| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: LB1927 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

LB1927

No. 6197-1/12

LB1927

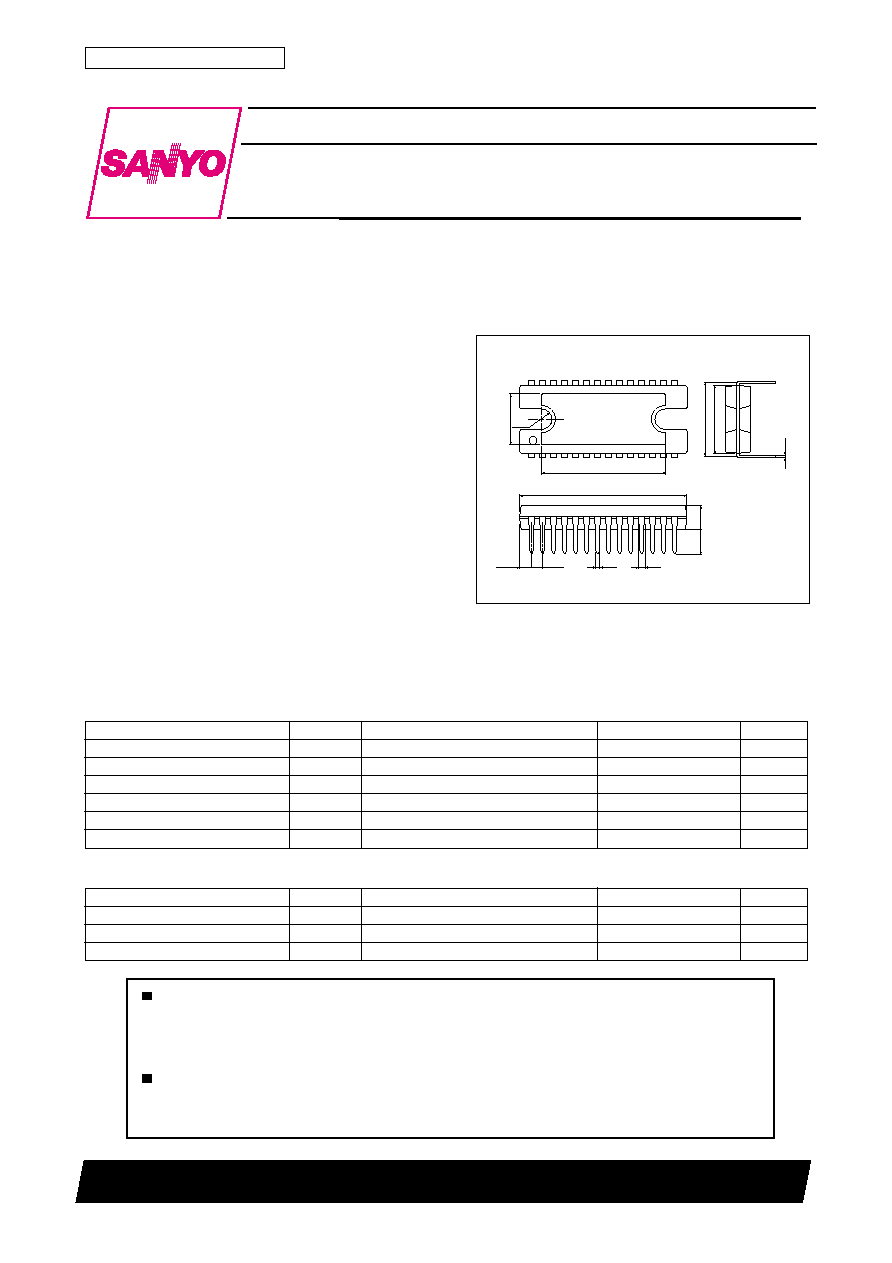

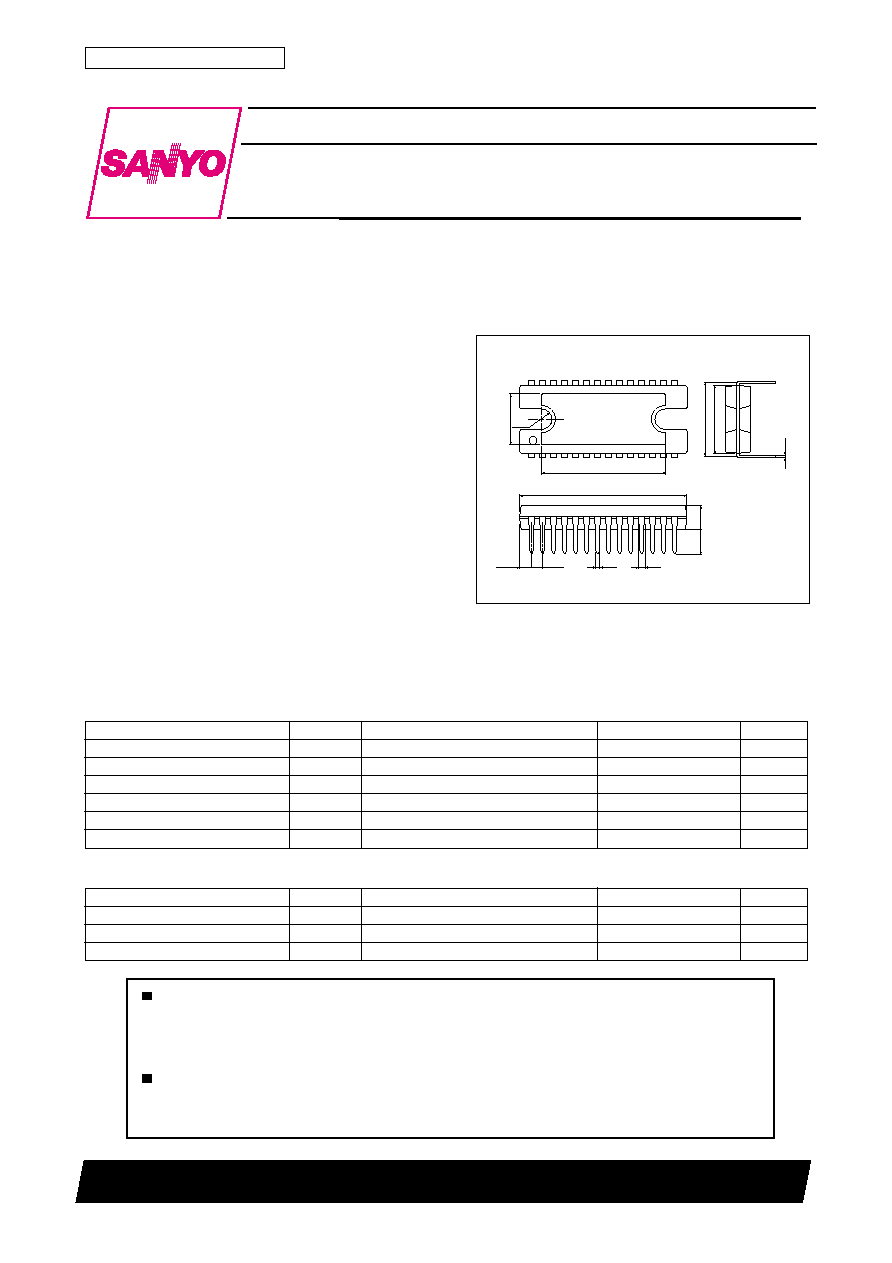

Package Dimensions

unit: mm

3147C-DIP28H

Overview

The LB1927 is a three-phase brushless motor driver well

suited for drum and paper feed motors in laser printers, plain-

paper copiers and other office automation equipment. Direct

PWM drive allows control with low power losses. Peripheral

circuitry including speed control circuit and FG amplifier is

integrated, thus allows drive circuit to be constructed with a

single chip.

Functions and Features

∑ Three-phase bipolar drive (30V, 2.5A)

∑ Direct PWM drive technique

∑ Built-in diode for absorbing output lower-side kickback

∑ Speed discriminator and PLL speed control

∑ Speed lock detection output

∑ Built-in forward/reverse switching circuit

∑ Built-in protection circuitry includes current limiter,

overheat protection, motor restraint protection, etc.

