2003 Feb 05

2

Philips Semiconductors

Preliminary specification

Full bridge current driven vertical

deflection booster

TDA4867J

FEATURES

∑

Fully integrated, few external components

∑

Maximum 2.5 A (p-p) deflection current

∑

No additional components in combination with the

deflection controller family TDA485x and SAA4856

∑

Pre-amplifier with differential high CMRR current mode

inputs

∑

Low offsets

∑

High linear sawtooth signal amplification

∑

High efficient DC-coupled vertical output bridge circuit

∑

High deflection frequency up to 200 Hz

∑

Power supply and flyback supply voltage independent

adjustable to optimize power consumption and flyback

time

∑

Excellent transition behaviour during flyback

∑

Guard circuit for screen protection

∑

Power save mode controlled by input pins

(in combination with SAA4856 only) or guard pin.

GENERAL DESCRIPTION

The TDA4867J is a power booster for use in colour vertical

deflection systems for frame frequencies of 50 to 200 Hz.

The circuit provides a high CMRR current driven

differential input. Due to the bridge configuration of the two

output stages DC-coupling of the deflection coil is

achieved. In conjunction with the deflection controller

family TDA485x and SAA4856 the ICs offer an extremely

advanced system solution.

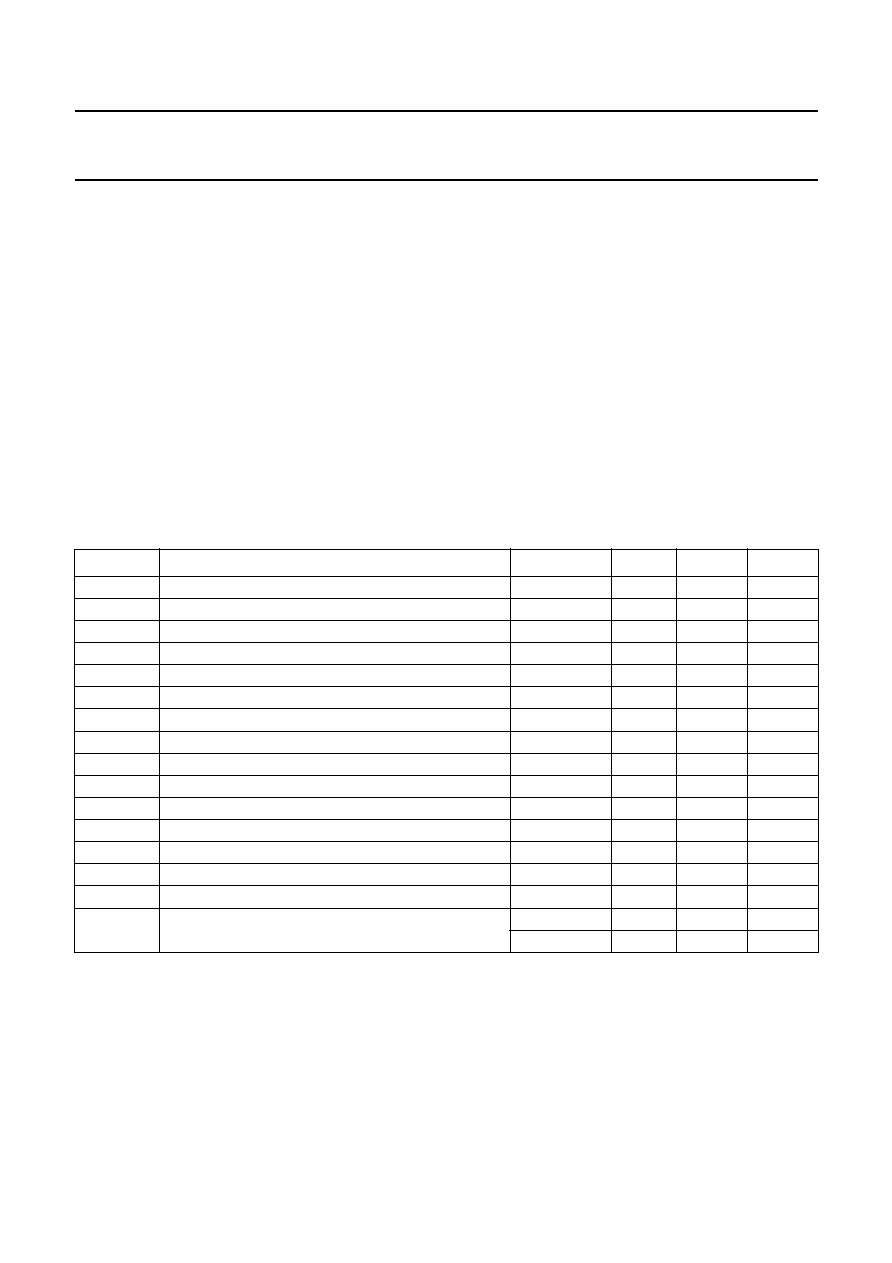

QUICK REFERENCE DATA

Notes

1. Voltages refer to pin GND.

2. If V

FB

is between 40 and 60 V a decoupling capacitor C

FB

= 22

Ķ

F (between pin V

FB

and pin GND) and a resistor

R

FB

= 100

(between pin V

FB

and flyback supply voltage) are required (see Fig.6).

3. Differential input current I

i(dif)

= I

INP

-

I

INN

.

SYMBOL

PARAMETER

CONDITIONS

MIN.

TYP.

MAX.

UNIT

DC supplies; note 1

V

P

supply voltage

8.2

-

25

V

V

FB

flyback supply voltage

note 2

V

P

+ 6

-

60

V

I

q(VFB)

quiescent flyback current

no load; no signal

-

2.5

4

mA

Vertical circuit

I

defl(p-p)

deflection current on pins OUTB

and OUTA (peak-to-peak value)

0.6

-

2.5

A

I

i(dif)

differential input current

note 3

-

Ī

500

Ī

600

Ķ

A

Flyback generator

I

FB(p-p)

