| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: 9312-11 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Page 1 of 7

Document No. 70-0119-02

www.psemi.com

©2005 Peregrine Semiconductor Corp. All rights reserved.

The PE9312 is a high-performance static UltraCMOSTM

prescaler with a fixed divide ratio of 4. Its operating frequency

range is DC to 1500 MHz. The PE9312 operates on a nominal

3 V supply and draws only 6.5 mA. It is packaged in a small

8-lead ceramic SOIC and is ideal for frequency scaling and

clock generation solutions.

The PE9312 is manufactured in Peregrine's patented Ultra-

Thin Silicon (UTSi

Æ

) CMOS process, offering the performance

of GaAs with the economy and integration of conventional

CMOS.

Product Description

Figure 1. Functional Diagram

Features

∑

DC to 1500 MHz operation

∑

Fixed divide ratio of 4

∑

Low-power operation: 6.5 mA typical

@ 3 V

∑

Ultra small package: 8-lead Ceramic

SOIC

∑

Guaranteed 100 Krads(Si) Total Dose

Performance

∑

Superior Single Event Upset Immunity

Table 1. Electrical Specifications @ +25 ∞C, V

DD

= 2.6 V

(Z

S

= Z

L

= 50

)

Parameter Conditions

Minimum

Typical

Maximum

Units

Supply Voltage

2.85

3.0

3.15

V

Supply Current

6.5

11

mA

Input Frequency (F

in

)

DC

1500

MHz

Input Power (P

in

)

DC <

Fin

∑

1000 MHz

-8

+10

dBm

1000 <

Fin

∑

1500 MHz

0

+10

dBm

Output Power (P

out

)

DC < Fin

∑

1500 MHz

0

dBm

V

DD

= 3.0 V, -40∞ C

T

A

85∞ C,

unless otherwise specified

D

QB

Q

CLK

D

QB

Q

CLK

Pre-Amp

Output

Buffer

IN

OUT

Product Specification

PE9312

1500 MHz Low Power UltraCMOSTM

Divide-by-4 Prescaler

Rad hard for Space Applications

Figure 2. Package Type

8-lead CSOIC

Product Specification

PE9312

Page 2 of 7

©2005 Peregrine Semiconductor Corp. All rights reserved.

