| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: PKFC15C | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

PKFC3.3C*

thru

PKFC36C*

1

05180.R3 12/05

www.protekdevices.com

PACKAGED FLIP CHIP ARRAY

Only One Name Means ProTek'TionTM

*PATENT PENDING"

APPLICATIONS

Cellular Phones

MCM Boards

Wireless Communication Circuits

IR LEDs

SMART & PCMCIA Cards

IEC COMPATIBILITY (EN61000-4)

61000-4-2 (ESD): Air - 15kV, Contact - 8kV

61000-4-4 (EFT): 40A - 5/50ns

FEATURES

CHIP SCALE PACKAGE 0.050" (1.270mm) x 0.030" (0.762mm)

ESD Protection > 25 kilovolts

Available in Multiple Voltage Types Ranging From 3.3V to 36V

250 Watts Peak Pulse Power per Line (tp = 8/20µs)

Bidirectional Configuration & Monolithic Structure

Protects 1 Line

RoHS Compliant in Lead-Free Versions

MECHANICAL CHARACTERISTICS

Encapsulated 0502 Chip

Weight 0.73 milligrams (Approximate)

Available in Tin-Lead or Lead-Free Pure-Tin Plating(Annealed)

Solder Reflow Temperature:

Tin-Lead - Sn/Pb, 85/15: 240-245∞C

Pure-Tin - Sn, 100: 260-270∞C

Flammability Rating UL 94V-0

8mm Plastic & Paper Tape and Reel Per EIA Standard 481

Device Marking On Reel

05180

PIN CONFIGURATION

2

www.protekdevices.com

05180.R3 12/05

PKFC3.3C*

thru

PKFC36C*

*PATENT PENDING

DEVICE CHARACTERISTICS

MAXIMUM RATINGS @ 25∞C Unless Otherwise Specified

Operating Temperature

SYMBOL

VALUE

-55∞C to 150∞C

∞C

∞C

-55∞C to 150∞C

UNITS

T

J

T

STG

PARAMETER

Storage Temperature

Peak Pulse Power (t

p

= 8/20µs) - See Figure 1

P

PP

250

Watts

0 5 10 15 20 25 30

t - Time - µs

0

20

40

60

80

100

120

I

PP

- Peak Pulse Current - % of I

PP

TEST

WAVEFORM

PARAMETERS

t

f

= 8µs

t

d

= 20µs

t

f

Peak Value I

PP

e

-t

t

d

= t

I

PP

/2

FIGURE 2

PULSE WAVE FORM

0.01 1 10 100 1,000 10,000

t

d

- Pulse Duration - µs

10

100

1,000

10,000

P

PP

- Peak Pulse Current - Watts

FIGURE 1

PEAK PULSE POWER VS PULSE TIME

250W, 8/20µs Waveform

ELECTRICAL CHARACTERISTICS PER LINE @ 25∞C Unless Otherwise Specified

PART

NUMBER

(See Note 1)

MINIMUM

BREAKDOWN

VOLTAGE

@ 1mA

V

(BR)

VOLTS

MAXIMUM

CLAMPING

VOLTAGE

(See Fig. 2)

@ I

P

= 1A

V

C

VOLTS

MAXIMUM

CLAMPING

VOLTAGE

(See Fig. 2)

@8/20µs

V

C

@ I

PP

TYPICAL

CAPACITANCE

@0V, 1 MHz

C

pF

PKFC3.3C

PKFC05C

PKFC08C

PKFC12C

PKFC15C

PKFC24C

PKFC36C

3.3

5.0

8.0

12.0

15.0

24.0

36.0

4.0

6.0

8.5

13.3

16.7

26.7

40.0

7.0

9.8

13.4

19.0

24.0

43.0

64.0

12.5V @ 20A

14.7V @ 17A

19.2V @ 13A

29.7V @ 9.0A

35.7V @ 7.0A

55.0V @ 5.0A

84.0V @ 3.0A

150

100

75

50

40

30

25

MAXIMUM

LEAKAGE

CURRENT

(See Note 2)

@V

WM

I

D

µA

75*

10**

10***

1

1

1

1

RATED

STAND-OFF

VOLTAGE

V

WM

VOLTS

Note 1: All devices are bidirectional. Electrical characteristics apply in both directions.

Note 2: *Typical leakage current < 5µA @ 2.8V. **Typical leakage current <500nA @ 3.3V. ***Typical leakage current <200nA @ 5V.

