| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: QT110-IS | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

APPLICATIONS -

!

Elevator buttons

!

Toys & games

!

Access systems

!

Pointing devices

!

Appliance control

!

Security systems

!

Light switches

!

Industrial panels

The QT110 / QT110H charge-transfer ("QT'") touch sensor is a self-contained digital IC capable of detecting near-proximity or touch.

It will project a sense field through almost any dielectric, like glass, plastic, stone, ceramic, and most kinds of wood. It can also turn

small metal-bearing objects into intrinsic sensors, making them respond to proximity or touch. This capability coupled with its ability

to self calibrate continuously can lead to entirely new product concepts.

It is designed specifically for human interfaces, like control panels, appliances, toys, lighting controls, or anywhere a mechanical

switch or button may be found; it may also be used for some material sensing and control applications provided that the presence

duration of objects does not exceed the recalibration timeout interval.

The IC requires only a common inexpensive capacitor in order to function. A bare piezo beeper can be connected to create a `tactile'

feedback clicking sound; the beeper itself then doubles as the required external capacitor, and it can also become the sensing

electrode. An LED can also be added to provide visual sensing indication. With a second inexpensive capacitor the device can

operated in 2-wire mode, where both power and signal traverse the same wire pair to a host. This mode allows the sensor to be wired

to a controller with only a twisted pair over a long distances.

Power consumption is under 20

µ

A in most applications, allowing operation from Lithium cells for many years. In most cases the

power supply need only be minimally regulated.

The IC's RISC core employs signal processing techniques pioneered by Quantum; these are specifically designed to make the device

survive real-world challenges, such as `stuck sensor' conditions and signal drift. Even sensitivity is digitally determined and remains

constant in the face of large variations in sample capacitor C

S

and electrode C

X

. No external switches, opamps, or other analog

components aside from C

S

are usually required.

The device includes several user-selectable built in features. One, toggle mode, permits on/off touch control, for example for light

switch replacement. Another makes the sensor output a pulse instead of a DC level, which allows the device to 'talk' over the power

rail, permitting a simple 2-wire interface. The Quantum-pioneered HeartBeatTM signal is also included, allowing a host controller to

monitor the health of the QT110 continuously if desired. By using the charge transfer principle, the IC delivers a level of performance

clearly superior to older technologies in a highly cost-effective package.

Quantum Research Group Ltd

Copyright © 1999 Quantum Research Group Ltd

R1.02/0109

!

!

!

!

Less expensive than many mechanical switches

!

!

!

!

Projects a `touch button' through any dielectric

!

!

!

!

Turns small objects into intrinsic touch sensors

!

!

!

!

100% autocal for life - no adjustments required

!

!

!

!

Only one external part required - a 1¢ capacitor

!

!

!

!

Piezo sounder direct drive for `tactile' click feedback

!

!

!

!

LED drive for visual feedback

!

!

!

!

2.5 to 5V 20

µ

µ

µ

µ

A single supply operation

!

!

!

!

Toggle mode for on/off control (strap option)

!

!

!

!

10s or 60s auto-recalibration timeout (strap option)

!

!

!

!

Pulse output mode (strap option)

!

!

!

!

Gain settings in 3 discrete levels

!

!

!

!

Simple 2-wire operation possible

!

!

!

!

HeartBeatTM health indicator on output

!

!

!

!

Active Low (QT110), Active High (QT110H) versions

-

QT110H-IS

-40

0

C to +85

0

C

-

QT110-IS

-40

0

C to +85

0

C

QT110H-D

QT110H-S

0

0

C to +70

0

C

QT110-D

QT110-S

0

0

C to +70

0

C

8-PIN DIP

SOIC

T

A

AVAILABLE OPTIONS

QProxTM

TM

TM

TM QT110 / QT110H

C

HARGE

-T

RANSFER

T

OUCH

S

ENSOR

Sns2

Vss

Sns1

Gain

Opt2

Opt1

Out

Vdd

1

2

3

4

5

6

7

8

Q

T

110

1 - OVERVIEW

The QT110 is a digital burst mode charge-transfer (QT)

sensor designed specifically for touch controls; it includes all

hardware and signal processing functions necessary to

provide stable sensing under a wide variety of changing

conditions. Only a single low cost, non-critical capacitor is

required for operation.

