| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: QT320-IS | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

L

Q

QP

ROX

TM

QT320

2-C

HANNEL

P

ROGAMMABLE

A

DVANCED

S

ENSOR

IC

Two channel digital advanced capacitive sensor IC

Projects two `touch buttons' through any dielectric

Cloning for user-defined sensing behavior

100% autocal - no adjustments required

Only one external capacitor per channel

User-defined drift compensation, threshold levels

Variable gain via Cs capacitor change

Selectable output polarities

Toggle mode / normal mode outputs

HeartBeatTM health indicator on outputs (can be disabled)

1.8 ~ 5V supply, 60µA

APPLICATIONS

Computer peripherals

Entertainment devices

Access systems

Pointing devices

Appliance control

Security systems

Light switches

Industrial panels

The QT320 charge-transfer ("QT'") touch sensor chip is a self-contained digital IC capable of detecting near-proximity or

touch on two sensing channels. It will project sense fields through almost any dielectric, like glass, plastic, stone, ceramic,

and most kinds of wood. It can also turn small metal-bearing objects into intrinsic sensors, making them respond to proximity

or touch. This capability coupled with its ability to self calibrate continuously can lead to entirely new product concepts.

It is designed specifically for human interfaces, like control panels, appliances, security systems, lighting controls, or

anywhere a mechanical switch or button may be found; it may also be used for some material sensing and control

applications provided that the presence duration of objects does not exceed the recalibration time-out interval.

The IC requires only a common inexpensive capacitor per channel in order to function.

Power consumption and speed can be traded off depending on the application; drain can be as low as 60

µA, allowing

operation from batteries.

The IC's RISC core employs signal processing techniques pioneered by Quantum; these are specifically designed to make

the device survive real-world challenges, such as `stuck sensor' conditions and signal drift. Even sensitivity is digitally

determined. All key operating parameters can be set by the designer via the onboard eeprom which can be configured to alter

sensitivity, drift compensation rate, max on-duration, output polarity, and toggle mode independently on each channel.

No external switches, opamps, or other analog components aside from Cs are usually required.

The Quantum-pioneered HeartBeatTM signal is also included, allowing a host controller to monitor the health of the QT320

continuously if desired; this feature can be disabled via the cloning process.

By using the charge transfer principle, the IC delivers a level of performance clearly superior to older technologies in a highly

cost-effective package.

L

Q

Copyright © 2002 QRG Ltd

QT320/R1.03 08/02

-

QT320-IS

-40

0

C to +85

0

C

QT320-D

-

0

0

C to +70

0

C

8-PIN DIP

SOIC

T

A

AVAILABLE OPTIONS

Serial clone data in

SDI

7

Serial clone data out

SDO

6

Serial clone data clock

SCK

3

Alternate Pin Functions for Cloning

Positive supply

VDD

8

Detection output, Ch. 2

OUT2

7

Sense Ch 2 pin A

S2A

6

Sense Ch 1 pin B

S1B

5

Negative supply (ground)

