| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: L6100240 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Board 2s SKYPERTM 32PRO -

Technical Explanations

1 / 11

2005-06-08 ≠ Rev02

© by

SEMIKRON

Evaluation Board 2s SKYPERTM 32PRO

Technical Explanations

Revision 02

Status:

evaluation board

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------

This Technical Explanation is valid for the following parts:

part number

type

date code (YYWW)

L6100240

Board 2s SKYPERTM 32PRO

0522

Related documents:

title version

Technical Explanations SKYPERTM 32PRO

Rev02

Prepared by: Markus Hermwille

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Content

Disclaimer................................................................................................................................................................ 2

Application and Handling Instructions...................................................................................................................... 3

Further application support...................................................................................................................................... 3

General Description................................................................................................................................................. 3

Dimensions.............................................................................................................................................................. 4

Component Placement Layout ................................................................................................................................ 4

PIN Array (not SKiiPÆ compatible).......................................................................................................................... 5

Signal IF_CMN_nHALT ........................................................................................................................................... 6

Setting Dead Time................................................................................................................................................... 6

Setting Dynamic Short Circuit Protection................................................................................................................. 6

Collector Series Resistance..................................................................................................................................... 7

Adaptation Gate Resistors....................................................................................................................................... 7

Setting Soft Turn-Off................................................................................................................................................ 7

Temperature Signal ................................................................................................................................................. 7

Over Temperature Protection Circuit (OTP) ............................................................................................................ 8

Mounting Notes ....................................................................................................................................................... 8

Schematics.............................................................................................................................................................. 9

Layouts.................................................................................................................................................................. 11

Parts List ............................................................................................................................................................... 11

Information furnished in this document is believed to be accurate and reliable. However, no representation or warranty is

given and no liability is assumed with respect to the accuracy or use of such information. Furthermore, this technical

information specifies semiconductor devices but promises no characteristics. No warranty or guarantee expressed or

implied is made regarding delivery, performance or suitability. Specifications mentioned in this document are subject to

change without notice. This document supersedes and replaces all information previously supplied and may be supersede

by updates.

Board 2s SKYPERTM 32PRO -

Technical Explanations

2 / 11

2005-06-08 ≠ Rev02

© by

SEMIKRON

Disclaimer

In accordance with SEMIKRON's quality procedures, we hereby notify you that the Evaluation Board 2s

SKYPERTM 32PRO should be considered as evaluation products only.

Evaluation products are experimental products and are therefore only intended for device evaluation. SEMIKRON

does not represent or guarantee that a final version will be made available after device evaluation. Evaluation

products are subject to the change service.

Although evaluation products have been manufactured using processes and procedures representative of final

production, they have not been subjected to all of our normal quality audits and controls. Additionally, neither the

product nor the manufacturing processes may have passed our internal qualification procedures.

IMPORTANT:

The evaluation boards are supplied without warranty of any kind, expressed, implied of statutory, including but

not limited to, any implied warranty of merchantability of fitness for a particular purpose. Credit or replacement

for evaluation products that fail to function will not be given nor will a failure analysis be performed. There is no

entitlement to technical support for evaluation products.

Claims for damages and reimbursement of expenses on the part of the undersigned customer shall be

excluded, regardless of the legal cause, especially claims in contract and in tort.

The liability exclusions shall not apply in cases of liability independent of the question of blame or negligence,

especially claims under the German Product Liability Act in cases of wilful intent, gross negligence, or injury to

life, limb or health and on account of a breach of major contractual obligations. Compensation for failure to

comply with major contractual obligations shall be limited, however, to typical, foreseeable damages, unless

wilful intent or gross negligence applies, or on account of liability for injury to life, limb or health. Any change in

the burden of proof to the detriment of the undersigned customer shall not be associated with the aforesaid

rulings

FOR SAFETY REASONS THE CUSTOMER IS NOT ALLOWED TO SELL EVALUATION PRODUCTS TO

ANY END CUSTOMER OR ANY OTHER THIRD PARTY.

If the customer fails not to sell the evaluation products to any end customer or any other third party, then the

customer shall indemnify SEMIKRON against all claims by the concerned end customer or third party in respect

of any loss, damage or injury arising from the aforesaid reason.

Board 2s SKYPERTM 32PRO -

Technical Explanations

3 / 11

2005-06-08 ≠ Rev02

© by

SEMIKRON

Application and Handling Instructions

Please provide for static discharge protection during handling. As long as the hybrid driver is not completely

assembled, the input terminals have to be short-circuited. Persons working with devices have to wear a

grounded bracelet. Any synthetic floor coverings must not be statically chargeable. Even during

transportation the input terminals have to be short-circuited using, for example, conductive rubber.

Worktables have to be grounded. The same safety requirements apply to MOSFET- and IGBT-modules.

Any parasitic inductances within the DC-link have to be minimised. Over-voltages may be absorbed by C- or

RCD-snubber networks between main terminals for PLUS and MINUS of the power module.

When first operating a newly developed circuit, SEMIKRON recommends to apply low collector voltage and

load current in the beginning and to increase these values gradually, observing the turn-off behaviour of the

free-wheeling diode and the turn-off voltage spikes generated across the IGBT. An oscillographic control will

be necessary. Additionally, the case temperature of the module has to be monitored. When the circuit works

correctly under rated operation conditions, short-circuit testing may be done, starting again with low collector

voltage.

It is important to feed any errors back to the control circuit and to switch off the device immediately in failure

events. Repeated turn-on of the IGBT into a short circuit with a high frequency may destroy the device.

The inputs of the hybrid driver are sensitive to over-voltage. Voltages higher than V

S

+0,3V or below -0,3V

may destroy these inputs. Therefore, control signal over-voltages exceeding the above values have to be

avoided.

The connecting leads between hybrid driver and the power module should be as short as possible (max.

20cm), the driver leads should be twisted.

Further application support

Latest information is available at

http://www.semikron.com

. For design support please read the SEMIKRON

Application Manual Power Modules available at

http://www.semikron.com

.

General Description

The Board 2s SKYPERTM 32PRO is an evaluation board for the IGBT module SEMiX

Æ

2s (spring contact version).

The board can be customized allowing adaptation and optimization to the used SEMiX

Æ

Module.

The switching characteristic of the IGBT can be influenced through user settings, e.g. changing turn-on and turn-

off speed by variation of R

Gon

and R

Goff

. Furthermore, it is possible to adjust the monitoring level and blanking time

for the DSCP, soft turn-off behaviour as well as an over temperature trip level by using the temperature sensor

integrated in SEMiX

Æ

modules (see Technical Explanations SKYPERTM 32PRO).

