| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: TDA8385 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

March 1994

2

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

FEATURES

∑

Bandgap reference generator

∑

Slow-start circuitry

∑

Low-loss peak current sensing

∑

Over-voltage protection

∑

Hysteresis controlled stand-by

function

∑

Error amplifier with gain setting

∑

Programmable transfer character

generator

∑

Protection against open- and

short-circuited feedback loop

∑

Over-load current fold back

characteristic

∑

LED driver

∑

Demagnetization protection

∑

Programmable determination of

switch-on moment of switching

transistor for low-switching losses

∑

Feed-forward input

∑

Regulation-indicator output

∑

Programmable minimum on-time of

switching transistor

∑

Accurate peak-current setting.

GENERAL DESCRIPTION

The TDA8385 is intended to be used

in combination with the opto-coupler

(CNR50) as a control unit for a

self-oscillating power supply.

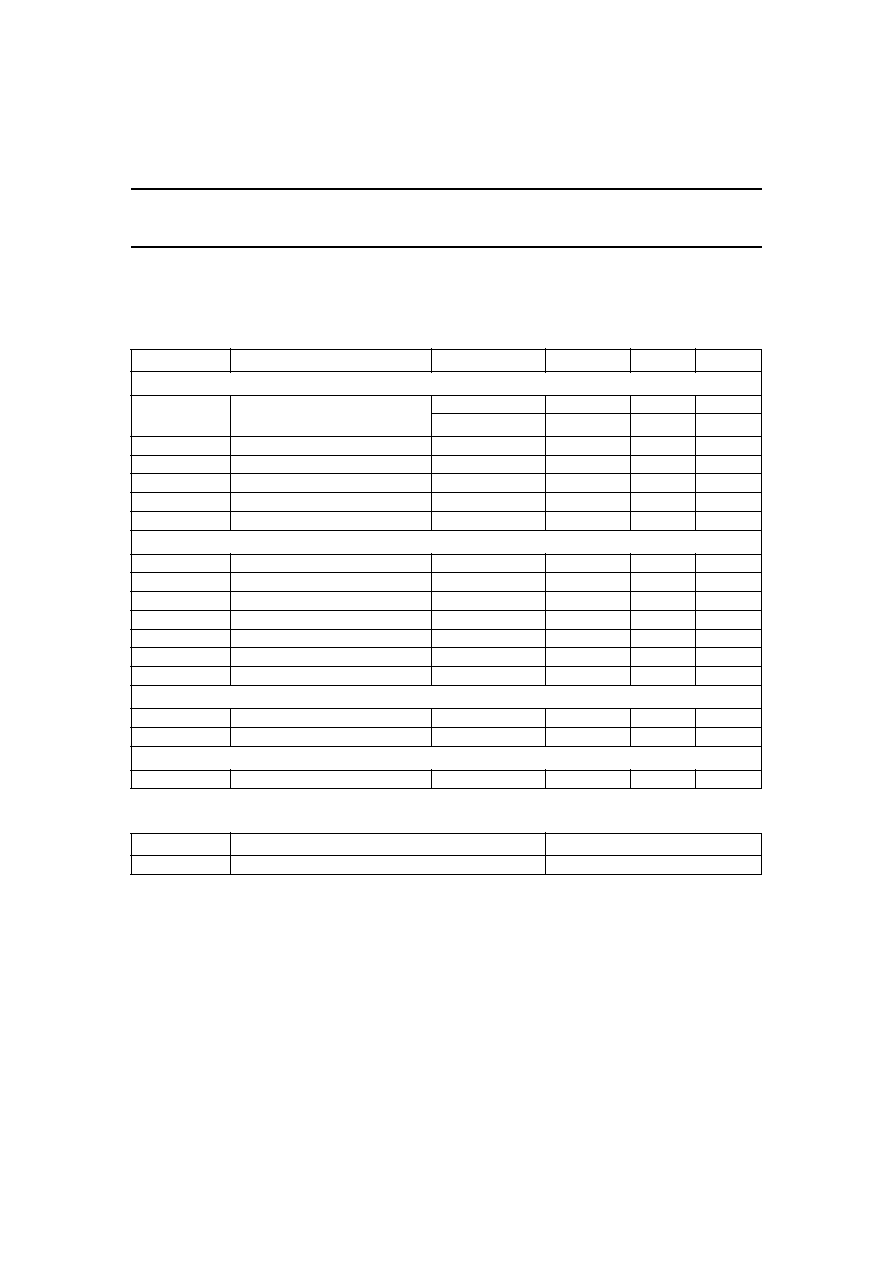

ORDERING INFORMATION

EXTENDED TYPE

NUMBER

PACKAGE

PINS

PIN POSITION

MATERIAL

CODE

TDA8385

16

DIL

plastic

SOT38WBE

March 1994

3

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

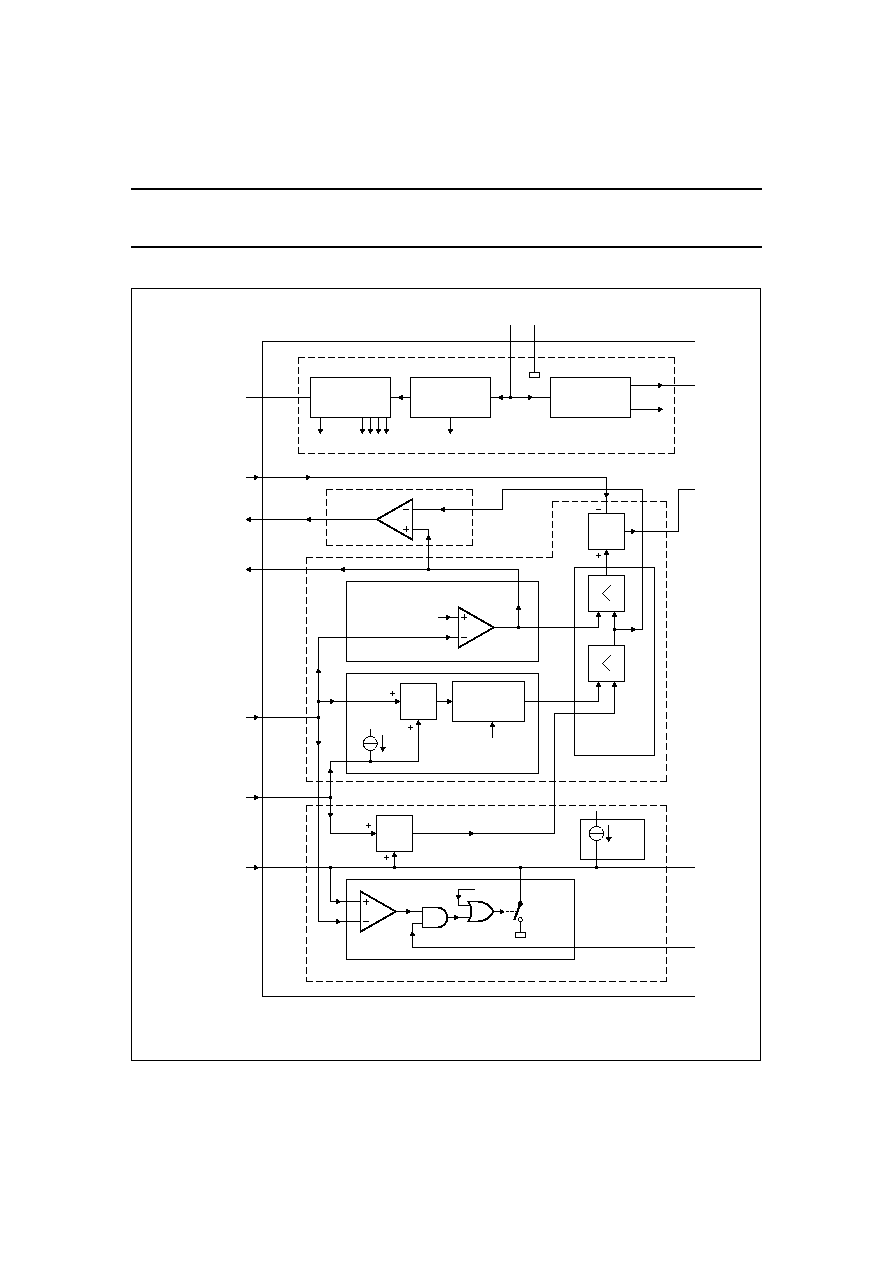

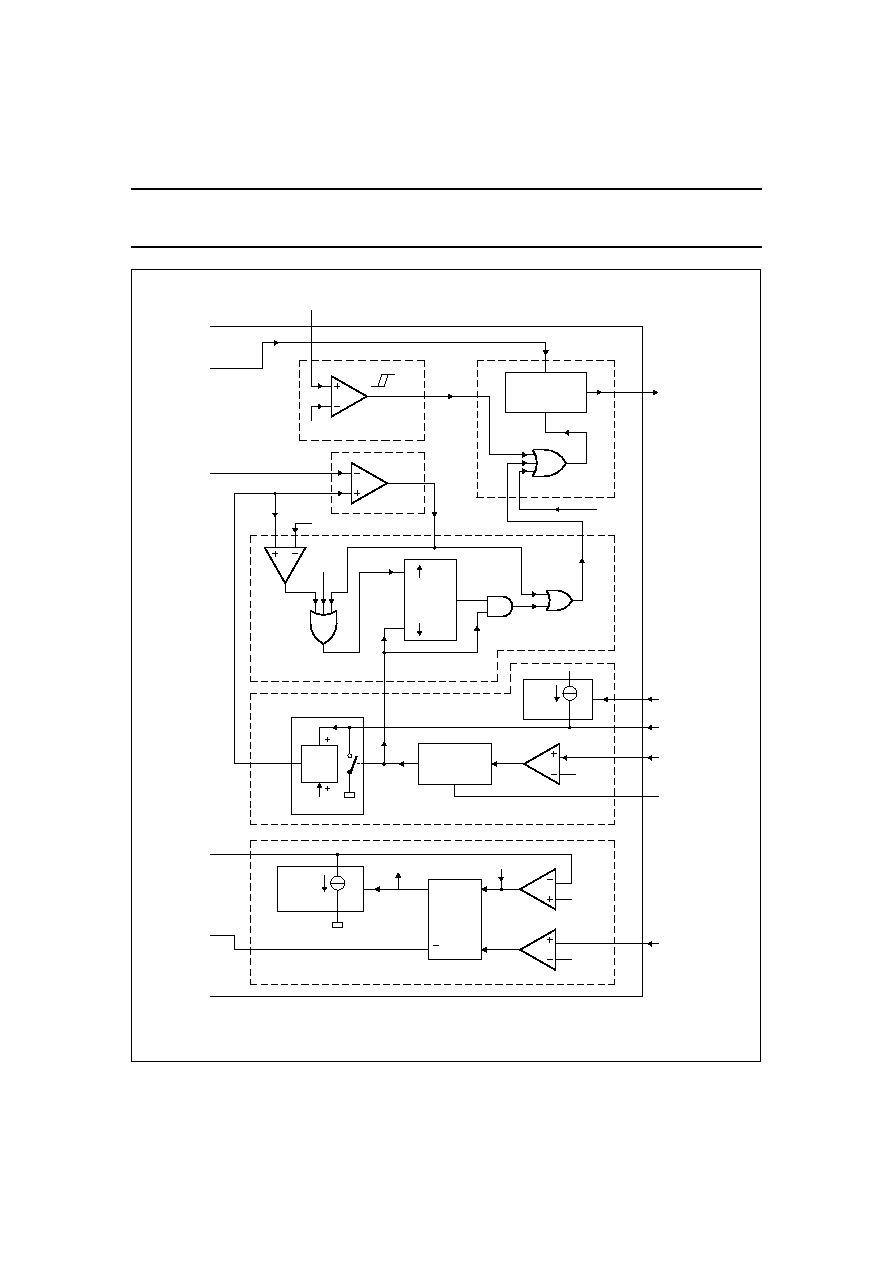

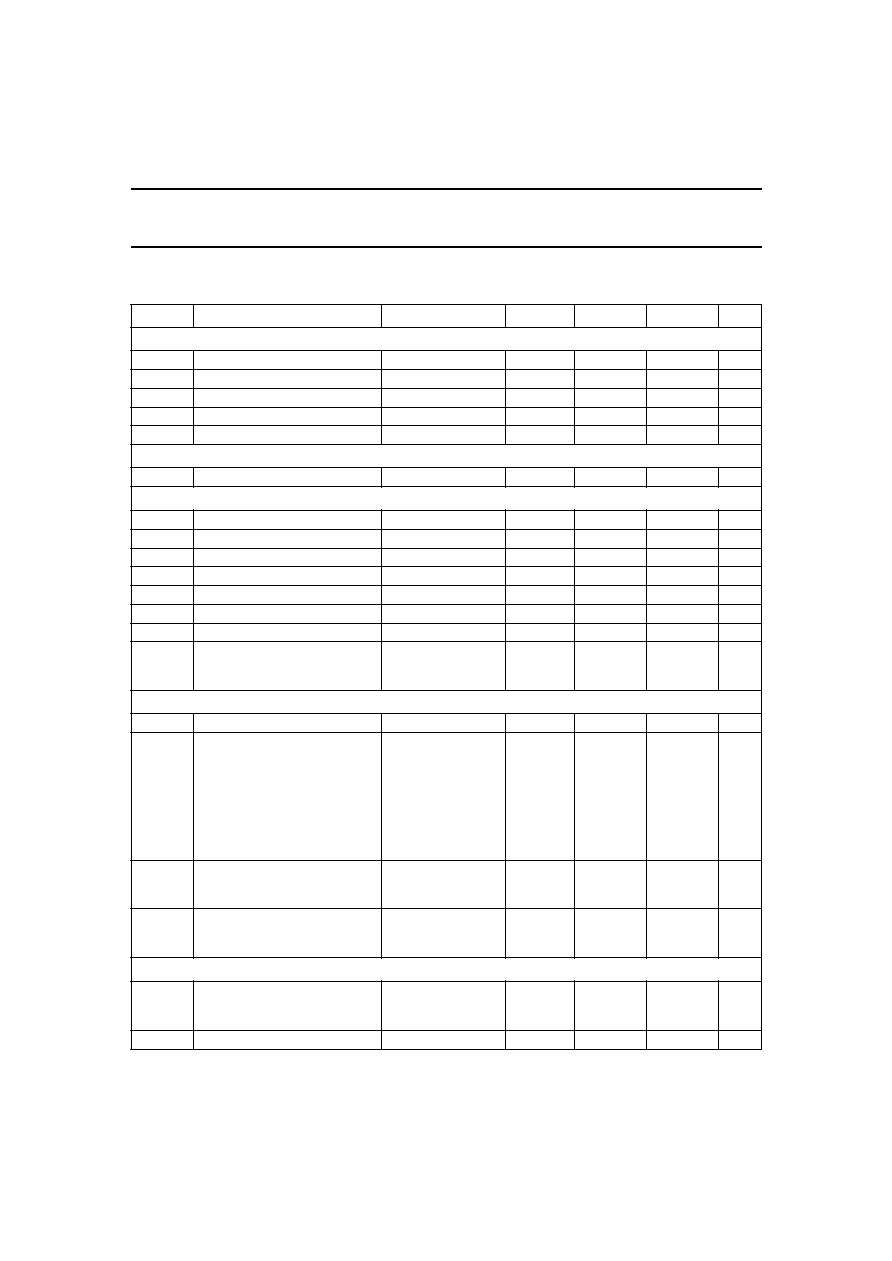

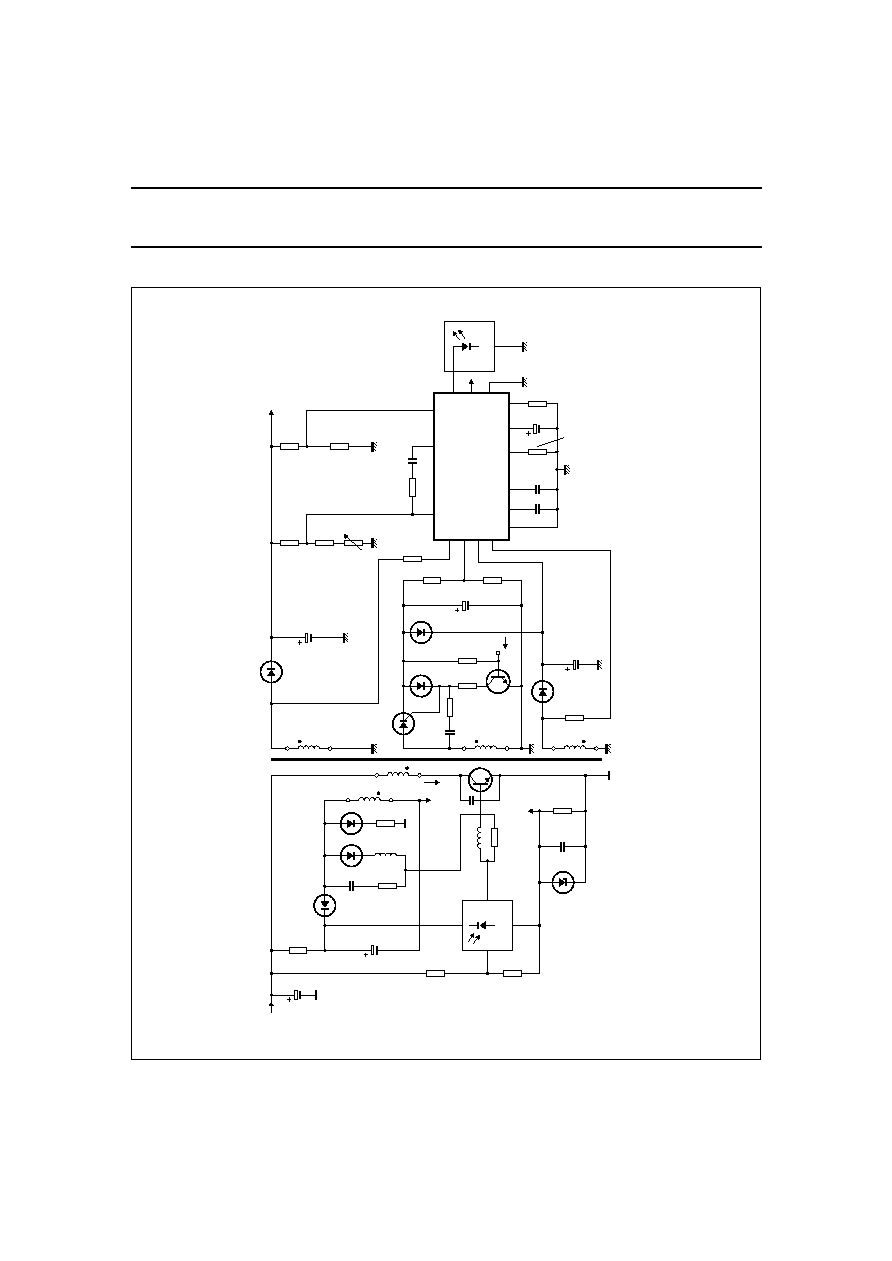

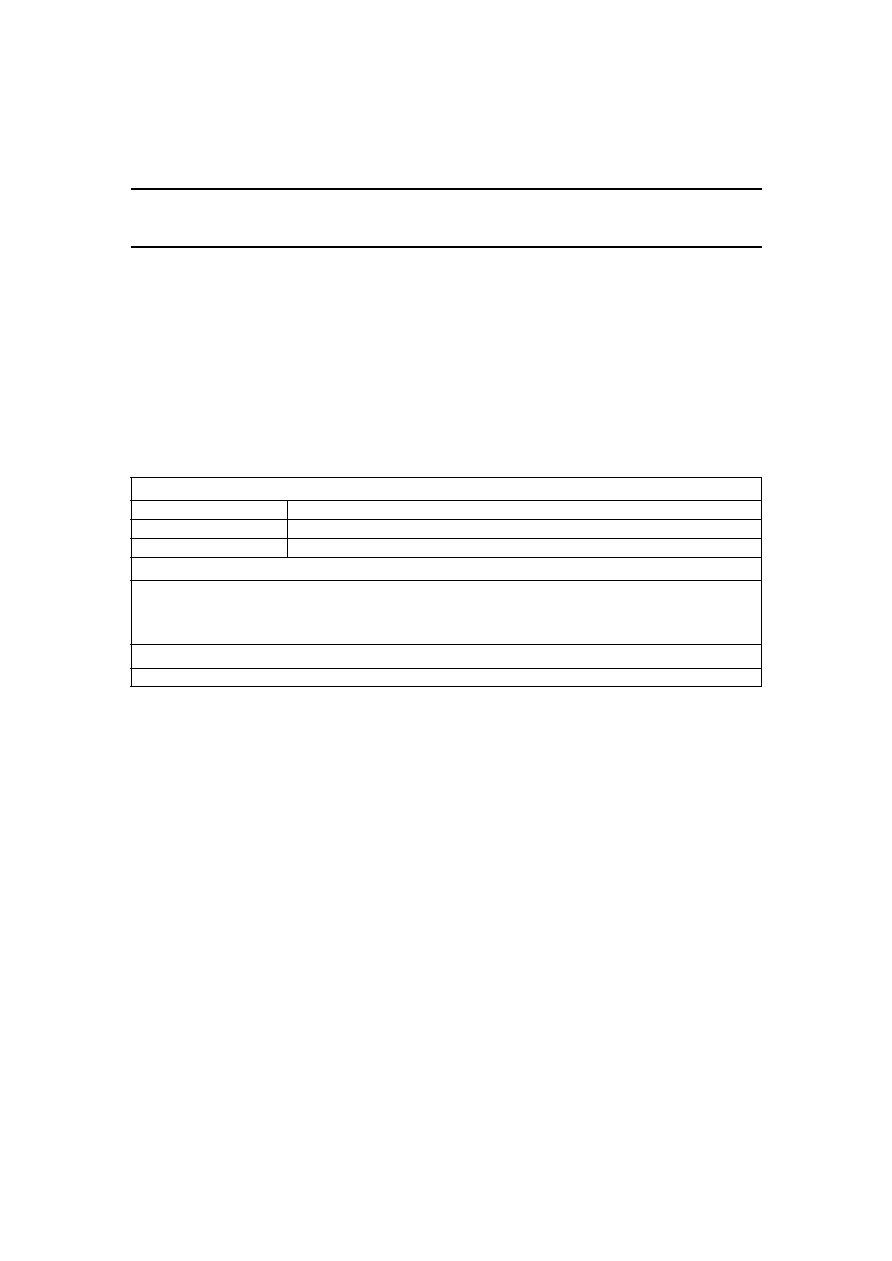

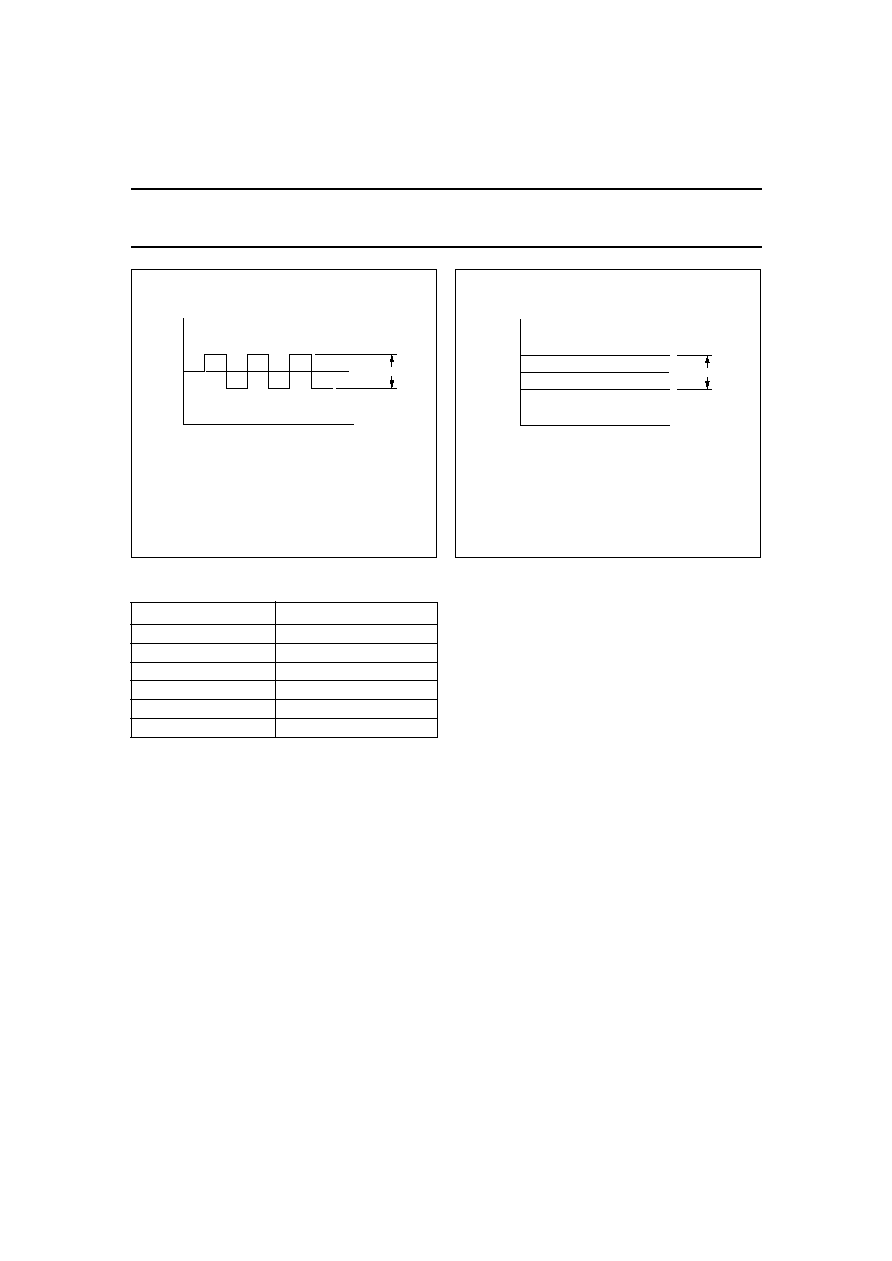

BLOCK DIAGRAMS

handbook, full pagewidth

MCD417

29

V ts

DIFFERENTIAL AMPLIFIER

CONTROL PART

REGULATION

INDICATOR

(2.5 V)

27

reset (28)

quick

discharge

CLAMP

50

µ

A

50

µ

A

charge

19

2.5 V

TCG

4

3

V TCG

V diff

Vss +

MINIMUM

VOLTAGE

CLAMP

6

X

III

