| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: SG6932 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Product Specification

Green mode PFC/Forward PWM Controller

SG6932

©System General Corp.

- 1 -

www.sg.com.tw

Version 1.0(IAO33.0011.B1) Feb.24, 2006

FEATURES OVERVIEW

Interleaved PFC/PWM switching

Green mode PFC and PWM operation

Low operating current

Innovative Switching-Charge

multiplier-divider

Multi-vector control for improved PFC output

transient response

Average-current-mode for input-current shaping

PFC over-voltage and under-voltage protections

PFC and PWM feedback open-loop protection

Cycle-by-cycle current limiting for PFC/PWM

Slope compensation for PWM

Selectable PWM maximum duty cycle 50% and 65%

Brownout protection

Power on sequence control and soft-start

APPLICATIONS

Switch mode Power Suppliers with Active PFC

Servo System Power Supplies

PC-ATX Power Supplies

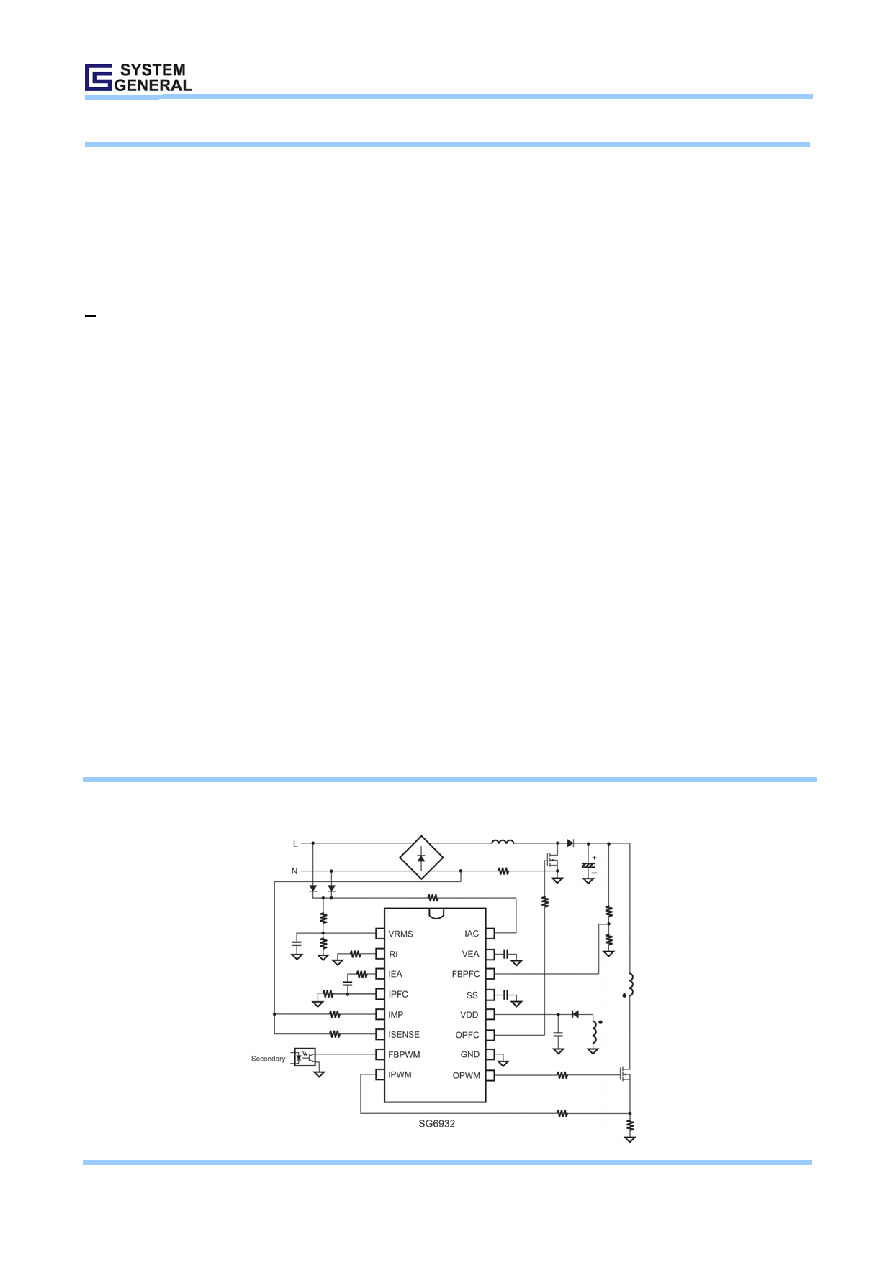

DESCRIPTION

The highly integrated SG6932 is specially designed

for power supplies consist of boost PFC and Forward

PWM. It requires very few external components to

achieve green-mode operation and versatile

protections/compensation. It is available in 16-pin DIP

and SO packages.

