S1ZAS4

40V 1.2A

Copyright & Copy;2000 Shindengen Electric Mfg.Co.Ltd

OUTLINE DIMENSIONS

RATINGS

SHINDENGEN

i

Unit : mm

Switching power supply

DC/DC converter

Home Appliances, Office Equipment

Telecommunication

APPLICATION

SMT

Tj150

P

RRSM

avalanche guaranteed

Array

FEATURES

Case : 1Z

Dual

Schottky Rectifiers (SBD)

Absolute Maximum Ratings (If not specified Tl=25)

Item

Symbol

Conditions

Ratings

Unit

Storage Temperature

Tstg

-40150

Operating Junction Temperature

Tj

150

Maximum Reverse Voltage

V

RM

40

V

Repetitive Peak Surge Reverse Voltage

V

RRSM

Pulse width 0.5ms, duty 1/40

45

V

50Hz sine wave, R-load, On alumina substrate, 1 element operation, Ta=49

1.2

Average Rectified Forward Current

I

O

50Hz sine wave, R-load, On alumina substrate, 2 element operation, Ta=45

0.9*

A

50Hz sine wave, R-load, On glass-epoxy substrate, 1 element operation, Ta=47

1.0

50Hz sine wave, R-load, On glass-epoxy substrate, 2 element operation, Ta=43

0.72*

Peak Surge Forward Current

I

FSM

50Hz sine wave, Non-repetitive 1 cycle peak value, Tj=125

40

A

Repetitive Peak Surge Reverse Power

P

RRSM

Pulse width 10s, Rating of per diode, Tj=25

160

W

Electrical Characteristics (If not specified Tl=25)