DEVICE

MARKING

CODE

03

05

08

12

15

24

36

3

www.protekdevices.com

05180.R3 12/05

PKFC3.3C*

thru

PKFC36C*

*PATENT PENDING

GRAPHS

0 25 50 75 100 125 150

T

L

- Lead Temperature - ∞C

20

40

60

80

100

% Of Rated Power

Peak Pulse Power

8/20µs

Average Power

FIGURE 3

POWER DERATING CURVE

0

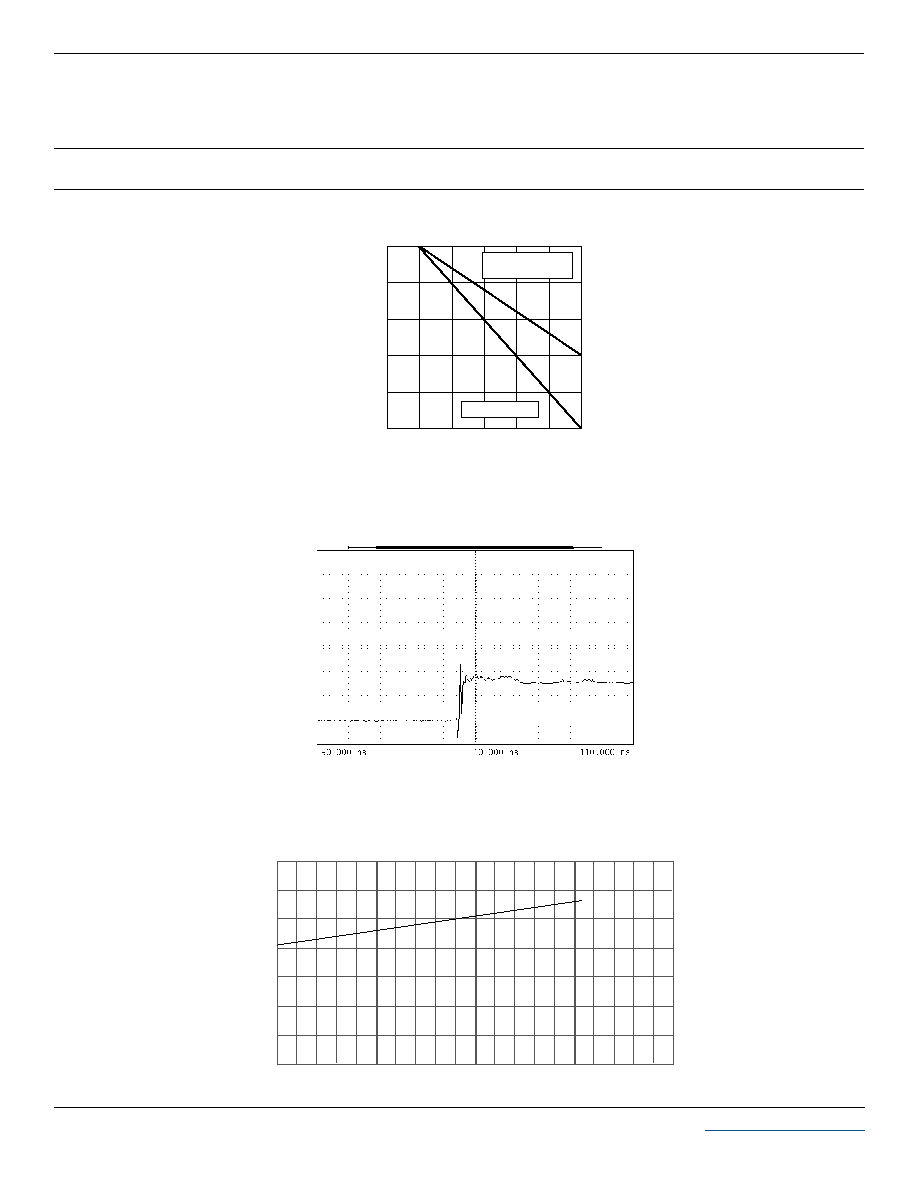

ESD Test Pulse - 25 kilovolt, 1/30ns (waveshape)

