| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: OM5193H | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Document Outline

- CONTENTS

- 1 FEATURES

- 1.1 Servo control

- 1.2 Motor control

- 1.3 Miscellaneous items

- 2 APPLICATIONS

- 3 GENERAL DESCRIPTION

- 3.1 Overview

- 3.2 Servo controller

- 3.3 Spindle and voice coil motor

- 3.4 Safety functions

- 4 QUICK REFERENCE DATA

- 5 ORDERING INFORMATION

- 6 BLOCK DIAGRAMS

- 7 PINNING

- 8 FUNCTIONAL DESCRIPTION

- 8.1 Serial interface

- 8.2 Commutation and sleep mode

- 8.3 Commutation control

- 8.4 10-bit ADC with 7 analog inputs

- 8.5 10-bit VCM DAC

- 8.6 Reference voltage

- 8.7 Stand-alone op-amps

- 8.8 Analog switch

- 8.9 Charge pump voltage

- 8.10 Spindle driver

- 8.11 VCM driver

- 8.12 Park the VCM

- 8.13 Precharge the VCM

- 8.14 Brake the motor

- 8.15 Power-on reset

- 8.16 Thermal monitor and shutdown

- 8.17 Power supply isolation

- 8.18 Thermal behaviour

- 9 LIMITING VALUES

- 10 HANDLING

- 11 THERMAL CHARACTERISTICS

- 12 CHARACTERISTICS

- 13 APPLICATION INFORMATION

- 14 PACKAGE OUTLINE

- 15 SOLDERING

- 15.1 Introduction

- 15.2 Reflow soldering

- 15.3 Wave soldering

- 15.4 Repairing soldered joints

- 16 DEFINITIONS

- 17 LIFE SUPPORT APPLICATIONS

DATA SHEET

Product specification

File under Integrated Circuits, IC11

1998 Nov 02

INTEGRATED CIRCUITS

OM5193H

Disk drive spindle and VCM with

servo controller

1998 Nov 02

2

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

CONTENTS

1

FEATURES

1.1

Servo control

1.2

Motor control

1.2.1

Spindle motor driver

1.2.2

Voice coil motor driver

1.3

Miscellaneous items

2

APPLICATIONS

3

GENERAL DESCRIPTION

3.1

Overview

3.2

Servo controller

3.3

Spindle and voice coil motor

3.4

Safety functions

4

QUICK REFERENCE DATA

5

ORDERING INFORMATION

6

BLOCK DIAGRAMS

7

PINNING

8

FUNCTIONAL DESCRIPTION

8.1

Serial interface

8.2

Commutation and sleep mode

8.3

Commutation control

8.3.1

Blanks, Watchdog and Start-up delays

8.3.2

Comdelim delay

8.4

10-bit ADC with 7 analog inputs

8.4.1

Input channels

8.4.2

Input ranges

8.4.3

Conversion modes

8.4.4

Programming register#0

8.4.5

Converter clock frequency values

8.5

10-bit VCM DAC

8.6

Reference voltage

8.7

Stand-alone op-amps

8.8

Analog switch

8.9

Charge pump voltage

8.10

Spindle driver

8.11

VCM driver

8.12

Park the VCM

8.13

Precharge the VCM

8.14

Brake the motor

8.15

Power-on reset

8.16

Thermal monitor and shutdown

8.17

Power supply isolation

8.17.1

External isolation diode

8.17.2

External power FET

8.18

Thermal behaviour

9

LIMITING VALUES

10

HANDLING

11

THERMAL CHARACTERISTICS

12

CHARACTERISTICS

13

APPLICATION INFORMATION

14

PACKAGE OUTLINE

15

SOLDERING

15.1

Introduction

15.2

Reflow soldering

15.3

Wave soldering

15.4

Repairing soldered joints

16

DEFINITIONS

17

LIFE SUPPORT APPLICATIONS

1998 Nov 02

3

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

1

FEATURES

1.1

Servo control

∑

10-bit VCM Digital-to-Analog Converter (DAC)

∑

7-channel 10-bit Analog-to-Digital Converter (ADC)

∑

Programmable spindle commutation control logic

∑

3-wire serial interface

∑

Two stand-alone operational amplifiers (op-amps) with

outputs connected to the ADC

∑

Analog multiplexer with two inputs used to select VCM

seek mode or track-following mode.

1.2

Motor control

1.2.1

S

PINDLE MOTOR DRIVER

∑

3-phase output motor driver

∑

1.9 A maximum available start-up current

∑

Total R

ds(on)

= 0.6

(typical) at 25

∞

C

∑

Back ElectroMotive Force (BEMF) processing for

sensorless motor commutation

∑

Linear current control

∑

External current sense resistor

∑

External current control loop compensation

∑

Adjustable slew rate control

∑

Short-circuit brake

∑

Adjustable brake-after-park delay time.

1.2.2

V

OICE COIL MOTOR DRIVER

∑

1.5 A maximum current capability

∑

Total R

ds(on)

= 0.8

(typical) at 25

∞

C

∑

Linear class AB output with low cross-over distortion

delay

∑

Precision current control loop with external current

sense resistor

∑

Programmable seek and track-following mode with

adjustable current loop gain

∑

External current control loop compensation

∑

Precharge during brake mode

∑

20 kHz current control loop bandwidth

∑

Parking function

∑

Adjustable park voltage with limiter.

1.3

Miscellaneous items

∑

Precision low voltage 5 and 12 V power monitor with

hysteresis

∑

Precision internal voltage reference for servo and power

control circuits

∑

Thermal sense circuit with over-temperature shutdown

sensor

∑

Internal charge pump voltage generator

∑

Automatic brake-after-park at power-down, thermal

shutdown or sleep mode

∑

Sleep mode: low power consumption mode.

2

APPLICATIONS

∑

12 V hard disk drive products.

3

GENERAL DESCRIPTION

3.1

Overview

The OM5193H is a combination of a voice coil motor and

a spindle motor driver with embedded servo controller

designed for use in disk drives. Configuration and control

registers are set via a 3-wire serial port running up to

30 MHz to interface commonly to a microcontroller or a

digital signal processor.

The device operates at 5 and 12 V power supplies and

integrates safety functions such as power stages

overvoltage protection, power and temperature monitor,

over-temperature shutdown and dynamic

brake-after-park.

The device is contained in a QFP80 package with 18 pins

connected to the leadframe thus providing low thermal

resistance.

3.2

Servo controller

The servo controller includes the following circuits:

∑

3-wire serial interface

∑

Spindle commutation logic

∑

A 10-bit ADC with 7 inputs selected by an internal

multiplexer

∑

A 10-bit VCM DAC with 1.5, 2.5 and 3.5 V voltage

references

∑

Two low-offset stand-alone op-amps

∑

Analog multiplexer with 2 inputs.

1998 Nov 02

4

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

The serial interface is used:

∑

To adjust the timing parameters for proper spindle

commutation sequence

∑

To accurately adjust head positioning via the 10-bit VCM

DAC

∑

To set VCM seek or track-following mode via the

low-impedance switch

∑

To select and process analog signals via a 7-channel

multiplexer connected to the 10-bit ADC.

The spindle commutation logic circuit ensures proper

spindle start-up (no reverse rotation) and commutation

sequence for the spindle driver by processing BEMF

sensing circuit output signals.

The two stand-alone op-amps, with the inputs connected

to the read channel IC, provide servo track signals

processed by the microcontroller to perform accurate

track-following mode.

3.3

Spindle and voice coil motor

The OM5193H drives a 3-phase brushless, sensorless DC

spindle motor and a voice coil motor.

Spindle and voice coil motor power stages with low R

ds(on)

and high current capability are suitable for mid-end and

low-end 12 V disk drives. Power stages are designed in

such a way that external Schottky diodes are not needed.

Spindle current is sensed by an external resistor and

monitored by the external signal SPCC (SPindle Current

Control). Spindle speed is regulated by the microcontroller

via the ZCROSS signal (Zero CROSSing detection

frequency output). BEMF comparators provide the digital

zero crossing signals. These are processed by the

commutation logic circuit to properly switch-on and

switch-off spindle power drivers thus ensuring the rotation

of the motor.

The control of the heads positioning is accomplished by

the internal 10-bit VCM DAC. Seek and track-following

VCM current loop gain is set by external resistors. VCM

zero current is referenced to the 2.5 V internal voltage

reference.

An internal precharge of the actuator (magnetic latch)

during brake mode guarantees total control of the current

when VCM starts running without current spikes.

3.4

Safety functions

The OM5193H is protected against transient voltage

spikes that are generated by the inductive loads of spindle

and VCM.

Power supplies and temperature are monitored in order to

guarantee data reliability and self-protection of the device

in case of power loss or temperatures beyond maximum

rating.

Park and brake functions secure heads and disk media in

case of power-down or high temperature failure. This

function is also activated by the sleep mode.

An internal temperature monitor is available to monitor the

chip temperature and thus prevents over-temperature

shutdown. Internally connected to the ADC channel 4, it

can be used by the microcontroller as an early

`temperature-too-high' warning during a long VCM seek

sequence.

1998 Nov 02

5

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

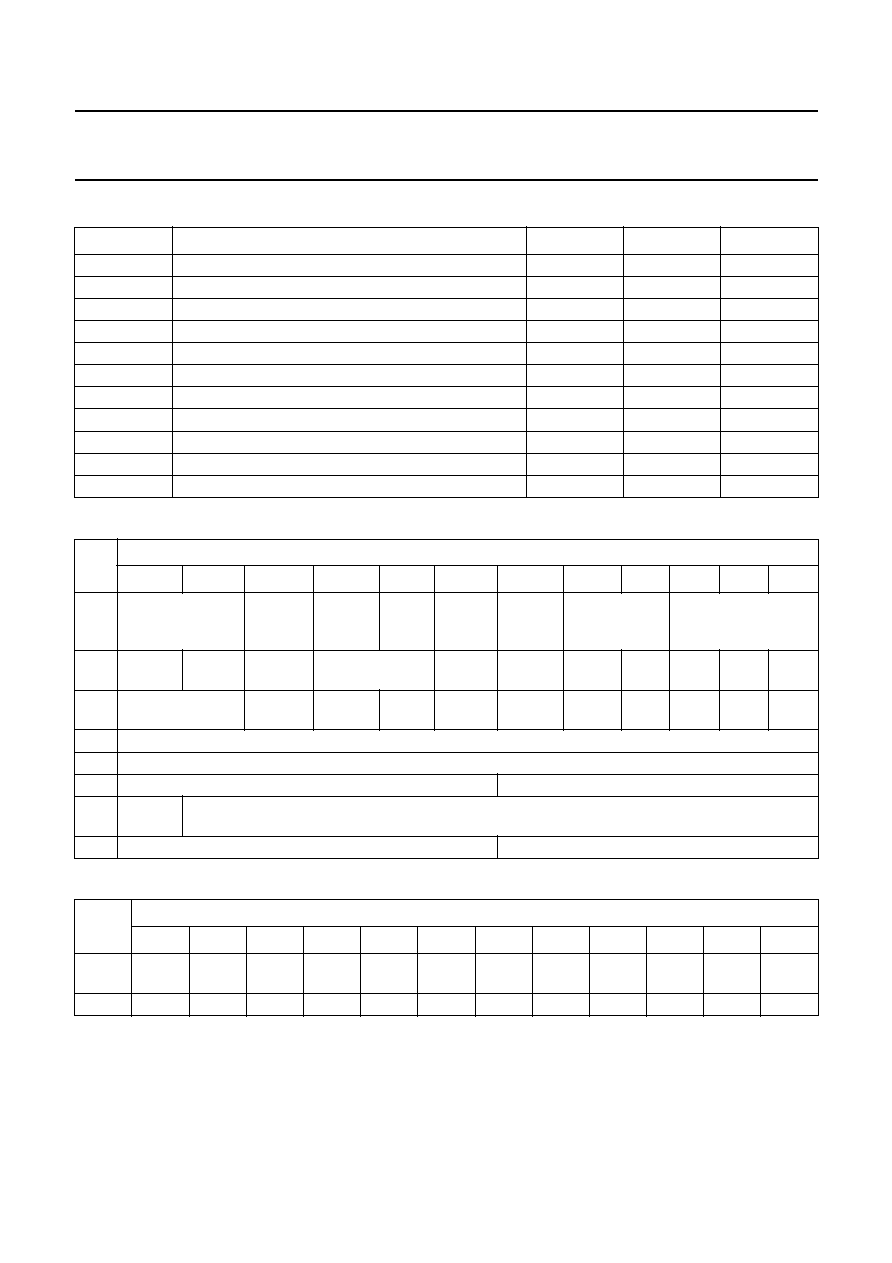

4

QUICK REFERENCE DATA

5

ORDERING INFORMATION

SYMBOL

PARAMETER

MIN.

TYP.

MAX.

UNIT

Supply voltage

V

DDA1

5 V analog supply voltage

4.5

5.0

5.5

V

V

DDD

5 V digital supply voltage

4.5

5.0

5.5

V

V

DDA2

12 V analog supply voltage

10.8

12.0

13.2

V

Drivers

I

SPOUT

spindle start-up current

-

-

1.9

A

I

VCMRUN

VCM current

-

-

1.5

A

TYPE

NUMBER

PACKAGE

NAME

DESCRIPTION

VERSION

OM5193H

QFP80

plastic quad flat package; 80 leads (lead length 1.95 mm);