The patented interleave-switching feature

synchronizes the PFC and PWM stages and reduces

switching noise. At light load, the switching frequency is

continuously decreased to reduce power consumption.

For PFC stage, the proprietary multi-vector control

scheme provides a fast transient response in a

low-bandwidth PFC loop, in which the overshoot and

undershoot of the PFC voltage are clamped. If the

feedback loop is broken, SG6932 will shut off to prevent

extra-high voltage on output.

For the Forward PWM stage, the synchronized

slope compensation ensures the stability of the current

loop under continuous-conduction-mode operation.

Hiccup operation during output overloading is guaranteed.

The soft start and programmable maximum duty cycle

ensure safe operation.

In addition, SG6932 provides complete protection

functions such as brownout protection and RI open/short

latch off.

TYPICAL APPLICATION

Product Specification

Green mode PFC/Forward PWM Controller

SG6932

©System General Corp.

- 2 -

www.sg.com.tw

Version 1.0(IAO33.0011.B1) Feb.24, 2006

MARKING DIAGRAMS PIN CONFIGURATION

ORDERING INFORMATION

Part Number

Package

SG6932DZ

16-pin DIP (Lead Free)

SG6932SZ

16-pin SOP (Lead Free)

PIN DESCRIPTIONS

Name Pin

No.

Type

Function

VRMS 1

Line-Voltage

Detection

Line voltage detection. The pin is used for PFC multiplier and brownout protection.

RI 2 Oscillator

Setting

Reference setting. One resistor connected between RI and ground determines the

switching frequency. A resistor having a resistance between 12k ~ 47k is recommended.

The switching frequency is equal to [1560 / RI] kHz, where RI is in k

. For example, if RI is

equal to 24k

, then the switching frequency will be 65 kHz.

IEA 3

Output of PFC Current

Amplifier

This is the output of the PFC current amplifier. The signal from this pin will be compared with

an internal saw-tooth and hence determine the pulse width for PFC gate drive.

IPFC 4

Inverting Input of PFC

Current Amplifier

The inverting input of the PFC current amplifier. Proper external compensation circuits will

result in excellent input power factor via average-current-mode control.

IMP 5

Non-inverting Input of

PFC Current Amplifier

and Output of

Multiplier

The non-inverting input of the PFC current amplifier and also the output of multiplier. Proper

external compensation circuits will result in excellent input power factor via average current

mode control. Refer to

ISENSE 6

Peak Current Limit

Setting for PFC

The peak current limit setting for PFC.

FBPWM

7

PWM Feedback Input

The control input for voltage-loop feedback of PWM stage. It is internally pulled high through

a 6.5 k

resistance. Usually an external opto-coupler from secondary feedback circuit is

connected to this pin.

IPWM

8

PWM Current Sense

The current sense input for the PWM stage. Via a current sense resistor, this pin provides

the control input for peak-current-mode control and cycle-by-cycle current limiting.

OPWM

9

PWM Gate Drive

The totem pole output drive for PWM MOSFET. This pin is internally clamped under 18V to

protect the MOSFET

.

GND

10

Ground

The power ground

OPFC

11

PFC Gate Drive

The totem pole output drive for the PFC MOSFET. This pin is internally clamped under 18V

to protect the MOSFET

.

9

8

IPWM

FBPWM

ISENSE

7

10

6

11

OPWM

GND

OPFC

14

3

IEA

IMP

IPFC

5

12

4

13

VRMS

RI

15

2

1

16

FBPFC

VDD

SS

VEA

IAC

T

: D=DIP, S=SOP

P :

Z =Lead Free + ROHS

Compatible

XXXXXXXX

: Wafer Lot

Y

: Year;

WW

: Week

V

: Assembly Location

SG6932TP

XXXXXXXXYWWV

Product Specification

Green mode PFC/Forward PWM Controller

SG6932

©System General Corp.

