PR308T11ESZ/

PR308T21ESZ

PR308T11ESZ/PR308T21ESZ

s

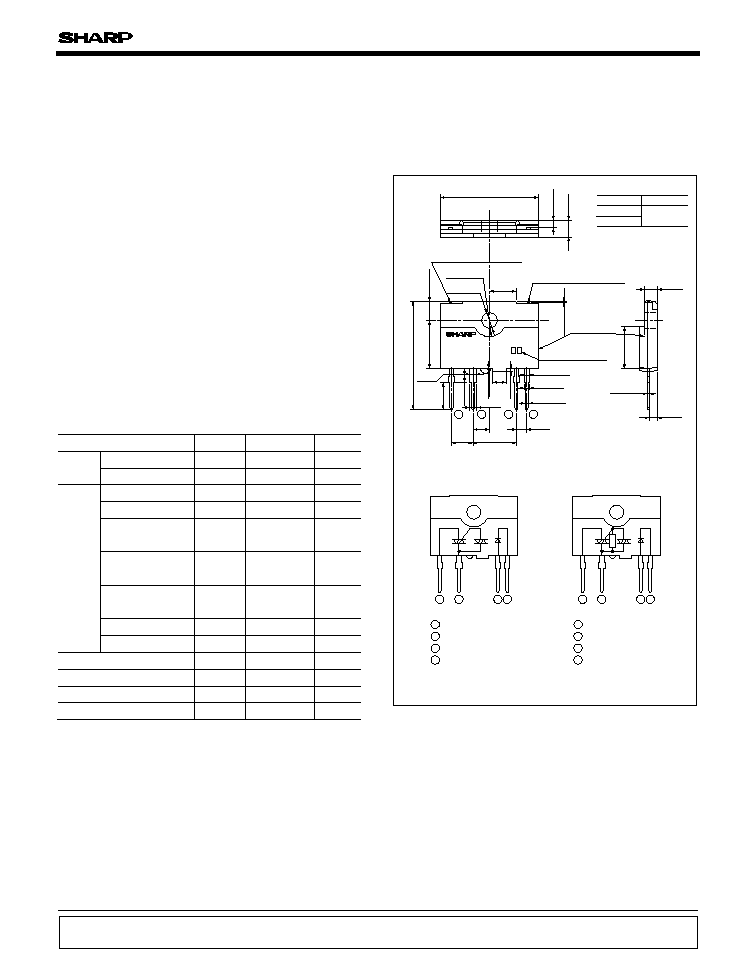

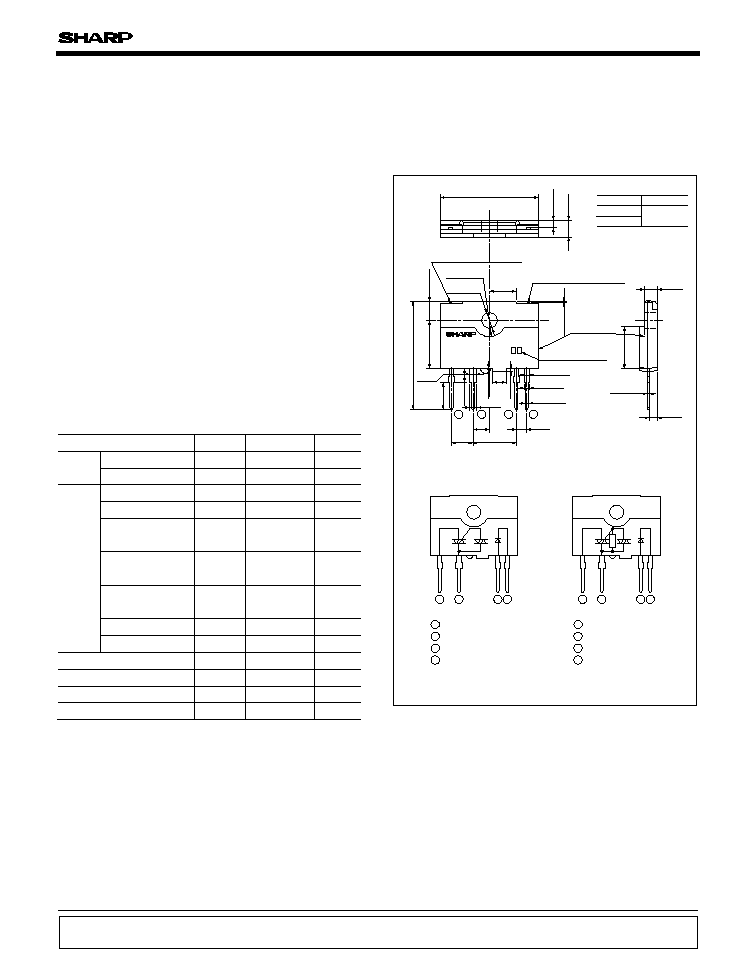

Outline Dimensions

(Unit : mm)

s

Absolute Maximum Ratings

*1 Sine wave, practical value, Refer to Fig.1, 2

*2 50Hz sine wave, start at Tj

=

25∞C

*3 AC60Hz, for 1 min, 40 to 60%RH

Isolation voltage measuring method

1) Dielectric withstand voltage tester with zero cross circuit shall be used.

2) The applied voltage waveform shall be sine wave.

3) Voltage shall be applied between input and output.

(Input and output terminals shall all be shorted respectively.)

Parameter

Symbol

Rating

Unit

Forward current

I

F

50

8

mA

Reverse voltage

RMS ON-state current

Repetitive peak

OFF-state voltage

Peak one cycle surge current

Input

Output

V

R

6

V

A

A

V

A/

µ

s

I

surge

80

600

50

45 to 65

260

600

V

DRM

Non repetitive peak

OFF-state voltage

V

V

Hz

V

DSM

f

V

iso (rms)

I

T (rms)

kV

Isolation voltage

Operating temperature

T

opr

Load supply voltage

Operating frequency

dI

T

/dt

Critical rate of rise

of ON-state current

V

OUT (rms)

-

30 to

+

125

-

25 to

+

100

∞

C

∞

C

Storage temperature

T

stg