body 14

◊

20

◊

2.8 mm

SOT318-2

1998 Nov 02

6

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

6

BLOCK DIAGRAMS

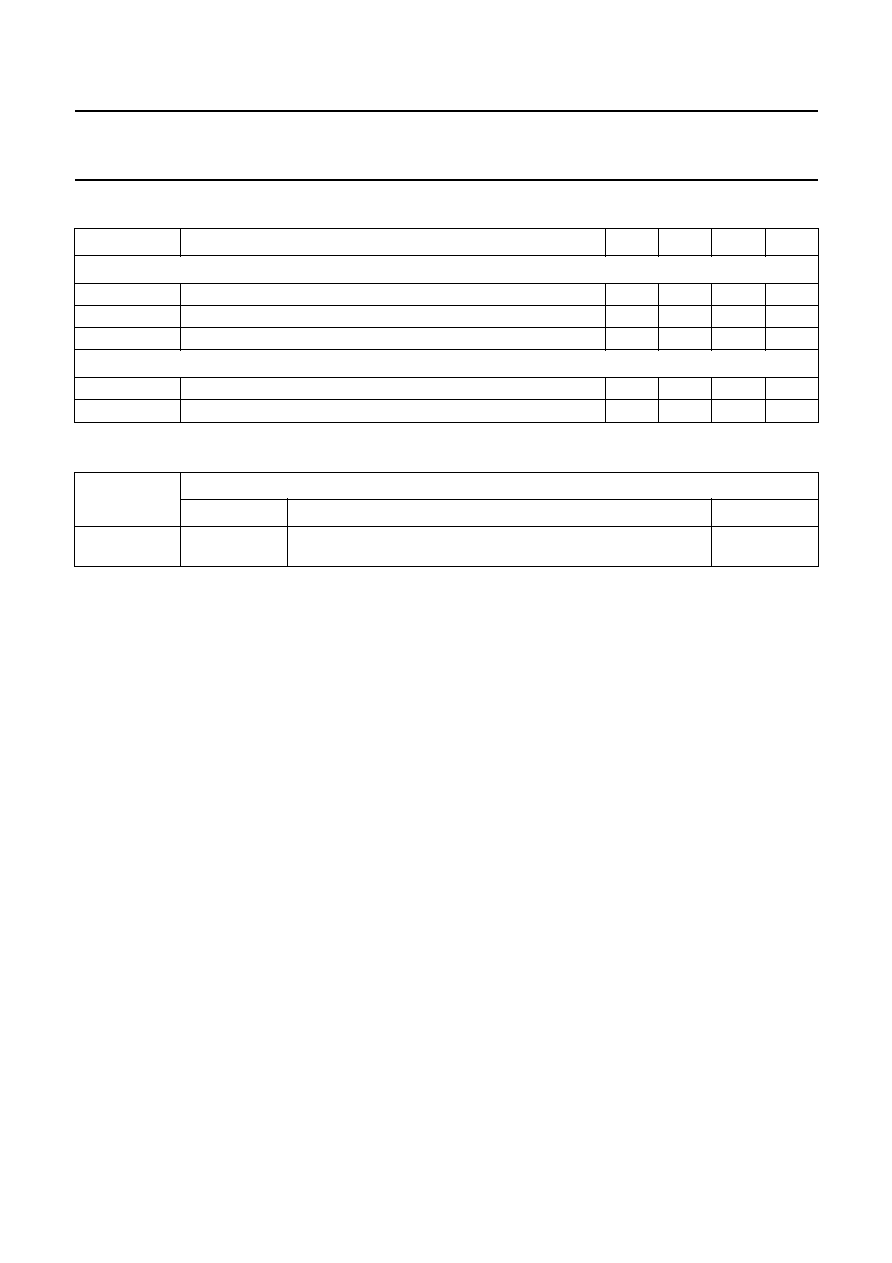

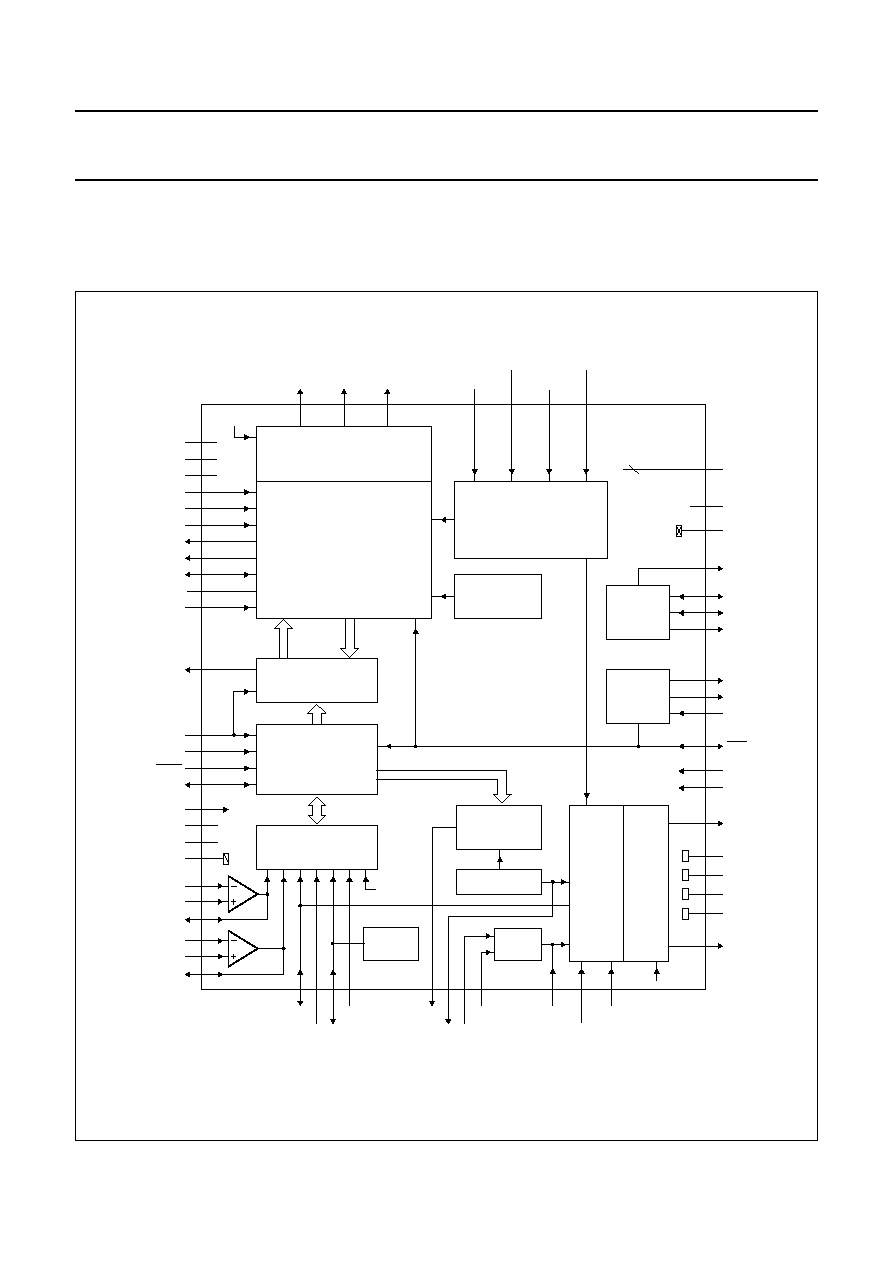

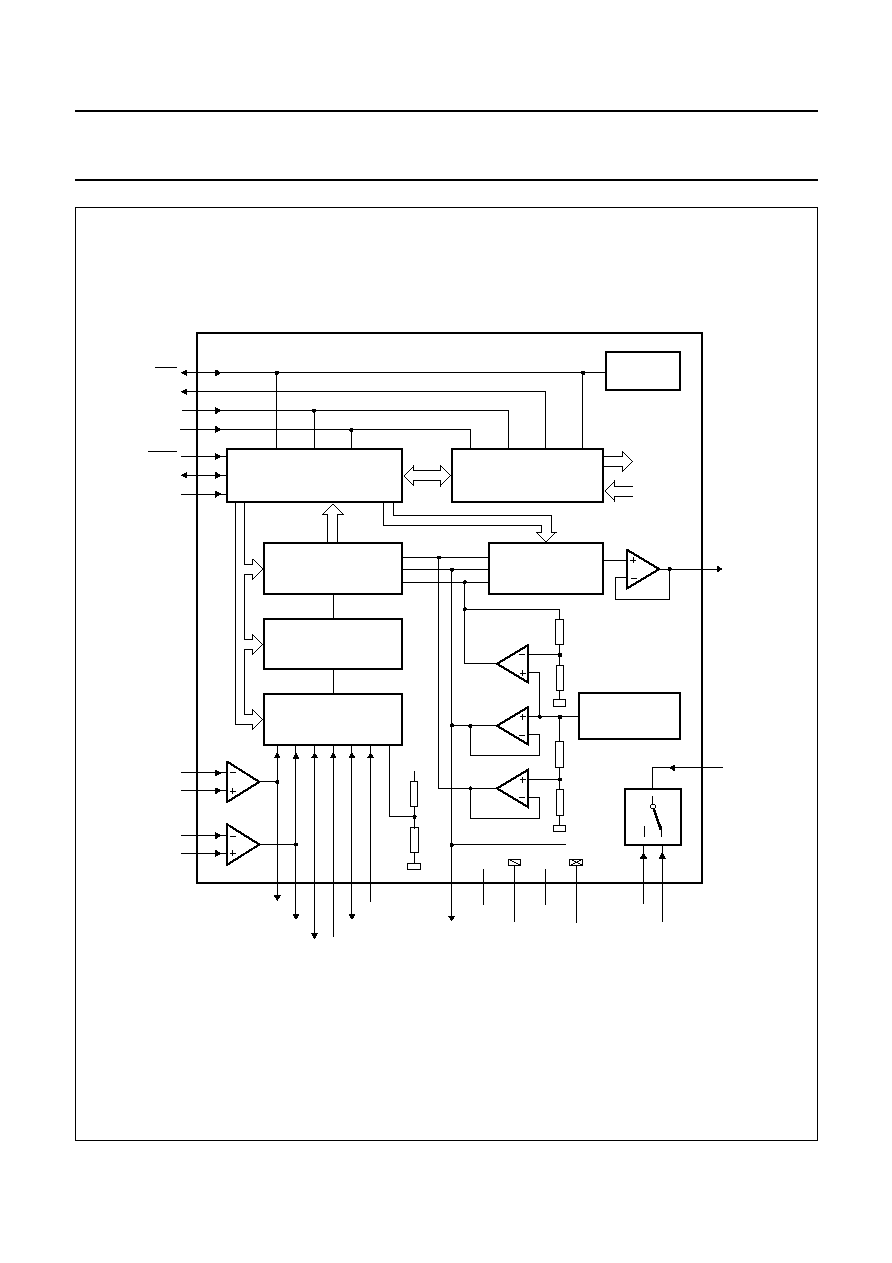

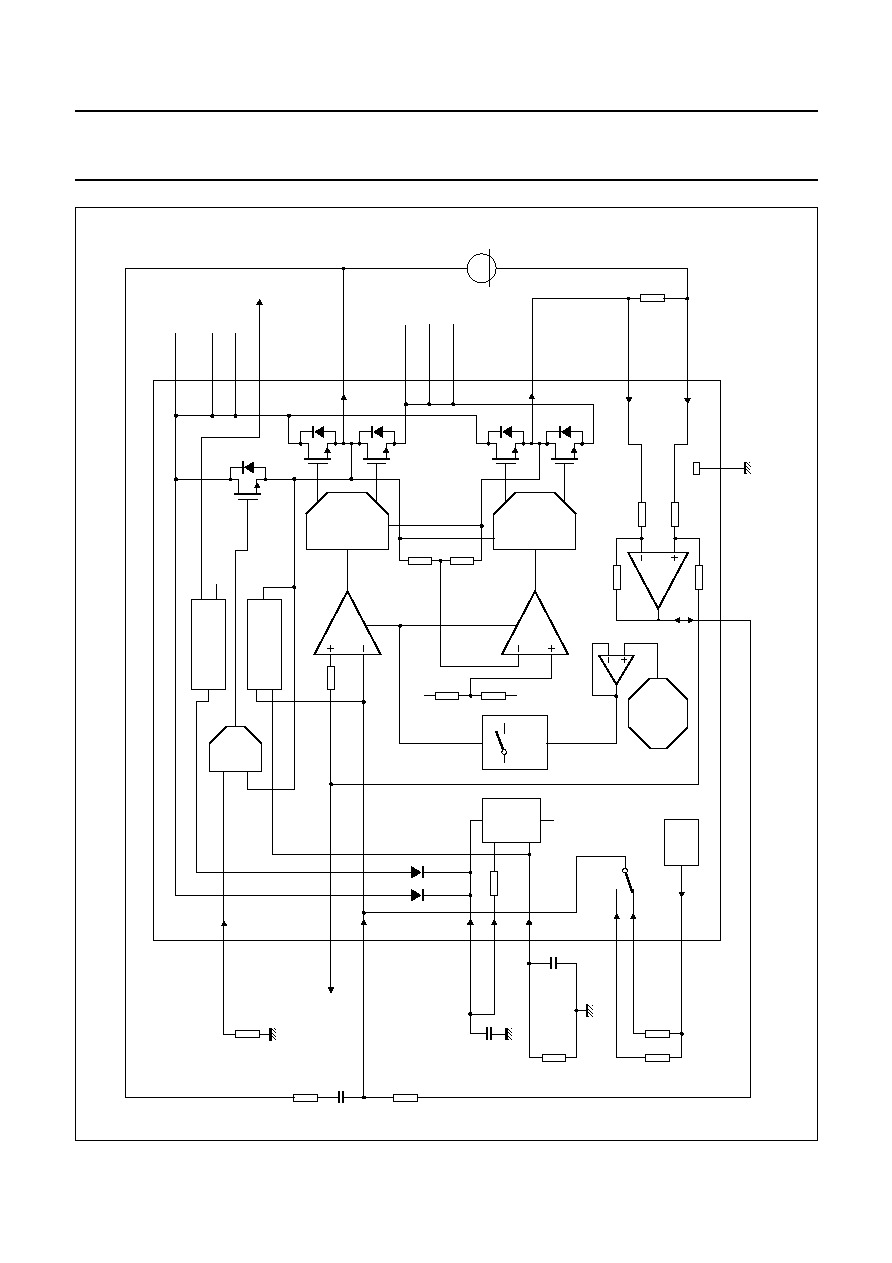

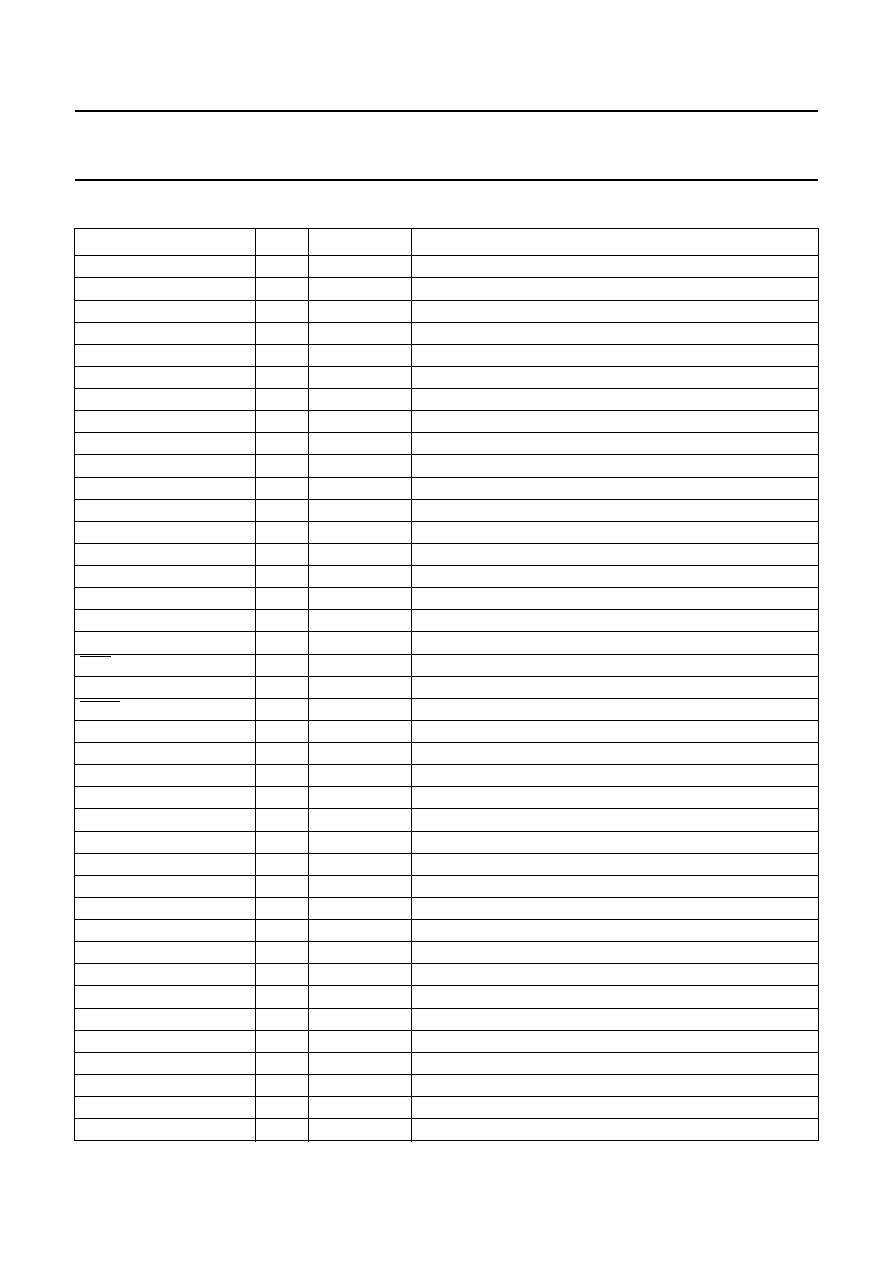

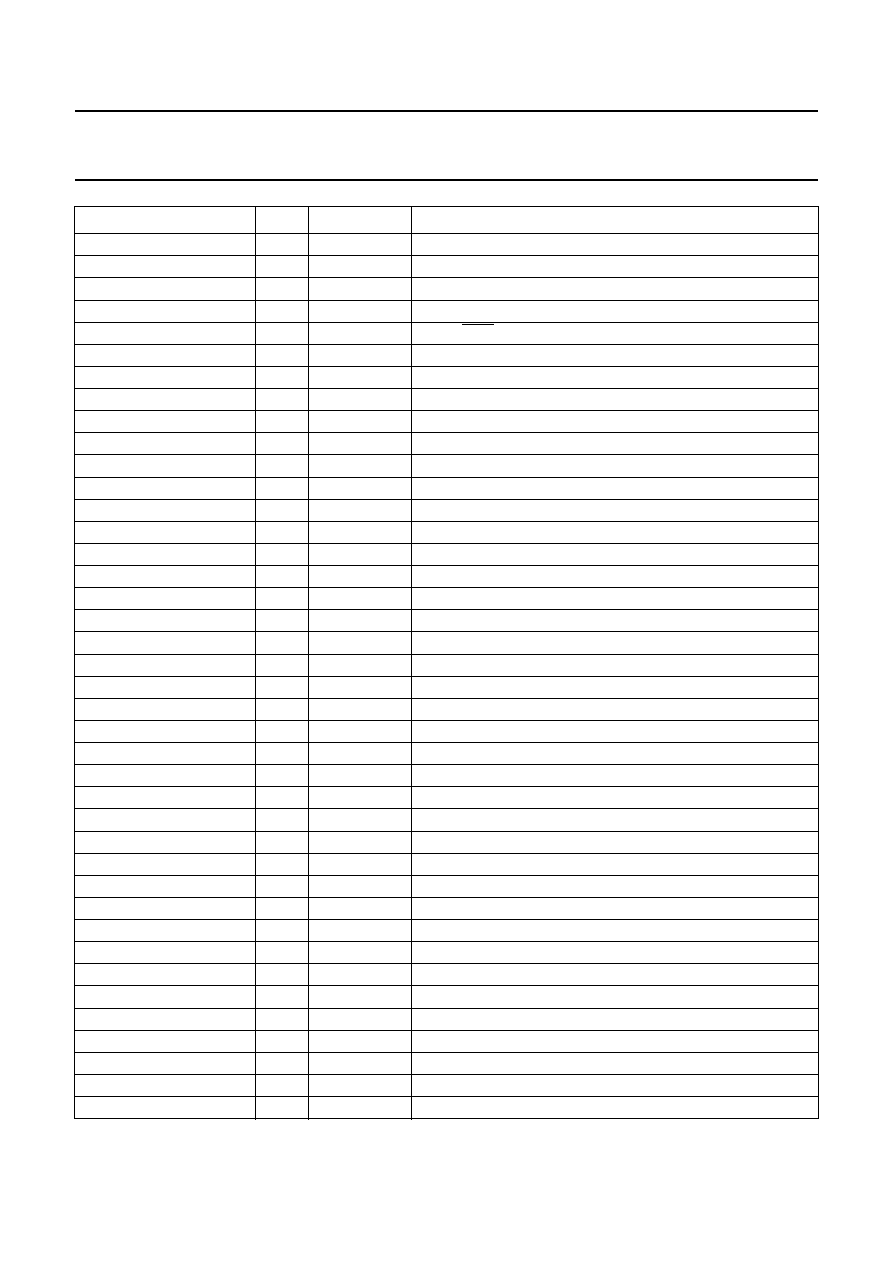

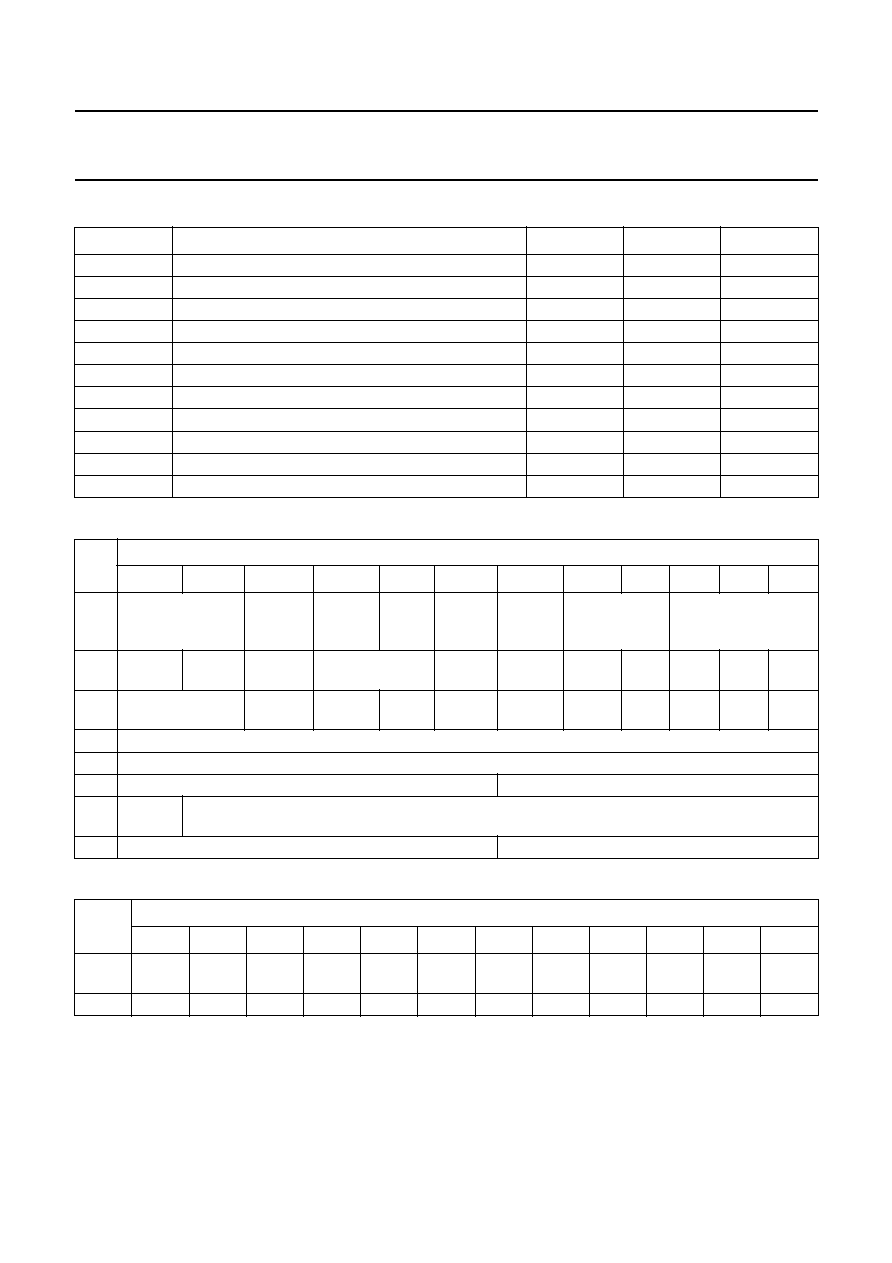

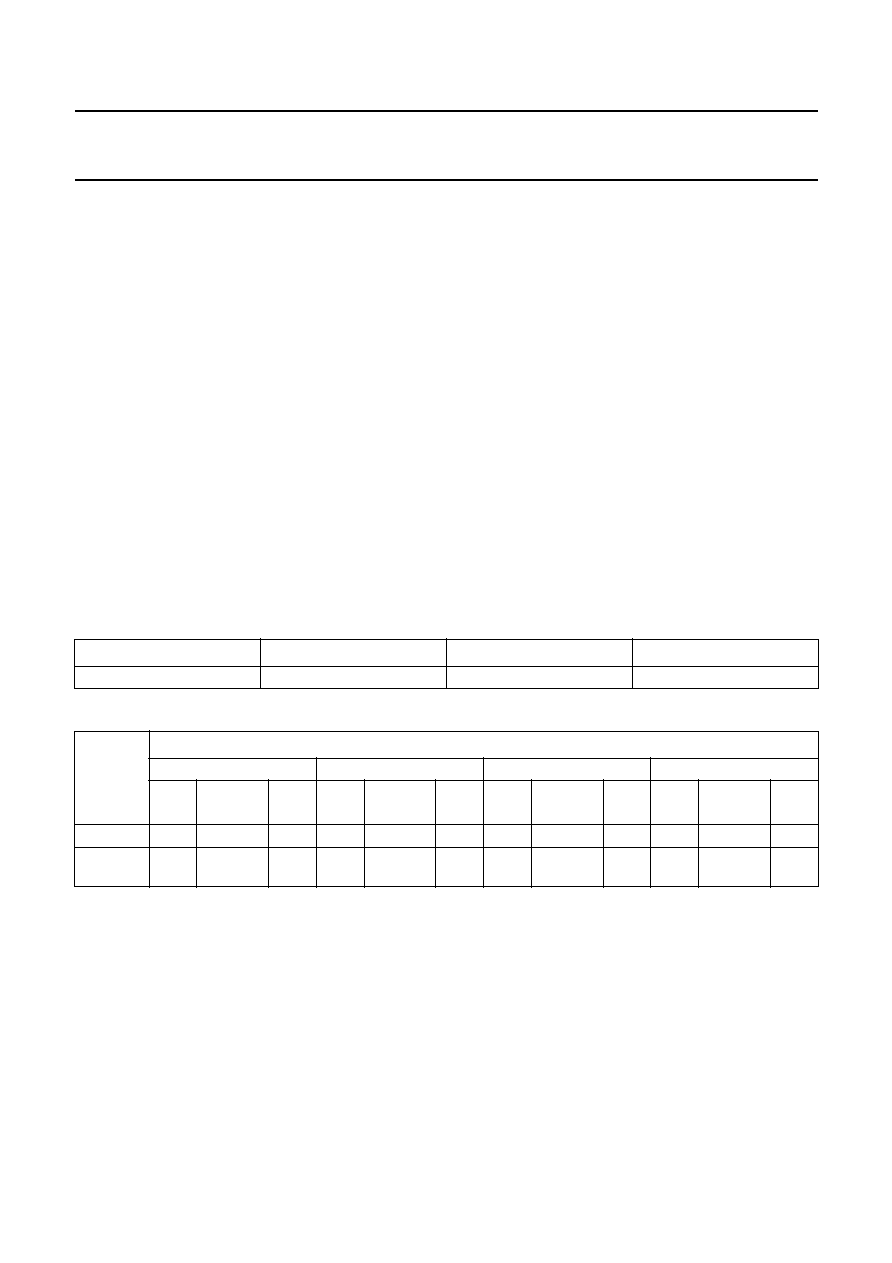

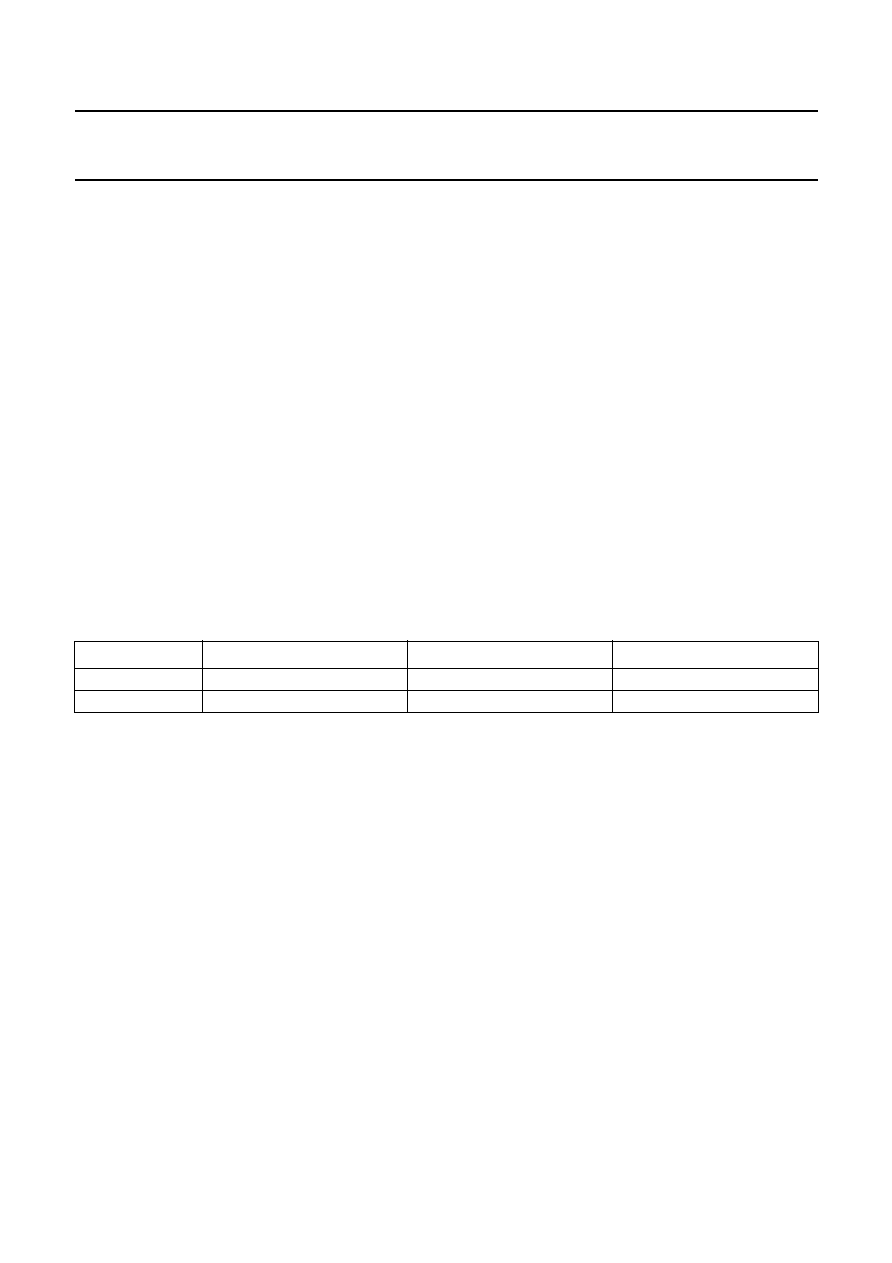

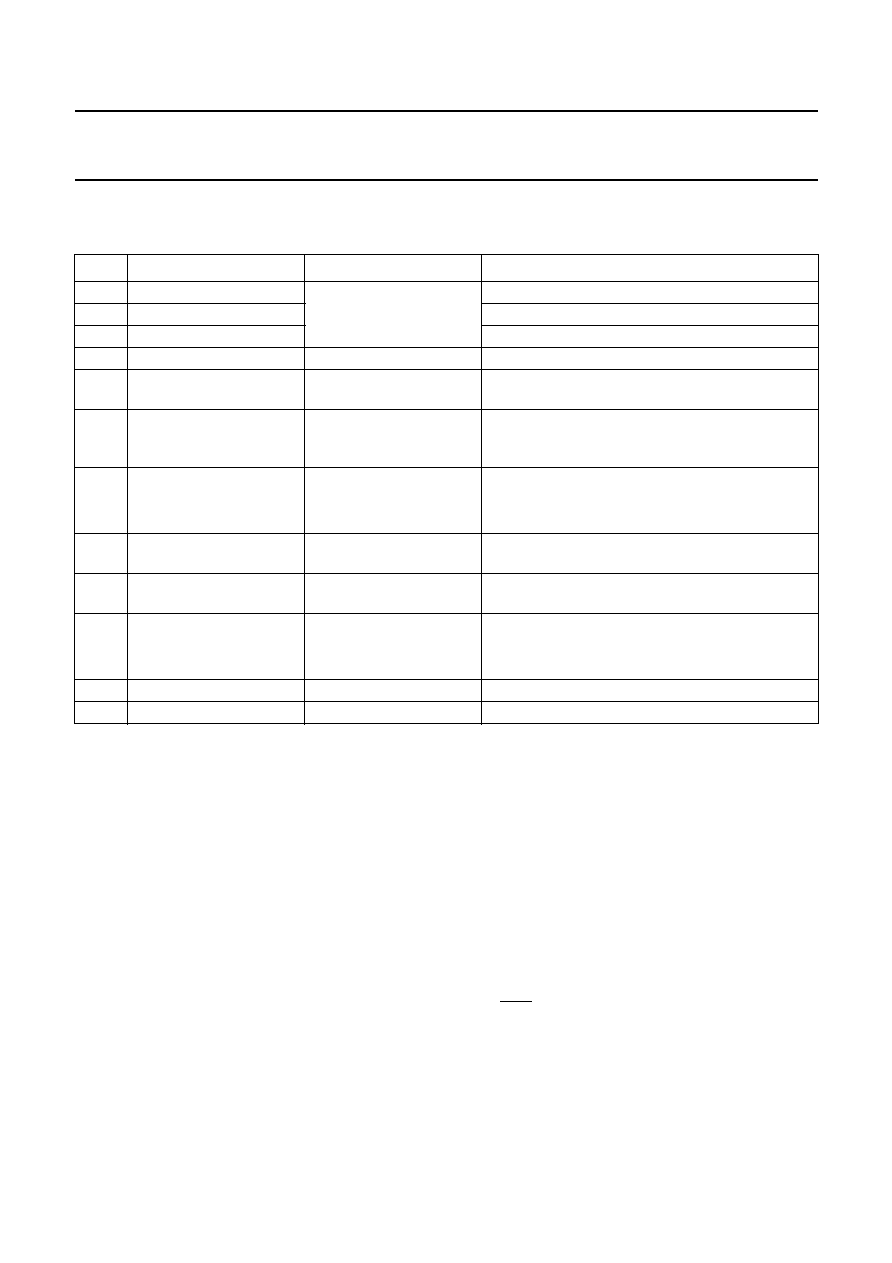

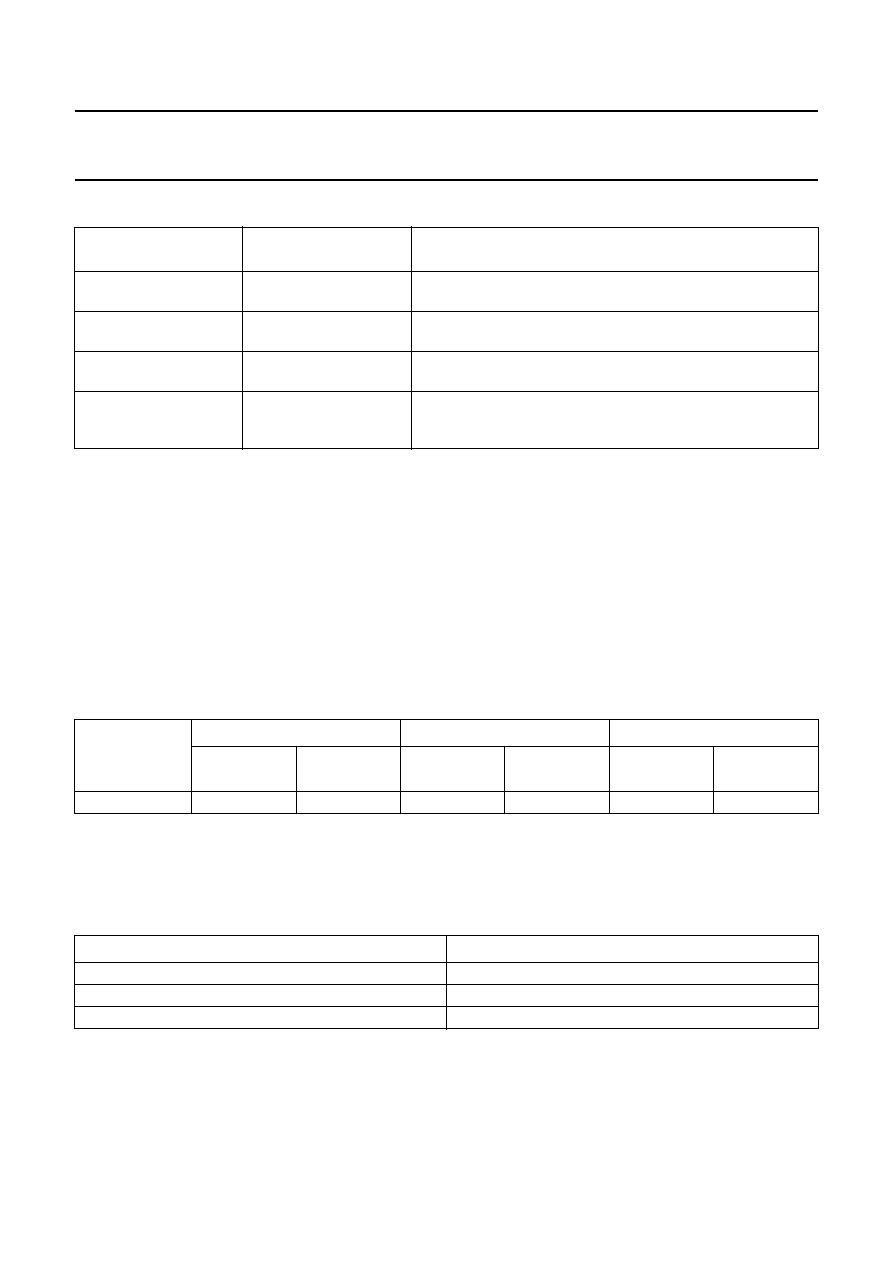

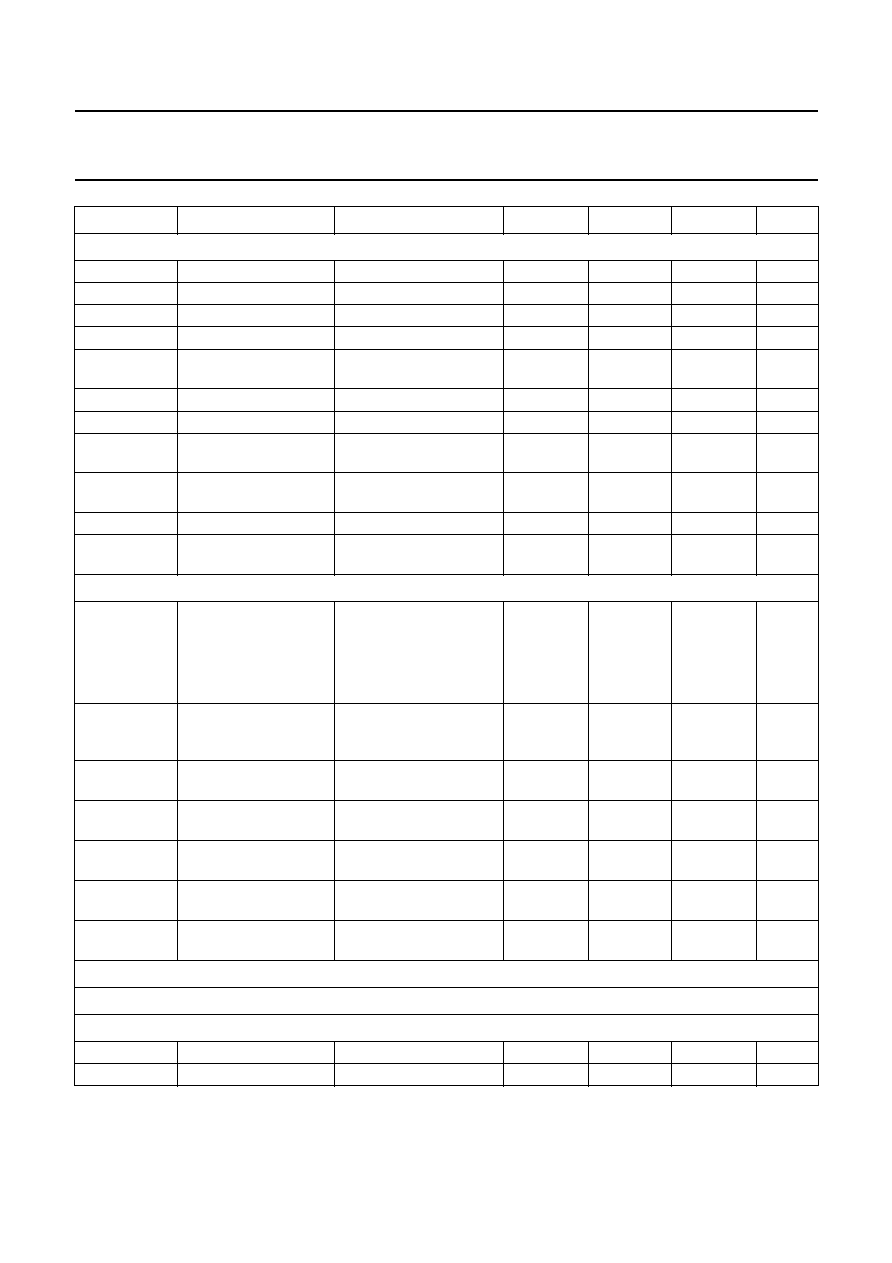

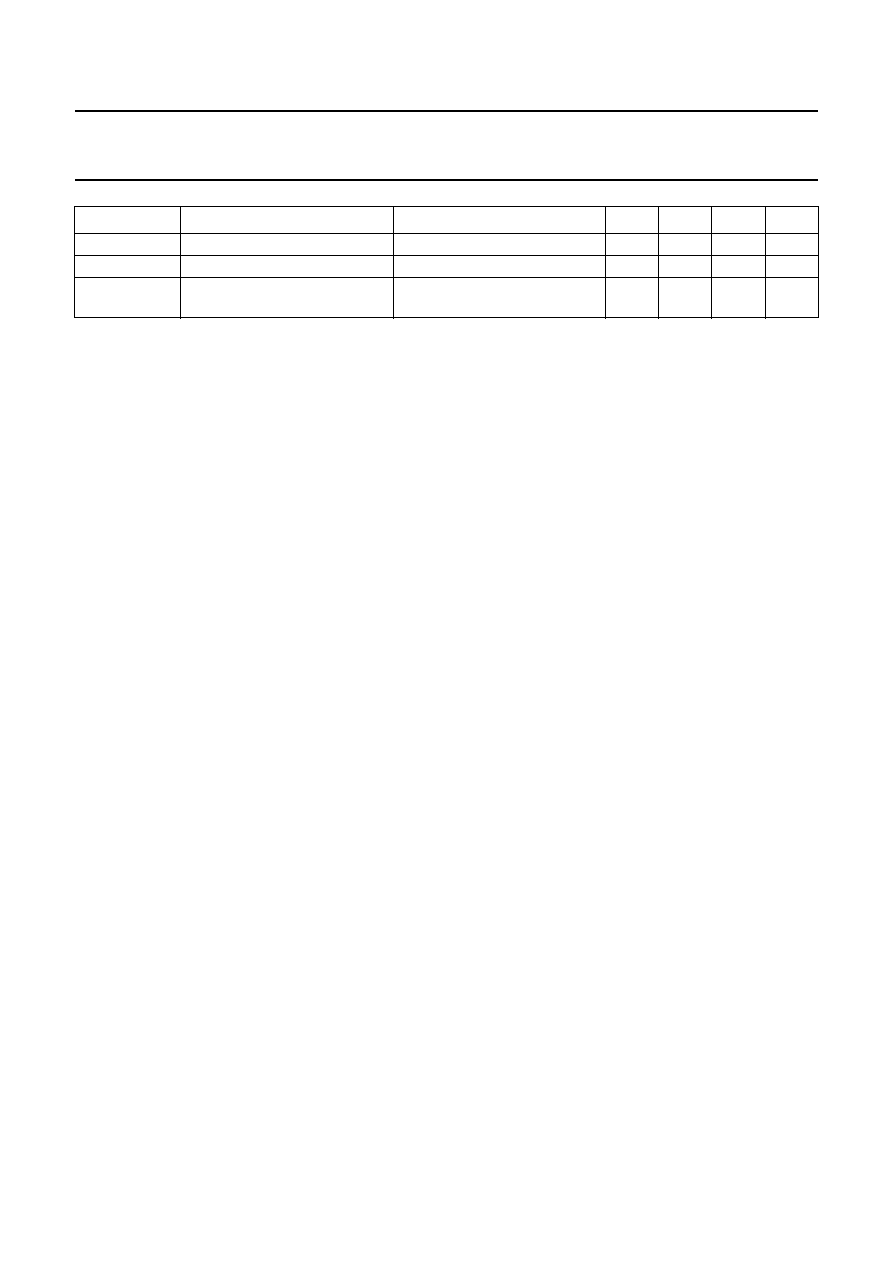

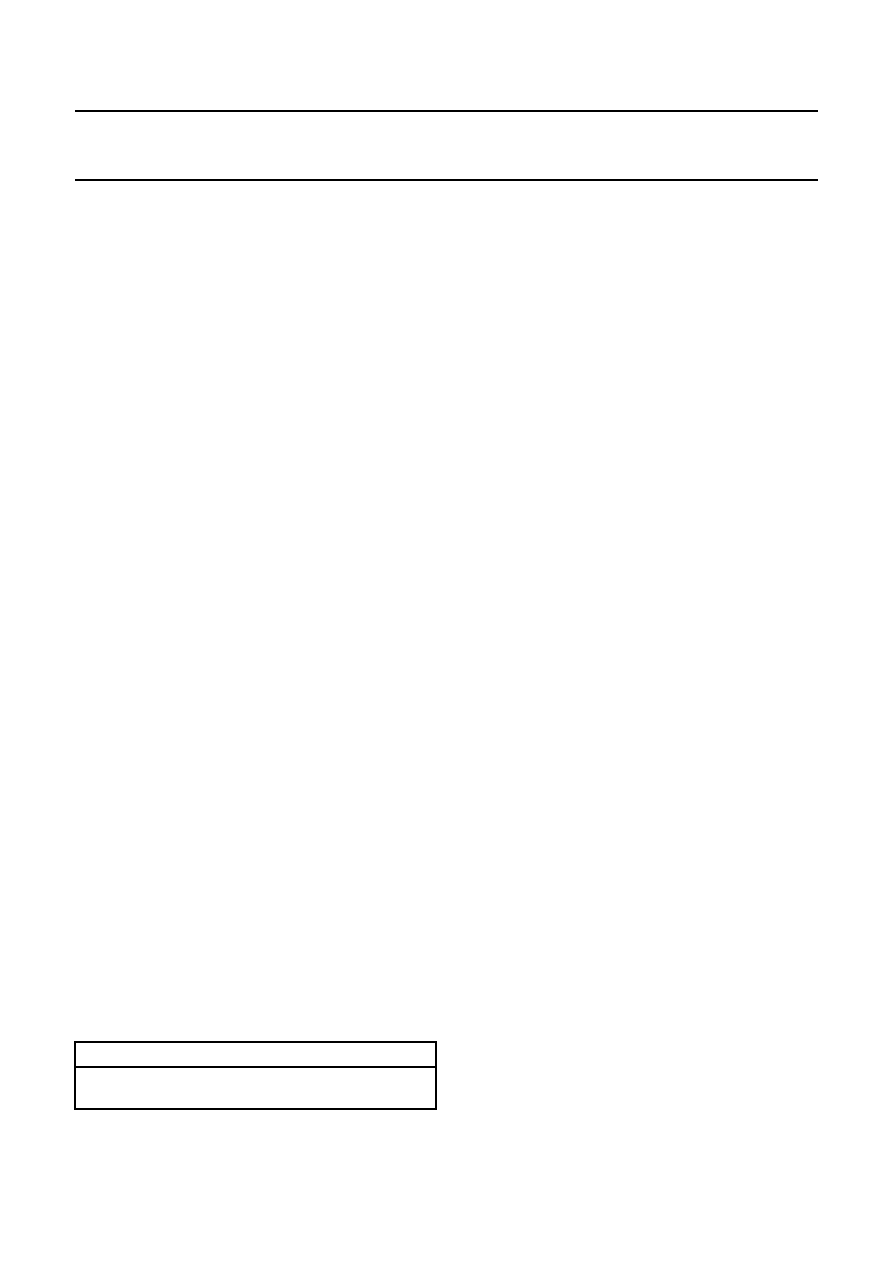

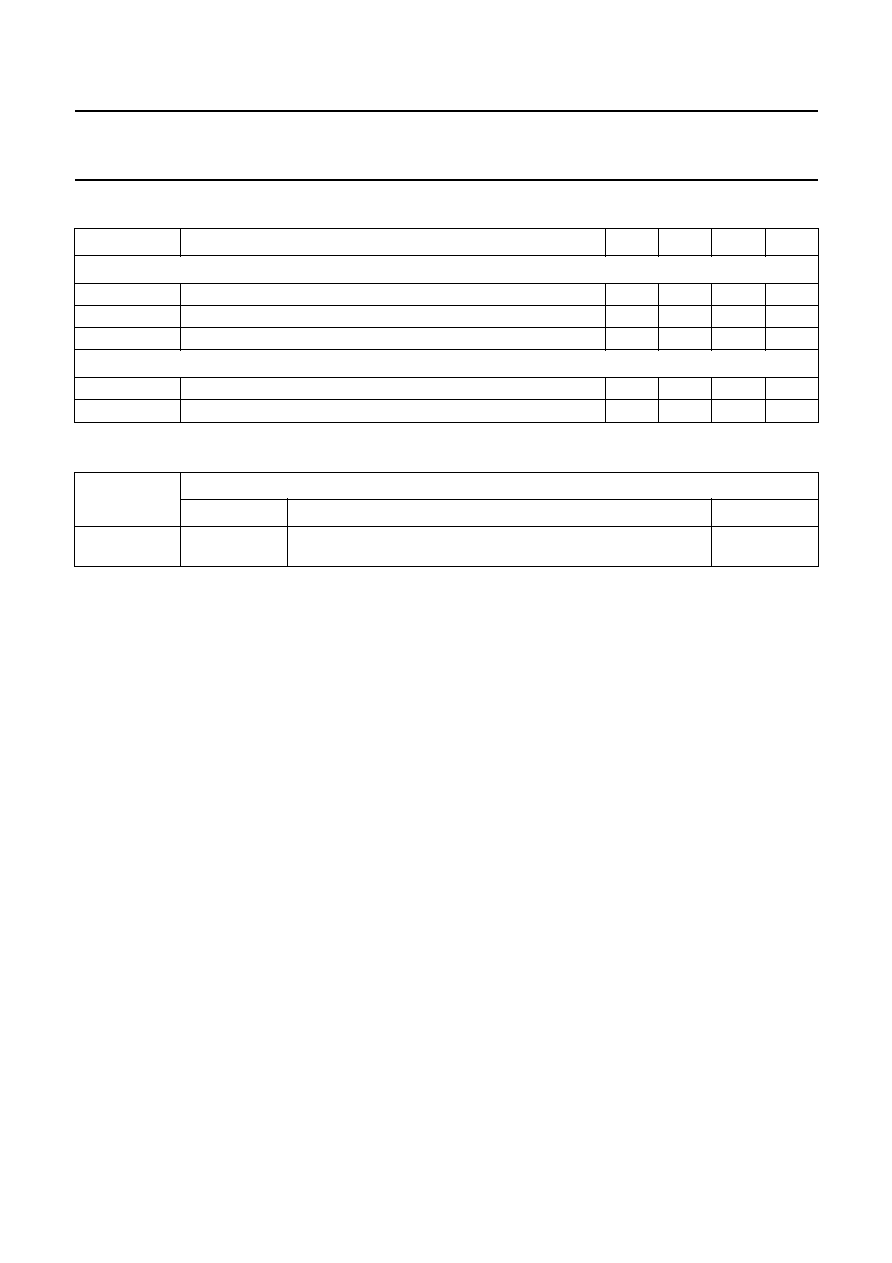

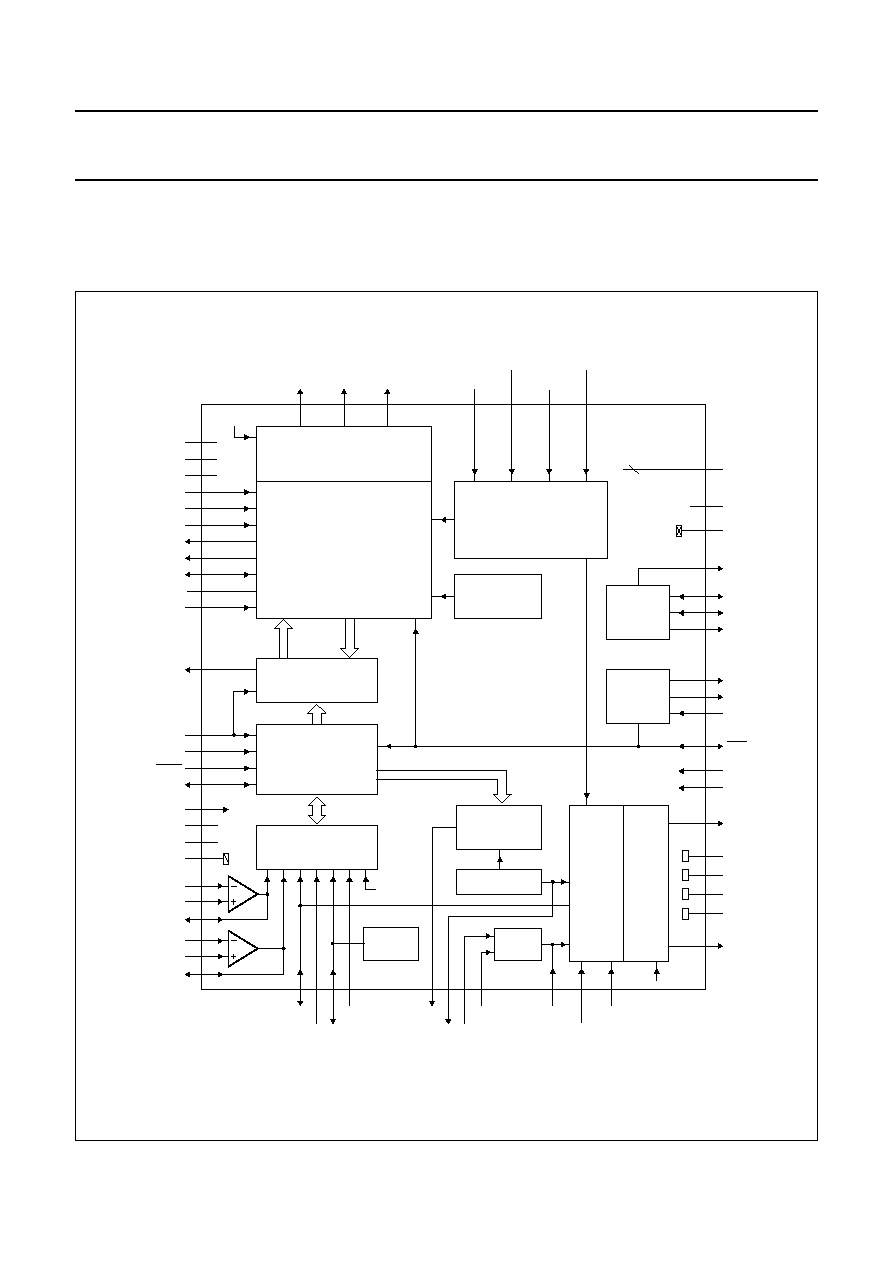

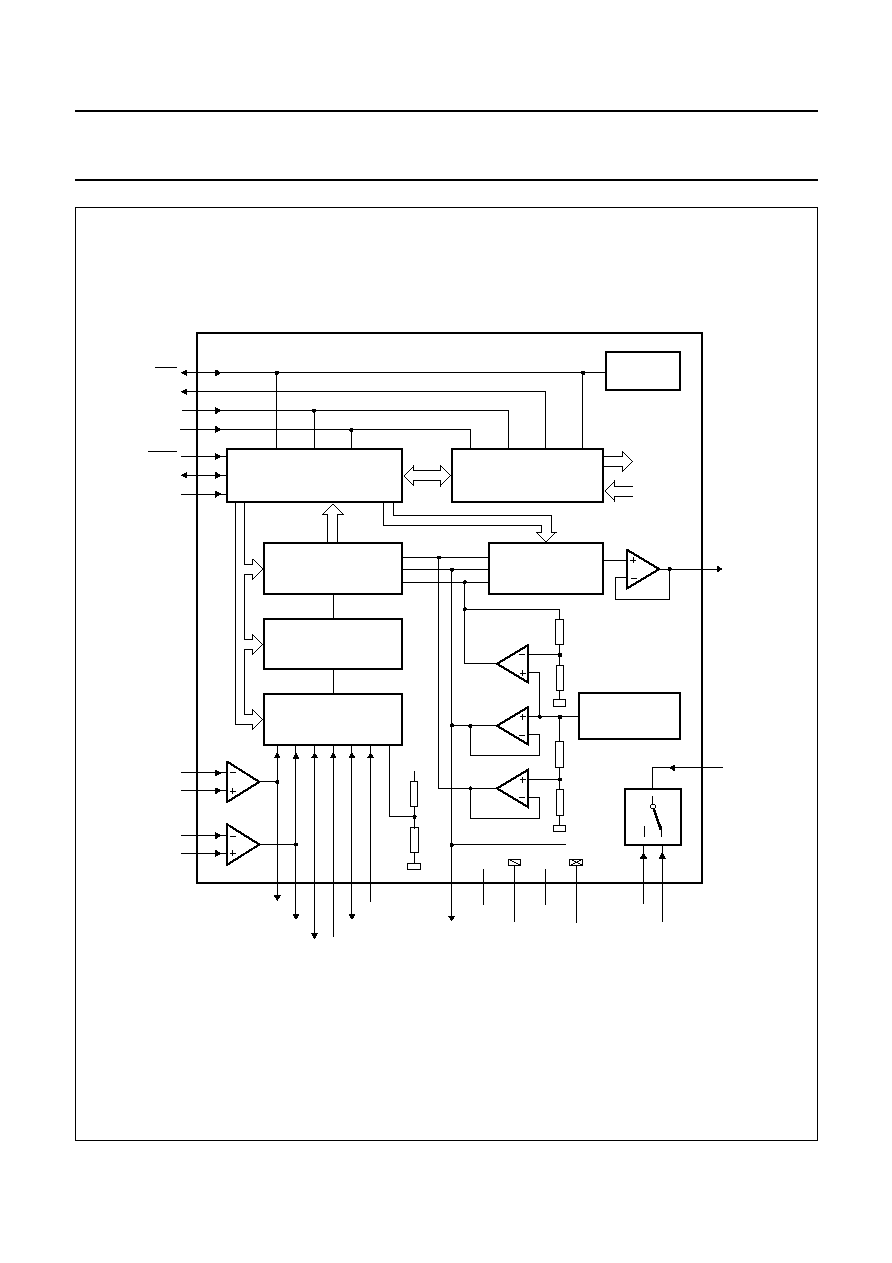

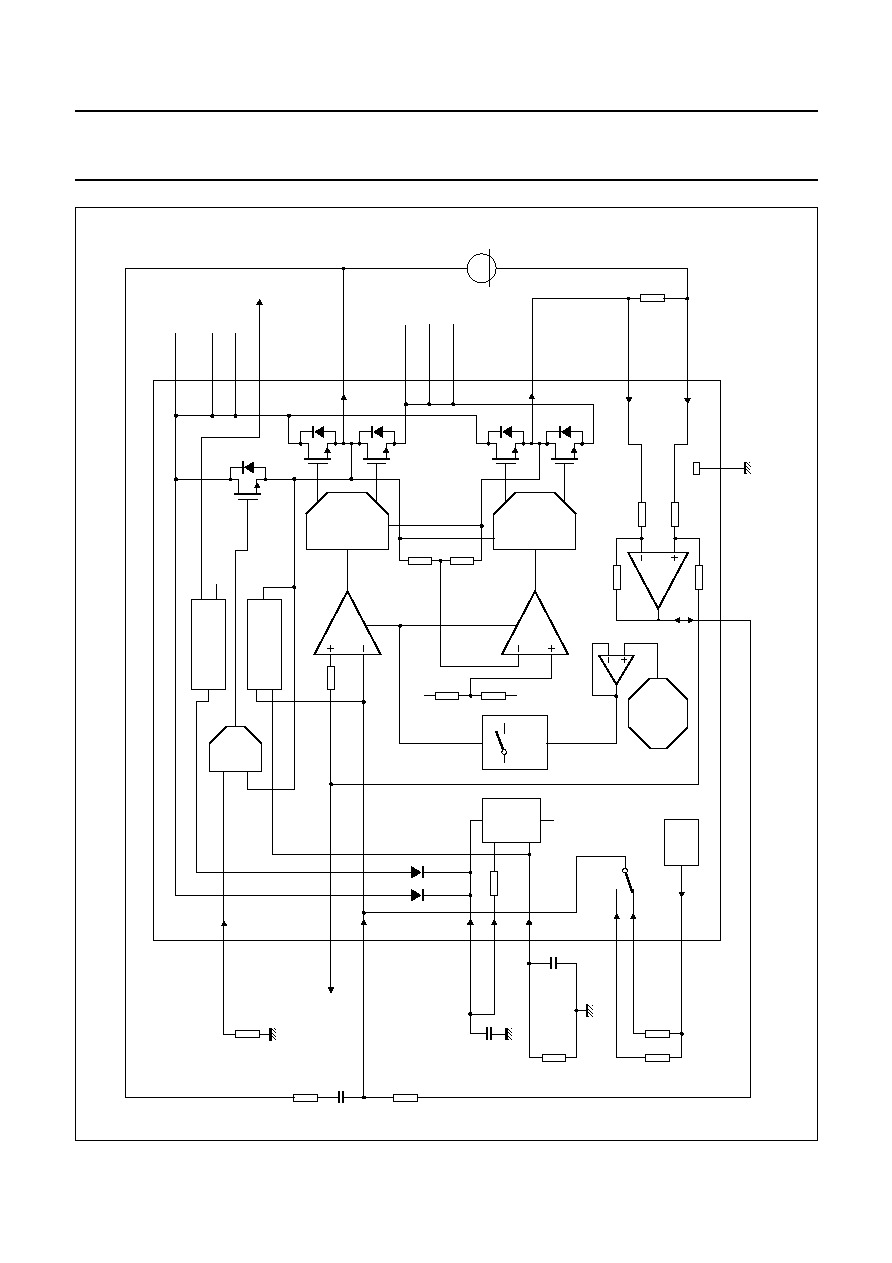

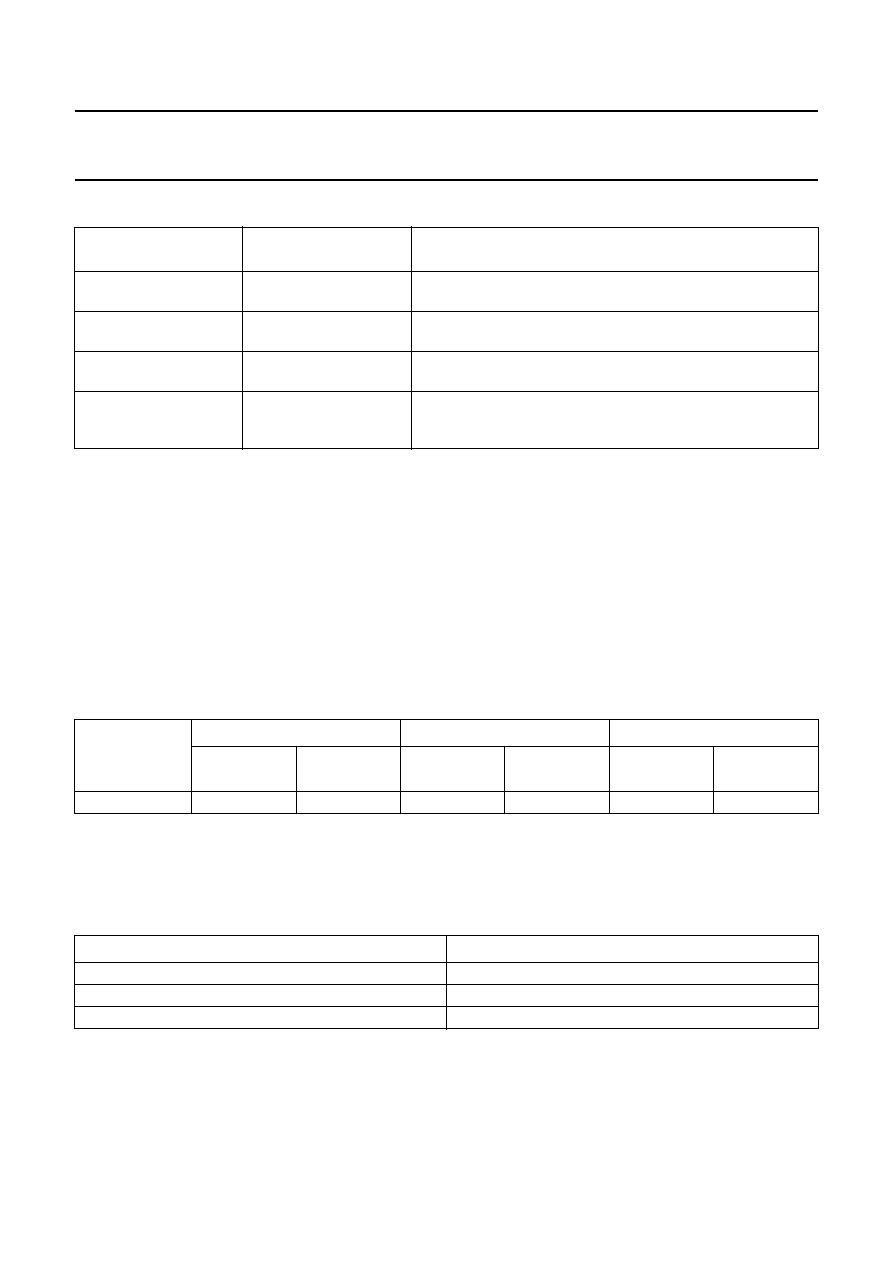

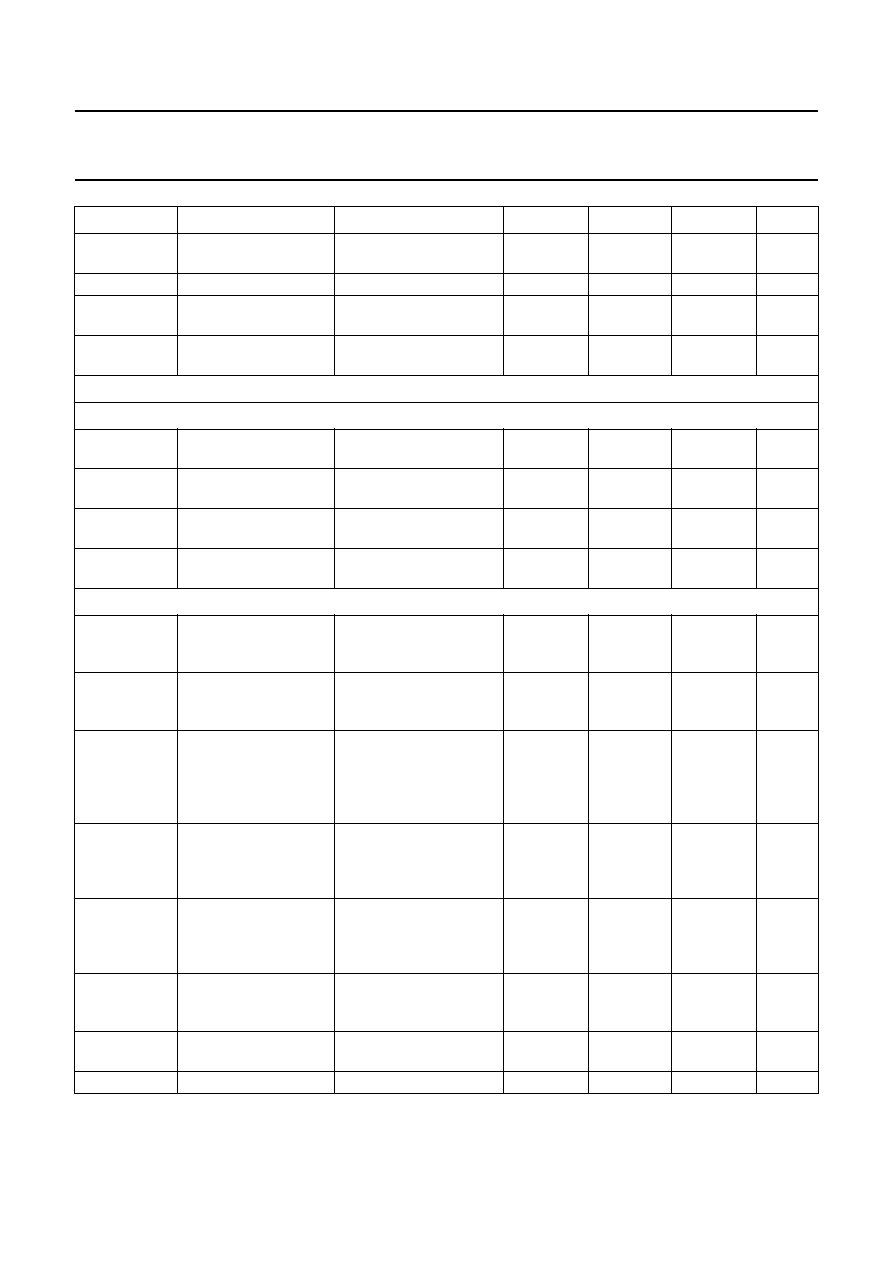

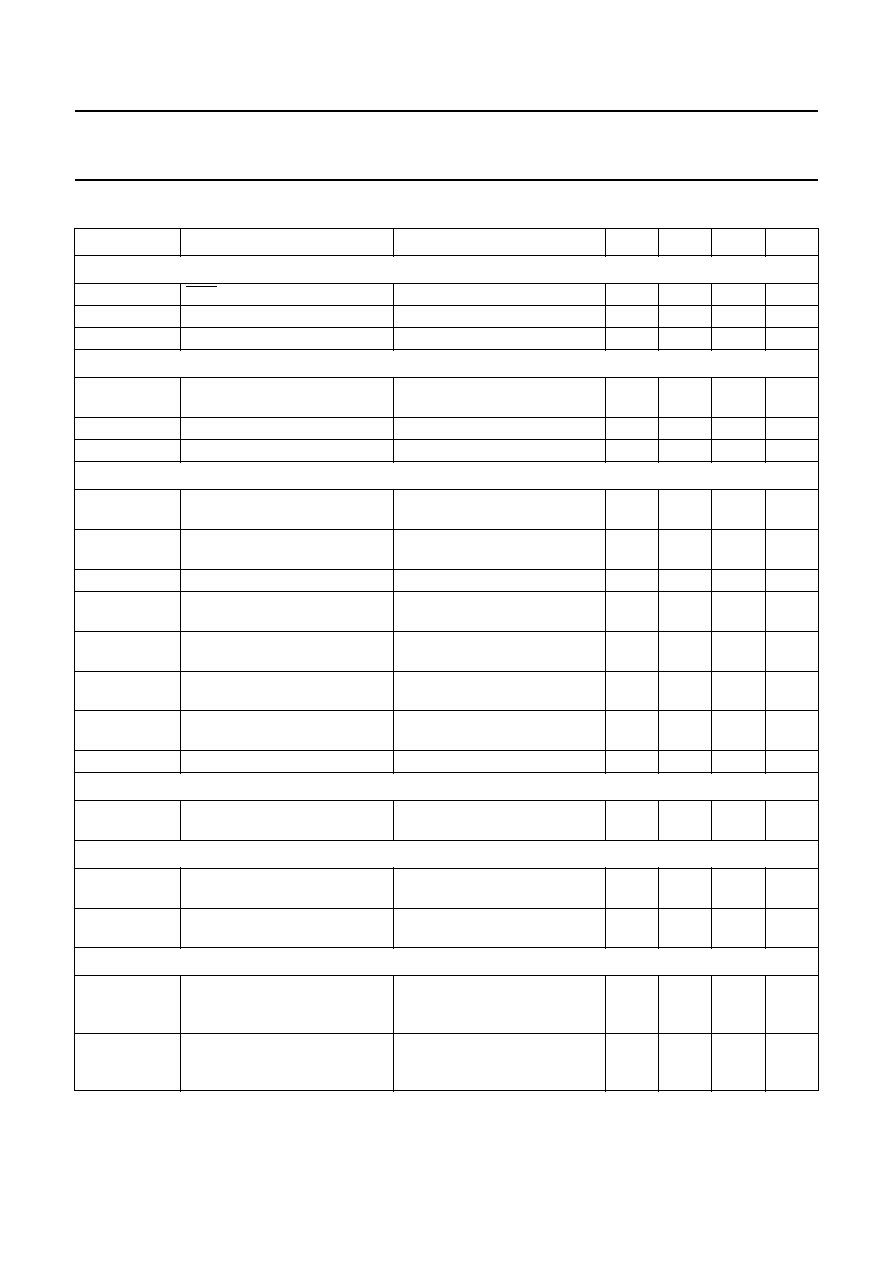

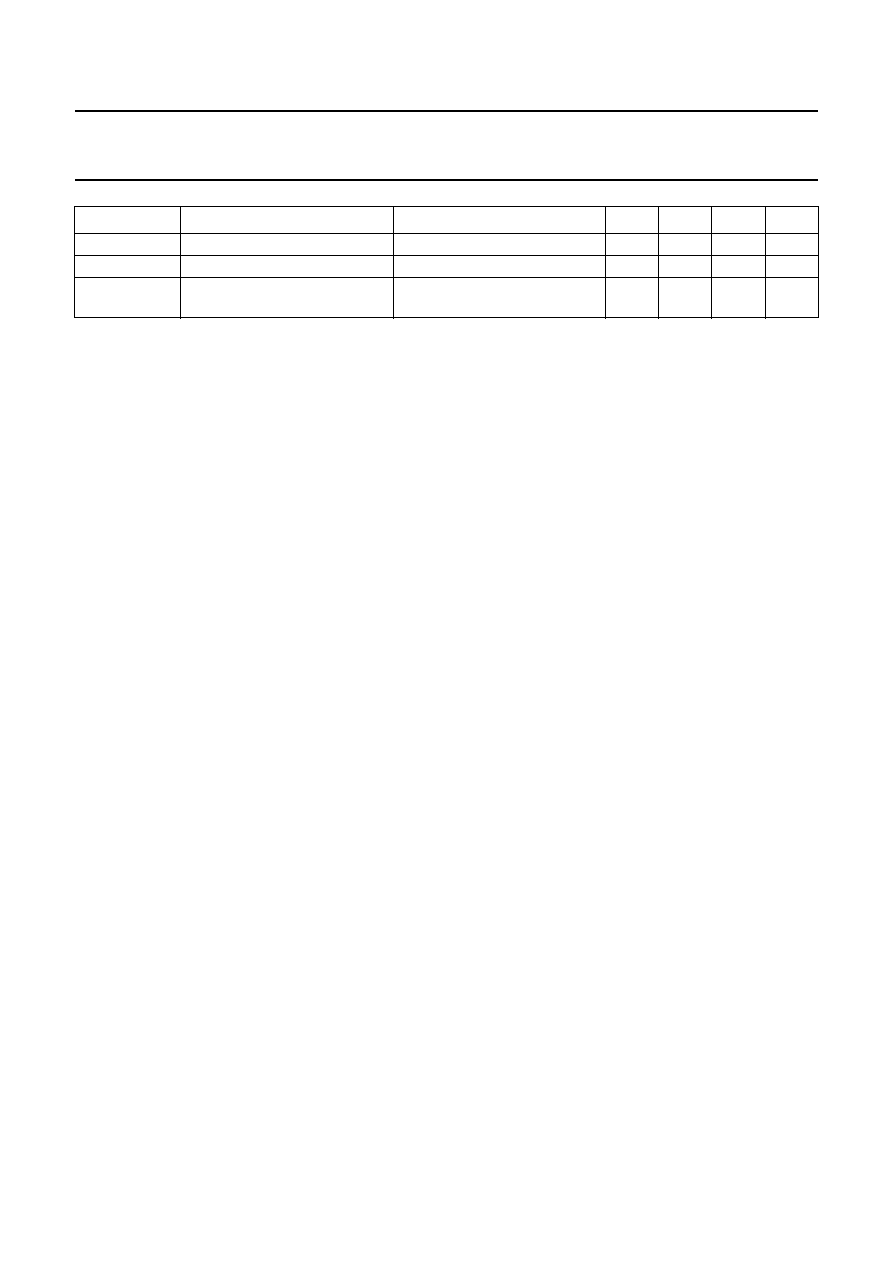

Figures 1, 2, 3 and 4 provide block diagrams of the OM5193H servo and motor control (top level diagram, servo

controller, spindle motor driver and voice coil motor driver).

Fig.1 Block diagram, top level.

handbook, full pagewidth

MGM972

7-CHANNEL

10-BIT ADC

SERIAL

INTERFACE

COMMUTATION

LOGIC

POWER

STAGE

SPINDLE

CONTROL

10

CLAMP1

CLAMP

72

COMA

COMB

COMC

ACROSS

BCROSS

CCROSS

MOTA

74

MOTB

3

48

50

49

51

MOTC

12

SLEW

14

SPCCOUT

13

SPCC

73

MOTSENSE3

24

CLOCK

23

SCLOCK

35

PESAMPN

36

PESAMP

26

SCANTEST

44

VDDA1

15

VDDA2

39

AGND

21

22

SDATA

25

ZCROSS

76

MOTSENSE2

2

