PQ070XH01Z

PQ070XH01Z

s

Absolute Maximum Ratings

s

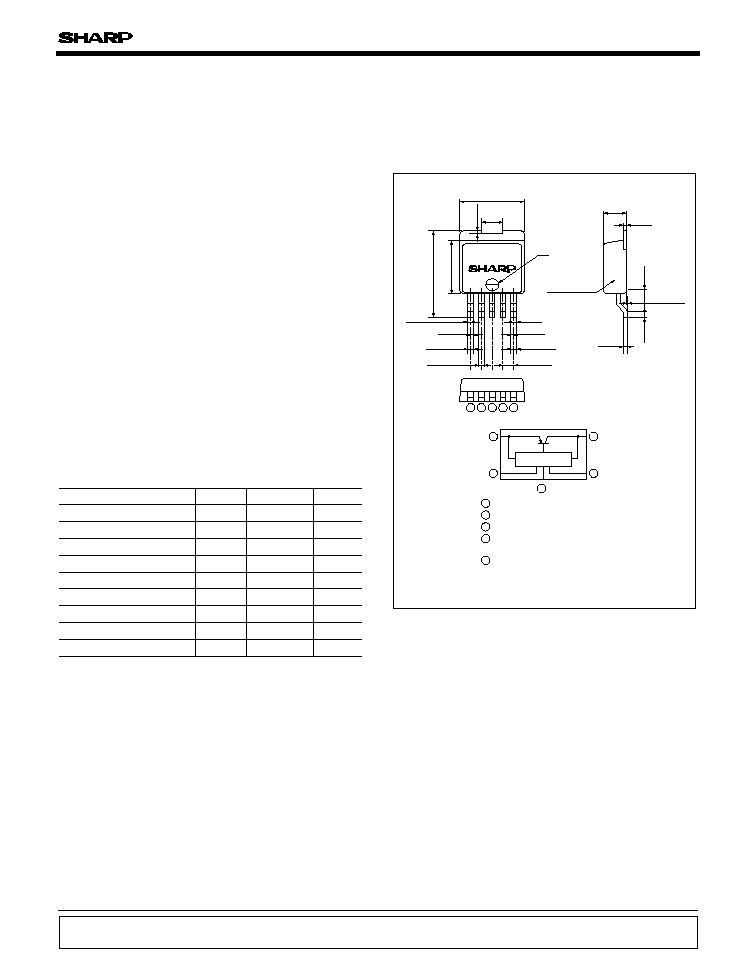

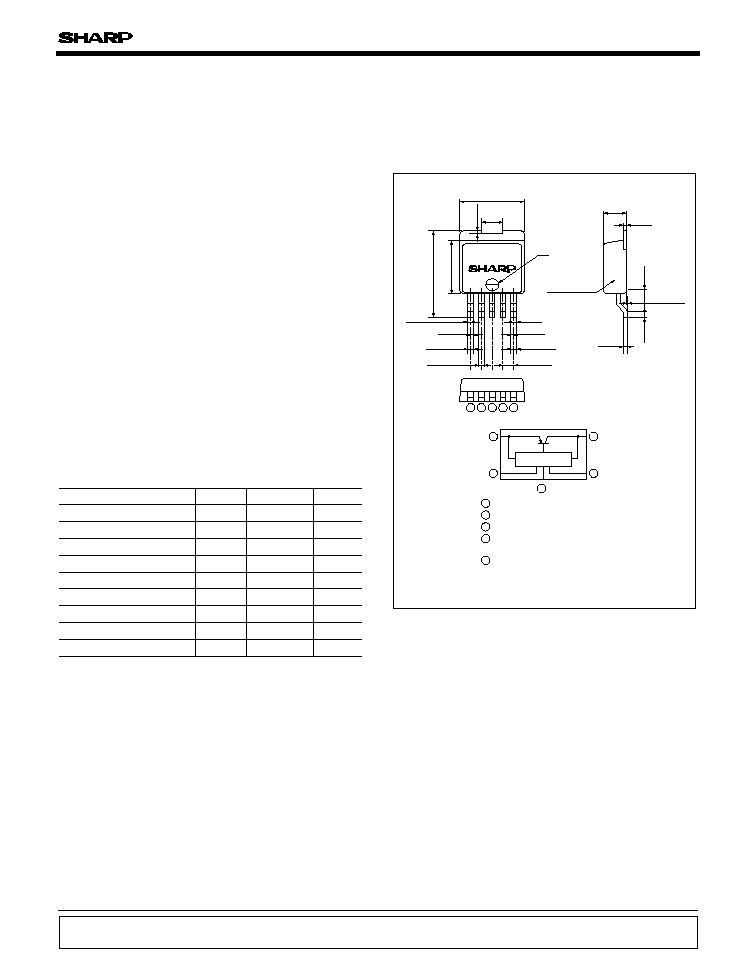

Outline Dimensions

(Unit : mm)

Parameter

Symbol

Rating

Unit

Input voltage

10

V

35

10

5

1

V

V

A

W

150

∞C

-

40 to

+

85

∞C

Junction temperature

Output adjustment terminal voltage

Output current

Output control voltage

V

IN

V

ADJ

I

O

V

C

T

j

(Ta

=

25

∞

C)

Operating temperature

Storage temperature

Soldering temperature

T

opr

-

40 to

+

150

∞C

T

stg

260 (10s)

∞C

T

sol

*1

*1

*1

*3

Power dissipation

P

D

*2

*1 All are open except GND and applicable terminals

*2 P

D

:With infinite heat sink

*3 Overheat protection may operate at the condition Tj

=

125∞C to 150∞C

1. Peripheral equipment of personal computers

2. Power supplies for various electronic equipment such as

DVD player or STB

s

Features

s

Applications

Low Voltage Operation Low

Power-loss Voltage Regulator

1. Low voltage operation (minimum operating voltage:2.35V)

2.5V input

available 1.5 to 1.8V

2. Large output current type (I

O

:1A)

3. Low dissipation current

(Dissipation current at no load:MAX.2mA

OFF-state dissipation current:MAX.5

µ

A)

4. Low power-loss

5. Built-in overcurrent and overheat protection functions

6. TO-263 package

PQ070XH01ZZ

:Sleeve-packaged product

PQ070XH01ZP

:Tape-packaged product

Notice

In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that may occur in equipment using any SHARP

devices shown in catalogs, data books, etc. Contact SHARP in order to obtain the latest device specification sheets before using any SHARP device.