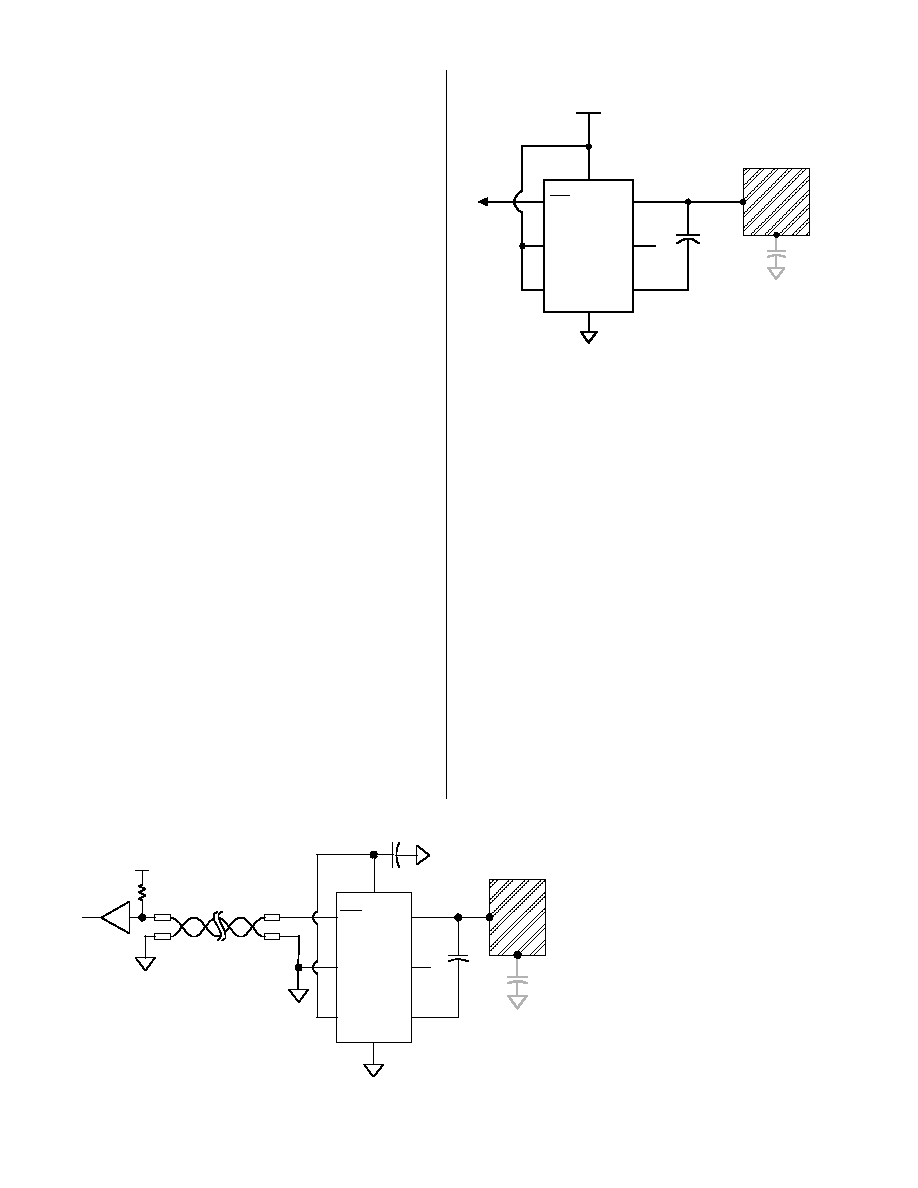

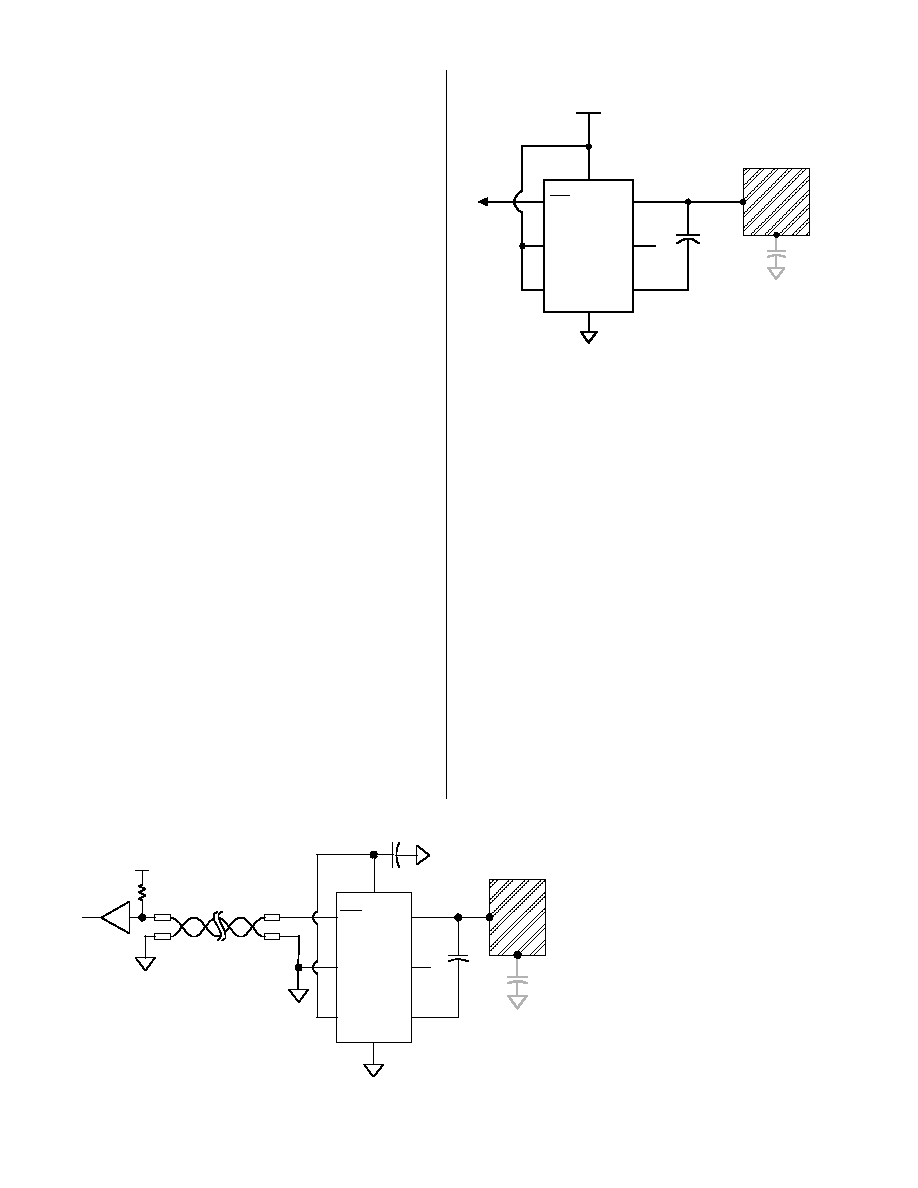

Figure 1-1 shows the basic QT110 circuit using the device,

with a conventional output drive and power supply

connections. Figure 1-2 shows a second configuration using

a common power/signal rail which can be a long twisted pair

from a controller; this configuration uses the built-in pulse

mode to transmit output state to the host controller (QT110

only).

1.1 BASIC OPERATION

The QT110 employs short, ultra-low duty cycle bursts of

charge-transfer cycles to acquire its signal. Burst mode

permits power consumption in the low microamp range,

dramatically reduces RF emissions, lowers susceptibility to

EMI, and yet permits excellent response time. Internally the

signals are digitally processed to reject impulse noise, using

a 'consensus' filter which requires four consecutive

confirmations of a detection before the output is activated.

The QT switches and charge measurement hardware

functions are all internal to the QT110 (Figure 1-3). A 14-bit

single-slope switched capacitor ADC includes both the

required QT charge and transfer switches in a configuration

that provides direct ADC conversion. The ADC is designed to

dynamically optimize the QT burst length according to the

rate of charge buildup on Cs, which in turn depends on the

values of Cs, Cx, and Vdd. Vdd is used as the charge

reference voltage. Larger values of Cx cause the charge

transferred into Cs to rise more rapidly, reducing available

resolution; as a minimum resolution is required for proper

operation, this can result in dramatically reduced apparent

gain. Conversely, larger values of Cs reduce the rise of

differential voltage across it, increasing available resolution

by permitting longer QT bursts. The value of Cs can thus be

increased to allow larger values of Cx to be tolerated

(Figures 4-1, 4-2, 4-3 in Specifications, rear).

The IC is highly tolerant of changes in Cs since it computes

the threshold level ratiometrically with respect to absolute

load, and does so dynamically at all times.