MOTSENSE1/

SPSENSEH

11

GNDS/SPSENSEL

9

CT

55

CLAMP2

56

CLAMP3

0

1

2

3

4

5

6

SDEN

29

ADC[1]/DIFOUT

37

INTINN

0.5VDDA1

38

NIVCM

69

IVCM

62

CPOR

45

CHK12

47

CHK5

46

CAPY

18

BSTCP2

17

BSTCP1

16

SWITCHGATE

8

DGND

27

VDDD

20

18

PWRBIAS1

57

PWRBIAS2

77

HEATSINK

1, 4 to 7,

58 to 61, 64 to 67,

70, 75, 78 to 80

INTIN

19

28

30 31 32 33

34 40 42 41

43

53

52

ADC[0]/INTOUT

ADC[2]/SOUT

ADC[3]

ADC[4]/TEMP

ADC[5]

THERMAL

MONITOR

THERMAL

SHUTDOWN

VCM

SWITCH

VCM

CONTROL

POWER

STAGE

BANDGAP

CLAMP

10-BIT

VCM DAC

POWER-ON

RESET

CHARGE

PUMP

PARK AND BRAKE

TRACKFWSELECT

SEEKSELECT

DACOUT

REF2V5

VCMSENSEL

VCMSENSEH

VCMIN

GNDV

54

GNDVCM1

71

GNDVCM2

68

GNDVCM3

63

OM5193H

PARKVOLT

BRAKEDELAY

BRAKEADJH

BRAKEPOWER

POR

A2

A1

1998 Nov 02

7

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

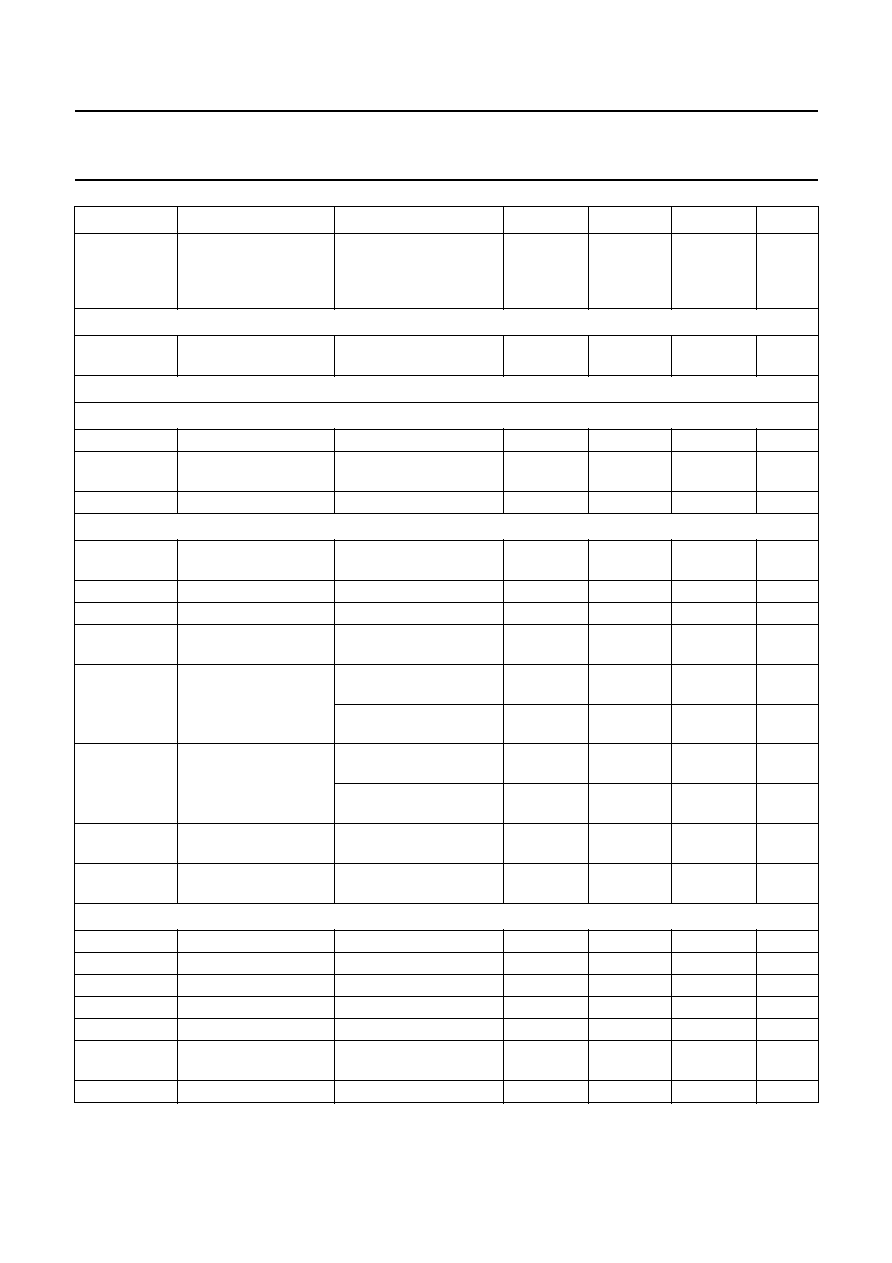

Fig.2 Block diagram, servo controller.

handbook, full pagewidth

MGM973

INPUT

MULTIPLEXER

36

PESAMP

35

PESAMPN

29

ADC[1]/DIFOUT

37

INTINN

VDDA1

Vref2V5

Vref3V5

Vref1V5

Vref2V5

38

INTIN

23

SCLOCK

22

SDATA

21

26

SCANTEST

24

CLOCK

25

ZCROSS

19

28

30 31 32 33

ADC[0]/INTOUT

ADC[2]/SOUT ADC[3]

ADC[4]/TEMP

ADC[5]

A2

A1

40

39

REF2V5

VDDD

AGND

DGND

RANGE

ADAPTER

10-BIT ADC

SERIAL INTERFACE

COMMUTATION LOGIC

10-BIT VCM DAC

20

VDDA1

44

for VCM

VCM switch

27

2.5 V BANDGAP

41

43

42

TRACKFWSELECT

SEEKSELECT

VCMIN

34

DACOUT

OM5193H

COMA

COMB

COMC

ACROSS

BCROSS

CCROSS

POWER-ON

RESET

POR

SDEN

1998 Nov 02

8

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

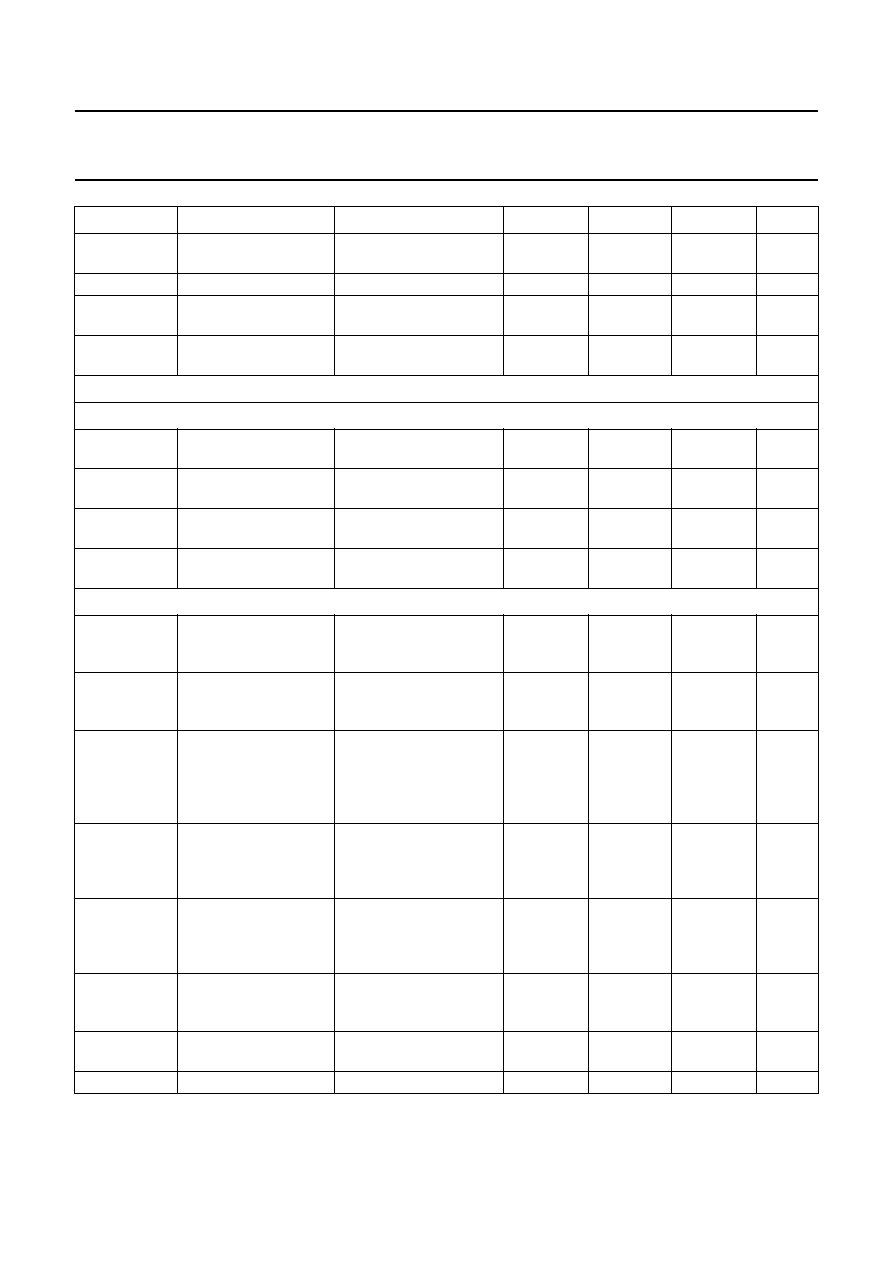