*3

*2

*1

Soldering temperature

T

sol

260 (For 10s)

3.0

∞

C

(Ta

=

25

∞

C)

1. Copiers

2. Facsimiles

3. Laser Printers

s

Features

s

Applications

Solid State Relay Approved by

European Safety Standard

1. Approved by European Safety Standards.

Thickness of the internal insulation:0.4mm or more

Creepage distance:6.4mm or more

Clearance:6.4mm or more

2. Isolation voltage (V

iso(rms)

:3kV)

3. RMS ON-state current I

T (rms)

:8A (Tc

80∞C)

4. Low profile package (23

◊

16

◊

4t mm)

5. Built-in zero-cross circuit

(PR308T21ESZ)

Notice

In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that may occur in equipment using any SHARP

devices shown in catalogs, data books, etc. Contact SHARP in order to obtain the latest device specification sheets before using any SHARP device.

Internet

Internet address for Electronic Components Group http://www.sharp.co.jp/ecg/

(3.8)

(5.08)

(10.16)

(2.54)

1

2

3

4

PR 3 0 8 T 1 1

8A260VAC

+ -

1.8

±

0.2

4.5

±

0.3

11.5

±

0.2

3.8

MAX.

.

0.2

MAX.

6.2

MIN.

1.6

±

0.2

3-1.2

±

0.2

6.4

±

0.2

Common to pin No.2

3-1.4

±

0.3

(3.5)

(0.8)

(25.8)

4

±

0.2

23

±

0.2

Z.C.

0.4

±

0.1

10

±

0.2

Lot No.

