3-Phase Brushless Motor Driver for

CD-ROM Spindle Motors

Overview

The LB1895 and LB1895D are 3-phase brushless motor drivers

for use in CD-ROM spindle motors.

Functions and Features

.

Current linear drive

.

V-type control amplifier built in

.

Because the power supply for the bias circuit on the upper

output side is separate, output with low saturation can be

attained by boosting only that power supply. (Effective when

V

CC

= 5 V)

.

Because current is detected on the upper side, there is no

voltage loss due to the RF resistance. In addition, the RF

voltage reduces the power dissipation within the IC.

(Effective when V

CC

= 5 V)

.

Start/Stop function built in

.

Thermal shutdown circuit built in

.

Overcurrent protection circuit built in

.

Two-channel Hall signal comparator built in.

(For detecting rotation direction and Hall FG output)

.

Hall device bias built in

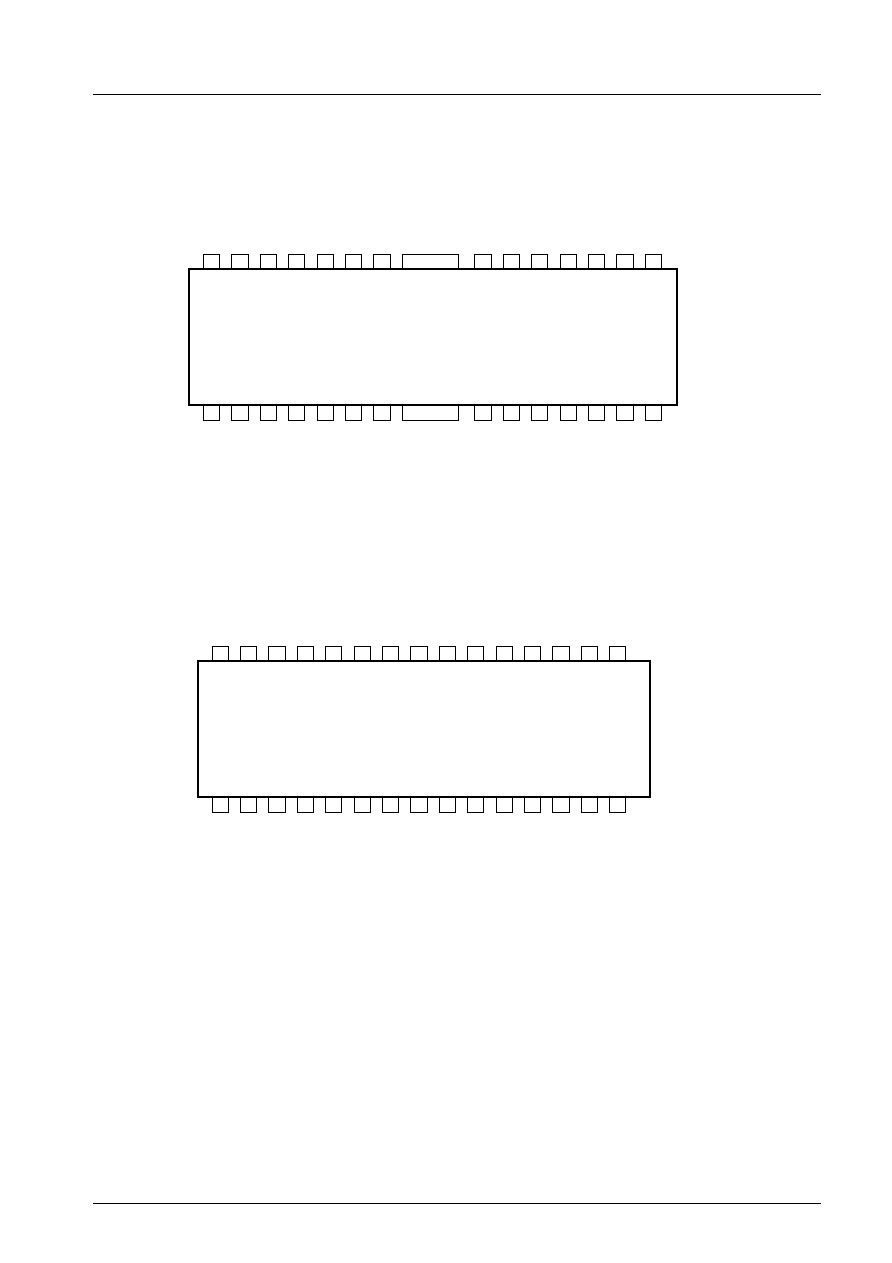

Package Dimensions

unit : mm

3222-HSOP28

[LB1895]

0.1

1.8max

7.6

1.0

1

14

0.3

0.8

15

28

2.7

15.2

0.8

5.6

0.5

0.2

SANYO : HSOP28

unit : mm

3196-DIP30SD

[LB1895D]

SANYO : DIP30SD

Ordering number: EN5634

Monolithic Digital IC

LB1895, 1895D

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110 JAPAN

4097HA(II) No.5634-1/12

Specifications

Maximum Ratings

at Ta = 25 �C

Parameter

Symbol

Conditions

Ratings

Unit

Maximum supply voltage 1

V

CC

1 max

7

V

Maximum supply voltage 2

V

CC

2 max

14.4

V

Maximum supply voltage 3

V

CC

3 max

14.4

V

Applied output voltage

V

O

max

14.4

V

Applied input voltage

V

I

max

V

CC

1

V

Output current

I

O

max

1.0

A

Allowable power dissipation

Pd max

Indepent IC [LB1895]

0.5

W

Glass epoxy board

(114.3

�

762

�

1.5 mm) [LB1895D]

2.4

W

Operating temperature

Topr

�20 to +75

�C

Storage temperature

Tstg

�55 to +150

�C

Operating Conditions

at Ta = 25 �C

Parameter

Symbol

Conditions

Ratings

Unit

Supply voltage

V

CC

1

4 to 6

V

V

CC

2

^

V

CC

1

4 to 13.6

V

V

CC

3

2 to 13.6

V

Application Examples

at Ta = 25 �C

(1) 12 V model

Power supply pins

Conditions

Ratings

Unit

V

CC

1

REG. voltage

4 to 6

V

V

CC

2 = V

CC

3

UN-REG. voltage

4 to 13.6

V

(2) 5 V model

Power supply pins

Conditions

Ratings

Unit

V

CC

1 = V

CC

3

REG. voltage

4 to 6

V

V

CC

2

Boost voltage or REG. voltage (Note)

4 to 13.6

V

Note: If V

CC

2 is used as the boost voltage, output with low saturation can be used.