Internet

Internet address for Electronic Components Group http://www.sharp.co.jp/ecg/

(2.4)

(

1.3)

0 to 0.25

0 7 0 X H 0 1

10.6

MAX.

2

3.28

±

0.5

(0.55)

8.4

±

0.5

13.7

MAX.

(0.6)

(0.6)

(0.6)

(0.45)

(0.45)

1.05

+

0.2

-

0.1

1.05

+

0.2

-

0.1

3

-

0.9

+

0.2

-

0.1

4

-

(1.7)

Epoxy resin

(0.6)

3.5

±

0.5

( ) : Typical dimensions

1

Output voltage adjustment

(V

ADJ

)

Specific IC

1

2

3

5

4

GND

DC output (V

O

)

DC input (V

IN

)

ON/OFF control (V

C

)

1

3

5

4

2

5

4

3

2

PQ070XH01Z

Parameter

Symbol

Conditions

V

IN

V

O

R

eg

L

R

eg

I

T

C

V

ref

RR

Unit

MAX.

TYP.

MIN.

-

-

-

-

45

-

-

I

O

=

5mA to 1A

V

IN

=

4 to 8V, I

O

=

5mA

T

j

=

0 to 125∞C, I

O

=

5mA

Refer to Fig.2

-

-

0.2

0.2

±

1.0

60

2

1

-

(Unless otherwise specified, condition shall be V

IN

=

5V, V

O

=

3V (R1

=

1k

), I

O

=

0.5A, V

C

=2.7V

,

Ta=25∞C)

V

V

%

%

%

dB

Input voltage range

Output voltage

Load regulation

V

ref

1.225

-

1.25

1.275

1.5

7

2.35

10

V

Reference voltage

Line regulation

Reference voltage temperature coefficient

Ripple Rejection

*4

Output on control voltage

Output off control voltage

Output off control current

Output off dissipation current

Output on control current

V

C (ON)

I

C (ON)

V

C (OFF)

I

C (OFF)