(DIN Standard)

Epoxy resin

4-0.8

±

0.2

1.8

±

0.3

0.1

MIN.

Common to pin No.2

3.7

±

0.2

R3.8

±

0.2

PR308T21ESZ

PR308T11ESZ

Internal connection diagram

1

2

3 4

1

2

3 4

Z.C. : Zero-cross circuit

( ) : Typical dimensions

2

1

3

4

Output (Triac T1)

Output (Triac T2)

Input (

+)

Input (

-)

2

1

3

4

Output (Triac T1)

Output (Triac T2)

Input (

+)

Input (

-)

Model No.

PR308T11

PR308T21

8A 260VAC

(1.8)

3

±

0.2

PR308T11ESZ/PR308T21ESZ

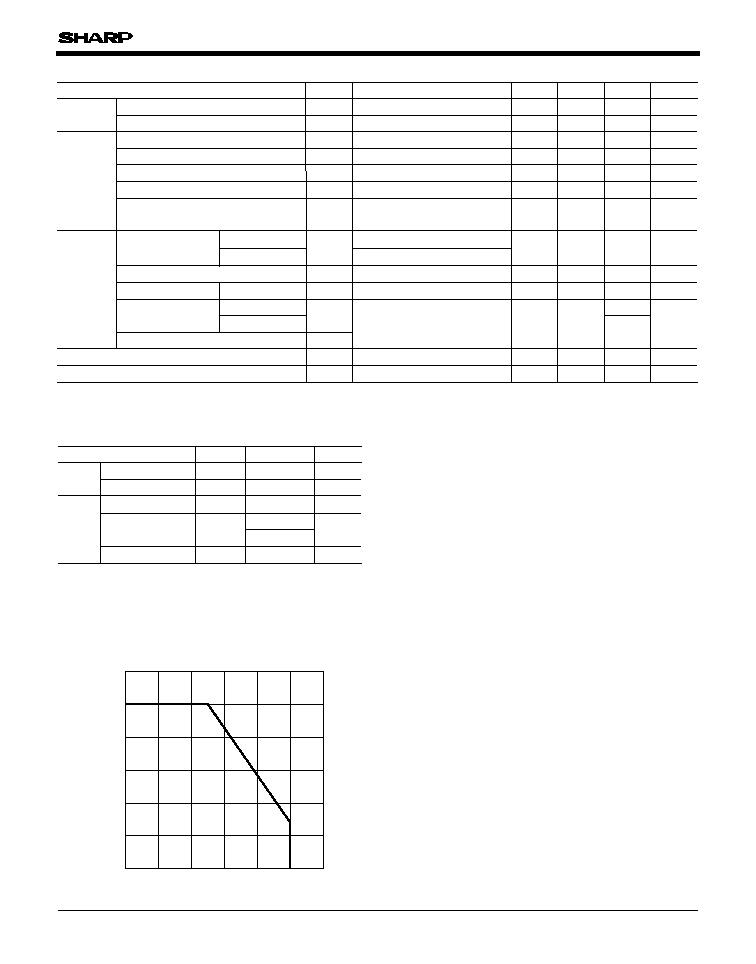

Parameter

Conditions

Input

Forward voltage

I

F

=

20mA

I

F

=

10mA

ON-state voltage

Output

Critical rate of rise of OFF-state voltage

V

D

=

2/3V

DRM

Tj

=

125∞C, V

D

=

2/3V

DRM

dI

T

/dt

=-

4.0A/mS

Transfer

charac-

teristics

Minimum trigger

current

V

D

=

12V, R

L

=

30

V

D

=

6V, R

L

=

30

V

D (rms)

=

200V, AC50Hz

I

T (rms)

=

2A, Resistance load, I

F

=

20mA

MIN.

-

-

30

10

10

TYP.

1.2

4.5

40

-

-

MAX.