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft's

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

O0702AS(OT)/D1099TH(KI)/62599RM(KI)

Ordering number : ENN6197B

SANYO Electric Co.,Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Monolithic Digital IC

Three-Phase Brushless Motor Driver

for Office Automation Equipment

[LB1927]

SANYO : DIP28H

Specifications

Absolute Maximum Ratings

at Ta = 25

∞

C

Parameter

Symbol

Conditions

Ratings

Unit

Maximum supply voltage

Vcc

max

30

V

Maximum output current

I

O

max

T

500 ms

2.5

A

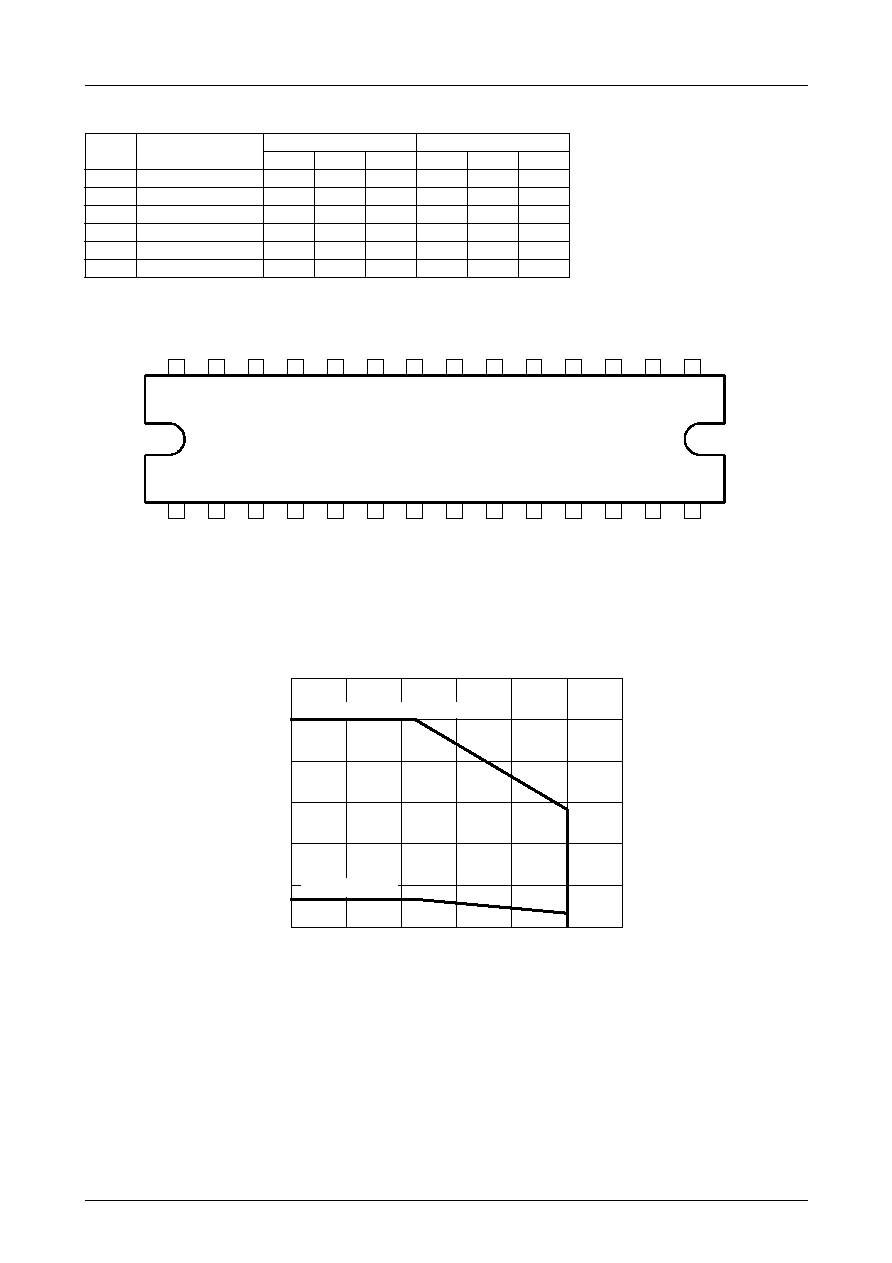

Allowable power dissipation 1

Pd max 1

IC only

3

W

Allowable power dissipation 2

Pd max 2

With an arbitrary large heat sink

20

W

Operating temperature

Topr

≠20 to +80

∞

C

Storage temperature

Tstg

≠55 to +150

∞

C

Allowable Operating Ranges

at Ta = 25

∞

C

Parameter

Symbol

Conditions

Ratings

Unit

Power supply voltage range 1

Vcc

9.5 to 28

V

Regulator voltage output current

IREG

≠30 to 0

mA

LD output current

ILD

0 to 15

mA

1

14

28

15

0.4

0.6

4.0

4.0

26.75

20.0

R1.7

8.4

(1.81)