VII

fo

V

Vmv

fb

V

13

1

RIO

11 V diff

9

4

7

Vss

7

16

14

3

REFERENCE

BLOCK

STABILIZED

SUPPLY

DETECTOR

VP (min)

28

1

2

SUPPLY REFERENCES

(28, 27, 23)

reset

latch

I ref

I ref

Vstab

Vref

Vref

I

current reference

setting

feed forward

input

regulation indicator

output

differential amplifier

output

slow start voltage

input

feedback voltage

input

transistor-on

setting input

VP

GND

SLOW START

V ts

5

Ton(min)

Ton (min)

Fig.1 Block diagram; part A (continued in Fig.2; part B).

March 1994

4

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

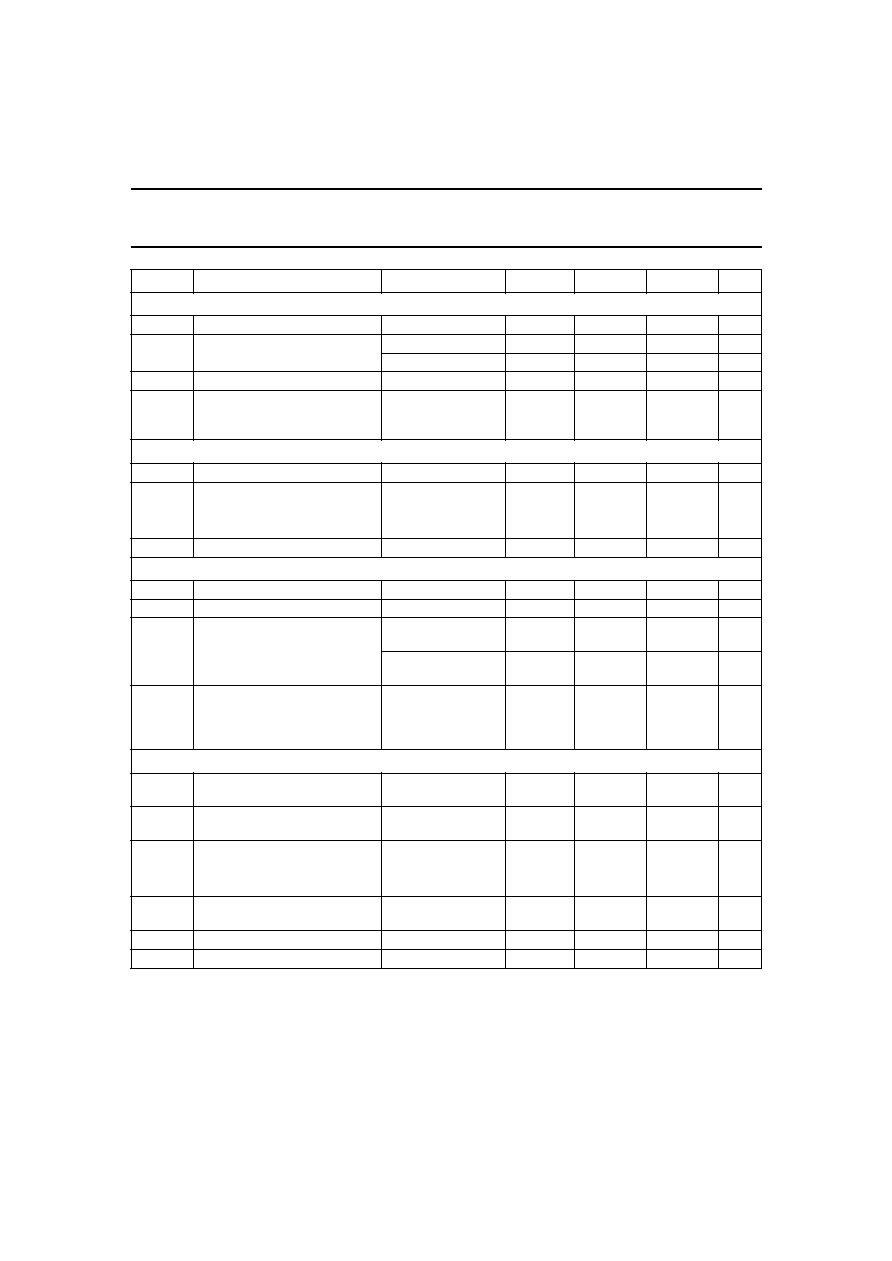

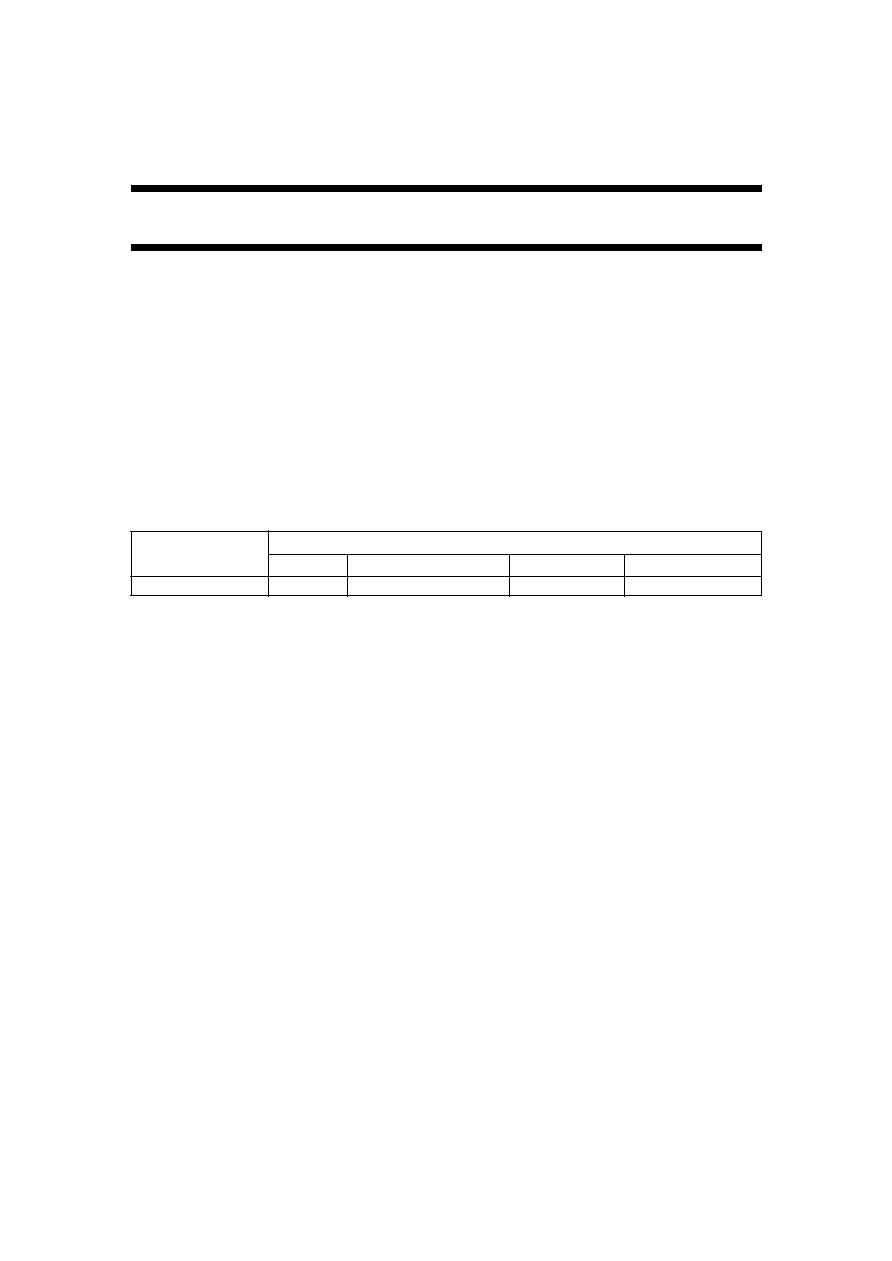

handbook, full pagewidth

stand-by voltage input

over-voltage

protection

latch

22

24

11

MCD418

100

µ

A

slow

discharge

21

(17)

(28)

VIII

Q

R

S

FF

23

over voltage

Q

115 mV

2.5 V

OVER-VOLTAGE PROTECTION

DELAY

12

115 mV

100 mV

SAWTOOTH GENERATOR

DEM

12

15

5

6

8

Q

13

R

S

Vr

Vsb

Vsim

8

PWM

IV

14

16

demagnetization

LED CONTROL

demagnetization

(28)

18

V

9

I12

12

0.2 I

I sim

I peak

25

2.5 V

2 V

STAND-BY

IX

2.5 V

latch

Q (23)

17

OUTPUT

STAGE

15

LED

LED DRIVER

VI

10

TDA8385

2

LED driver output

delay setting

demagnetization

input

peak-current

setting input

current simulation

input

26

comparator

II

V

c

10

FF

Fig.2 Block diagram; part B (continued from Fig.1; part A).

March 1994

5

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

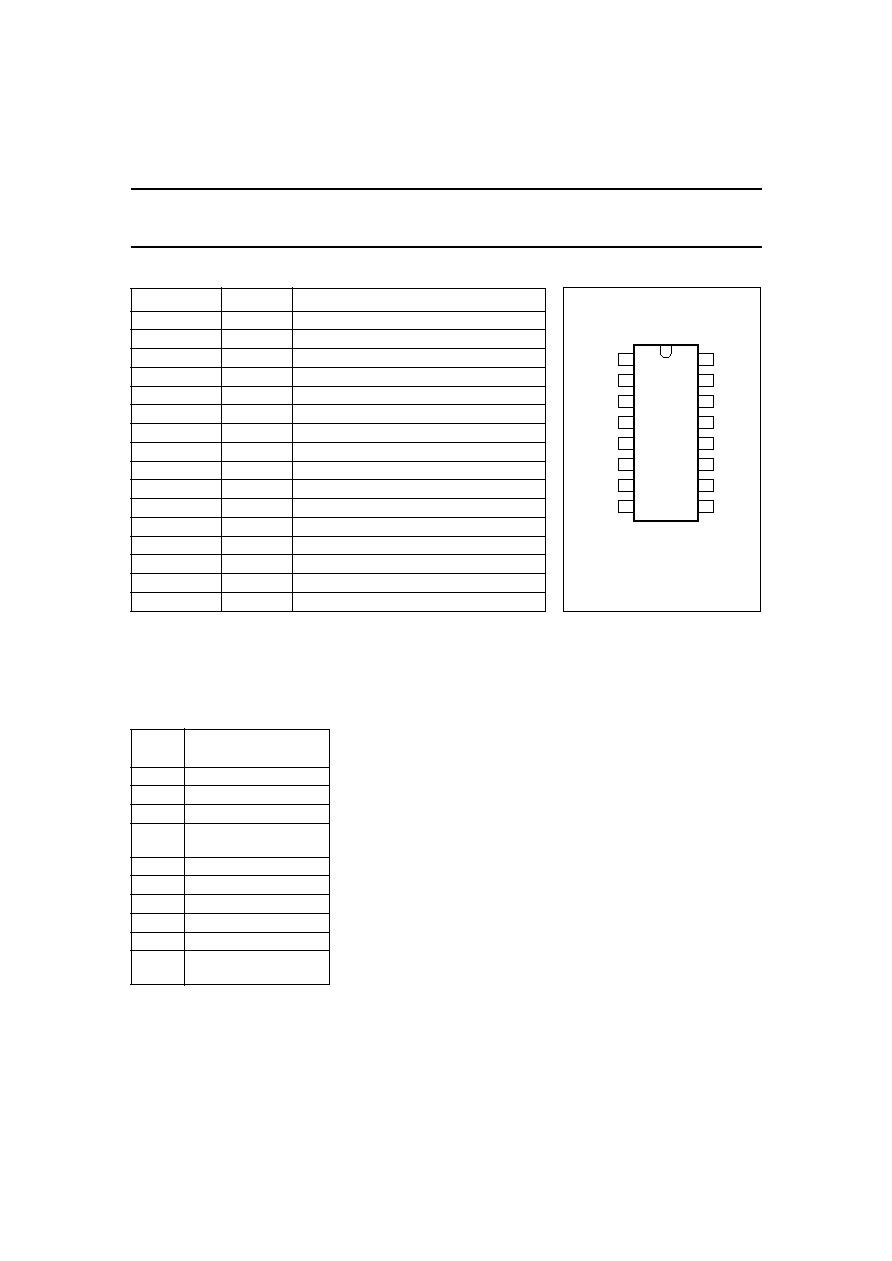

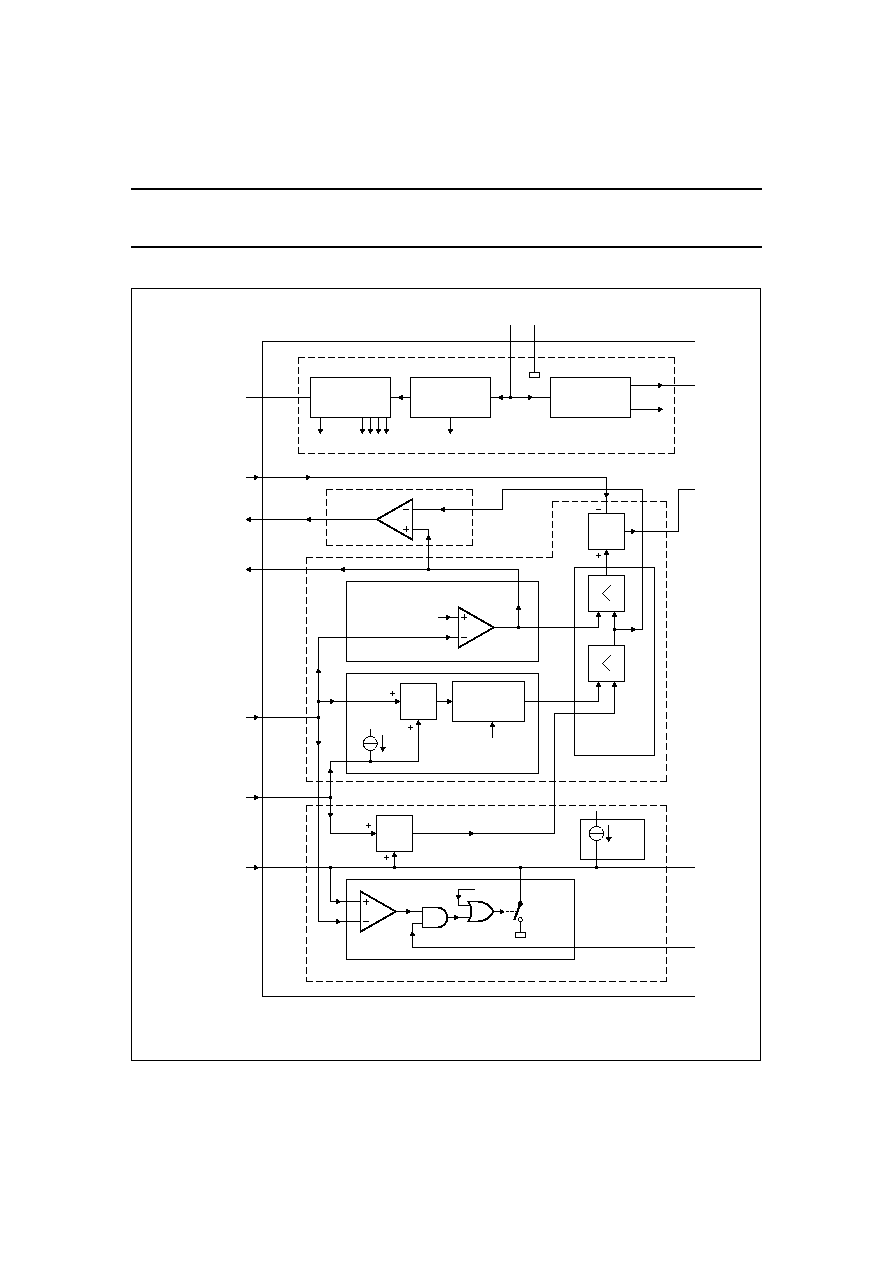

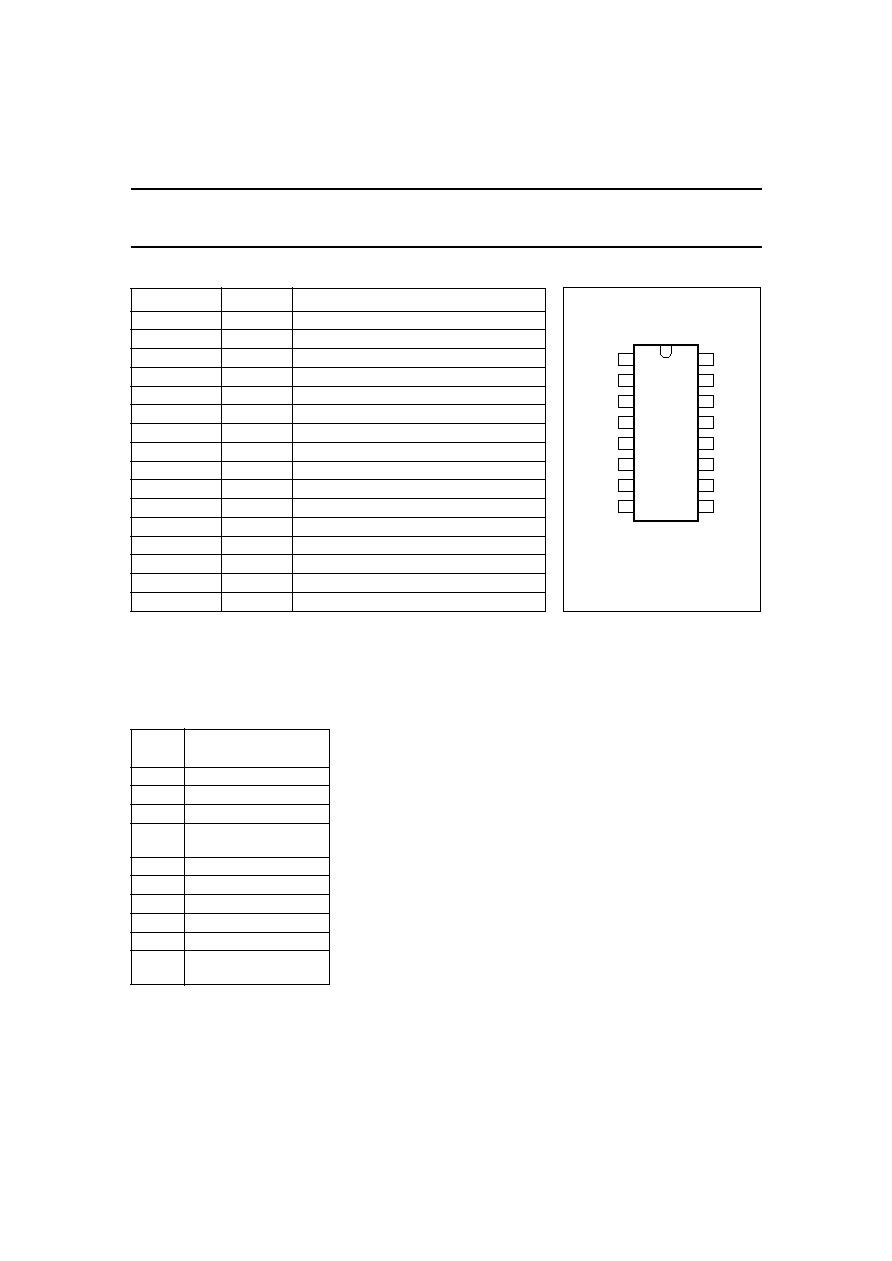

PINNING

SYMBOL

PIN

DESCRIPTION

RIO

1

regulation indicator output

LED

2

LED driver output

I

ref

3

current reference setting

T

on(min)