FIGURE 4

OVERSHOOT & CLAMPING VOLTAGE FOR PKFC05C

5 Volts per Division

-5

5

15

25

35

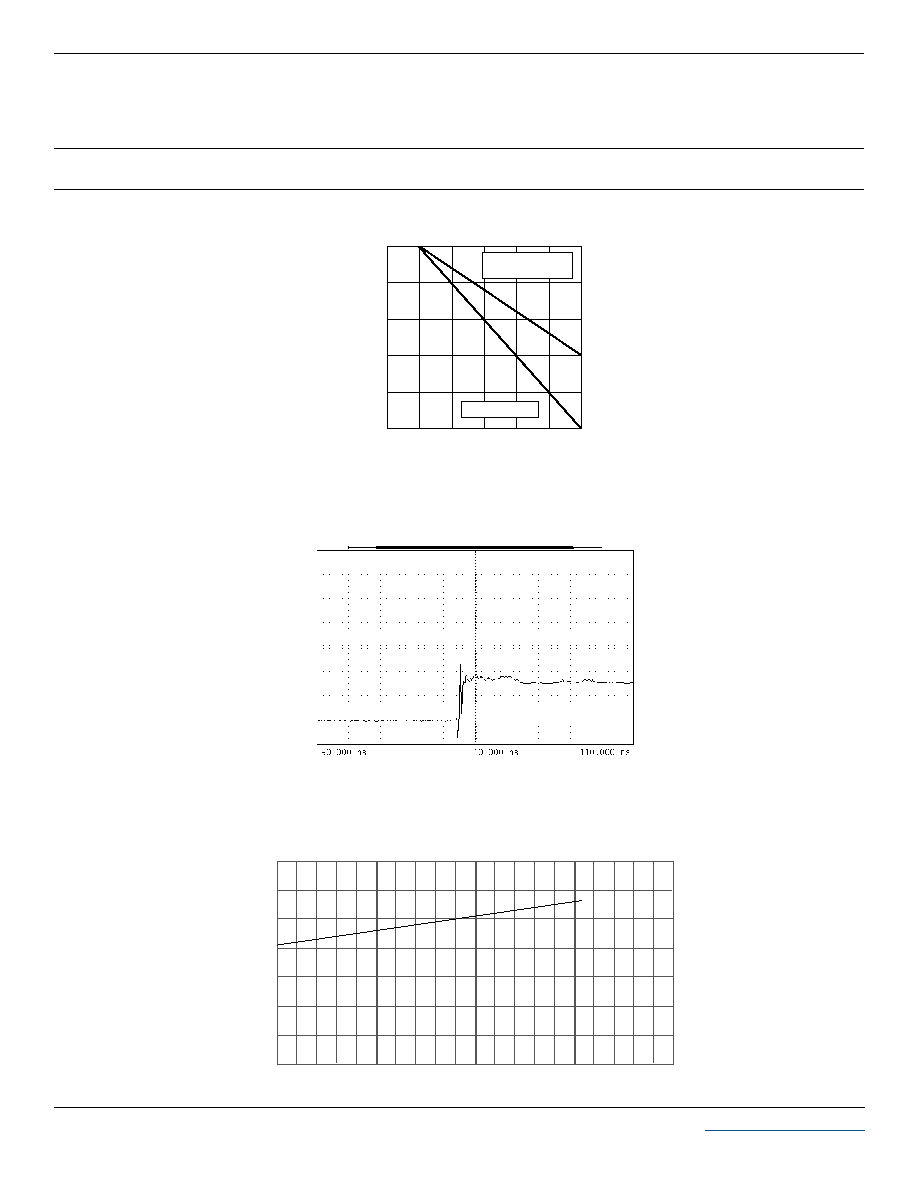

0 5 10 15 20

V

C

- Clamping Voltage - Volts

0

4

8

12

14

FIGURE 5

TYPICAL CLAMPING VOLTAGE VS PEAK PULSE CURRENT FOR PKFC05C

10

6

2

I

PP

- Peak Pulse Current - Amps

4

www.protekdevices.com

05180.R3 12/05

PKFC3.3C*

thru

PKFC36C*

*PATENT PENDING

APPLICATION INFORMATION

Ramp-up

Ramp-down

Ramp-up

15 seconds

Solder Time

15-20 seconds

Ramp-down

T

S

- Preheat

T

SMAX

T

SMIN

T

L

t 25∞C to Peak

30-60 seconds

T

emperature - ∞C

T

P

155∞

140∞

0.275mm

Round

Non-Solder Mask Defined Pads

0.325mm Round

0.150mm

0.330mm Round

No Clean

OSP(Entek Cu Plus 106A)

±50µm

±20µm

60 Seconds

270∞C

Pad Size on PCB

Pad Shape

Pad Definition

Solder Mask Opening

Solder Stencil Thickness

Solder Stencil Aperture Opening (laser cut, 5% tapered walls)

Solder Paste Type

Pad Protective Finish

Tolerance - Edge To Corner Ball

Solder Ball Side Coplanarity

Maximum Dwell Time Above Liquidous (183∞C)

Soldering Maximum Temperature

PRINTED CIRCUIT BOARD RECOMMENDATIONS

PARAMETER

VALUE

REQUIREMENTS

Temperature:

T

P

for Lead-Free (SnAgCu): 260-270∞C

T

P

for Tin-Lead: 240-245∞C

Preheat time and temperature depends on solder paste and flux

activation temperature, component size, weight, surface area &

plating.