1.78

1.0

12.7

11.2

LB1927

No. 6197-2/12

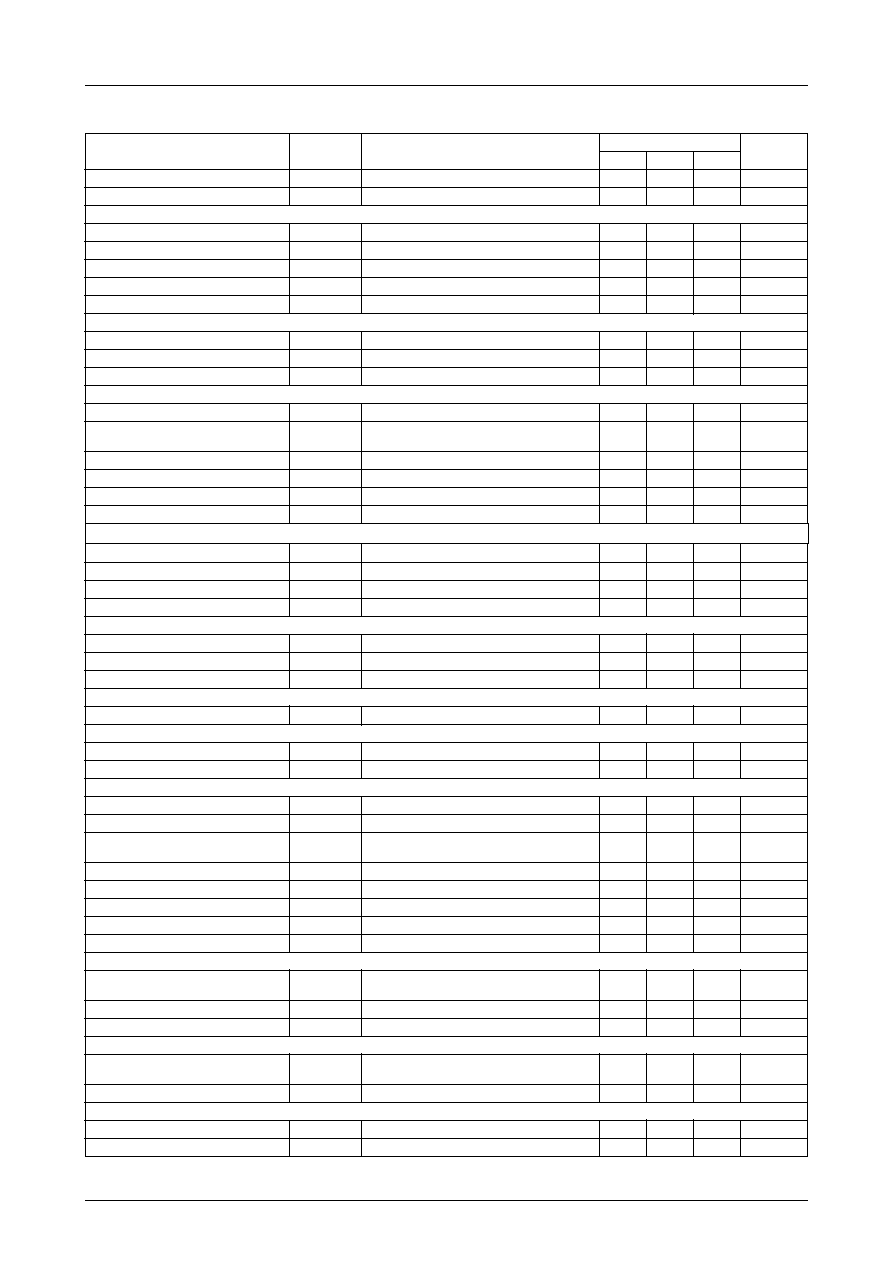

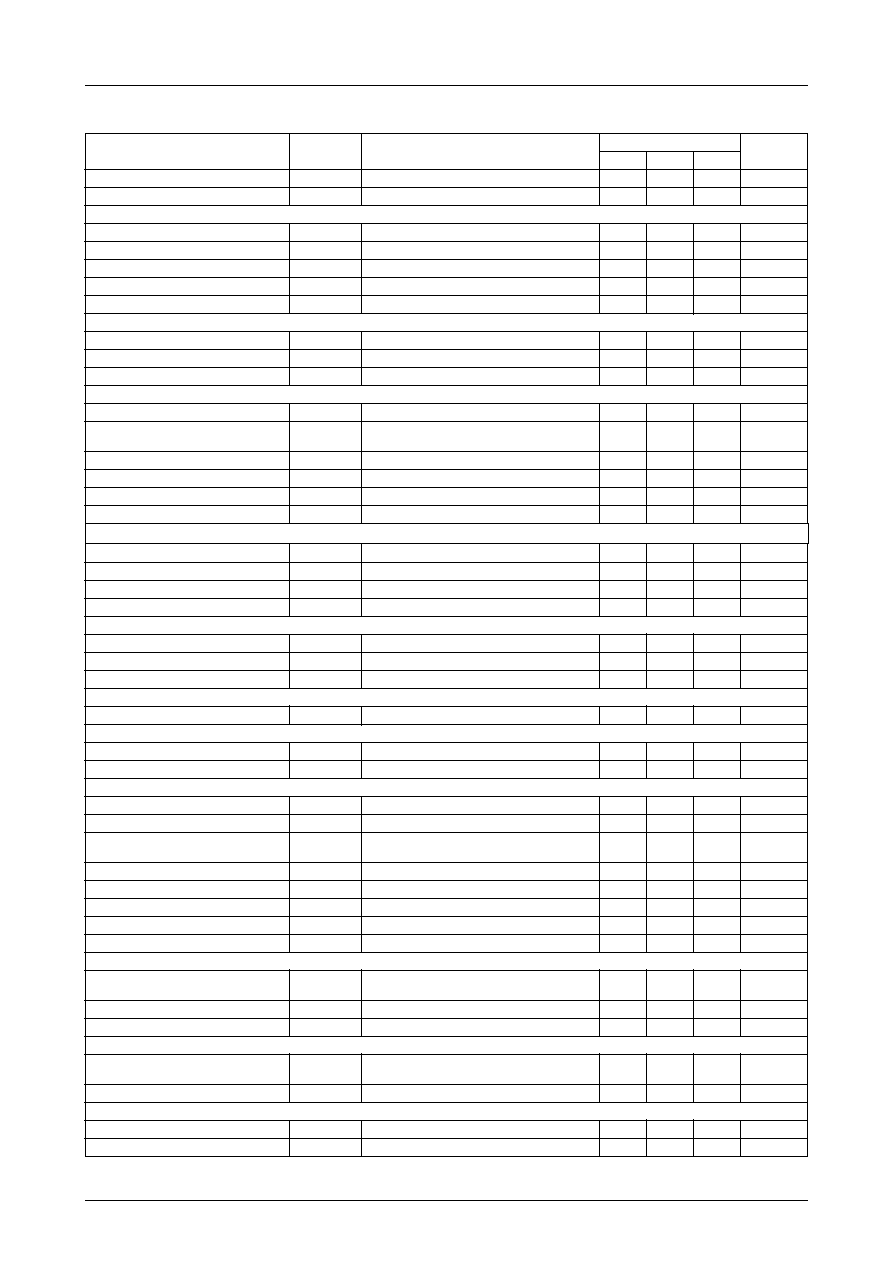

Electrical Characteristics

at Ta = 25∞C, Vcc = VM = 24V

Parameter

Symbol

Conditions

Ratings

Unit

min

typ

max

Power supply current 1

Icc1

23

30

mA

Power supply current 2

Icc2

In STOP mode

3.5

5.0

mA

[Output]

Output saturation voltage 1

Vosat1

Io = 1.0A, Vo(SINK) + Vo(SOURCE)

2.0

2.5

V

Output saturation voltage 2

Vosat2

Io = 2.0A, Vo(SINK) + Vo(SOURCE)

2.6

3.2

V

Output leak current

Ioleak

100

µ

A

Lower-side diode forward voltage 1

VD1

ID = ≠1.0A

1.2

1.5

V

Lower-side diode forward voltage 2

VD2

ID = ≠2.0A

1.5

2.0

V

[5V regulator voltage output]

Output voltage

VREG

Io = ≠5 mA

4.65

5.00

5.35

V

Voltage fluctuation

VREG1

Vcc = 9.5 to 28V

30

100

mV

Load fluctuation

VREG2

Io = ≠5 to ≠20 mA

20

100

mV

[Hall amplifier]

Input bias current

IHB

≠2

≠0.5

µ

A

Common mode input voltage range

VICM

1.5

VREG

V

≠1.5

Hall input sensitivity

80

mVp-p

Hysteresis width

VIN

15

24

42

mV

Input voltage L -> H

VSLH

12

mV

Input voltage H-> L

VSHL

≠12

mV

[PWM oscillator]

Output High level voltage

VOH(PWM)

2.5

2.8

3.1

V

Output Low level voltage

VOL(PWM)

1.2

1.5

1.8

V

Oscillator frequency

f(PWM)

C = 3900 pF

18

kHz

Amplitude

V(PWM)

1.05

1.30

1.55

Vp-p

[CSD circuit]

Operating voltage

VOH(CSD)

3.6

3.9

4.2

V

External capacitance charge current

ICHG

≠17

≠12

≠9

µ

A

Operating time

T(CSD)

C = 10

µ

F Design target value

3.3

s

[Current limiter operation]

Limiter

VRF

V

CC

-VM

0.45

0.5

0.55

V

[Thermal shutdown operation]

Thermal shutdown operating temperature

TSD

Design target value (junction temperature)

150

180

∞

C

Hysteresis width

TSD

Design target value (junction temperature)

50

∞

C

[FG amplifier]

Input offset voltage

VIO(FG)

≠10

+10

mV

Input bias current

IB(FG)

≠1

+1

µ

A

Output High level voltage

VOH(FG)

IFGO = ≠0.2 mA

VREG

VREG

V

≠1.2

≠0.8

Output Low level voltage

VOL(FG)

IFGO = 0.2 mA

0.8

1.2

V

FG input sensitivity

GAIN 100 times

3

mV

Next-stage Schmitt comparator width

Design target value

100

180

250

mV

Operation frequency range

2

kHz

Open-loop gain

f(FG) = 2 kHz

45

51

dB

[Speed discriminator]

Output High level voltage

VOH(D)

IDO = ≠0.1 mA

VREG

VREG

V

≠1.0

≠0.7

Output Low level voltage

VOL(D)

IDO = 0.1 mA

0.8

1.1

V

Count number

512

[PLL output]

Output High level voltage

VOH(P)

IPO = ≠0.1 mA

VREG

VREG

VREG

V

≠1.8

≠1.5

≠1.2

Output Low level voltage

VOL(P)

IPO = 0.1 mA

1.2

1.5

1.8

V

[Lock detection]

Output Low level voltage

VOL(LD)

ILD = 10 mA

0.15

0.5

V

Lock range

6.25

%

Continued on next page

LB1927

No. 6197-3/12

Continued from preceding page

Parameter

Symbol

Conditions

Ratings

Unit

min

typ

max

[Integrator]

Input bias current

IB(INT)

≠0.4

+0.4

µ

A

Output High level voltage

VOH(INT)

IINTO = ≠0.2 mA

VREG

VREG

V

≠1.2

≠0.8

Output Low level voltage

VOL(INT)

IINTO = 0.2 mA

0.8

1.2

V

Open-loop gain

f(INT) = 1 kHZ

45

51

dB

Gain bandwidth product

Design target value

450

kHz

Reference voltage

Design target value

≠5% VREG/2

5%

V

[Crystal oscillator]

Operating frequency range

fOSC

3

10

MHz

Low level pin voltage

VOSCL

IOSC = ≠0.5 mA

1.65

V

High level pin current

IOSCH

VOSC = VOSCL + 0.3V

0.4

mA

[Start/stop pin]

High level input voltage range

VIH(S/S)

3.5

VREG

V

Low level input voltage range

VIL(S/S)

0

1.5

V

Input open voltage

VIO(S/S)

VREG

VREG

V

≠0.5

Hysteresis width

VIN

0.35

0.50

0.65

V

High level input current

IIH(S/S)

V(S/S) = VREG

≠10

0

10

µ

A

Low level input current

IIL(S/S)

V(S/S) = 0V

≠280

≠210

µ

A

[Forward/reverse pin]

High level input voltage range

VIH(F/R)

3.5

VREG

V

Low level input voltage range

VIL(F/R)

0

1.5

V

Input open voltage

VIO(F/R)

VREG

VREG

V

≠0.5

Hysteresis width

VIN

0.35

0.50

0.65

V

High level input current

IIH(F/R)

V(F/R) = VREG

≠10

0

+10

µ

A

Low level input current

IIL(F/R)