maximum current during flyback on

pin V

FB

(peak-to-peak value)

-

-

2.5

A

Guard circuit; note 1

V

GUARD

guard voltage

guard on

5.5

6.2

-

V

2003 Feb 05

4

Philips Semiconductors

Preliminary specification

Full bridge current driven vertical

deflection booster

TDA4867J

PINNING

FUNCTIONAL DESCRIPTION

The TDA4867J consists of a differential input stage, two

output stages, a flyback generator, a protection circuit for

the output stages and a guard circuit.

Differential input stage

The differential input stage has a high CMRR differential

current mode input (pin INP and pin INN) that results in a

high electromagnetic immunity and is especially suitable

for driver units with differential (e.g. TDA485x or SAA4856)

and single-ended current signals.

The differential input stage delivers the driver signals for

the output stages.

In combination with the SAA4856 the power save mode

can be achieved via the input pins without additional

components.

Output stages

The two output stages are current driven in opposite phase

and operate in combination with the deflection coil in a full

bridge configuration. Therefore, the TDA4867J requires no

external coupling capacitor and operates with one supply

voltage (V

P

) and a separate adjustable flyback supply

voltage (V

FB

) only. The deflection current through the coil

(I

defl

) is measured with the resistor R

m

which produces a

voltage drop: U

rm

R

m

◊

I

defl

. At pin FEEDB a part of I

defl

is fed back to the input stage. The feedback input has a

current input characteristic which holds the differential

voltage between pin FEEDB and pin OUTB on zero.

Therefore the feedback current (I

FEEDB

) through R

ref

is:

The input stage directly compares the driver currents into

pins INP and INN with the half of the feedback current

(I

FEEDB

). Any difference of this comparison leads to a more

or less driver current for the output stages. The relation

between the deflection current and the differential input

current (I

i(dif)

= I

INP

-

I

INN

) is:

or:

The deflection current can be adjusted up to

Ī

1.25 A by

varying R

ref

when R

m

is fixed to 1

.