I

qs

-

-

-

-

-

-

-

-

I

O

=0A

I

O

=0A, V

C

=0.4V

I

O

=0A, V

C

=0.4V

2.0

-

-

200

0.8

2

-

V

µ

A

V

Dropout voltage

V

I-O

-

V

IN

=

2.85V, I

O

=

0.5A

-

0.5

V

µ

A

µ

A

-

5

Quiescent current

I

q

I

O

=0A

1

mA

-

2

*4 In case of opening control terminal , output voltage turns off

2

s

Electrical Characteristics

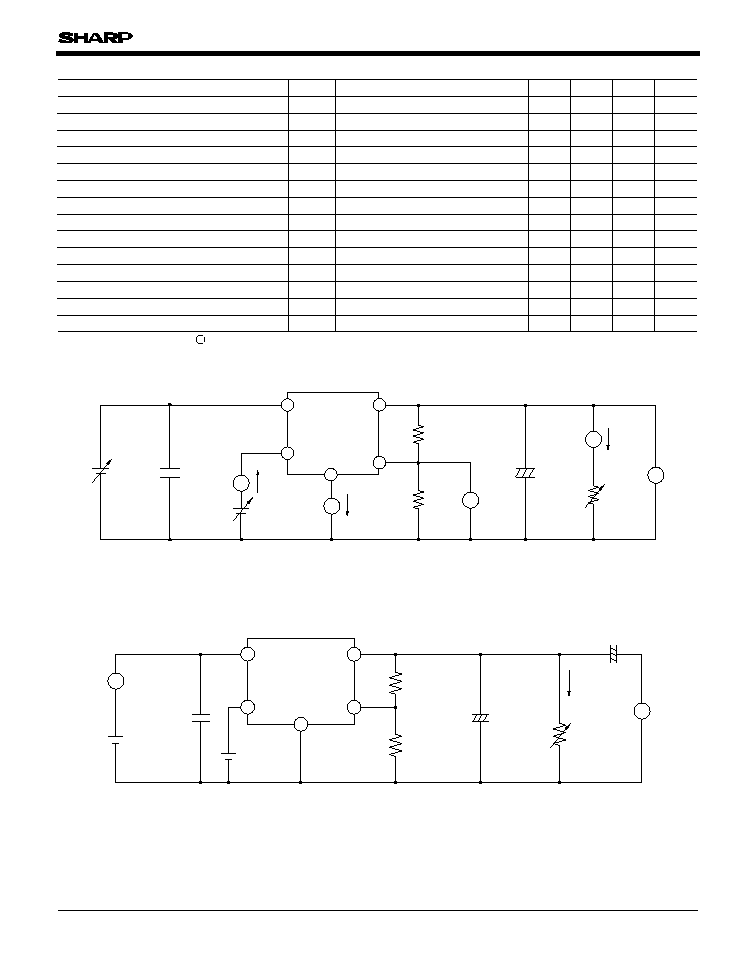

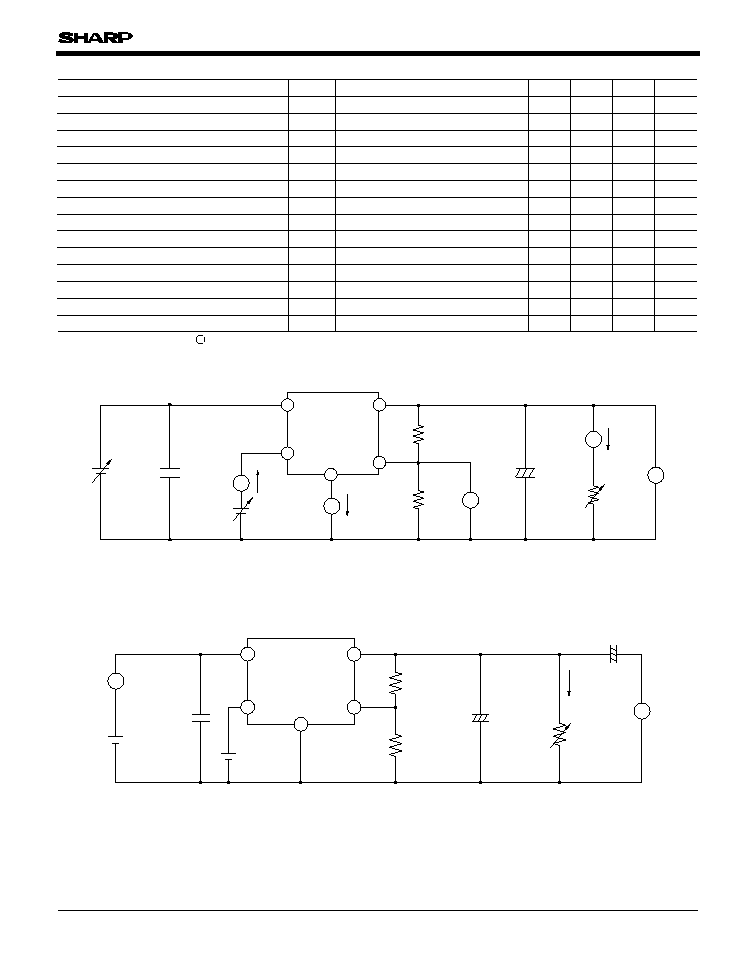

R

L

I

C

V

C

I

q

I

O

V

O

V

ref

+

0.33

µ

F

47

µ

F

R

1

R

2

1k

V

IN

A

A

A

3

4

5

2

1

V

V

V

O

=

V

ref

◊

(1

+

R

2

/R

1

)

.=.

1.25

◊

(1

+

R

2

/R

1

)

[R

1

=

1k

, V

ref

.=.

1.25V]

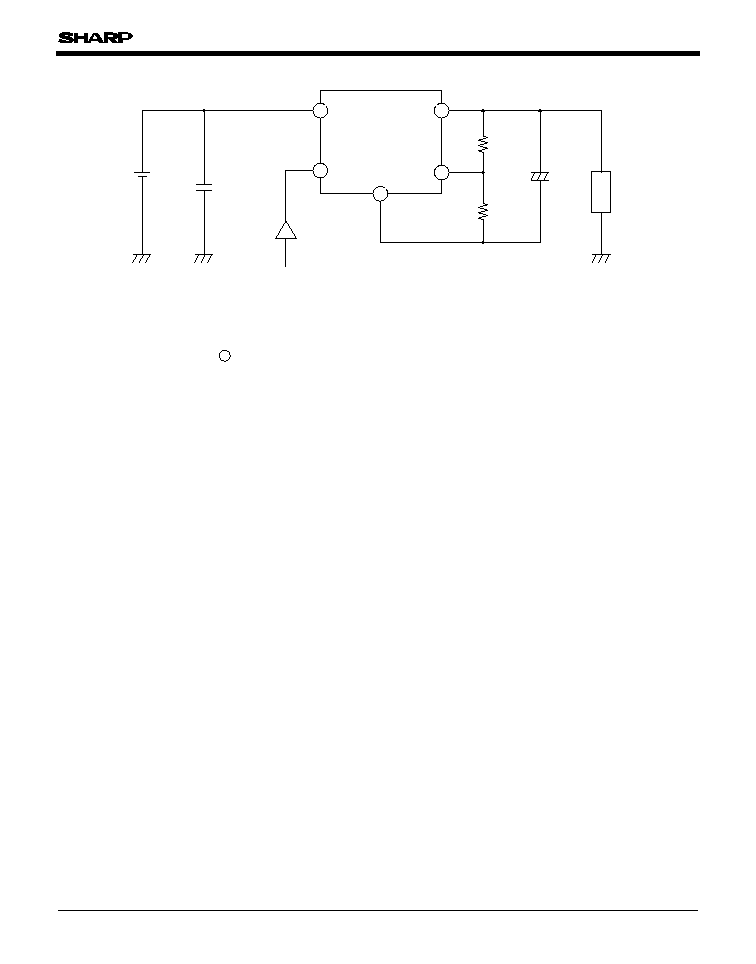

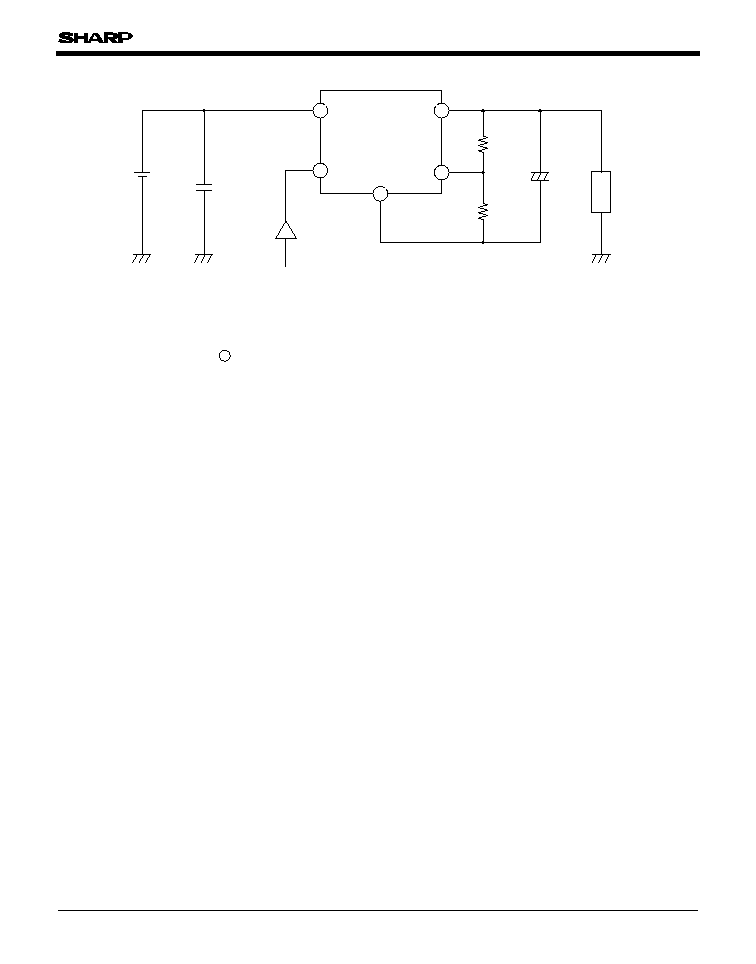

Fig.1

Standard Test Circuit

I

O

R

L

R

2

V

IN

V

ref

V

C

ei

eo

R

1

1k

2.7V

+

+

3

1

2

4

5

0.33

µ

F

47

µ

F

f

=

120Hz(sine wave)