VSS

4

Sense Ch 1 pin A

S1A

3

Sense Ch 2 pin B

S2B

2

Detection output, Ch. 1

OUT1

1

Function

Name

Pin

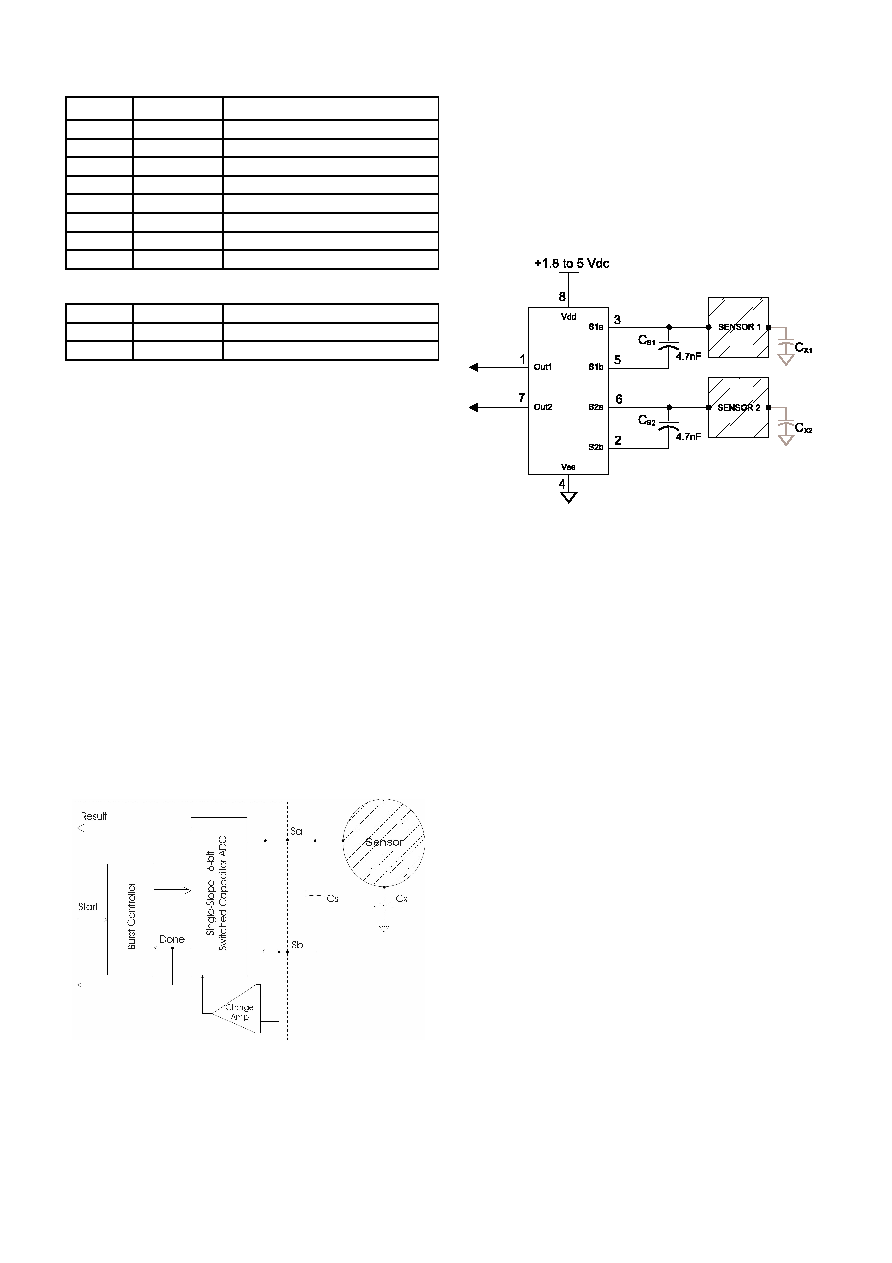

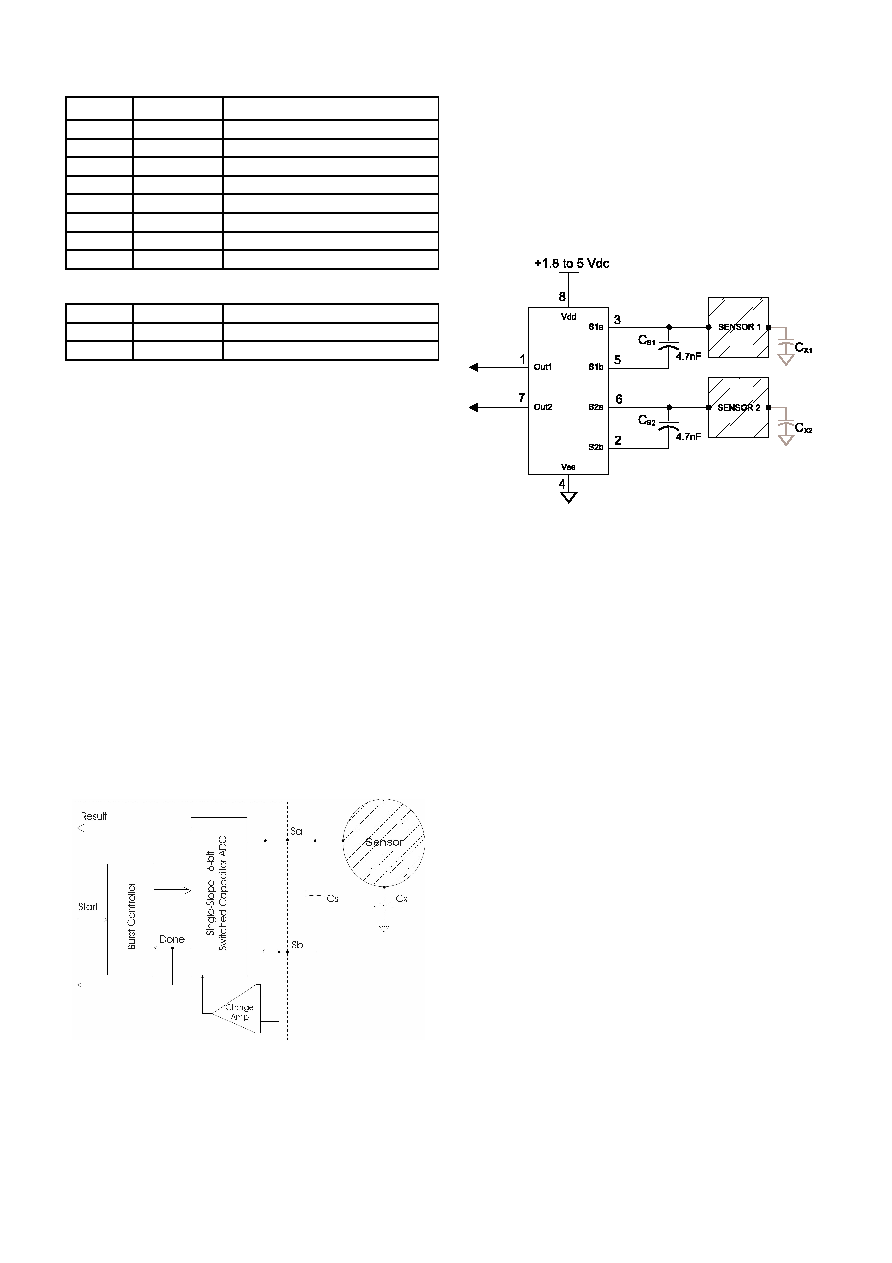

Table 1-1 Pin Descriptions

1 - OVERVIEW

The QT320 is a 2 channel digital burst mode charge-transfer

(QT) sensor designed specifically for touch controls; it

includes all hardware and signal processing functions

necessary to provide stable sensing under a wide variety of

changing conditions. Only two low-cost, non-critical capacitors

are required for operation.

A unique aspect of the QT320 is the ability of the designer to

`clone' a wide range of user-defined setups into the part's

eeprom during development and in production. Cloned setups

can dramatically alter the behavior of each channel,

independently. For production, the parts can be cloned

in-circuit or can be procured from Quantum pre-cloned.