1.4

1.5

-

-

-

Symbol

V

F

V

T (rms)

dV/dt

Commutation critical rate of rise

of OFF-state voltage

(dV/dt)c

I

FT

Isolation resistance

Zero-cross voltage

R

iso

V

OX

I

T (rms)

=

2A, Resistance load, I

F

=

20mA

Unit

V

Reverse current

V

R

=3V

V

D

=V

DRM

I

R

I

DRM

-

-

-

50

Holding current

I

H

mA

-

-

10

-

4

-

-

10

-

4

A

A

V/

µ

s

5

-

-

V/

µ

s

-

-

10

mA

V

-

-

35

V

(Ta

=

25∞C)

Turn-on time

Turn-off time

Thermal resistance (Between junction and case)

Thermal resistance (Between junction and ambience)

-

-

-

-

-

-

-

-

1

10

t

on

t

off

R

th (j-c)

R

th (j-a)

ms

∞C/W

∞C/W

DC

=

500V, 40 to 60%RH

PR308T11ESZ

PR308T21ESZ

PR308T21ESZ

PR308T11ESZ

PR308T21ESZ

Repetitive peak OFF-state current

s

Electrical Characteristics

*1 Without external heat sink (Ta

40∞C)

*2 With external heat sink (Tc

80∞C)

Parameter

Symbol

Conditions

Unit

20 to 30

80 to 240

mA

Input

Output

0 to 0.1

mA

V

A

Hz

0.5 to 2.0

0.5 to 8.0

47 to 63

*2

*1

I

F (on)

V

OUT (rms)

f

I

F (off)

I

OUT (rms)

Load supply voltage

Operating frequency

Load supply current

Signal current at ON

Signal current at OFF

s

Recommend Operating Conditions

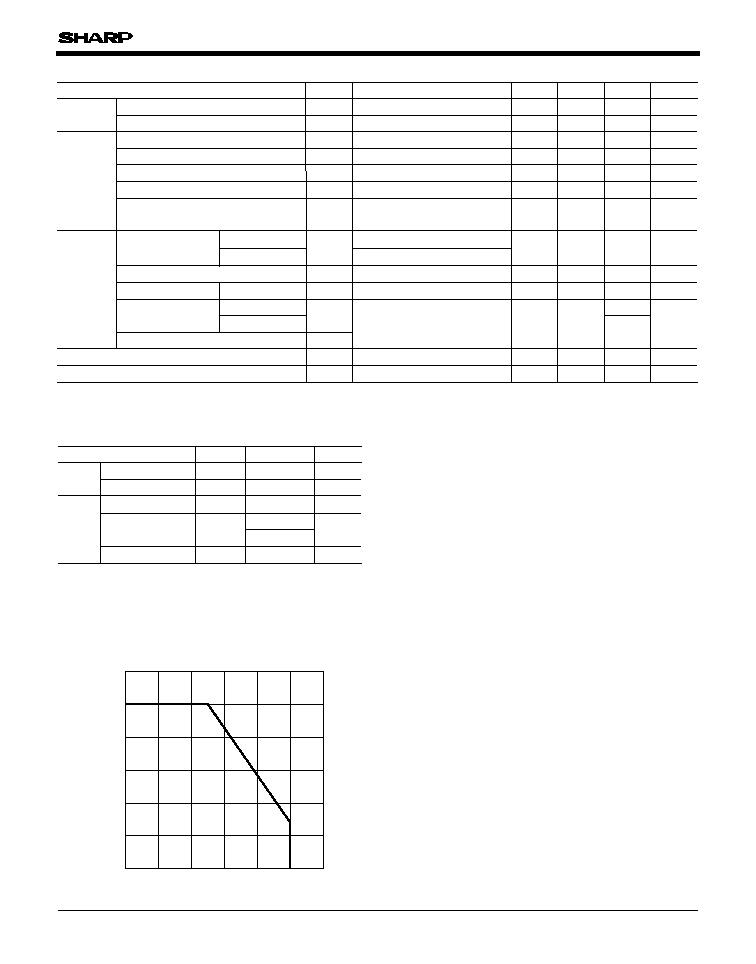

0

10

20

30

40

50

60

-

25

0

25

50

75

100

125

Forward current I

F

(mA)

