GREEN component and

BVCO

provides the BLUE component.

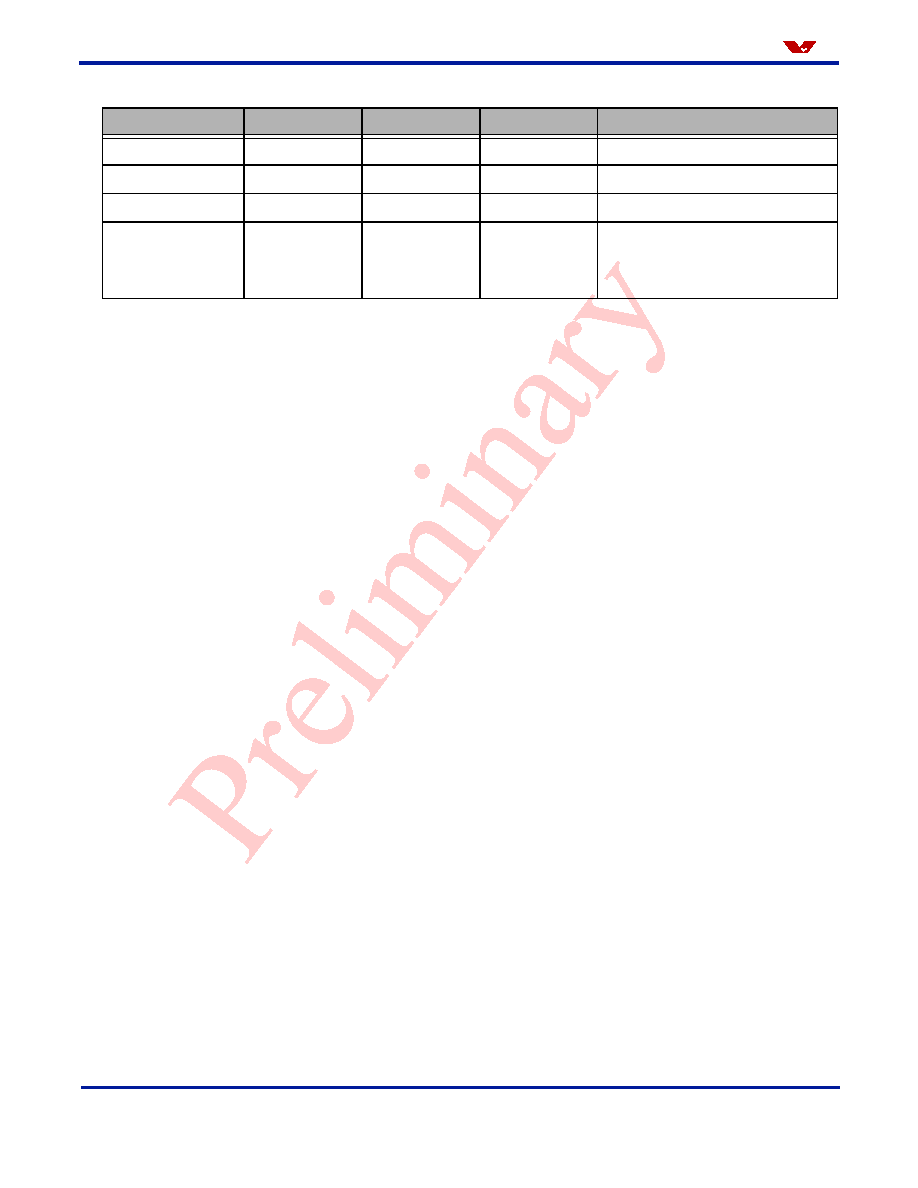

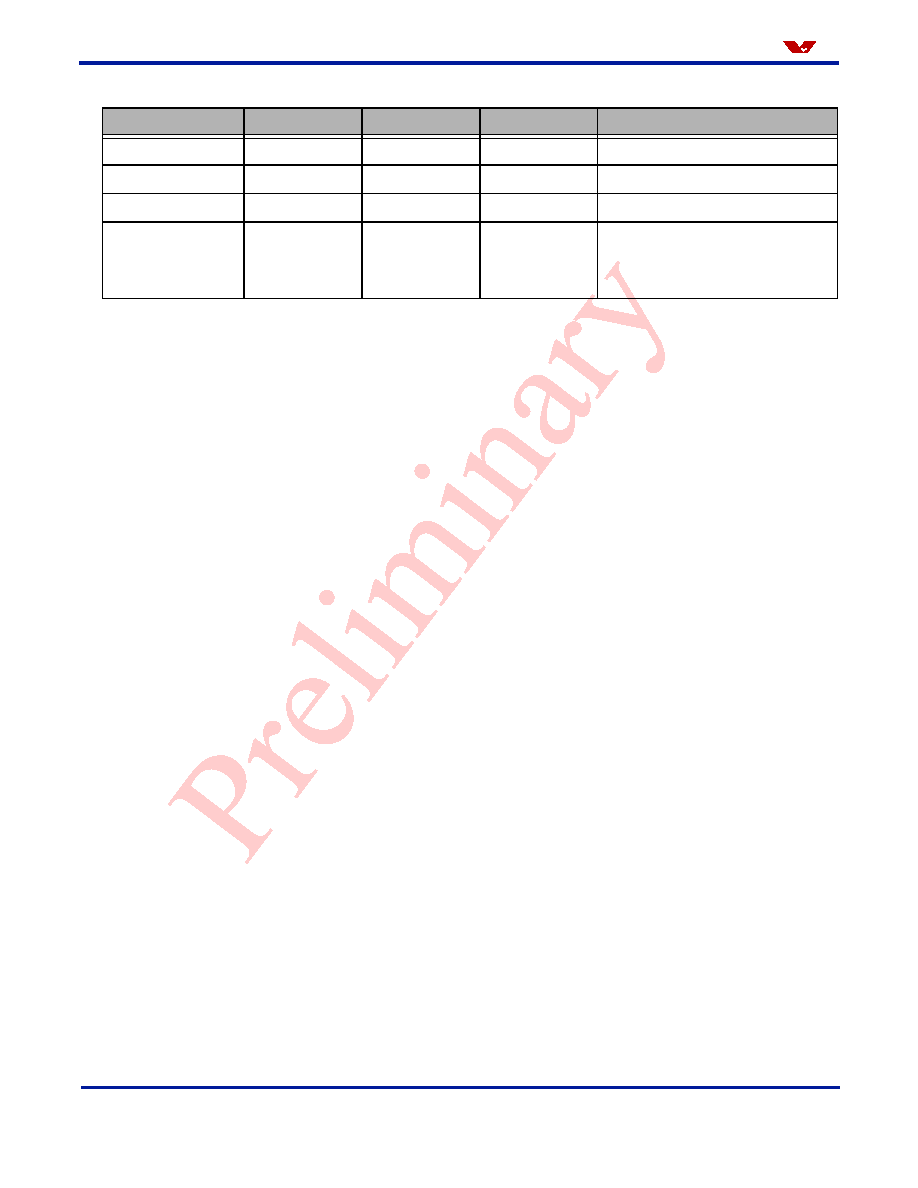

Table 1

Standard Configurations

Standard

PAL Setting

(Pin 24)

Clock

Comments

NTSC

0

14.31818 MHz

Clock in =

4 x F

SC

PAL

1

17.734475 MHz

Clock in =

4 x F

SC

YUV Format

Setting

AMOD0

= 0 and

AMOD1

= 1 configures the

OV7910/OV7411 sensors to operate in YUV mode or

B&W mode. In this configuration,

GYYO

outputs the Y

component,

RVCVO

provides the Cr component, and

BVCO

outputs the Cb component. On the OV7411 image

sensor, only the

GYYO

(Y component) output is valid.

