September 2003

1

Document Control # ML0004 rev 0.1

PIN CONFIGURATIONS

V

CAP

NC

A

7

A

6

A

5

A

4

A

3

A

2

A

1

A

0

DQ

0

DQ

1

DQ

2

V

SS

V

CCX

HSB

A

8

A

9

NC

G

W

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

A

10

E

DQ

7

DQ

6

DQ

5

DQ

4

DQ

3

28 - 300 PDIP

28 - 600 PDIP

28 - 300 SOIC

28 - 350 SOIC

PIN NAMES

A

0

- A

10

Address Inputs

DQ

0

-DQ

7

Data In/Out

E

Chip Enable

W

Write Enable

G

Output Enable

HSB

Hardware Store Busy (I/O)

V

CCX

Power (+ 5V)

V

CAP

Capacitor

V

SS

Ground

STK22C48

2K x 8 AutoStoreTM nvSRAM

QuantumTrapTM CMOS

Nonvolatile Static RAM

FEATURES

∑ 25ns, 35ns and 45ns Access Times

∑ "Hands-off" Automatic STORE with External

68

µ

F Capacitor on Power Down

∑ STORE to Nonvolatile Elements Initiated by

Hardware or AutoStoreTM on Power Down

∑ Automatic RECALL on Power Up

∑ 10mA Typical I

CC

at 200ns Cycle Time

∑ Unlimited READ, WRITE and RECALL Cycles

∑ 1,000,000 STORE Cycles to Nonvolatile Ele-

ments

∑ 100-Year Data Retention in Nonvolatile Ele-

ments

∑ Single 5V + 10% Operation

∑ Commercial and Industrial Temperatures

∑ 28-Pin DIP and SOIC Packages

DESCRIPTION

The Simtek STK22C48 is a fast static

RAM

with a

nonvolatile element incorporated in each static

memory cell. The

SRAM

can be read and written an

unlimited number of times, while independent, non-

volatile data resides in Nonvolatile Elements. Data

transfers from the

SRAM

to the Nonvolatile Elements

(the

STORE

operation) can take place automatically

on power down. A 68

µ

F or larger capacitor tied from

V

CAP

to ground guarantees the

STORE

operation,

regardless of power-down slew rate or loss of power

from "hot swapping". Transfers from the Nonvolatile

Elements to the

SRAM

(the

RECALL

operation) take

place automatically on restoration of power. A hard-

ware

STORE

may be initiated with the HSB pin.

BLOCK DIAGRAM

COLUMN I/O

COLUMN DEC

STATIC RAM

ARRAY

32 x 512

R

O

W

DE

COD

E

R

INP

U

T BUFFER

S

Quantum Trap

32 x 512

STORE/

RECALL

CONTROL

STORE

RECALL

POWER

CONTROL

A

5

A

6

A

9

DQ

0

DQ

1

DQ

2

DQ

3

DQ

4

DQ

5

DQ

6

DQ

7

G

E

W

A

8

A

7

A

10

A

3

A

2

A

0

A

1

A

4

V

CCX

V

CAP

HSB

STK22C48

September 2003

2

Document Control # ML0004 rev 0.1

ABSOLUTE MAXIMUM RATINGS

a

Voltage on Input Relative to Ground . . . . . . . . . . . . . ≠0.5V to 7.0V

Voltage on Input Relative to V

SS

. . . . . . . . . .≠0.6V to (V

CC

+ 0.5V)

Voltage on DQ

0-7

or HSB . . . . . . . . . . . . . . . .≠0.5V to (V

CC

+ 0.5V)

Temperature under Bias. . . . . . . . . . . . . . . . . . . . . .≠55

∞

C to 125

∞

C

Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . .≠65

∞

C to 150

∞

C

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1W

DC Output Current (1 output at a time, 1s duration) . . . . . . . 15mA

Note a: Stresses greater than those listed under "Absolute Maximum

Ratings" may cause permanent damage to the device. This is a

stress rating only, and functional operation of the device at con-

ditions above those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rat-

ing conditions for extended periods may affect reliability.