Cs is thus non-critical; as it drifts with temperature, the

threshold algorithm compensates for the drift automatically.

A simple circuit variation is to replace Cs with a bare piezo

sounder (Section 2), which is merely another type of

capacitor, albeit with a large thermal drift coefficient. If C

piezo

is in the proper range, no other external component is

required. If C

piezo

is too small, it can simply be `topped up'

with an inexpensive ceramic capacitor connected in parallel

with it. The QT110 drives a 4kHz signal across SNS1 and

SNS2 to make the piezo (if installed) sound a short tone for

75ms immediately after detection, to act as an audible

confirmation.

Option pins allow the selection or alteration of several

special features and sensitivity.

1.2 ELECTRODE DRIVE

The internal ADC treats Cs as a floating transfer capacitor;

as a direct result, the sense electrode can be connected to

either SNS1 or SNS2 with no performance difference. In both

cases the rule Cs >> Cx must be observed for proper

operation. The polarity of the charge buildup across Cs

during a burst is the same in either case.

It is possible to connect separate Cx and

Cx' loads to SNS1 and SNS2

simultaneously, although the result is no

different than if the loads were

connected together at SNS1 (or SNS2).

It is important to limit the amount of

stray capacitance on both terminals,

especially if the load Cx is already large,

for example by minimizing trace lengths

and widths so as not to exceed the Cx

load specification and to allow for a

larger sensing electrode size if so

desired.

The PCB traces, wiring, and any

components associated with or in

contact with SNS1 and SNS2 will

become touch sensitive and should be

- 2 -

Figure 1-1 Standard mode options

S E NS ING

E LEC TRO DE

C

s

1 0nF

3

4

6

5

1

+2.5 to 5

7

2

OU T

OP T1

OP T2

G A IN

S NS1

S NS2

Vss

Vdd

OU TP UT=D C

TIM EO UT= 10 S ecs

TOGG LE=OF F

GA IN= HIGH

C

x

8

Figure 1-2 2-wire operation, self-powered (QT110 only)

C

x

+

22 µF 10V AL

10 nF

C M O S

GATE

+3V

2.2k

Tw isted

pair

C

s

8

S E NS IN G

E LE C TRO DE

O UT

O PT1

O PT2

G A IN

S NS 1

S NS 2

V ss

V dd

3

4

6

5

1

7

2

treated with caution to limit the touch

area to the desired location. Multiple

touch electrodes can be used, for

example to create a control button on

both sides of an object, however it is

impossible for the sensor to distinguish

between the two touch areas.

1.3 ELECTRODE DESIGN

1.3.1 E

LECTRODE

G

EOMETRY

AND

S

IZE

There is no restriction on the shape of

the electrode; in most cases common

sense and a little experimentation can

result in a good electrode design. The

QT110 will operate equally well with

long, thin electrodes as with round or

square ones; even random shapes are

acceptable. The electrode can also be

a 3-dimensional surface or object.

Sensitivity is related to electrode

surface area, orientation with respect

to the object being sensed, object composition, and the

ground coupling quality of both the sensor circuit and the

sensed object.

If a relatively large electrode surface is desired, and if tests

show that the electrode has more capacitance than the

QT110 can tolerate, the electrode can be made into a sparse

mesh (Figure 1-4) having lower Cx than a solid plane.

Sensitivity may even remain the same, as the sensor will be

operating in a lower region of the gain curves.

1.3.2 K

IRCHOFF

'

S

C

URRENT

L

AW

Like all capacitance sensors, the QT110 relies on Kirchoff's

Current Law (Figure 1-5) to detect the change in capacitance

of the electrode. This law as applied to capacitive sensing

requires that the sensor's field current must complete a loop,

returning back to its source in order for capacitance to be

sensed. Although most designers relate to Kirchoff's law with

regard to hardwired circuits, it applies equally to capacitive

field flows. By implication it requires that the signal ground

and the target object must both be coupled together in some

manner for a capacitive sensor to operate properly. Note that

there is no need to provide actual hardwired ground

connections; capacitive coupling to ground (Cx1) is always

sufficient, even if the coupling might seem very tenuous. For

example, powering the sensor via an isolated transformer

will provide ample ground coupling, since there is

capacitance between the windings and/or the transformer

core, and from the power wiring itself directly to 'local earth'.