Board 2s SKYPERTM 32PRO

Please note:

This technical explanation is based on the Technical Explanations for SKYPERTM 32PRO. Please read the Technical

Explanations SKYPERTM 32PRO before using the Evaluation Board.

Please note:

All values in this technical explanation are typical values. Typical values are the average values expected in large

quantities and are provided for information purposes only. These values can and do vary in different applications. All

operating parameters should be validated by user's technical experts for each application.

Board 2s SKYPERTM 32PRO -

Technical Explanations

4 / 11

2005-06-08 ≠ Rev02

© by

SEMIKRON

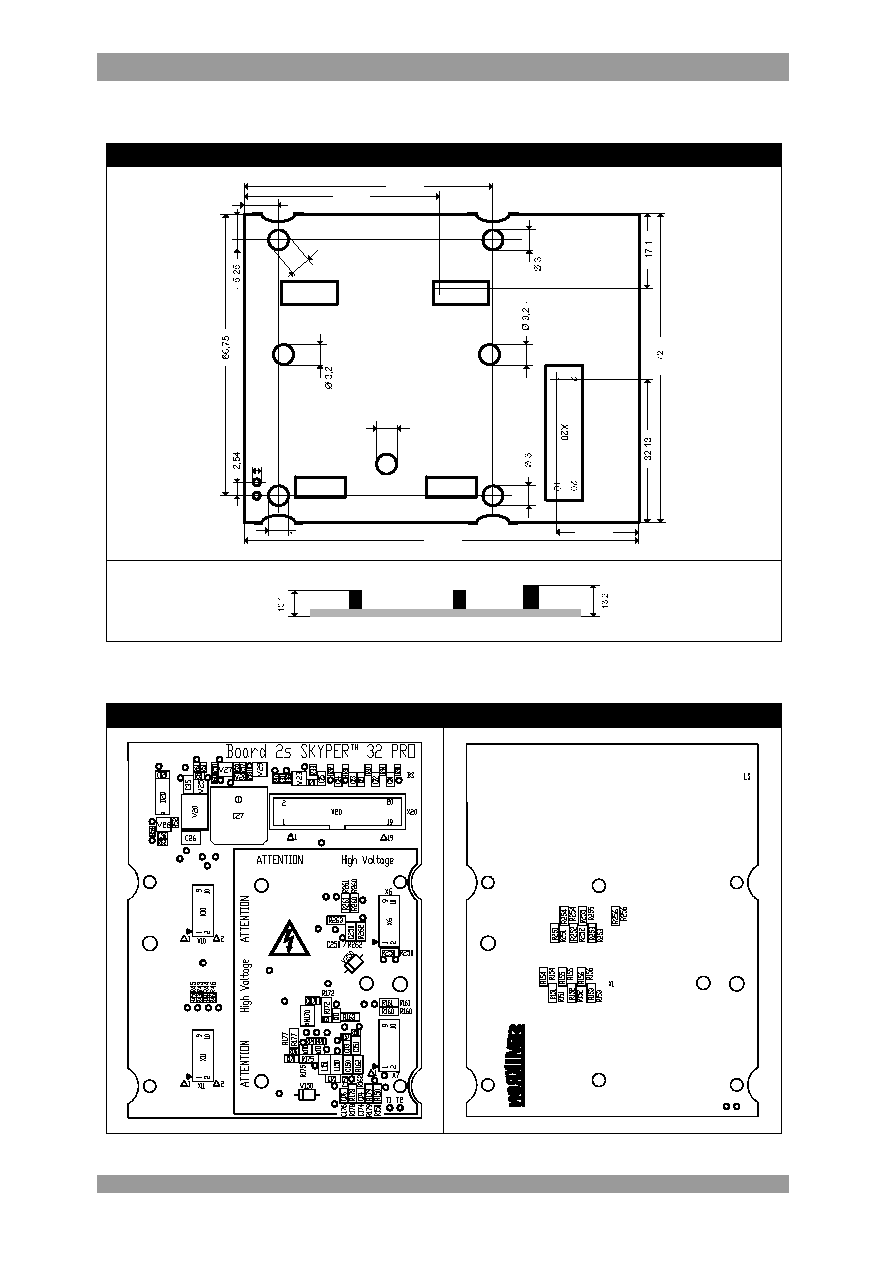

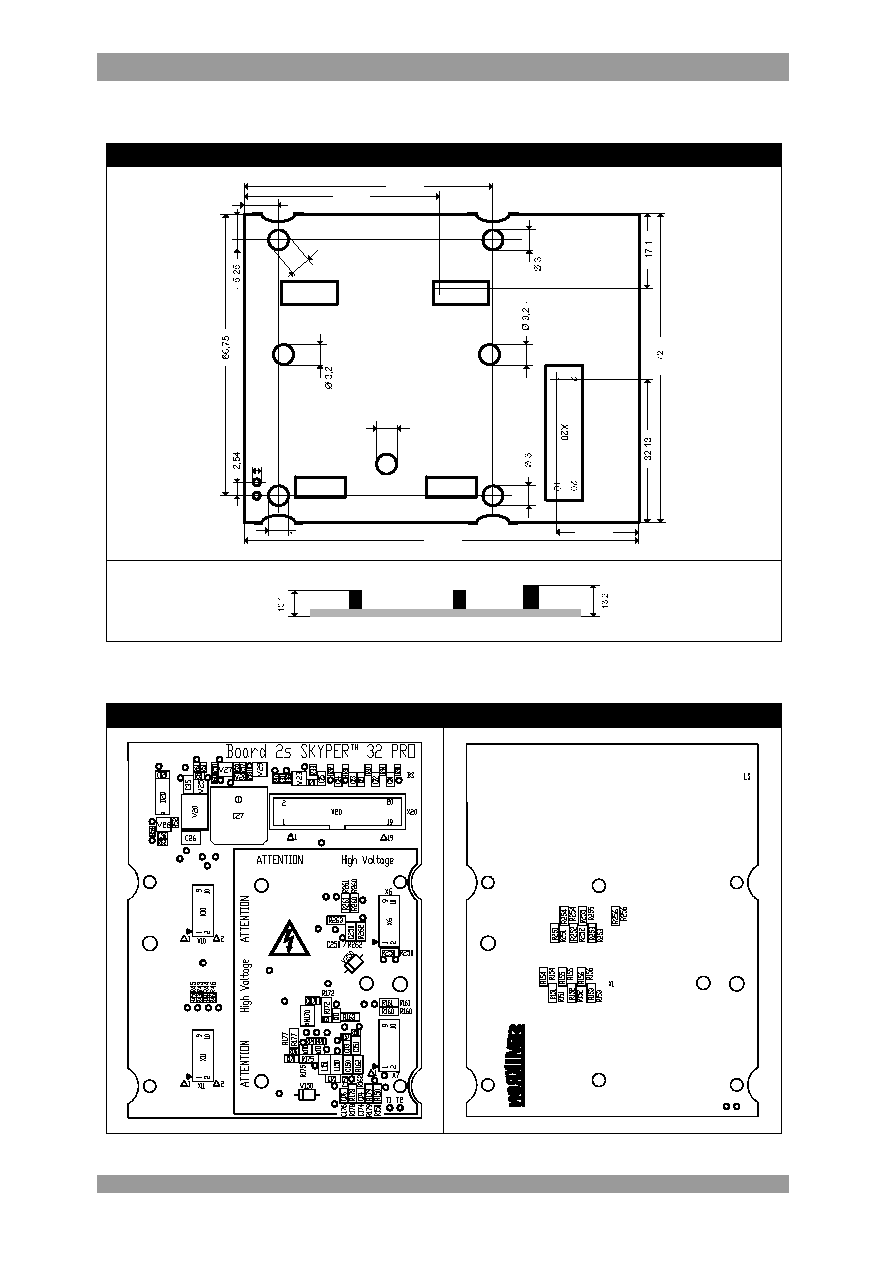

Dimensions

Dimensions in mm

ÿ 1,3

ÿ

3

X10

18,25

45,75

57,8

2

1

10

9

92

7,8

ÿ 3

ÿ 3,2

Component Placement Layout

Evaluation Board

Board 2s SKYPERTM 32PRO -

Technical Explanations

5 / 11

2005-06-08 ≠ Rev02

© by

SEMIKRON

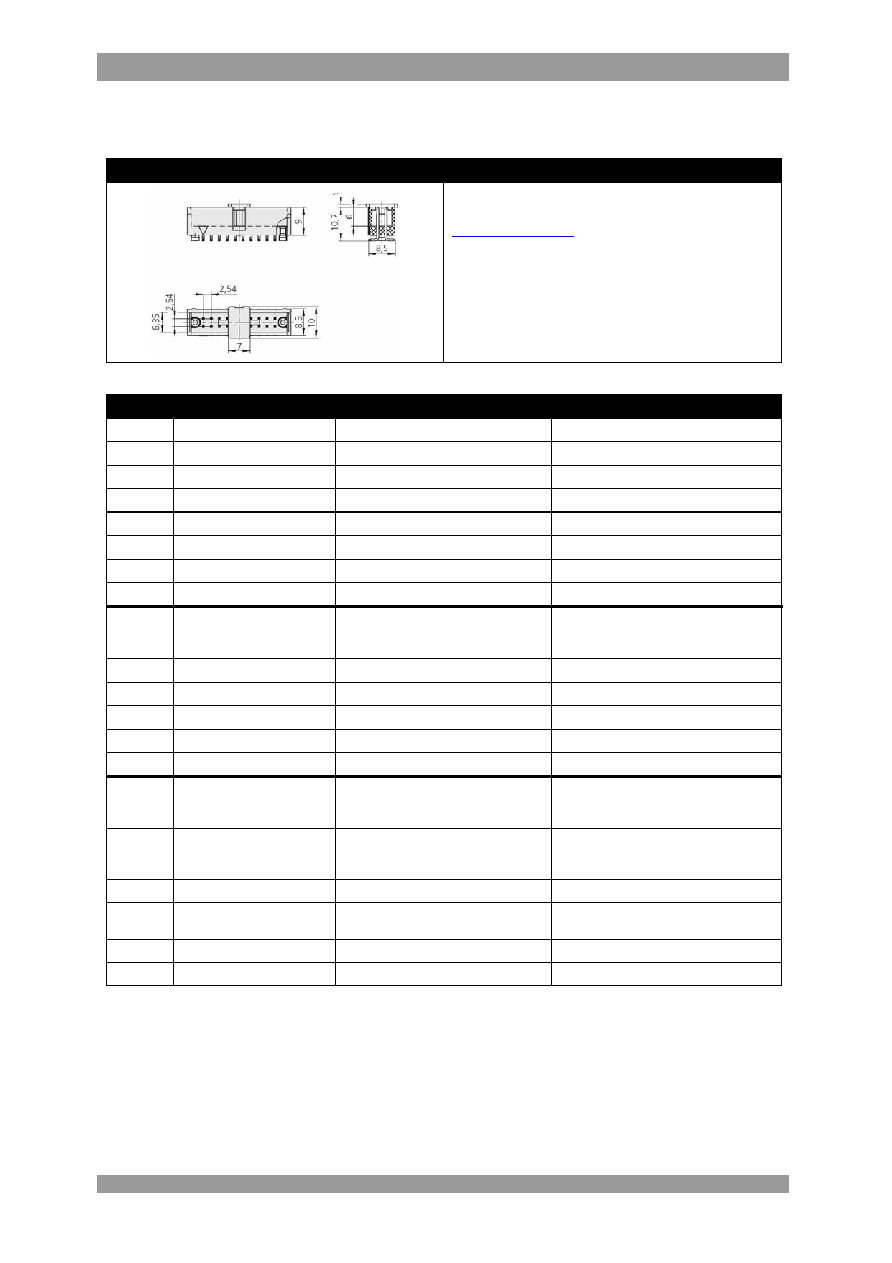

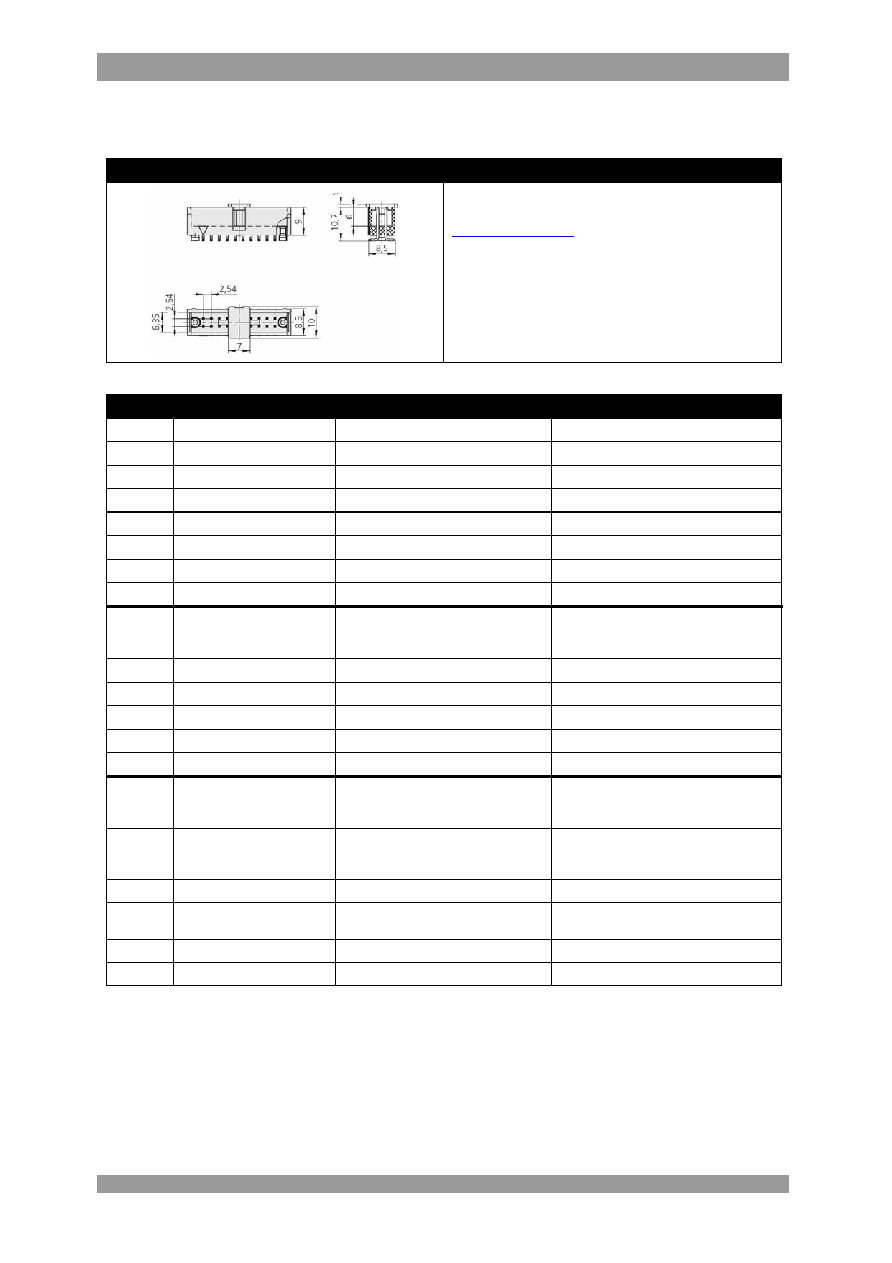

PIN Array

(not SKiiPÆ compatible)