ei(rms)

=

0.5V

V

O

=

3V(R

1

=

1k

)

V

IN

=

5V

I

O

=

0.3A

RR

=

20log(ei(rms)/eo(rms))

V

~

~

Fig.2

Test Circuit for Ripple Rejection

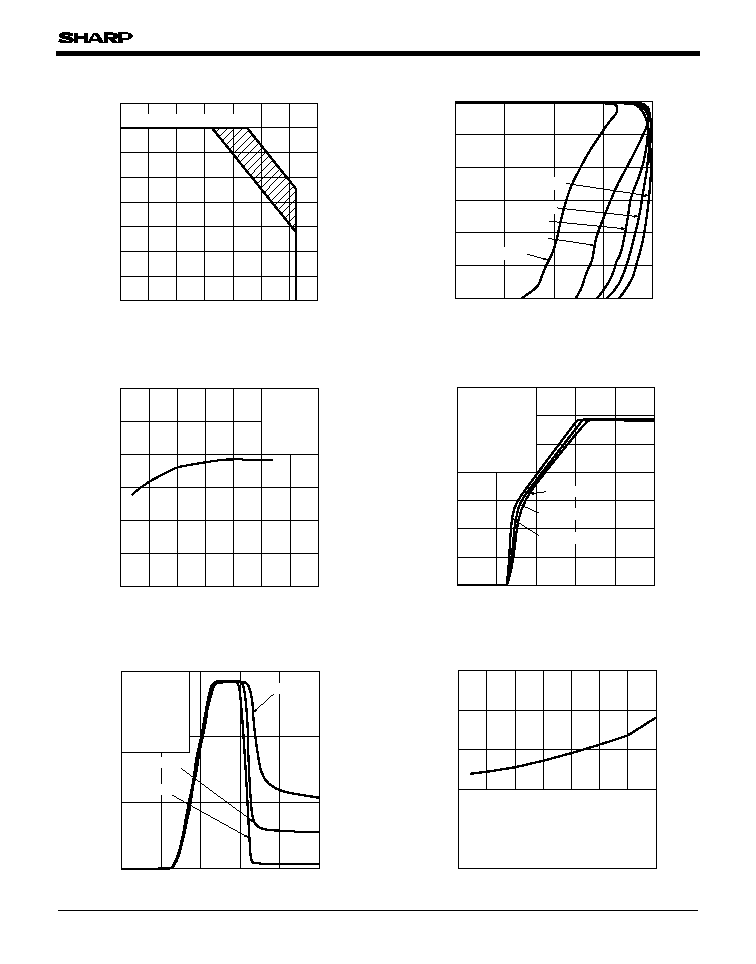

PQ070XH01Z

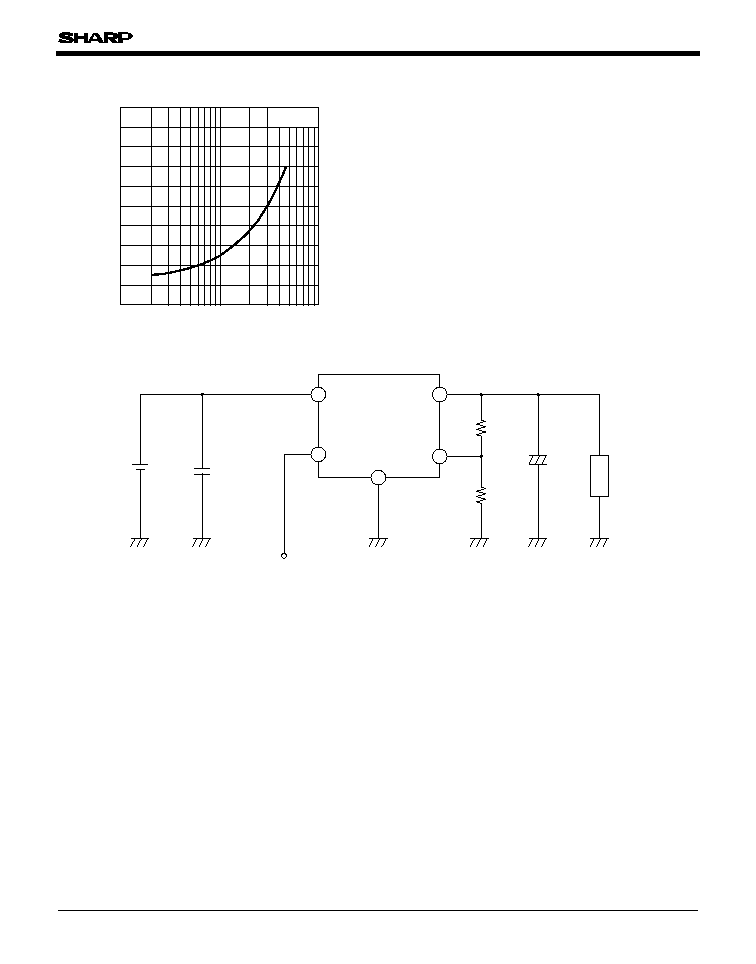

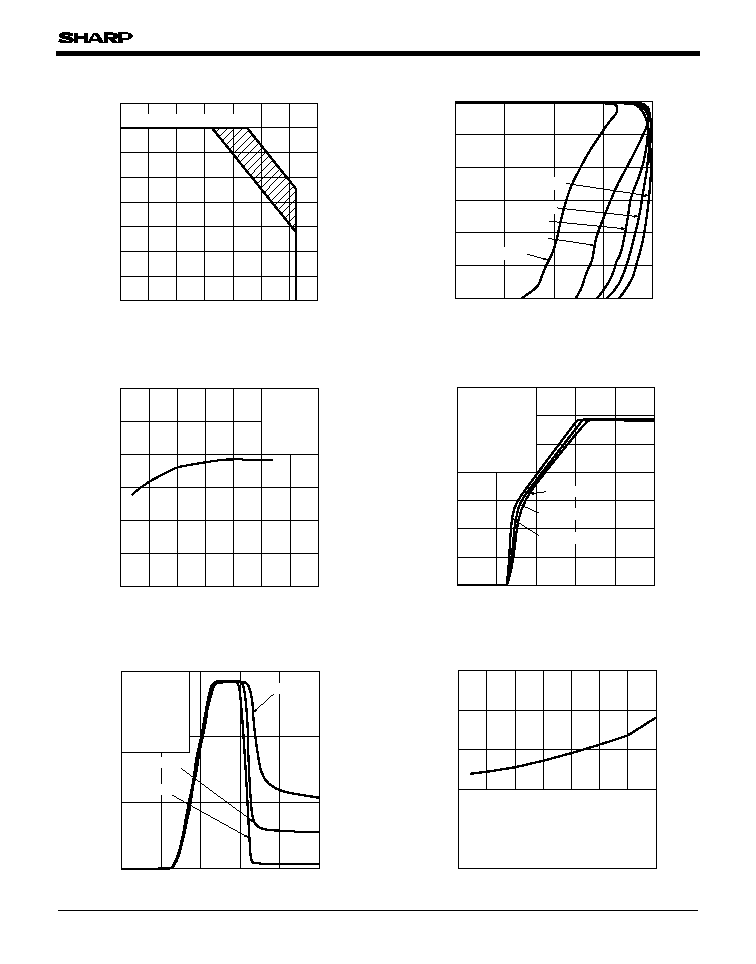

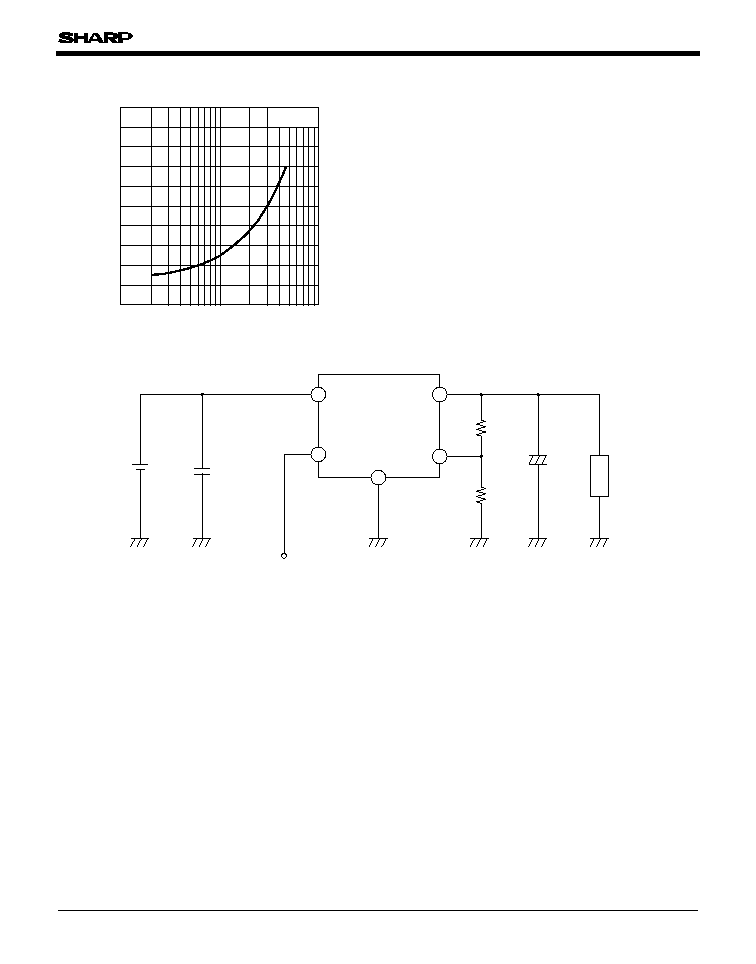

Fig.6 Output Voltage vs. Input Voltage

Fig.5 Reference Voltage vs. Ambient

Temperature

Fig.7 Circuit Operating Current vs. Input

Voltage

Fig.8 Dropout Voltage vs. Junction

Temperature

Reference voltage V

ref

(V)

1.23

1.235

1.24

1.245

1.25

1.255

1.26

-

50

-

25

0

25

50

75

100

125

Ambient temperature T

a

(

∞

C)

V

IN

=

4V

I

O

=

0.5A

V

C

=

2.7V

R

1

=

1k

R

2

=

1.4k

Circuit operating current I

BIAS

(mA)

Input voltage V

IN

(V)

0

10

20

30

0

1

2

3

4

5

R

L

=

3

(I

O

=

1A)

R

L

=

6

(I

O

=

0.5A)

R

L

=

(I

O

=

0A)

V

C

=

2.7V

T

a

=

Room temp.

R

1

=

1k

R

2

=

1.4k

(V

O

=

3V)

C

IN

=

0.33

µ

F

C

O

=

47

µ

F

Output voltage V

O

(V)

Input voltage V

IN

(V)

0

0.5

1

1.5

2

2.5

3

3.5

0

1

2

3

4

5

R

L

=

(I

O

=

0.3A)

R

L

=

3

(I

O

=

1A)

R

L

=

6

(I

O

=

0.5A)

V

C

=

2.7V

T

a

=

Room temp.