4

transistor-on setting input

I

peak

5

peak current setting input

DELAY

6

delay setting

V

ss

7

slow start voltage input

OVP

8

over-voltage protection

V

fb

9

feedback voltage input

V

sb

10

stand-by voltage input

V

diff

11

differential amplifier output

I

sim

12

current simulation input

V

fo

13

feed forward input

GND

14

ground (0 V)

DEM

15

demagnetization input

V

P

16

positive supply voltage

Fig.3 Pinning diagram.

handbook, 2 columns

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

RIO

LED

DELAY

OVP

I ref

Ton(min)

I peak

Vss

DEM

GND

VP

Vfo

I sim

Vdiff

sb

V

fb

V

TDA8385

MCD402

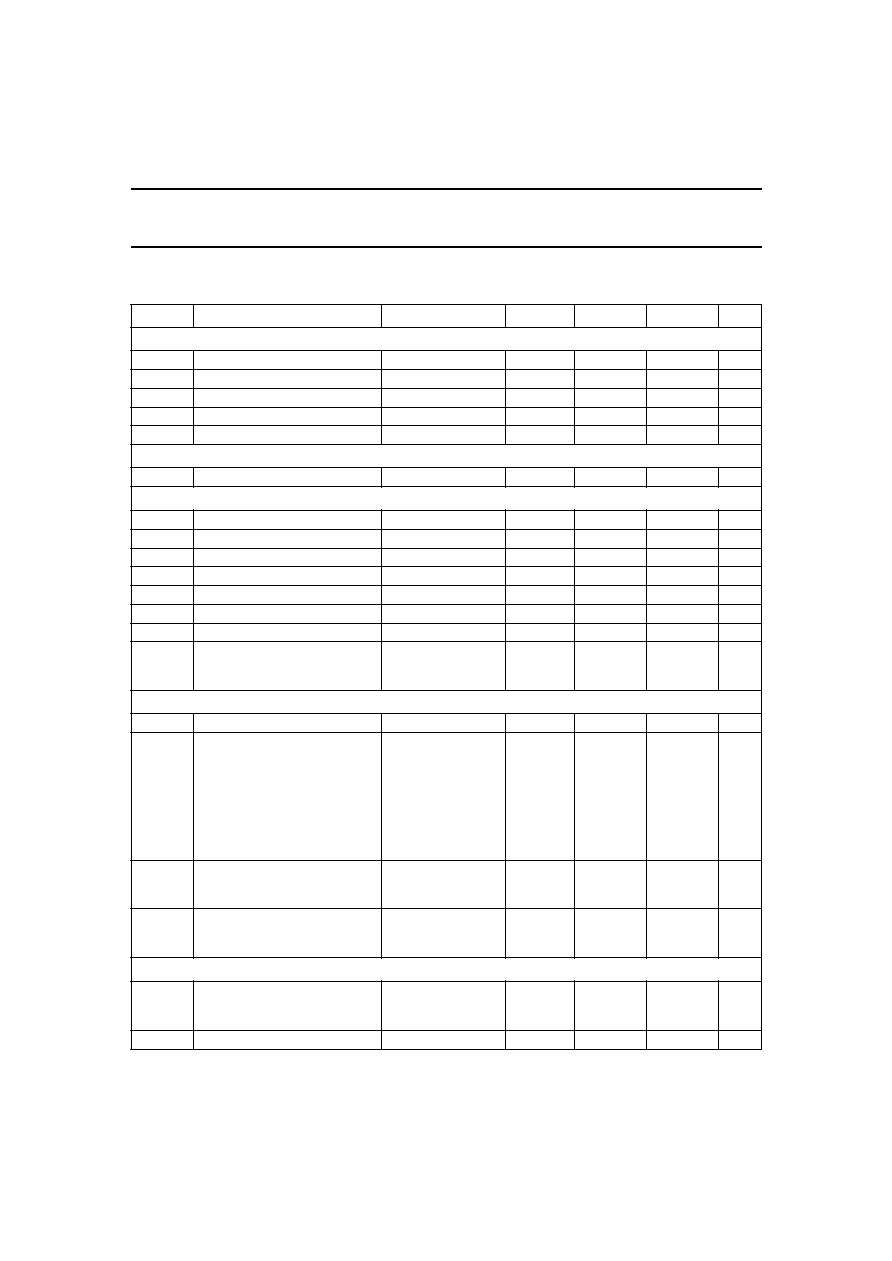

FUNCTIONAL DESCRIPTION

The TDA8385 can be divided into

10 functional blocks as shown in Fig.1

and Fig.2.

Block for Figs 1 and 2

These 10 functional blocks of Fig.1

and Fig.2 contain sub-sections

numbered 1 to 28 which are

BLOCK

NO.

DESCRIPTION

I

supply references

II

sawtooth generator

III

control part

IV

pulse width modulator

(PWM)

V

LED control

VI

LED driver

VII

slow-start circuitry

VIII

over-voltage protection

IX

stand-by circuit

X

regulation-indicator

output

cross-referenced in the following

description.

Supply references (Block I)

The TDA8385 is intended to be used

on the secondary side of the

self-oscillating power supply. It can be

supplied either by an auxiliary winding

of the transformer or an external

supply e.g. 50 Hz transformer.

Charging of the capacitor C

P

(see

Fig.16) takes place during transistor

on-time (T

on

; see Fig.17). During

stand-by the IC is supplied by the

stand-by voltage V

sb

(pin 10). The

operating voltage range is from 7.5 to

20 V. The supply current, inclusive

drive current for the LED, is less than

20 mA. A bandgap based reference

(2.5 V) generates a stabilized voltage

V

stab

of 3.9 V to supply all internal

circuits of the IC except the LED

driver. The LED driver is directly

supplied by V

P

. The reference block

generates all the reference voltages

in the circuit. By means of a resistor

connected to pin 3, a reference

current (I

ref

) is defined.

This current is reflected several times

and is used to obtain IC-independent

settings e.g. T

on(min)

setting, delay

setting, charging and discharging of

slow-start capacitor C

ss

on pin 7

(see Fig.16).

The power supply is released by the

opto-coupler IC at an input voltage

level, which is high enough to

guarantee correct operation of the

TDA8385 e.g. V

P

= 10 V by sensing

the mains voltage V

I

. As soon as the

SOPS switching transistor (T1, see

Fig.16) is conductive the capacitor C

P

is charged. As long as the IC supply

voltage is below 7.5 V the LED driver

is blocked (see latch output;

sub-section 28) in order to guarantee

start-up of SOPS.

During the initialization phase the

quick-discharge-switch

(sub-section 27), set input of

flip-flop (13) and reset input of

flip-flop (23) are also activated.

As soon as the voltage of 7.5 V is

reached the control functions of the IC

are operative. Hysteresis on the

initialization level is 2.3 V.

March 1994

6

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

Fig.4 Latch initialization as a function of supply voltage V

P

.

5.2

7.5

20

latch

initialization

operation

VP (V)

MCD403

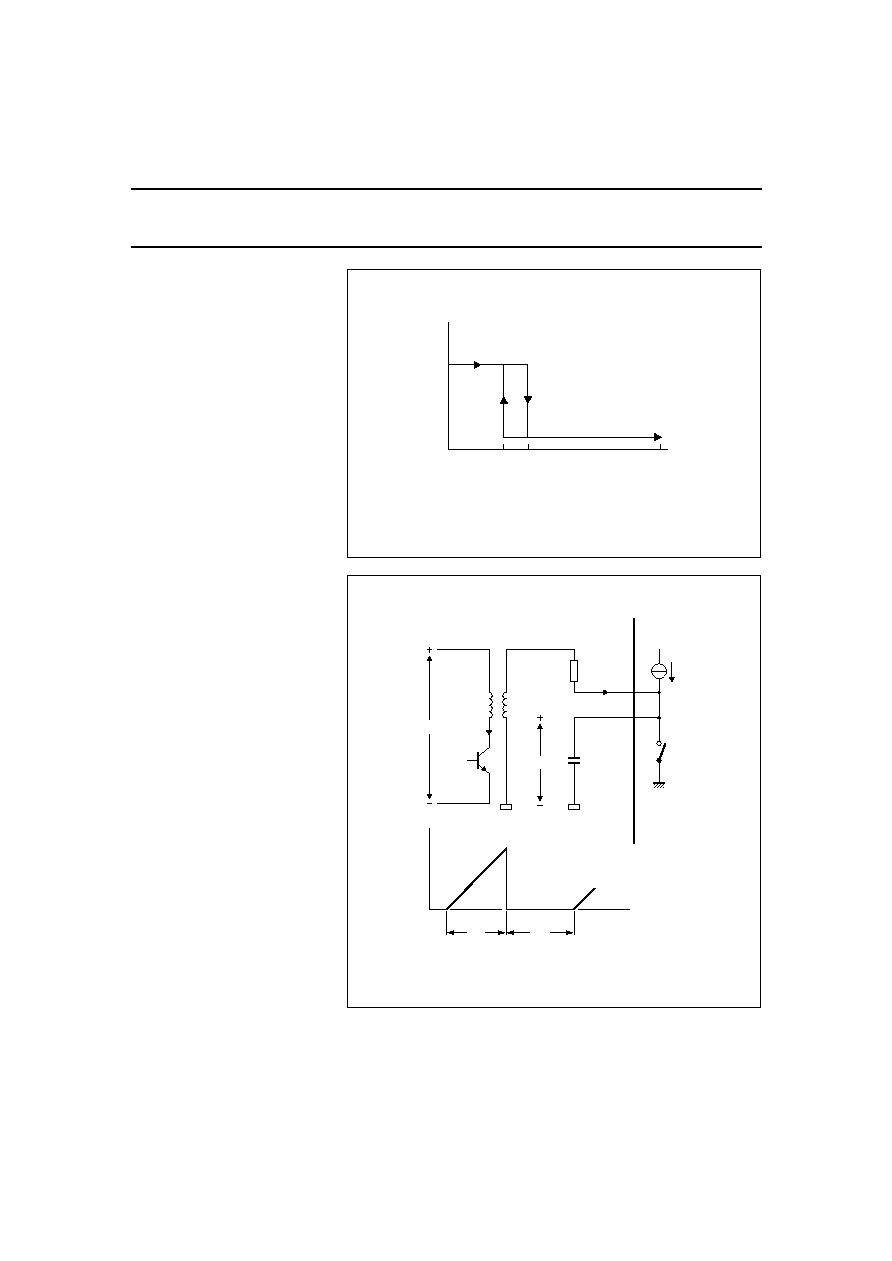

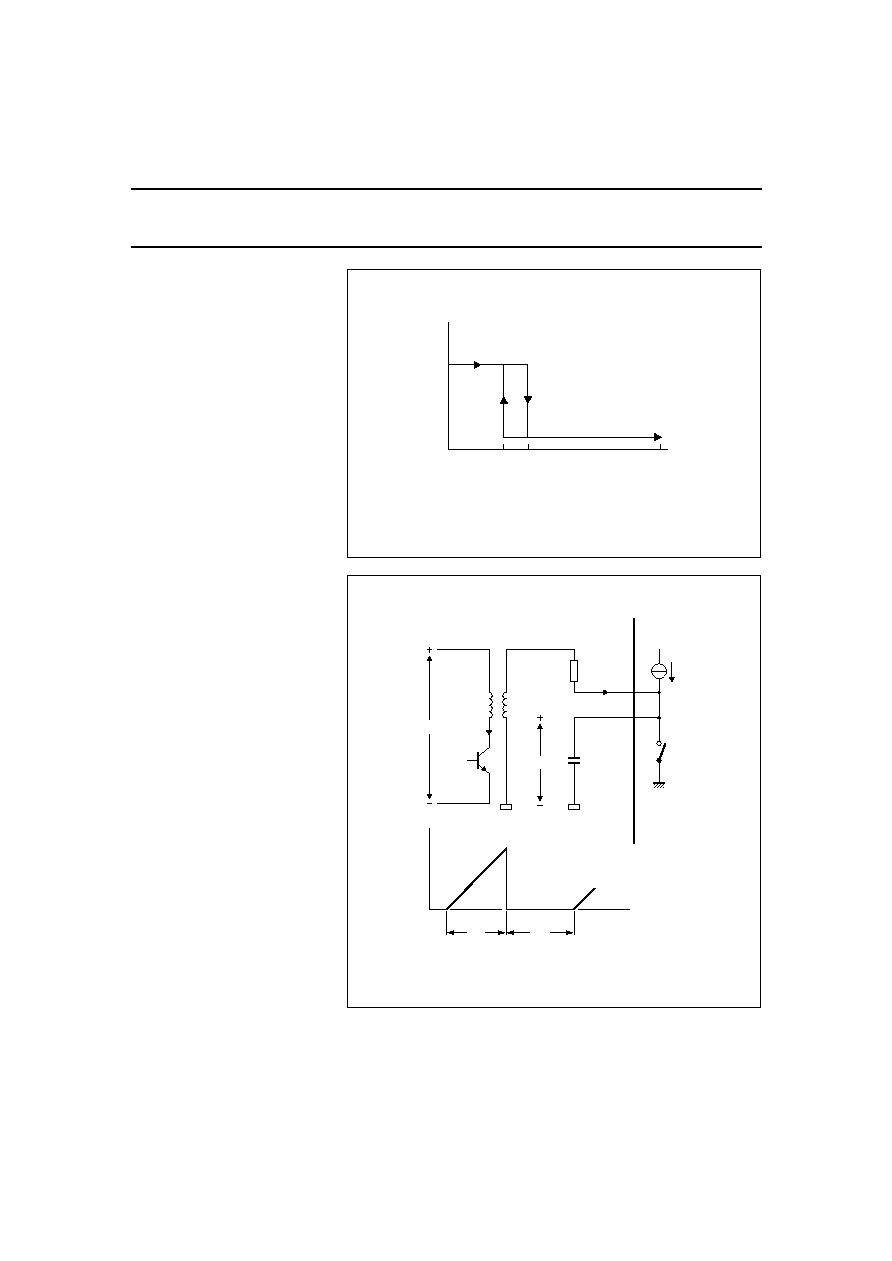

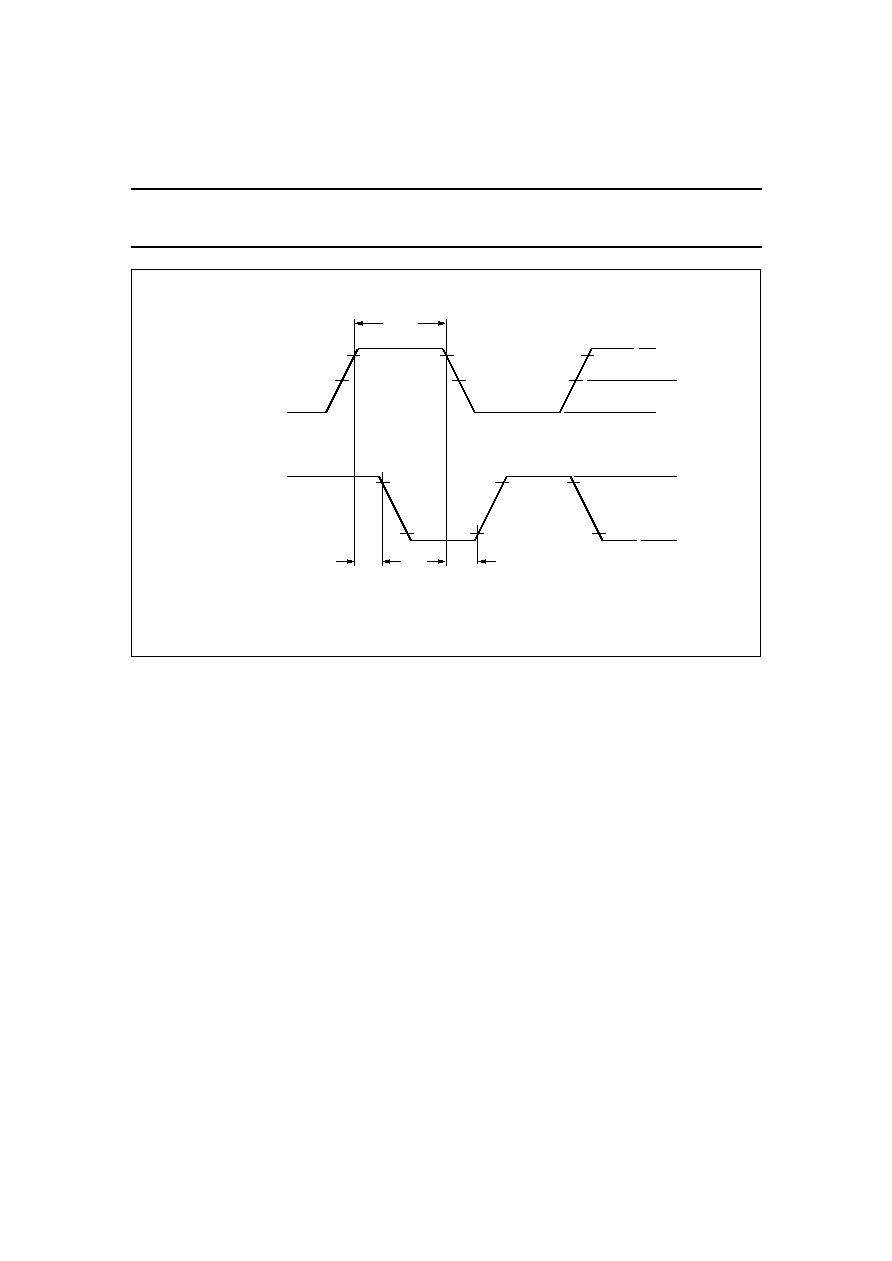

Sawtooth generator (Block II)

C

URRENT SIMULATION

(

SEE FIGS

5

AND

16)

The current of the power supply

switching transistor is detected on the

secondary side by an indirect method

of current sensing.

Information of the collector current (I

c

)

is obtained by integrating the voltage

of an auxiliary winding of the

transformer during transistor on-time

(T

on

). An external capacitor C on pin 5

is charged during T

on

by the current

source I

sim

. The current I

sim

is the

reflection of the current which flows

into pin 12. This current is obtained by

connecting an external resistor R12 to

the auxiliary transformer winding.

During transistor on-time this current

is related to the input voltage V

I

.

During transistor off time (T

off

) the

capacitor C is discharged by switch

sw1. This switch is active during the

total T

off

time. In this way a sawtooth

voltage V

c

is formed across C. This

sawtooth is a measure for the

collector current of the switching

transistor T1.