V(F/R) = 0V

≠280

≠210

µ

A

LB1927

No. 6197-4/12

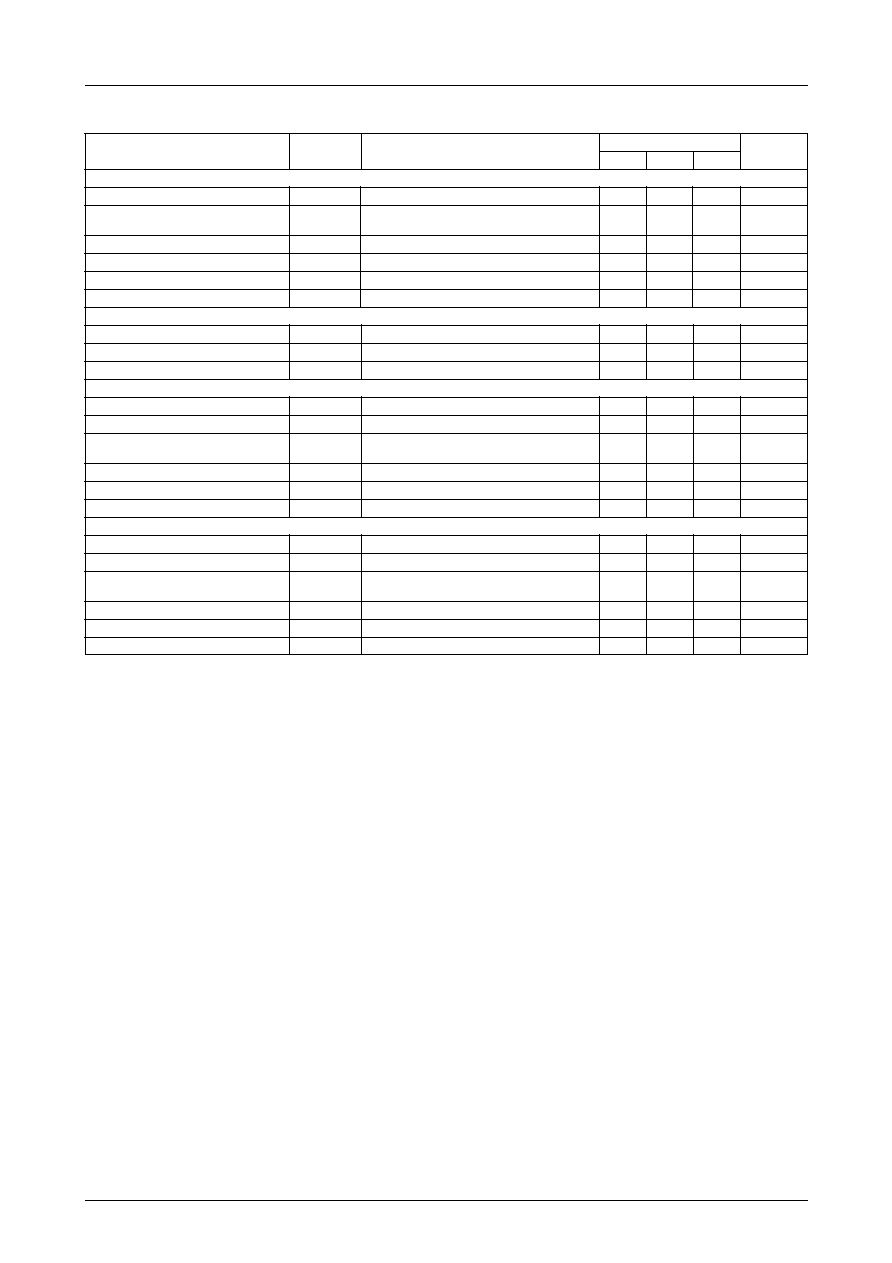

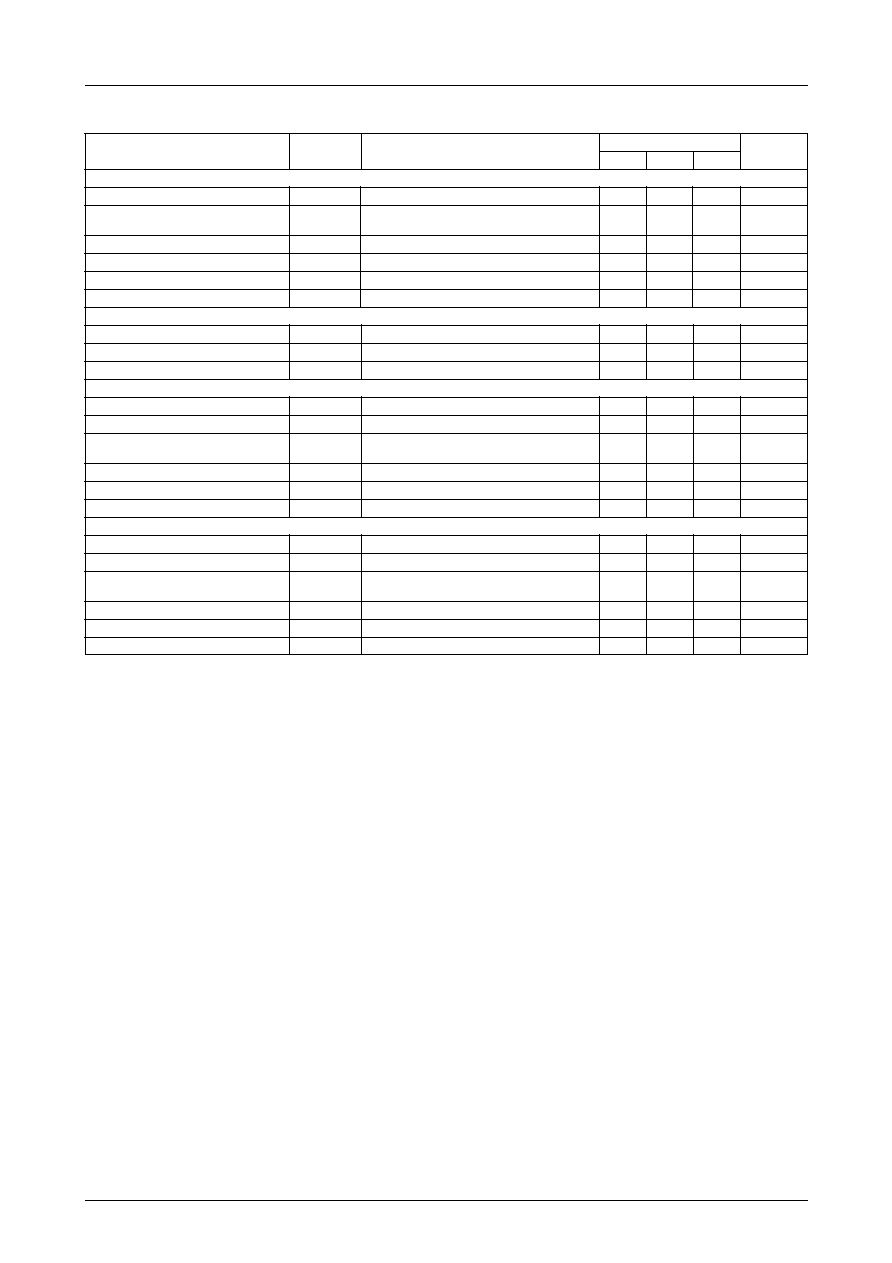

Truth Table

Source

F/R = "L"

F/R = "H"

Sink

IN1

IN2

IN3

IN1

IN2

IN3

1

OUT2 -> OUT1

H

L

H

L

H

L

2

OUT3 -> OUT1

H

L

L

L

H

H

3

OUT3 -> OUT2

H

H

L

L

L

H

4

OUT1 -> OUT2

L

H

L

H

L

H

5

OUT1 -> OUT3

L

H

H

H

L

L

6

OUT2 -> OUT3

L

L

H

H

H

L

Pin Assignment

27

26

28

24

23

25

21

20

22

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

OUT1

F/R

IN3+

IN3≠

IN2+

IN2≠

OUT2 OUT3 GND2 VCC

VM

IN1+

IN1≠ GND1

S/S

FGIN+ FGIN≠ FGOUT LD

VREG PWM CSD

X I

X O INTOUT INTIN POUT DOUT

Top view

LB1927

Relationship between crystal oscillator frequency fosc and FG frequency fFG is as follows.

fFG (servo) = fosc/ (ECL divide-by-16

◊

count number)