Connector X20 (ODU FLAKAFIX 511.068.803.020)

Product information of suitable female connectors and

distributor contact information is available at e.g.

http://www.harting.com

(part number 09 18 520 6 813).

PIN

Signal

Function

Specification

X20:01

IF_PWR_15P

Drive power supply

Stabilised +15V ±4%

X20:02

IF_PWR_GND

GND for power supply

X20:03

IF_PWR_15P

Drive power supply

Stabilised +15V ±4%

X20:04

IF_PWR_GND

GND for power supply

X20:05

IF_PWR_15P

Drive power supply

Stabilised +15V ±4%

X20:06

IF_PWR_GND

GND for power supply

X20:07 reserved

X20:08

IF_PWR_GND

GND for power supply

X20:09 IF_CMN_nHALT

Driver core status signal

(bidirectional signal with dominant

recessive behaviour)

Digital 15V logic;

LOW (dominant) = driver disabled;

HIGH (recessive) = ready to operate

X20:10 reserved

X20:11 reserved

X20:12

IF_CMN_GND

GND for signal IF_CMN_nHALT

X20:13 reserved

X20:14 reserved

X20:15

IF_HB_TOP

Switching signal input (TOP switch)

Digital 15 V logic; 10 kOhm impedance;

LOW = TOP switch off; HIGH = TOP

switch on

X20:16 IF_HB_BOT

Switching signal input (BOTTOM

switch)

Digital 15 V logic; 10 kOhm impedance;

LOW = BOT switch off; HIGH = BOT

switch on

X20:17 reserved

X20:18 IF_HB_GND

GND for signals IF_HB_TOP &

IF_HB_BOT

X20:19 reserved

X20:20 reserved

Board 2s SKYPERTM 32PRO -

Technical Explanations

6 / 11

2005-06-08 ≠ Rev02

© by

SEMIKRON

Signal IF_CMN_nHALT

The Halt Logic Signals PRIM_HALT_IN and PRIM_HALT_OUT of the driver core are coupled to one bidirectional

signal (IF_CMN_nHALT) with dominant recessive behaviour. IF_CMN_nHALT shows the driver core status.

When IF_CMN_nHALT is HIGH (recessive), the driver core is ready to operate. When IF_CMN_nHALT is LOW

(dominant), the driver core is disabled / not ready to operate because of e. g. detected failure or driver core

system start.

A controller can hold with the IF_CMN_nHALT signal the driver core in a safe state (e.g. during a start up of a

system or gathered failure signal of other hardware) or generate a coeval release of paralleled driver.

Furthermore, paralleled drivers can send and receive IF_CMN_nHALT signals among each other by using a

single-wire bus.