Ambient temperature T

a

(∞C)

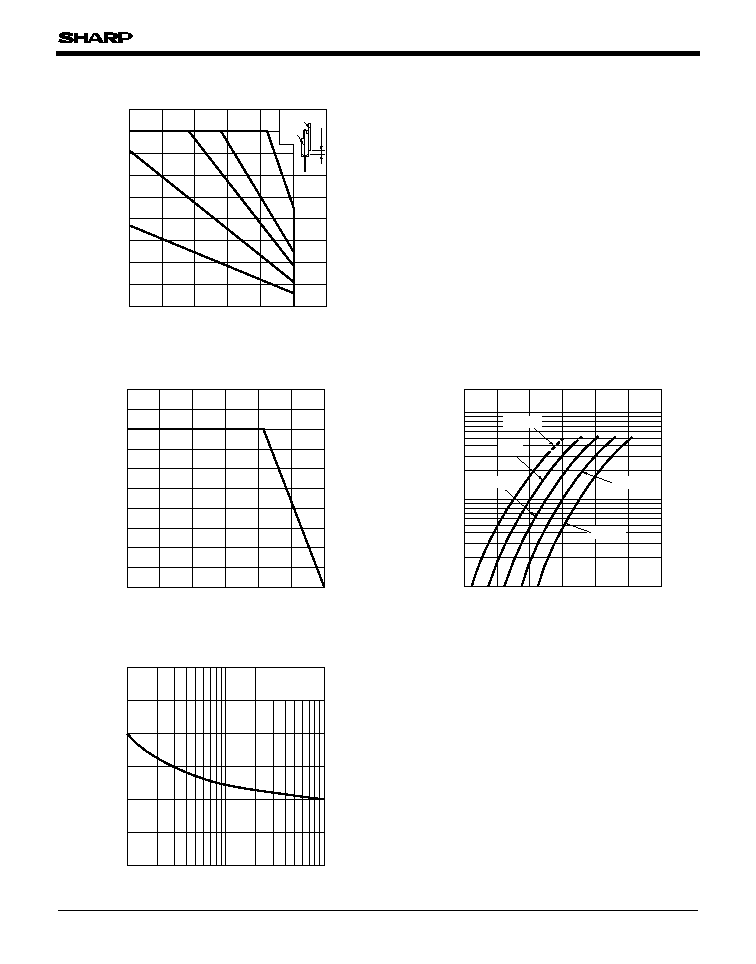

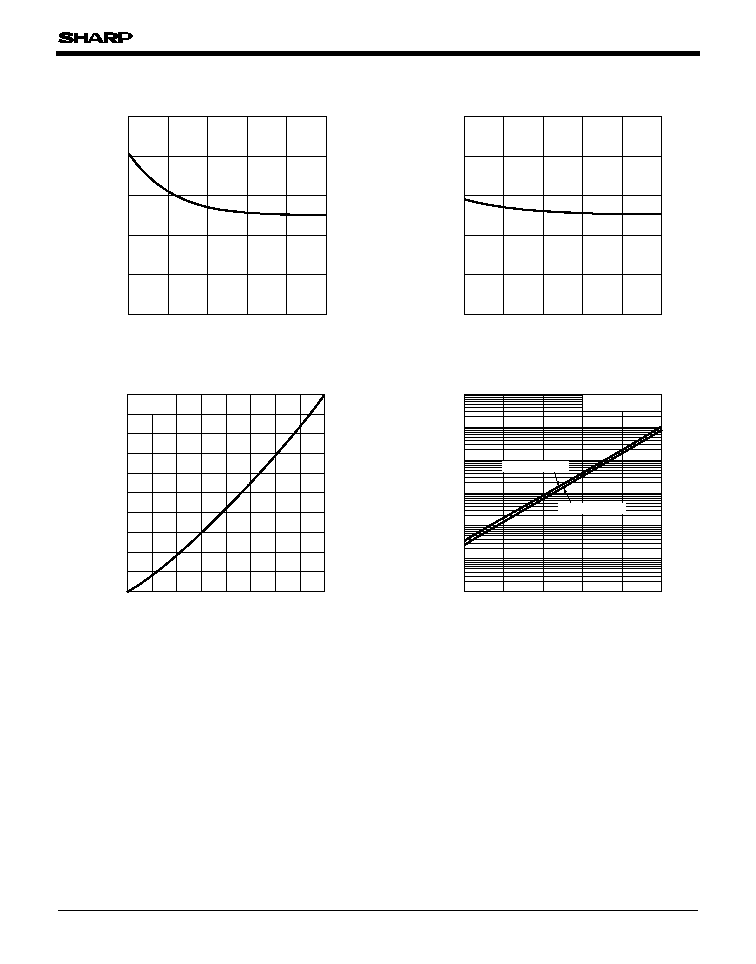

Fig.1

Forward Current vs. Ambient

Temperature

PR308T11ESZ/PR308T21ESZ

RMS ON-state current I

T (rms)

(A)

Case temperature T

C

(

∞

C)

0

10

-

25

0

25

50

75

100

125

9

8

7

6

5

4

3

2

1

1

2

5