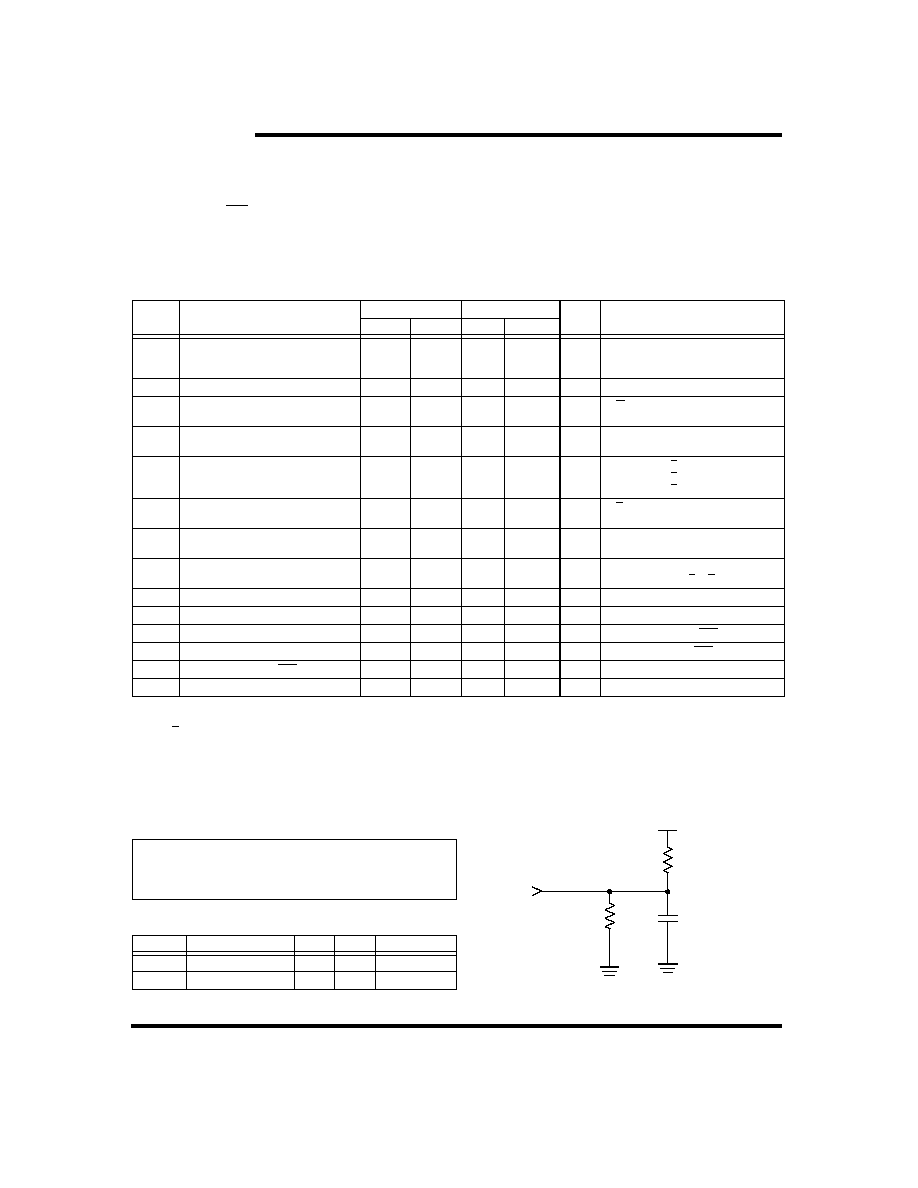

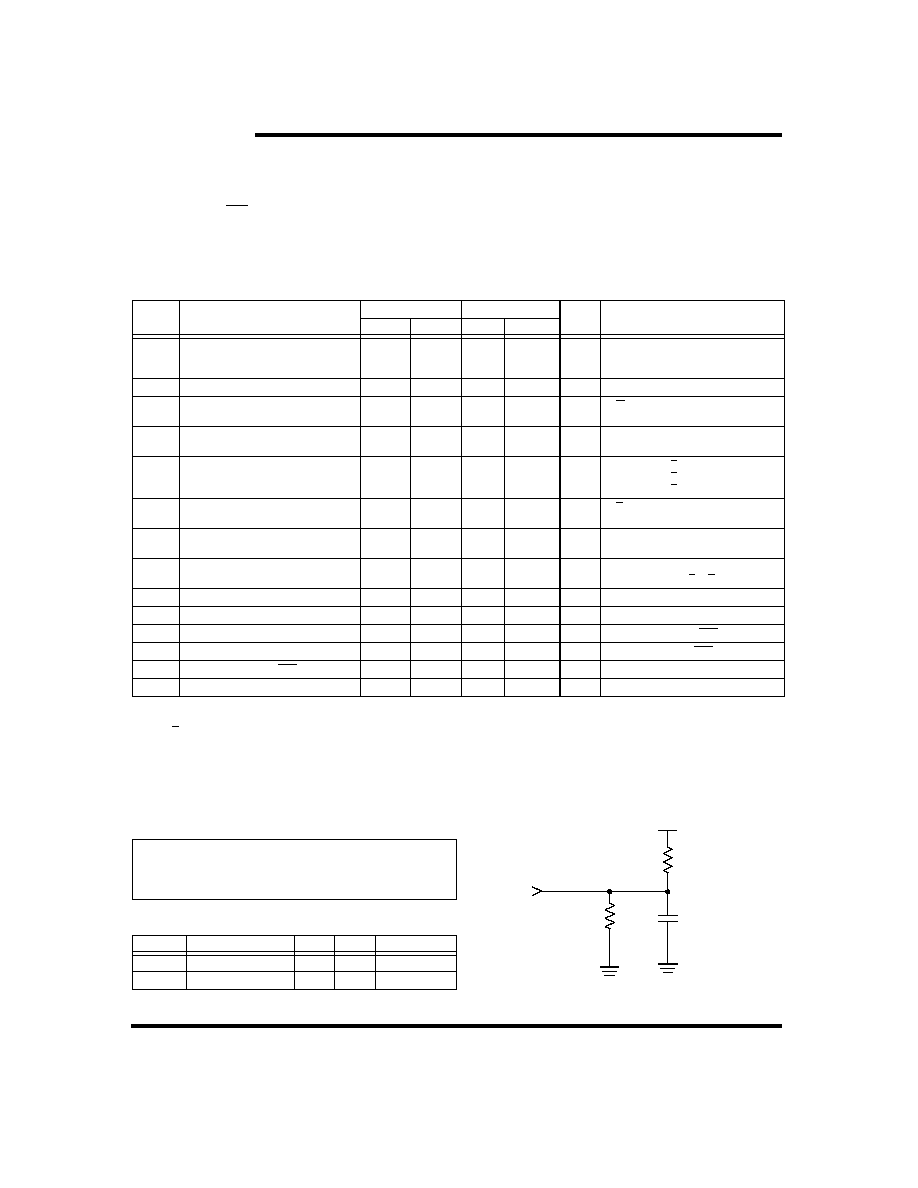

DC CHARACTERISTICS

(V

CC

= 5.0V

±

10%)

e

Note b: I

CC1

and I

CC3

are dependent on output loading and cycle rate. The specified values are obtained with outputs unloaded.

Note c: I

CC2

and I

CC4

are the average currents required for the duration of the respective

STORE

cycles (t

STORE

) .

Note d: E

V

IH

will not produce standby current levels until any nonvolatile cycle in progress has timed out.

Note e: V

CC

reference levels throughout this datasheet refer to V

CCX

if that is where the power supply connection is made, or V

CAP

if V

CCX

is con-

nected to ground.

SYMBOL

PARAMETER

COMMERCIAL

INDUSTRIAL

UNITS

NOTES

MIN

MAX

MIN

MAX

I

CC1

b

Average V

CC

Current

85

75

65

90

75

65

mA

mA

mA

t

AVAV

= 25ns

t

AVAV

= 35ns

t

AVAV

= 45ns

I

CC2

c

Average V

CC

Current during STORE

3

3

mA

All Inputs Don't Care, V

CC

= max

I

CC3

b

Average V

CC

Current at t

AVAV

= 200ns

5V, 25∞C, Typical

10

10

mA

W

(V

CC

≠ 0.2V)