= fosc/8192

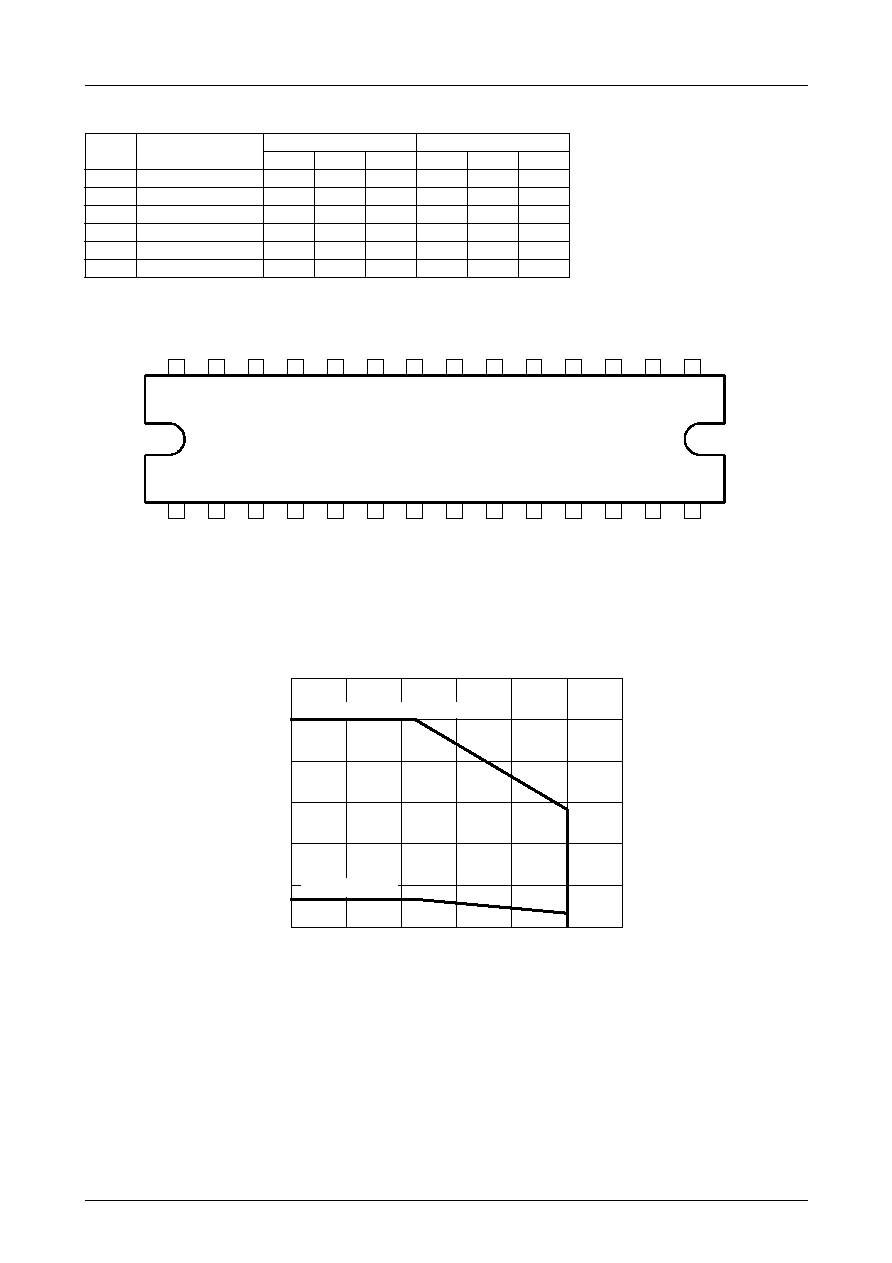

≠20

0

20

40

60

80

100

Ambient temperature, Ta ≠

∞

C

0

4

3

8

12

16

20

24

With an arbitrary large heat sink

Without heat sink

Pd max ≠ Ta

Allowable power dissipation, Pd max - W

LB1927

No. 6197-5/12

Equivalent Circuit Block Diagram

FG

RST

LOCK

DET

SPEED

DISCRI

ECL

1/16

Xtal

OSC

CSD

CIRCUIT

CURR

LIM

PLL

S/S

F/R

5VREG

LOGIC

DRIVER

COMP

TSD

1/512

BGP

VREF

OUT1

OUT2

OUT3

VM

Rf

Vcc

Vcc

PWM

CSD

INT. OUT

INT.IN

DOUT

POUT

LD

LD

FGOUT

FGIN+

FGIN≠

FG AMP

GND1

+

≠

+

≠

+

≠

XI

XO

S/S

F/R

VREG

IN1

IN2

IN3

GND2

VREF

VREG

VREG/2

INT AMP

PWM OSC

HALL HYS AMP

LB1927

No. 6197-6/12

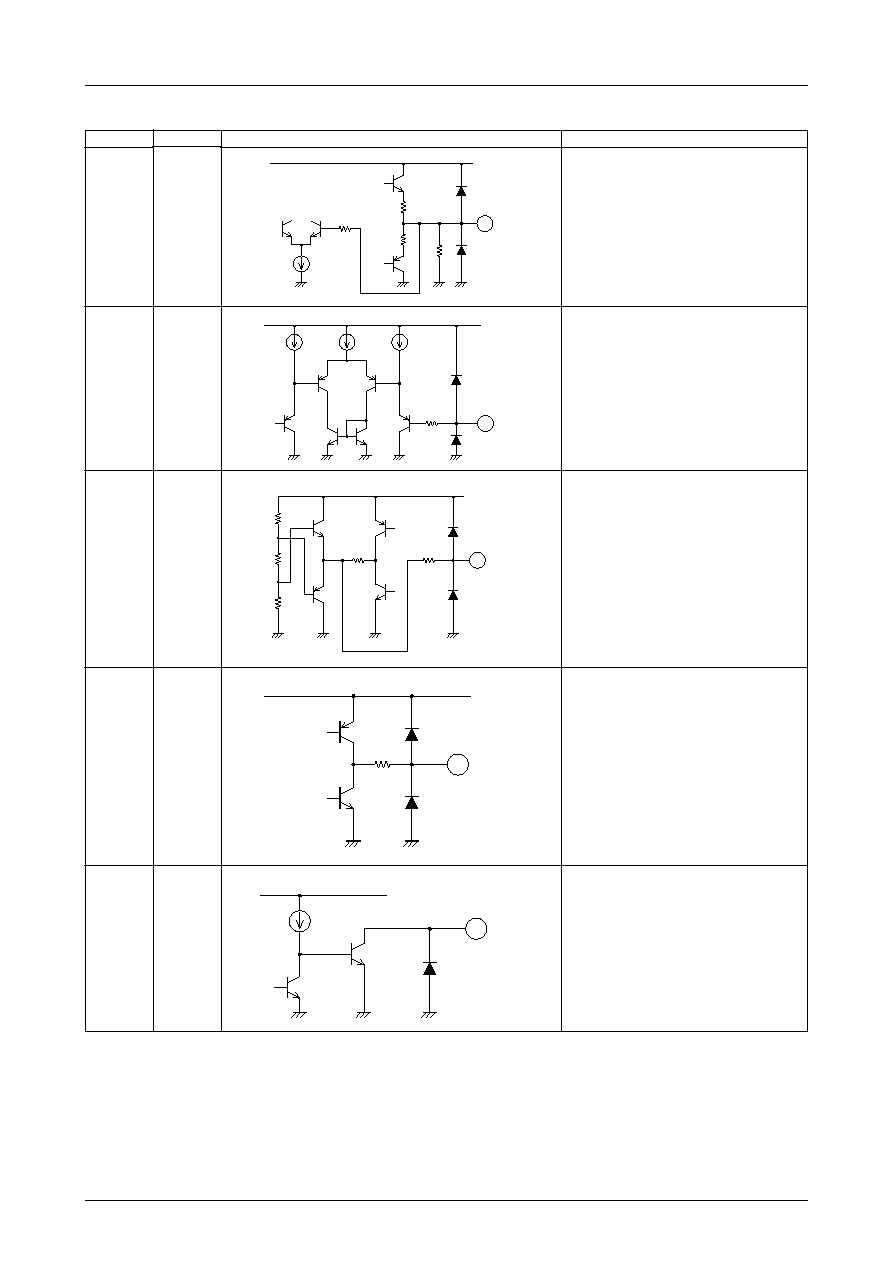

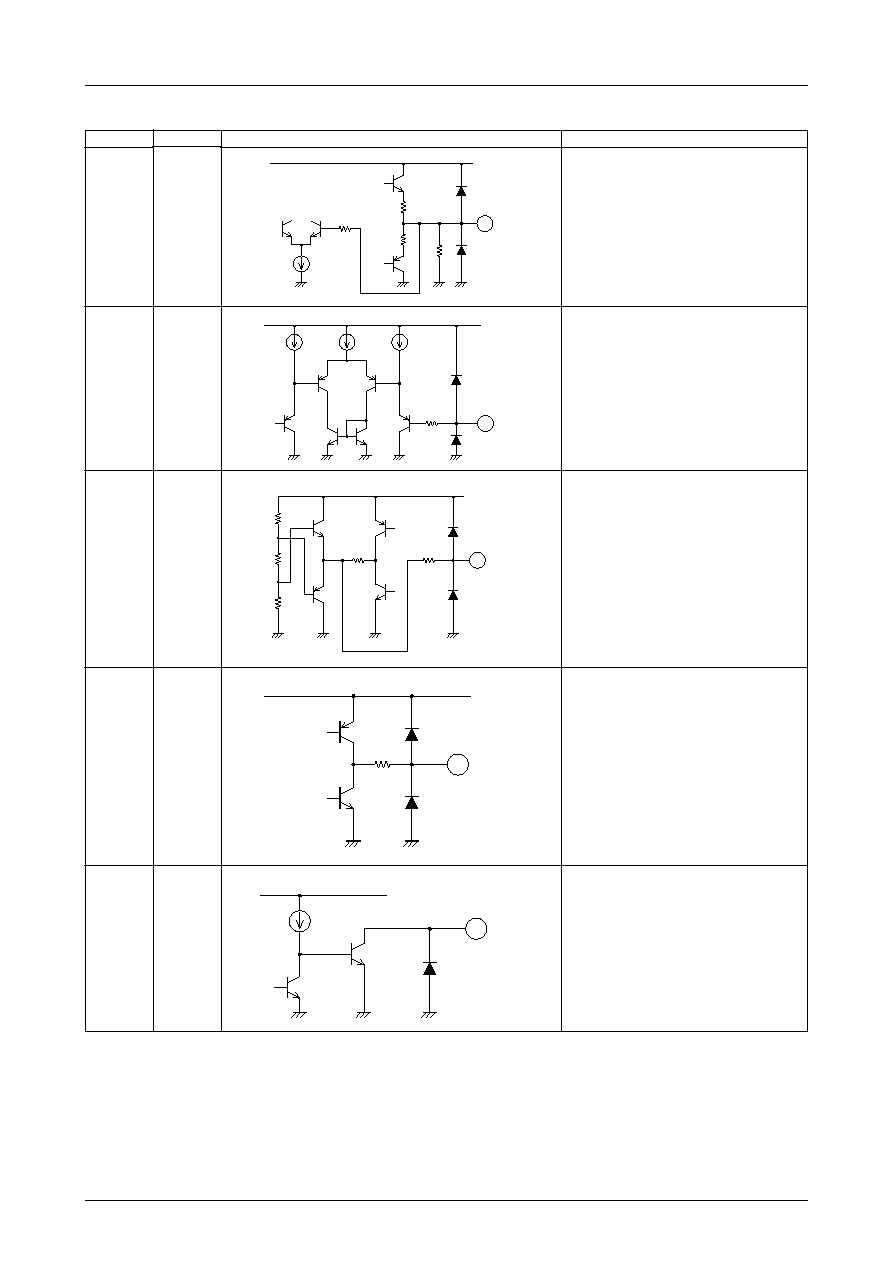

Pin number

28

1

2

3

5

4

6

7

8

9

10

Pin name

OUT1

OUT2

OUT3

GND2

VM

V

CC

VREG

PWM

CSD

XI

XO

Equivalent circuit

Pin Description

Pin function

Motor drive output pins.

Connect a Schottky diode between these

outputs and V

CC

.

Output ground pin.

Output block power supply and output

current detection pin.

Connect a resistor (Rf) between this pin and

V

CC

to detect the output current as a voltage.

The output current is limited according to the

equation I

OUT

= VRF/Rf.

Power supply pin (except for output block)

Regulated power supply output pin (5V

output)

Connect a capacitor (approx. 0.1

µ

F) between

this pin and ground to stabilize the output.

PWM frequency setting pin.

Connect a capacitor between this pin and

ground.

C = 3900 pF results in a frequency of about

18 kHz.

Lock protection circuit operation time

setting pin.

Connecting a capacitor of about 10

µ

F

between this pin and ground results in a

protection circuit operation time of about 3.3

seconds.

Quartz oscillator pins.

Connect to quartz oscillator to generate the

reference clock.