Fig.3 Block diagram, spindle motor driver.

handbook, full pagewidth

MGM974

SLOPE

CURRENT

CONTROL

SPINDLE

SWITCH

DECODER

PREDRIVER

PREDRIVER

PREDRIVER

THERMAL

SHUTDOWN

THERMAL

MONITOR

POWER-ON

RESET

CHARGE

PUMP

BEMF

COMPARATOR

MOTB

74

3 MOTC

MOTA

72

CT

2

76

73

12

11

13

14

SLEW

RSLEW

RSPSENSE

MOTSENSE1/

SPSENSEH

MOTSENSE2

MOTSENSE3

GNDS/SPSENSEL

SPCC

SPCCOUT

CSPCCOUT

9

SENSE

AMPLIFIER

CONTROL

AMPLIFIER

ACROSS

BCROSS

to commutation logic

CCROSS

8

SWITCH GATE

10

55

56

CLAMP1

CLAMP2

CLAMP3

VDDA2POWER

32

ADC[4]/TEMP

19

POR

47

CHK12

44

15

45

16

46

CHK5

Vref (from VCM)

Ibrake (from VCM)

COMA

COMB

COMC

from

commu-

tation

logic

CCHK5

CCHK12

17

18

77

57

CCAPY

VCAPY

CCPOR

VDDA2

VDDA1

CCAPX

CPOR

BSTCP1 BSTCP2

CAPY

PWRBIAS1 PWRBIAS2

OM5193H

1998

Nov

02

9

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

a

ndbook, full pagewidth

MGM975

VCM

DAC

BRAKE

AFTER

PARK

PRE

DRIVER

PRE

DRIVER

GND

12 V

GNDVCM1

71

GNDVCM2

68

CLAMP3

56

SWITCHGATE

8

CLAMP2

55

CLAMP1

10

NIVCM

69

VCMSENSEL

RVCMSENSE

53

VCMSENSEH

52

IVCM

62

GNDVCM3

63

ERROR

SENSE

ERROR

PARK

REF2V5

RPARKVOLT

RVCMCOMPRC

RFEEDBACK

CVCMCOMPRC

ERROR

master

slave

SWITCH

BANDGAP

Vref

(to spindle)

Ibrake

(to spindle)

VCM switch

42

41

TRACKFWSELECT

SEEKSELECT

34

30

DACOUT

M

PRECHARGE

POWER-DOWN

40

VCMIN

43

BRAKEPOWER

CBRAKEP

RBRAKED

CBRAKED

48

BRAKEADJH

49

BRAKEDELAY

50

PARKVOLT

51

54

ADC[2]/SOUT

GNDV

RVCMSEEK

RVCMTRACKFW

OM5193H

VCAPY

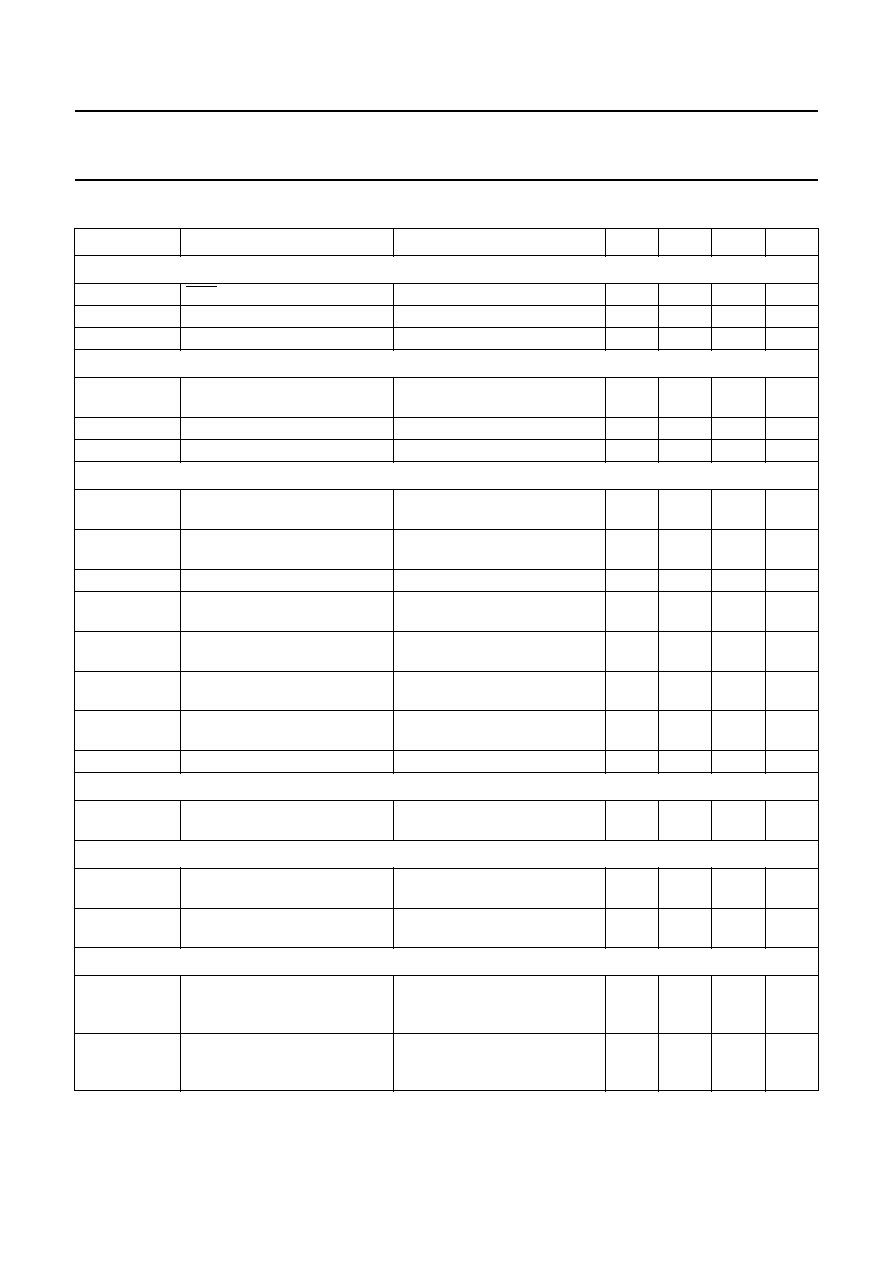

Fig.4 Block diagram, voice coil motor driver.