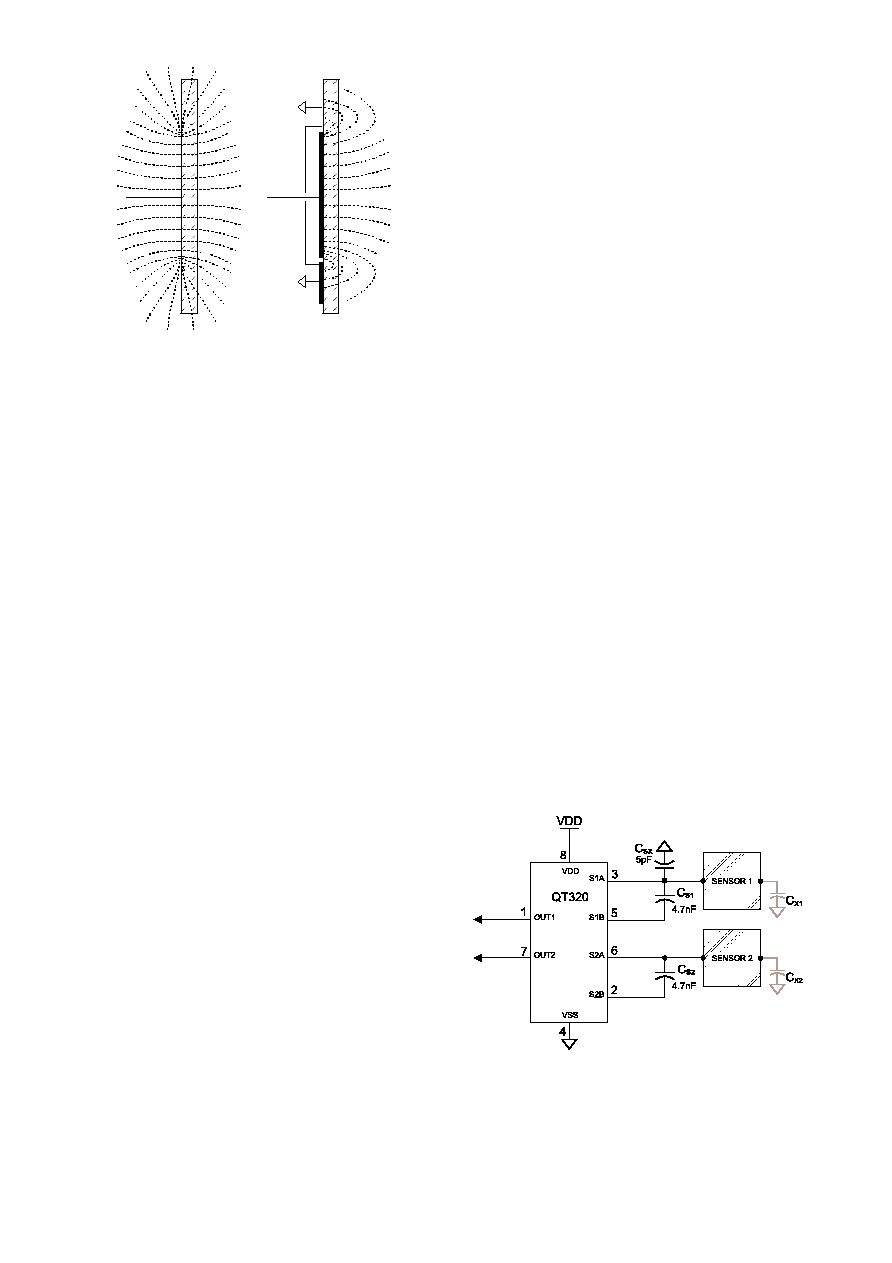

Figure 1-1 shows the basic QT320 circuit using the device,

with a conventional output drive and power supply

connections.

1.1 BASIC OPERATION

The QT320 employs bursts of variable-length charge-transfer

cycles to acquire its signal. Burst mode permits power

consumption in the microamp range, dramatically reduces RF

emissions, lowers susceptibility to EMI, and yet permits

excellent response time. Internally the signals are digitally

processed to reject impulse noise using a 'consensus' filter

which requires several consecutive confirmations of a

detection before an output is activated.

The two channels of sensing operate in a completely

independent fashion. A unique cloning process allows the

internal eeprom of the device to be programmed for each

channel, to permit unique combinations of sensing and

processing functions for each.

The two sensing channels operate in interleaved

time-sequence and thus cannot interfere with each other.

1.2 ELECTRODE DRIVE

1.2.1 S

WITCHING

O

PERATION

The IC implements two channels of direct-to-digital

capacitance acquisition using the charge-transfer method, in

a process that is better understood as a capacitance-

to-digital converter (CDC). The QT switches and charge

measurement functions are all internal to the IC (Figure 1-2).

The CDC treats sampling capacitor Cs as a floating store of

accumulated charge which is switched between the sense

pins; as a result, the sense electrode can be connected to

either pin with no performance difference. In both cases the

rule Cs >> Cx must be observed for proper operation. The

polarity of the charge build-up across Cs during a burst is the

same in either case. Typical values of Cs range from 2nF to

100nF for touch operation.

Larger values of Cx cause charge to be transferred into Cs

more rapidly, reducing available resolution and resulting in

lower gain. Conversely, larger values of Cs reduce the rise of

differential voltage across it, increasing available resolution

and raising gain. The value of Cs can thus be increased to

allow larger values of Cx to be tolerated (Figures 5-1 to 5-4).

As Cx increases, the length of the burst decreases resulting in

lower signal numbers.

It is possible to connect separate Cx and Cx' loads to Sa and

Sb simultaneously, although the result is no different than if

the loads were connected together at Sa (or Sb). It is

important to limit the amount of stray Cx capacitance on both

terminals, especially if the load Cx is already large. This can

be accomplished by minimising trace lengths and widths.

l

Q

2

QT320/R1.03 08/02

Figure 1-2 Internal Switching

Figure 1-1 Basic QT320 circuit

1.2.2 C

ONNECTION

TO

E

LECTRODES

The PCB traces, wiring, and any components associated with

or in contact with Sa and Sb of either channel will become

touch sensitive and should be treated with caution to limit the

touch area to the desired location.

Multiple touch electrodes can be connected to one sensing

channel, for example to create a control button on both sides

of an object, however it is impossible for the sensor to

distinguish between the two connected touch areas.

1.2.3 B

URST

M

ODE

O

PERATION

The acquisition process occurs in bursts (Figure 1-7) of

variable length, in accordance with the single-slope CDC

method. The burst length depends on the values of Cs and

Cx. Longer burst lengths result in higher gains and more

sensitivity for a given threshold setting, but consume more

average power and are slower.