10

0.9

1.1

1

1.2

1.3

1.4

1.5

20

50

100

Forward current I

F

(mA)

Forward voltage V

F

(V)

T

a

=75∞C

50∞C

25∞C

0∞C

-

25∞C

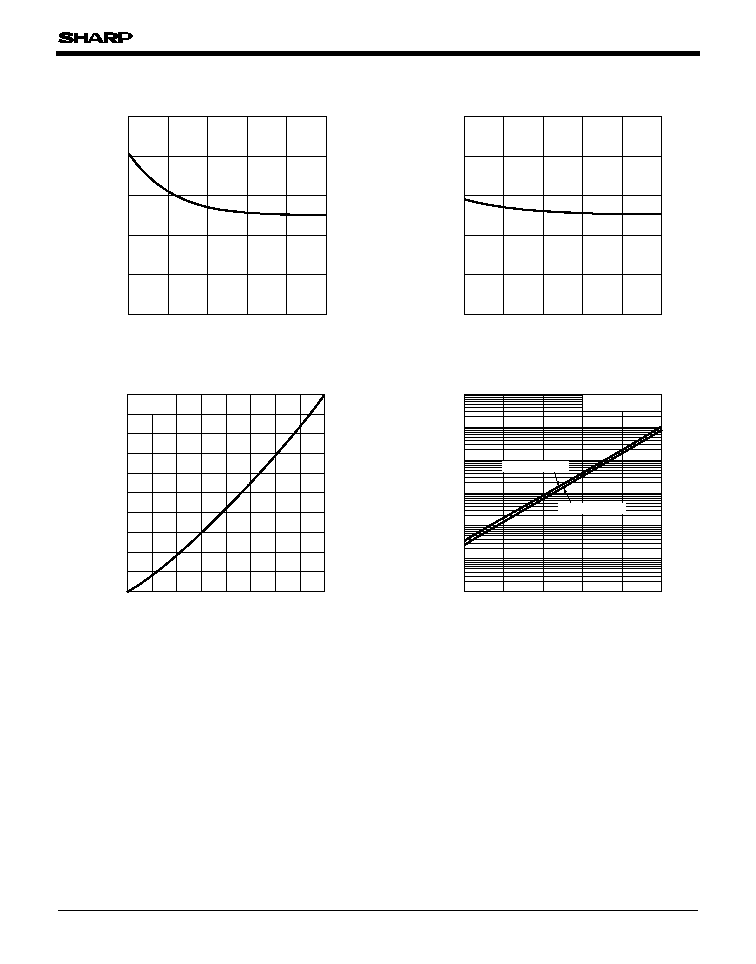

Fig.3

RMS ON-state Current vs. Case

Temperature

Fig.5

Surge Current vs. Power-on Cycle

Fig.4

Forward Current vs. Forward Voltage

(Typical Value)