Configuring the OV7910/OV7411

The OV7910/OV7411 sensors are designed for

ease-of-use in many standalone applications. Most of the

on-chip functions are configurable by connecting

appropriate pins high (logic "1") or low (logic "0") using a

10K

resistor. The image sensor reads the input pins at

power up which enable user-defined default

configurations.

The OV7910/OV7411 sensors also contain a Serial

Camera Control Bus (SCCB) interface for programmable

access to all register functions. For further details on the

SCCB port, see

"Serial Camera Control Bus (SCCB)" on

page 4

. By default, the SCCB interface is disabled. To

enable the SCCB interface for controlling the sensor, a

10K

. pull-up resistor must be connected to the

FODD/I2CEN

pin (pin 34). With the FODD/I2CEN pin

pulled high at power-up, the OV7910/OV7411 image

sensors will enable the SCCB port for access.

White Balance

The White Balance function in the OV7910/OV7411

image sensor is used to adjust and calibrate the image

device sensitivity on the primary (RGB) colors to match

the color cast of the light source. The Auto White Balance

(AWB) can be enabled or disabled through either the

AWBEN

pin (pin 29) or through the SCCB port. If AWB is

enabled, the image sensors continuously perform white

balancing. A fast or slow mode of white balancing may be

user-selected through the

AWBTM

pin (pin 30). Fast AWB

updates color every 2 fields while slow AWB updates

every 16 fields.

By using the SCCB port, the color temperature may be

further fine tuned to the requirement of the application.

Note that the "blue" (

BLUE

and

BBS

registers) and "red"

(

RED

and

RBS

registers) bias control are only available

through the SCCB port. This function enables the user to

define a "cooler" or "warmer" background for image

capture.

4

Proprietary to OmniVision Technologies

Version 1.4, March 21, 2003

OV7910/OV7411

CMOS NTSC/PAL C

AMERA

C

HIP

TM

O

mni

ision

Table 2

Video Format Options

Format Type

RVCVO (Pin 17)

GYYO (Pin 16)

BUCO (Pin 15)

Pin Settings

Composite/S-Video

CVBS

YO

CO

AMOD0 = 0, AMOD1 = 0

RGB Component

RED

GREEN

BLUE

AMOD0 = 1, AMOD1 = x

YUV Component

Cr

Y

Cb

AMOD0 = 0, AMOD1 = 1

Black and White

--

Y

--

AMOD0 = 0, AMOD1 = 1

Note: Pins 15 and 17 are undefined

in the OV7411 sensor.

Additional Picture Control

A number of functions/registers are available which

enable the user to configure OV7910/OV7411 image

capturing parameters. These functions include Automatic

Gain Control (AGC), AGC Gain, Automatic Exposure

Control (AEC), GAMMA, and Backlight control.

AGC Gain can be set at 2x normal by programming pin 20,

HGAIN

. This function may be configured through the

SCCB port as well.

GAMMA

(pin 27) can be used to set

the color correction.

BKLT

(pin 21) controls how the

OV7910/OV7411 image sensors manage backlight

conditions. These functions may also be controlled by the

SCCB interface.

At power up, AGC and AEC are enabled. AGC can be

disabled at power-up by configuring the

AGCEN

pin

(pin 28) as required. AEC cannot be enabled/disabled

externally and must be programmed through the SCCB

port.

Other Image Sensor Control Functions

Additional programmable functions for OV7910/OV7411

image sensors include sharpness adjustment, brightness

level fine tune, color saturation adjustment, hue

adjustment. All these functions (except for power down)

can be configured by either an external pin or through the

SCCB interface.

