1

D

a

te of Is

sue

16.

08.20

00

Subject to reasonable modifications due to technical advances.

Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group ∑ Tel.: Germany (06 21) 7 76-0 ∑ USA (330) 4 25 35 55 ∑ Singapore 7 79 90 91 ∑ Internet http://www.pepperl-fuchs.com

Vibrating

Limit Switch LVL

∑ Vibration limit switch for liquids

∑ Ex-version with intrinsically safe

NAMUR-switching signal, applicable

in Ex-Zone 0

∑ Lead short circuit and lead breakage

control

∑ Stainless steel housing for rough

environmental conditions

∑ Function test with testing magnet in

mounted position.

∑ Put the testing magnet to the shown

location. The state of the output will

be the same as with a covered

vibration fork.

LVL-N

Features

Function test with the testing

magnet

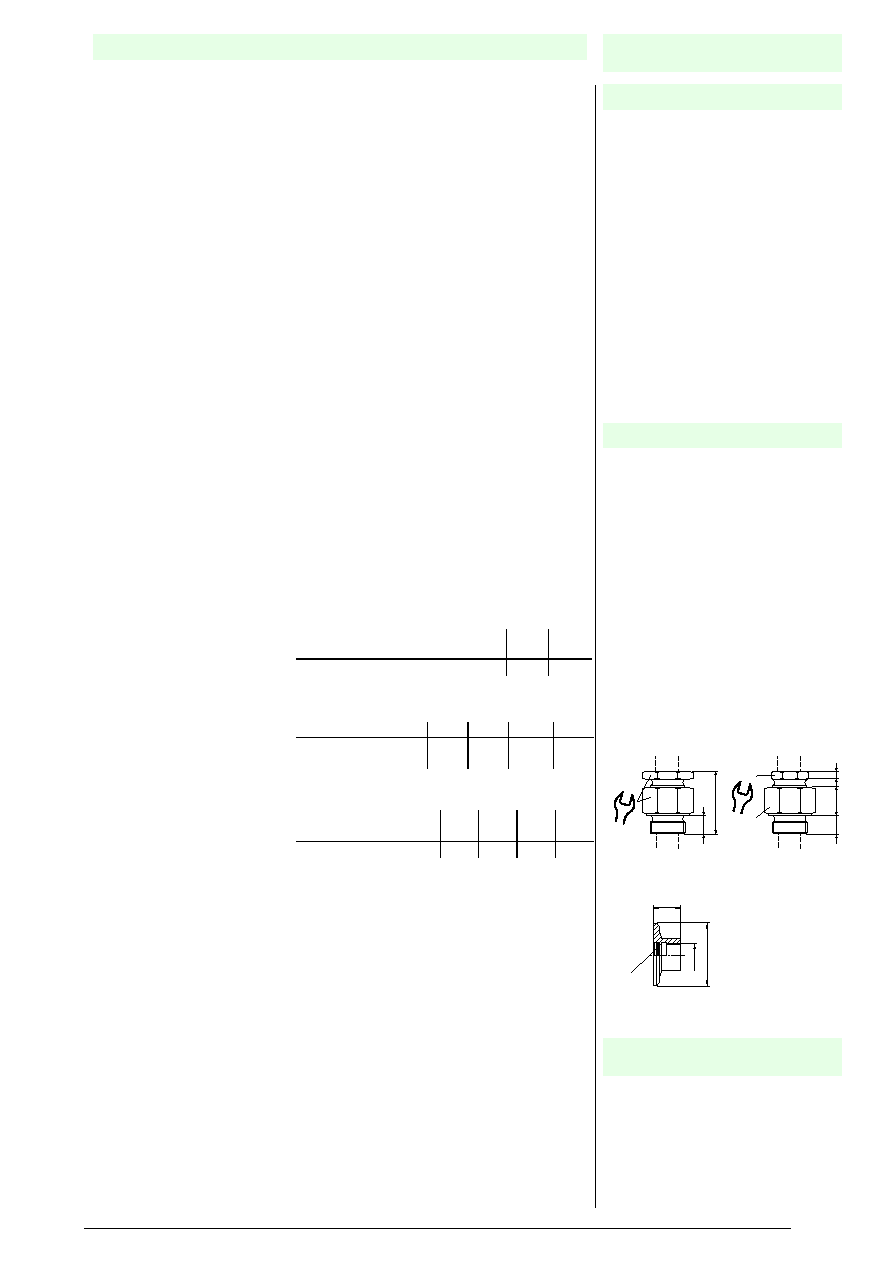

Dimensions

Function principle

The vibration fork is actuated piezoelectrically. It is vibrating with its resonance