When an external clock (of several MHz) is

used, the clock signal should be input via a

resistor of about 5.1 k

connected in series

with the XI pin. In this case, the XO pin must

be left open.

Continued on next page

5

3

1

2

28

VCC

300

VM

A12983

6

VCC

A12984

7

200

2k

VREG

A12985

10

9

VREG

A12987

8

300

1k

VREG

A12986

LB1927

No. 6197-7/12

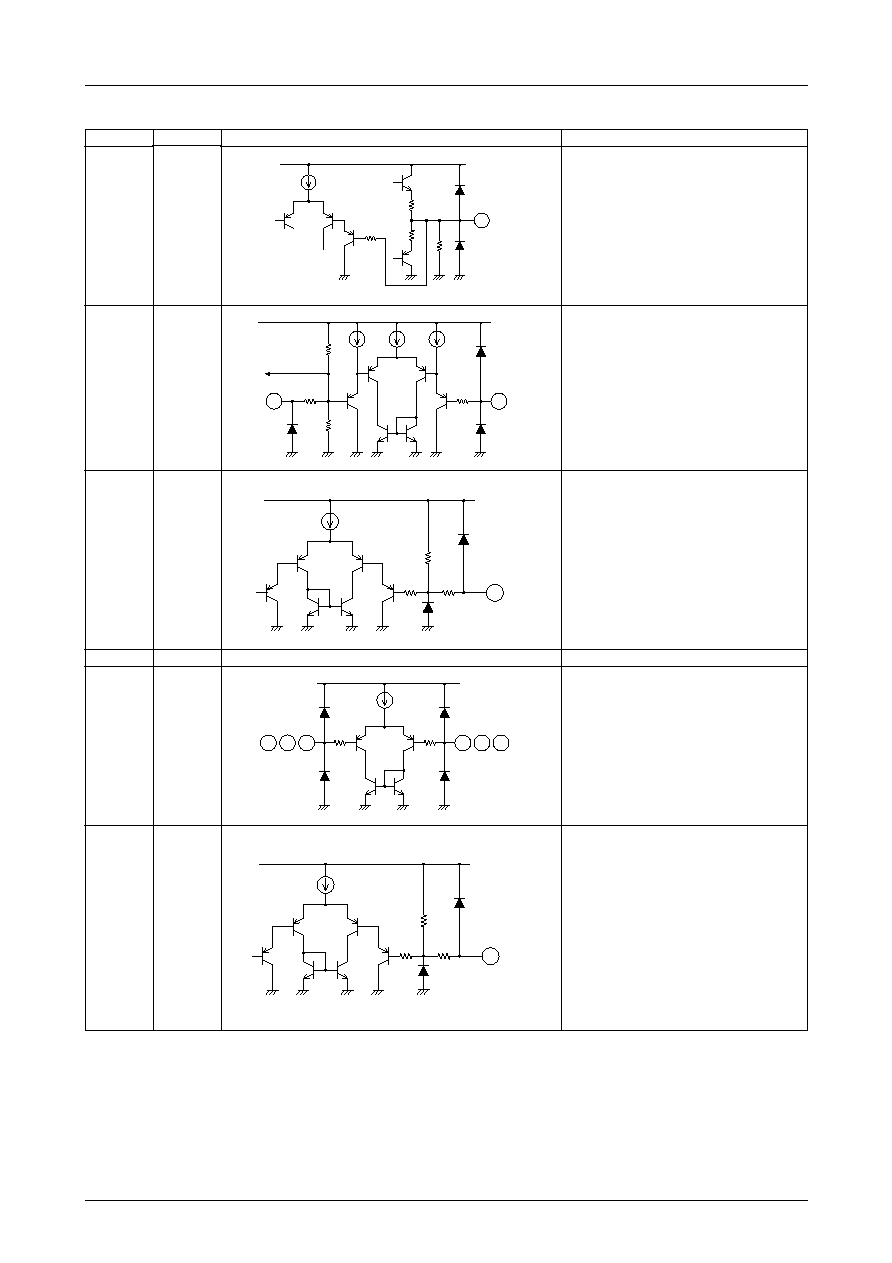

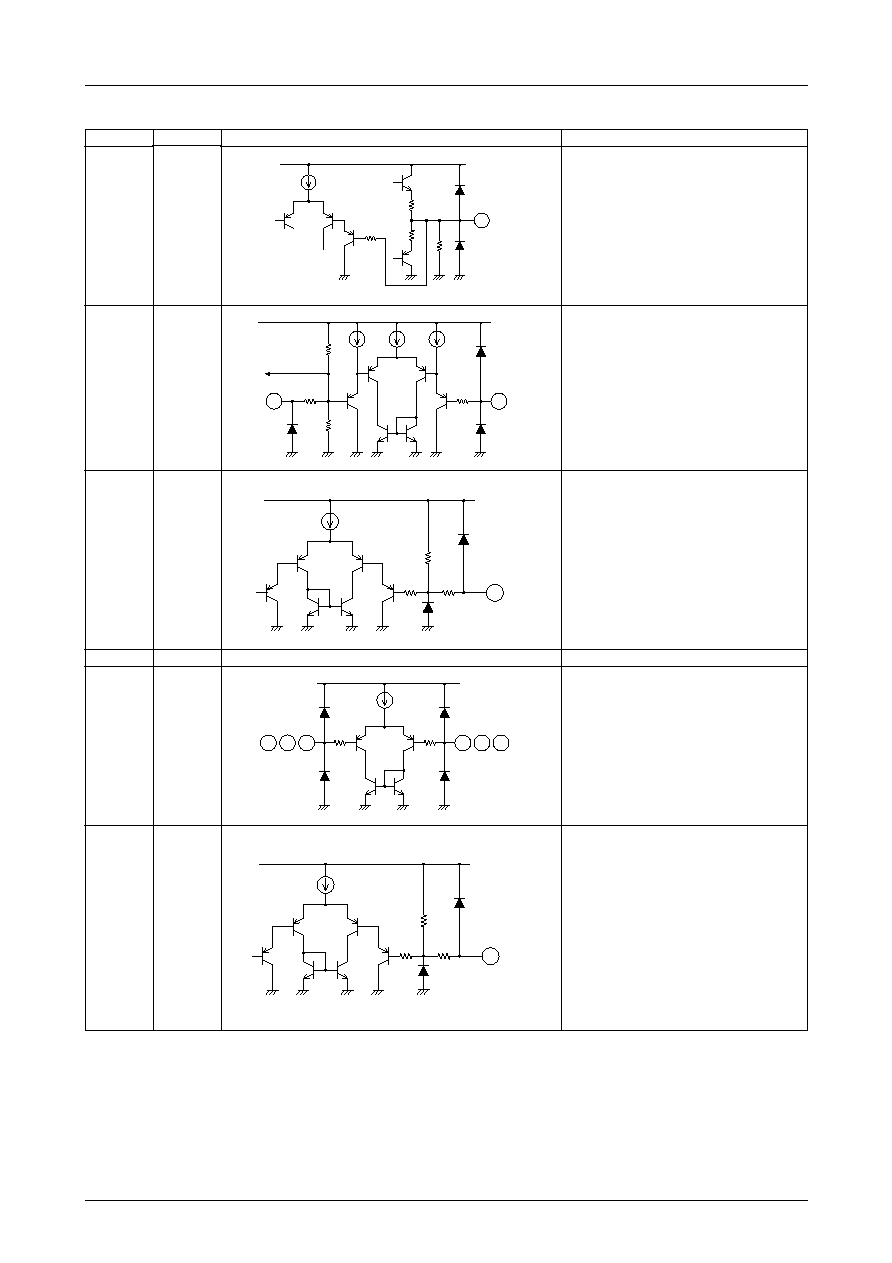

Pin number

11

12

13

14

15

Pin name

INT

OUT

INT

IN

POUT

DOUT

LD

Equivalent circuit

Pin function

Integrator output pin (speed control pin)

Integrator input pin.

PLL output pin.

Speed discriminator output pin.

Acceleration: High, Deceleration: Low

Speed lock detection pin.

When motor rotation is within lock range

(

±

6.25%): Low

Withstand voltage: 30V max.