R

1

=

1k

R

2

=

1.4k

(V

O

=

3V)

C

IN

=

0.33

µ

F

C

O

=

47

µ

F

Dropout voltage V

I-O

(V)

0

0.05

0.1

0.15

0.2

0.25

-

50

-

25

0

25

50

75

100

125

Junction temperature T

j

(

∞

C)

V

IN

:Input voltage shall be the value when output

voltage is 95% in camparison with the initial

value

I

O

=

0.5A

V

C

=

2.7V

R

1

=

1k

R

2

=

1.4k

(V

O

=

3V)

Power dissipation P

D

(W)

0

5

10

15

20

25

30

35

40

-

40

-

20

0

20

40

60

80

100

P

D

: With infinite heat sink

Ambient temperature T

a

(

∞

C)

Note) Oblique line prtion:Overheat protection may operate in this area

Output voltage V

O

(V)

Output current I

O

(A)

0

0.5

1

1.5

2

2.5

3

0

0.5

1

1.5

2

V

O

=

3V

V

IN

=

10V

V

IN

=

7V

V

IN

=

5.5V

V

IN

=

5V

V

IN

=

4.5V

Fig.3 Power Dissipation vs. Ambient

Temperature

Fig.4 Overcurrent Protection Characteristics

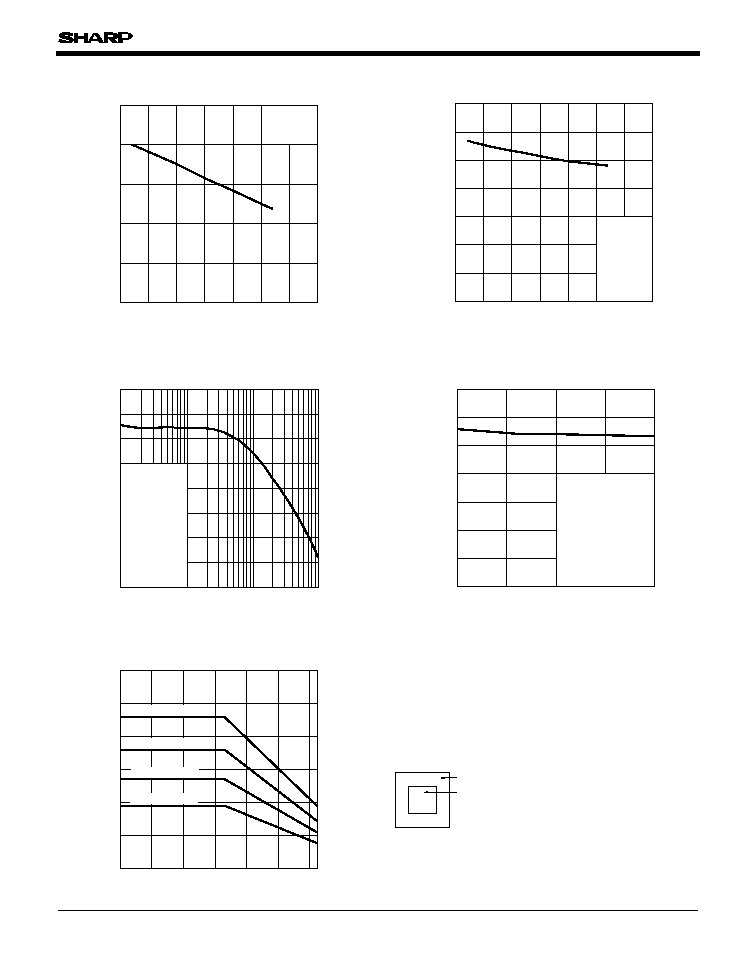

PQ070XH01Z

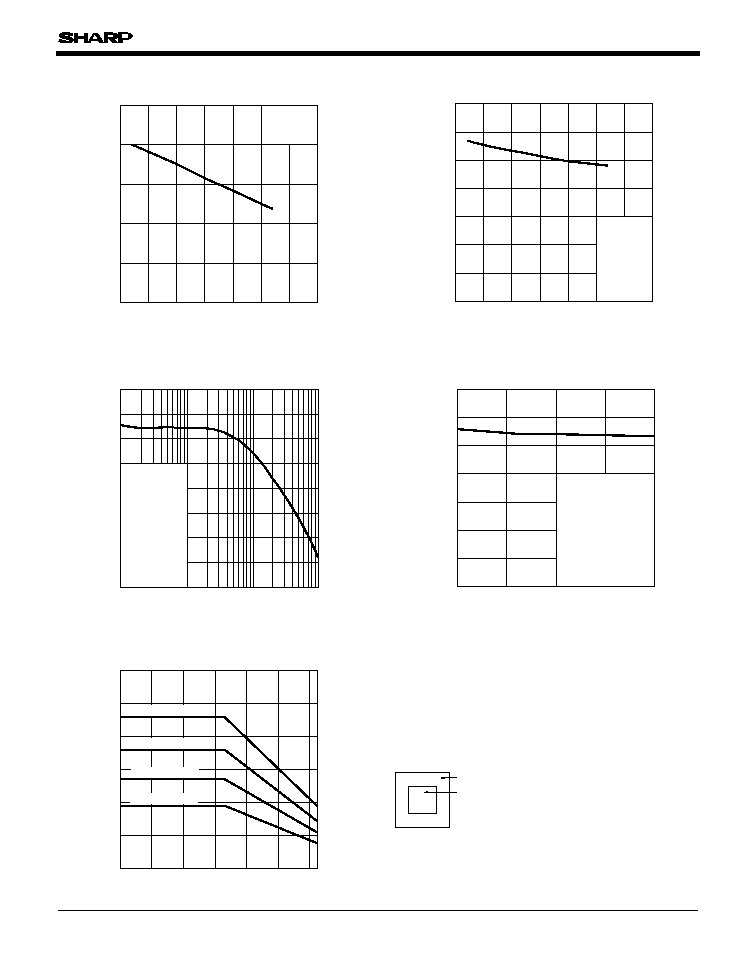

Fig.12 Ripple Rejection vs. Output Current

Fig.11 Ripple Rejection vs. Input Ripple

Frequency

Ripple rejection RR (dB)

0.1

1

10

100

Input ripple frequency f (kHz)

35

40

45

50

55

60

65

70

75

ei(rms)

=

0.5V

V

IN

=

5V

V

C

=

2.7V

I

O

=

0.3A

C

O

=

47

µ

F

T

a

=

Room temp.