Serial Camera Control Bus (SCCB)

Many of the functions and configuration registers in the

OV7910/OV7411 image sensors are available through the

SCCB interface. The SCCB port is enabled by asserting

the I2CEN line (pin 34, see

"FODD/I2CEN" on page 8

)

through a 10K

resistor to V

DD

. When the SCCB

capability is enabled (I2CEN = 1), the OV7910/OV7411

image sensor operates as a slave device that supports up

to 400 kbps serial transfer rate using a 7-bit address/data

transfer protocol.

NOTE: When the SCCB interface is enabled, the

OV7410/OV7411 will output in color by default. To output

in B&W mode, set register

COMB

[1:0] = 10b.

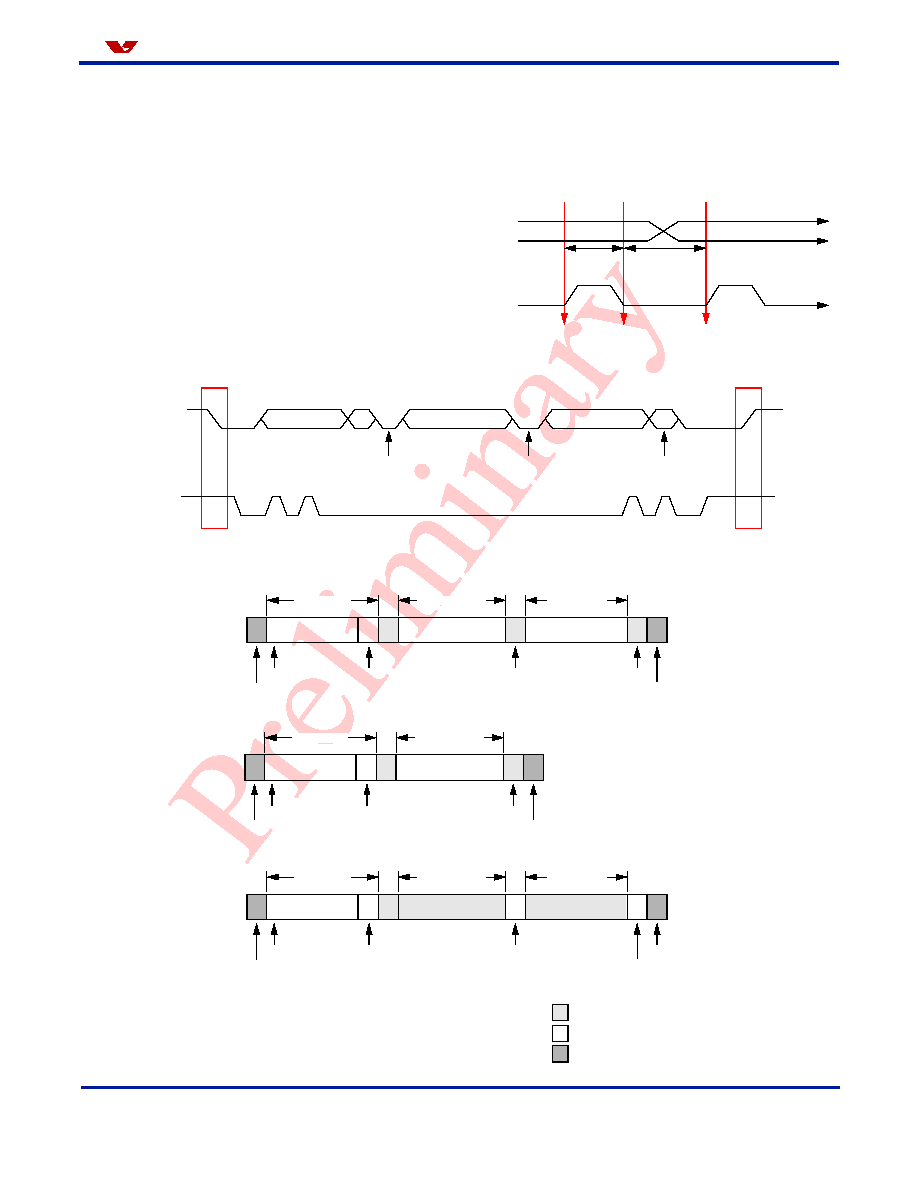

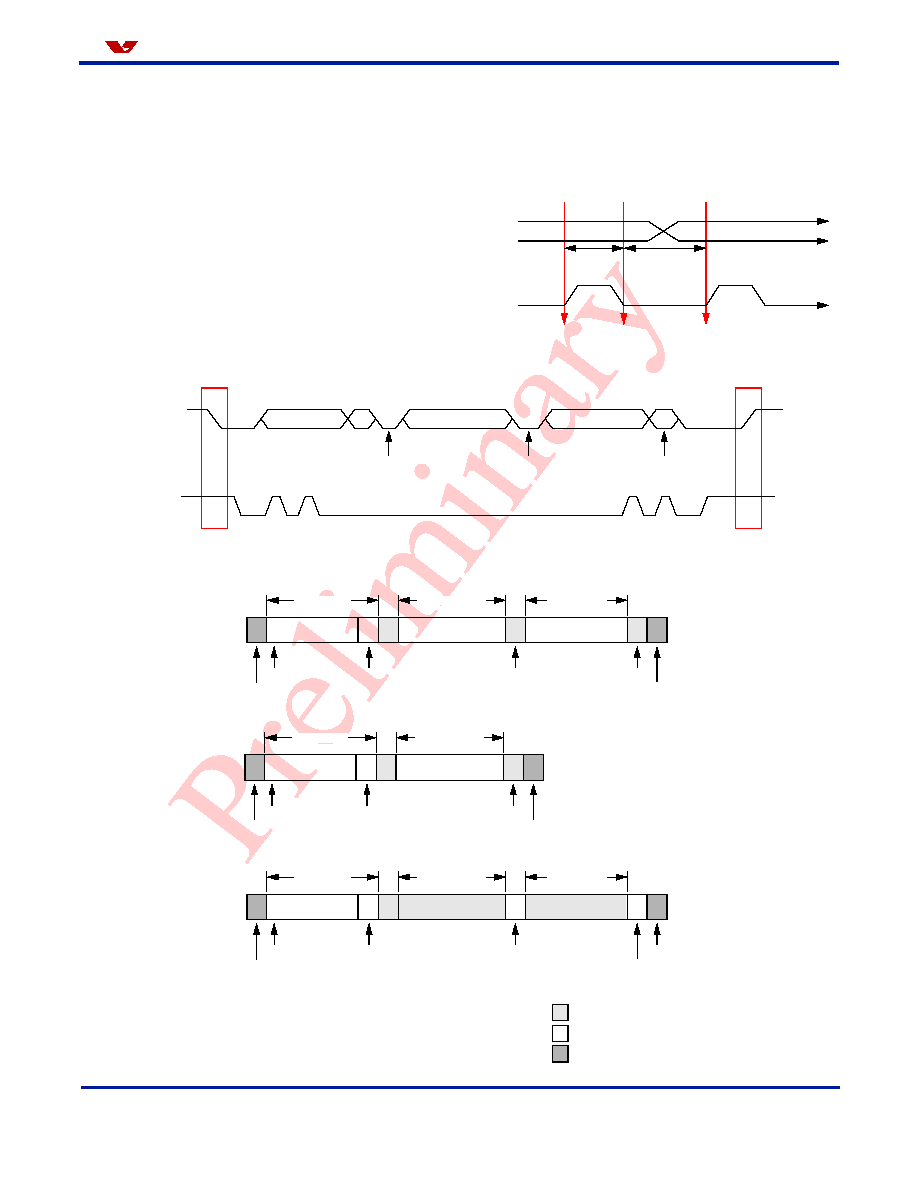

SCCB Protocol Format

In SCCB operation (see

Figure 5

), the master must

perform the following operations:

∑

Generate the Start/Stop condition

∑

Provide the serial clock on SCL

∑

Place the 7-bit slave address (RW bit) and the 8-bit

sub-address on SDA

The receiver must pull down

SDA

during the

acknowledgement bit time. During the write cycle, the

OV7910/OV7411 device returns the acknowledgement

and, during the read cycle, the master returns the

acknowledgement, indicating to the slave that the read

cycle can be terminated. Note that the restart feature is

not supported here.