For the voltage V

c

yields:

(1)

(2)

Where: p = reflection factor;

(2)

(1) gives:

(3)

V

c

I

sim

T

on

◊

C

-------------------------

=

I

sim

p

n

h

n

p

------

◊

V

I

R12

-----------

◊

=

p

I

sim

I

12

---------

0.2

=

=

V

c

p

C

----

n

h

n

p

------

◊

V

I

R12

-----------

◊

T

on

◊

=

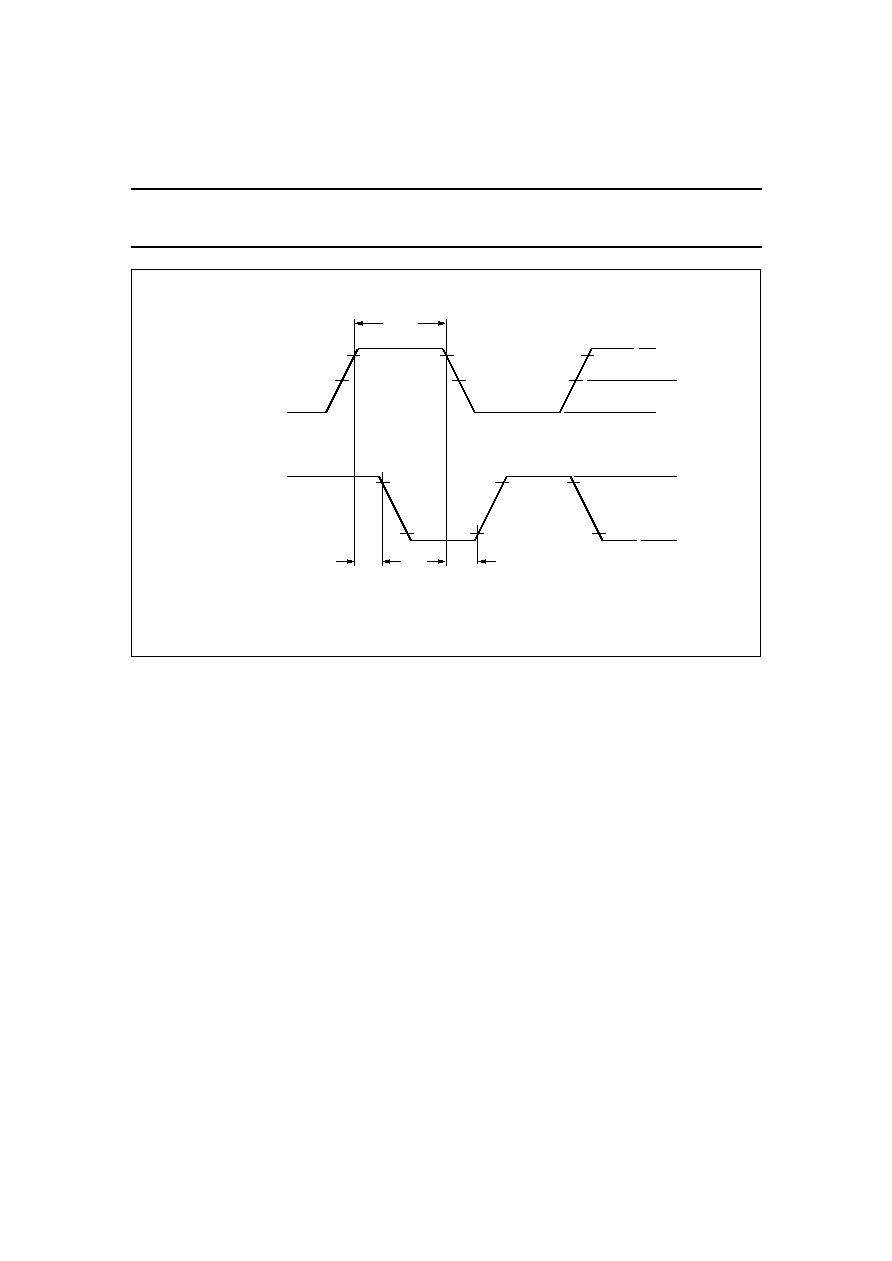

Fig.5 Determination of the peak current I

c

.

handbook, full pagewidth

VI

C

R12

I 12

12

5

Isim

L

T1

n p

Ic

n h

Vc

t

MCD404

Vc

Ton

Toff

sw1

March 1994

7

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

For `T

on

' yields:

(4)

For the primary current I

c

yields:

(5)

Substitution (4) into (5):

(6)

Equation (6) shows that by limiting the

voltage V

c

the collector peak current

can be limited. The peak current is

limited by means of the clamping

circuit in the transfer character

generator (TCG); see Fig.1

sub-section 4.

The clamping level can be externally

influenced by means of a resistor

on pin 7.

The collector peak current can be

influenced in several ways:

∑

Resistor R12 on pin 12

∑

Capacitor C on pin 5

∑

Capacitor on pin 7

∑

Transfer ratio n

h

/n

p

∑

Inductance L

Before comparing the sawtooth

voltage V

c

with the control voltage V

r

in the pulse width modulator, a

voltage of 100 mV is added to V

c

. In

this way it will be possible for V

r

to

become smaller than V

sim

, which is

important for a stabilized no-load

operation (see Fig.6 area 3).

D

EMAGNETIZATION INPUT

(

PIN

15)

This input prevents the switching

transistor from conducting during

demagnetization of the transformer in

order to prevent the transformer from

going into saturation. The output of

comparator (11) is HIGH as soon as

the voltage of the transformer winding

exceeds 115 mV.

T

on

V

c

C

◊

n

p

◊

R12

◊

p

n

h

◊

V

I

◊

-----------------------------------------------

=

I

c

V

I

L

-----

T

on

◊

=

I

c

C

L

----

1

p

---

◊

n

p

n

h

------

◊

R12

◊

V

c

◊

=

D

ELAY SETTING

(

PIN

6)

The output of sub-section 11 is

extended by the delay circuit of

sub-section 12. The starting

(reference) point of the delay circuit is

the falling edge of the output of

demagnetizing comparator (11) The

delay can be determined externally by

capacitor (C

delay

) on pin 6.

The switch-on moment of the

switching transistor can be

determined by capacitor C

delay

.

A minimum delay time is required to

prevent transistor T1 from switching

during demagnetization of the

transformer because of oscillations

caused by the leakage inductance.

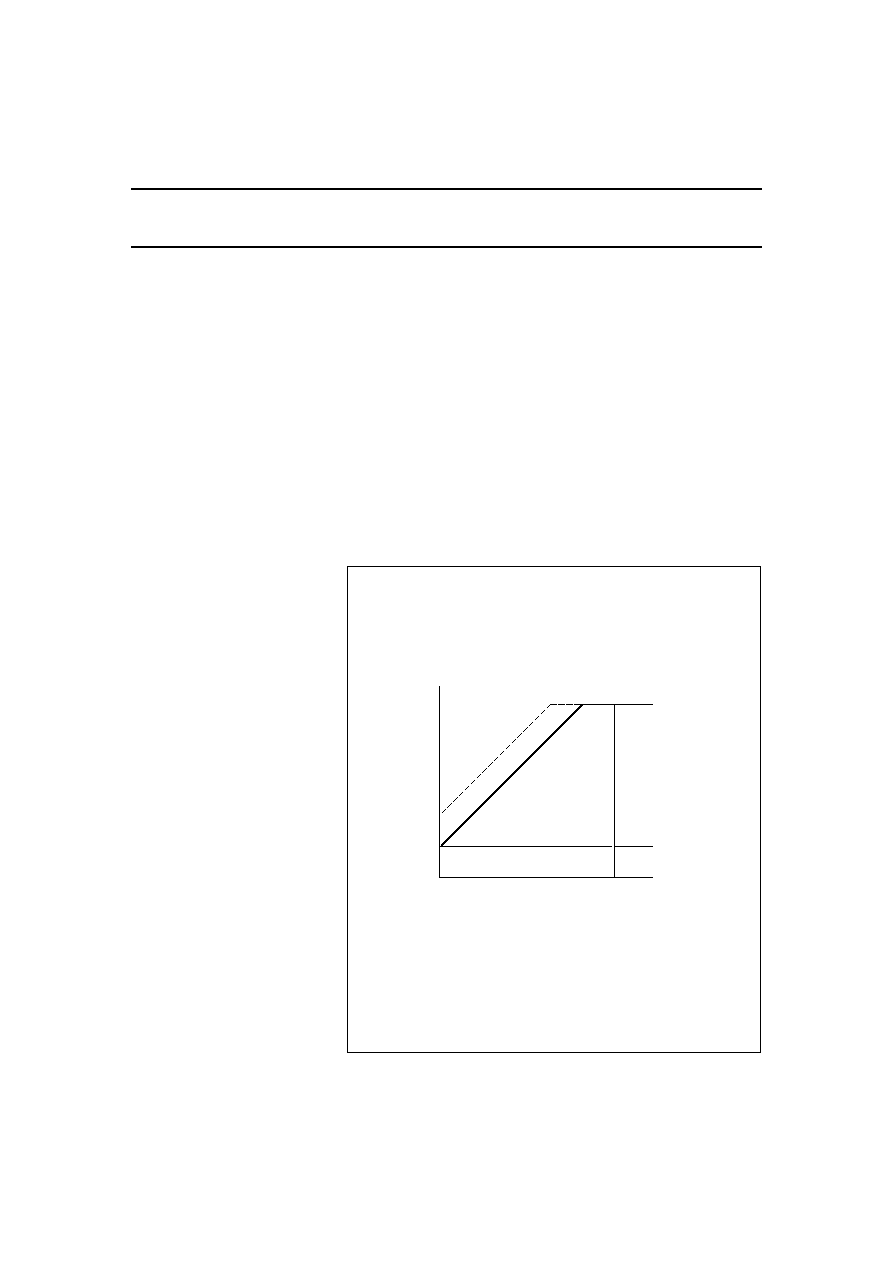

Control part (Block III)

The differential amplifier,

sub-section 3, compares the

feedback voltage (V

fb

) with the

reference voltage V

ref

. The output of

the differential amplifier is available

on pin 11 to allow gain setting. The

differential amplifier is internally

compensated for 0 dB feedback

stability.

The feedback input (pin 9) is also

used as the input for the TCG

(see Fig.6) with which a current

foldback characteristic can be

obtained as shown in Fig.7.

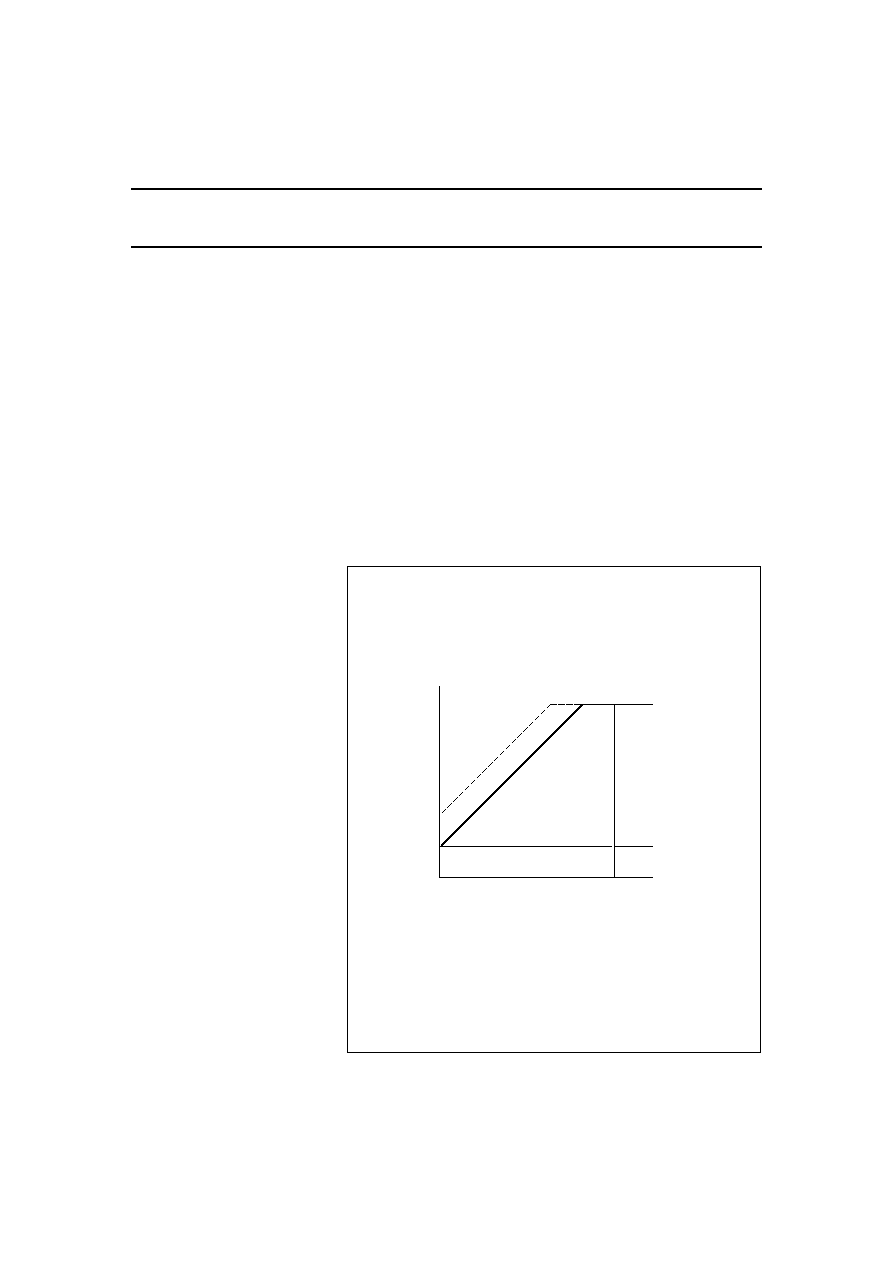

Fig.6 Reference voltage (V

mv

) as a function of feedback voltage (V

fb

).

(1), (2), (3) = V

TCG

.

(4), (5) = V

diff

.

(5)

(4)

(3)

(2)

(1)

MCD405

fb

V

Vmv

VTon(min)

Vclamp

March 1994

8

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

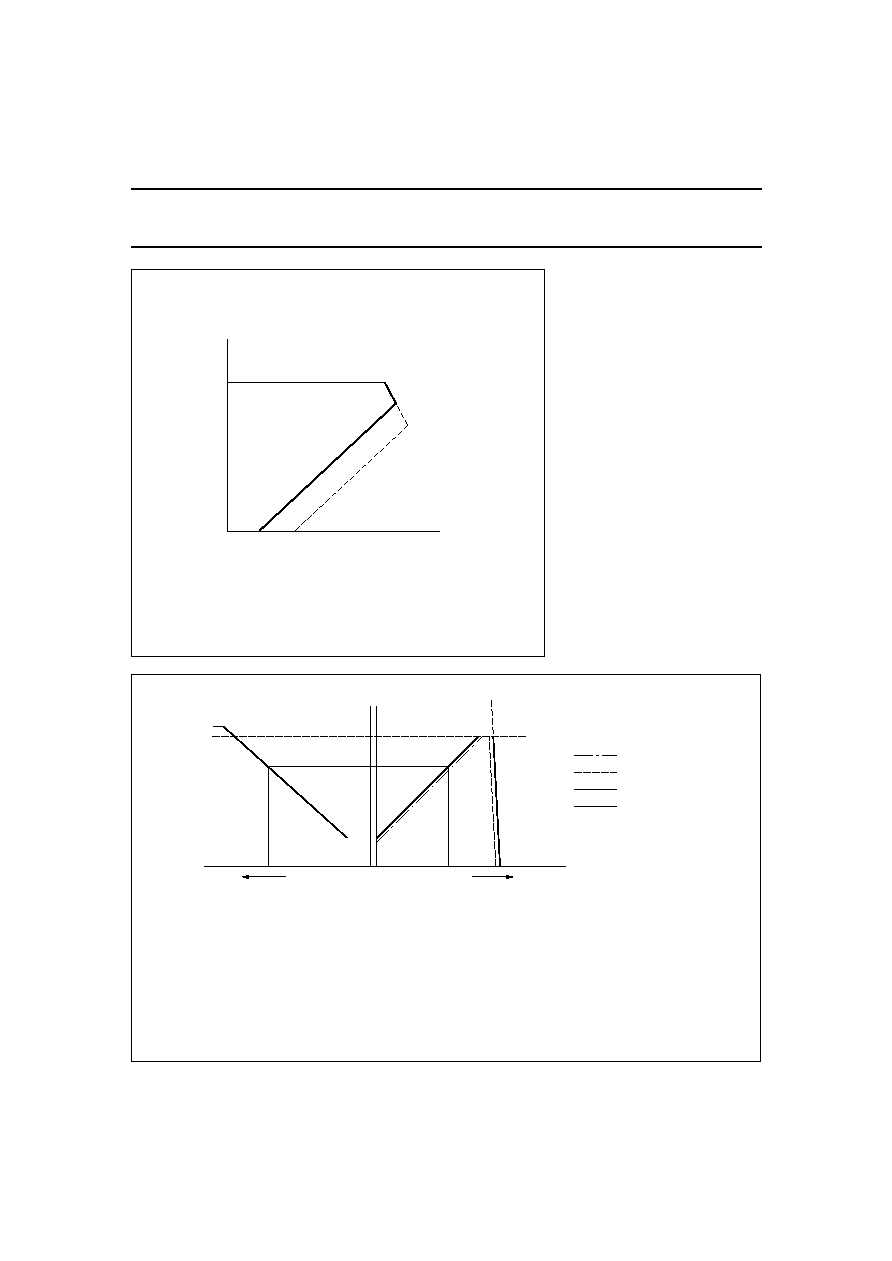

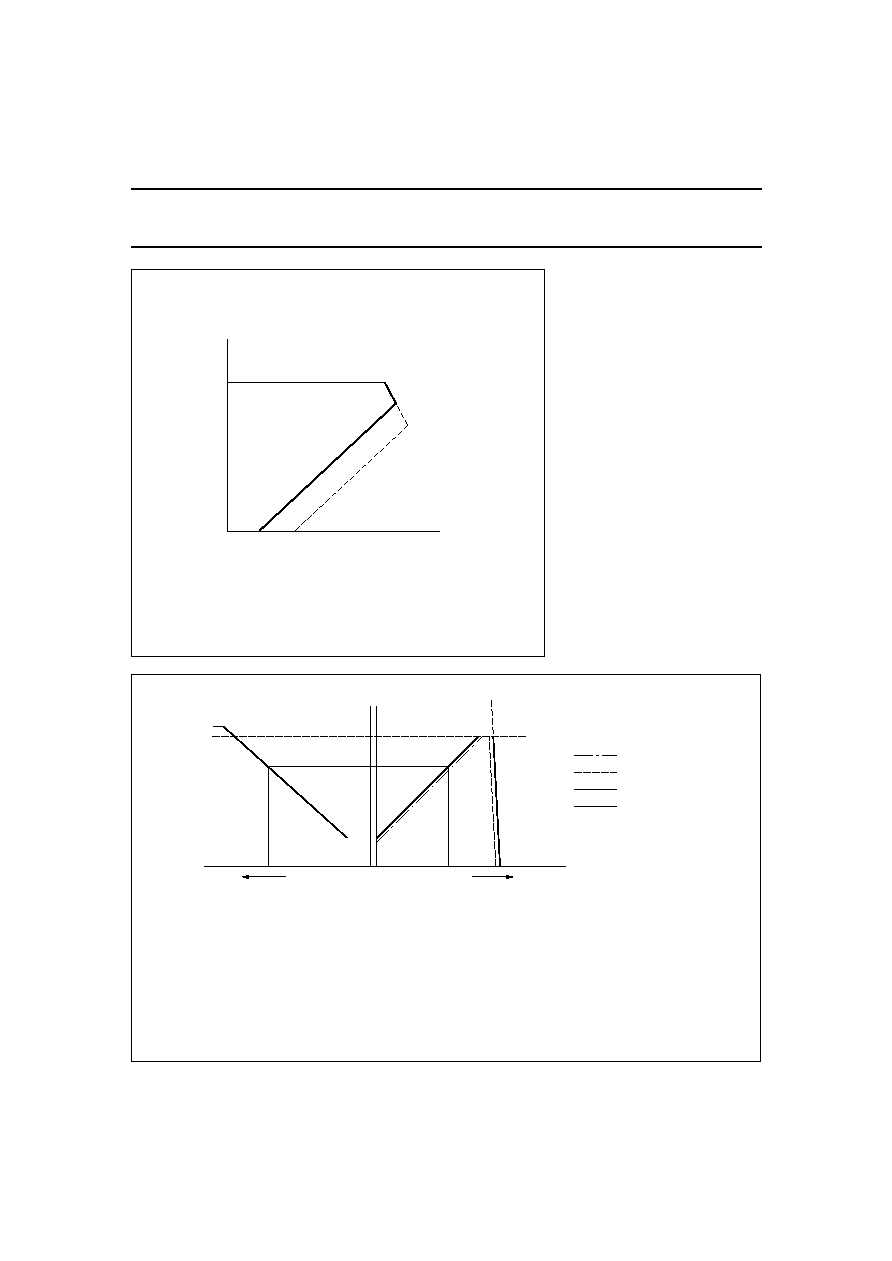

Fig.7

Current foldback characteristic; stabilized output voltage (V

O

)

as function of load current (I

O

).

(5)

V

O

I

O

(4)

(3)

(2)

(1)

MCD406

(1), (2), (3) = V

TCG

.

(4), (5) = V

diff

.

The voltage V

Ton(min)

determines the

minimum on-time of the switching

transistor. This voltage can be

determined externally with a resistor

on pin 4. With this resistor the current

foldback characteristic can be

influenced (see dotted line in Figs 6

and 7).

The minimum on-time is of

importance for the following.

∑

Stand-by operation

∑

Starting-up of power supply

∑

Overload and short-circuit

conditions.

The output of the differential amplifier

(V

diff

), the output of the TCG (V

TCG

)

and the voltage V

ss

+ V

Ton(min)

are

compared in a minimum voltage

clamping circuit (see Fig.1

sub-section 6). The output voltage is

equal to the lowest input voltage.

Some relevant characteristics of the

control part are depicted in Fig.8.

Fig.8 Characteristics of the control part.