LB1895, 1895D

No.5634-2/12

Electrical Characteristics

at Ta = 25 �C, V

CC

1 = 5 V, V

CC

2 = V

CC

3 = 12 V

(Unless otherwise specified)

Parameter

Symbol

Conditions

min

typ

max

Unit

[Supply current]

Supply current 1

I

CC

1

VC = VC

REF

4

7

mA

Supply current 2

I

CC

2

VC = VC

REF

0

0.5

mA

Supply current 3

I

CC

3

VC = VC

REF

150

250

�A

Output quiescent current 1

I

CC

1

OQ

V

S/S

= 0 V

200

�A

Output quiescent current 2

I

CC

2

OQ

V

S/S

= 0 V

30

�A

Output quiescent current 3

I

CC

3

OQ

V

S/S

= 0 V

30

�A

[Output]

Upper saturation voltage 1

V

OU

1

I

O

= �0.5 A, V

CC

1 = 5 V, V

CC

2 = V

CC

3 = 12 V

0.8

1.3

V

Lower saturation voltage 1

V

OD

1

I

O

= 0.5 A, V

CC

1 = 5 V, V

CC

2 = V

CC

3 = 12 V

0.3

0.5

V

Upper saturation voltage 2

V

OU

2

I

O

= �0.5 A, V

CC

1 = V

CC

3 = 5 V, V

CC

2 = 12 V

0.3

0.5

V

Lower saturation voltage 2

V

OD

2

I

O

= 0.5 A, V

CC

1 = V

CC

3 = 5 V, V

CC

2 = 12 V

0.3

0.5

V

Current limiter setting voltage

VC

L

RRF = 0.43

0.25

0.32

0.4

V

[Hall Amplifier]

Hall amplifier common-mode

input voltage range

VH

COM

1.2

V

CC

1

�1.0

V

Hall amplifier input bias current

IH

IB

1

2

�A

Minimum Hall input level

VH

IN

60

mVp-p

[S/S pin]

High-level voltage

V

S/SH

2.0

V

CC

1

V

Low-level voltage

V

S/SL

0.7

V

Input current

I

S/SI

V

S/S

= 5 V

200

�A

LEAK current

I

S/SL

V

S/S

= 0 V

�30

�A

[Control stage]

VC pin input current

I

VC

VC = VC

REF

= 2.5 V

1

3

�A

VC

REF

pin input current

I

VCREF

VC = VC

REF

= 2.5 V

1

3

�A

Voltage gain

VG

CO

VRF/

VC

0.2

0.25

0.3

Times

Rising threshold voltage

VC

TH

VC

REF

= 2.5 V

2.35

2.65

V

Rising threshold voltage width

VC

TH

VC

REF

= 2.5 V

50

150

mV

[Hall supply]

Hall supply voltage

V

H

I

H

= 5 mA

1.0

1.6

V

Allowable current

I

H

20

mA

[Thermal shutdown]

Operating temperature

T

TSD

*

D

150

180

210

�C

Hysteresis

T

TSD

*

D

15

�C

[Hall comparator]

Input offset voltage

V

HCI

offset

10

mV

Input hysteresis

V

HCI

hys

3

8

15

mV

Output ON voltage

V

OU

0.3

V

Output OFF voltage

V

OD

Note

4.7

V

Output current (sink)

I

SINK

3

mA

Note: When in S/S OFF (standby) state, the Hall comparator goes high.

*D stands for design target; this value is not measured.

LB1895, 1895D

No.5634-3/12

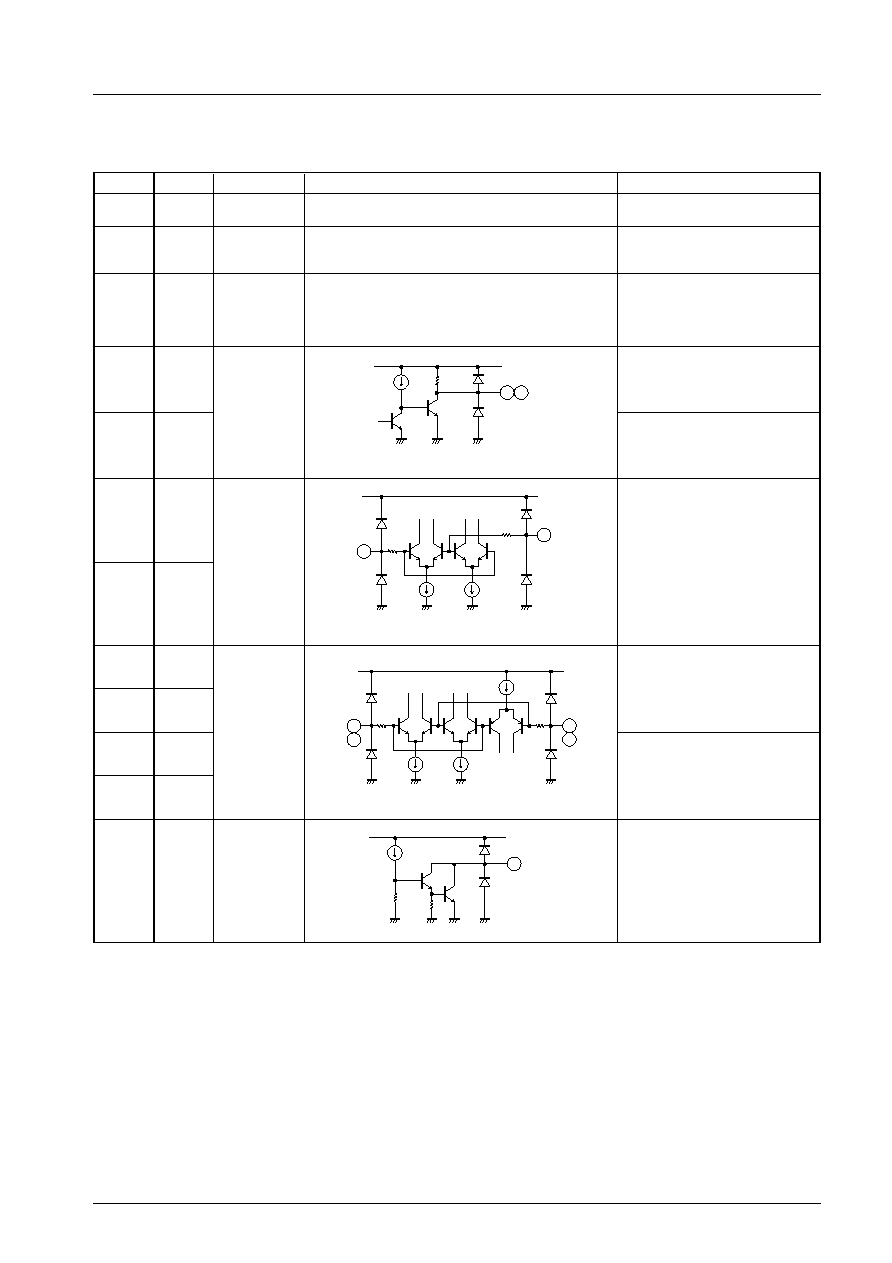

Truth Table

Source

sink

Input

Control

VC

U

V

W

1

W phase

V phase

H

H

L

H

V phase

W phase

L

2

W phase

U phase

H

L

L

H

U phase

W phase

L

3

V phase

W phase

L

L

H

H

W phase

V phase

L

4

U phase

V phase

L

H

L

H

V phase

U phase

L

5

V phase

U phase

H

L

H

H

U phase

V phase

L

6

U phase

W phase

L

H

H

H

W phase

U phase

L

Inputs

H: For each phase input 2, phase input 1 is at a higher electric potential of 0.2 V or more.