RECOMMENDED NON-SOLDER MASK

DEFINED PAD ILLUSTRATION

Non-Solder Mask Defined Pad

0.275mm DIA.

Solder Mask Opening

0.325mm DIA.

Solder Stencil Opening

0.330mm DIA.

5

www.protekdevices.com

05180.R3 12/05

PKFC3.3C*

thru

PKFC36C*

*PATENT PENDING

PACKAGE OUTLINE & DIMENSIONS

COPYRIGHT © ProTek Devices 2005

SPECIFICATIONS: ProTek reserves the right to change the electrical and or mechanical characteristics described herein without notice (except

JEDEC).

DESIGN CHANGES: ProTek reserves the right to discontinue product lines without notice, and that the final judgement concerning selection and

specifications is the buyer's and that in furnishing engineering and technical assistance, ProTek assumes no responsibility with respect to the

selection or specifications of such products.

NOTES

1. Controlling dimensions in inches.

2. Decimal tolerances for mounting pad : ± 0.003" (± 0.08mm).

3. Maximum size: 0.052" (1.321mm) by 0.036" (0.914mm).

4. All dimensions ±0.003" on package outline.

PACKAGE OUTLINE

MOUNTING PAD

DIM

MILLIMETERS

INCHES

PACKAGE DIMENSIONS

A

B

C

D

E

F

G

H

J

K

0.73

1.22

0.73

0.54

0.10

0.55

0.27

0.38

0.35

0.35

0.029

0.048

0.029

0.021

0.004

0.022

0.011

0.015

0.014

0.014

DIM

MILLIMETERS

INCHES

PAD DIMENSIONS

A

B

C

E

F

G

J

1.00

0.62

1.44

0.18

0.49

0.31

0.31

0.040

0.025

0.058

0.008

0.020

0.013

0.013

TAPE & REEL ORDERING NOMENCLATURE

1. Surface mount product is taped and reeled in accordance with EIA 481.

2.

8mm Plastic Tape: 7 Inch Reels - 5,000 pieces per reel. Ordering Suffix: -T75-1 (i.e., PKFC05C-T75-1).

3. Suffix - LF = Lead-Free, Pure-Tin Plating, i.e.,

PKFC05C-LF-T75-1.

Outline & Dimensions: Rev 1 - 8/03, 06040

TAPE & REEL ORIENTATION

NOTE

1. Top view of tape. Solder PADS face down in tape package.

ProTek Devices

2929 South Fair Lane, Tempe, AZ 85282

Tel: 602-431-8101 Fax: 602-431-2288

E-Mail:

sales@protekdevices.com

Web Site:

www.protekdevices.com

A

TOP

BOTTOM

SIDE

H

C

G

J

D

F

E

B

K

A

F

G

Solder Print Diameter

0.010" - 0.012"

J

B

C

E

Package Contact Pads

Package Outline

0.76

1.27

0.76

0.57

0.13

0.58

0.30

0.41

0.38

0.38

0.79

1.32

0.79

0.60

0.16

0.61

0.33

0.44

0.41

0.41

0.030

0.050

0.030

0.023

0.005

0.023

0.012

0.016

0.015

0.015

0.031

0.052

0.031

0.024

0.006

0.024

0.013

0.017

0.016

0.016

MIN

MIN

MAX

NOM

MAX

NOM

MIN

MIN

MAX

NOM

MAX

NOM

1.02

0.64

1.47

0.20

0.51

0.33

0.33

1.04

0.66

1.50

0.22

0.53

0.35

0.35

0.039

0.024

0.056

0.007

0.019

0.012

0.012

0.041

0.026

0.060

0.009

0.021

0.014

0.014

XX

Top cover tape

K0

t

D

P0

P2

10 Pitches Cumulative

Tolerance on Tape. ± 0.2

A0

B0

P

E

F

W

User Direction of Feed

Tape & Reel Specifications (Dimensions in millimeters)

D

E

P0

t

F

P2

W

1.50 ± 0.10 1.75 ± 0.10 3.50 ± 0.05 8.00 ±0.30 4.00 ±0.10 2.00 ±0.05

P

4.00 ±0.10 0.20±0.025

A0

B0

K0

Reel Dia.

Tape Width

178mm (7")

8mm

1.08 ± 0.05 1.60 ± 0.05 0.72 ± 0.05