1998 Nov 02

10

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

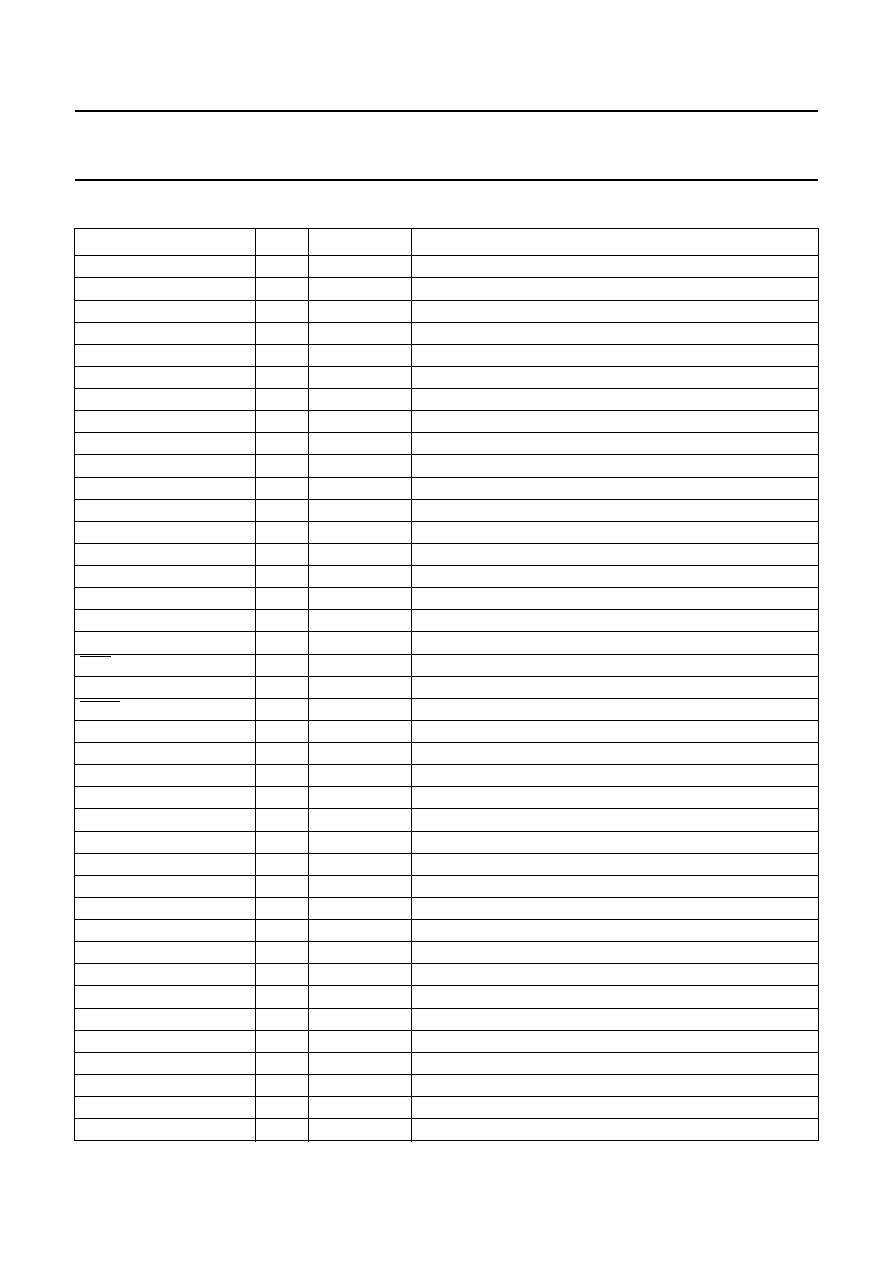

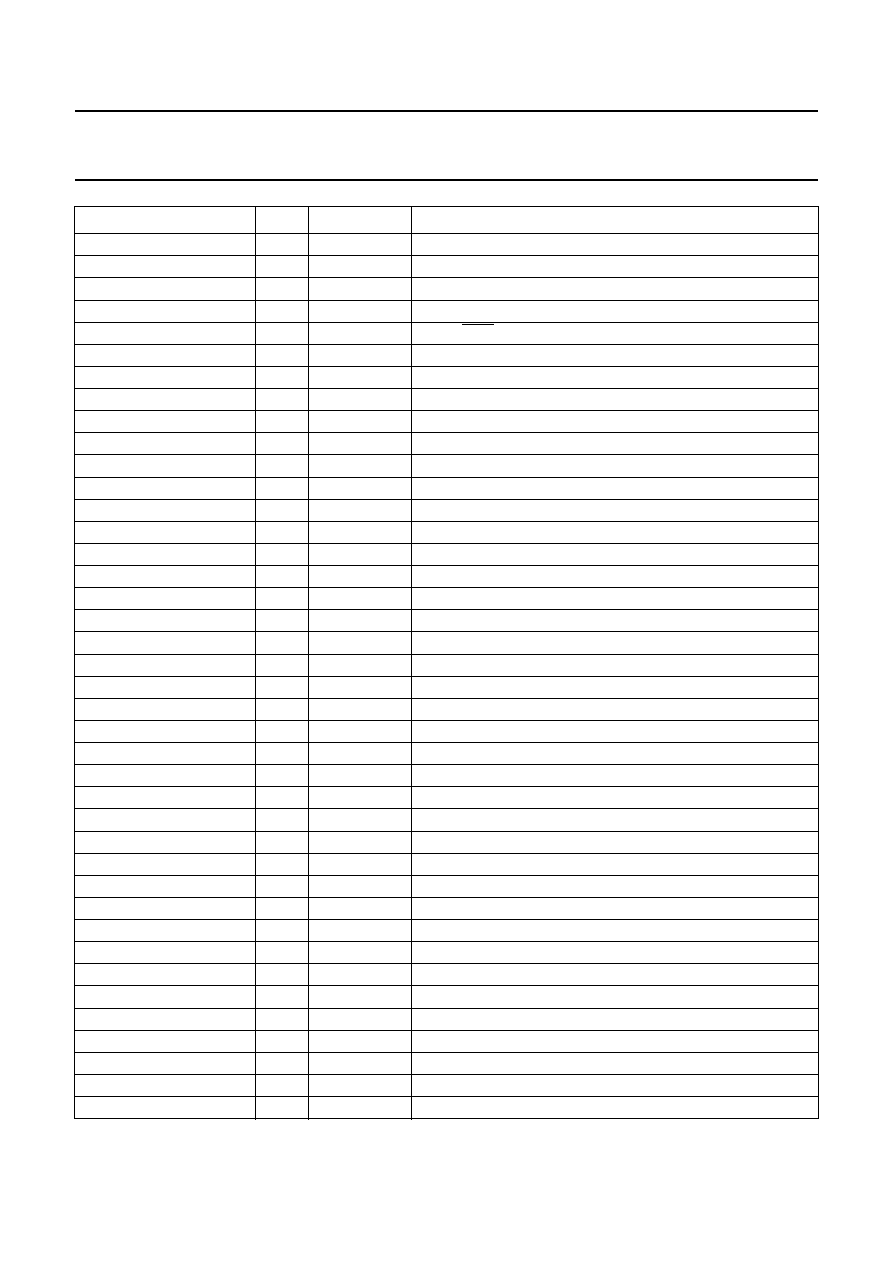

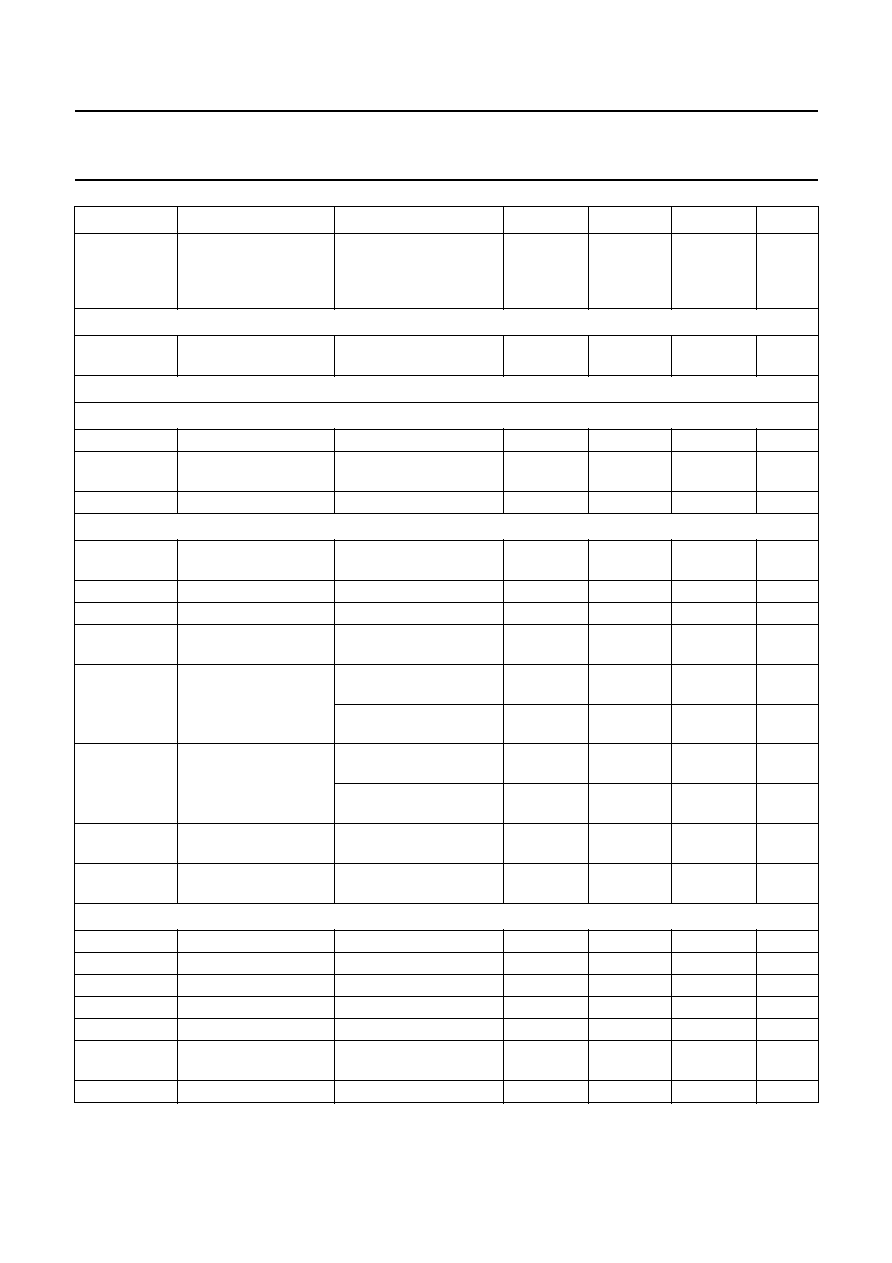

7

PINNING

SYMBOL

PIN

I/O

DESCRIPTION

HEATSINK

1

-

dissipation pin; internally connected to the leadframe

MOTSENSE1/SPSENSEH

2

analog I/O

sense line of the spindle/spindle sense amplifier input

MOTC

3

analog output

spindle motor power output

HEATSINK

4

-

dissipation pin; internally connected to the leadframe

HEATSINK

5

-

dissipation pin; internally connected to the leadframe

HEATSINK

6

-

dissipation pin; internally connected to the leadframe

HEATSINK

7

-

dissipation pin; internally connected to the leadframe

SWITCHGATE

8

analog output

isolation FET driver

CT

9

analog input

centre tap of the spindle

CLAMP1

10

supply

power stage supply voltage

GNDS/SPSENSEL

11

ground

spindle ground connection/spindle sense amplifier ground

SLEW

12

analog input

spindle motor slope control

SPCC

13

analog input

spindle current control

SPCCOUT

14

analog input

compensation point of the spindle current control loop

V

DDA2

15

supply

12 V analog supply voltage

BSTCP1

16

analog I/O

booster capacitor 1

BSTCP2

17

analog I/O

booster capacitor 2

CAPY

18

analog output

DC-to-DC converter output (19 V)

POR

19

digital I/O

power-on reset signal; active LOW

V

DDD

20

supply

5 V digital supply voltage

SDEN

21

digital input

serial interface data enable; active LOW

SDATA

22

digital I/O

serial interface data line

SCLOCK

23

digital input

serial interface clock line

CLOCK

24

digital input

clock input

ZCROSS

25

digital output

zero crossing detection signal

SCANTEST

26

digital input

scantest mode control; at LOW-level in normal conditions

DGND

27

ground

servo digital ground

ADC[0]/INTOUT

28

analog I/O

ADC channel 0 input/output of the A2 amplifier

ADC[1]/DIFOUT

29

analog I/O

ADC channel 1 input/output of the A1 amplifier

ADC[2]/SOUT

30

analog I/O

ADC channel 2 input/VCM sense amplifier output

ADC[3]

31

analog input

ADC channel 3 input

ADC[4]/TEMP

32

analog I/O

ADC channel 4 input/temperature monitor, thermal shutdown

ADC[5]

33

analog input

ADC channel 5 input

DACOUT

34

analog output

10-bit VCM DAC output

PESAMPN

35

analog input

inverting input of the A1 amplifier.

PESAMP

36

analog input

non-inverting input of the A1 amplifier

INTINN

37

analog input

inverting input of the A2 amplifier

INTIN

38

analog input

non-inverting input of the A2 amplifier

AGND

39

ground

servo analog ground

REF2V5

40

analog output

2.5 V bandgap reference voltage

1998 Nov 02

11

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

SEEKSELECT

41

analog input

input for the seek mode

TRACKFWSELECT

42

analog input

input for the track-following mode

VCMIN

43

analog input

VCM control input

V

DDA1

44

supply

5 V analog supply voltage

CPOR

45

analog input

set the POR delay time

CHK5

46

analog output

set the V

DDA1

POR threshold

CHK12

47

analog output

set the V

DDA2

POR threshold

BRAKEPOWER

48

analog input

brake power capacitor

BRAKEADJH

49

analog input

adjust current consumption during park mode

BRAKEDELAY

50

analog input

set the brake-after-park delay time

PARKVOLT

51

analog input

set the park voltage

VCMSENSEH

52

analog input

positive input of the VCM sense amplifier

VCMSENSEL

53

analog input

negative input of the VCM sense amplifier

GNDV

54

ground

VCM ground connection

CLAMP2

55

supply

power stage supply voltage

CLAMP3

56

supply

power stage supply voltage

PWRBIAS1

57

analog input

power stages isolation bias; externally connected to the clamp

HEATSINK

58

-

dissipation pin; internally connected to the leadframe

HEATSINK

59

-

dissipation pin; internally connected to the leadframe

HEATSINK

60

-

dissipation pin; internally connected to the leadframe

HEATSINK

61

-

dissipation pin; internally connected to the leadframe

IVCM

62

analog output

inverted output of the VCM (master stage)

GNDVCM3

63

ground

VCM power stage ground

HEATSINK

64

-

dissipation pin; internally connected to the leadframe

HEATSINK

65

-

dissipation pin; internally connected to the leadframe

HEATSINK

66

-

dissipation pin; internally connected to the leadframe

HEATSINK

67

-

dissipation pin; internally connected to the leadframe

GNDVCM2

68

ground

VCM power stage ground

NIVCM

69

analog output

non-inverted VCM output (slave stage)

HEATSINK

70

-

dissipation pin; internally connected to the leadframe

GNDVCM1

71

ground

VCM power stage ground

MOTA

72

analog output

spindle motor power output

MOTSENSE3

73

analog output

sense line of the spindle

MOTB

74

analog output

spindle motor power output

HEATSINK

75

-

dissipation pin; internally connected to the leadframe

MOTSENSE2

76

analog output

sense line of the spindle

PWRBIAS2

77

analog input

power stages isolation bias; externally connected to the clamp

HEATSINK

78

-

dissipation pin; internally connected to the leadframe

HEATSINK

79

-

dissipation pin; internally connected to the leadframe

HEATSINK

80

-

dissipation pin; internally connected to the leadframe

SYMBOL

PIN

I/O

DESCRIPTION

1998 Nov 02

12

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

Fig.5 Pin configuration.

handbook, full pagewidth

OM5193H

MGM976

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

60

59

58

57

56

64

63

62

61

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

HEATSINK

HEATSINK

HEATSINK

PWRBIAS1

CLAMP3

HEATSINK

GNDVCM3

IVCM

HEATSINK

CLAMP2

GNDV

VCMSENSEL

VCMSENSEH

PARKVOLT

BRAKEDELAY

BRAKEADJH

BRAKEPOWER

CHK12

CHK5

CPOR

VDDA1

VCMIN

TRACKFWSELECT

SEEKSELECT

HEATSINK

HEATSINK

HEATSINK

SWITCHGATE

CT

HEATSINK

MOTSENSE1/

SPSENSEH

MOTC

HEATSINK

CLAMP1

GNDS/SPSENSEL

SLEW

SPCC

SPCCOUT

VDDA2

BSTCP1

BSTCP2

CAPY

POR

VDDD

SDEN

SDATA

SCLOCK

CLOCK

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

ZCROSS

SCANTEST

DGND

ADC[0]/INTOUT

ADC[1]/DIFOUT

ADC[2]/SOUT

ADC[3]

ADC[4]/TEMP

ADC[5]

DACOUT

PESAMPN

PESAMP

INTINN

INTIN

AGND

REF2V5

HEATSINK

HEATSINK

HEATSINK

PWRBIAS2

MOTSENSE2

HEATSINK

MOTB

MOTSENSE3

MOTA

GNDVCM1

HEATSINK

NIVCM

GNDVCM2

HEATSINK

HEATSINK

HEATSINK

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

1998 Nov 02

13

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

8

FUNCTIONAL DESCRIPTION

8.1

Serial interface

The serial interface is a 3-wire bidirectional port for writing

and reading data to and from the internal registers of the

OM5193H. Each read or write will be composed of 16 bits.

For data transfer SDEN is brought LOW, serial data is

presented at the SDATA pin, and a serial clock is applied

to the SCLOCK pin. After the SDEN pin goes LOW, the

first 16 pulses applied to the SCLOCK pin shift the data

presented at the SDATA pin into an internal shift register

on the rising edge of each clock pulse. An internal counter

prevents more than 16 bits from being shifted into the

register. The data in the shift register is latched when

SDEN goes HIGH. If less than 16 clock pulses are

provided before SDEN goes HIGH, the data transfer is

aborted.

All transfers are shifted into the serial port with the MSB

first. The first 4 bits of the transfer contain address and

instruction information. The MSB is the R/W bit which

determines if the transfer is a read (logic 1) or a

write (logic 0).

The remaining 3 bits determine the internal register to be

accessed. The other 12 bits contain the programming

data. In the read mode (R/W = 1), the OM5193H outputs

the register contents of the selected address. In the write

mode (R/W = 0), the OM5193H loads the selected register

with the data presented on the SDATA pin. During sleep

mode, the serial port remains active and register

programmed data is retained.

SCLOCK is driven by the microcontroller. When the

microcontroller drives the SDATA line, the data is valid on

the rising edge of SCLOCK. When the OM5193H is driving

the SDATA line (in read mode after the R/W bit and 3 bits)

the data is valid on the falling edge of SCLOCK.

SDEN marks the end of the serial transfer. When the

SDEN pin goes HIGH, the shift register data is latched into

the addressed register of the OM5193H.

Fig.6 Serial port timing information.

handbook, full pagewidth

MGM977

SDEN

A1

A2

D11

A0

D9

D10

D7

D8

D5

D6

D3

D4

D2

D0

D1

direction

tst

tren

tsu

tex

thd

R/W

3

2

5

4

7

6

9

8

11

10

13

12

14

16

15

1

A1

A2

D11

A0

D9

D10

D7

D8

D5

D6

D3

D4

D2

D0

D1

R/W

SDATA

SCLOCK

Write to the OM5193H

SDATA

Write to, then read from the OM5193H

write registers

read back data

send/receive data

address

1998 Nov 02

14

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

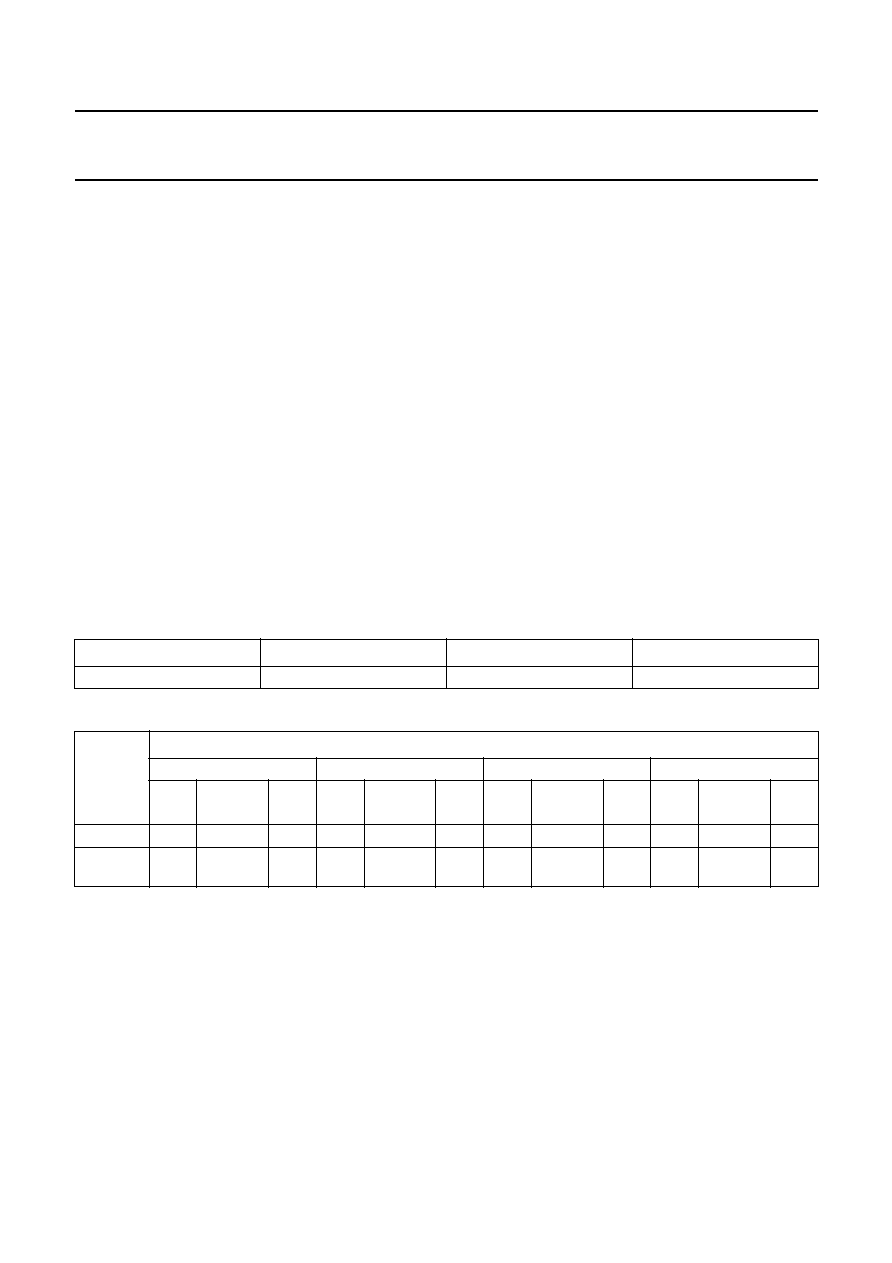

Table 1

Timing information for the serial interface

Table 2

Writeable registers of the serial interface

Table 3

Readable registers of the serial interface

SYMBOL

PARAMETER

MIN.

MAX.

UNIT

f

clk

clock frequency

-

30

MHz

t

st

chip select to first active clock edge

1

/

2

T

clk

-

ns

t

su

data to clock set-up time

12

-

ns

t

hd

clock to data hold time

12

-

ns

t

rd

time data line is driven after 5th negative clock

-

5

ns

t

ren

time from positive clock for data line to be driven

0

-

ns

t

rhd

receive data hold time

0

-

ns

t

rsu

receive data set-up time

12

-

ns

t

exW

last active clock to chip select; inactive on write

0

-

ns

t

exR

last active clock to chip select; inactive on read

10

-

ns

T

bpa

time between successive serial port accesses

5

-

clock cycles

REG

BITS

11

10

9

8

7

6

5

4

3

2

1

0

0

not used

opamp

Select_N

increm.