Connection IF_CMN_nHALT

Setting Dead Time

DT adjustment

Designation Pattern

Name

Setting

R43

(connected to GND)

0603

PRIM_CFG_TDT2_IN

Factory setting: 0

R44

(connected to GND)

0603

PRIM_CFG_SELECT_IN

Factory setting: not equipped

R45

(connected to GND)

0603

PRIM_CFG_TDT3_IN

Factory setting: 0

R46

(connected to GND)

0603

PRIM_CFG_TDT1_IN

Factory setting: not equipped

Factory setting: 4µs

Setting Dynamic Short Circuit Protection

R

CE

& C

CE

Designation Pattern

Name

Setting

R162 1206

R

CE

Factory setting: not equipped

TOP

C150 1206

C

CE

Factory setting: not equipped

TOP

R262 1206

R

CE

Factory setting: not equipped

BOT

C250 1206

C

CE

Factory setting: not equipped

BOT

Board 2s SKYPERTM 32PRO -

Technical Explanations

7 / 11

2005-06-08 ≠ Rev02

© by

SEMIKRON

Collector Series Resistance

R

VCE

Designation Pattern

Name

Setting

R150 MiniMELF

R

VCE

*

Factory setting: not equipped

TOP

R250 MiniMELF

R

VCE

*

Factory setting: not equipped

BOT

* 1200V IGBT operation: 0

*

1700V IGBT operation: 1k / 0,4W

Adaptation Gate Resistors

R

Gon

& R

Goff

Designation Pattern

Name

Setting

R151, R152, R153

(parallel connected)

MiniMELF

R

Gon

Factory setting: not equipped

TOP

R154, R155, R156

(parallel connected)

MiniMELF

R

Goff

Factory setting: not equipped

TOP

R251, R252, R253

(parallel connected)

MiniMELF

R

Gon

Factory setting: not equipped

BOT

R254, R255, R256

(parallel connected)

MiniMELF

R

Goff

Factory setting: not equipped

BOT

Setting Soft Turn-Off

R

Goff_SC

Designation Pattern

Name

Setting

R160, R161

(parallel connected)

MiniMELF

R

Goff_SC

Factory setting: not equipped

TOP

R260, R261

(parallel connected)

MiniMELF

R

Goff_SC

Factory setting: not equipped

BOT

Temperature Signal

The temperature sensor inside the SEMiX

Æ

module is directly connected to contacting points T1 and T2. For

details to the temperature sensor, see Modules Explanations SEMiX

Æ

.

Safety Warnings:

The contacting points T1 and T2 are not electrical isolated. Due to high voltage that may be present at the

contacting points T1 and T2, some care must be taken in order to avoid accident. There is no cover or potential

isolation that protect the high voltage sections / wires from accidental human contact.

Board 2s SKYPERTM 32PRO -

Technical Explanations

8 / 11

2005-06-08 ≠ Rev02

© by

SEMIKRON

Over Temperature Protection Circuit (OTP)

The external error input SEC_TOP_ERR_IN on the secondary side (high potential) of the driver core is used for

an over temperature protection circuit to place the gate driver into halt mode.

Dimensioning OTP

1. Define an over temperature trip level according to the application.

2. Calculate the nominal ohmic resistance value of the temperature sensor at the defined trip

level (see "Modules ≠ Explanations - SEMiX

Æ

" on SEMiX

Æ

product overview page at

http://www.semikron.com

).

3. The trip level on the adapter board is set with R172 by using the calculated resistance value.

Factory setting R172: not equipped

If no resistor is used, a failure signal is generated.

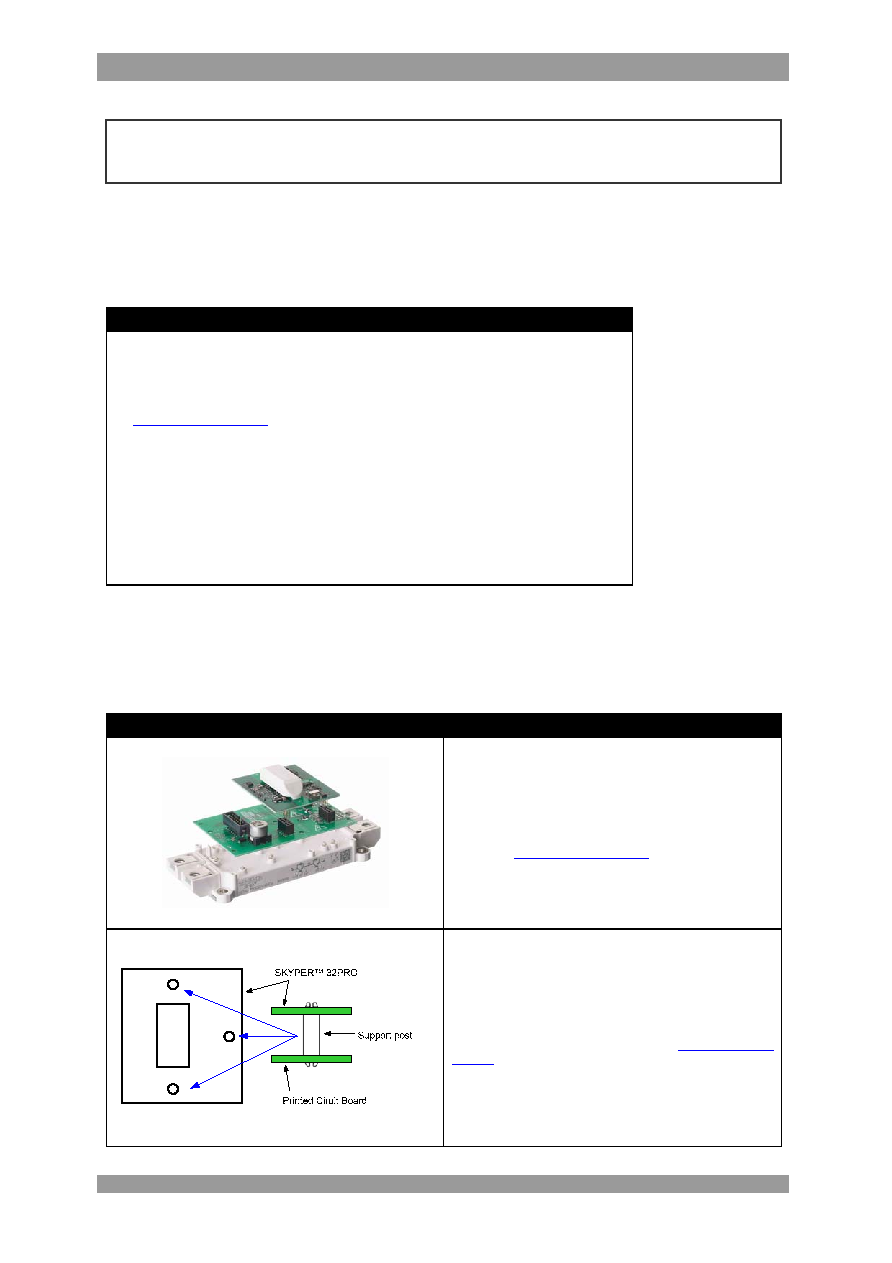

Mounting Notes

The electrical connections between evaluation board and SEMiX

Æ

are realised via spring contacts integrated in

SEMiX

Æ

power modules and via landing pads on the bottom side of the evaluation board.