Continued on next page

Continued from preceding page

11

VREG

PWM comparator

40k

A12988

12

300

VREG

A12989

13

300

VREG

A12990

14

300

VREG

A12991

15

VREG

A12992

LB1927

No. 6197-8/12

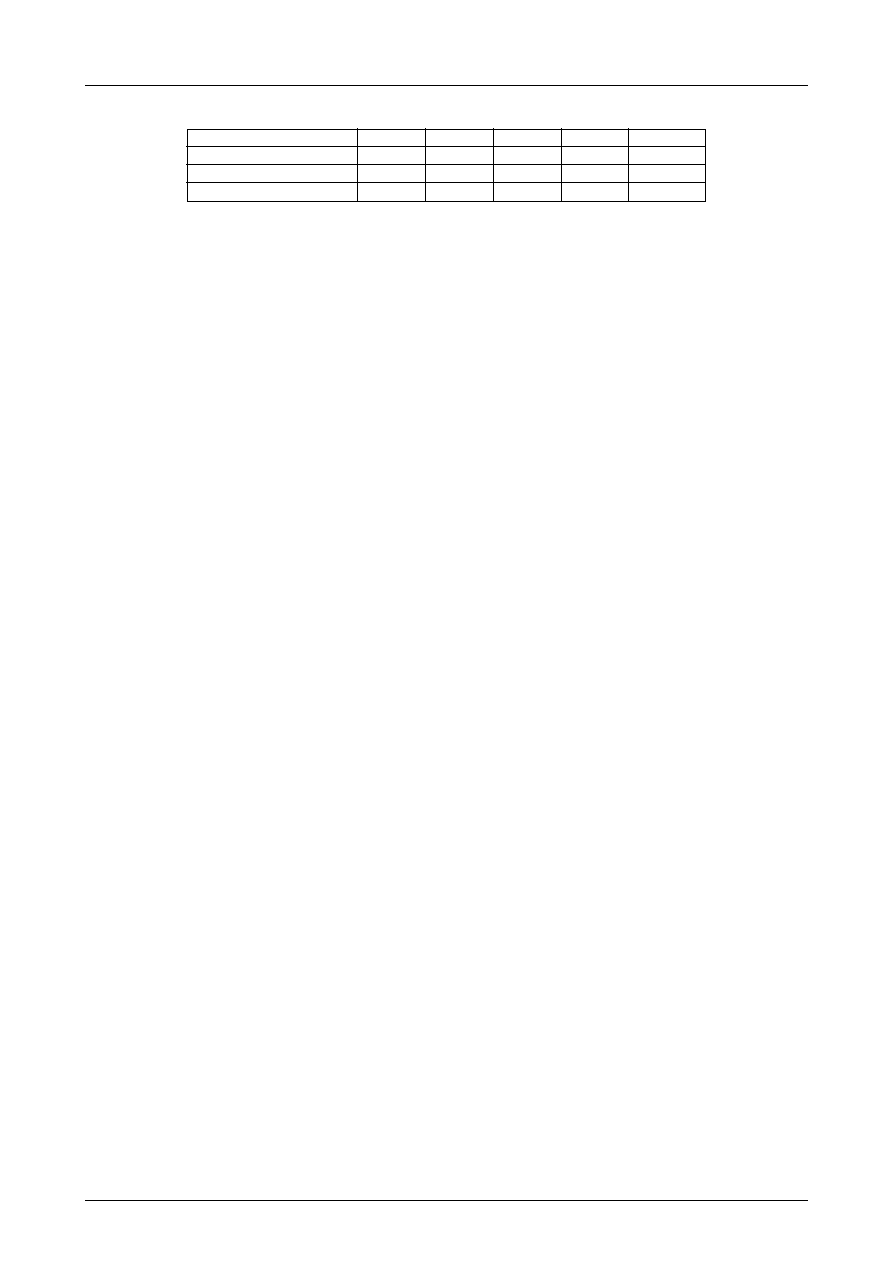

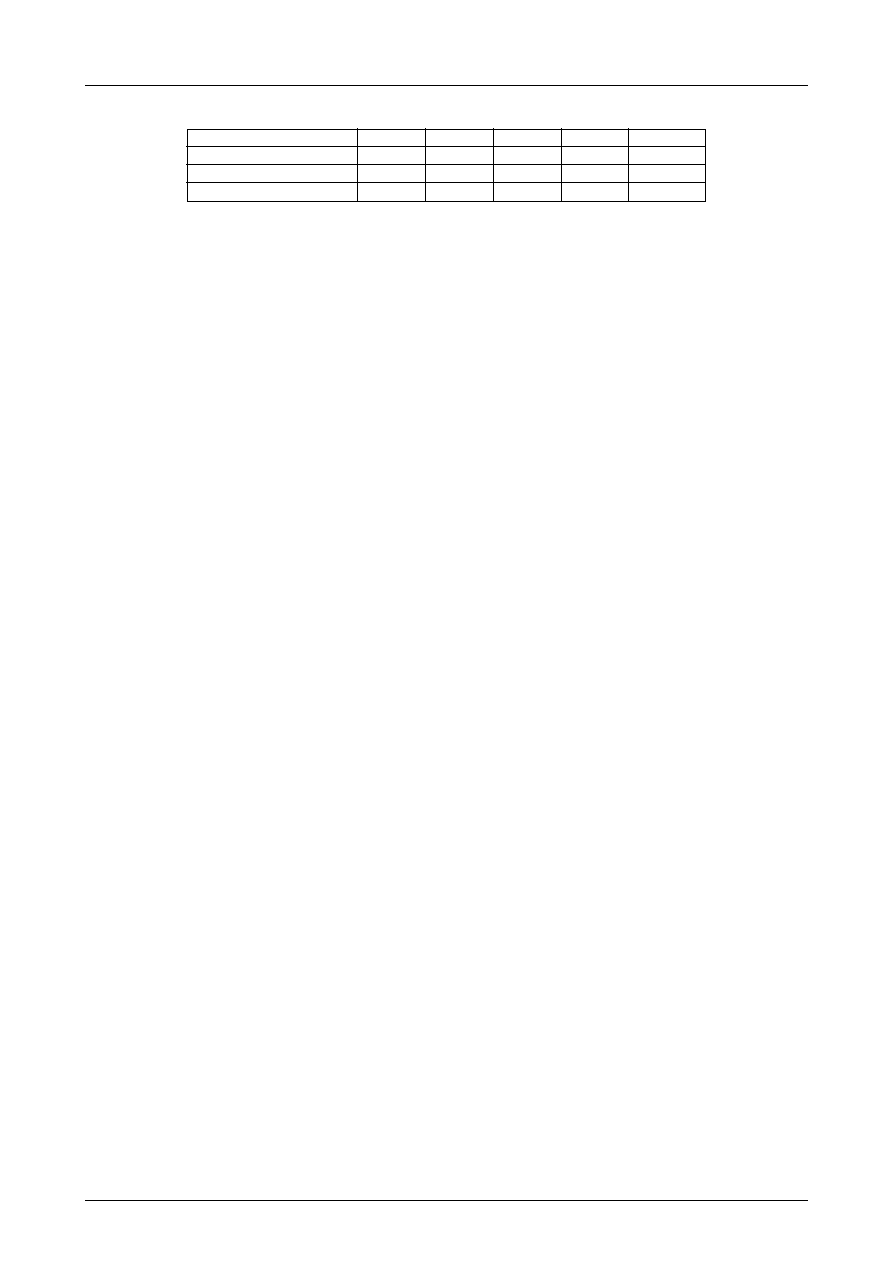

Pin number

16

17

18

19

20

22

21

24

23

26

25

27

Pin name

FG

OUT

FGIN≠

FGIN+

S/S

GND1

IN1+

IN1≠

IN2+

IN2≠

IN3+

IN3≠

F/R

Equivalent circuit

Pin function

FG amplifier output pin.

FG amplifier input pin.

By connecting a capacitor (approx. 0.1

µ

F)

between FGIN+ and ground, the logic circuitry

is reset.

Start/stop control pin.

Start (Low): 0V to 1.5V

Stop (High): 3.5V to VREG

High when open.

Hysteresis width: approx. 0.5V.

Ground pin (except for output block).

Hall input pins.

High when IN+ > IN≠, Low when IN+ < IN≠.

Hall signal should have an amplitude of at least

100 mVp≠p (differential operation). When Hall

signal noise is a problem, connect a capacitor

between IN+ and IN≠.

Forward/reverse control pin.

Forward (Low): 0V to 1.5V

Reverse (High): 3.5V to VREG

High when open.

Hysteresis width: approx. 0.5V.

Continued from preceding page

16

VREG

FG schmitt comparator

40k

A12993

18

17

300

300

20k

20k

VREG

FG reset circuit

A12994

22k

19

2k

VREG

A12995

22

24

26

300

25

23

21

300

VREG

A12996

22k

27

2k

VREG

A12997

LB1927

No. 6197-9/12

Description of the LB1927

1.

Speed control circuit

The IC performs speed control through combined use of a speed discrimination circuit and PLL circuit. The speed

control circuit counts FG cycles and outputs a deviation signal every 2 FG cycles. The PLL circuit outputs a phase

deviation signal every FG cycle.

The FG servo frequency is determined by the following equation. The motor rotation speed is set by the number of

FG pulses and the crystal oscillator frequency.

fFG (servo) = fOSC/8192

fOSC: Crystal oscillator frequency

2.

Output drive circuit

In order to reduce power loss at the output, the LB1927 uses the PWM drive technique. While ON, the output

transistors are always saturated, and motor drive power is adjusted by varying the output ON duty ratio. Because

output PWM switching is performed by the lower-side output transistor, a Schottky diode must be connected

between OUT and VCC. (If the reverse recovery time of the diode is too long, a feedthrough current will flow at the

instant when the lower-side transistor goes ON.) An internal diode is provided between OUT and GND. If large

output current causes a problem (waveform distortion during lower-side kickback, etc.), an external rectifying diode

or Schottky diode should be connected.

The output diode is integrated only on the lower side.

3.

Current limiting circuit

The current limiting circuit limits the peak current to the value I = VRF/Rf (VRF = 0.5 V typ., Rf: current detector

resistance). Current limiting is achieved by reducing the ON duty ratio of the output, which reduces the current.

4.

Power save circuit

In order to reduce current drain in the STOP condition, the IC goes into power save mode. In this condition, bias

current to most circuits is cut off, but the 5V regulator output remains active.

5.

Reference clock

The reference clock for speed control can be input using one of the following two methods.

[1] Using a crystal oscillator

When a crystal is used for oscillation, connect the crystal, capacitors, and a resistor as shown in the figure

below.

R1

C1

VREG

XI

XO

C2

C3

C4

C1, R1: For stable oscillation

C3: For oscillator coupling

C2: For stabilization and to prevent oscillation at upper harmonic frequencies

C4: Prevents oscillation at upper harmonic frequencies

LB1927

No. 6197-10/12

The circuit configuration and values are for reference only. The crystal oscillator's characteristics as well as the

possibility of floating capacitance and noise due to layout factors must be taken into consideration when

designing an actual application.