The voltage V

mv

determines the collector peak current I

c

of transistor T1. The right-hand curve is passed through at start-up. When the feedback voltage

slowly increases from zero, the peak current starts at I

c(min)

and rises along the straight line until I

c(max)

is reached. At a slightly higher feedback voltage

the regulation slope is reached, which is approximately V

ref

.

The plateau of the top between the points x and y has to be kept as small as possible.

The voltage V

diff

decreases with the decreasing load. For good no-load operation the peak current has to be made zero with V

diff

.

Due to the characteristic of the TCG open- and short-circuit feedback loop will result in low peak current.

An additional signal on pin 13 can be supplied which is subtracted from the signal V

mv

. This input can be used for feed forward information.

If no feed forward information is used, pin 13 should be connected to ground.

handbook, full pagewidth

MCD407

Vss +

fb

V

Ic (max)

Ic (min)

Ic

Vmv

x

y

Vref

VTCG

external peak-current

setting (pin 7)

diff

V

mv

V

VTon(min)

March 1994

9

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

Pulse width modulator (Block IV)

The pulse width modulator compares

the control voltage V

r

with the

sawtooth voltage V

sim

. If V

sim

>

V

r

output sub-section 8 is HIGH the LED

is switched on and then the switching

transistor is switched off. In this way

the output voltage is controlled.

E

XAMPLE

If the load decreases, V

O

increases

and therefore V

r

decreases. This

causes the LED to start conducting

prematurely, which implies that the

switching transistor is turned off

sooner. The consequence is that the

collector peak current decreases and

hence less energy is stored in the

transformer and V

O

will decrease.

LED control (Block V)

If either output of sub-section 8 or

output of sub-section 16 are HIGH the

LED is conductive. In order to

improve the start-up behaviour of the

power supply, the demagnetization

signal of sub-section 12 will only

activate the LED driver if flip-flop (13)

has previously been set. The set

signal is generated in the following

three ways.

1. Pulse width modulator

(sub-section 8)

2. Comparator (18)

3. V

P(min)

detector

Set signal (2.) and (3.) are added as

extra security to guarantee a

demagnetization pulse in the event of

the switching transistor not having

enough base current. In that situation

e.g. at start-up, no comparator signal,

set signal (3.) is generated by

sub-section 8.

LED driver (Block VI)

The LED driver (pin 2) is blocked if the

supply voltage V

P

is in the

initialization phase (see Fig.4). The

output stage is a push-pull stage,

which can sink 5 mA and source

10 mA.

Slow-start circuit (Block VII)

The slow-start circuit is active at

start-up, over voltage protection or

after an overload (short-circuited),

and stand-by mode. The voltage V

ss

and therefore the voltage V

mv

and the

peak current I

c

slowly increase at

start-up.

By means of sub-section 27 the slow

start voltage V

ss

is clamped to the

voltage V

fb

. If the feedback voltage is

reduced, e.g. as overload, the

slow-start capacitor is discharged to

the level of V

fb

. In this way a slow

start-up is also guaranteed after an

overload, short-circuit situation or

after a stand-by mode. The circuit of

sub-section 27 is not active during an

over voltage protection.

When the supply voltage V

P

is below

the reset-level of 5.2 V

(sub-section 28) the slow-start

capacitor is quickly discharged.

The slow-start input (pin 7) can also

be used for I

c(max)

setting by

connecting a resistor to this pin.

Over voltage protection

(Block VIII)

The operation of the over voltage

protection circuit is, in the event of the

IC being SOPS-supplied, quite

different from when the IC is

externally supplied.

O

PERATION WHEN THE

IC

IS

EXTERNALLY SUPPLIED

When the voltage on pin 8 exceeds

2.5 V the slow-start capacitor is

slowly discharged. During discharge

the LED is permanently conducting.

Discharge is stopped when V

ss

is

below 115 mV. Flip-flop (23) will then

be reset and the circuit is ready again

for a new slow-start procedure.

During an over voltage sub-section 27

is not active so that the output voltage

V

O

cannot influence the slow-start

discharge procedure.

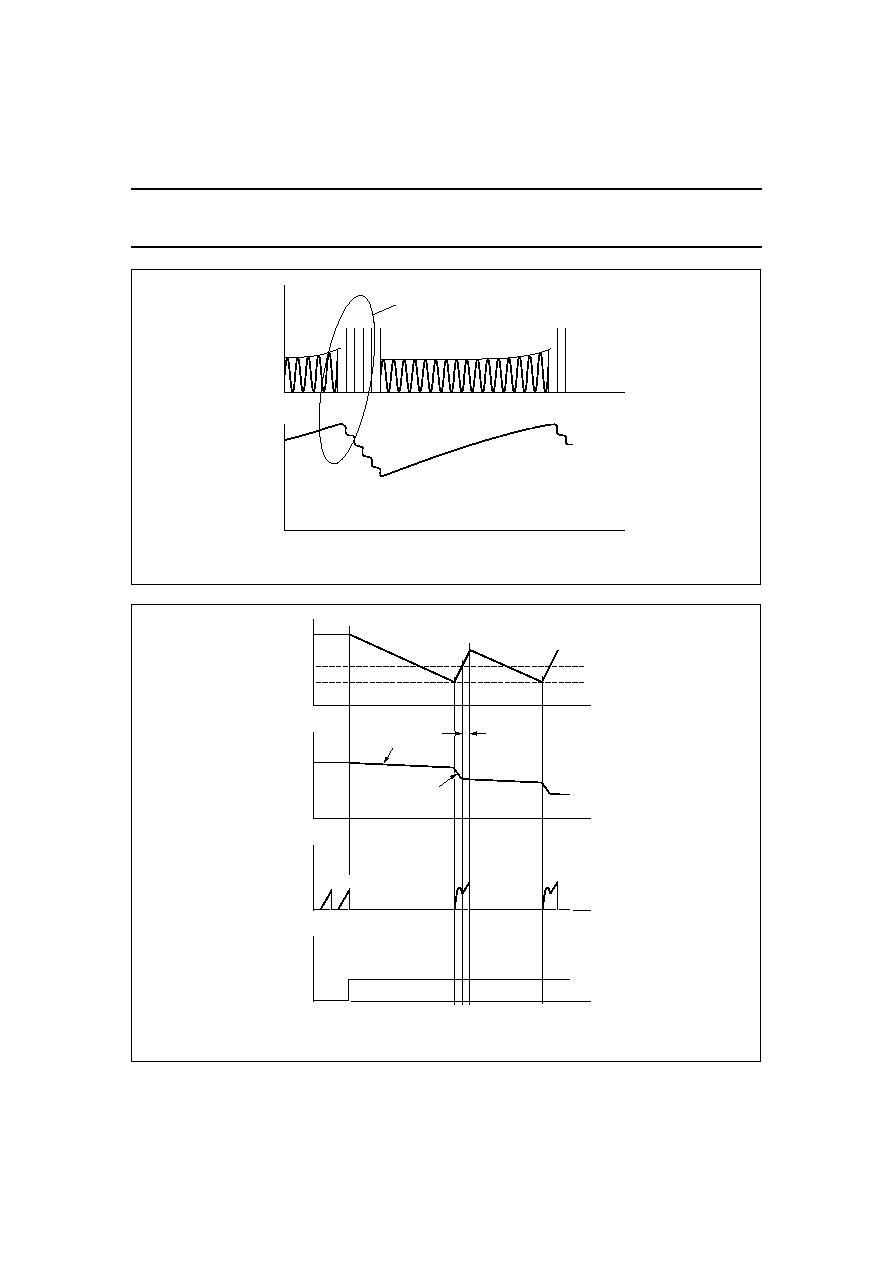

O

PERATION WHEN

IC

IS

SOPS-

SUPPLIED

(

SEE FIGS

9

AND

10)

When the voltage on pin 8 exceeds

2.5 V the slow-start capacitor is

slowly discharged. During discharge

of C

ss

the supply capacitor C

P

is also

discharged. Because the capacitors

C

P

and C

ss

have almost the same

value and the supply current I

P

(

15 mA) is much larger than the slow

discharge current (

50

µ

A), the LED

will be switched off by means of the

V

P(min)

detection circuit (5.2 V). At that

moment the switching transistor will

be switched on again until the 7.5 V

level is reached. During this

hysteresis interval the slow-charge

capacitor is quickly discharged. At the

7.5 V level the LED will be switched

on again because flip-flop (23) output

is still HIGH.

The same procedure will be repeated

several times until the slow-start

capacitor reaches the 115 mV reset

level. At that moment the slow-start

procedure is started again.

If there is still an over voltage the

procedure will be repeated.

Figure 10 is a detailed exposure of

Fig.11.

March 1994

10

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

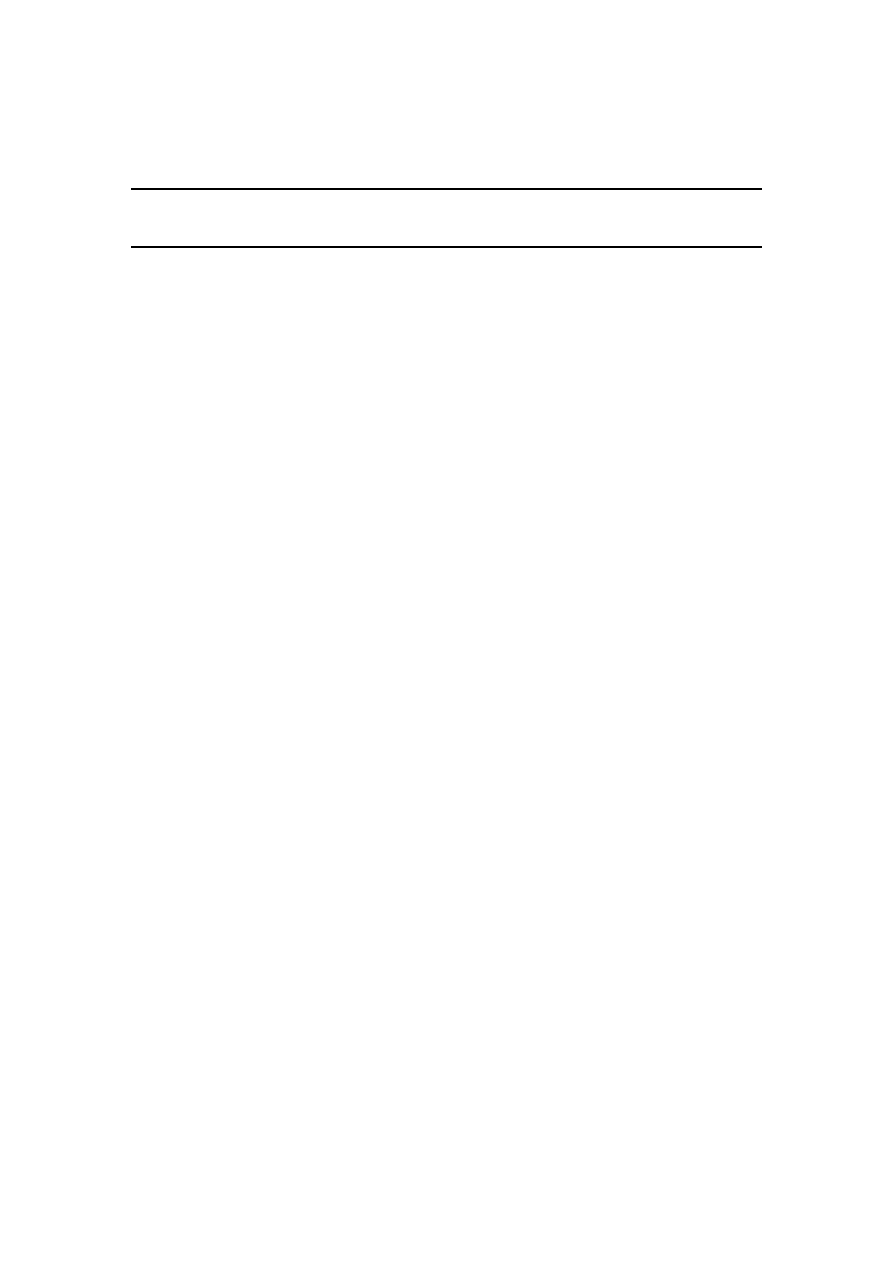

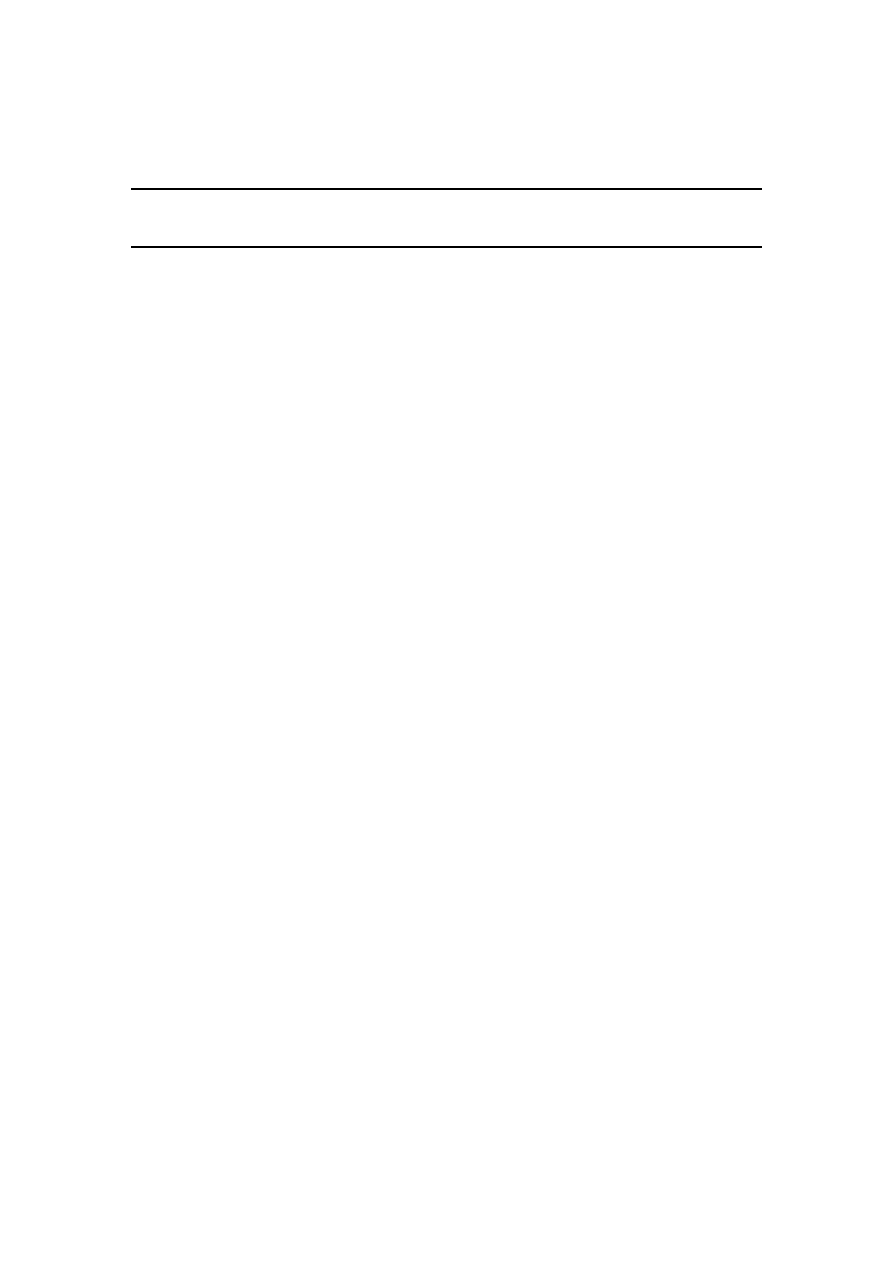

handbook, full pagewidth

MCD408

I c

t

V ss

t

(1)

Fig.9 Over voltage protection.

(1) For detail see Fig.10.

Fig.10 Detailed over voltage protection of Fig.9.

0

V P

(V)

t

7.5 V

5.2 V

MCD409

t

Q FF23

t

delay

0

V

ss

(V)

t

slow discharge

quick discharge

I c

t

March 1994

11

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

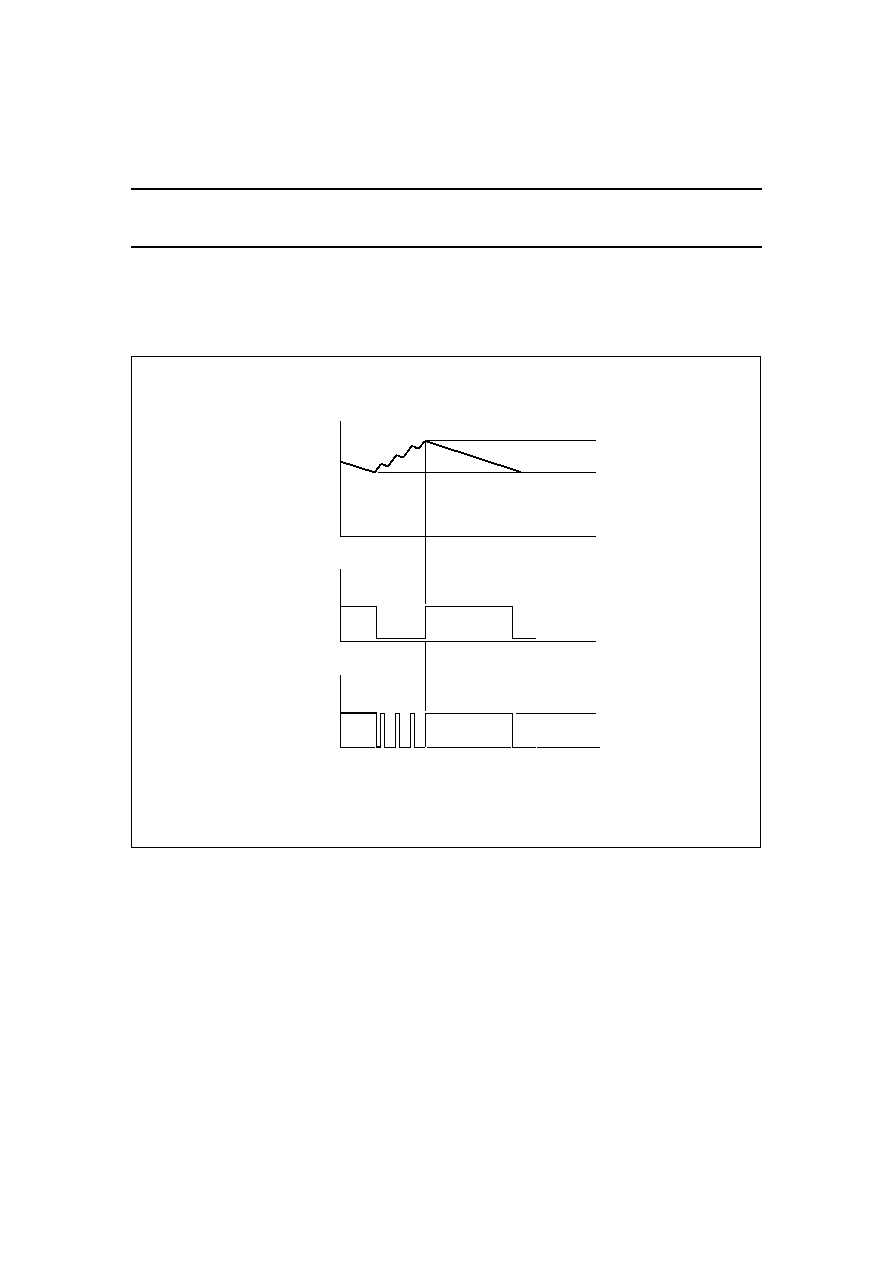

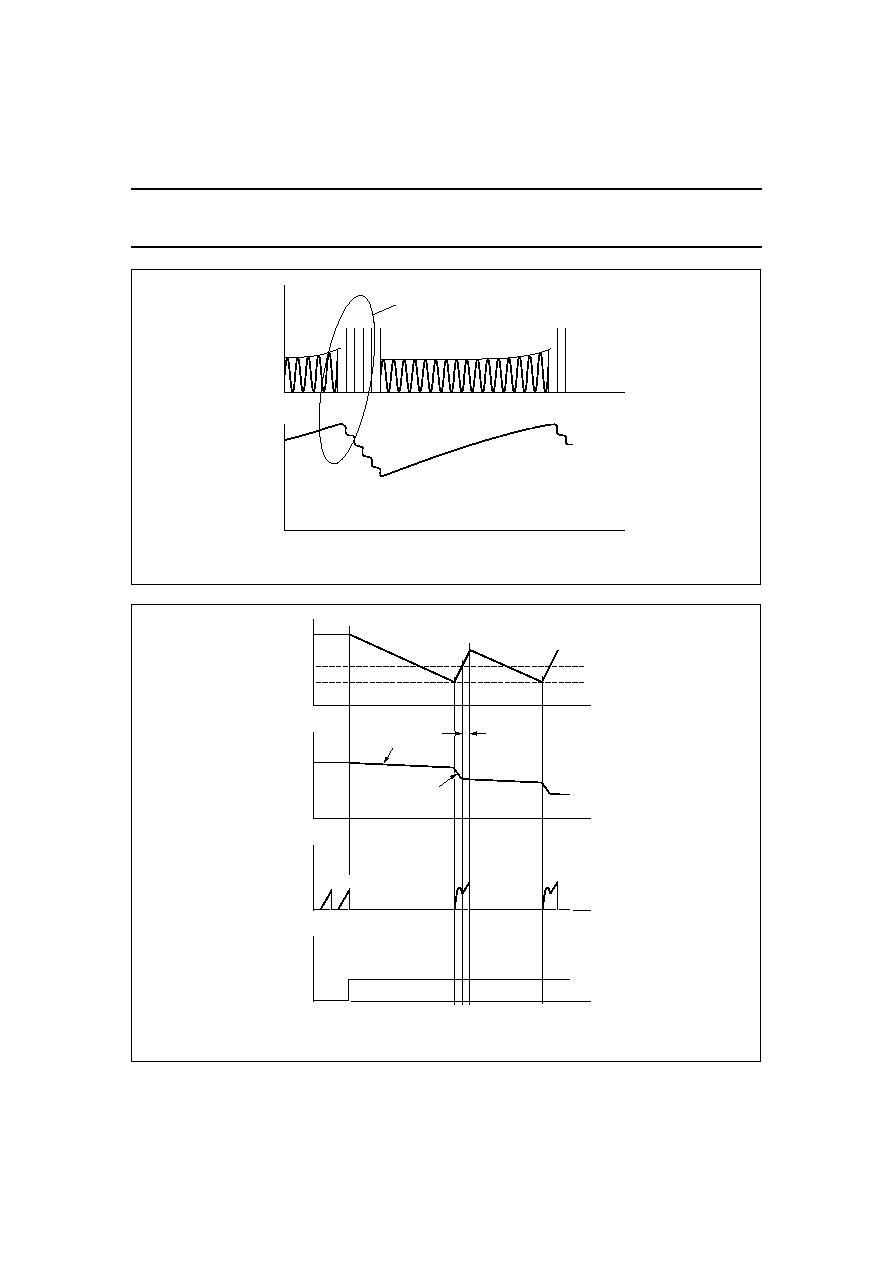

Stand-by circuit (Block IX)

During stand-by operation the voltage V

sb

is supplied from the SOPS via thyristor TH1 (see Fig.16). In the stand-by state,

SOPS operates in a burst mode. When the voltage on pin 10 exceeds 2.5 V the LED driver is permanently activated. The

LED driver is released again if the voltage is below 2 V (see Fig.11).