R

1

=

1k

R

2

=

1.4k

(V

O

=

3V)

40

45

50

55

60

65

70

75

0

0.25

0.5

0.75

1

Ripple rejection RR (dB)

Output current I

O

(A)

ei (rms)

=

0.5V

f

=

120Hz

V

IN

=

5V

V

C

=

2.7V

C

O

=

47

µ

F

T

a

=

Room temp.

R

1

=

1k

R

2

=

1.4k

(V

O

=

3V)

ON-OFF threshold voltage V

C

(ON/OFF) (V)

0

0.5

1

1.5

2

2.5

-

50

-

25

0

25

50

75

100

125

Ambient temperature T

a

(

∞

C)

V

IN

=

2.5V

I

O

=

0A

Quiescent current I

q

(mA)

-

50

-

25

0

25

50

75

100

125

Ambient temperature T

a

(

∞

C)

0

0.2

0.4

0.6

0.8

1

1.2

1.4

V

IN

=

4V

I

O

=

0A

V

C

=

2.7V

R

1

=

1k

R

2

=

1.4k

(V

O

=

3V)

Fig.9 ON-OFF Threshold Voltage vs.

Ambient Temperature

Fig.10 Quiescent Current vs. Ambient

Temperature

Power dissipation P

D

(W)

0

1

2

3

4

5

6

-

40

-

20

0

20

40

60

80

Ambient temperature T

a

(

∞

C)