Burst mode operation acts to lower average power while

providing a great deal of signal averaging inherent in the CDC

process, making the signal acquisition process more robust.

The QT method is a very low impedance method of sensing

as it loads Cx directly into a very large capacitor (Cs). This

results in very low levels of RF susceptibility.

1.3 ELECTRODE DESIGN

1.3.1 E

LECTRODE

G

EOMETRY

AND

S

IZE

There is no restriction on the shape of the electrodes; in most

cases common sense and a little experimentation can result

in a good electrode design. The QT320 will operate equally

well with long, thin electrodes as with round or square ones;

even random shapes are acceptable. The electrode can also

be a 3-dimensional surface or object. Sensitivity is related to

electrode surface area, orientation with respect to the object

being sensed, object composition, and the ground coupling

quality of both the sensor circuit and the sensed object.

Smaller electrodes will have less sensitivity than large ones.

If a relatively large electrode surfaces are desired, and if tests

show that an electrode has a high Cx capacitance that

reduces the sensitivity or prevents proper operation, the

electrode can be made into a mesh (Figure 1-3) which will

have a lower Cx than a solid electrode area.

1.3.2 K

IRCHOFF

'

S

C

URRENT

L

AW

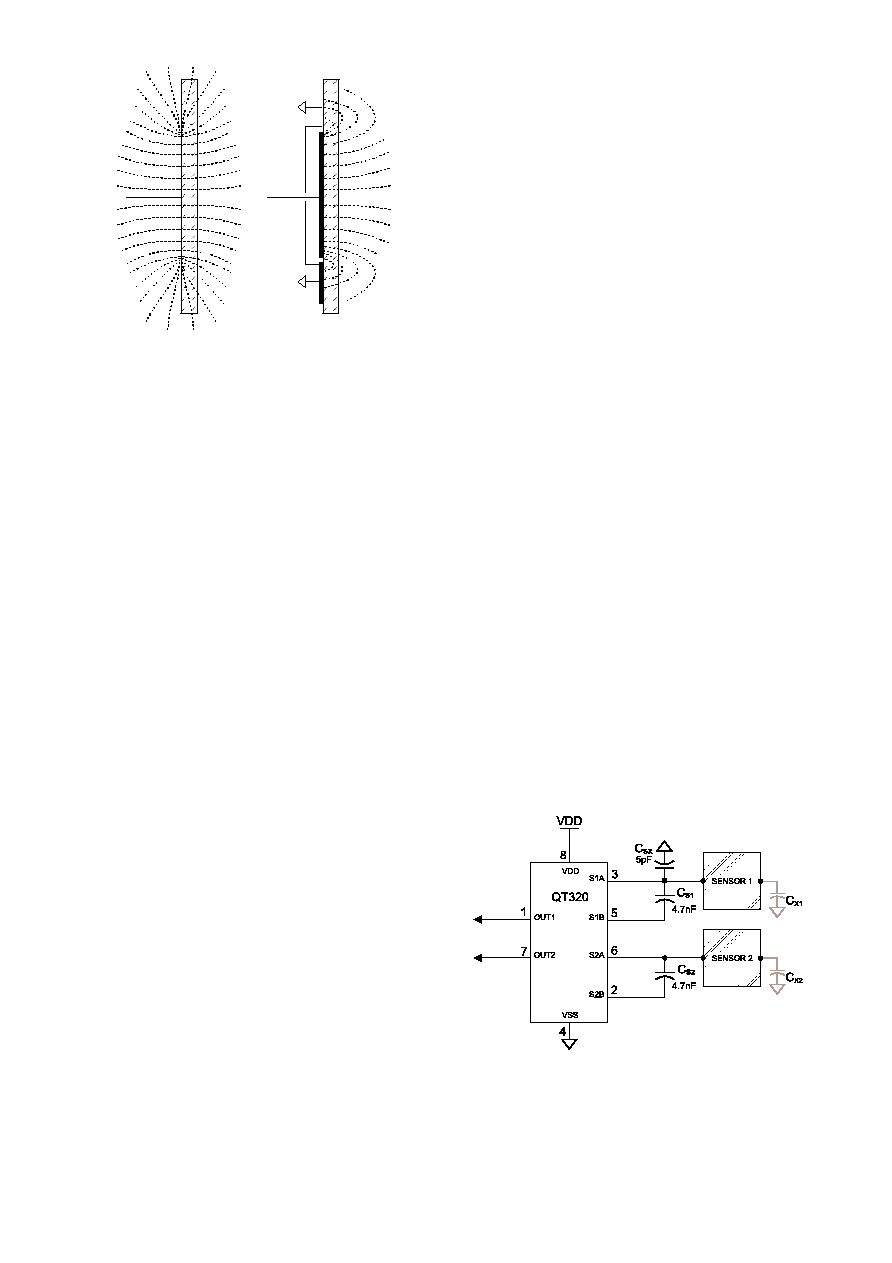

Like all capacitance sensors, the QT320 relies on Kirchoff's

Current Law (Figure 1-4) to detect the change in capacitance

of the electrode. This law as applied to capacitive sensing

requires that the sensor's field current must complete a loop,

returning back to its source in order for capacitance to be

sensed. Although most designers relate to Kirchoff's law with

regard to hardwired circuits, it applies equally to capacitive

field flows. By implication it requires that the signal ground

and the target object must both be coupled together in some

manner in order for the sensor to operate properly. Note that

there is no need to provide an actual hardwired ground

connection; capacitive coupling to ground (Cx1) often is

sufficient, even if the coupling might seem very tenuous. For

example, powering the sensor via an isolated transformer will

almost always provide ample ground coupling, since there is

plenty of capacitance between the primary and secondary

windings via the transformer core and from there to the power

wiring itself directly to 'local earth'. Even when battery

powered, just the physical size of the PCB and the object into

which the electronics is embedded is often enough to couple

enough back to local earth.

The implications of Kirchoff's law can be most visibly

demonstrated by observing the E3B eval board's sensitivity

change between laying the board on a table versus holding

the board in your hand by it's batteries. The effect can also be

observed by holding the board only by one electrode, letting it

recalibrate, then touching the battery end; the board will work