Surge current I

surge

(A)

Power-on cycle (Times)

0

1

10

100

f

=

50Hz

T

j

=

25

∞

C start

100

80

60

40

20

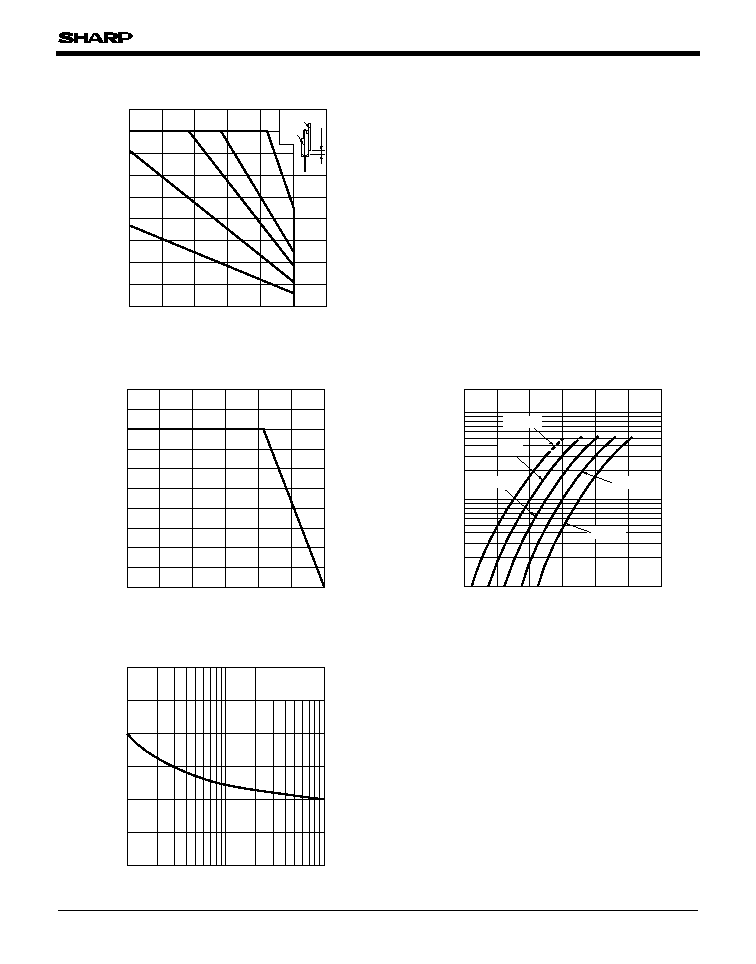

RMS ON-state current I

T

(A

rms

)

Ambient temperature T

a

(

∞

C)

0

9

8

7

6

5

4

3

2

1

-

25

100

75

50

25

125

0

(1)

(2)

(3)

(4)

(5)

4mm

Al plate

SSR

(1) With infinite heat sink

(2) With heat sink (200

◊

200

◊

2mm Al plate)

(3) With heat sink (100

◊

100

◊

2mm Al plate)

(4) With heat sink (50

◊

50

◊

2mm Al plate)

(5) Without heat sink

(Note) With the Al heat sink set up vertically, tighten the

device with a torque of 0.4N∑m and apply thermal

conductive silicone grease on the mounting face of

heat sink. Forced cooling shall not be carried out.

(Please use an isolation sheet if necessary.)