Even when battery powered, just the physical size of the

PCB and the object into which the electronics is embedded

will generally be enough to couple a few picofarads back to

local earth.

1.3.3 V

IRTUAL

C

APACITIVE

G

ROUNDS

When detecting human contact (e.g. a fingertip), grounding

of the person is never required. The human body naturally

has several hundred picofarads of `free space' capacitance

to the local environment (Cx3 in Figure 1-5), which is more

than two orders of magnitude greater than that required to

create a return path to the QT110 via earth. The QT110's

PCB however can be physically quite small, so there may be

little `free space' coupling (Cx1 in Figure 1-5) between it and

the environment to complete the return path. If the QT110

circuit ground cannot be earth grounded by wire, for example

via the supply connections, then a `virtual capacitive ground'

may be required to increase return coupling.

- 3 -

Figure 1-3 Internal Switching & Timing

C

s

C

x

SNS2

SNS1

ELE C TRO DE

S

i

ng

le

-

S

lo

p

e

1

4

-

b

i

t

S

w

i

t

c

h

e

d

C

a

p

a

c

i

to

r

A

D

C

Charge

Am p

Bu

rst

C

o

n

t

ro

l

l

e

r

Result

Do ne

Start

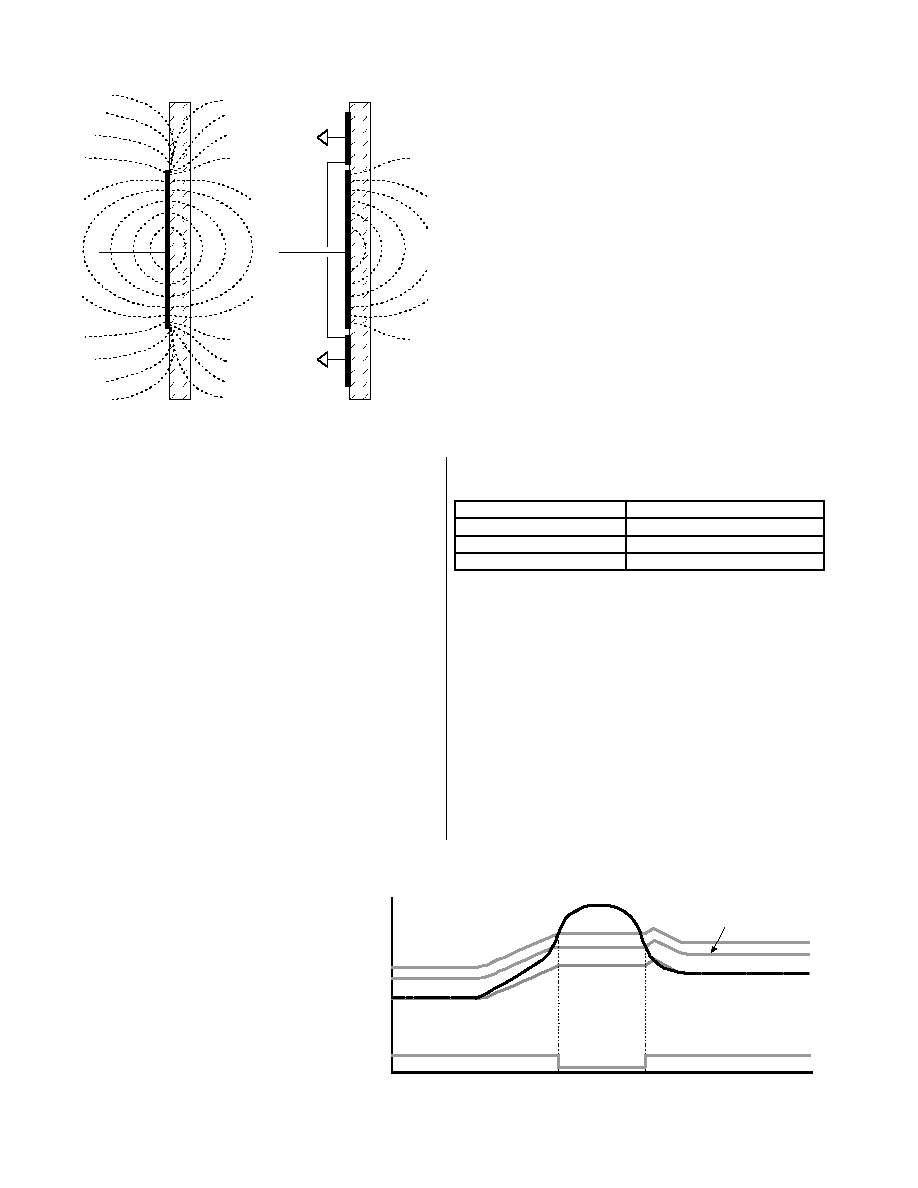

Figure 1-4 Mesh Electrode Geometry

Figure 1-5 Kirchoff's Current Law

S e n se E le ctro de

C

X2

Su rro und ing e nv iro nm ent

C

X3

S ENSO R

C

X1

A `virtual capacitive ground' can be created by connecting

the QT110's own circuit ground to:

(1) A nearby piece of metal or metallized housing;

(2) A floating conductive ground plane;

(3) A nail driven into a wall when used with small

electrodes;

(4) A larger electronic device (to which its output might be

connected anyway).

Free-floating ground planes such as metal foils should

maximize exposed surface area in a flat plane if possible. A

square of metal foil will have little effect if it is rolled up or

crumpled into a ball. Virtual ground planes are more

effective and can be made smaller if they are physically

bonded to other surfaces, for example a wall or floor.

1.3.4 F

IELD

S

HAPING

The electrode can be prevented from sensing in undesired

directions with the assistance of metal shielding connected

to circuit ground (Figure 1-6). For example, on flat surfaces,

the field can spread laterally and create a larger touch area

than desired. To stop field spreading, it is only necessary to

surround the touch electrode on all sides with a ring of metal

connected to circuit ground; the ring can be on the same or

opposite side from the electrode. The ring will kill

field spreading from that point outwards.

If one side of the panel to which the electrode is

fixed has moving traffic near it, these objects can

cause inadvertent detections. This is called

`walk-by' and is caused by the fact that the fields

radiate from either surface of the electrode

equally well. Again, shielding in the form of a

metal sheet or foil connected to circuit ground