L: For each phase input 2, phase input 1 is at a lower electric potential of 0.2 V or more.

|

20

20

40

0

60

80

100

0

0.4

0.8

1.6

1.2

2.0

2.4

2.8

LB1895D

LB1895

Allowable

power

dissipation,

Pd

max

�

W

Pd max � Ta

Ambient temperature, Ta � �C

LB1895, 1895D

No.5634-4/12

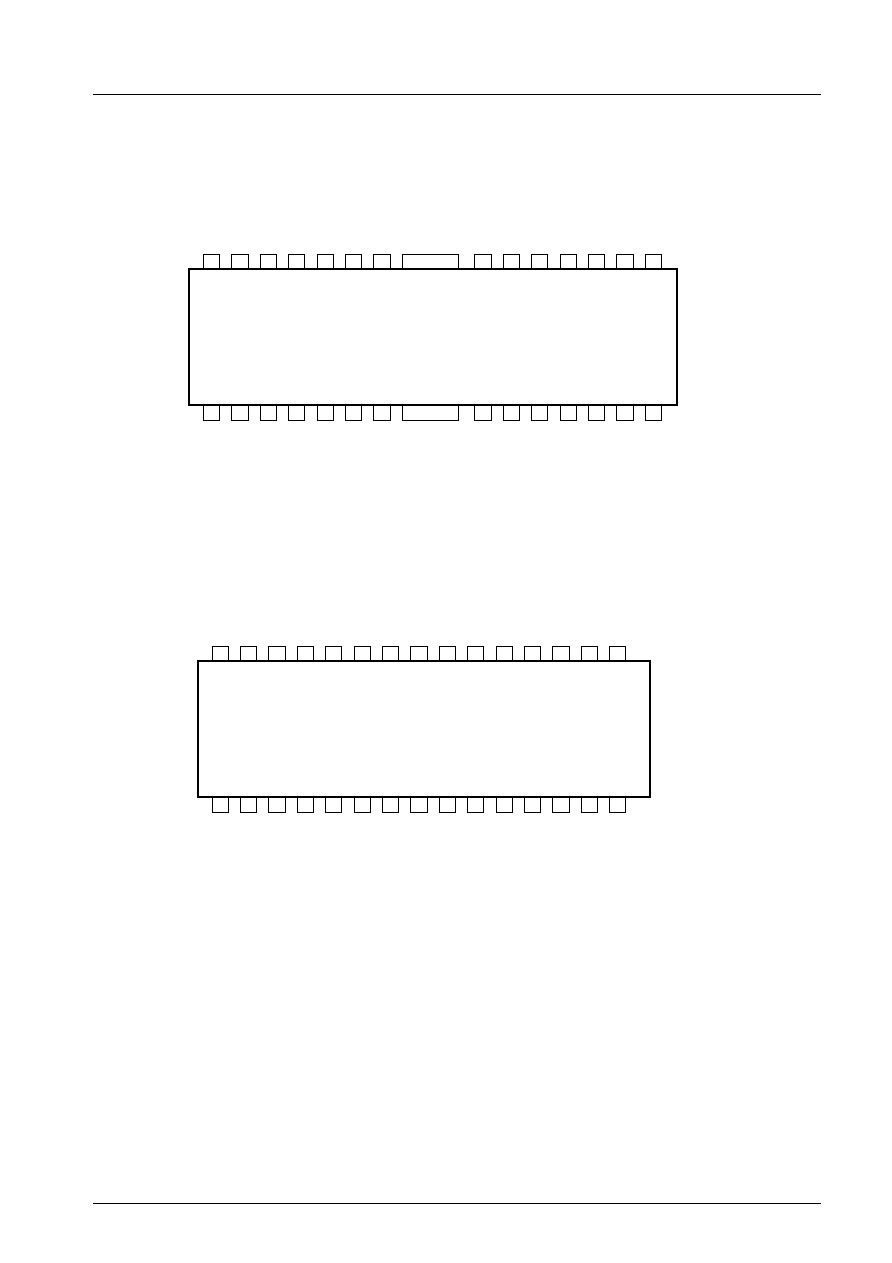

LB1895 Pin Assignment

1

2

3

4

5

6

7

V

OUT

U

OUT

NC

V

CC

2

NC

V

CC

3

RF

FRAME GND

V

CC

1

V

COMPO

W

COMPO

NC

U

IN

1

U

IN

2

V

IN

1

NC

PWR GND

NC

W

OUT

VC

VCREF

FC

FRAME GND

NC

SIG GND

S/S

VH

W

IN

2

W

IN

1

V

IN

2

HSOP-28

8

9

10

11

12

13

14

21

20

19

18

17

16

15

28

27

26

25

24

23

22

L B 1 8 9 5

A06714

Top view

VC

REF

1

2

3

4

5

6

7

8

9

10

11

V

OUT

U

OUT

NC

V

CC

2

V

CC

3

RF

FRAME GND

FRAME GND

FRAME GND

V

CC

1

V

COMPO

W

COMPO

U

IN

1

U

IN

2

V

IN

1

PWR GND

W

OUT

NC

VC

VCREF

FC

FRAME GND

FRAME GND

FRAME GND

SIG GND

S/S

VH

W

IN

2

W

IN

1

V

IN

2

DIP-30SD

12

13

14

15

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