Flyback generator

The flyback generator supplies the output stage A during

flyback. This makes it possible to optimize power

consumption (supply voltage V

P

) and flyback time (flyback

voltage V

FB

) separately. Due to the absence of a

decoupling capacitor the flyback voltage is fully available.

In parallel with the deflection yoke and the damping

resistor (R

p

) an additional capacitor (C

SP

) and a series

resistor (R

SP

) have to be used. The flyback time can be

optimized depending on the value of C

SP

.

SYMBOL

PIN

DESCRIPTION

INP

1

non-inverted input

INN

2

inverted input

V

P

3

supply voltage

OUTB

4

output B

GND

5

ground

OUTA

6

output A

V

FB

7

flyback supply voltage

GUARD

8

guard output or power save

mode input

FEEDB

9

feedback input

handbook, halfpage

TDA4867J

MGU989

1

2

3

4

5

6

7

8

9

INP

INN

VP

OUTB

GND

OUTA

VFB

GUARD

FEEDB

Fig.2 Pin configuration.

I

FEEDB

R

m

R

ref

----------

I

defl

◊

I

i dif

(

)

2

I

FEEDB

◊

R

m

R

ref

----------

I

defl

◊

2

◊

=

I

defl

I

i dif

(

)

R

ref

2

R

◊

m

-----------------

◊

2003 Feb 05

5

Philips Semiconductors

Preliminary specification

Full bridge current driven vertical

deflection booster

TDA4867J

Protection

The output stages are protected against:

∑

Thermal overshoot in normal operation

∑

Short-circuit of the coil (pins OUTB and OUTA).

Guard circuit

The internal guard circuit provides a blanking signal for the

CRT. The guard signal is active HIGH:

∑

At thermal overshoot

∑

During flyback

∑

When missing flyback supply voltage

∑

When power supply voltage too low, V

P

< V

P(min)

.

The internal guard circuit will not be activated, if the input

signals on pins INP and INN delivered from the driver

circuit are out of range or at short-circuit of the coil

(pins OUTB and OUTA).

For this reason an external guard circuit can be applied to

detect failures of the deflection (see Fig.5). This circuit will

be activated when flyback pulses are missing, which is the

indication of any abnormal operation.

The guard output pin can be used as input for the power

save mode. A current or a voltage has to be applied to the

pin. In this case the output stages are switched off

completely.