Channel

auto

Conv.

select

range

Select

test

Mode_N

not used

ADC MUX address

1

reverse

break

not

used

seek/

trackfw

not used

sleep_N

spindiv

manual

run/

stop

comC comB

comA

2

not used

DAC

(9)

DAC

(8)

DAC

(7)

DAC

(6)

DAC

(5)

DAC

(4)

DAC

(3)

DAC

(2)

DAC

(1)

DAC

(0)

3

not used

4

not used

5

Watchdog

Blank 1

6

high

Clock_N

Comdelim

7

Start-up

Blank 2

REG

BITS

11

10

9

8

7

6

5

4

3

2

1

0

0

ADC

status

ADC

(9)

ADC

(8)

ADC

(7)

ADC

(6)

ADC

(5)

ADC

(4)

ADC

(3)

ADC

(2)

ADC

(1)

ADC

(0)

1

Ccross

Bcross

Across

1998 Nov 02

15

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

Table 4

Address of registers

R/W

A2

A1

A0

REG.

DESCRIPTION

0

0

0

0

0

ADC channel and programmable options

1

0

0

0

0

ADC status and value

0

0

0

1

1

commutation, sleep, and VCM switch controls

1

0

0

1

1

commutation state in manual mode

0

0

1

0

2

10-bit DAC

0

0

1

1

3

not used

0

1

0

0

4

not used

0

1

0

1

5

Blank 1 and Watchdog delays

0

1

1

0

6

commutation delay limit (11 bits), internal clock divider factor

0

1

1

1

7

Start-up and Blank 2 delays

8.2

Commutation and sleep mode

Spindle control and sleep mode are controlled by writing or

reading on register#1.

∑

Register#1 (0, 1 and 2) control the spindle

commutations in manual mode when run/stop, manual

and sleep bits are correctly set. The commutation

sequence is described in Section "Spindle driver" (see

also Table 16 and Fig.12).

∑

Register#1 (3) is the run/stop bit. After the power is

turned on and POR is HIGH, the motor will not start

spinning until register#1 (3) has been set to logic 1.

The motor stops spinning when this bit is set to logic 0.

∑

Register#1 (4) is the manual commutation mode bit.

When this bit is set to logic 1 and register#1 (3) set to

logic 1, the commutation logic in the OM5193H will be

disabled so that the spindle will not automatically go to

the next commutation.

When register#1 (3 and 4) are set to logic 1, the

microcontroller is expected to generate the different

commutation states for the motor. The OM5193H will

still provide the coil status which will be available by

reading register#1. The different waveforms are shown

in Section "Spindle driver" (see also Fig.12). Note that

depending on the coil status acquisition moment,

transient states (due to the flyback pulses) can be read.

When register#1 (4) is set to logic 0, the manual mode

is disabled and the OM5193H will automatically

commutate the motor each time a zero crossing is

detected. The time between the zero crossing and the

next commutation is half the time between the two

preceding zero crossings. This is explained in the

detailed description in Section "Commutation control".

∑

Register#1 (5) is the spindiv bit. This bit together with

register#6 (11) enables the selection of a divider factor

for both converter clock and spindle clock. Clock

configurations are described in Section "Commutation

control" (see also Table 6).

∑

Register#1 (6) is the sleep mode bit. When it is set to

logic 0, the OM5193H will enter the low power mode.

Then the commutation control generates (101) output

codes on commutation signals to set spindle and VCM

head into sleep mode. This causes the OM5193H to go

into the brake-after-park mode. The only operating

circuits are the power monitor, the voltage reference

generator, the VCM precharge circuit and the serial

interface. The OM5193H is in sleep mode when POR is

LOW.

When the power is first turned on, the POR signal goes

HIGH after the POR delay. The OM5193H is then

automatically set in sleep mode and thus in low power

consumption mode. The VCM DAC output is in

high-impedance mode, the spindle is in the brake mode

and the VCM is in the precharge mode. Only after POR

is HIGH and register#1 (6) is set to logic 1, OM5193H is

ready to be functional. When register#1 (6) goes HIGH,

the VCM DAC outputs the 2.5 V reference voltage.

∑

Register#1 (11) is dedicated to brake the spindle motor

without going in `brake-after-park' mode.

The commutation sequence is shifted in order to

efficiently brake the motor. This brake, called reverse

brake, is activated when register#1 (11) bit is set to

logic 1. Note that there is no action on the VCM input

signal when the reverse brake is used. When this bit is

set to logic 0, the spindle motor starts again with normal

spindle commutations.

1998 Nov 02

16

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

Reading register#1 will read the state of the 3 coils coming

from the spindle control block (ACROSS, BCROSS and

CCROSS). The 3 input lines will be in bits 0, 1, and 2.

The different waveforms are shown in Section "Spindle

driver" (see also Fig.12). Note that depending on the coil

status acquisition moment, transient states (due to the

flyback pulses) can be read.

Table 5

Writing register#1

BIT

DEFAULT

VALUE

NAME

DESCRIPTION

0

0

comA

drives COMA when in manual commutation

1

0

comB

drives COMB when in manual commutation

2

0

comC

drives COMC when in manual commutation

3

0

run/stop

0 = motor to brake-after-park mode

1 = motor spinning; VCM active

4

0

manual

0 = automatic commutation mode with run/stop = 1

1 = manual commutation mode with run/stop = 1

5

0

spindiv

0 = the internal spindle clock frequency is controlled by register#6 (11)

(bit highClock_N)

1 = an additional divider by 4 is added on the internal spindle clock

6

0

sleep_N

0 = sleep mode: low power mode, serial interface active, power stages in

brake-after-park mode

1 = fully functional mode: sleep_N has higher priority than run/stop if both are

active

7

0

-

not used

8

0

-

not used

9

1

seek/trackfw

0 = VCMIN connected to SEEKSELECT

1 = VCMIN connected to TRACKFWSELECT

10

1

-

not used

11

0

reverse break 1 = active brake control

0 = normal commutations as defined by bits above

8.3

Commutation control

The commutation logic block generates the six different

states to rotate the spindle motor. The spindle driver block

provides the BEMF zero crossing information.

The commutation block interprets the zero crossing

information and determines the commutation delay time

and the next coil state. The commutation block must take

into account the following situations:

∑

Start-up

∑

No start

∑

Reverse rotating

∑

Run

∑

Manual commutation.

The commutation logic keeps the motor spinning by

commutating the motor after each detected zero crossing.

It measures the time between two successive BEMF zero

crossings and then determines the next commutation.

The delay (commutation delay) between a zero crossing

and the next commutation is half the time between the two

preceding zero crossings. The commutation delay

(Comdelim) can be limited to guarantee a faster lock after

the motor has gone out of lock. A maximum commutation

delay can be set via the serial port. The time is a function

of both the external clock frequency, the individual register

prescalers and the time programmed into the registers.

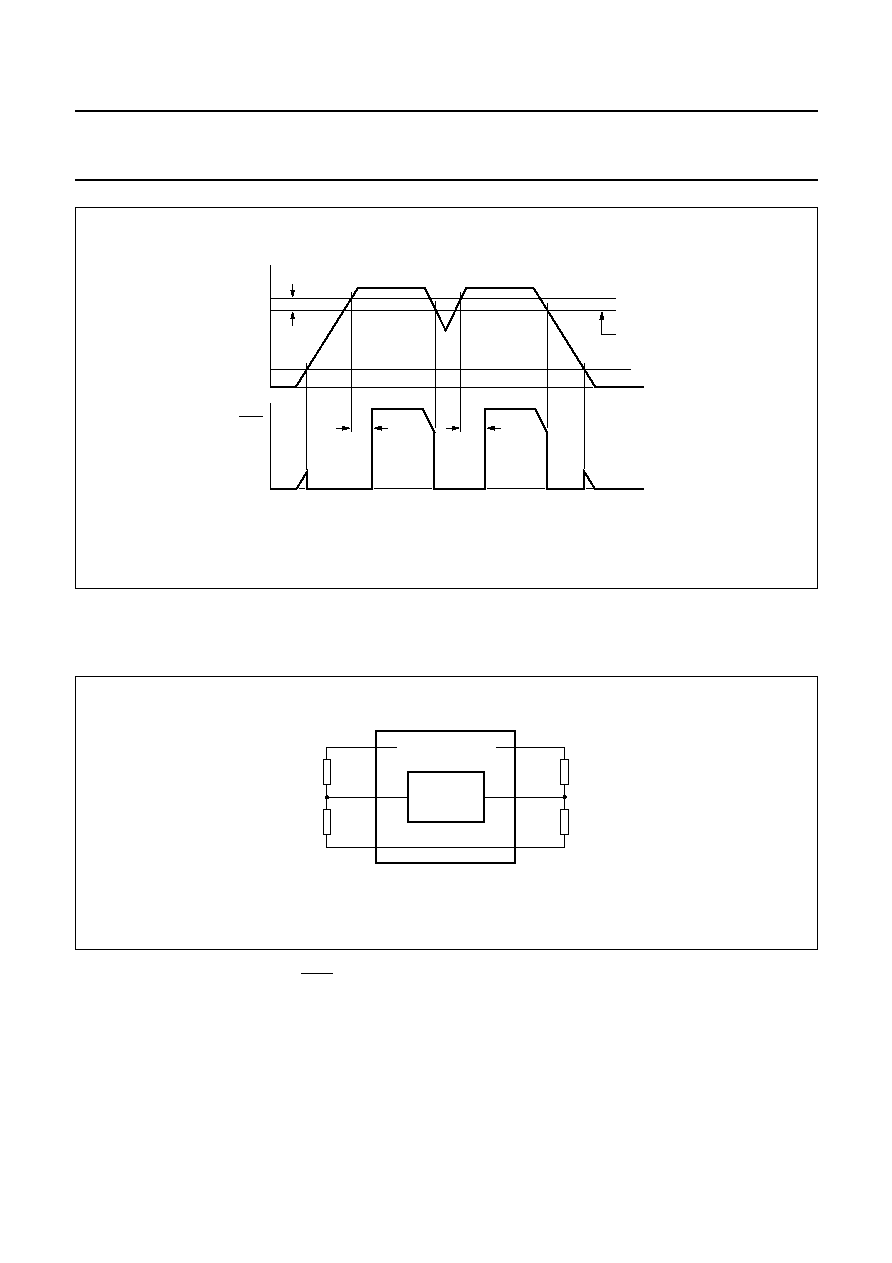

Figure 7 shows a typical motor commutation timing

diagram.

1998 Nov 02

17

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

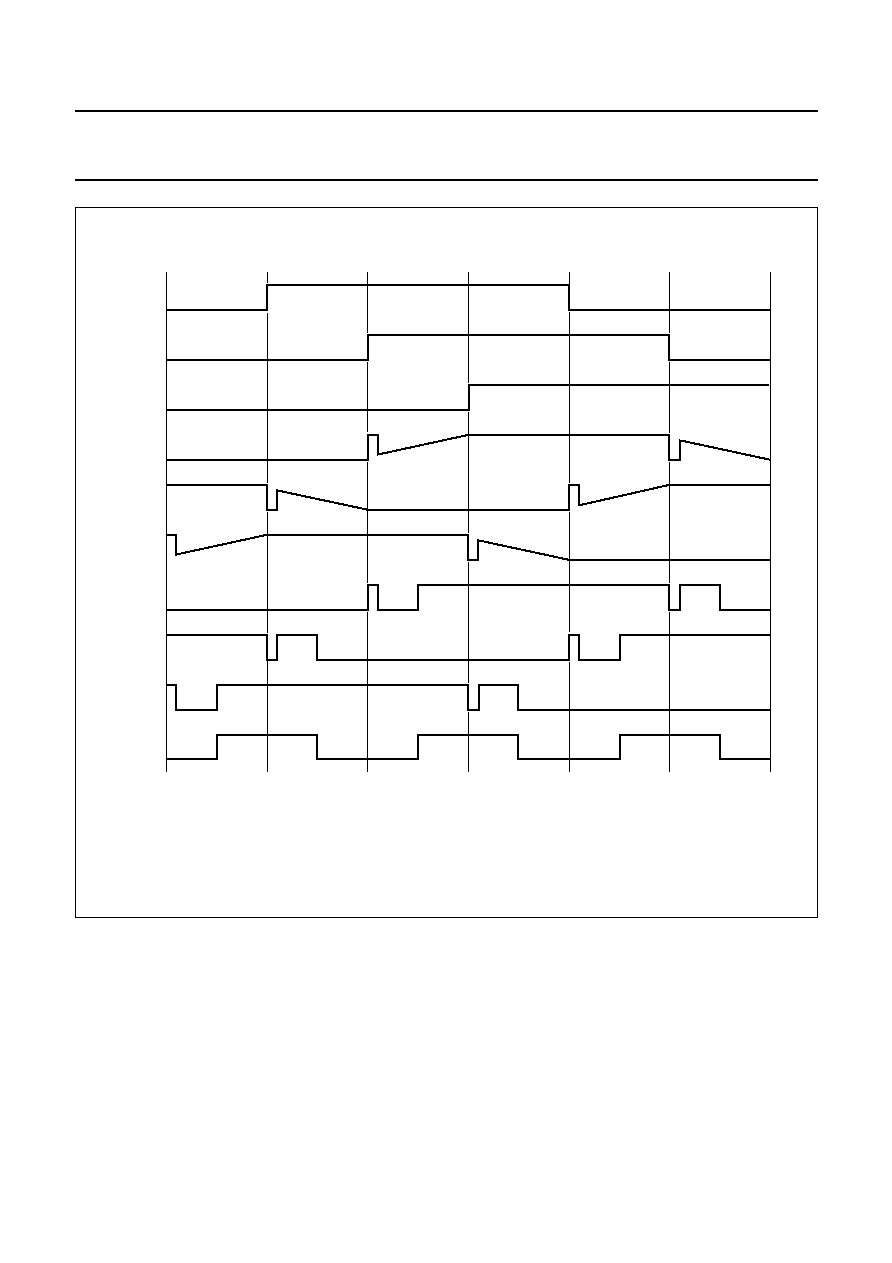

Fig.7 A typical motor commutation diagram.

handbook, full pagewidth

MGM978

centre tap

commutation

Blank 1

Zc1

Zc2

Zc3

flyback pulse

false zero crossings

true zero crossing

commutation

Commutation

delay

Blank 2

Start-up

Watchdog

∑

Blank 1

After a commutation occurs, the leading edge of the

flyback pulse has a zero crossing (Zc

1

). Blank 1 timer is

used to ignore this zero crossing by masking it while the

timer initialized at Blank 1 value is counting. The state

associated to Blank 1 down-counter will end when the

counter reaches the zero value.

∑

Blank 2

The Blank 2 timer starts counting as soon as the second

zero crossing occurs (Zc

2

). After the second flyback

pulse zero crossing, all extra zero crossings are ignored

during the Blank 2 time. This allows the ringing of the

coil voltage without causing a commutation advance.

The state associated to Blank 2 down-counter will end

when the counter reaches the zero value.

∑

Watchdog

The Watchdog timer makes sure the motor is running in

forward direction. If the motor is rotating in reverse

direction, the BEMF voltage is inverted and the second

crossing of the flyback pulse (Zc

2

) will not occur until the

true BEMF zero crossing is detected. Therefore, if the

Watchdog timer expires before a zero crossing occurs,

the motor is assumed to be rotating backwards.

The commutation is advanced by one step to correct

this condition. The Watchdog time must be set to a value

that is greater than the flyback pulse duration, measured

when the spindle motor stands still.

The state associated to the Watchdog timer will start

when the one associated to Blank 1 timer is finished and

will end when Zc

2

occurs or when the Watchdog counter

expires.

∑

Start-up

If the motor is not spinning, the BEMF zero crossings will

not occur. The Start-up timer detects this if it expires

before the true zero crossing (Zc

3

) has occurred. It will

advance the commutation by one step if this happens.

The state associated to Start-up timer will start when the

one associated to Blank 2 timer is finished and will end

when Zc

3

occurs or when Start-up expires.

∑

Comdelim

The timer associated to Comdelim value allows to

control the maximum commutation delay (between zero

crossing and next commutation). When the true zero

crossing is detected (Zc

3

), the timer will count until it

expires and then will commutate the motor to the next

step. This commutation delay time is equal to half the

measured value between 2 zero crossings.

The Comdelim value should be set to the maximum

allowable delay value. If

Zc

meas

is lower than the

programmed Comdelim value, the next timer value will

be

Zc

meas

divided by 2. If

Zc

meas

is higher than the

programmed Comdelim value, the next timer value will

be the programmed Comdelim value divided by 2.

1998 Nov 02

18

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

The clock used in the commutation logic block is obtained

by dividing the master clock of the chip (f

CLOCK

) by a clock

divider (Prescaler). This internal clock will be named

internalSpindleClock. Internal spindle clock configurations

are described in Table 6.

All the delays described above (Blank 1, Watchdog,

Blank 2, Start-up and Comdelim) are generated by one

down-counter (called TIMER 1), see Fig.8 and one

up-counter (called TIMER 2), see Fig.9. Each of them

uses internalSpindleClock signal.

Table 6

Spindle clock configurations

8.3.1

B

LANKS

, W

ATCHDOG AND

S

TART

-

UP DELAYS

An internal down-counter called TIMER 1 is used to generate Blank 1, Blank 2, Watchdog and Start-up delays. It loads

one of these programmed values and counts down till it reaches zero.

spindiv

REGISTER#1 (5)

highClock_N

REGISTER#6 (11)

internalSpindleClock

0

0

1

/

16

f

CLOCK

0

1

1

/

32

f

CLOCK

1

0

1

/

64

f

CLOCK

1

1

1

/

128

f

CLOCK

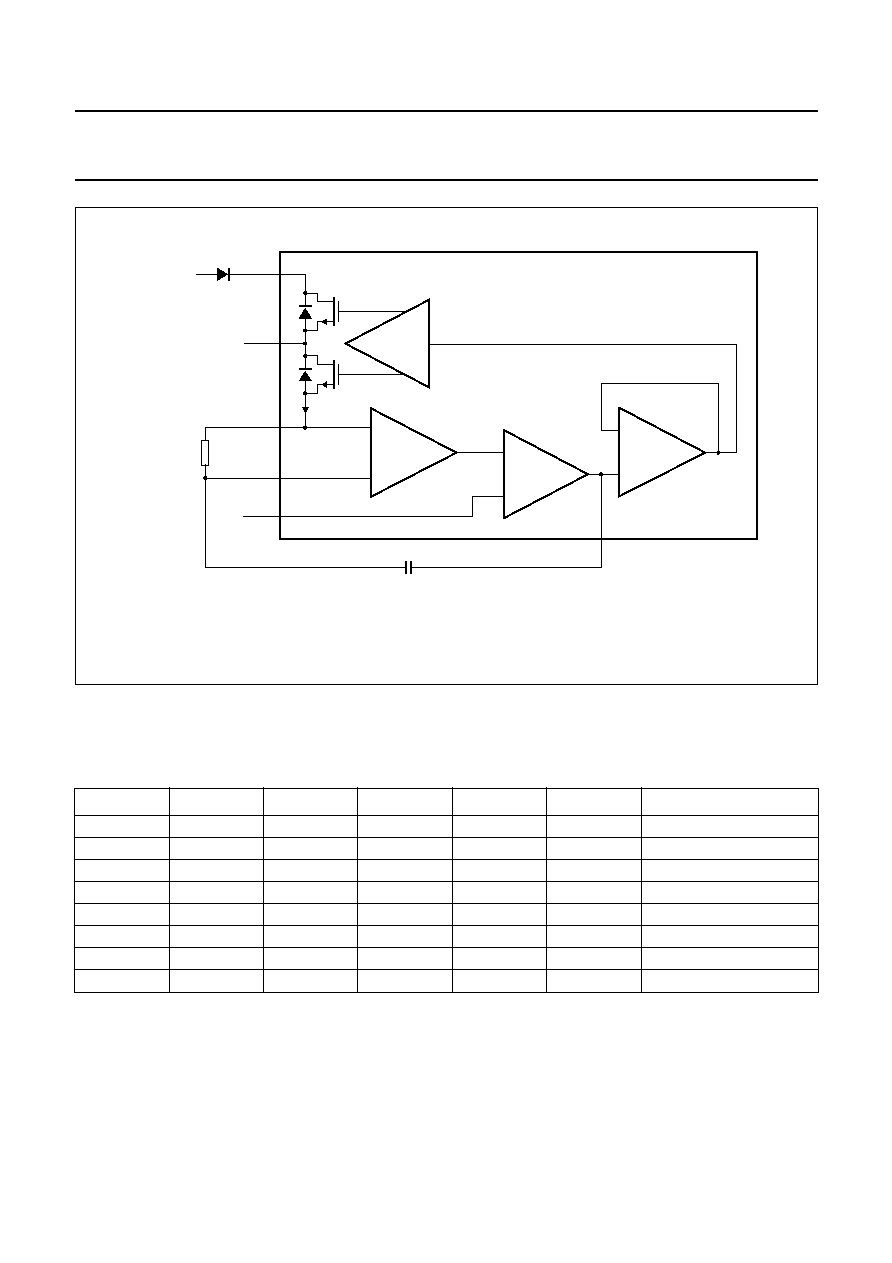

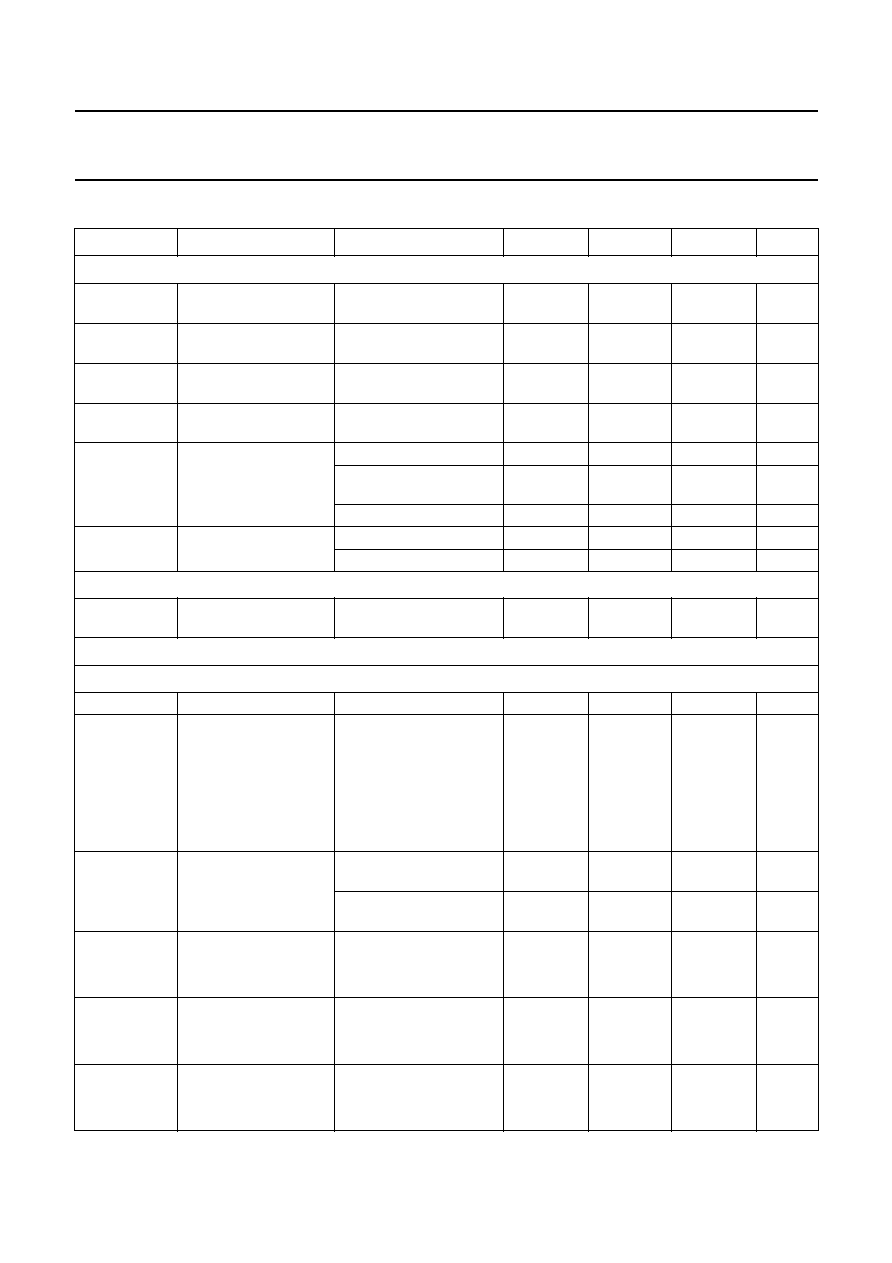

Fig.8 Down-counter TIMER 1.

handbook, full pagewidth

19

Start-up

Blank 1

Blank 2

Watchdog

18

15

14

13

12

11

10

17

16

9

8

5

4

3

2

1

0

7

6

MGL481

The actual delay time will be:

(1)

Value is the decimal representation of the binary code

programmed in one of the 6 bit registers.

(2)

Delay

value

step

◊

=

Step

2

LSB

internalSpindleClock

---------------------------------------------------------------

=

(3)

We have to subtract (2

LSB

-

1) to obtain maxValue

because all the bits from 0 to (LSB

-

1) are set internally to

zero by design.

maxValue

2

MSB

1

+

(

)

1

≠

2

LSB

1

≠

≠

internalSpindleClock

----------------------------------------------------------------------------

2

MSB

1

+

(

)

2

LSB

≠

internalSpindleClock

------------------------------------------------------

=

=

1998 Nov 02

19

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

Table 7

Delays used for TIMER 1

Table 8

Numerical application with f

CLOCK

= 30 MHz

Notes

1. The first zero crossing of the flyback should occur within this time.

2. The real zero crossing should not come within this time after the second zero crossing of the flyback pulse.

3. The time should be larger than the duration of the flyback pulse measured when the motor stands still.

4. The actual zero crossing should occur within this time after the Blank 2 time has expired.

8.3.2

C

OMDELIM DELAY

An internal up-counter called TIMER 2 is used to measure the time between two zero crossings and also to set the

maximum commutation delay through Comdelim delay.

DELAY

LSB

MSB

BITS

Blank 1

2

7

6

Blank 2

5

10

6

Watchdog

7

12

6

Start-up

14

19

6

DELAYS

internalSpindleClock

1

/

16

f

CLOCK

1

/

32

f

CLOCK

1

/

64

f

CLOCK

1

/

128

f

CLOCK

STEP

MAX.

STEP

MAX.

STEP

MAX.

STEP

MAX.