L B 1 8 9 5 D

A06715

Top view

VC

REF

LB1895, 1895D

No.5634-5/12

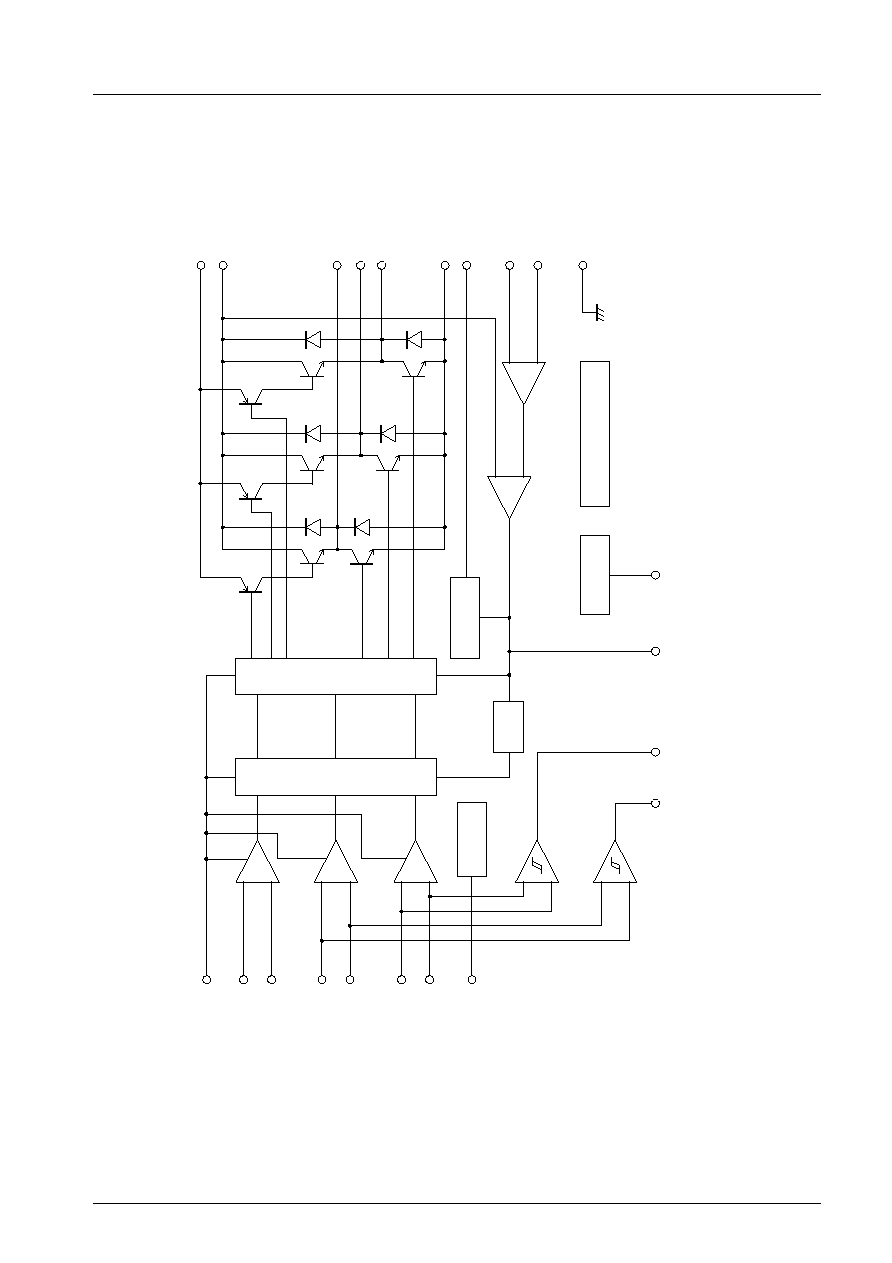

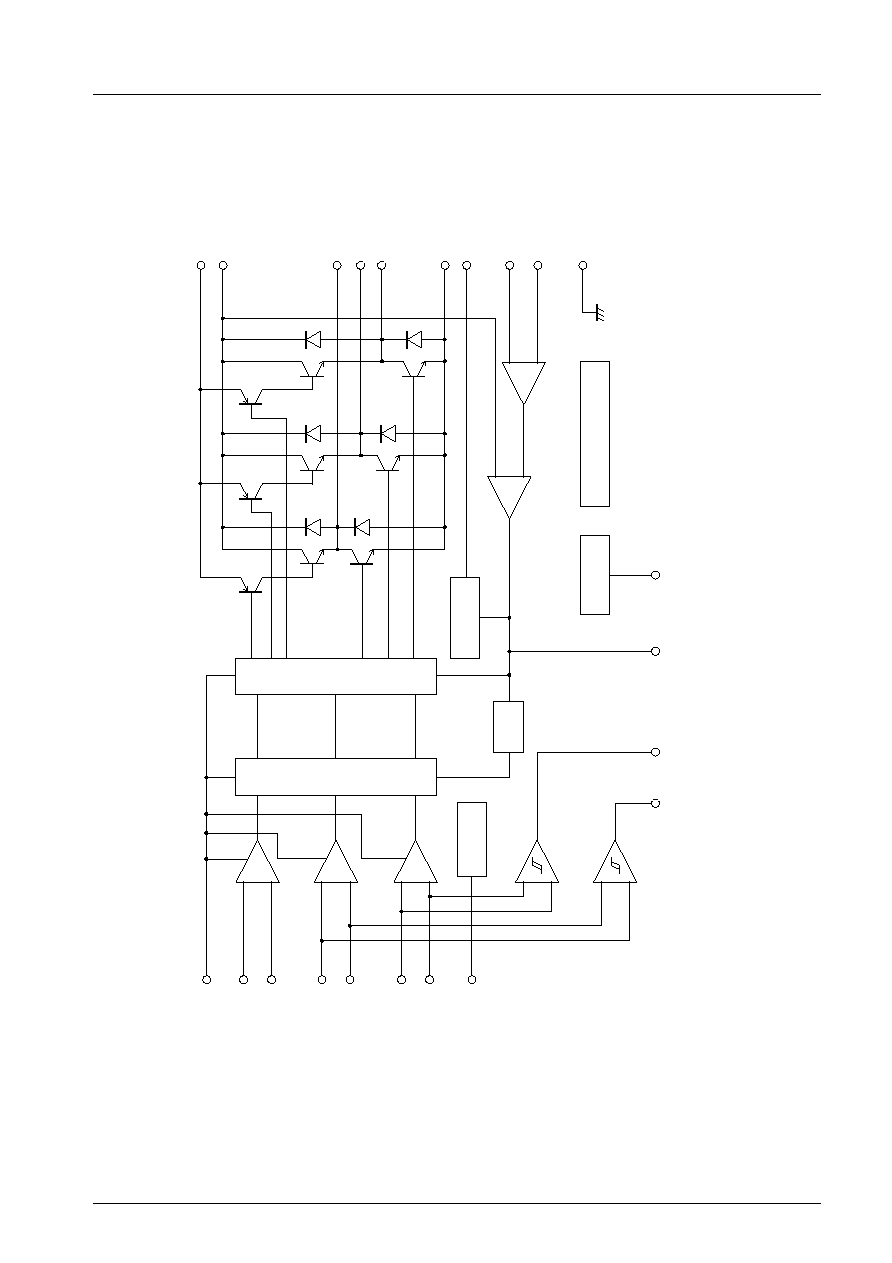

LB1895 Block Diagram

V

CC

1

U

IN

1

U

IN

2

V

IN

1

+

�

+

�

+

�

+

�

+

�

+

�

+

�

V

IN

2

W

IN

1

W

IN

2

VH

V

COMPO

W

COMPO

FC

S/S

SIG GND

VC

VCREF

V

CC

3

PWR GND

W

OUT

V

OUT

U

OUT

RF

V

CC

2

A06716

Matrix FR

Output control

Hall

power

supply

Current

limiter

Reference

voltage

Thermal

shutdown

For/Rev

VC

REF

LB1895, 1895D

No.5634-6/12

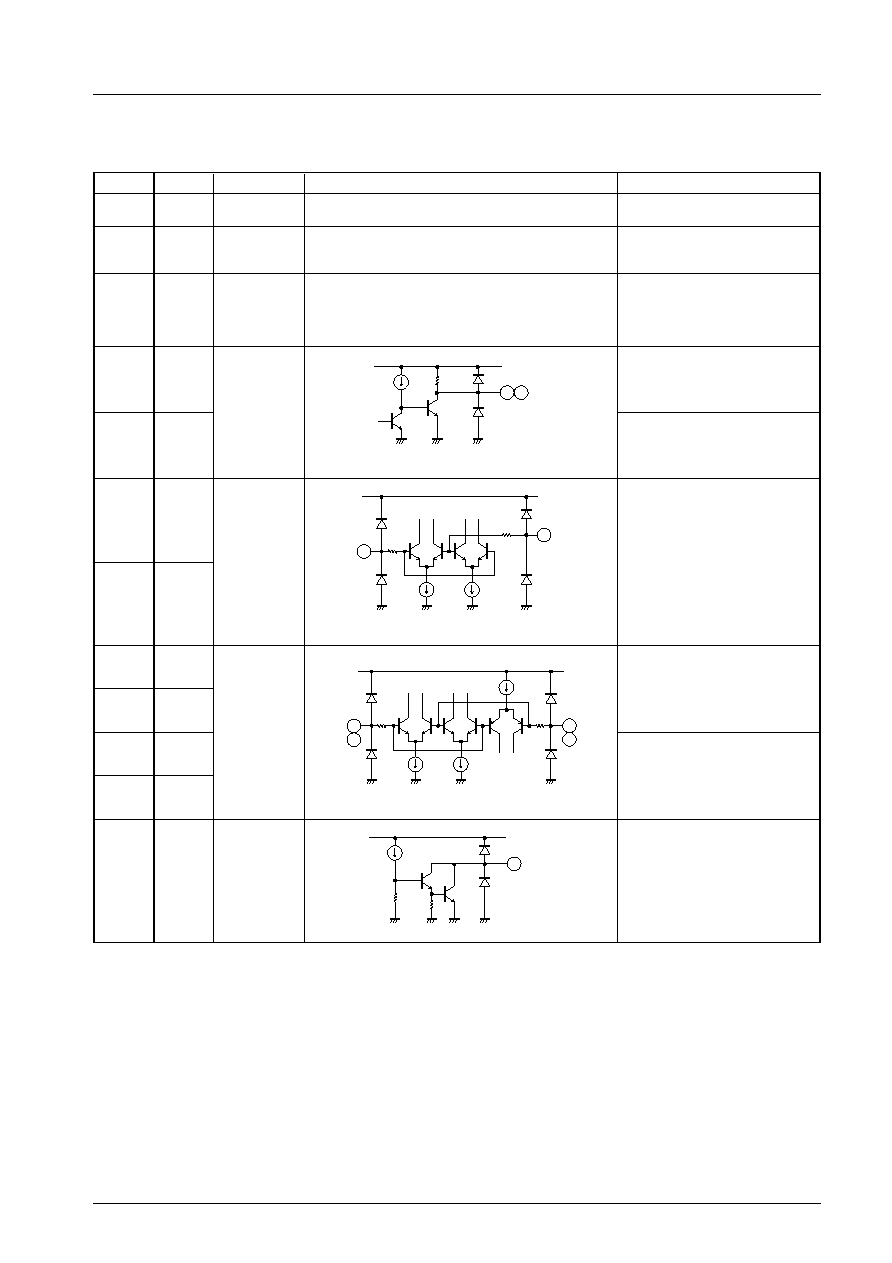

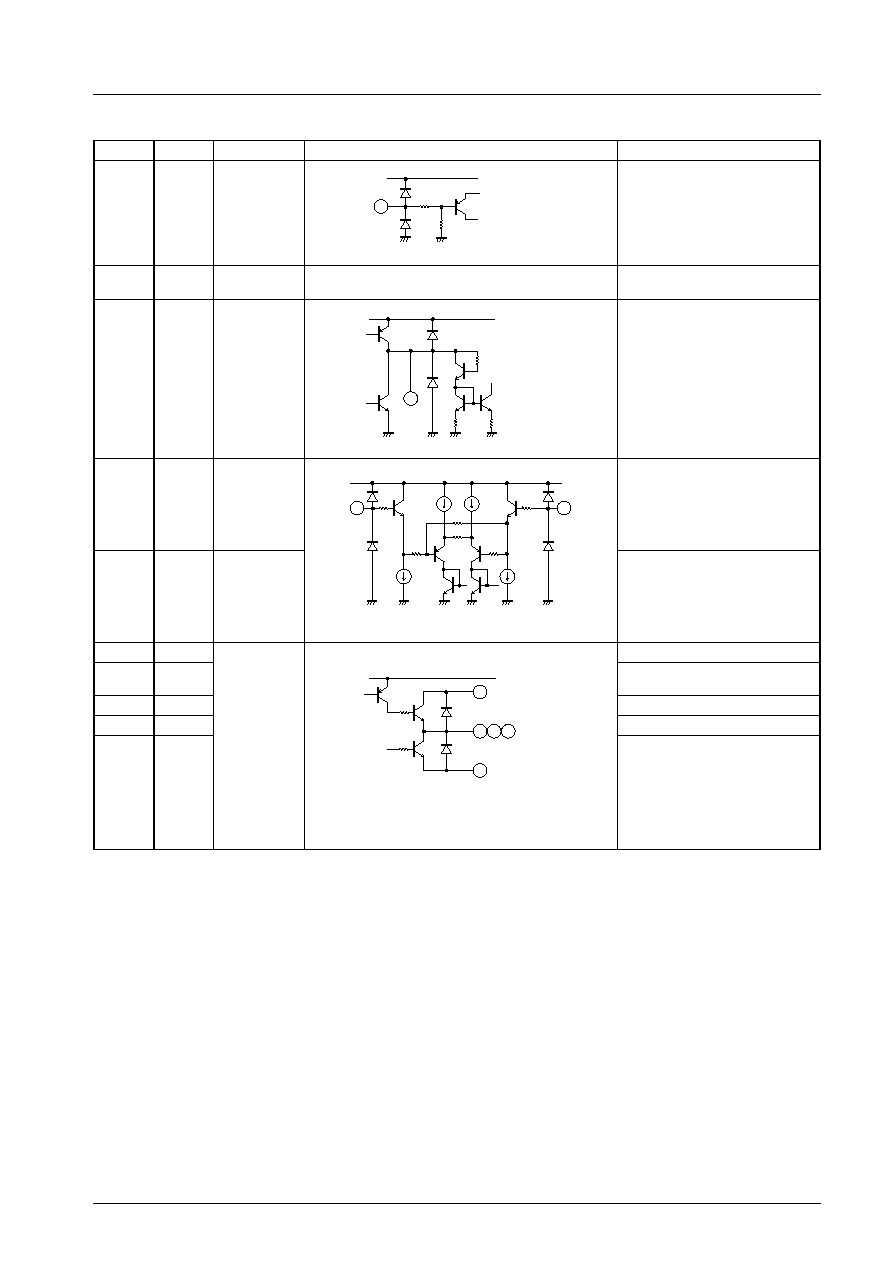

Pin Descriptions

Note: Numbers within (

) are for LB1895D

Pin No.

Symbol

Voltage

Equivalent circuit

Description

4

V

CC

2

4 V to 13.6 V

Supply pin that provides pre-drive

voltage for the source side.

6 (5)

V

CC

3

2 V to 13.6 V

Supply pin that provides voltage

for the constant current control

amplifier.

8 (10)

V

CC

1

4 V to 6 V

Supply pin that provides voltage

for all circuits except the output