Fig.11 Stand-by operation; burst mode.

handbook, full pagewidth

MCD410

t

0

output sub-section 25

t

0

t

0

V

sb

(V)

I LED

(mA)

5 mA

2.5 V

2 V

March 1994

12

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

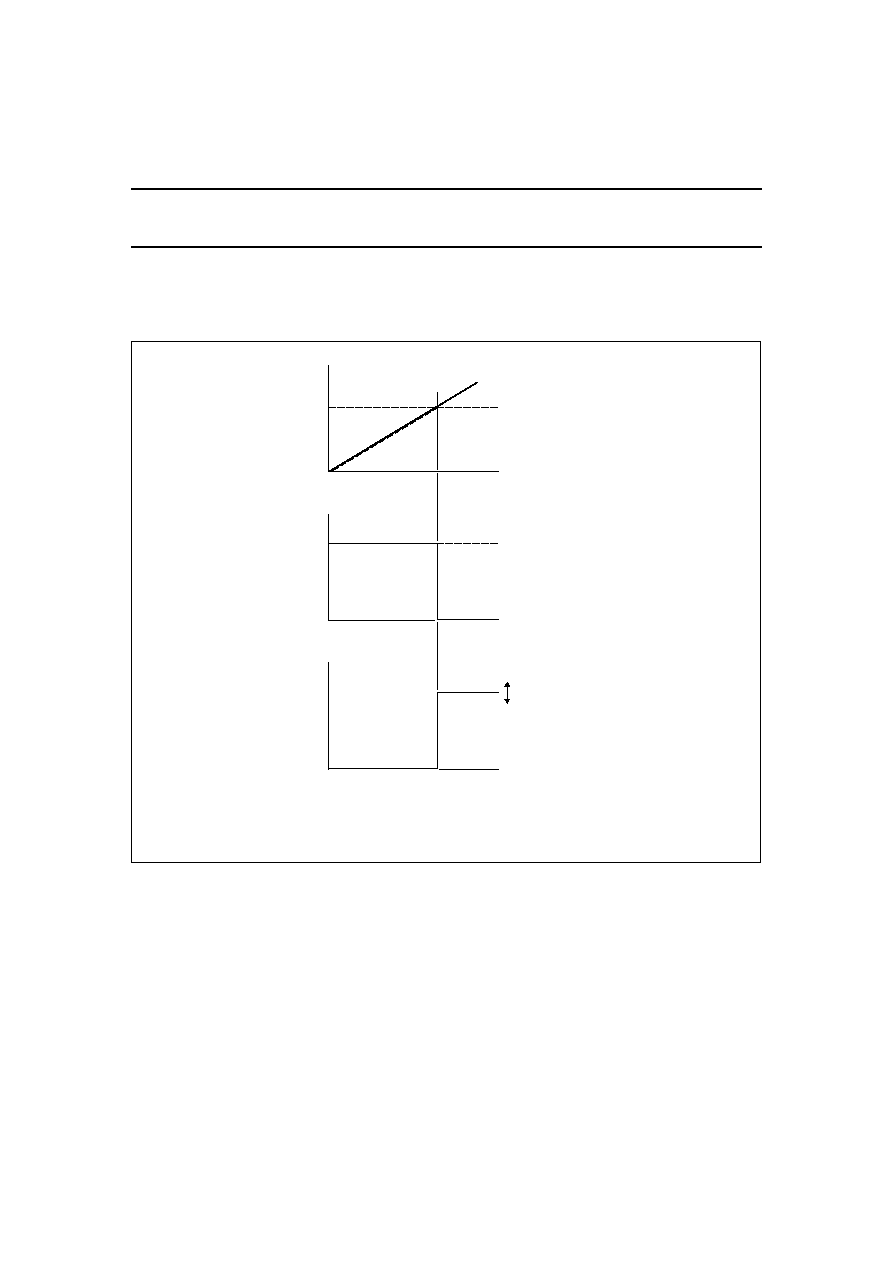

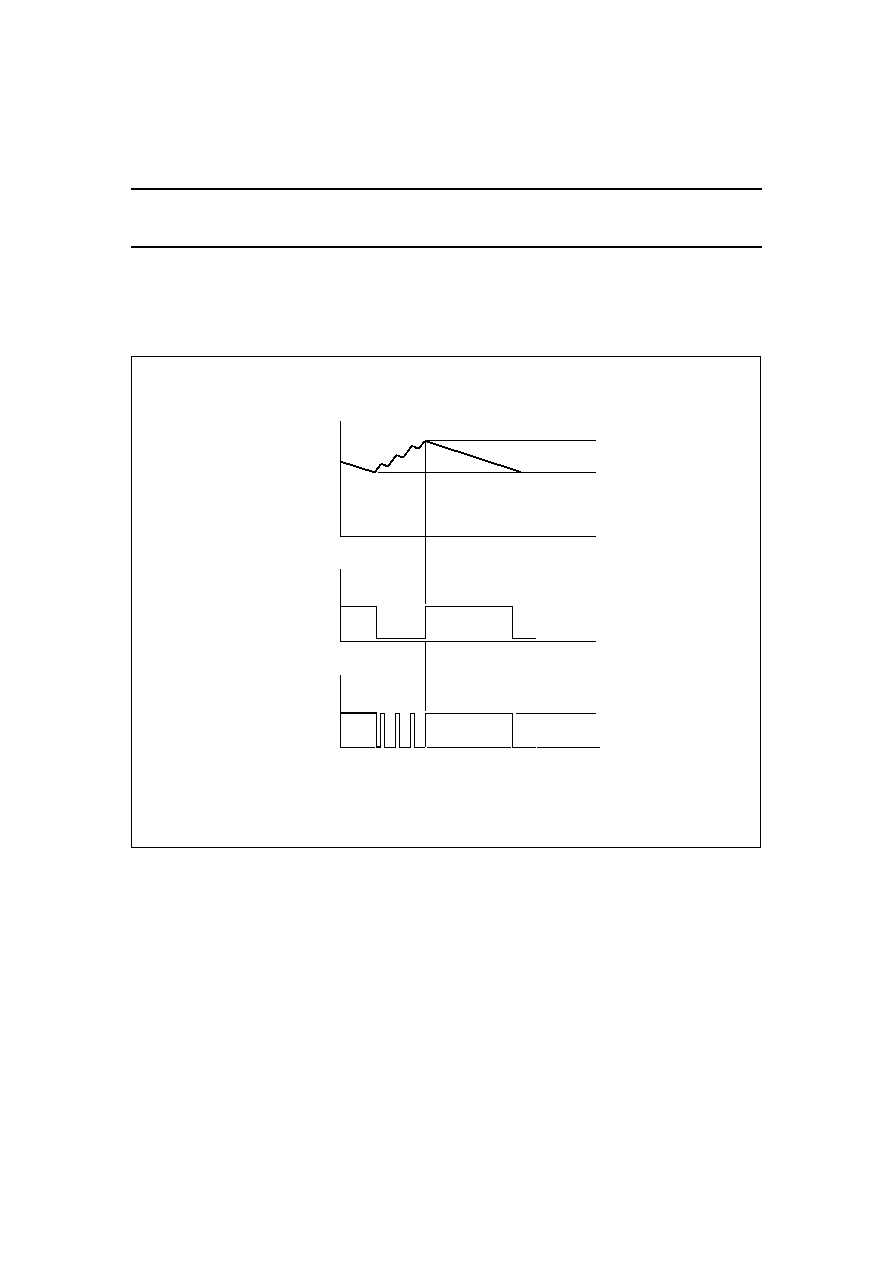

Regulation indicator output (Block X)

Pin 1 can be used to reset the logic circuit in the TV receiver at power on and off. Sub-section 29 has an open-collector

output. The output of this block is LOW during the regulation mode (V

diff

<

V

ts

; see Fig.12).

handbook, full pagewidth

V

2.5

0

t

0

t

V

RIO

0

t

Vfb

Vts

V

diff

VP

V

RIO : open-collector output

MCD411

Fig.12 Regulation indicator output; pin 1.

A desired delay at power-on reset can be made externally.

March 1994

13

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

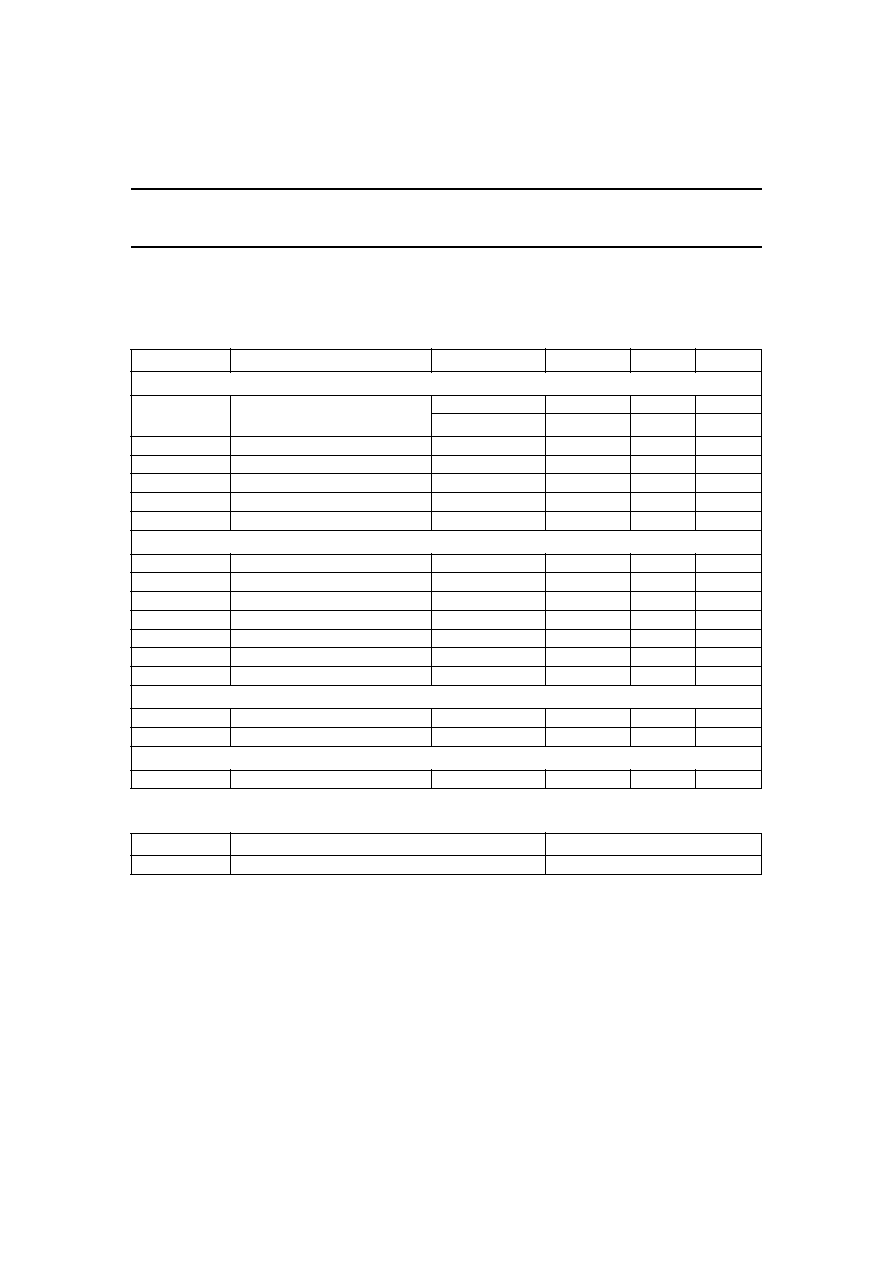

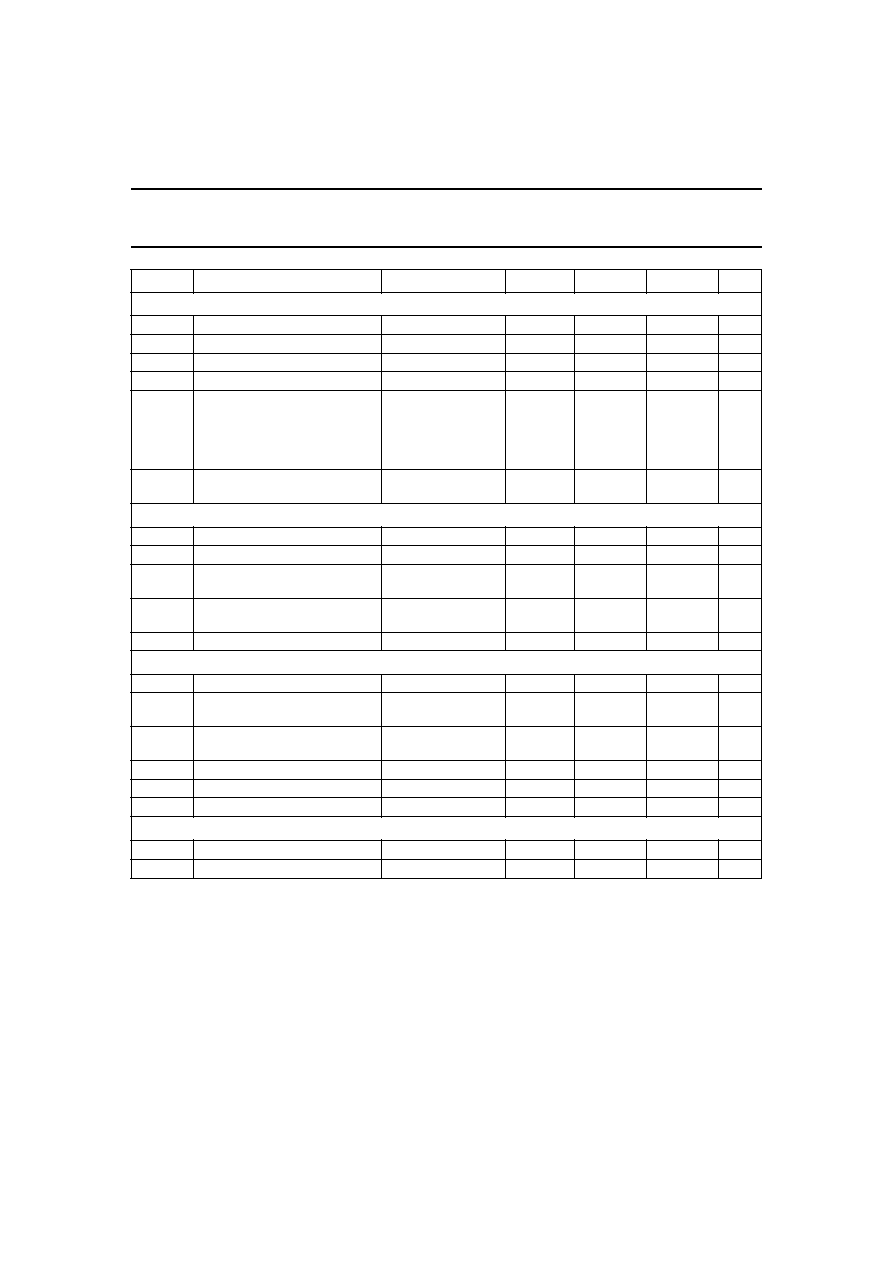

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

All voltages are measured with respect to ground; positive current flow into the IC; all pins not mentioned in the voltage

list are not allowed to be voltage driven. The voltage ratings are valid provided other ratings are not violated; current

ratings are valid provided the power rating is not violated.

THERMAL RESISTANCE

SYMBOL

PARAMETER

CONDITIONS

MIN.

MAX.

UNIT

Voltages

V

P

supply voltage

pin 2 connected

-

0.5

20

V

pin 2 open-circuit

-

0.5

18

V

V

n

voltage on pins 1, 2, 4, 7, 9 and 13

-

0.5

+18

V

V

3

voltage on pin 3

-

0.5

+6

V

V

8,10

voltage on pins 8 and 10

-

0.5

+3.9

V

V

12

voltage on pin 12

-

0.1

+0.5

V

V

15

voltage on pin 15

-

0.5

+0.5

V

Currents

I

1

current on pin 1

0

2

mA

I

n

current on pins 2, 12 and 15

-

10

+10

mA

I

3

current on pin 3

-

1

0

mA

I

5, 6

current on pins 5 and 6

-

1

+1

mA

I

7

current on pin 7

-

1

+25

mA

I

11

current on pin 11

-

10

+0.5

mA

I

16

current on pin 16

0

20

mA

Temperatures

T

amb

operating ambient temperature

-

25

+70

∞

C

T

stg

storage temperature

-

55

+150

∞

C

Power dissipation

P

tot

total power dissipation

-

500

mW

SYMBOL

PARAMETER

THERMAL RESISTANCE

R

th j-a

from junction to ambient in free air

55 K/W

March 1994

14

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

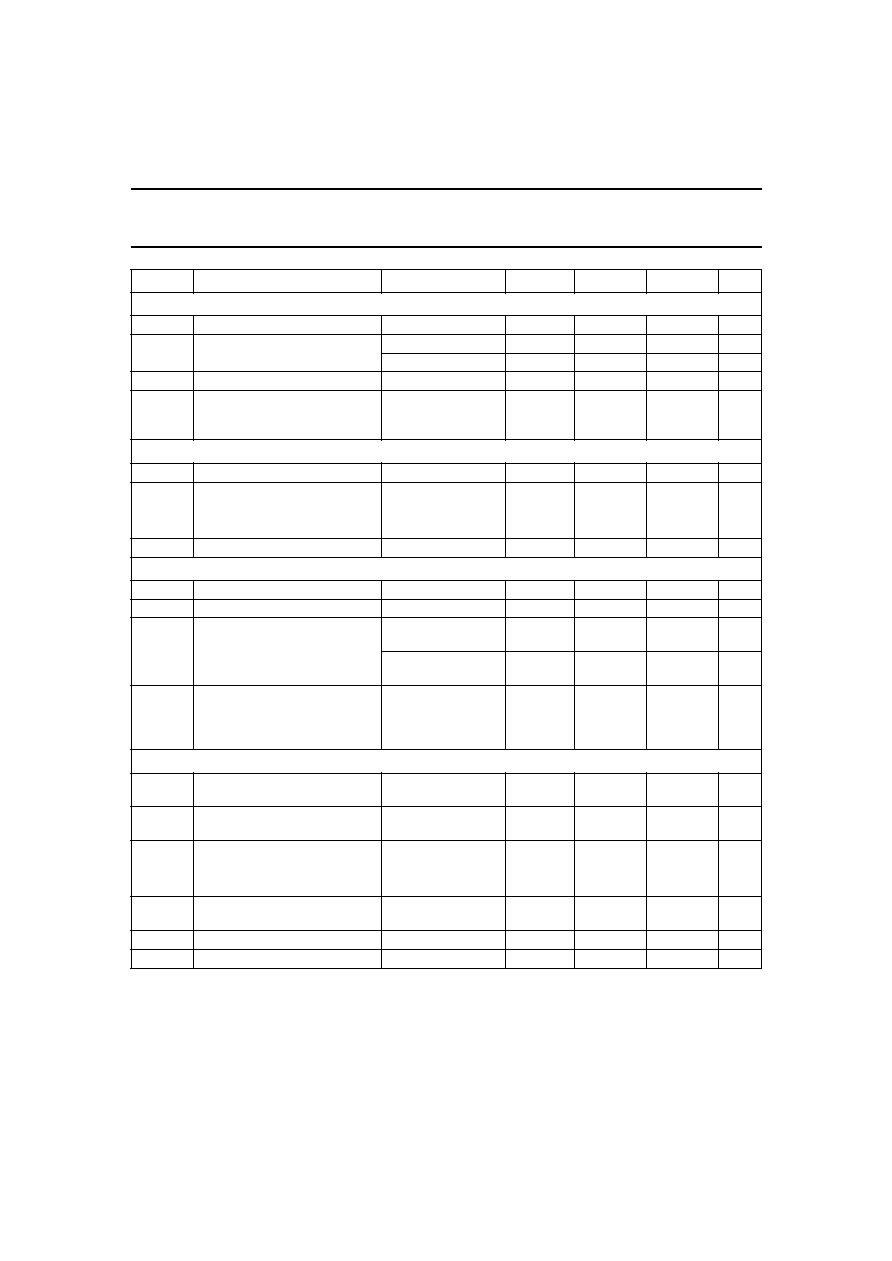

CHARACTERISTICS

V

P

= 15 V; I

3

= 200

µ

A; T

amb

= 25

∞

C; unless otherwise specified.