quite well in this mode.

1.3.3 V

IRTUAL

C

APACITIVE

G

ROUNDS

When detecting human contact (e.g. a fingertip), grounding of

the person is never required, nor is it necessary to touch an

exposed metal electrode. The human body naturally has

several hundred picofarads of `free space' capacitance to the

local environment (Cx3 in Figure 1-4), which is more than two

orders of magnitude greater than that required to create a

return path to the QT320 via earth. The QT320's PCB

however can be physically quite small, so there may be little

`free space' coupling (Cx1 in Figure 1-4) between it and the

environment to complete the return path. If the QT320 circuit

ground cannot be grounded via the supply connections, then

l

Q

3

QT320/R1.03 08/02

Figure 1-4 Kirchoff's Current Law

Figure 1-3 Mesh Electrode Geometry

a `virtual capacitive ground' may be required to increase

return coupling.

A `virtual capacitive ground' can be created by connecting the

QT320's own circuit ground to:

(1) A nearby piece of metal or metallized housing;

(2) A floating conductive ground plane;

(3) A fastener to a supporting structure;

(4) A larger electronic device (to which its output might be

connected anyway).

Because the QT320 operates at a relatively low frequency,

about 500kHz, even long inductive wiring back to ground will

usually work fine.

Free-floating ground planes such as metal foils should

maximise exposed surface area in a flat plane if possible. A

square of metal foil will have little effect if it is rolled up or

crumpled into a ball. Virtual ground planes are more effective

and can be made smaller if they are physically bonded to

other surfaces, for example a wall or floor.

1.3.4 F

IELD

S

HIELDING

AND

S

HAPING

The electrode can be prevented from sensing in undesired

directions with the assistance of metal shielding connected to

circuit ground (Figure 1-5). For example, on flat surfaces, the

field can spread laterally and create a larger touch area than

desired. To stop field spreading, it is only necessary to

surround the touch electrode on all sides with a ring of metal

connected to circuit ground; the ring can be on the same or

opposite side from the electrode. The ring will kill field

spreading from that point outwards.

If one side of the panel to which the electrode is fixed has

moving traffic near it, these objects can cause inadvertent

detections. This is called `walk-by' and is caused by the fact

that the fields radiate from either surface of the electrode

equally well. Again, shielding in the form of a metal sheet or

foil connected to circuit ground will prevent walk-by; putting a

small air gap between the grounded shield and the electrode

will keep the value of Cx lower and is encouraged. In the case

of the QT320, sensitivity can be high enough (depending on

Cx and Cs) that 'walk-by' signals are a concern; if this is a

problem, then some form of rear shielding may be required.