transistor, source-side pre-drive,

and constant current control

amplifier.

9 (11)

V

COMPO

9 10

VCC1

10k

150�A

(11, 12)

A06717

V-phase Hall element waveform

Schmitt comparator output pin.

10 (12)

W

COMPO

W-phase Hall element waveform

Schmitt comparator output pin.

12 (13)

U

IN

1

1.2 V to

V

CC

1 �1 V

12

VCC1

200

200

25�A

25�A

(13)

A06718

13

(14)

U-phase Hall element input pin.

Logic HIGH is represented by

U

IN

1 > U

IN

2.

13 (14)

U

IN

2

14 (15)

V

IN

1

1.2 V to

V

CC

1 �1 V

VCC1

200

200

25�A

25�A

25�A

A06719

17

15

(16)

16

14

(15)

(17)

(18)

V-phase Hall element input pin,

and V-phase Schmitt comparator

input pin for reverse detection.

Logic HIGH is represented by

V

IN

1 > V

IN

2.

15 (16)

V

IN

2

16 (17)

W

IN

1

W-phase Hall element input pin,

and W-phase Schmitt comparator

input pin for reverse detection.

Logic HIGH is represented by

W

IN

1 > W

IN

2.

17 (18)

W

IN

2

18 (19)

VH

VCC1

30k

2k

75�A

A06720

18

(19)

This pin provides the lower bias

voltage for the Hall element.

Continued on next page.