SYMBOL

PARAMETER

CONDITIONS

MIN.

TYP.

MAX.

UNIT

Supply

V

P

supply voltage (pin 16)

7.9

-

20

V

V

16

supply initialization level

7.1

7.5

7.9

V

V

16(hys)

internal fixed hysteresis

2.5

-

2.55

V

I

16

supply current

active LED output

-

-

20

mA

V

11

supply voltage ripple rejection

see Figs 13 and 14

-

60

-

mV

Reference voltage

V

3

reference voltage at pin 3

0.52

0.55

0.58

V

Error amplifier

V

9

threshold voltage error amplitude

2.4

2.5

2.6

V

I

9

input current feedback input

-

-

0.5

µ

A

I

11

sink current output

V

11

= 80 mV

400

-

-

µ

A

I

11

source current output

V

11

= 2.5 V

500

-

-

µ

A

G

o

open loop gain

-

100

-

dB

B

unity gain bandwidth

-

600

-

kHz

V

9

/

T

temperature coefficient

-

±

300

◊

10

-

6

-

K

-

1

V

5

threshold for switching output

V

diff

= 1.25 V;

V

4

= 2 V; V

13

= 0 V;

V

7

>

V

9

; I

2

= 2 mA

-

V

diff

-

V

os

(1)

-

V

Transfer characteristic generator

I

4

/I

3

current ratio

V

4

= 0.5 V

0.23

0.25

0.27

V

5

threshold for switching output

V

4

= 0.5 V; V

13

= 0 V;

V

7

>

V

9

; I

2

= 2 mA

T

on(min)

V

9

= 0 V

0.4

-

V

os

0.5

-

V

os

0.6

-

V

os

V

V

fb

= 20%

V

9

= 0.4 V

-

0.9

-

V

os

-

V

V

fb

= 50%

V

9

= 1 V

1.4

-

V

os

1.5

-

V

os

1.6

-

V

os

V

V

fb

= 80%

V

9

= 1.6 V

-

2.1

-

V

os

-

V

clamp

V

9

= 2.25 V

2.4

-

V

os

-

2.6

-

V

os

V

t

PLH

response time pulse width

modulation pin 5 to pin 2

LOW-to-HIGH

note 2

-

-

700

ns

t

PHL

response time pulse width

modulation pin 5 to pin 2

HIGH-to-LOW

note 2

-

-

1

µ

s

Feed forward

V

5

threshold for switching output

(V

fo

)

V

4

= 0.5 V; V

13

= 0 V;

V

7

= V

9

= 3 V;

I

2

= 2 mA; V

11

= 1 V

0.6

-

V

os

0.7

-

V

os

0.8

-

V

os

V

I

13

input bias current

V

13

= 0 V

-

-

1

µ

A

March 1994

15

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

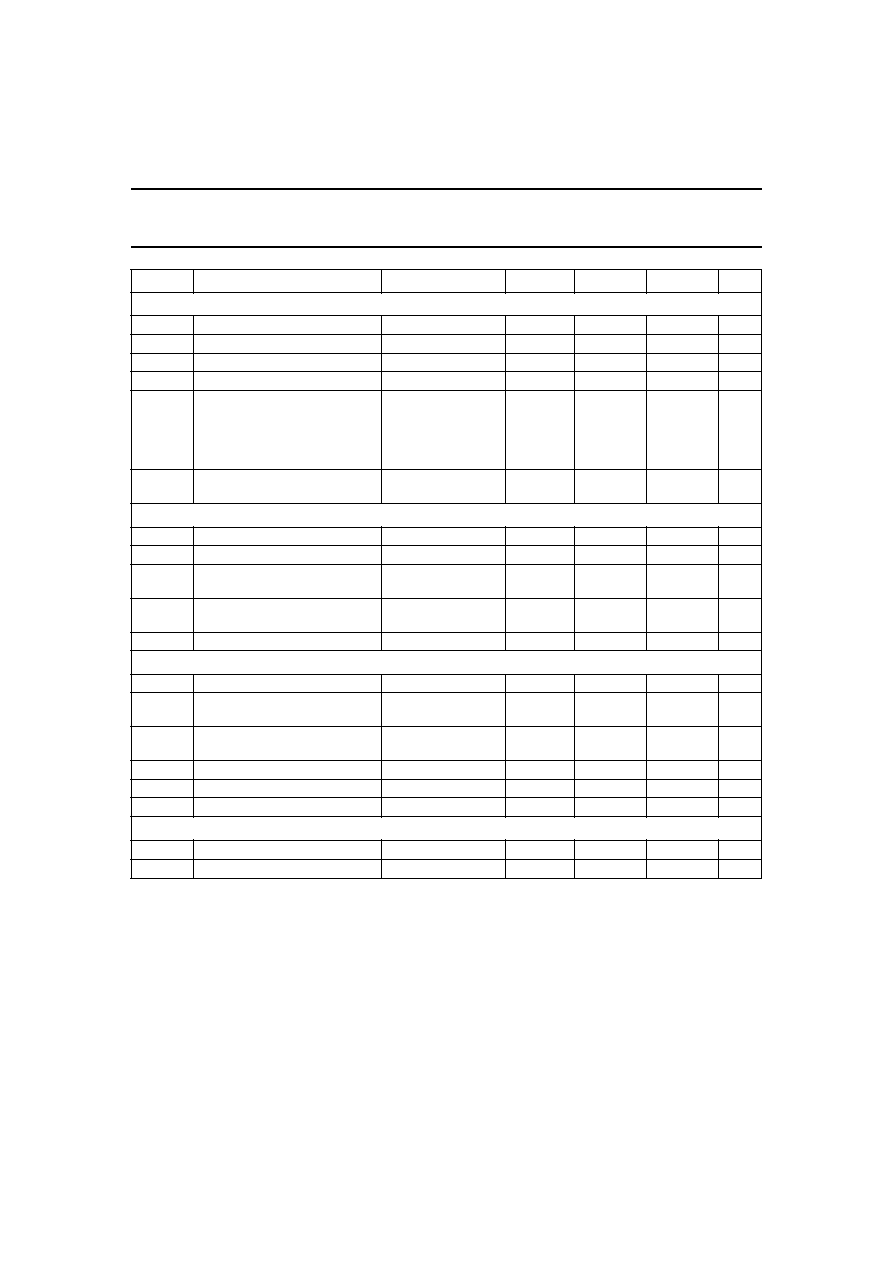

Slow-start

I

7

/I

3

charge current ratio

V

7

= 0.5 V

0.22

0.24

0.26

I

7

quick discharge current

V

7

= 1 V

20

-

-

mA

V

7

= 100 mV

50

-

-

µ

A

V

7

clamping level

I

7

= 100

µ

A

2.8

3.0

3.2

V

V

5

threshold for switching output

(V

ss

)

V

4

= 0.5 V; V

13

= 0 V;

V

7

= 1 V; I

2

= 2 mA;

V

9

= 2 V

1.4

-

V

os

1.5

-

V

os

1.6

-

V

os

V

Output stage

V

2(sat)

saturation voltage

I

2

= 2 mA

-

-

300

mV

I

2

source current

V

2

= 2 V

operating

4.8

5.3

6.3

mA

initialization phase

-

-

50

µ

A

V

2

open output voltage HIGH

I

2

= 5 mA

12

-

-

V

Current simulation

I

5

/I

12

current ratio

V

5

= 1 V; I

12

= 0.5 mA 0.19

0.2

0.21

V

12

simulation input voltage

I

12

= 0.5 mA

-

-

1.1

V

V

5(sat)

saturation voltage

V

15

= V

6

= 0 V;

I

5

= 1 mA

-

-

300

mV

V

15

= V

6

= 0 V;

I

5

= 200

µ

A

-

-

200

mV

V

threshold for switching output;

voltage difference between pins 5

and 11; offset simulation voltage

(V

os

)

V

4

= 0.5 V; V

13

= 0 V;

V

7

= V

9

= 3 V;

I

2

= 2 mA;

V

11

= 0.5 V

60

100

140

mV

Demagnetization input

t

demLH

delay from pin 15 to pin 5

LOW-to-HIGH

see Fig.15;

pin 6 not connected

-

-

500

ns

t

demHL

delay from pin 15 to pin 5

HIGH-to-LOW

see Fig.15

-

-

1

µ

s

V

15

clamping level

I

15

= 10 mA

positive

-

-

1.2

V

negative

-

-

-

1

V

V

15

demagnetization threshold

voltage

90

115

140

mV

C

15

input capacitance

-

-

10

pF

I

15

input bias current

V

15

= 60 mV

-

-

0.5

µ

A

SYMBOL

PARAMETER

CONDITIONS

MIN.

TYP.

MAX.

UNIT

March 1994

16

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

Notes

1. V

os

= V

offset.

2. V

5

pulse = 1 V; V

4

= 0.5 V; V

9

= V

7

= 3 V; V

11

= 0.5 V; V

13

= 0 V; I

2

= 2 mA.

Delay setting

I

6

/I

3

charge current ratio

V

6

= 1 V

1.1

1.2

1.3

I

6

charge current initialization phase V

6

= 1 V; V

16

= 5 V

2

-

-

mA

V

6

clamping level

2.8

-

3.2

V

V

6(sat)

saturation voltage

V

15

= 140 mV

-

50

100

mV

t

dLH

delay from pin 6 to pin 2;

V

6

crossing the 2.5 V level;

LOW-to-HIGH

C

6

= 470 pF;

V

5

= 0 V; I

2

= 2 mA;

V

15

see Fig.15;

excluding capacitive

tolerances

-

-

1.2

µ

s

t/c

delay setting (t = C

6

◊

V/I)

V

6

= 2.5 V;

I

3

= 250

µ

A

-

10

-

ns/pF

Stand-by

V

10H

threshold level HIGH

2.4

2.5

2.6

V

V

10(hys)

hysteresis

450

500

550

mV

t

dLH

delay to output pin 10 to pin 2

LOW-to-HIGH

-

-

1

µ

s

t

dHL

delay to output pin 10 to pin 2

HIGH-to-LOW

-

-

1

µ

s

I

10

input current

V

10

= 2.3 V

-

-

5

µ

A

Over voltage protection

V

8

threshold level

2.4

2.5

2.6

V

t

dLH

delay to output pin 8 to pin 2

LOW-to-HIGH

-

-

1

µ

s

t

dHL

delay to output pin 8 to pin 2

HIGH-to-LOW

-

-

1

µ

s

V

7

reset level

90

-

140

mV

I

7

/I

3

slow discharge current ratio

V

7

= 1 V

0.12

0.23

0.31

I

8

input current

V

8

= 3 V

-

-

1

µ

A

Regulation indicator output

V

1

saturation voltage

I

1

= 1 mA

-

-

300

mV

I

1

leakage current

V

1

= V

16

-

-

1

µ

A

SYMBOL

PARAMETER

CONDITIONS

MIN.

TYP.

MAX.

UNIT

March 1994

17

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

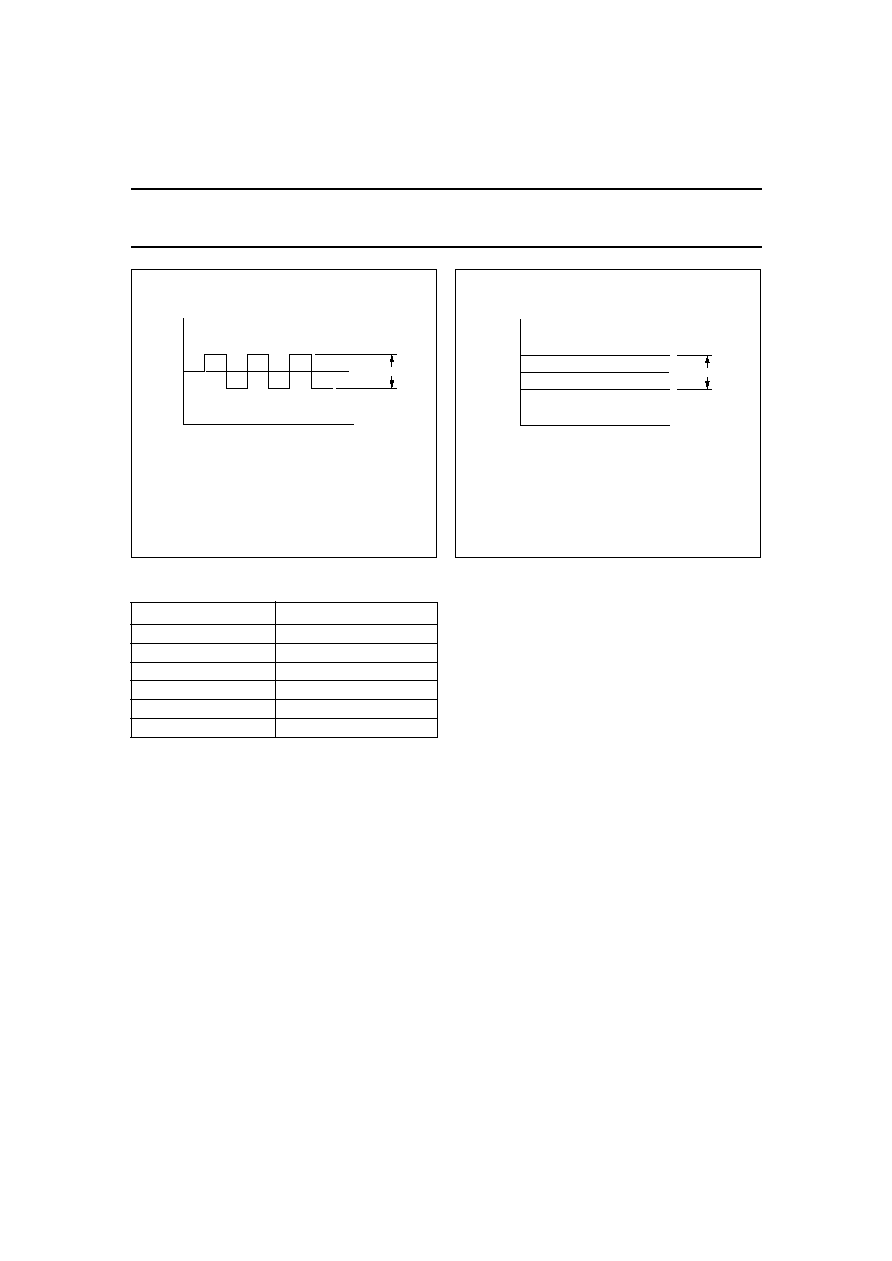

Frequency = 50 kHz.

Slew rate = 0.2

µ

s.

Fig.13 Supply voltage ripple rejection;

V

P

as a function of time.

2 V

15 V

t

V

P

MCD412

Fig.14 Supply voltage ripple rejection;

V

diff

as a function of time.

t

V

diff

MCD413

3 V

~

~

(pin 11)

Frequency = 50 kHz.

Slew rate = 0.2

µ

s.

Table 1 Condition of test circuit used for Figs 13 and 14.

PINS

STATUS

1, 2, 4 to 6, 12, 13

not connected

8 to 10, 14, 15

ground

3

R

ref

= 2.7 k

7

C

ss

= 4.7

µ

F

16

V

P

; see Fig.13

11

V

diff

; see Fig.14

March 1994

18

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

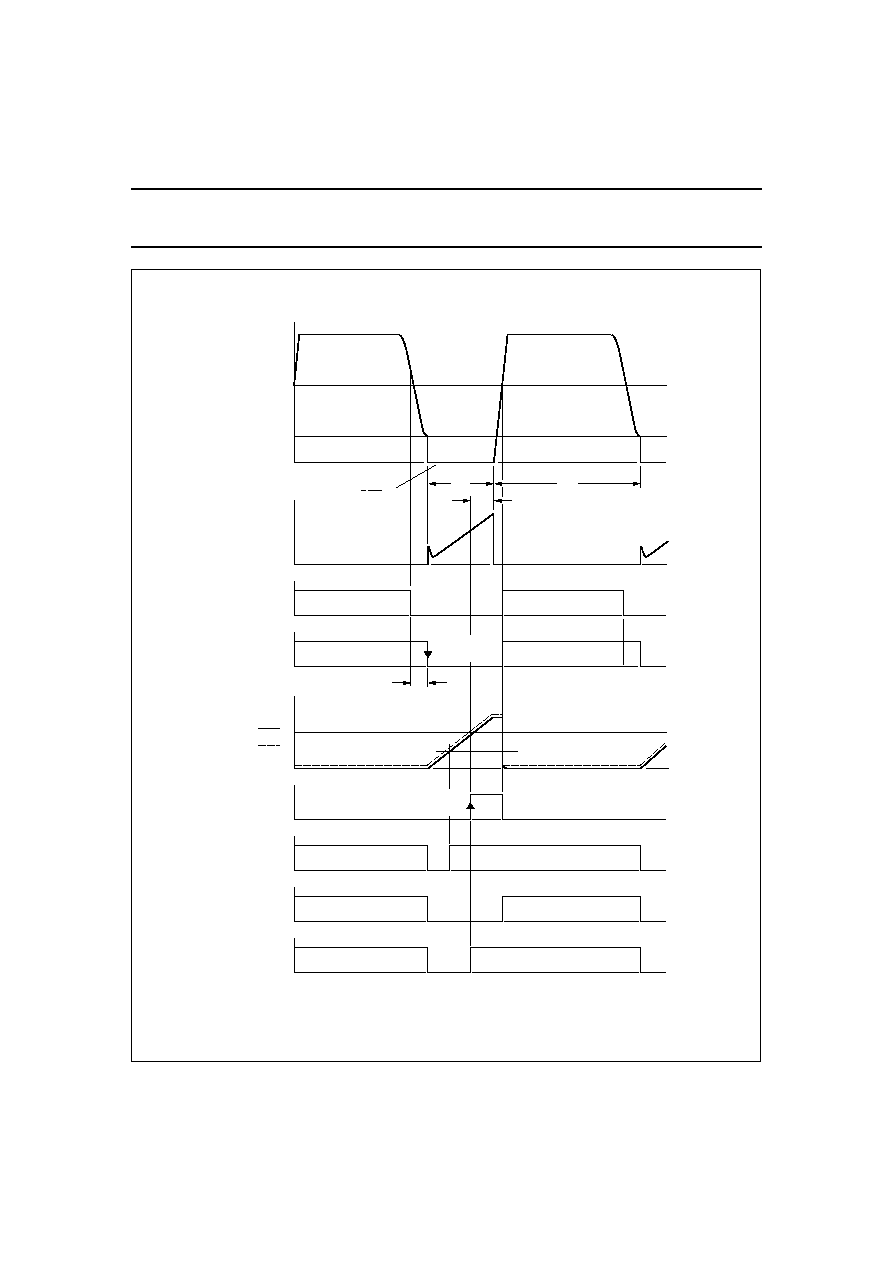

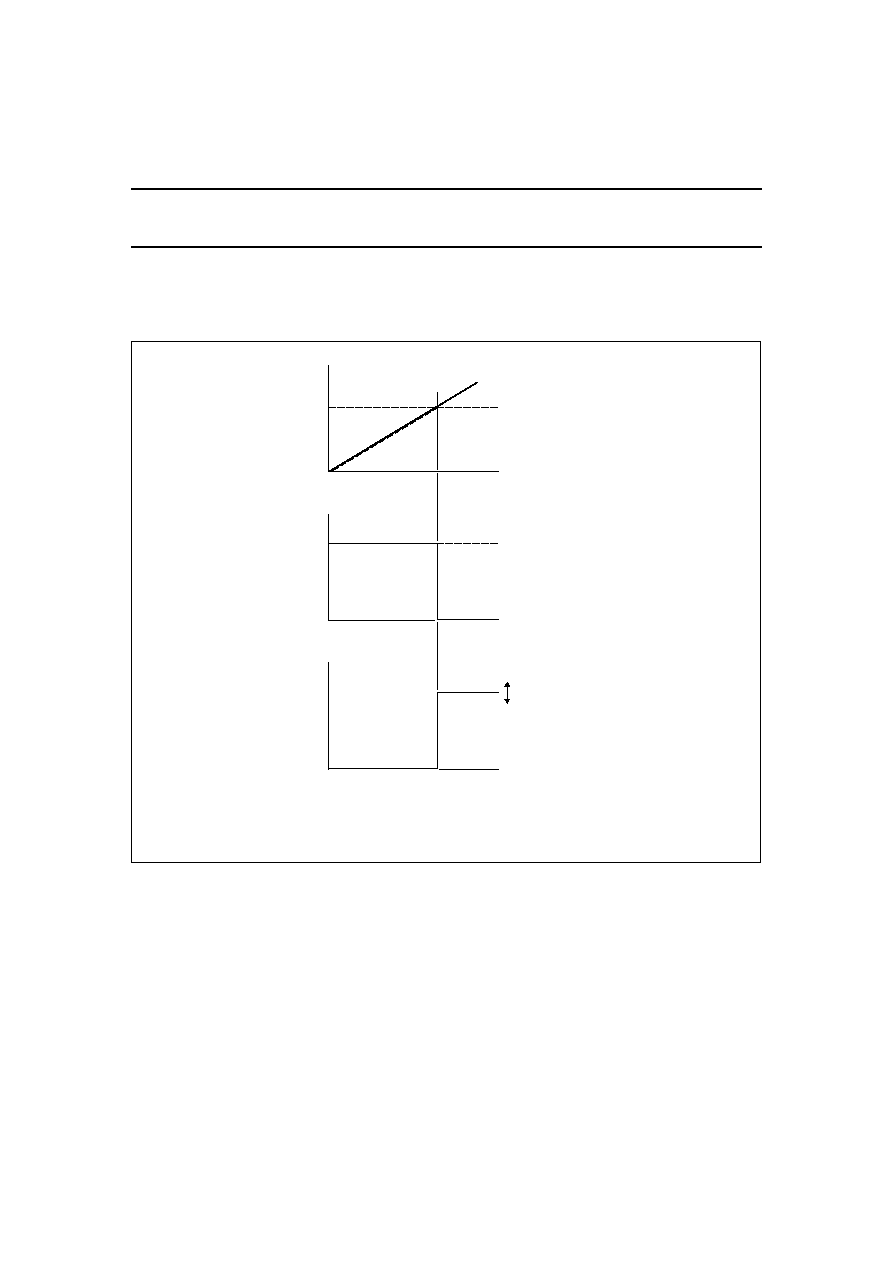

Fig.15 Timing diagram; demagnetization delay time.