frequency in air. Liquids getting into contact with the fork are changing this

frequency. This change is evaluated electronically and produces the switching

signal.

Electrical connection

V1 connector

PG9

Testing magnet

Testing magnet

Housing

Housing

LED

Switching point

LED

Switching state (yellow)

41

G1A

G1A

Compact version

LVL1

ooo

-V1

Extended version

LVL2

ooo

-PG

¯29

10

22

25

127

5.5

19

110

22

10

120

L

Please specify the length (L) if you order an extended version.

The testing magnet has to be ordered separately (accessory).

For a V1-connection - the necessary accessory is a V1 cable connection

box (see accessories).

1 / BN

2 / BU

+

-

1 = +

2 = -

Plug connector V1

Electrical connection

1

2

4

3

PG9

3 = +

4 = -

N

V

Terminal compartment

connection

3

4

2

D

a

te of Is

sue

16.

08.20

00

Subject to reasonable modifications due to technical advances.

Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group ∑ Tel.: Germany (06 21) 7 76-0 ∑ USA (330) 4 25 35 55 ∑ Singapore 7 79 90 91 ∑ Internet http://www.pepperl-fuchs.com

Vibrating Limit Switch

LVL-N

Technical data

Approvals/Certifications

Information about approvals and

certifications can be found at

www.pepperl-fuchs.com.

Z.65-11.172 (Wasserhaushaltsgesetz WHG ß 19)

DMT 98 ATEX E 004 (acc. to directive 94/9/EG

(ATEX): II 1G, II ΩD, II

1

/

3

D) (Explosion Protection)

13376-98HH (Germanischer Lloyd)

Ignition protection class

Gas-Ex:

EEx ia IIC

EEx ia IIB

LVL

oo

-

ooo

-N-PG

Dust Ex:

IP65 T 160 ∞C

Device groups

Gas-Ex-zone 0:

all variants

Dust-Ex-zone 20/21:

LVL

oo

-

ooo

S-N-CSM

Dust-Ex-zone 20/22:

LVL

oo

-

ooo

-N-PG

Data according to the

design test certificate

U

i

I

i

P

i

£

16 V

£

88 mA

£

198 mW

Supply

Nominal voltage

Nominal current

max. self capacitance

max. self inductance

Protection class

according to EN 60947-5-6 (NAMUR)

DC 8.2 V ± 2 % from the isolation amplifier

unswitched <1.2 mA/switched >2.1 mA

negligible

<

60

m

H

lll

Function test

Performed with test magnet (accessories) on

mounted device. Sequential circuits can be proved

(like PLCs or control systems) without demounting

the device and without media contact.

Switching delay

when covering

when uncovering

approx. 0.5 s

approx. 0.5 s

Indicators

Switching state

LED, yellow

Temperature conditions

Ambient temperature

-25 ∞C ... +70 ∞C

Limitation in dust-Ex-zone 21 and 22:

Media temperature

-25 ∞C ... +120 ∞C

Limitation in gas-Ex:

Limitation in dust Ex-zone 20:

Process conditions

Pressure

Density

r

Viscosity

£

40 bar

≥

0.6 g/cm

3

max. 10 000 mPa s

Protection class acc. to IEC 60529

IP67

max. surface temperature

sensor housing ∞C

50

80

Ambient temperature ∞C

40

70

Temperature class

T6

T5

T4

T3

Media temperature

∞C

<80

<95

<120 <120

max. surface temp. of

the fork ∞C

50

80

120

120

Media temperature ∞C

40

70

120

120

Compact version LVL1

∑ LVL1S-G3S-N-V1

fork: stainless

steel housing: plastic

∑ LVL1O-G3OS-N-V1

fork: polished stainless steel

housing: stainless steel

Extended version LVL2

∑ LVL2S-G3S-N-V1

fork: stainless steel

housing: plastic

∑ LVL2O-G3OS-N-V1

fork: polished stainless steel

housing: stainless steel

1" NPT-version

∑ all types are available with 1" NPT

threadtype LVL

oo

-N3

o

-N-V1

∑ V1-G-N-5M-PUR, cable connection

box, straight

∑ V1-G-N-5M-PUR, cable connection

box, straight, with 5 m cable

∑ V1-W-N-5M-PUR, cable connection

box, 90∞ angled

∑ V1-W-N-5M-PUR, cable connection

box, 90∞ angled, with 5 m cable

∑ LVL-Z15, test magnet

∑ LVL2-Z41, sliding bushing G1ΩA,

stainless steel 1.4571 (for

unpressurised operation)

∑ LVL2-Z49, sliding bushing G1ΩA,

PVC (for unpressurised operation)

∑ LVL-Z61, welding bushing for vessels

G1, Viton sealing

∑ a vibration limit switch LVL-N, a cable

connection box and a transformer

isolated barrier

e. g. KFD2-SR2-Ex1.W

Conventional versions

Accessories

A measuring system consists

of:

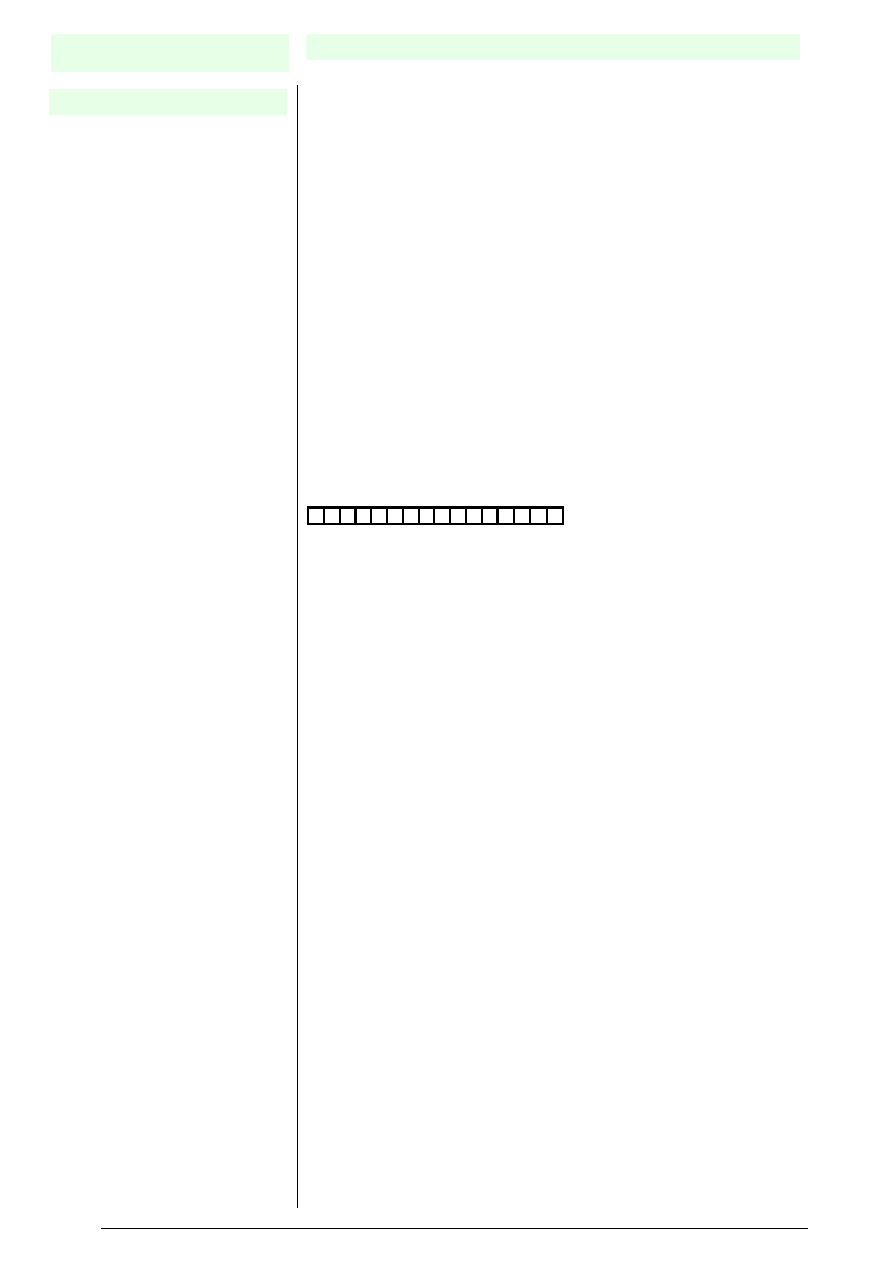

Viton sealing

¯

60

27

G1

Welding bushing

LVL-Z61

Sliding bushing G1ΩA

LVL2-Z41, stainless steel

SW 60

22

78

Sliding bushing G1ΩA

LVL2-Z49, PVC

SW 60

SW 41

30

20

10

3

D

a

te of Is

sue

16.

08.20

00

Subject to reasonable modifications due to technical advances.

Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group ∑ Tel.: Germany (06 21) 7 76-0 ∑ USA (330) 4 25 35 55 ∑ Singapore 7 79 90 91 ∑ Internet http://www.pepperl-fuchs.com

Vibrating Limit Switch

LVL-N

∑ When using a sliding bushing, special

attention must be paid to the

resistance of the sealing

rings and plastic material to the

medium that is involved. Faults lead

to a down grading in zone

classification.

∑ On versions with Varivent, milk tube

or Triclamp connection, it must be

ensured that they are safely isolated

in zone 0.

∑ On flanged versions, the flange rated

pressure must not be exceeded.

∑ When using the external connections

for the equipotential bonding

conductor, these should be smeared

with terminal grease.

Notes

Key to model numbers/ordering code

Vibracon LVL-Namur

Measuring range

1 Compact version

2 Extended version, rod length 170 mm ... 3000 mm

| Surface of fork

|

S Stainless steel (1.4581)

|

O Polished stainless steel (1.4581)

|

H ECTFE (Halar coated)(in combination with process connection F*and A*)

|

C Hasteloy C (2.4610)(in combination with process connection G3, N3, FC, AC)

|

|

Process connection

|

|

G

3 G1A thread

|

|

N

3 1" NPT thread

|

|

M

4 Milk pipe DN40, DIN11851

|

|

T

2 Triclamp 2"

|

|

F

1 Flange DN50 PN40

|

|

F

C Flange DN50 PN40 (Hastelloy C plated)

|

|

A

2 Flange ANSI 2", 150 lbs

|

|

A

C Flange ANSI 2", 150 lbs (Hastelloy C plated)

|

|

-

-

other process connections

|

|

|

| Material/surface process connection

|

|

|

|

S Stainless steel (1.4571)

|

|

|

|

O Polished stainless steel (1.4571)

|

|

|

|

H ECTFE (Halar coated)(in combination with process connection F*and A*)

|

|

|

|

C Hasteloy C (2.4610)(in combination with process connection G3, N3, FC, AC)

|

|

|

|

| Material housing

|

|

|

|

|

/ Plastic (PBT), with V1 connection

|

|

|

|

|

S Stainless steel, with V1 connection or terminal compartment connection PG9

|

|

|

|

|

|

Electrical output

|

|

|

|

|

|

N According to EN 60947-5-6 (Namur)

|

|

|

|

|

|

|

Specialities

|

|

|

|

|

|

|

V

1

Plug connection

|

|

|

|

|

|

|

P

G Terminal compartment connection PG9

|

|

|

|

|

|

|

|

|

Approvals

|

|

|

|

|

|

|

|

|

G Approval GL (only for stainless steel housing

and plug connector V1)

|

|

|

|

|

|

|

|

|

|

L V L

-

-

-