LB1895, 1895D

No.5634-7/12

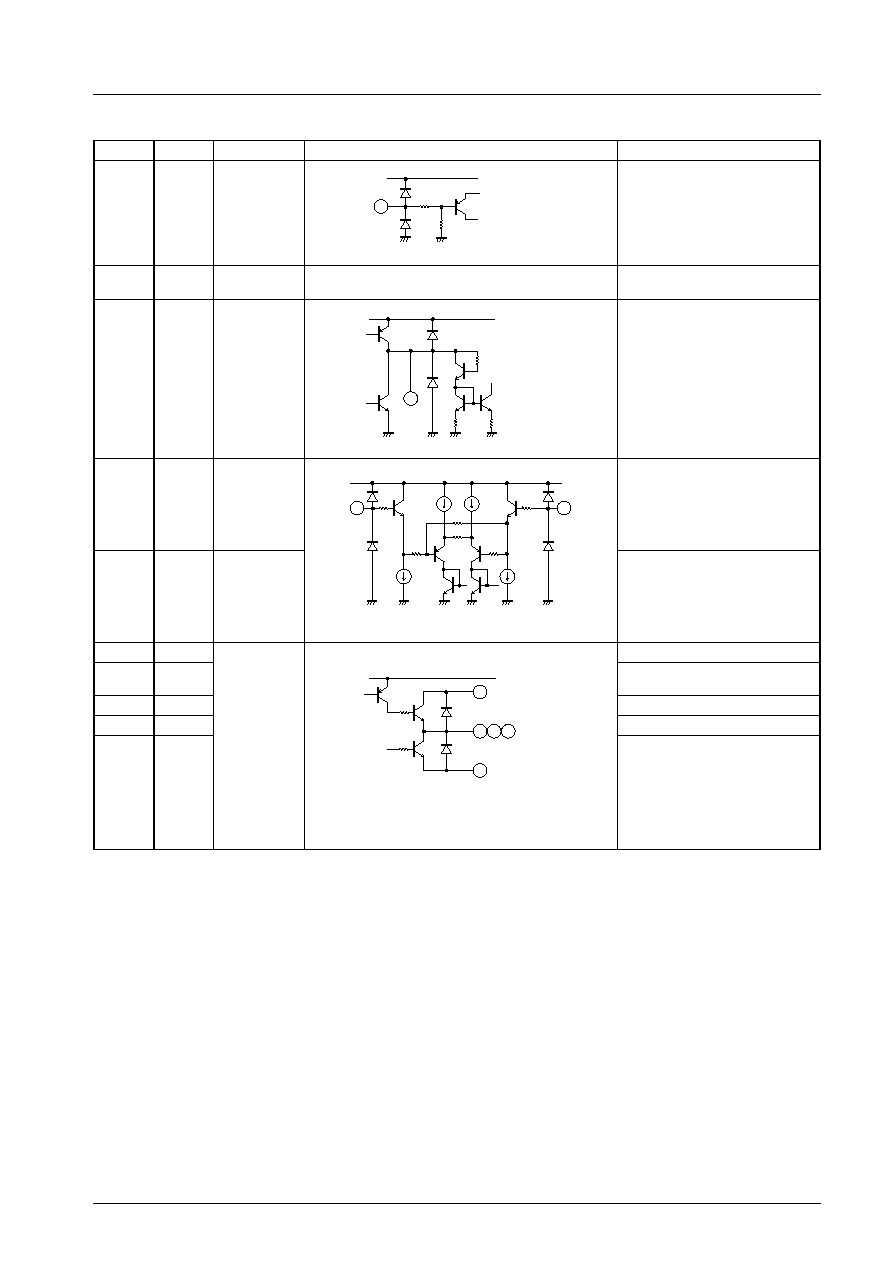

Continued from preceding page.

Pin No.

Symbol

Voltage

Equivalent circuit

Description

19 (20)

S/S

0 V to V

CC

1

75k

VCC1

50k

A06721

19

(20)

None of the circuits operate if the

voltage on this pin is 0.7 V or less,

or if this pin is open.

When driving the motor, the

voltage on this pin must be 2 V or

more.

20 (21)

SIG

GND

Ground connection for all circuits

except the outputs.

22 (25)

FC

VCC1

A06722

20k

5k

2k

22

(25)

Control loop frequency

characteristics compensation pin.

Connect a capacitor between this

pin and GND to stop closed loop

oscillation in the current control

system.

23 (26)

VC

REF

2 V to 3 V

VCC1

A06723

200

200

100�A

100�A

24

(27)

23

(26)

Control reference voltage

application pin. This voltage

determines the control start

voltage.

24 (27)

VC

0 V toV

CC

1

Speed control voltage application

pin. V-type control, where:

VC > VC

REF

= forward and

VC < VC

REF

= reverse

25 (29)

W

OUT

VCC2

A06724

7 (6)

25 1

2

(29)

27

(30)

W-phase output pin.

27 (30)

PWR

GND

Output transistor ground.

1

V

OUT

V-phase output pin.

2

U

OUT

U-phase output pin.

7 (6)

RF

Upper output NPN transistor

collector pin (three-phase

common). Connect a resistor

between V

CC

3 and the RF pin for

current detection. When this

voltage is detected, the constant

current control and current limiter

circuits function.