Fig.2 RMS ON-state Current vs. Ambient

Temperature

PR308T11ESZ/PR308T21ESZ

Maximum ON-state power dissipation (W)

RMS ON-state current I

T

(A)

0

10

8

6

4

2

7

5

3

1

0

8

6

4

2

9

7

5

3

1

T

a

=

25

∞

C

Repetitive peak OFF-state current I

DRM

(A)

Ambient temperature T

a

(

∞

C)

10

-

9

10

-

3

10

-

4

10

-

5

10

-

6

10

-

7

10

-

8

-

25

0

25

50

75

100

V

D

=

600V

PR308T21ESZ

PR308T11ESZ

Fig.8

Maximum ON-state Power Dissipation

vs. RMS ON-state Current (Typical Value)

Fig.9

Repetitive Peak OFF-state Current vs.

Ambient Temperature (Typical Value)

Minimum trigger current I

FT

(mA)

Ambient temperature T

a

(

∞

C)

(PR308T11ESZ)

0

10

-

25

0

25

50

75

100

8

6

4

2

V

D

=

12V

Minimum trigger current I

FT

(mA)

Ambient temperature T

a

(

∞

C)

(PR308T21ESZ)

0

10

-

25

0

25

50

75

100

8

6

4

2

V

D

=

6V

Fig.6

Minimum Trigger Current vs. Ambient

Temperature (Typical Value)

Fig.7

Minimum Trigger Current vs. Ambient

Temperature (Typical Value)

115

Application Circuits

NOTICE

qThe circuit application examples in this publication are provided to explain representative applications of

SHARP devices and are not intended to guarantee any circuit design or license any intellectual property

rights. SHARP takes no responsibility for any problems related to any intellectual property right of a

third party resulting from the use of SHARP's devices.

qContact SHARP in order to obtain the latest device specification sheets before using any SHARP device.

SHARP reserves the right to make changes in the specifications, characteristics, data, materials,

structure, and other contents described herein at any time without notice in order to improve design or

reliability. Manufacturing locations are also subject to change without notice.

qObserve the following points when using any devices in this publication. SHARP takes no responsibility

for damage caused by improper use of the devices which does not meet the conditions and absolute

maximum ratings to be used specified in the relevant specification sheet nor meet the following

conditions:

(i) The devices in this publication are designed for use in general electronic equipment designs such as:

--- Personal computers

--- Office automation equipment

--- Telecommunication equipment [terminal]

--- Test and measurement equipment

--- Industrial control

--- Audio visual equipment

--- Consumer electronics

(ii)Measures such as fail-safe function and redundant design should be taken to ensure reliability and

safety when SHARP devices are used for or in connection with equipment that requires higher

reliability such as:

--- Transportation control and safety equipment (i.e., aircraft, trains, automobiles, etc.)

--- Traffic signals

--- Gas leakage sensor breakers

--- Alarm equipment

--- Various safety devices, etc.

(iii)SHARP devices shall not be used for or in connection with equipment that requires an extremely

high level of reliability and safety such as:

--- Space applications

--- Telecommunication equipment [trunk lines]

--- Nuclear power control equipment

--- Medical and other life support equipment (e.g., scuba).

qContact a SHARP representative in advance when intending to use SHARP devices for any "specific"

applications other than those recommended by SHARP or when it is unclear which category mentioned

above controls the intended use.

qIf the SHARP devices listed in this publication fall within the scope of strategic products described in the

Foreign Exchange and Foreign Trade Control Law of Japan, it is necessary to obtain approval to export

such SHARP devices.

qThis publication is the proprietary product of SHARP and is copyrighted, with all rights reserved. Under

the copyright laws, no part of this publication may be reproduced or transmitted in any form or by any

means, electronic or mechanical, for any purpose, in whole or in part, without the express written

permission of SHARP. Express written permission is also required before any use of this publication

may be made by a third party.

qContact and consult with a SHARP representative if there are any questions about the contents of this

publication.