will prevent walk-by; putting a small air gap

between the grounded shield and the electrode

will keep the value of Cx lower and is

encouraged. In the case of the QT110, the

sensitivity is low enough that 'walk-by' should not

be a concern if the product has more than a few

millimeters of internal air gap; if the product is very thin and

contact with the product's back is a concern, then some form

of rear shielding may be required.

1.3.5 S

ENSITIVITY

The QT110 can be set for one of 3 gain levels using option

pin 5 (Table 1-1). If left open, the gain setting is high. The

sensitivity change is made by altering the numerical

threshold level required for a detection. It is also a function

of other things: electrode size, shape, and orientation, the

composition and aspect of the object to be sensed, the

thickness and composition of any overlaying panel material,

and the degree of ground coupling of both sensor and object

are all influences.

1.3.5.1 Increasing Sensitivity

In some cases it may be desirable to increase sensitivity

further, for example when using the sensor with very thick

panels having a low dielectric constant.

Sensitivity can often be increased by using a bigger

electrode, reducing panel thickness, or altering panel

composition. Increasing electrode size can have diminishing

returns, as high values of Cx will reduce sensor gain

(Figures 4-1 ~ 4-3). Also, increasing the electrode's surface

area will not substantially increase touch sensitivity if its

diameter is already much larger in surface area than the

object being detected. The panel or other intervening

material can be made thinner, but again there are

diminishing rewards for doing so. Panel material can also be

changed to one having a higher dielectric constant, which

will help propagate the field through to the front. Locally

adding some conductive material to the panel (conductive

materials essentially have an infinite dielectric constant) will

also help dramatically; for example, adding carbon or metal

fibers to a plastic panel will greatly increase frontal field

strength, even if the fiber density is too low to make the

plastic bulk-conductive.

1.3.5.2 Decreasing Sensitivity

In some cases the QT110 may be too sensitive, even on low

gain. In this case gain can be lowered further by any of a

- 4 -

Figure 1-6

Shielding Against Fringe Fields

Sen se

wire

Sense

wire

U nshielded

Electrode

S hielded

E lectrode

Figure 2-1 Drift Compensation

T hr eshold

S ignal

H ysteresis

R eference

Output

Pin 7

Low

Pin 6

Medium

None

High

Tie Pin 5 to:

Gain

Table 1-1 Gain Setting Strap Options

number of strategies: making the electrode smaller,

connecting a very small capacitor in series with the sense

lead, or making the electrode into a sparse mesh using a

high space-to-conductor ratio (Figure 1-4). A deliberately

added Cx capacitor can also be used to reduce sensitivity

according to the gain curves (see Section 4).