1.4 SENSITIVITY ADJUSTMENTS

There are three variables which influence sensitivity

independently for each channel:

1. Cs (sampling capacitor)

2. Cx (unknown capacitance)

3. Signal threshold value

There is also a sensitivity dependence of the whole device on

Vdd. Cs and Cx effects are covered in Section 1.2.1.

The threshold setting can be adjusted independently for each

channel from 1 to 16 counts of signal swing (Section 2.2).

Note that sensitivity is also a function of other things like

electrode size, shape, and orientation, the composition and

aspect of the object to be sensed, the thickness and

composition of any overlaying panel material, and the degree

of mutual coupling of the sensor circuit and the object (usually

via the local environment, or an actual galvanic connection).

It is advisable to set the sensitivity to the approximate desired

result by changing Cx and Cs first using a signal threshold

fixed at 10. Use the threshold value thereafter to fine-tune

sensitivity.

1.4.1 I

NCREASING

S

ENSITIVITY

In some cases it may be desirable to greatly increase

sensitivity, for example when using the sensor with very thick

panels having a low dielectric constant, or when sensing low

capacitance objects.

Sensitivity can be increased by using a bigger electrode,

reducing panel thickness, or altering panel composition.

Increasing electrode size can have diminishing returns, as

high values of Cx load will also reduce sensor gain (Figures

5-1 to 5-4). The value of Cs also has a dramatic effect on

sensitivity, and this can be increased in value up to a limit.

Increasing electrode surface area will not substantially

increase sensitivity if its area is already larger than the object

to be detected. The panel or other intervening material can be

made thinner, but again there are diminishing rewards for

doing so. Panel material can also be changed to one having a

higher dielectric constant, which will help propagate the field.

Locally adding some conductive material to the panel

(conductive materials essentially have an infinite dielectric

constant) will also help; for example, adding carbon or metal

fibers to a plastic panel will greatly increase frontal field

l

Q

4

QT320/R1.03 08/02

Figure 1-5 Field Shielding & Shaping

Sense

wire

Sense

wire

Unshielded

Electrode

Shielded

Electrode

Figure 1-6 Circuit with Csx gain equalization capacitor

strength, even if the fiber density is too low to make the

plastic electrically conductive.

1.4.2 D

ECREASING

S

ENSITIVITY

In some cases the circuit may be too sensitive, even with high

signal threshold values. In this case gain can be lowered by

making the electrode smaller, using sparse mesh with a high

space-to-conductor ratio (Figure 1-3), and most importantly by

decreasing Cs. Adding Cx capacitance will also decrease

sensitivity.

It is also possible to reduce sensitivity by making a capacitive

divider with Cx by adding a low-value capacitor in series with

the electrode wire.

1.4.3 H

YSTERESIS

Hysteresis is required to prevent chattering of the output lines

with weak, noisy, or slow-moving signals.

The hysteresis can be set independently per channel.

Hysteresis is a reference-based number; thus, a threshold of

10 with a hysteresis of 2 will yield 2 counts of hysteresis

(20%); the channel will become active when the signal equals

or exceeds a count of 10, and go inactive when the count falls

to 7 or lower.

Hysteresis can also be set to zero (0), in which case the

sensor will go inactive when the count falls to 9 or lower in the

above example.

Threshold levels of under 4 counts are hard to deal with as

the hysteresis level is difficult to set properly.

1.4.4 C

HANNEL

B

ALANCE

Channel 1 has less internal Cx than Channel 2, which makes

it more sensitive than Channel 2 given equal Cx loads and Cs

capacitors. This can be useful in some designs where one

more sensitive channel is desired, but if equal sensitivity is

required a few basic rules should be followed:

1. Use a symmetrical PCB layout for both channels: Place

the IC half way between the two electrodes to match Cx

loading. Avoid routing ground plane (or other traces) close

to either sense line or the electrodes; allow 4-5 mm

clearance from any ground or other signal line to the

electrodes or their wiring. Where ground plane is required

(for example, under and around the QT320 itself) the

sense wires should have minimized adjacency to ground.