LB1895, 1895D

No.5634-8/12

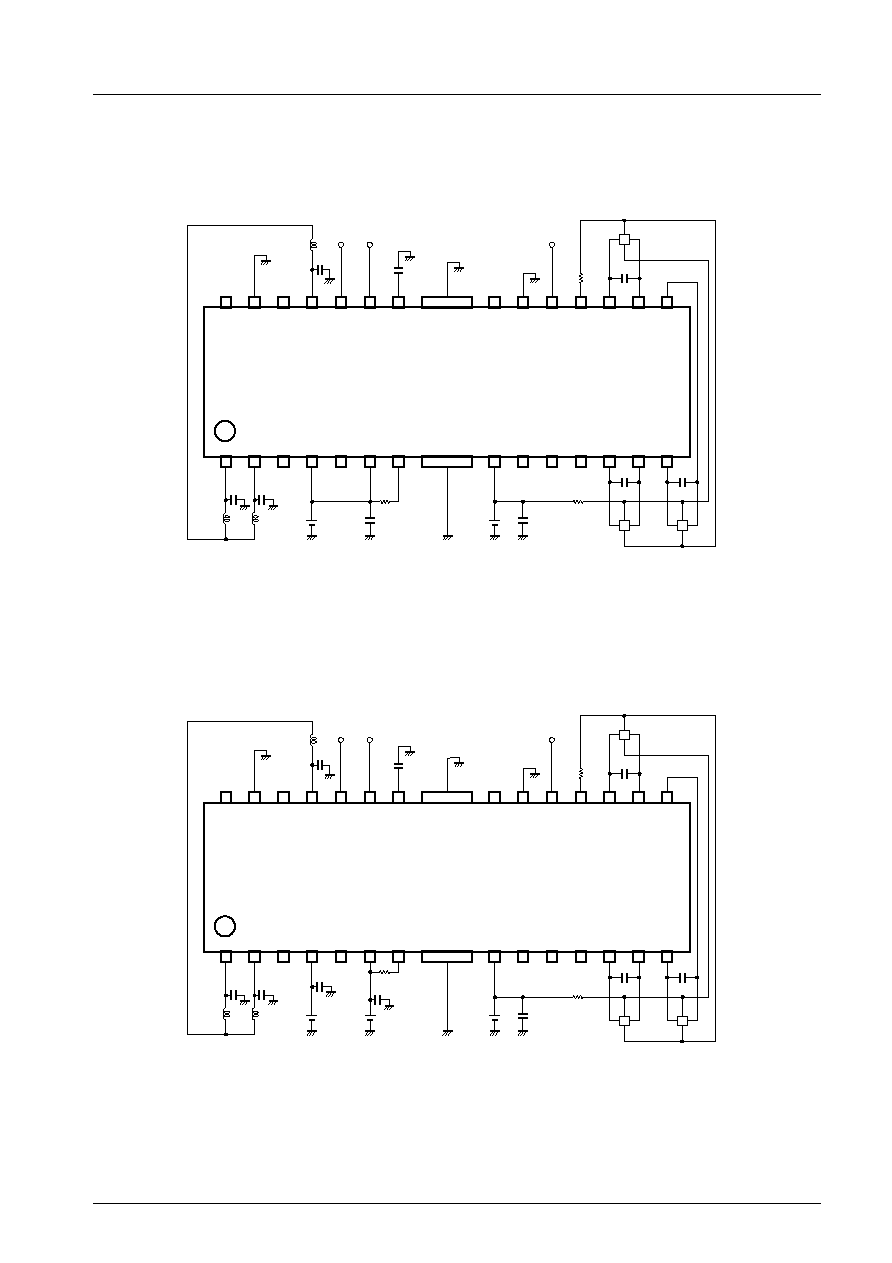

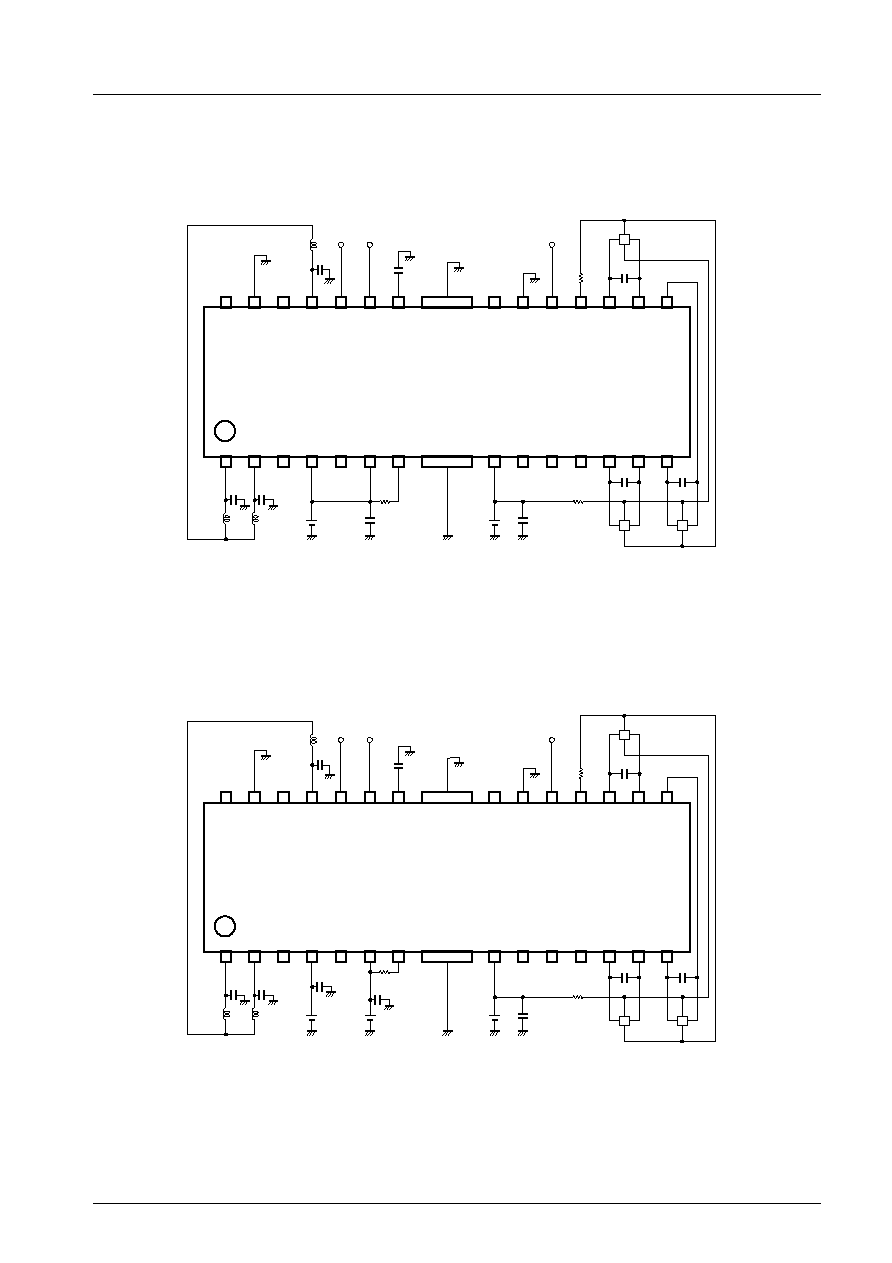

LB1895 Sample Application Circuit (1)

LB1895 Sample Application Circuit (2)

Between power supply and GND, Output and GND, and between Hall inputs:

The capacitors may change, depending on the motor.

The capacitor between the Hall inputs in particular may not be required with some motors.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

12V

0.1�F

0.1�F

0.1�F

0.1�F

S/S

0.1�F

0.1�F

0.047�F

0.047�F

0.047�F

0.2 to 0.5

L B 1 8 9 5

A06725

5V

CTL

signal

CTL

reference

voltage

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

6V

5V

0.1�F

0.1�F

0.1�F

0.1�F

0.1�F

S/S

0.1�F

0.1�F

0.047�F

0.047�F

0.047�F

0.2 to 0.5

L B 1 8 9 5

5V

A06726

CTL

signal

CTL

reference

voltage

LB1895, 1895D

No.5634-9/12

LB1895D Sample Application Circuit (1)

LB1895D Sample Application Circuit (2)

Between power supply and GND, Output and GND, and between Hall inputs:

The capacitors may change, depending on the motor.

The capacitor between the Hall inputs in particular may not be required with some motors.