Blank 1; note 1

2.13

µ

s

134

µ

s

4.27

µ

s

269

µ

s

8.53

µ

s

538 ms

17.1

µ

s

1.08 ms

Blank 2; note 2

17.1

µ

s

1.08 ms

34.1

µ

s

2.15 ms

68.3

µ

s

4.30 ms

137

µ

s

8.60 ms

Watchdog; note 3

68.3

µ

s

4.30 ms

137

µ

s

8.60 ms

273

µ

s

17.2 ms

546

µ

s

34.4 ms

Start-up; note 4

8.74 ms

550 ms

17.5 ms

1.101 s

35 ms

2.202 s

70 ms

4.404 s

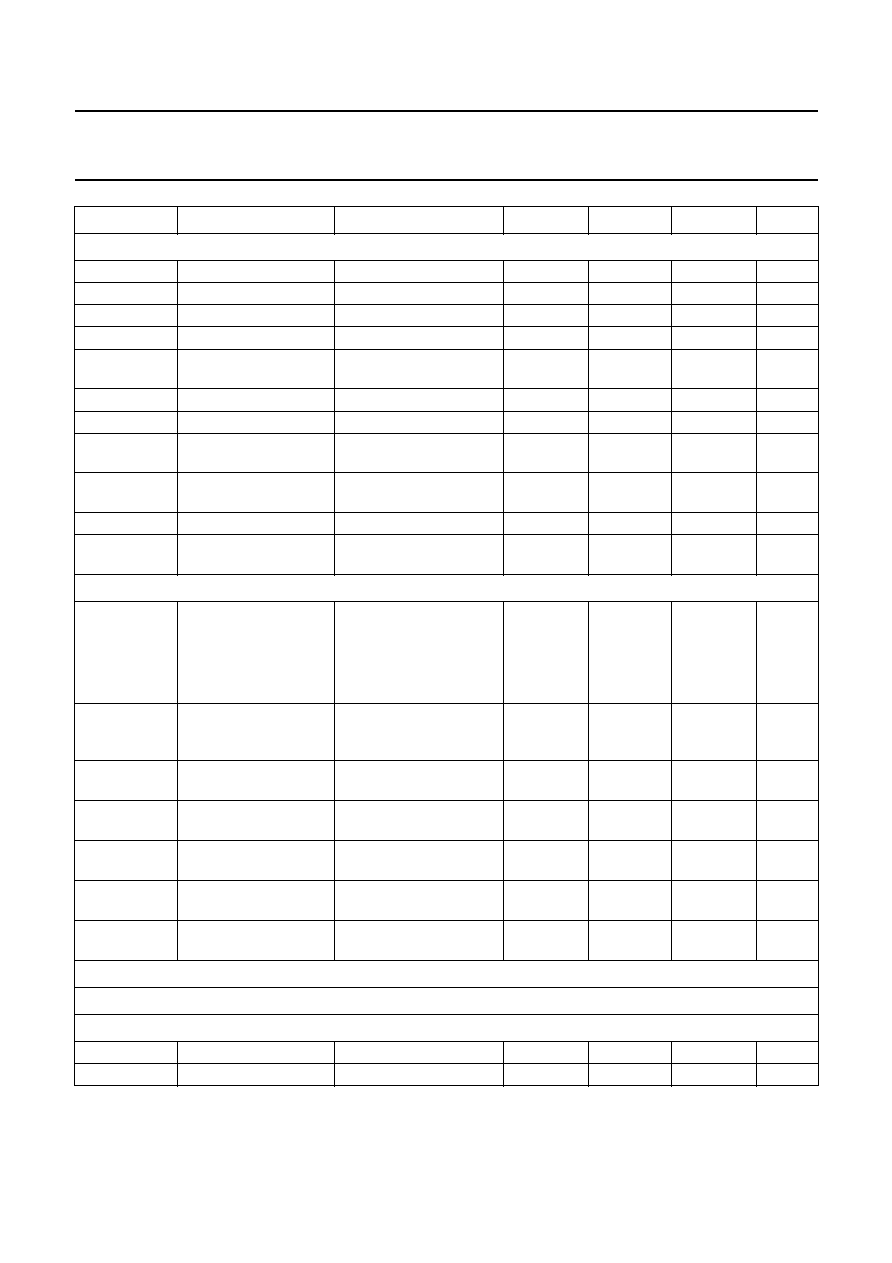

Fig.9 Up-counter TIMER 2.

handbook, full pagewidth

Comdelim

12

11

10

9

8

5

4

3

2

1

0

7

6

MGL482

1998 Nov 02

20

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

Comdelim is the maximum value that can be reached by TIMER 2. So, this is the maximum time between 2 zero

crossings (

Zc). The maximum commutation delay (Comdelim delay) is then half this value.

The actual delay will be:

(4)

(5)

Value is the decimal representation of the binary code programmed in the 11-bit register.

(6)

(7)

(we have to add this offset because bits 0 and 1 are set internally to logic 1 by design).

(8)

(9)

Table 9

Delay used for TIMER 2

Table 10 Numerical application with f

CLOCK

= 30 MHz

The commutation delay counter, which starts counting at a zero crossing, has two operating modes:

∑

In the adaptive mode, the next zero crossing is detected before the commutation delay counter has reached its

programmed value. In this mode, the next commutation will occur at the measured t

Zcross

divided by 2 after the last

zero crossing.

∑

In the forced mode, the next zero crossing is detected after the commutation delay counter reaches its programmed

value. In this mode, the counter is stopped and the commutation logic block waits until the next zero crossing occurs.

After it occurs, the next commutation will be forced at the programmed commutation delay divided by 2.

DELAY

LSB

MSB

BITS

Comdelim

2

12

11

DELAYS

CLOCKOUT/PRESCALER

1

/

16

f

CLOCK

1

/

32

f

CLOCK

1

/

64

f

CLOCK

1

/

128

f

CLOCK

STEP

(

µ

s)

OFFSET

(

µ

s)

MAX.

(ms)

STEP

(

µ

s)

OFFSET

(

µ

s)

MAX.

(ms)

STEP

(

µ

s)

OFFSET

(

µ

s)

MAX.

(ms)

STEP

(

µ

s)

OFFSET

(

µ

s)

MAX.

(ms)

Zc

2.13

1.6

4.37

4.27

3.2

8.74

8.53

6.4

17.48 17.1

12.8

35

Comdelim

delay

1.07

0.8

2.18

2.13

1.6

4.37

4.27

3.2

8.74

8.53

6.4

17.48

Zc

value

step

◊

Offset

+

=

ComdelimDelay

Zc

2

-----------

=

Step

2

LSB

internalSpindleClock

---------------------------------------------------------------

=

Offset

3

internalSpindleClock

---------------------------------------------------------------

=

maximum

Zc

2

MSB

1

+

(

)

1

≠

internalSpindleClock

---------------------------------------------------------------

=

maximumComdelimDelay

2

MSB

(

)

1

2

---

≠

internalSpindleClock

---------------------------------------------------------------

=

1998 Nov 02

21

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

8.4

10-bit ADC with 7 analog inputs

The ADC is a signed 10-bit converter which uses the

successive approximation conversion technique.

The overall accuracy is 2% absolute error not including

contribution of the reference voltage and guaranteed

monotonicity.

8.4.1

I

NPUT CHANNELS

7 analog input channels can be sampled and converted:

∑

Channel 0: conversion of the op-amp A2 output

∑

Channel 1: conversion of the op-amp A1 output

∑

Channel 2: conversion of the VCM sense amplifier

output

∑

Channel 3: conversion of an analog external signal

∑

Channel 4: conversion of the temperature

monitor + temperature shutdown signal

∑

Channel 5: conversion of an analog external signal

∑

Channel 6: conversion of an internal signal, controlling

analog supply voltage over two ranges.

Channels 0 and 1 can be used as external inputs by

deactivating the 2 stand-alone op-amps A1 and A2

(op-amps are put in sleep mode), that means by putting

register#0 (9) at logic 1.

The ADC does not include input filtering. If this is required

in the application then it must be implemented externally.

8.4.2

I

NPUT RANGES

Two analog input ranges are possible: either between

1.5 and 3.5 V or between 0 and 5 V. The input range is

selected with register#0 (6):

∑

Register#0 (6) = 0: means input analog value between

1.5 and 3.5 V

∑

Register#0 (6) = 1: means input analog value between

0 and 5 V.

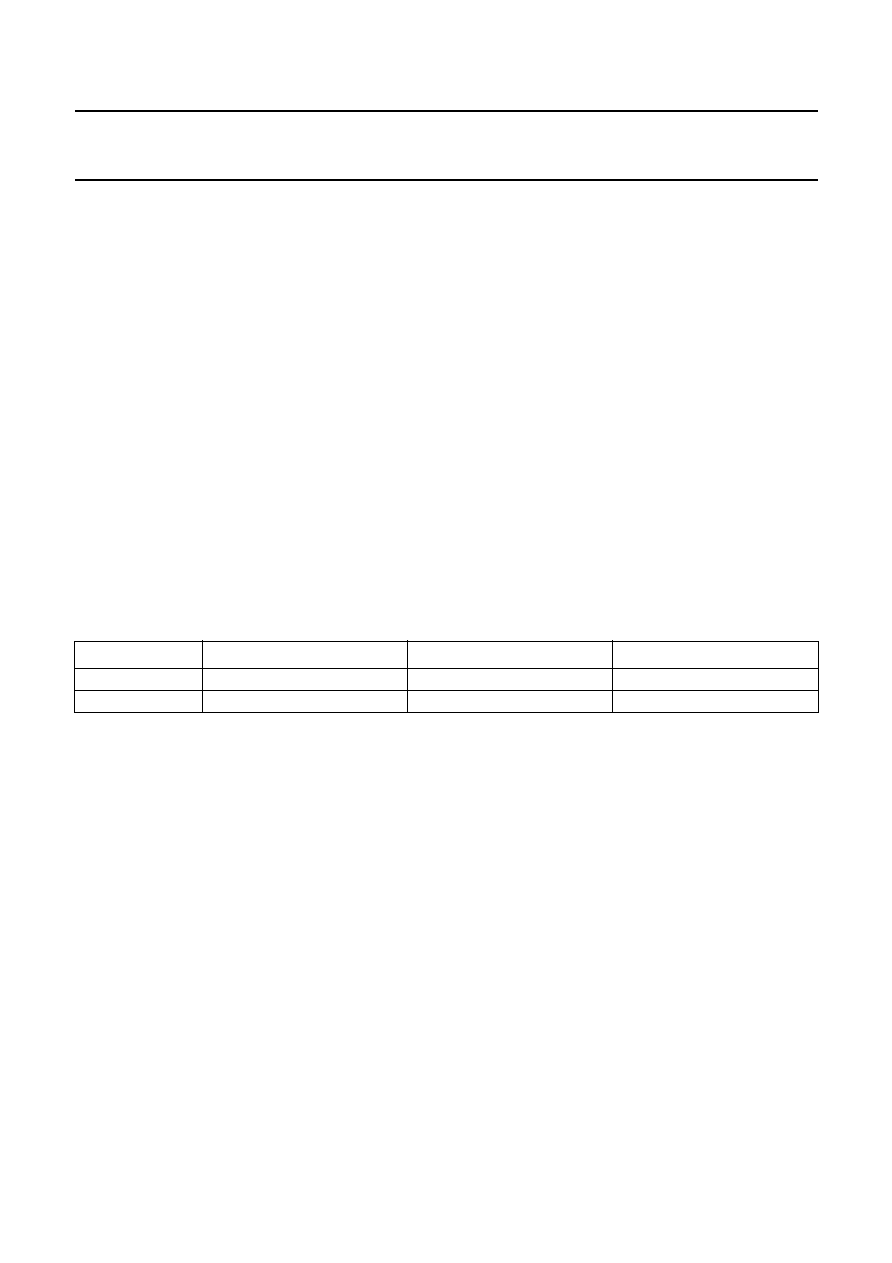

Table 11 Input analog voltage and corresponding output code

BIT

MIN. OUTPUT = 200H

MIDDLE OUTPUT = 000H

MAX. OUTPUT = 1FFH

register#0 (6) = 0

minimum input value = 1.5 V

middle input value = 2.5 V

maximum input value = 3.5 V

register#0 (6) = 1

minimum input value = 0 V

middle input value = 2.5 V

maximum input value = 5 V

8.4.3

C

ONVERSION MODES

Three different conversion modes are possible depending

on the states of register#0 (7) and register#0 (8):

∑

Auto conversion and input channel auto incrementation

mode.

This mode is obtained with register#0 (7) = 1 and

register#0 (8) = 1. The conversion sequence works as

follows: the first A/D conversion is started by writing to

serial port register#0. The address of the channel is

decoded from the three LSBs in register#0 [2 to 0].

Then the OM5193H selects the addressed analog

channel, samples and holds the analog input and starts

the analog to digital conversion. The conversion result is

obtained by reading the serial port register#0.

Register#0 (10) provides the status of the conversion: it

is set to 0 as long as the conversion is running and

indicates that the low 10 bits of register#0 are invalid.

Register#0 (10) going HIGH means the conversion is

complete and guarantees the validity of the data in

register#0 [9 to 0].

∑

Auto conversion on the same channel.

This input channel automatic incrementation option can

be deactivated by setting register#0 (8) to logic 0 with

register#0 (7) at logic 1. So the behaviour of the ADC is

the same as explained above, except that all the

conversions are made on the channel specified by the

last write access on register#0.

∑

Single conversion mode.

The automatic conversion mode can also be

deactivated by setting register#0 (7) to logic 0. In this

mode, a write access on register#0 will start a

conversion on the specified channel and a read access

will not launch any other conversion.

1998 Nov 02

22

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

8.4.4

P

ROGRAMMING REGISTER

#0

Table 12 Writing register#0

Note

1. Possible addresses:

a) ADC MUX address = 000: channel 0 selected;

b) ADC MUX address = 001: channel 1 selected;

c) ADC MUX address = 010: channel 2 selected;

d) ADC MUX address = 011: channel 3 selected;

e) ADC MUX address = 100: channel 4 selected;

f) ADC MUX address = 101: channel 5 selected;

g) ADC MUX address = 110: channel 6 selected;

h) ADC MUX address = 111 is an illegal address. No analog input will be selected if a conversion is asked in this

channel and the ADC will convert a random analog value.

For a correct initialization of the converter just after power up, when POR is HIGH (before using the ADC or the DAC),

the register#0 has to be programmed as follows: write 020H and then write 000H. A read of register#0 between the

2 write accesses is not necessary.

BIT

DEFAULT VALUES

NAME

DESCRIPTION

0

ADC MUX address; note 1 ADC MUX address 0

1

ADC MUX address 1

2

ADC MUX address 2

3

not used

4

not used

should be at logic 0 under normal operating

conditions

5

0

testMode_N

dedicated for test purposes of the DAC in ADC or

DAC mode; should be at logic 0 under normal

operating conditions

6

0

rangeSelect

selects the analog input range of the ADC:

0 = range 1.5 to 3.5 V

1 = range 0 to 5 V

7

0

autoConvSelect

selects the automatic conversion option; see details

in Table 13

8

0

incrementChannel

selects the automatic channel increment option; see

details in Table 13

9

0

opampSelect_N

selects the stand-alone op-amps:

0 = op-amps activated

1 = op-amps deactivated

10

not used

11

not used

1998 Nov 02

23

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

Table 13 Truth table for bits 7 and 8 on register#0 in write mode; conversion mode options; note 1

Note

1. The autoConvSelect bit has priority over the incrementChannel bit.

8.4.5

C

ONVERTER CLOCK FREQUENCY VALUES

The ADC internal clock named converterClock can have two different frequency values by programming register#6 (11)

(bit highClock_N):

Register#6 (11) = 1: means converterClock = Master clock (f

CLOCK

) divided by 8 (clockDivider = 8)

Register#6 (11) = 0: means converterClock = Master clock (f

CLOCK

) divided by 4 (clockDivider = 4)

(10)

Table 14 Numerical application

8.5

10-bit VCM DAC

The VCM DAC is a signed 10-bit digital-to-analog convertor. It will start the conversion when register#2 is written.

The lowest 10 bits contain the value to be converted.

Table 15 Input code and corresponding output analog voltage

The overall accuracy is 2% absolute error not including the contribution of the reference voltage and guaranteed

monotonicity.

autoConvSelect

REGISTER#0 (7)

incrementChannel

REGISTER#0 (8)

DESCRIPTION

0

0

Default state: no auto channel incrementation, no A/D

conversion started automatically after each read of the result.

1

0

Starts automatically an A/D conversion on the same channel

(no channel incrementation) after each read of the result.

1

1

Starts automatically an A/D conversion on the next channel

(increment the channel by 1) after each read of the result.

0

1

No auto channel incrementation, no A/D conversion started

automatically after each read of the result (similar to the default

state `00').

TIME

MASTER CLOCK = 10 MHz

MASTER CLOCK = 20 MHz

MASTER CLOCK = 30 MHz

DIVISION

BY 8

DIVISION

BY 4

DIVISION

BY 8

DIVISION

BY 4

DIVISION

BY 8

DIVISION

BY 4

Conversion time

10.4

µ

s

5.2

µ

s

5.2

µ

s

2.6

µ

s

3.4

µ

s

1.7

µ

s

INPUT CODE

OUTPUT VOLTAGE

200H

1.5 V

000H

2.5 V

1FFH

3.5 V

conversionTime

13

clockDivider

◊

f

CLOCK

---------------------------------------------

=

1998 Nov 02

24

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

8.6

Reference voltage

V

ref2V5

is a 2.5 V bandgap reference used as the reference

voltage for the VCM circuit. Stable voltages of

1.5 and 3.5 V are generated from the 2.5 V reference and

used as reference voltages for the VCM DAC and for the

ADC. The 1.5 and 3.5 V voltages are only available inside

the IC and are not connected to external pins.

8.7

Stand-alone op-amps

This block is composed of two low-offset stand-alone

op-amps (A1 and A2) with outputs connected to the ADC

channels 0 and 1.

The stand-alone op-amps can be deactivated if they are

not used in the application. When deactivated, they are put

in sleep mode and outputs are in high-impedance. In that

case, ADC channels 0 and 1 can be used as input signals.

The op-amps are controlled by writing to the serial port on

register#0 (9); bit opampSelect_N:

Register#0 (9) = 0: means the op-amps are selected

and put in normal mode

Register#0 (9) = 1: means the op-amps are not selected

and put in sleep mode.

8.8

Analog switch

This block is composed of a 2 input analog multiplexer

used to select the seek mode or the track-following mode.

It is controlled by writing to serial port register#1 (9);

bit seek/trackfw:

Register#1 (9) = 0: means input SEEKSELECT is

selected and connected to VCMIN

Register#1 (9) = 1: means input TRACKFWSELECT is

selected and connected to VCMIN.

8.9

Charge pump voltage

The charge pump voltage circuit (voltage doubler)

generates a power supply voltage higher than V

DDA2

(12 V) power supply. This voltage is used to:

∑

Drive the upper N-channel FETs of the power stages

∑

Drive an optional external FET (see Section 8.18)

∑

Set a voltage independent of the power supply and

temperature for the functions BRAKEPOWER and

BRAKEDELAY.

Two external capacitors are used to generate the higher

voltage on pin CAPY. The capacitor between

BSTCP1 and BSTCP2 is charged and discharged with a

frequency, which is a function of the charge pump output

current and an internal oscillator frequency. The voltage

on pin CAPY is typically 19.2 V. Figure 10 illustrates the

charge pump block diagram.

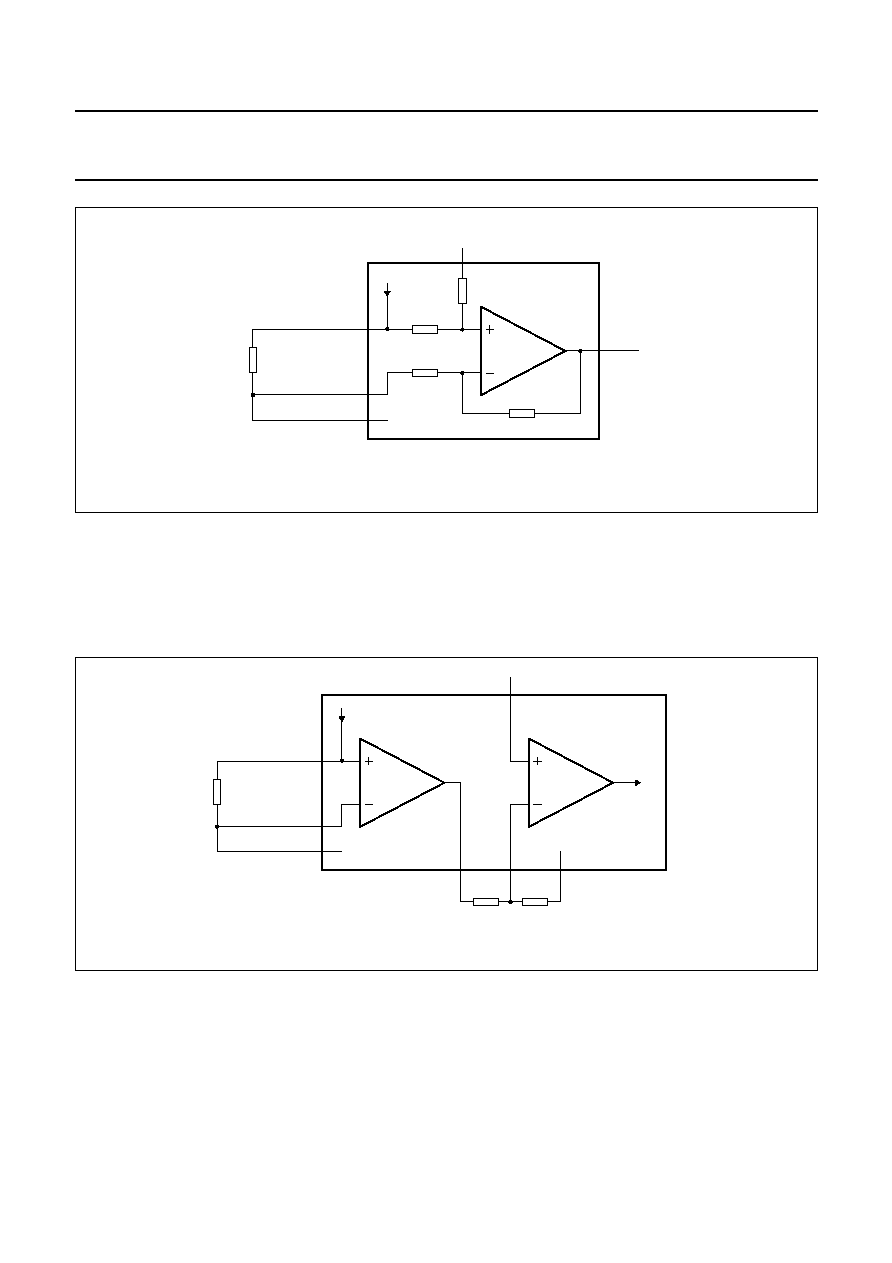

Fig.10 Charge pump voltage generator.

handbook, full pagewidth

MGM979

COMPARATOR

OSCILLATOR

200 kHz

reference

BSTCP1

BSTCP2

CAPY

GNDS

CCAPX

CCAPY

VDDA2

1998 Nov 02

25

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

8.10

Spindle driver

The spindle block contains both the low-side and high-side

drivers configured as a H-bridge for a 3-phase DC

brushless, sensorless motor. In each of the six possible

states, two outputs are active, one sourcing current and

one sinking current. The third output presents a high

impedance to the motor which enables measurement of

the BEMF in the corresponding motor coil. The BEMF zero

crossing comparator outputs (xCROSS) are processed by

the commutation logic circuit to calculate the correct

moment for the next commutation, so the change to the

next output state. The commutation logic circuit provides

proper commutation commands for the spindle drivers

thus ensuring the rotation of the motor. The commutation

logic circuit also controls the spindle motor driver during

start-up (no reverse rotation).

The spindle should be set in the high-impedance mode

(see Table 16) between the sleep mode (brake-after-park

mode) and the normal running mode. Register#1 should

be programmed as follows:

∑

Write 00x001x11010 to activate the manual mode

during typically less than 1 ms (time discharge of

low-side power FETs)

∑

Write 00x001x01xxx to activate the automatic running

mode. The `x' states concern the seek or track-following

mode register#1 (9) and the spindle prescaler value

used on the application register#1 (5). Their states are

specific to the application needs.

The ZCROSS signal is a combination of the xCROSS

signals. It can be used by the microcontroller as a tacho

information for the spindle speed control loop.

The external SPCC signal is used to control the spindle

current. The external SPCCOUT capacitor is connected to

the spindle current control amplifier to ensure the stability

of the spindle current control loop.

The short-circuit brake mode is entered if power-down,

thermal shutdown or sleep mode occurs.

A Miller network is used to obtain soft switching on the

low-side and high-side drivers.

The slew rate of the driver stage that is switched-off can be

controlled by means of a resistor connected to the pins

SLEW and GND. The slew rate is calculated using the

following equation:

(11)

SR

3

µ

A

2.55

4

1 k

R

SLEW

+

(

)

◊

-------------------------------------------------------

+

20 pF

---------------------------------------------------------------------------

=

R

SLEW

is in

and SR in V/s. Without a resistor, SR is

typical 0.15 V/

µ

s and with a resistor of 90 k

, the typical

value is 0.5 V/

µ

s. The maximum slew rate depends on the

limit for stability of the spindle loop.

The spindle current I

SPRUN

is sensed by an external

resistor R

SPSENSE

connected to a sense amplifier

providing the internal signal SPOUT. The gain G

v

of the

sense amplifier is typical 10.

(12)

The transconductance gain of the spindle loop is given by

the following equation:

(13)

The control amplifier differentiates the control signal on

pin SPCC from the signal SPOUT. A 0.25 V offset is

subtracted from the input voltage on pin SPCC to ensure

that the current command includes the zero current. With

the spindle loop closed, the voltage SPOUT is given by the

following equation:

(14)

The control signal V

CONTROL

provided by the control

amplifier is then applied to the spindle drivers. The spindle

drivers control the voltage on the gate of the low-side

power drivers. One of the three high-side drivers is fully on.

The charge pump voltage is applied to the gate. One of the

three low-side drivers is controlled by the control amplifier.

Purpose is to adjust the voltage on the gate to adjust the

total output resistance R

ds(on)

at the specified running

current.

The current in the spindle loop is given by the following

formula:

(15)

With R

SPSENSE

= 0.25

:

(16)

The maximum start-up current is I

SPRUN

= 1.9 A with

SPCC signal at 5 V.

Figure 11 illustrates the spindle current control loop.