[Precautions for wiring layout design]

Since the crystal oscillator circuit operates at high frequencies, it is susceptible to the influence of floating

capacitance from the circuit board. Wiring should be kept as short as possible and traces should be kept

narrow.

When designing the external circuitry, pay special attention to the wiring layout between the oscillator and C3

(C2), to minimize the influence of floating capacitance. The capacitor C4 is quite effective at reducing the

negative resistance (gain) at high frequencies. However, care is required to avoid excessive reduction in the

negative resistance at the fundamental frequency.

[2] External clock input (equivalent to crystal oscillator, several MHz)

When using an external signal source instead of a crystal oscillator, the clock signal should be input from the

XI pin through a resistor of about 5.1 k

connected to the pin in series. The XO pin should be left open.

Signal input level

Low : 0 to 0.8V

High : 2.5 to 5.0V

6.

Speed lock range

The speed clock range is

±

6.25% of the rated speed. When the motor rotation is within the lock range, the LD pin

becomes Low (open collector output). When the motor rotation goes out of the lock range, the ON duty ratio of the

motor drive output is varied according to the amount of deviation to bring the rotation back into the lock range.

7.

PWM frequency

The PWM frequency is determined by the capacitance connected to the PWM pin.

f PWM

=

1/(14400

◊

C)

PWM frequency in the range 15 to 25 kHz is desirable. The ground side of the connected capacitor must be

connected to the GND1 pin with a lead that is as short as possible.

8.

Hall input signal

The Hall input requires a signal with an amplitude of at least the hysteresis width (42 mV max.). Taking possible

noise influences into consideration, an amplitude of at least 100 mV is desirable. If noise during output phase

switching disrupts the output waveform, insert capacitors across the Hall signal inputs (between the + and - inputs),

and position those capacitors as close as possible to the pins.

.

.

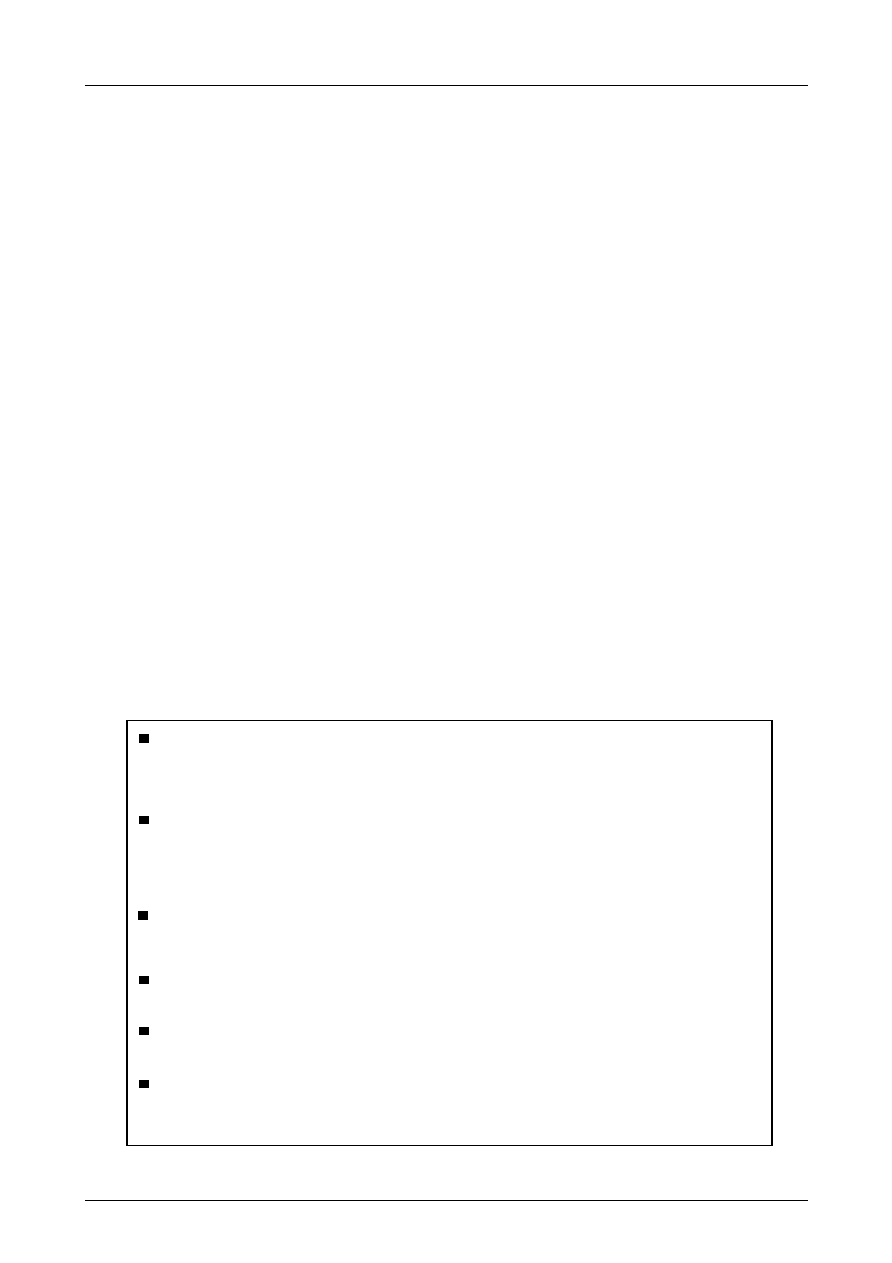

(Reference values)

Oscillator frequency (MHz)

C1 (

µ

F)

C2 (pF)

C3 (pF)

C4 (pF)

R1 (

)

3 to 5

0.1

15

47

10

330k

5 to 8

0.1

10

47

None

330k

8 to 10

0.1

10

22

None

330k

LB1927

No. 6197-11/12

9.

Forward/reverse switching

Forward/reverse switching of motor rotation is carried out with the F/R pin. If this is performed while the motor is

running, the following points must be observed:

∑

Feedthrough current during switching is handled by proper circuit design. However, the VCC voltage rise

during switching (caused by momentary return of motor current to power supply) must not exceed the rated

voltage (30V). If problems occur, the capacitance between VCC and GND must be increased.

∑

If the motor current after switching exceeds the current limiter value, the lower-side transistors go OFF but the

upper-side transistors go into the short brake state, which causes a current flow. The magnitude of the current is

determined by the motor counterelectromotive voltage and the coil resistance. This current may not exceed the

rated current (2.5A). (Forward/reverse switching at high speed therefore is not safe.)

10. Motor restraint protection circuit

To protect the IC and the motor itself when rotation is inhibited, a restraint protection circuit is provided. If the LD

output is High (unlocked) for a certain interval in the start condition, the lower-side transistors are turned off. The

length of the interval is determined by the capacitance at the CSD pin. A capacitance of 10

µ

F results in a set

interval of about 3.3 seconds. (Tolerance approx.

±

30%)

Set interval (s)

=

0.33

◊

C (

µ

F)

If the capacitor arrangement is subject to leak current, possible adverse effects such as setting time tolerances must

be taken into consideration.

When the restraint protection circuit has been activated, the condition can only be canceled by setting the system to

the stop condition or by turning the power off and on again (in the stop condition). When wishing not to use the

restraint protection circuit, connect the CSD pin to ground.

If the stop time when releasing the restraint protection is short, the capacitor charge will not be fully dissipated. This

in turn will cause a shorter restraint protection activation time after the motor has been restarted. The stop time

should therefore be designed to be sufficiently long, using the equation shown below (also when restarting in the

motor start transient state).

Stop time (ms)

15

◊

C (

µ

F)

11. Power supply stabilization

Because this IC provides a high output current and uses a switching drive technique, power supply line fluctuations

can occur easily. Therefore, a capacitor of sufficient capacitance (several ten

µ

F or higher) must be connected

between the V

CC

pin and ground to assure stable operation. The ground connection of this capacitor must be

connected to the GND2 pin, which is the power block ground, at a point as close as possible to the IC. If, due to

problems associated with the heat sink, the (electrolytic) capacitor cannot be connected near the this pin, a ceramic

capacitor of about 0.1

µ

F must be connected near the pin.

Since the likelihood of power line fluctuation increases if diodes are inserted in the power supply lines to prevent

destruction of the IC if power is connected with reverse polarity, a larger capacitance will be required.

12. VREG stabilization

A capacitor (about 0.1

µ

F) must be connected to the VREG pin (the 5 V regulator output), which functions as the

control circuit power supply, for stabilization. The ground side of this capacitor must be connected to the GND1 pin

with a lead that is as short as possible.

13. Integrating amplifier related component values

The external components used in the integrating amplifier must be located as close as possible to the IC to minimize

the circuit's susceptibility to noise. These components must be located as far as possible from the motor.

.

.

LB1927

No. 6197-12/12

.

.

This catalog provides information as of October, 2002. Specifications and information herein are subject to change

without notice.

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer's

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer's products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

I n t h e e v e n t t h a t a n y o r a l l S A N Y O p r o d u c t s ( i n c l u d i n g t e c h n i c a l d a t a , s e r v i c e s ) d e s c r i b e d o r

contained herein are controlled under any of applicable local export control laws and regulations,

such products must not be exported without obtaining the export license from the authorities

concerned in accordance with the above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co. , Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the "Delivery Specification"

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only ; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

PS