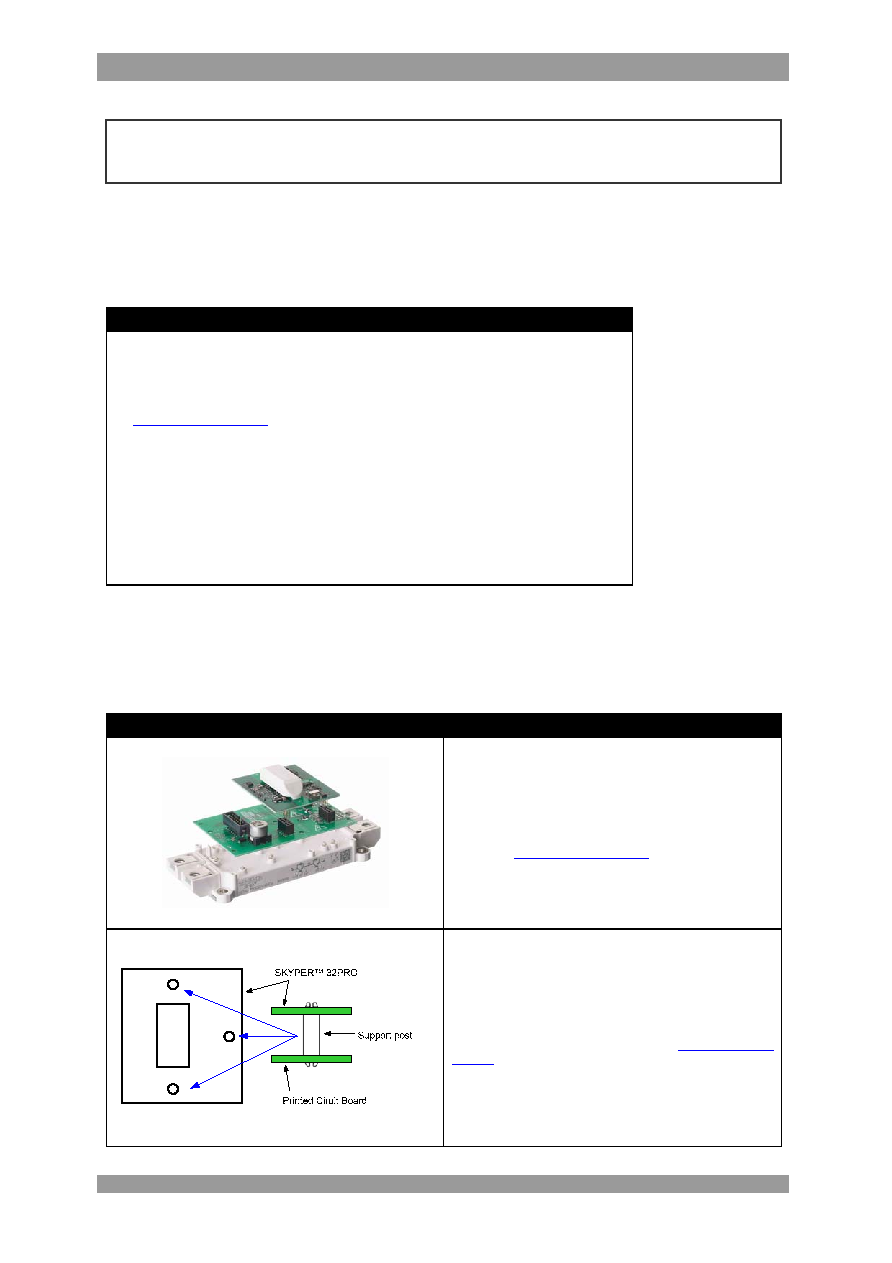

Evaluation Board & Driver Core Mounting

1. Soldering of components (e.g. R

Gon

, R

Goff

, etc.) on

adapter board.

2. Evaluation Board has to be fixed to the SEMiX

Æ

module

(see "Mounting Instruction and Application Notes

for SEMiX

Æ

IGBT modules" on SEMiX

Æ

product overview

page at

http://www.semikron.com

).

3. Insert driver core into the box connector on evaluation

board.

The connection between driver core and evaluation board

should be mechanical reinforced by using support posts.

The posts have to be spaced between driver core and

evaluation board.

Product information of suitable support posts and distributor

contact information is available at e.g.

http://www.richco-

inc.com

(part number MSPM-8-01).

Please note:

If the contacting points T1 and T2 are used for evaluation of the temperature sensor, the Over Temperature Protection

Ciruit must be disabled by taking out the resistors R175, R178 and R179.