Document No. 70-0119-02

UltraCMOSTM RFIC Solutions

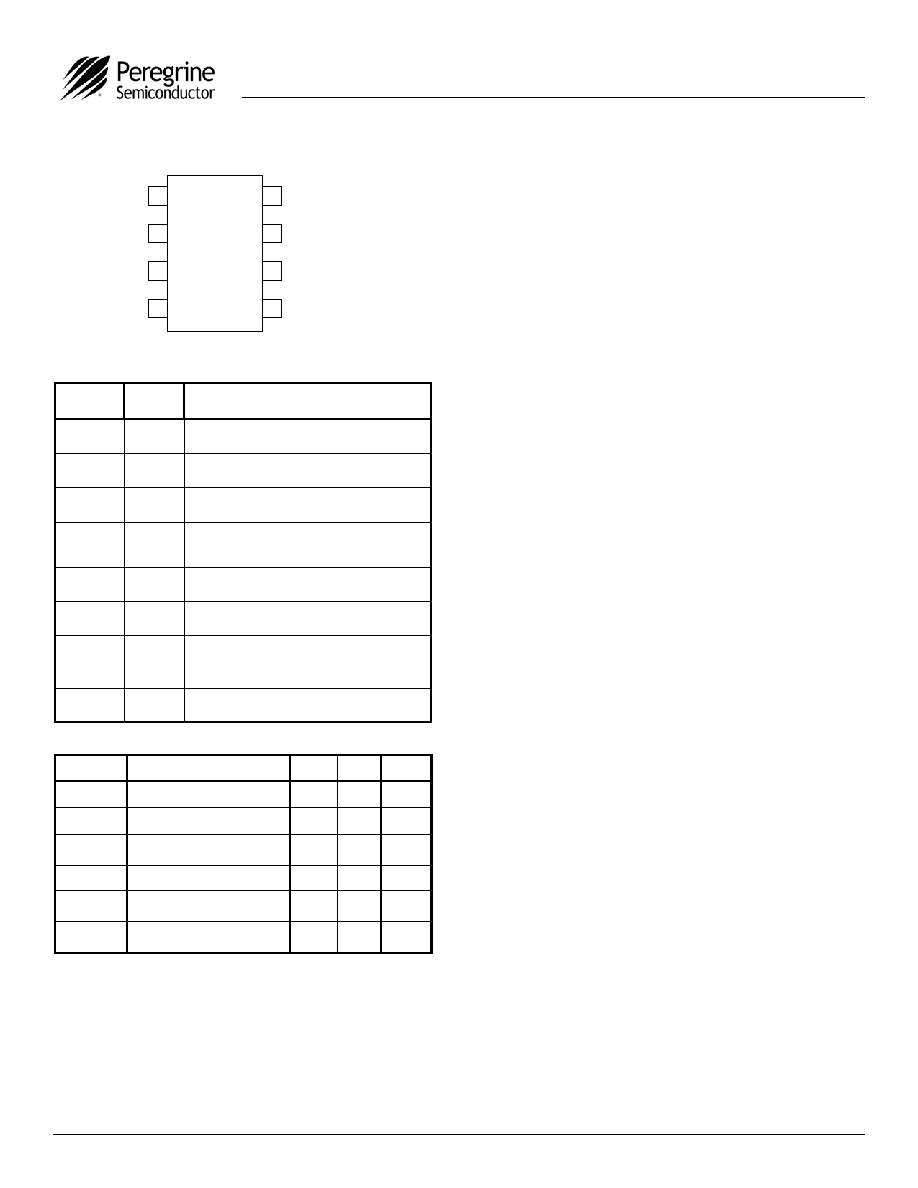

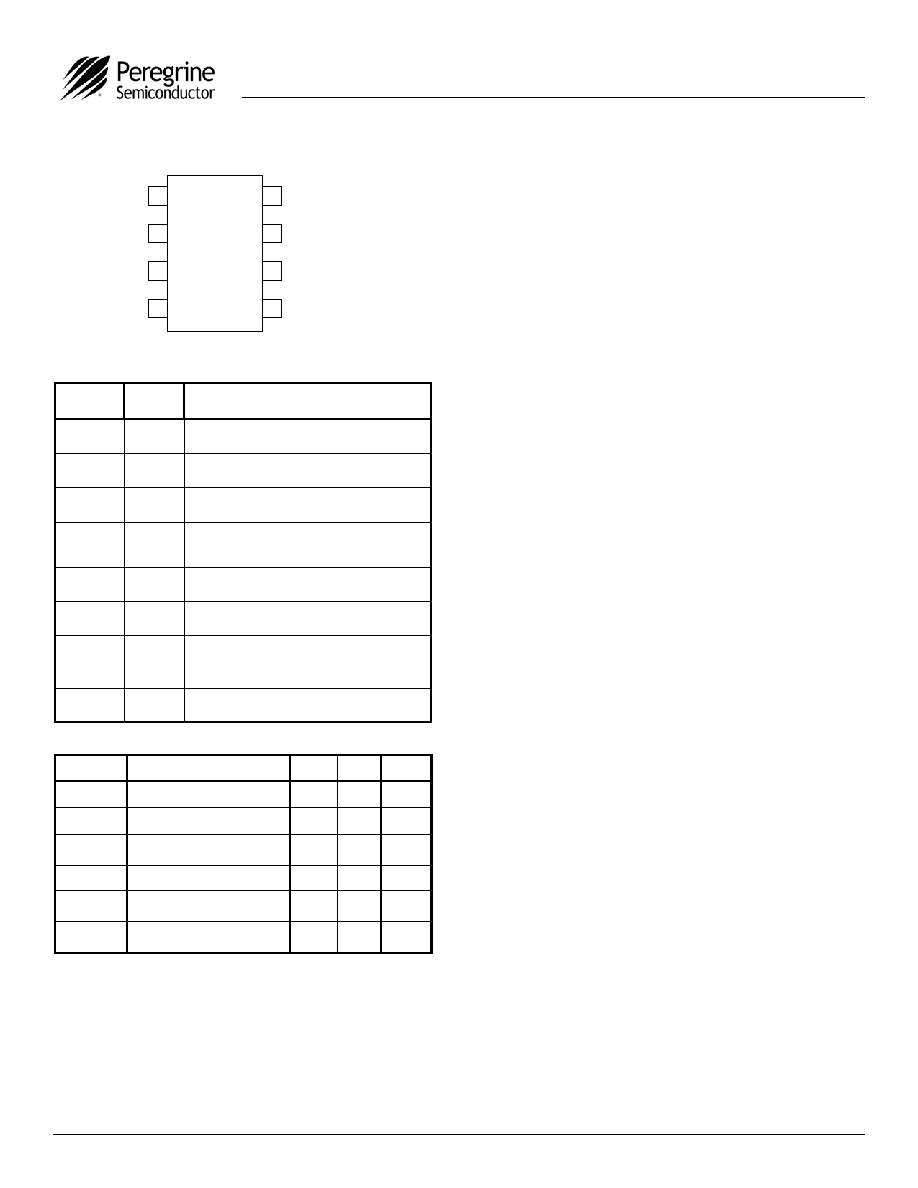

Table 2. Pin Descriptions

Table 3. Absolute Maximum Ratings

Device Functional Considerations

The PE9312 divides an input signal, up to a

frequency of 1500 MHz, by a factor of four thereby

producing an output frequency at a quarter of the

input frequency. To work properly at higher

frequency, the input and output signals (pins 2 &

7) must be AC coupled via an external capacitor,

as shown in the test circuit in Figure 8. The input

may be DC coupled for low frequency operation

with care taken to remain within the specified DC

input range for the device.