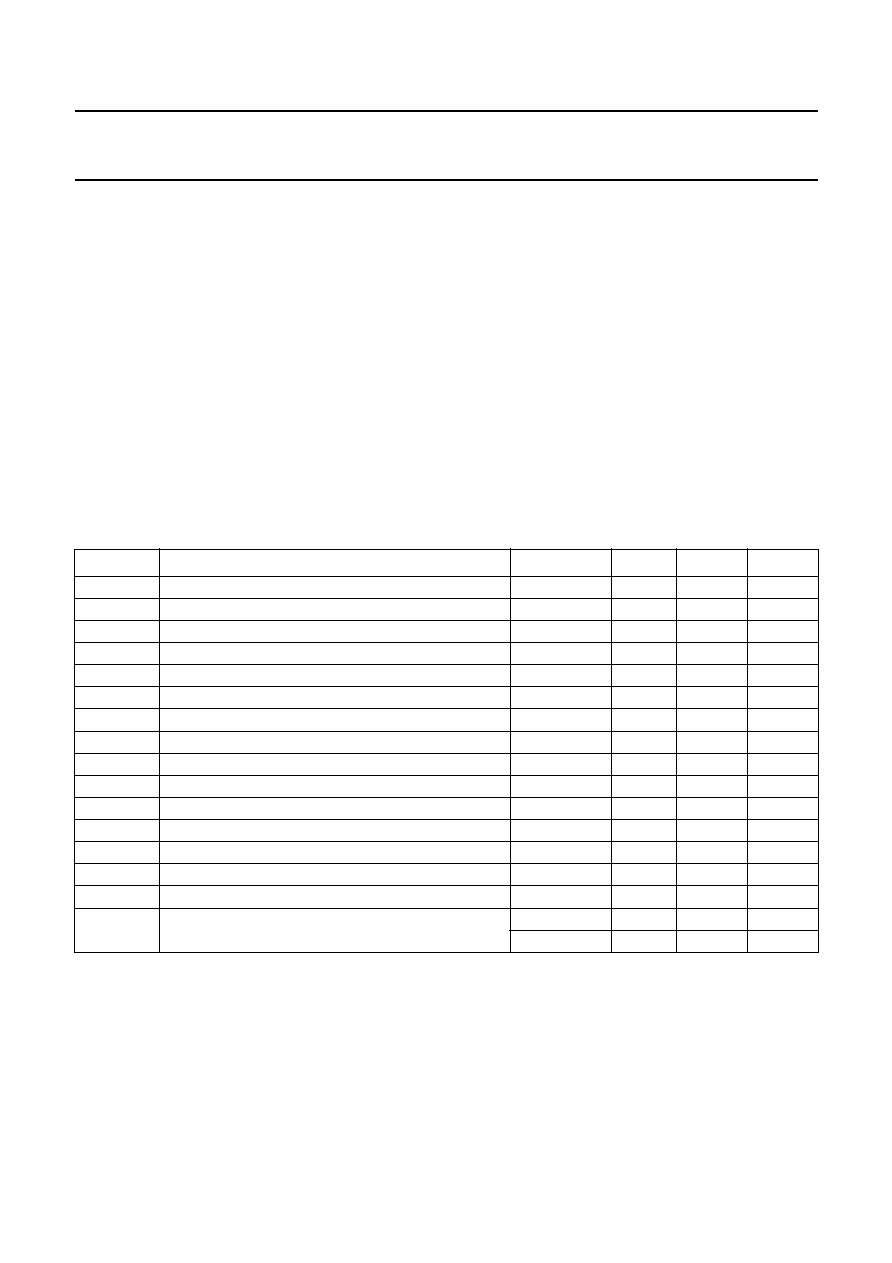

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134); voltages referenced to ground (pin GND);

unless otherwise specified.

Notes

1. Maximum output currents I

OUTB

and I

OUTA

are limited by current protection.

2. Internally limited by thermal protection; will be activated for T

j

150

į

C.

3. Human body model: equivalent to discharging a 100 pF capacitor through a 1.5 k

resistor.

4. Machine model: equivalent to discharging a 200 pF capacitor through a 0.75

Ķ

H inductance.

SYMBOL

PARAMETER

CONDITIONS

MIN.

MAX.

UNIT

V

P

supply voltage

0

30

V

V

FB

flyback supply voltage

0

60

V

I

FB

flyback supply current

0

Ī

1.8

A

V

INP

, V

INN

input voltage

0

5

V

I

INP

, I

INN

input current

0

Ī

5

mA

V

OUTB

output voltage on pin OUTB

0

V

P

V

V

OUTA

output voltage on pin OUTA

0

V

FB

V

I

OUTB

, I

OUTA

output current

note 1

0

Ī

1.6

A

V

FEEDB

feedback voltage

0

V

P

V

I

FEEDB

feedback current

0

Ī

5

mA

V

GUARD

guard voltage

0

10

V

I

GUARD

guard current

0

Ī

5

mA

T

stg

storage temperature

-

20

+150

į

C

T

amb

ambient temperature

-

20

+75

į

C

T

j

junction temperature

note 2

-

20

+150

į

C

V

esd

electrostatic discharge voltage

note 3

-

4000

+4000

V

note 4

-

250

+250

V