Intermediate levels of gain (e.g. between 'medium' and 'low'

can be obtained by a combination of jumper settings with

one or more of the above strategies.

2 - QT110 SPECIFICS

2.1 SIGNAL PROCESSING

The QT110 processes all signals using 16 bit math, using a

number of algorithms pioneered by Quantum. The

algorithms are specifically designed to provide for high

'survivability' in the face of all kinds of adverse

environmental changes.

2.1.1 D

RIFT

C

OMPENSATION

A

LGORITHM

Signal drift can occur because of changes in Cx and Cs over

time. It is crucial that drift be compensated for, otherwise

false detections, non-detections, and sensitivity shifts will

follow.

Drift compensation (Figure 2-1) is performed by making the

reference level track the raw signal at a slow rate, but only

while there is no detection in effect. The rate of adjustment

must be performed slowly, otherwise legitimate detections

could be ignored. The QT110 drift compensates using a

slew-rate limited change to the reference level; the threshold

and hysteresis values are slaved to this reference.

Once an object is sensed, the drift compensation

mechanism ceases since the signal is legitimately high, and

therefore should not cause the reference level to change.

The QT110's drift compensation is 'asymmetric': the

reference level drift-compensates in one direction faster than

it does in the other. Specifically, it compensates faster for

decreasing signals than for increasing signals. Increasing

signals should not be compensated for quickly, since an

approaching finger could be compensated for partially or

entirely before even touching the sense pad. However, an

obstruction over the sense pad, for which the sensor has

already made full allowance for, could suddenly be removed

leaving the sensor with an artificially elevated reference level

and thus become insensitive to touch. In this latter case, the

sensor will compensate for the object's removal very quickly,

usually in only a few seconds.

2.1.2 T

HRESHOLD

C

ALCULATION

Sensitivity is dependent on the threshold level as well as

ADC gain; threshold in turn is based on the internal signal

reference level plus a small differential value. The threshold

value is established as a percentage of the absolute signal

level. Thus, sensitivity remains constant even if Cs is altered

dramatically, so long as electrode coupling to the user

remains constant. Furthermore, as Cx and Cs drift, the

threshold level is automatically recomputed in real time so

that it is never in error.

The QT110 employs a hysteresis dropout below the

threshold level of 50% of the delta between the reference

and threshold levels.

2.1.3 M

AX

O

N

-D

URATION

If an object or material obstructs the sense pad the signal

may rise enough to create a detection, preventing further

operation. To prevent this, the sensor includes a timer which

monitors detections. If a detection exceeds the timer setting,

the timer causes the sensor to perform a full recalibration.

This is known as the Max On-Duration feature.

After the Max On-Duration interval, the sensor will once

again function normally, even if partially or fully obstructed,

to the best of its ability given electrode conditions. There are

two timeout durations available via strap option: 10 and 60

seconds.

2.1.4 D

ETECTION

I

NTEGRATOR

It is desirable to suppress detections generated by electrical

noise or from quick brushes with an object. To accomplish

this, the QT110 incorporates a detect integration counter that

increments with each detection until a limit is reached, after

which the output is activated. If no detection is sensed prior

to the final count, the counter is reset immediately to zero.

In the QT110, the required count is 4.

The Detection Integrator can also be viewed as a

'consensus' filter, that requires four detections in four

successive bursts to create an output. As the basic burst

spacing is 75ms, if this spacing was maintained throughout

all 4 counts the sensor would react very slowly. In the

QT110, after an initial detection is sensed, the remaining

three bursts are spaced about 18ms apart, so that the

slowest reaction time possible is 75+18+18+18 or 129ms

and the fastest possible is 54ms, depending on where in the

initial burst interval the contact first occurred. The response

time will thus average 92ms.

- 5 -

10s

Vdd

Gnd

Pulse

10s

Gnd

Gnd

Toggle

60s

Gnd

Vdd

DC Out

10s

Vdd

Vdd

DC Out

Max On-

Duration

Tie

Pin 4 to:

Tie

Pin 3 to:

Table 2-1 Output Mode Strap Options

Figure 2-2 Powering From a CMOS Port Pin

0 . 0 1 µF

C MO S

m icro controller

O U T

P O RT X .m

P O RT X .n

V d d

V ss

Q T110