2. Connect a small capacitor (~5pF) between S1a or S1b

(either Channel 1 pin) and circuit ground (Csx in Figure

1-6), this will increase the load capacitance of Channel 1,

thus balancing the sensitivity of the two channels (see

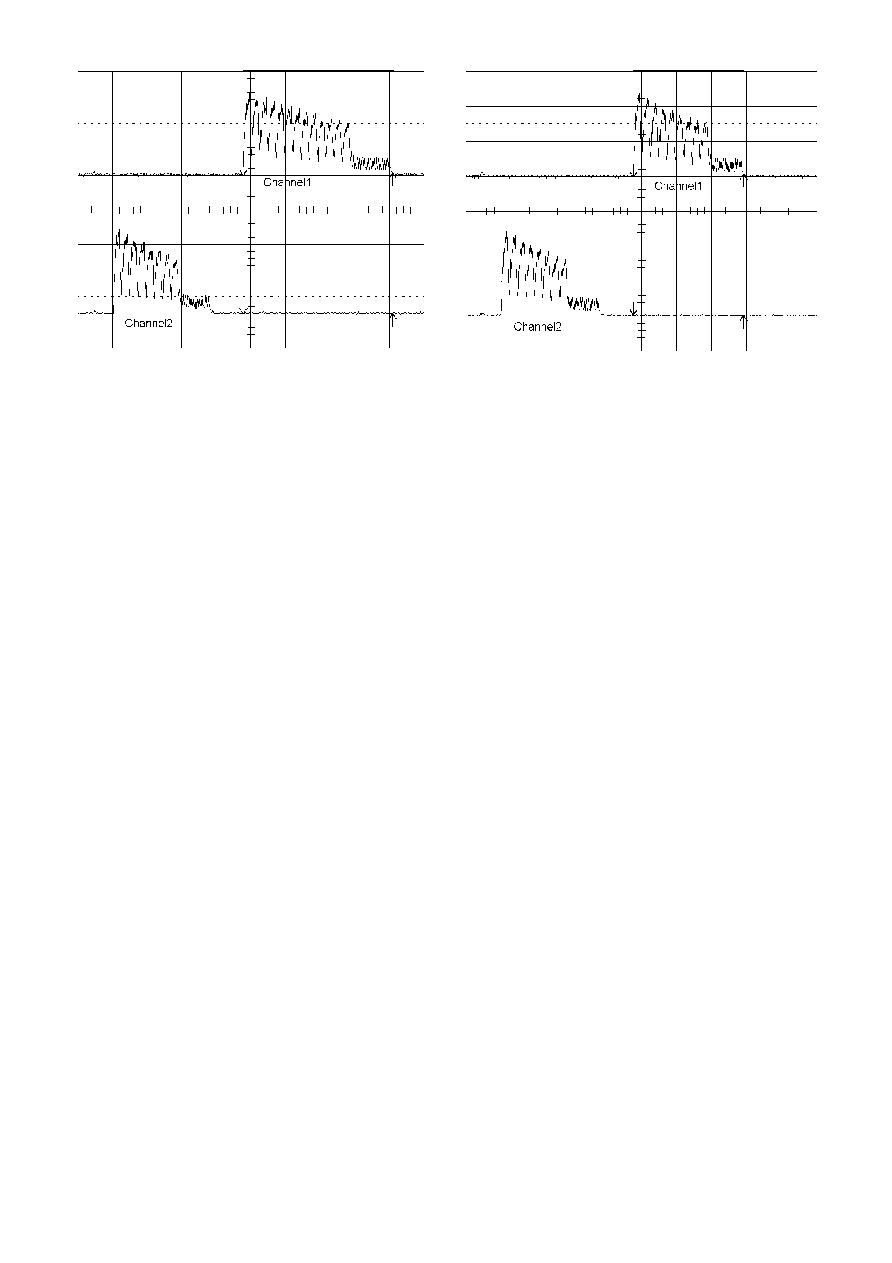

Figures 1-7, 1-8).

3. Adjust Cs and/or the internal threshold of the two channels

until the sensitivities of the two channels are

indistinguishable from each other.

Since the actual burst length is proportional to sensitivity, you

can use an oscilloscope to balance the two channels with

more accuracy than by empirical methods (See Figures 1-7

and 1-8). Connect one scope probe to Channel 1 and the

other to Channel 2, via large resistors (750K ohms) to avoid

disturbing the measurement too much, or, use a low-C FET

probe. The Csx balance capacitor should be adjusted so that

the burst lengths of Channels 1 and 2 look nearly the same.

With some diligence the PCB can also be designed to include

some ground plane nearer to Channel 1 traces to induce

about 5pF of Csx load without requiring an actual discrete

capacitor.

l

Q

5

QT320/R1.03 08/02

Figure 1-8 Burst lengths with Csx installed

(observed using a 750K resistor in series with probe)

Figure 1-7 Burst lengths without Csx installed

(observed using a 750K resistor in series with probe)