handbook, full pagewidth

MCD414

115 mV

90%

10%

t

demLH

demHL

t

~

~ + 0.8 V

0 V

~

~ ≠ 0.8 V

1 V

0 V

peak-current setting input

(pin 5)

demagnetization input

(pin 15)

March 1994

19

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

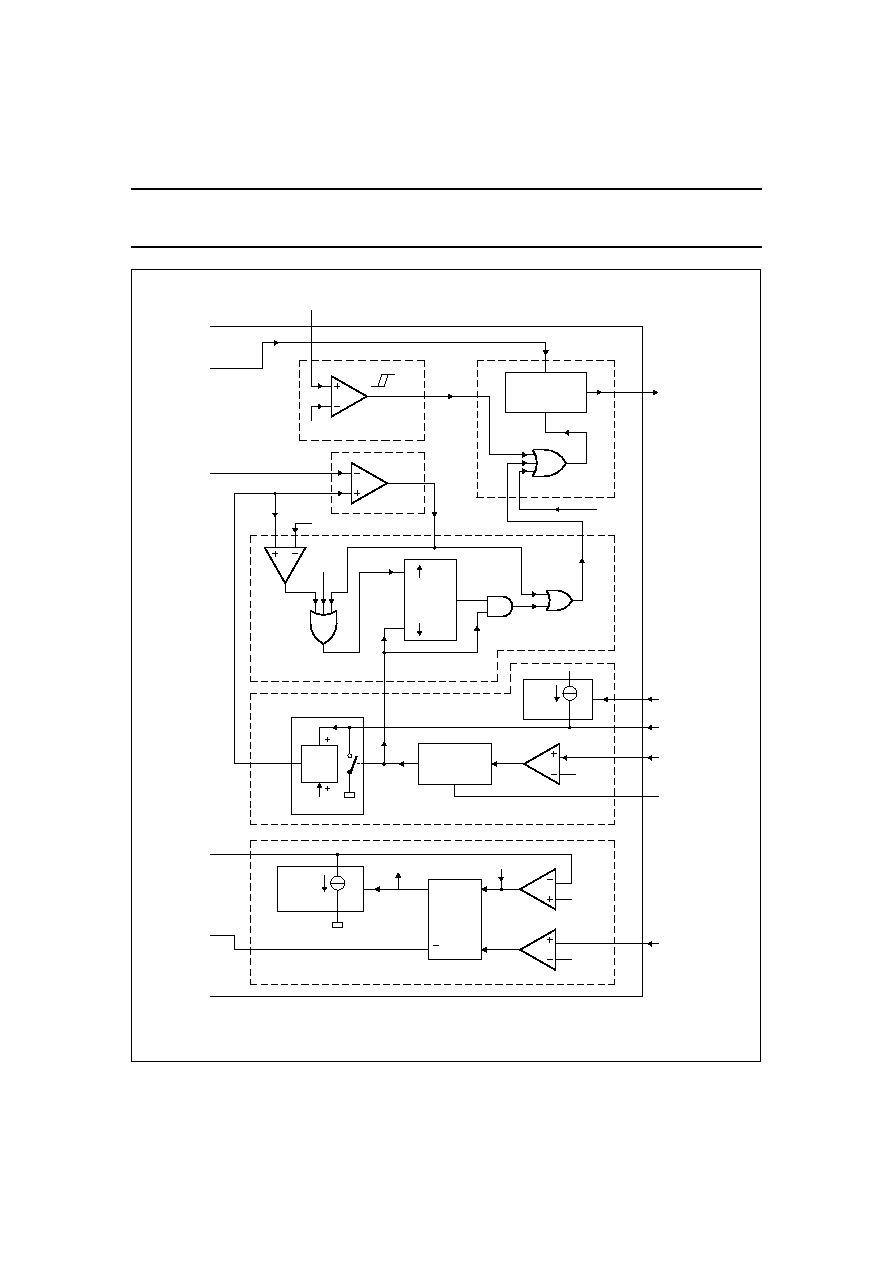

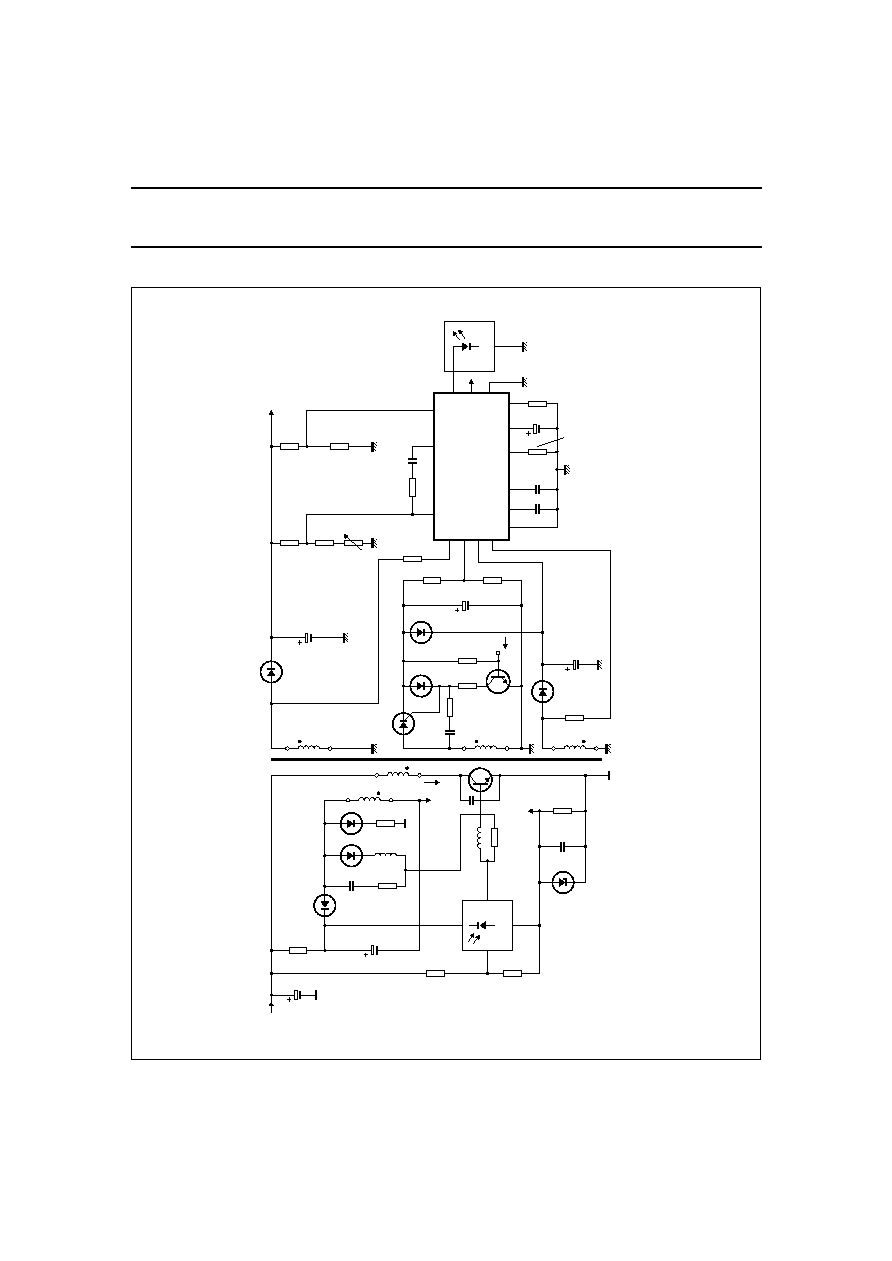

APPLICATION INFORMATION

handbook, full pagewidth

V

O

n

s

V

stab

V

P

C

P

V

f

n

h

1/2 CNR50

n

p

I c

C

o

V

(mains)

I

1/2 CNR50

TDA8385

9

11

8

14

5

6

4

7

3

15

10

16

12

2

1

13

C

ss

R

ref

R

Ton(min)

C

delay

C

R15

R12

RC

TH1

T1

MCD415

A

A

Fig.16 Application circuit of SOPS with stand-by facility.

March 1994

20

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

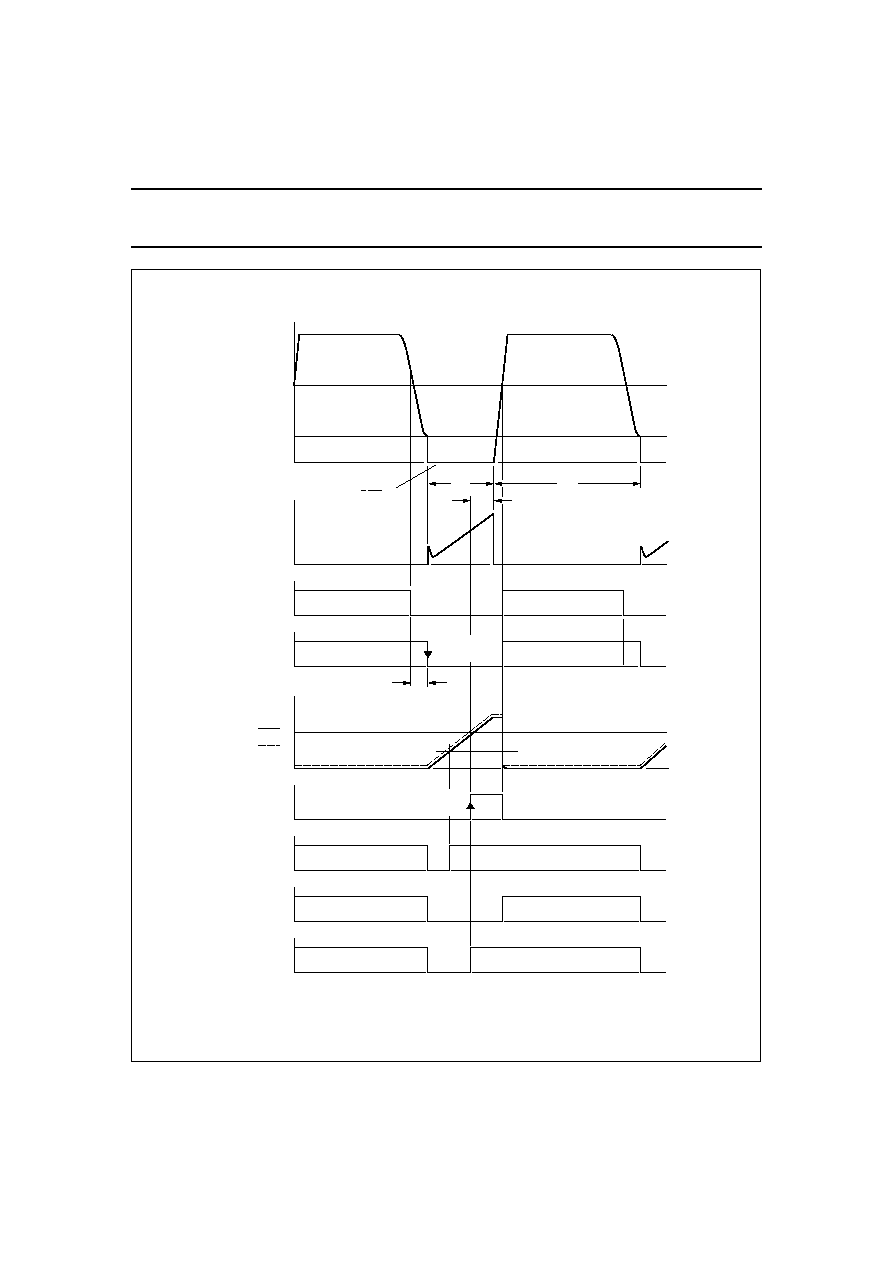

Fig.17 Application timing diagram.

handbook, full pagewidth

output sub-section 11

output sub-section 12

DEMAGNETIZATION

output sub-section 8

COMPARATOR

output sub-section 13

Q

output sub-section 16

DEMAGNETIZATION

output sub-section 14

LED driver

SET

(sub-section 13)

RESET

(sub-section 13)

Toff

Ton

storage time and delay

(SOPS)

delay

Vf

V O

I c

Vsim

Vc

Vr (output sub-section 7)

(output sub-section 10)

Vsim

comparator (18)

level = 1 V

V

I

ns

n p

MCD416

t

March 1994

21

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

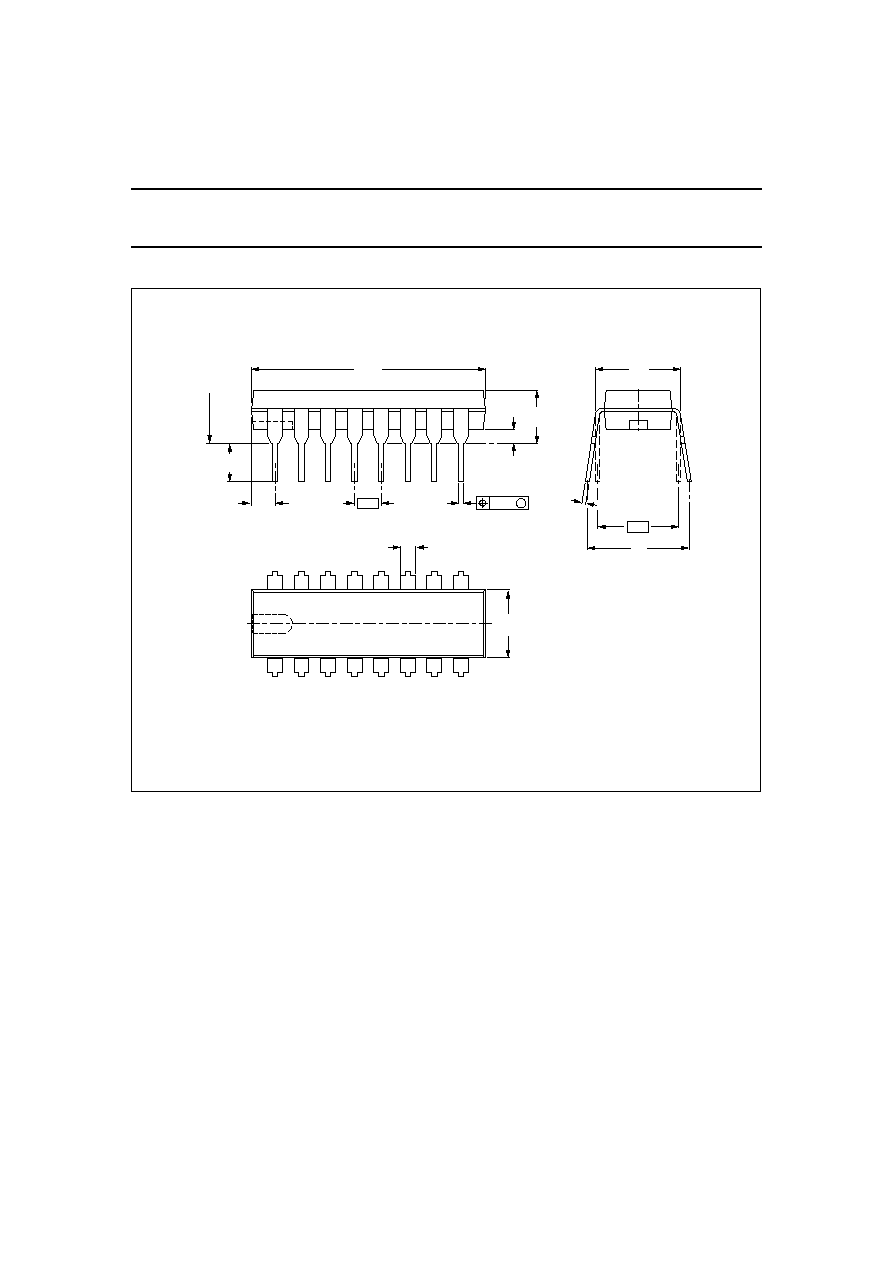

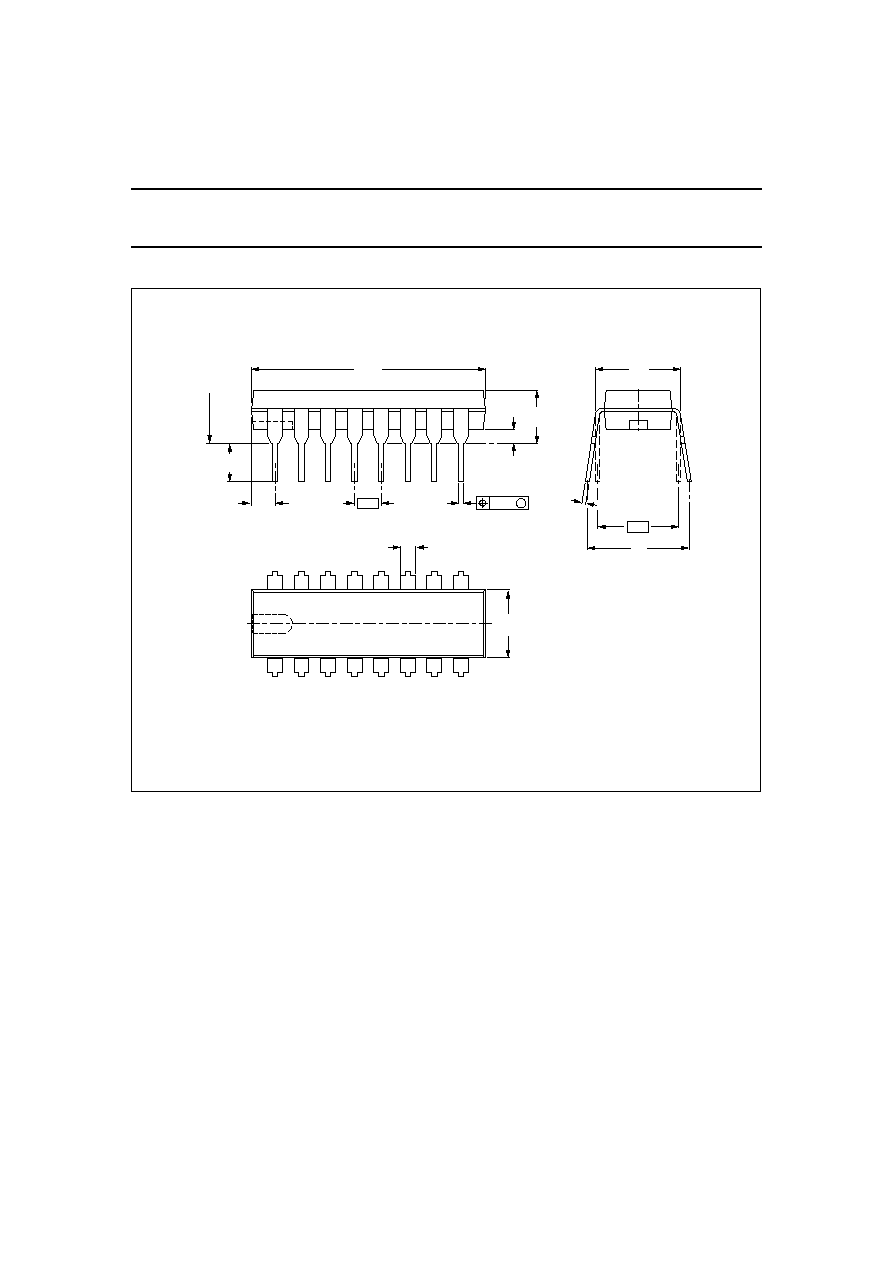

PACKAGE OUTLINE

Fig.18 16-lead dual in-line; plastic with internal heat spreader; opposite bent leads (SOT38WBE).

Dimensions in mm.

8.25

7.80

0.32 max

7.62

9.5

8.3

MSA349

16

1

9

8

1.4 max

6.48

6.14

22.00

21.35

5.1

max

1.2 min

3.9

3.4

seating plane

0.254

M

0.53

max

2.54

(14x)

2.2

max

March 1994

22

Philips Semiconductors

Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

SOLDERING

Plastic dual in-line packages

B

Y DIP OR WAVE

The maximum permissible

temperature of the solder is 260

∞

C;

this temperature must not be in

contact with the joint for more than

5 s. The total contact time of

successive solder waves must not

exceed 5 s.

The device may be mounted up to the

seating plane, but the temperature of

the plastic body must not exceed the

specified storage maximum. If the

printed-circuit board has been

pre-heated, forced cooling may be

necessary immediately after

soldering to keep the temperature

within the permissible limit.

R

EPAIRING SOLDERED JOINTS

Apply a low voltage soldering iron

below the seating plane (or not more

than 2 mm above it). If its temperature

is below 300

∞

C, it must not be in

contact for more than 10 s; if

between 300 and 400

∞

C, for not

more than 5 s.

DEFINITIONS

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

Data sheet status

Objective specification

This data sheet contains target or goal specifications for product development.

Preliminary specification

This data sheet contains preliminary data; supplementary data may be published later.

Product specification

This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.