Board 2s SKYPERTM 32PRO -

Technical Explanations

9 / 11

2005-06-08 ≠ Rev02

© by

SEMIKRON

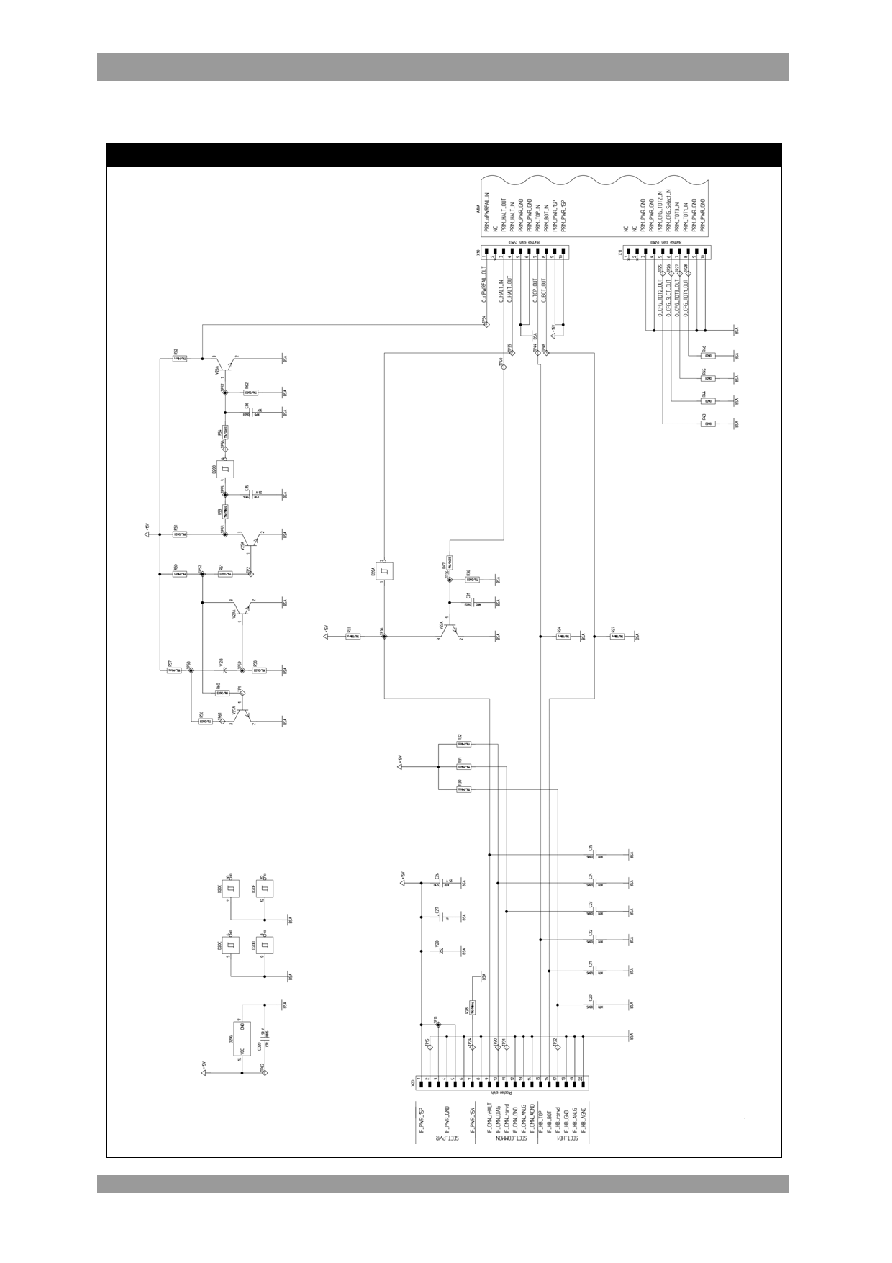

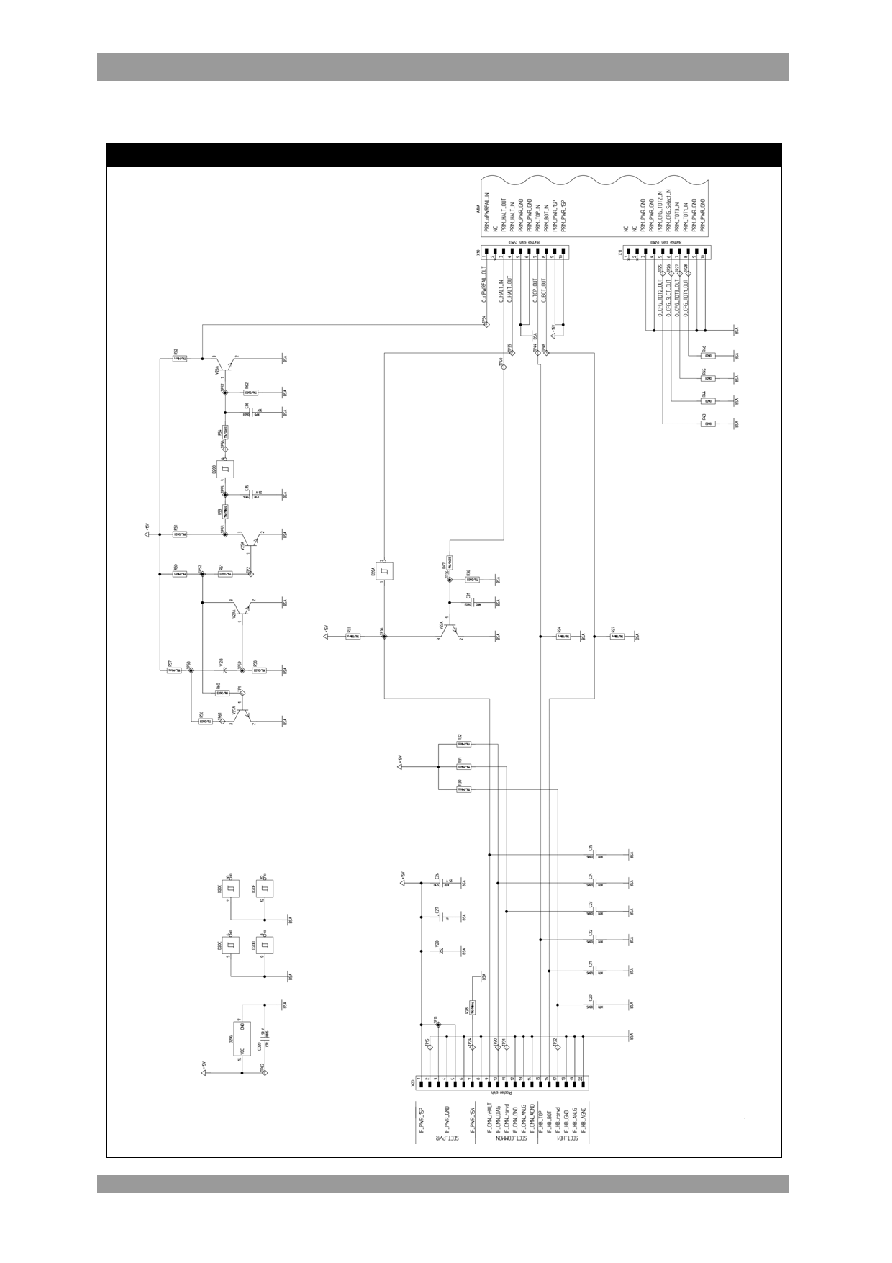

Schematics

Schematic I Evaluation Board

Board 2s SKYPERTM 32PRO -

Technical Explanations

10 / 11

2005-06-08 ≠ Rev02

© by

SEMIKRON

Schematic II Evaluation Board

Board 2s SKYPERTM 32PRO -

Technical Explanations

11 / 11

2005-06-08 ≠ Rev02

© by

SEMIKRON

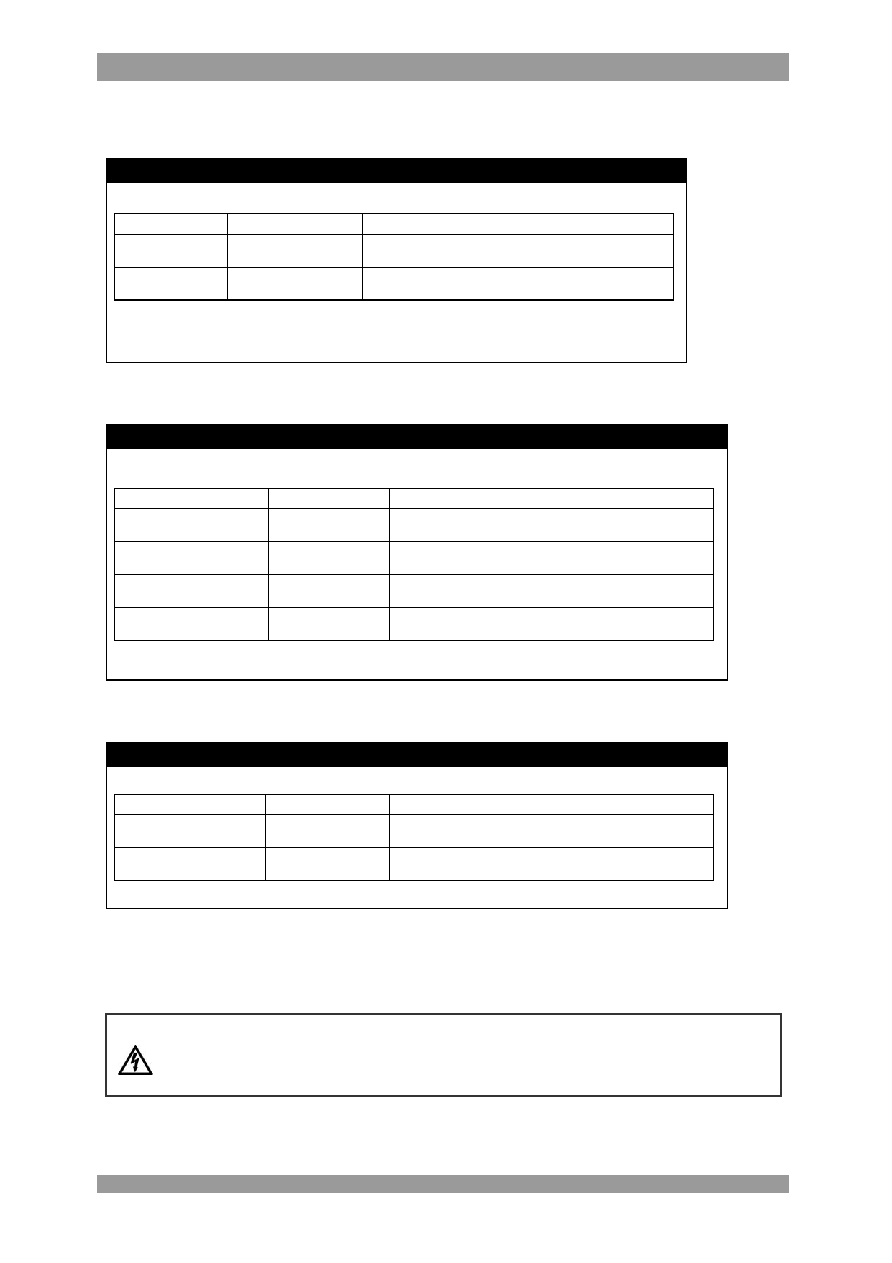

Layouts

Primary & Secondary Layout

Parts List

Parts List Evaluation Board

Count

Ref. Designator

Value

Pattern Name

Description

8

C170, C171, C173, C174, C175,

C176, CD20, CN170

100nF

0805 (SMD)

Capacitor X7R

6

C20, C21, C22, C23, C24, C25

1nF

0805 (SMD)

Capacitor X7R

1

C26

2,2µF

1210 (SMD)

Capacitor X7R

1

C27

220uF/35V

SMD

Longlife-Elko

1

C31

68pF

0603 (SMD)

Capacitor NP0

2

C35, C151

1uF

1206 (SMD)

Capacitor X7R

1

C36

100pF

0603 (SMD)

Capacitor NP0

1

D20

74C14

SOIC 14 (SMD)

Logic-IC 74C...

2

L150, L151

100uH

SIMID02 (SMD)

Inductor

1

N170

LM2904

SOIC 8 (SMD)

Operational Amplifier