The ground pattern on the board should be made

as wide as possible to minimize ground

impedance. See Figure 7 for a layout example.

Latch-Up Avoidance

Unlike conventional CMOS devices, UltraCMOSTM

devices are immune to latch-up.

Figure 3. Pin Configuration

Electrostatic Discharge (ESD) Precautions

When handling this UltraCMOSTM device, observe

the same precautions that you would use with

other ESD-sensitive devices. Although this device

contains circuitry to protect it from damage due to

ESD, precautions should be taken to avoid

exceeding the rating specified in Table 3.

PE9312

1

2

3

4

8

7

6

5

IN

GND

N/C

GND

OUT

V

DD

NC

GND

Pin No.

Pin

Name

Description

1 V

DD

Power supply pin. Bypassing is required

(eg 1000 pF & 100 pF).

2 IN

Input signal pin. Should be coupled with a

capacitor (eg 1000 pF).

3 NC

No connection. This pin should be left

open.

4 GND

Ground pin. Ground pattern on the board

should be as wide as possible to reduce

ground impedance.

5 GND

Ground

pin.

6 NC

No connection. This pin should be left

open.

7 OUT

Divided frequency output pin. This pin

should be coupled with a capacitor

(eg 1000 pF).

8 GND

Ground

Pin.

Symbol Parameter/Conditions Min Max Units

V

DD

Supply voltage

4.0

V

P

in

Input

Power

15

dBm

V

IN

Voltage on input

-0.3

V

DD

+0.3

V

T

ST

Storage temperature range

-65

150

∞C

T

OP

Operating temperature

range

-40 85 ∞C

V

ESD

ESD voltage (Human Body

Model, MIL-STD 883)

1000

V

Absolute Maximum Ratings are those values

listed in the above table. Exceeding these values

may cause permanent device damage.

Functional operation should be restricted to the

limits in the DC Electrical Specifications table.

Exposure to absolute maximum ratings for

extended periods may affect device reliability.

Product Specification

PE9312

Page 3 of 7

Document No. 70-0119-02

www.psemi.com

©2005 Peregrine Semiconductor Corp. All rights reserved.

Typical Performance Data: V

DD

= 3.0 V

Figure 4. Input Sensitivity

Figure 5. Device Current

Figure 6. Output Power

Product Specification

PE9312

Page 4 of 7

©2005 Peregrine Semiconductor Corp. All rights reserved.

Document No. 70-0119-02

UltraCMOSTM RFIC Solutions

Figure 7. Test Circuit Block Diagram

50

VDD

IN

N/C

GND

GND

OUT

N/C

GND

1000 pF

100 pF

1000pF

1000pF

3 V

Power Meter or

Frequency Counter

50

Product Specification

PE9312

Page 5 of 7

Document No. 70-0119-02

www.psemi.com

©2005 Peregrine Semiconductor Corp. All rights reserved.

Evaluation Kit Operation

The Ceramic SOIC Prescaler Evaluation Board was

designed to help customers evaluate the PE9312

divide-by-2 prescaler. On this board, the device

input (pin 2) is connected to the SMA connector J1

through a 50

transmission line. A series capacitor

(C3) provides the necessary DC block for the device

input. A value of 1000 pF was used for the

evaluation board; other applications may require a

different value. It is also possible to place a 0

resistor in this location for very low frequency

applications.

The device output (pin 7) is connected to SMA

connector J3 through a 50

transmission line. A

series capacitor (C1) provides the necessary DC

block for the device output. This capacitor value

must be chosen to have a low impedance at the

desired output frequency of the device. A value of

1000 pF was chosen for the evaluation board.

The board is constructed of a two-layer FR4 material

with a total thickness of 0.031". The bottom layer

provides ground for the RF

transmission lines. The

transmission lines were designed using a coplanar

waveguide above ground plane model with trace

width of 0.030", trace gaps of 0.0061", dielectric

thickness of 0.028", metal thickness of 0.0014", and

r

of 4.6. Note that the predominate mode of these

transmission lines is coplanar waveguide.

J2 provides DC power to the device via pin 1. Two

decoupling capacitors (C2=100 pF, C10=1000 pF)

are included on this trace. It is the responsibility of

the customer to determine proper supply decoupling

for their design application.

Figure 8. Evaluation Board Layout

Figure 9. Evaluation Board Schematic

Peregrine specification 102/0202

Peregrine specification 102/0034