Item

Symbol

Conditions

Ratings

Unit

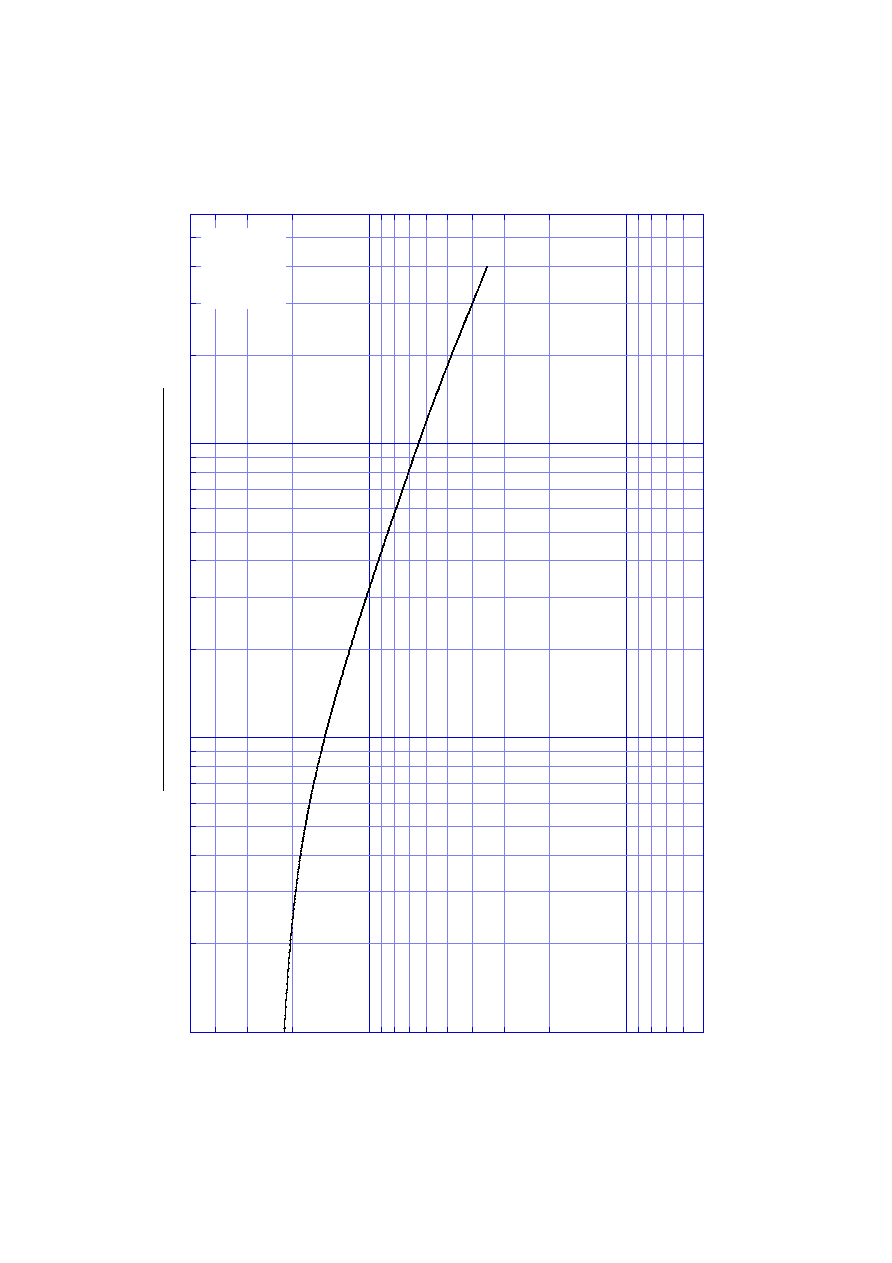

Forward Voltage

V

F

I

F

=1A, Pulse measurement, Rating of per diode

Max.0.55

V

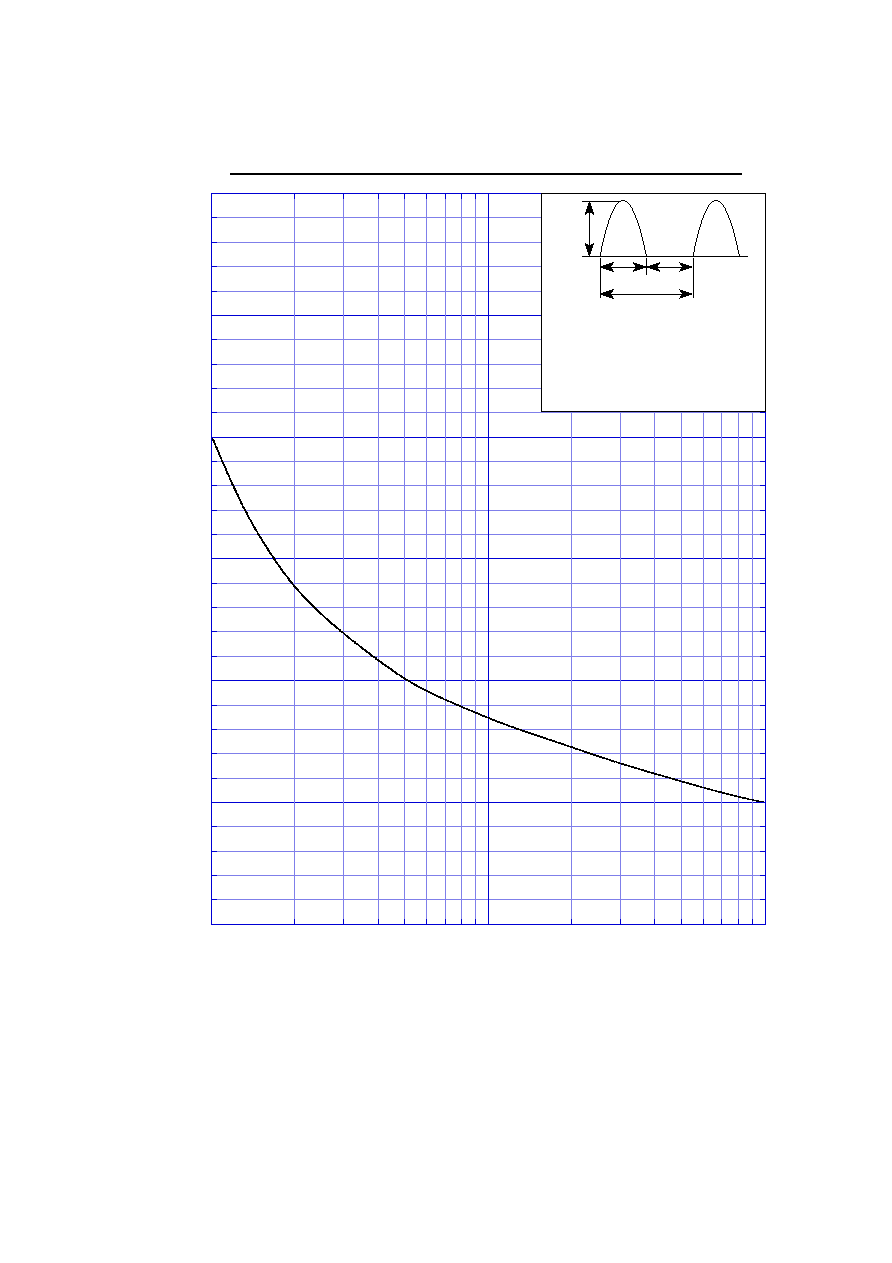

Reverse Current

I

R

V

R

=V

RM

, Pulse measurement, Rating of per diode

Max.1

mA

Junction Capacitance

Cj

f=1MHz, V

R

=10V, Rating of per diode

Typ.65

pF

jl

junction to lead

Max.25

junction to ambient, On alumina substrate, 1 element operation

Max.93

Thermal Resistance

ja

junction to ambient, On alumina substrate, 2 element operation

Max.140* /W

junction to ambient, On glass-epoxy substrate, 1 element operation

Max.120

junction to ambient, On glass-epoxy substrate, 2 element operation

Max.186*

Raitng of per diode