Within each byte, the MSB is transferred first. The

read/write control bit is the LSB of the first byte. Standard

SCCB communications require only two pins,

SCL

and

SDA

. SDA is configured as an open drain for bidirectional

purposes. A HIGH to LOW transition on the SDA while

SCL is HIGH indicates a START condition. A LOW to

HIGH transition on the SDA while SCL is HIGH indicates

a STOP condition. Only a master can generate

START/STOP conditions.

Except for these two special conditions, the protocol that

SDA remain stable during the HIGH period of the clock,

SCL. Each bit is allowed to change state only when SCL

is LOW (see

Figure 3

and

Figure 4

).

The OV7910/OV7411 SCCB interface supports multi-byte

write and multi-byte read. The master must supply the

sub-address in the write cycle, but not in the read cycle.

Therefore, the OV7910/OV7411 takes the read

sub-address from the previous write cycle. In multi-byte

write or multi-byte read cycles, the sub-address

automatically increments after the first data byte so that

Functional Description

Version 1.4, March 21, 2003

Proprietary to OmniVision Technologies

5

O

mni

ision

continuous locations can be accessed in one bus cycle. A

multi-byte cycle overwrites its original sub-address;

therefore, if a read cycle immediately follows a multi-byte

cycle, a single byte write cycle that provides a new

address must be inserted.

The OV7910/OV7411 supports a single slave ID. The ID

is preset to 80 for write and 81 for read.

In the write cycle, the second byte in the SCCB is the

sub-address for selecting the individual on-chip registers,

and the third byte is the data associated with this register.

Writing to the unimplemented sub-address is ignored.

In the read cycle, the second byte is the data associated

with the previously stored sub-address. Reading of an

unimplemented sub-address returns unknown.

Figure 3 Bit Transfer on the SCCB

DATA

DATA

SDA

SCL

STABLE

CHANGE

ALLOWED

Figure 4 Data Transfer on the SCCB

Figure 5 SCCB Protocol Format

SDA

SCL

SLAVE ID

SUB-ADDRESS

DATA

RW

S

P

A

A

A

RW

SUB-ADDRESS (8-BIT)

DATA (8-BIT)

SLAVE (7-BIT)

S

A

A

A

P

STOP

ACK

ACK

LSB=0

MSB

START

FIRST BYTE

SECOND BYTE

THIRD BYTE

MASTER TRANSMIT, SLAVE RECEIVE (WRITE CYCLE)

RW

SUB-ADDRESS (8-BIT)

SLAVE (7-BIT)

S

A

A

P

STOP

ACK

LSB=0

MSB

START

FIRST BYTE

SECOND BYTE

MASTER TRANSMIT, SLAVE RECEIVE (DUMMY WRITE CYCLE)

RW

DATA (8-BIT)

DATA (8-BIT)

SLAVE (7-BIT)

S

A

A

1

P

STOP

NO ACK IN

ACK

LSB=1

MSB

START

FIRST BYTE

SECOND BYTE

THIRD BYTE

MASTER RECEIVE, SLAVE RECEIVE (READ CYCLE)

LAST BYTE

≠

SLAVE TRANSMIT

≠

MASTER TRANSMIT

≠

MASTER INITIATE

S ≠ START CONDITION

A ≠ ACKNOWLEDGE BIT

P ≠ STOP CONDITION

SLAVE ID ≠ 1000000X

X ≠ RW BIT, 1: READ, 0: WRITE