Cu area 3 600mm

2

Cu area 900mm

2

Cu area 400mm

2

Cu area 115mm

2

Material : Glass-cloth epoxy resin

Size : 60

◊

60

◊

1.6mm

Cu thickness : 65

µ

m

PWB

PWB

Cu

Fig.13 Power Dissipation vs. Ambient

Temperature

PQ070XH01Z

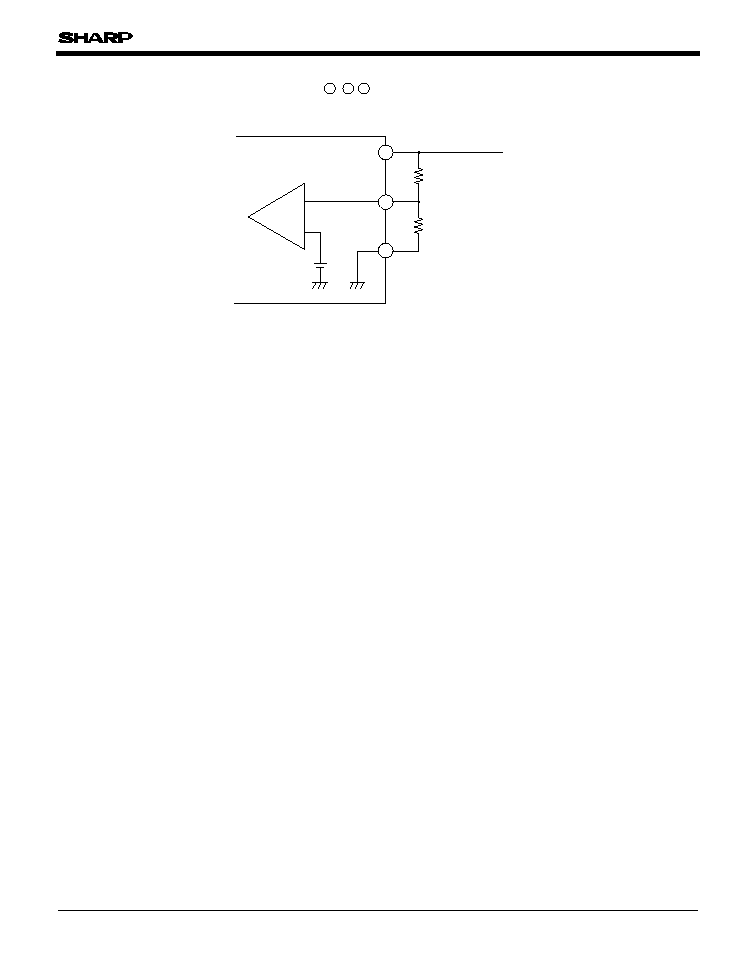

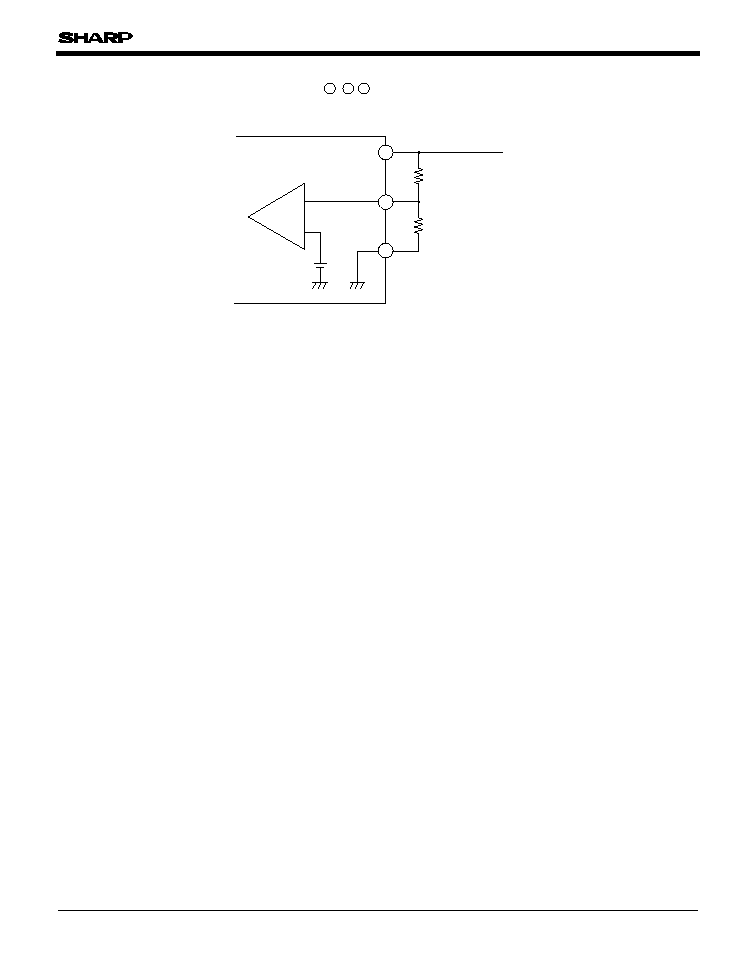

Fig.15 Example of Application

1

3

2

5

4

V

O

V

IN

R

2

C

IN

R

1

1k

C

O

+

Load

ON/OFF signal

High:Output ON

Low or open Output OFF

Fig.14 Output Voltage vs. R2 (Typical Value)

Output voltage V

O

(V)

R

2

(

)

0

1

2

3

4

5

6

7

8

9

10

100

1 000

10 000

R

1

=

1k

PQ070XH01Z

s

Precautions for Use

1

3

2

5

4

V

IN

C

IN

R

2

R

1

C

O

V

O

+

C-MOS or TTL

Load

1. External connection

(1) The connecting wiring of C

O,

C

IN

and each terminal, fin portion must be as short as possible. It may oscillate by type, value and

wiring condition of capacitor. Confirm the output wareform in actual using condition beforehand.

(2) ON/OFF control terminal is compatible with LS-TTL. It enables to be direcrly driven by TTL or C-MOS standard logic

(RCA4000 series).

(3) If voltage is applied under the conditions that device pin is connected divergently or reversely, the deterioration of

characteristics or damage may occur. Never allow improper mounting.

2. Thermal protection design

Power dissipation of devices is obtained by the following equation.

P

D

=

I

O

◊

(V

IN

-

V

O

)

+

V

IN

◊

I

q

When ambient temperature T

a

and power dissipation P

D

during operation are determined, operate element within the safety

operation area specified by the derating curve. Insufficient radiation gives an unfavorable influence to the normal operation and

reliability of the device.

In the external area of the safety operation area shown by the derating curve, the overheat protection circuit may operate to shut-

down output. However please avoid keeping such condition for a long time.

3. ESD (Electrostatic Sensitivity Discharge)

Be careful not to apply electrostatic discharge to the device since this device employs a bipolar IC and may be damaged by electro

static discharge. Followings are some methods against excessive voltage caused by electro static discharge.

(1) Human body must be grounded to discharge the electro charge which is charged in the body or cloth.

(2) Anything that is in contact with the device such as workbench, inserter, or measuring instrument must be grounded.

(3) Use a soldering dip basin with a minimum leak current (isolation resistance 10M

or more) from the AC power supply line.

Also the soldering dip basin must be grounded.

2

PQ070XH01Z

s

Output Voltage Fine Tuning

1. Connecting external resistors R

1

and R

2

to terminals , , allows the output voltage to be fine tuned from 1.5V to 7V. Refer to

the figure below and Fig.14 when connecting external resistors for fine tuning output voltage.

4

5

3

R

2

R

1

V

O

V

ref

+

-

V

O

=

V

ref

◊

(1

+

R

2

/R

1

)

.=.

1.25

◊

(1

+

R

2

/1 000)

[R

1

=

1k

, V

ref

.=.

1.25V]

3

4

5

115

Application Circuits

NOTICE

qThe circuit application examples in this publication are provided to explain representative applications of

SHARP devices and are not intended to guarantee any circuit design or license any intellectual property

rights. SHARP takes no responsibility for any problems related to any intellectual property right of a

third party resulting from the use of SHARP's devices.

qContact SHARP in order to obtain the latest device specification sheets before using any SHARP device.

SHARP reserves the right to make changes in the specifications, characteristics, data, materials,

structure, and other contents described herein at any time without notice in order to improve design or

reliability. Manufacturing locations are also subject to change without notice.

qObserve the following points when using any devices in this publication. SHARP takes no responsibility

for damage caused by improper use of the devices which does not meet the conditions and absolute

maximum ratings to be used specified in the relevant specification sheet nor meet the following

conditions:

(i) The devices in this publication are designed for use in general electronic equipment designs such as:

--- Personal computers

--- Office automation equipment

--- Telecommunication equipment [terminal]

--- Test and measurement equipment

--- Industrial control

--- Audio visual equipment

--- Consumer electronics

(ii)Measures such as fail-safe function and redundant design should be taken to ensure reliability and

safety when SHARP devices are used for or in connection with equipment that requires higher

reliability such as:

--- Transportation control and safety equipment (i.e., aircraft, trains, automobiles, etc.)

--- Traffic signals

--- Gas leakage sensor breakers

--- Alarm equipment

--- Various safety devices, etc.

(iii)SHARP devices shall not be used for or in connection with equipment that requires an extremely

high level of reliability and safety such as:

--- Space applications

--- Telecommunication equipment [trunk lines]

--- Nuclear power control equipment

--- Medical and other life support equipment (e.g., scuba).

qContact a SHARP representative in advance when intending to use SHARP devices for any "specific"

applications other than those recommended by SHARP or when it is unclear which category mentioned

above controls the intended use.

qIf the SHARP devices listed in this publication fall within the scope of strategic products described in the

Foreign Exchange and Foreign Trade Control Law of Japan, it is necessary to obtain approval to export

such SHARP devices.

qThis publication is the proprietary product of SHARP and is copyrighted, with all rights reserved. Under

the copyright laws, no part of this publication may be reproduced or transmitted in any form or by any

means, electronic or mechanical, for any purpose, in whole or in part, without the express written

permission of SHARP. Express written permission is also required before any use of this publication

may be made by a third party.

qContact and consult with a SHARP representative if there are any questions about the contents of this

publication.