L B 1 8 9 5 D

A06727

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

12V

0.1�F

0.1�F

0.1�F

0.1�F

S/S

0.1�F

0.1�F

0.047�F

0.047�F

0.047�F

0.2 to 0.5

5V

CTL

signal

CTL

reference

voltage

L B 1 8 9 5 D

A06728

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

6V

0.1�F

0.1�F

0.1�F

S/S

0.1�F

0.1�F

0.047�F

0.047�F

0.047�F

5V

5V

0.1�F

0.2 to 0.5

CTL

signal

CTL

reference

voltage

LB1895, 1895D

No.5634-10/12

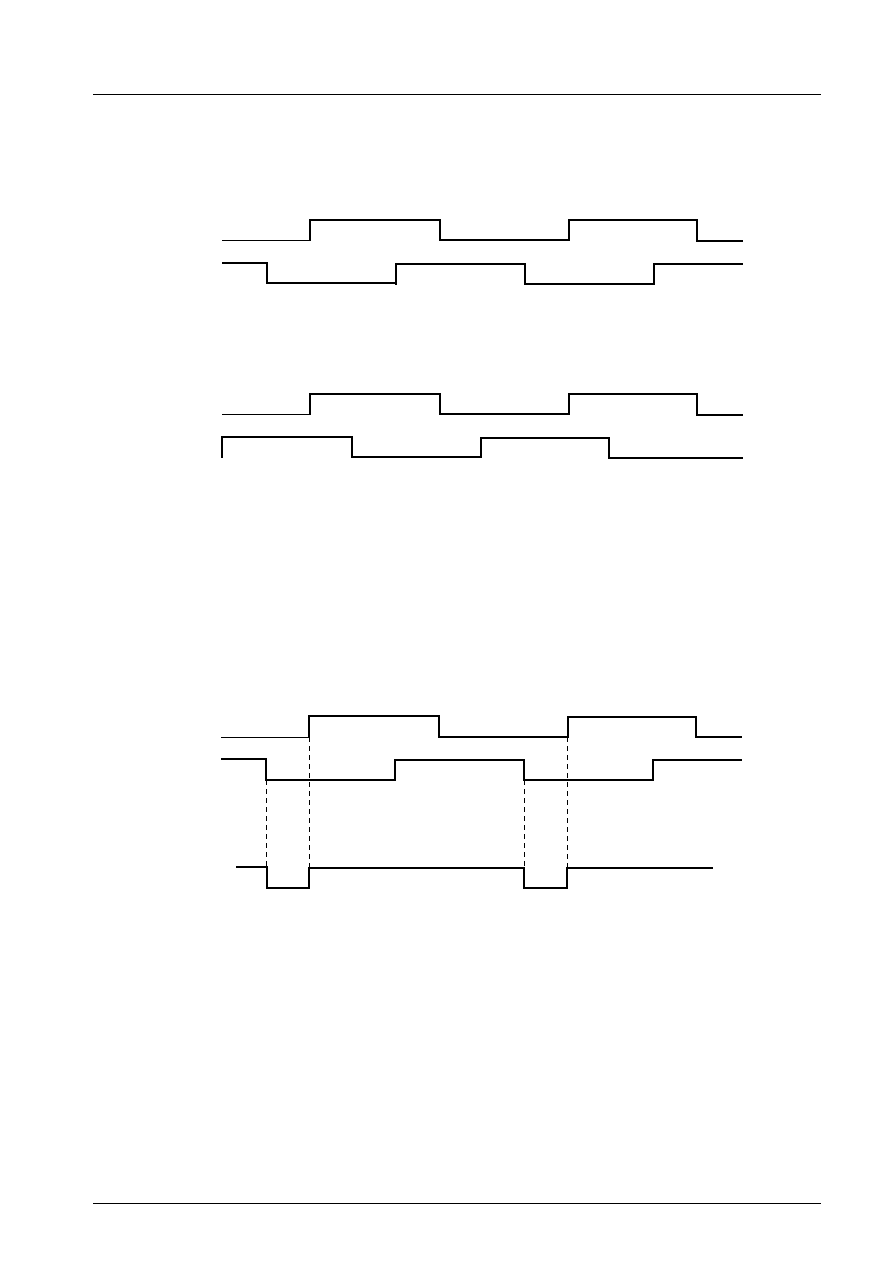

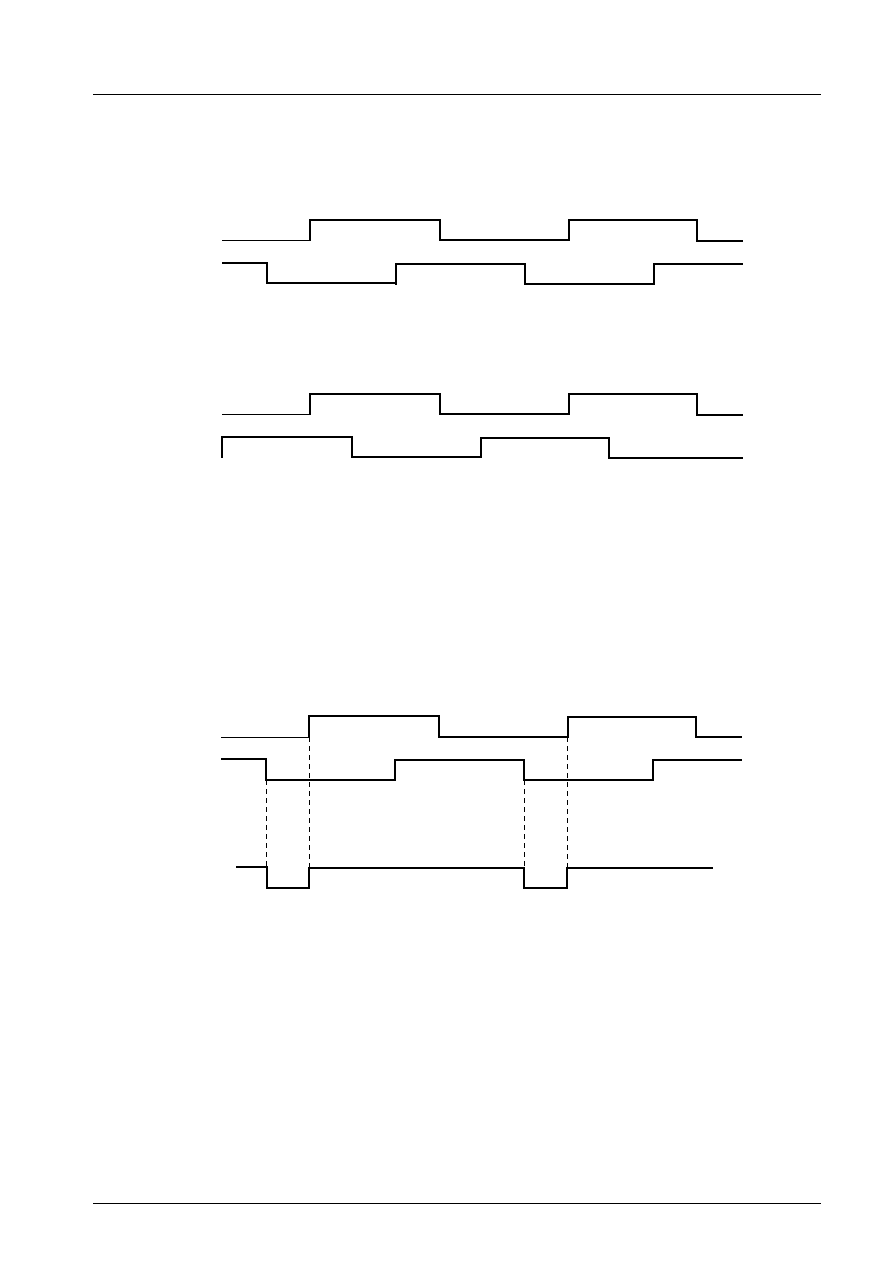

LB1895,1895D -- Example of using a comparator to detect the direction of rotation

When the phasing is as shown above, the direction of rotation is determined to be

``forward'' if W

COMPO

is low at the rising edge of V

COMPO

, and

``reverse'' if W

COMPO

is high at the rising edge of V

COMPO

.

1)

Reverse full braking method

Braking is applied with VC = L until reverse rotation is detected. The moment that reverse rotation is detected, the driving

power is turned off or a short pulse is input.

2)

Intermittent braking method

If braking is applied according to the value obtained by OR logic in V

COMPO

and W

COMPO

together, for example, reverse braking

is applied according to the following timing.

As a result, when the rotation speed is fast, braking is applied many times; at slower speeds, braking is applied fewer times.

Furthermore, if the V

COMPO

and W

COMPO

logic combination is changed, the duty of VC = 0 V � 2.5 V also changes.

VCOMPO

WCOMPO

VCOMPO

WCOMPO

A06729

When VC

^

VC

REF

When VC

%

VC

REF

VCOMPO

WCOMPO

VC = 2.5V

VC = 0V

A06730

fig. 1

fig. 2

LB1895, 1895D

No.5634-11/12

The following graph illustrates the change in the rotation speed after braking is applied under methods 1 and 2 described above.

No products described or contained herein are intended for use in surgical implants, life-support systems, aerospace equipment,

nuclear power control systems, vehicles, disaster/crime-prevention equipment and the like, the failure of which may directly or

indirectly cause injury, death or property loss.

Anyone purchasing any products described or contained herein for an above-mentioned use shall:

1

Accept full responsibility and indemnify and defend SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and distributors

and all their officers and employees, jointly and severally, against any and all claims and litigation and all damages, cost and

expenses associated with such use:

2

Not impose any responsibility for any fault or negligence which may be cited in any such claim or litigation on SANYO

ELECTRIC CO., LTD., its affiliates, subsidiaries and distributors or any of their officers and employees jointly or severally.

Information (including circuit diagrams and circuit parameters) herein is for example only; it is not guaranteed for volume

production. SANYO believes information herein is accurate and reliable, but no guarantees are made or implied regarding its use

or any infringements of intellectual property rights or other rights of third parties.

This catalog provides information as of April, 1997. Specifications and information herein are subject to change without notice.

A06731

1

2

Motor

rotation

speed

Method

2

has less

overshoot

Time after brakes were applied

LB1895, 1895D

No.5634-12/12