- 3 -

www.sg.com.tw

Version 1.0(IAO33.0011.B1) Feb.24, 2006

VDD 12 Supply

The power supply pin. The threshold voltages for start-up and turn-off are 14V and 10V,

respectively. The operating current is lower than 10mA.

SS

13

PWM Soft Start

During startup, the SS pin will charge an external capacitor with a 50uA constant current

source. The voltage on FBPWM will be clamped by SS during startup. In the event of a

protection condition occurring and/or PWM being disabled, the SS pin will be quickly

discharged. The voltage of SS pin also can be used for select 50% or 65% Maximum duty

FBPFC 14

Voltage Feedback

Input for PFC

The feedback input for PFC voltage loop. The inverting input of PFC error amp. This pin is

connected to the PFC output through a divider network.

VEA 15

Error-Amp Output for

PFC voltage feedback

loop

The error-amp output for PFC voltage feedback loop. A compensation network (usually a

capacitor) is connected between this pin and ground. A large capacitor value will result in a

narrow bandwidth and hence improve the power factor.

IAC

16

Input AC Current

For normal operation, this input is used to provide current reference for the multiplier. The

suggested maximum IAC is 360 uA.

Product Specification

Green mode PFC/Forward PWM Controller

SG6932

©System General Corp.

- 4 -

www.sg.com.tw

Version 1.0(IAO33.0011.B1) Feb.24, 2006

BLOCK DIAGRAM

Product Specification

Green mode PFC/Forward PWM Controller

SG6932

©System General Corp.

- 5 -

www.sg.com.tw

Version 1.0(IAO33.0011.B1) Feb.24, 2006

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter

Test

Conditions

Value

Unit

V

DD

DC Supply Voltage*

25

V

I

AC

Input AC Current

2

mA

V

High

OPWM, OPFC, IAC

-0.5 to 25V

V

V

Low

Others

At

T

A

<50

-0.5 to 7V

V

P

D

Power

Dissipation

0.8

W

T

J

Operating Junction Temperature

-40 to 125

T

stg

Storage Temperature Range

-55 to +150

DIP 33.64

R

j-C

Thermal resistance (Junction to Case)

SOP 41.95

/W

DIP 260

T

L

Lead Temperature (soldering 10sec)

SOP 230

ESD capability, HBM model

4.5

KV

ESD

ESD capability, Machine model

250

V

*All voltage values, except differential voltages, are given with respect to the network ground terminal

RECOMMENDED OPERATING JUNCTOIN TEMPERATURE: -30∞C~ 85∞C*

* For proper operation

ELECTRICAL CHARACTERISTICS (V

DD

= 15V, T

A

= 25∞C UNLESS NOTED)

VDD section

Symbol Parameter

Test

Conditions

Min.

Typ.

Max. Unit

V

DD-OP

Continuously Operating Voltage

20

V

I

DD ST

Start-Up

Current

V

DD

-0.16V

10 20 uA

I

DD-OP

Operating

Current

V

DD

= 15V; OPFC OPWM open

6

10

mA

V

TH-ON

Start

Threshold

Voltage

13 14 15 V

V

DD-min

Min. Operating Voltage

9

10

11

V

V

DD-OVP

VDD OVP1 (turn off PWM with delay)

23.5

24.5

25.5

V

TV

DD-OVP

Delay time of VDD OVP1

RI= 24k 8

25

uS

Oscillator & Green-Mode Operation

Symbol Parameter

Test

Conditions Min.

Typ.

Max.

Unit

V

RI

RI Voltage

1.176

1.2

1.224

V

F

OSC

PWM frequency

RI= 24k

62 65 68 KHz

F

OSC-MINFREQ

Minimum frequency in green mode

RI= 24k

18 20 22 KHz

RI

RI range

12

47

k

RI

OPEN

RI Pin Open Protection

If RI> RI

open

, PWM will be turned off

200

k

RI

SHORT

RI Pin Short Protection

If RI< RI

short

, PWM will be turned off

2 k