V

SPOUT

G

v

R

SPSENSE

I

SPRUN

◊

◊

G

v

V

SPSENSEH

◊

=

=

g

s

I

SPRUN

V

SPOUT

---------------------

1

R

SPSENSE

---------------------------

V

SPSENSEH

V

SPOUT

-------------------------------

◊

1

R

SPSENSE

G

v

◊

-----------------------------------------

=

=

=

V

SPOUT

V

SPCC

V

OFFSET

≠

=

I

SPRUN

g

s

V

SPCC

V

OFFSET

≠

(

)

◊

=

I

SPRUN

0.4

V

SPCC

0.25

≠

(

)

◊

=

1998 Nov 02

26

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

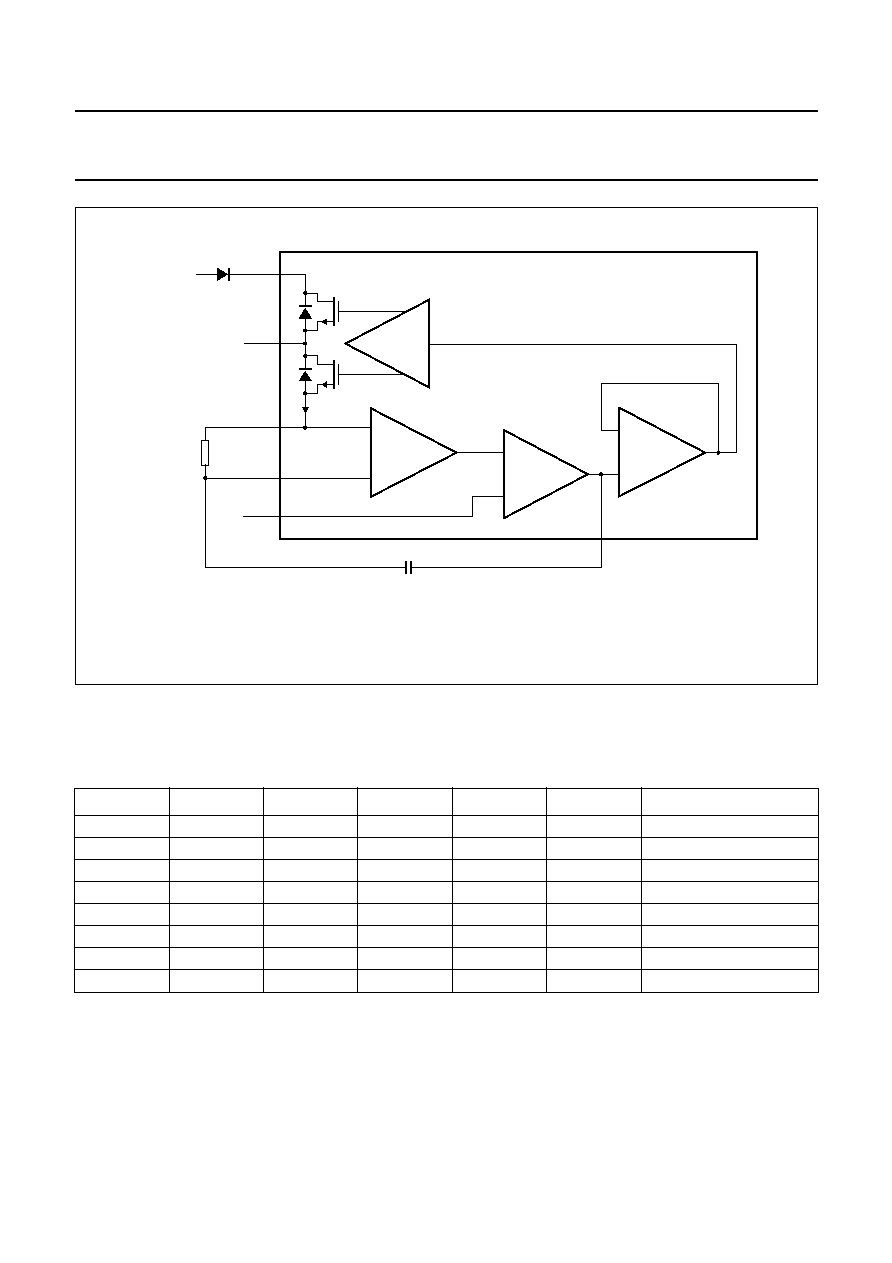

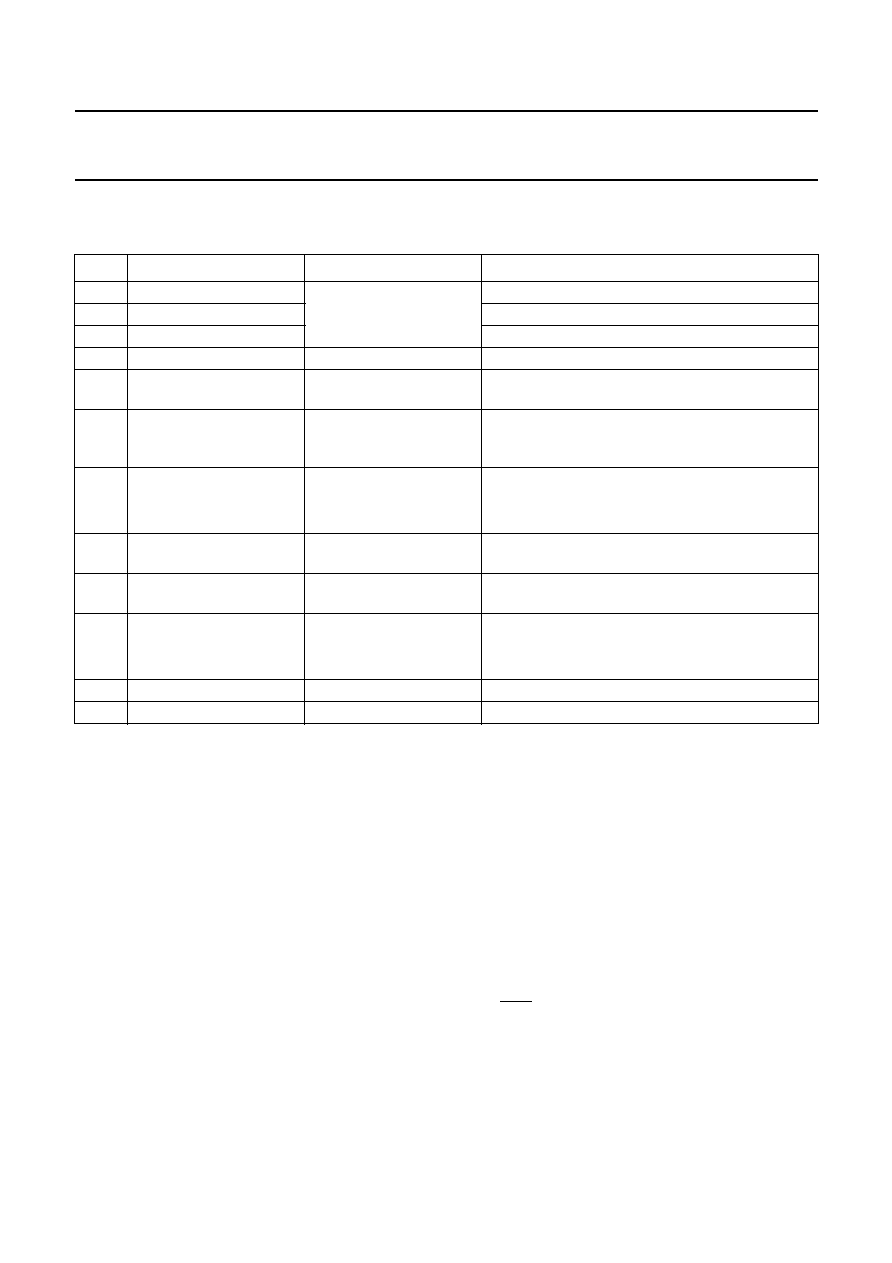

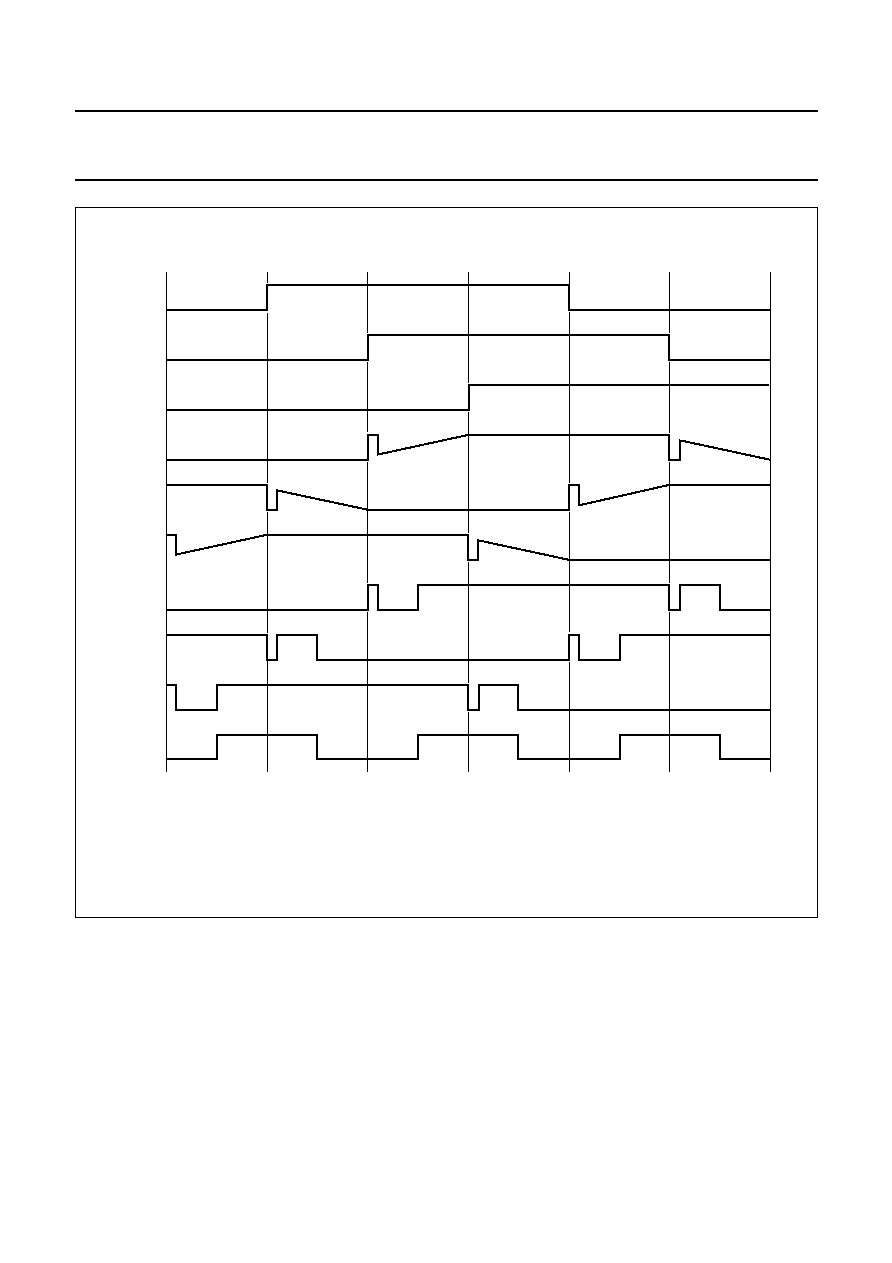

Table 16 and Fig.12 illustrate the relationship between the commutation signals and the associated output drivers and

output comparators.

Table 16 Input commutations to output drivers

Note

1. F_L is for float-and-then-LOW (brake-after-park mode).

COMA

COMB

COMC

MOTA

MOTB

MOTC

STATE

0

0

0

LOW

HIGH

float

1

1

0

0

LOW

float

HIGH

2

1

1

0

float

LOW

HIGH

3

1

1

1

HIGH

LOW

float

4

0

1

1

HIGH

float

LOW

5

0

0

1

float

HIGH

LOW

6

1

0

1

F_L

(1)

F_L

(1)

F_L

(1)

SLEEP

0

1

0

float

float

float

Spindle high-impedance

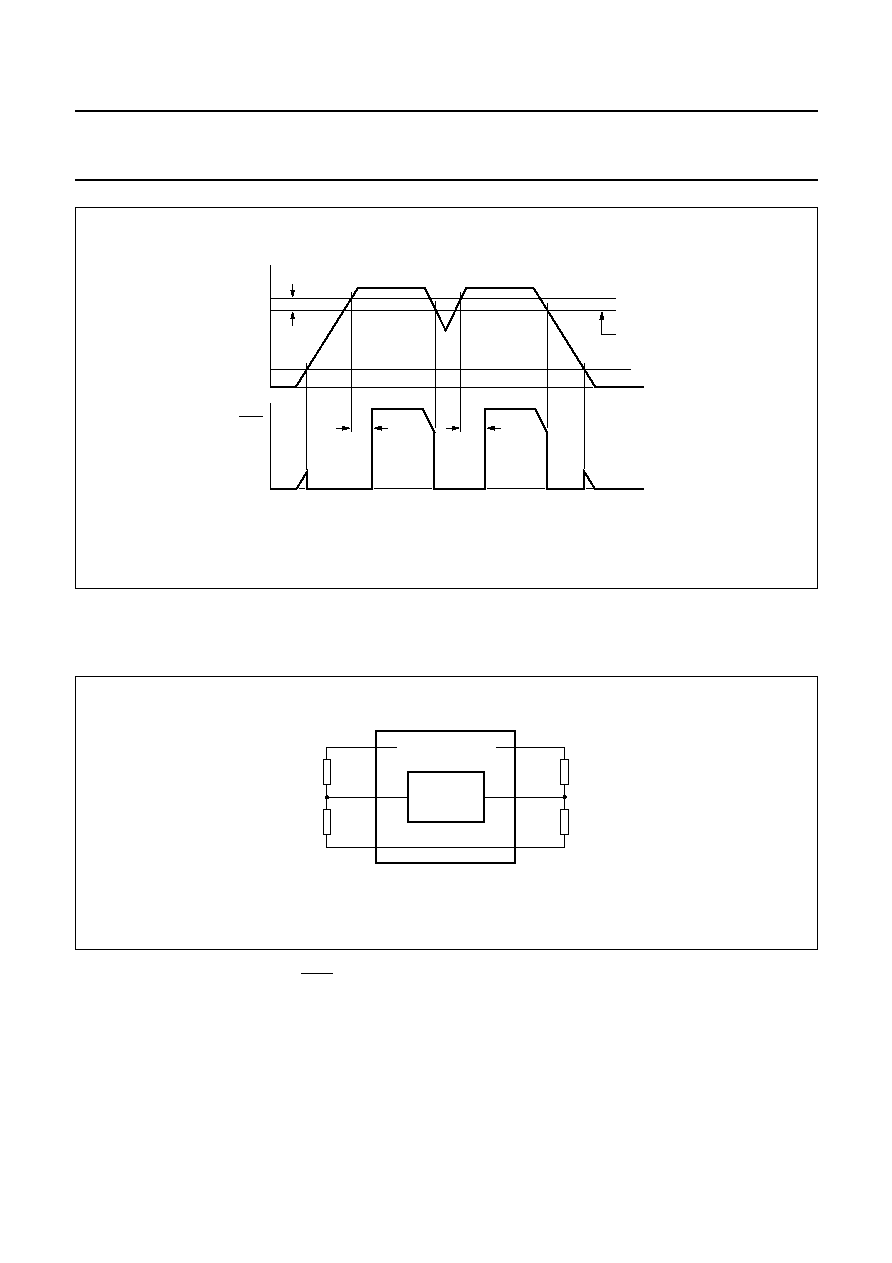

Fig.11 Spindle transconductance loop schematic.

handbook, full pagewidth

SENSE

AMPLIFIER

CONTROL

AMPLIFIER

PRE-

DRIVER

SPOUT

GNDS/

SPSENSEL

MOTSENSE/

SPSENSEH

VUPPER

VCONTROL

VLOWER

ISPRUN

external

diode

CLAMP

SPCC

CSPCCOUT

SPCCOUT

VDDA2POWER

MOTx

RSPSENSE

MGM980

0.25 V

OFFSET

1998 Nov 02

27

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

8.11

VCM driver

The VCM driver is a linear, class AB amplifier with both low-side and high-side drivers configured as an H-bridge.

The zero-current reference voltage for the VCM loop is internally set at 2.5 V. The sense resistor R

VCMSENSE

enables the

VCM current (I

VCMRUN

) to be measured through the sense amplifier. The gain G

v

of the sense amplifier is typically 4.

The output voltage (V

sout

) on pin ADC[2]/SOUT is given by the following equation:

(17)

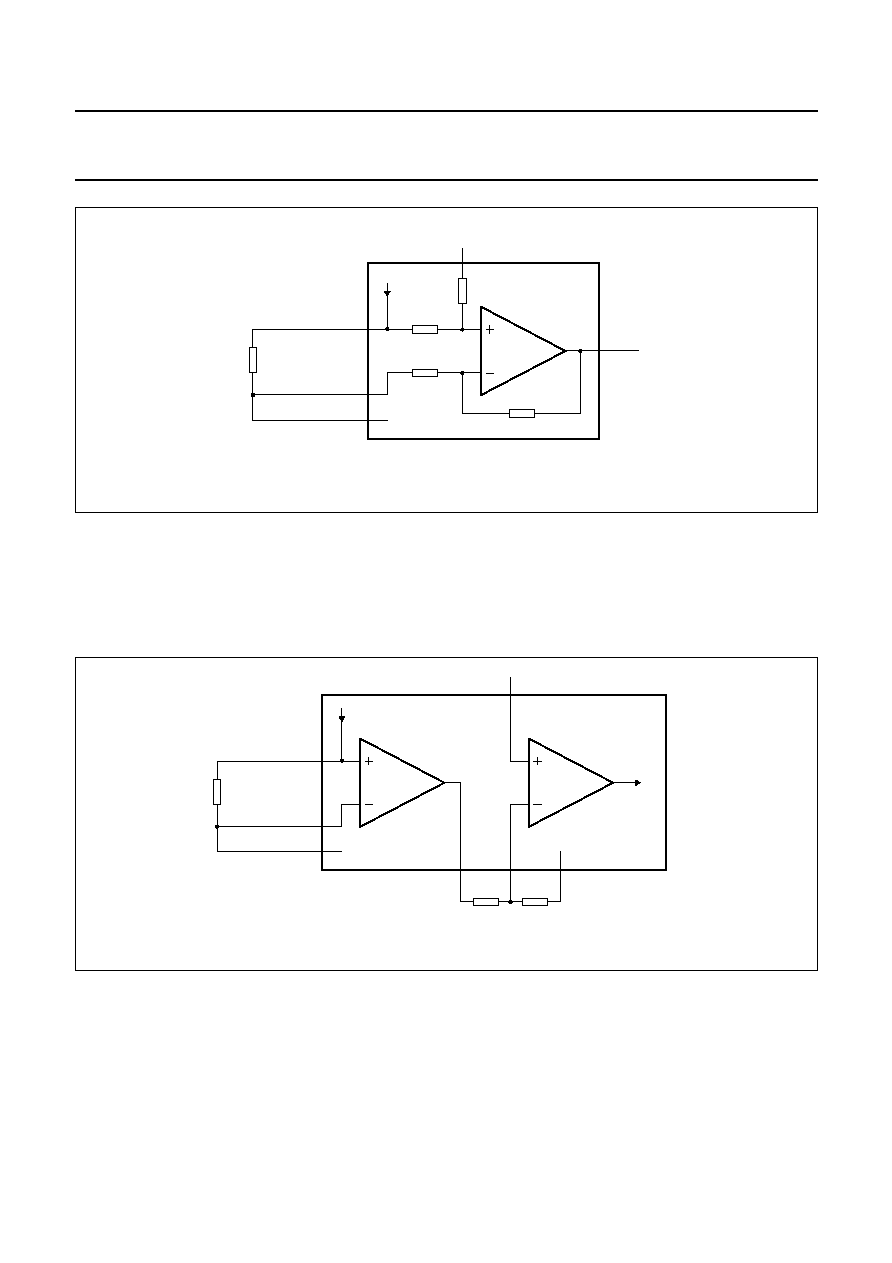

Figure 13 presents the VCM sense amplifier.

Fig.12 Input commutations to output drivers.

handbook, full pagewidth

MGM981

COMA

0

1

1

1

0

0

0

0

1

1

1

0

0

0

0

1

1

1

L

L

F

H

H

F

H

F

L

L

F

H

F

H

H

F

L

L

COMB

COMC

MOTA

MOTB

MOTC

ACROSS

BCROSS

CCROSS

ZCROSS

L = LOW.

H = HIGH.

F = Floating.

V

sout

G

v

R

VCMSENSE

I

VCMRUN

V

ref2V5

G

v

V

VCMSENSEH

V

VCMSENSEL

≠

(

)

V

ref2V5

+

◊

=

+

◊

◊

=

1998 Nov 02

28

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

The error amplifier (see Fig.14) compares the DACOUT input command and the output signal V

sout

of the sense amplifier

to generate the control voltage of the power drivers.

(18)

Finally, the transconductance gain of the VCM loop is given by the following equation:

(19)

Fig.13 VCM sense amplifier.

handbook, full pagewidth

MGM982

IVCMRUN

R

R

4R

VCMSENSEH

RVCMSENSE

VCMSENSEL

NIVCM

REF2V5

4R

ADC[2]/SOUT

V

ref2V5

V

DACOUT

≠

R

i

--------------------------------------------------

V

sout

V

ref2V5

≠

R

o

---------------------------------------

G

v

R

VCMSENSE

I

VCMRUN

◊

◊

R

o

---------------------------------------------------------------------------

=

=

Fig.14 VCM transconductance gain schematic.

handbook, full pagewidth

MGM983

SENSE

AMPLIFIER

Ga

ERROR

AMPLIFIER

IVCMRUN

Ro

Ri

VCMSENSEH

RVCMSENSE

VCMSENSEL

NIVCM

REF2V5

to power

drivers

VCMIN

DACOUT

ADC[2]/SOUT

g

v

I

VCMRUN

V

ref2V5

V

DACOUT

≠

--------------------------------------------------

R

o

R

i

-------

1

G

v

R

VCMSENSE

◊

---------------------------------------------

◊

=

=

1998 Nov 02

29

Philips Semiconductors

Product specification

Disk drive spindle and VCM with

servo controller

OM5193H

The VCM loop gain is set through external resistors. The seek (high gain) or the track-following (low gain) mode is

controlled with the serial bus. Purpose is to set the appropriate gain by selecting the R

i

resistor through the low

impedance analog 2 input switch.

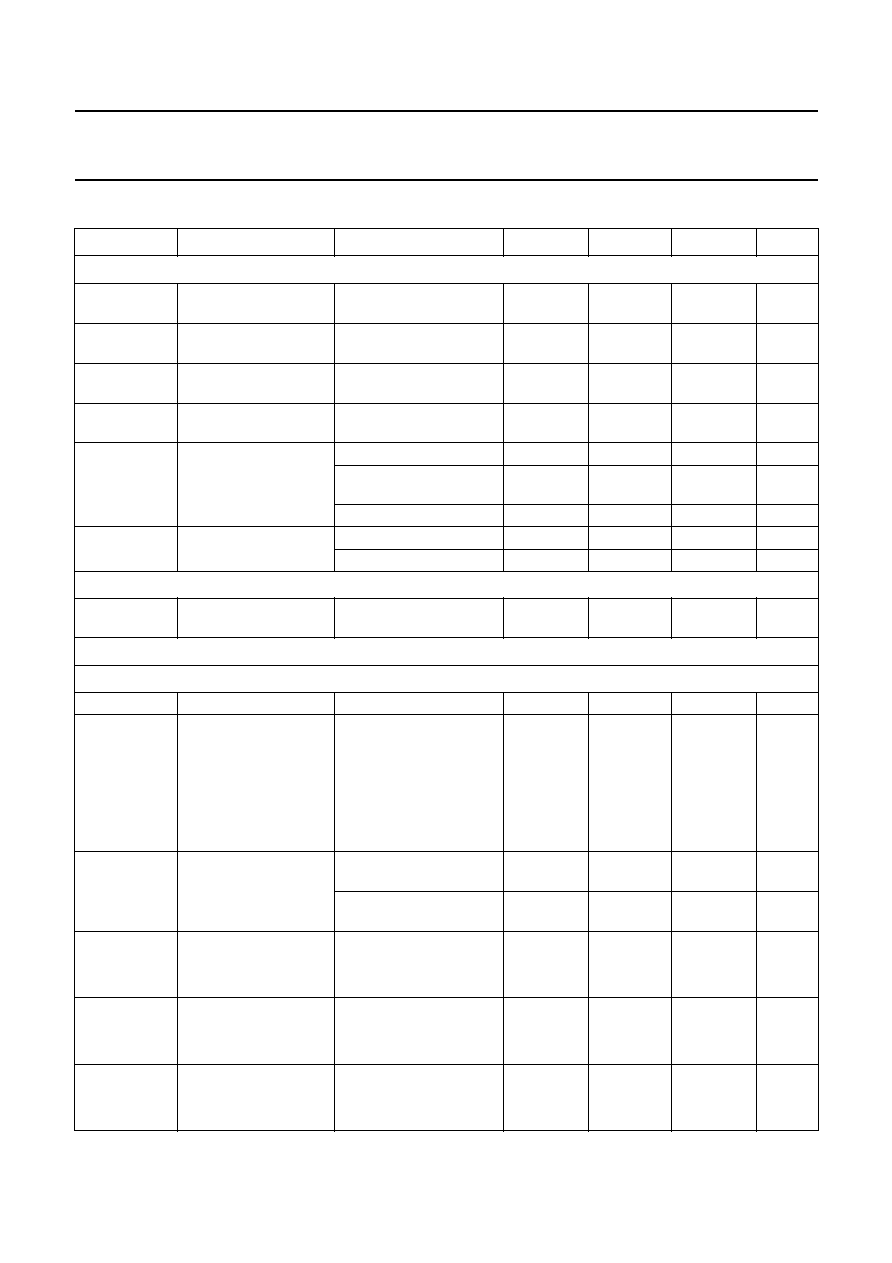

Fig.15 VCM selectable loop gain.

handbook, full pagewidth

VCM DAC

VCM switch

to VCM

drivers

MGM984

VCMIN

Ro

(1)

(2)

SEEKSELECT

TRACKFWSELECT

Ri(TRACKFW)

Ri(SEEK)

DACOUT

ADC[2]/SOUT

(1) High gain.

(2) Low gain.

8.12

Park the VCM

A VCM park sequence is initiated any time a power-down,

a thermal shutdown and/or a sleep mode situation occurs.

The fault signal (FAULT) initiates the VCM park sequence.

This secure function is accomplished even in case of

power loss. In this case, the energy provided by the

rectified BEMF of the spindle motor coils is used to supply

the park circuit and park the heads above a landing area.

Otherwise, the energy is provided by the V

DDA2

power

supply through an external diode or power FET.

To accomplish this function, the spindle power stage is

automatically set in a high-impedance mode. The NIVCM

low-side power driver is fully on while the remaining power

drivers of the VCM power stage are off.

The current flowing in the PARKVOLT resistor sets the

voltage on the PARKVOLT pin. The voltage across the

VCM load is internally regulated by the voltage on the

PARKVOLT pin. An internal circuit clamps the voltage on

PARKVOLT at 3V

BE

. Without resistor, the voltage on

PARKVOLT is 3V

BE

. The park current I