2

R157, R171

15,0KOhm

0603 (SMD)

1%

1

R158

10,0Ohm

0603 (SMD)

1%

2

R163, R263

10,0KOhm

MiniMelf (SMD)

1%

3

R170, R174, R176

30,1KOhm

0603 (SMD)

1%

1

R175

5,62KOhm

MiniMelf (SMD)

1%

1

R177

3,01KOhm

1206 (SMD)

1%

2

R178, R179

0,00Ohm

MiniMelf (SMD)

3

R28, R50, R52

10,0KOhm

MikroMelf (SMD)

1%

6

R30, R31, R32, R33, R34, R37

5,11KOhm

MikroMelf (SMD)

1%

1

R36

3,32KOhm

0603 (SMD)

1%

2

R43, R45

0,00Ohm

0603 (SMD)

3

R47, R54, R56

10,0KOhm

0603 (SMD)

1%

1

R51

121KOhm

0603 (SMD)

1%

1

R53

100Ohm

MikroMelf (SMD)

1%

1

R57

1,50KOhm

MikroMelf (SMD)

1%

1

R58

1,00KOhm

0603 (SMD)

1%

2

R60, R61

2,00KOhm

0603 (SMD)

1%

1

R62

3,92KOhm

0603 (SMD)

1%

2

V150, V250

BY203/20S

High Voltage Diode

2

V170, V171

BAV70W

SOT323 (SMD)

Double Diode

1

V20

SMCJ15

DO214AB (SMD)

Suppressor Diode

5

V23, V25, V26, V27, V29

BC847B

SOT23 (SMD)

NPN-Transistor

1

V28

BZX284-C7V5

SOD110 (SMD)

Zener-Diode

1

X20

20p.

SMD

Connector

4

X6, X7, X10, X11

RM2,54 10p.

SMD

Box Connector

TP: Test Point

Box Connector: SUYIN 254100FA010G200ZU