All Others Cycling, CMOS Levels

I

CC4

c

Average V

CAP

Current during

AutoStoreTM Cycle

2

2

mA

All Inputs Don't Care

I

SB1

d

Average V

CC

Current

(Standby, Cycling TTL Input Levels)

25

21

18

26

22

19

mA

mA

mA

t

AVAV

= 25ns, E

V

IH

t

AVAV

= 35ns, E

V

IH

t

AVAV

= 45ns, E

V

IH

I

SB2

d

V

CC

Standby Current

(Standby, Stable CMOS Input Levels)

1.5

1.5

mA

E

(V

CC

≠ 0.2V)

All Others V

IN

0.2V or

(V

CC

≠ 0.2V)

I

ILK

Input Leakage Current

±

1

±

1

µ

A

V

CC

= max

V

IN

= V

SS

to V

CC

I

OLK

Off-State Output Leakage Current

±

5

±

5

µ

A

V

CC

= max

V

IN

= V

SS

to V

CC

, E or G

V

IH

V

IH

Input Logic "1" Voltage

2.2

V

CC

+ .5

2.2

V

CC

+ .5

V

All Inputs

V

IL

Input Logic "0" Voltage

V

SS

≠ .5

0.8

V

SS

≠ .5

0.8

V

All Inputs

V

OH

Output Logic "1" Voltage

2.4

2.4

V

I

OUT

= ≠ 4mA except HSB

V

OL

Output Logic "0" Voltage

0.4

0.4

V

I

OUT

= 8mA except HSB

V

BL

Logic "0" Voltage on HSB Output

0.4

0.4

V

I

OUT

= 3mA

T

A

Operating Temperature

0

70

≠40

85

∞

C

AC TEST CONDITIONS

CAPACITANCE

f

(T

A

= 25

∞

C, f = 1.0MHz)

Note f:

These parameters are guaranteed but not tested.

Input Pulse Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0V to 3V

Input Rise and Fall Times

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5ns

Input and Output Timing Reference Levels . . . . . . . . . . . . . . . 1.5V

Output Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Figure 1

SYMBOL

PARAMETER

MAX

UNITS

CONDITIONS

C

IN

Input Capacitance

8

pF

V = 0 to 3V

C

OUT

Output Capacitance

7

pF

V = 0 to 3V

Figure 1

:

AC Output Loading

480 Ohms

30 pF

255 Ohms

5.0V

INCLUDING

SCOPE AND

OUTPUT

FIXTURE

STK22C48

September 2003

3

Document Control # ML0004 rev 0.1

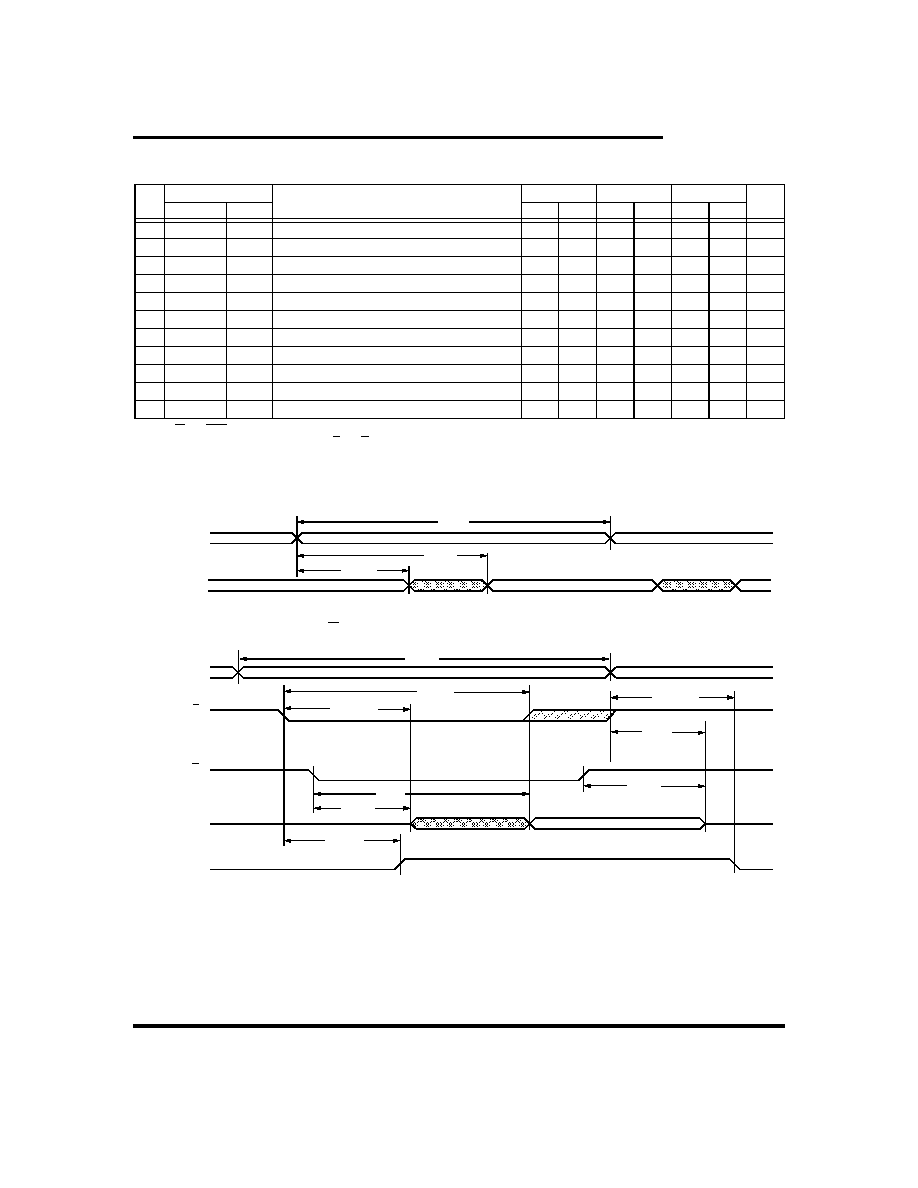

SRAM READ CYCLES #1 & #2

(V

CC

= 5.0V

±

10%)

e

Note g: W and HSB must be high during SRAM READ cycles.

Note h: Device is continuously selected with E and G both low.

Note i:

Measured

±

200mV from steady state output voltage.

SRAM READ CYCLE #1: Address Controlled

g,

h

SRAM READ CYCLE #2: E Controlled

g

NO.

SYMBOLS

PARAMETER

STK22C48-25

STK22C48-35

STK22C48-45

UNITS

#1, #2

Alt.

MIN

MAX

MIN

MAX

MIN

MAX

1

t

ELQV

t

ACS

Chip Enable Access Time

25

35

45

ns

2

t

AVAV

g

t

RC

Read Cycle Time

25

35

45

ns

3

t

AVQV

h

t

AA

Address Access Time

25

35

45

ns

4

t

GLQV

t

OE

Output Enable to Data Valid

10

15

20

ns

5

t

AXQX

h

t

OH

Output Hold after Address Change

5

5

5

ns

6

t

ELQX

t

LZ

Chip Enable to Output Active

5

5

5

ns

7

t

EHQZ

i

t

HZ

Chip Disable to Output Inactive

10

13

15

ns

8

t

GLQX

t

OLZ

Output Enable to Output Active

0

0

0

ns

9

t

GHQZ

i

t

OHZ

Output Disable to Output Inactive

10

13

15

ns

10

t

ELICCH

f

t

PA

Chip Enable to Power Active

0

0

0

ns

11

t

EHICCL

f

t

PS

Chip Disable to Power Standby

25

35

45

ns

DATA VALID

5

t

AXQX

3

t

AVQV

DQ (DATA OUT)

ADDRESS

2

t

AVAV

6

t

ELQX

STANDBY

DATA VALID

8

t

GLQX

4

t

GLQV

DQ (DATA OUT)

E

ADDRESS

2

t

AVAV

G

I

CC

ACTIVE

1

t

ELQV

10

t

ELICCH

11

t

EHICCL

7

t

EHQZ

9

t

GHQZ

STK22C48

September 2003

4

Document Control # ML0004 rev 0.1

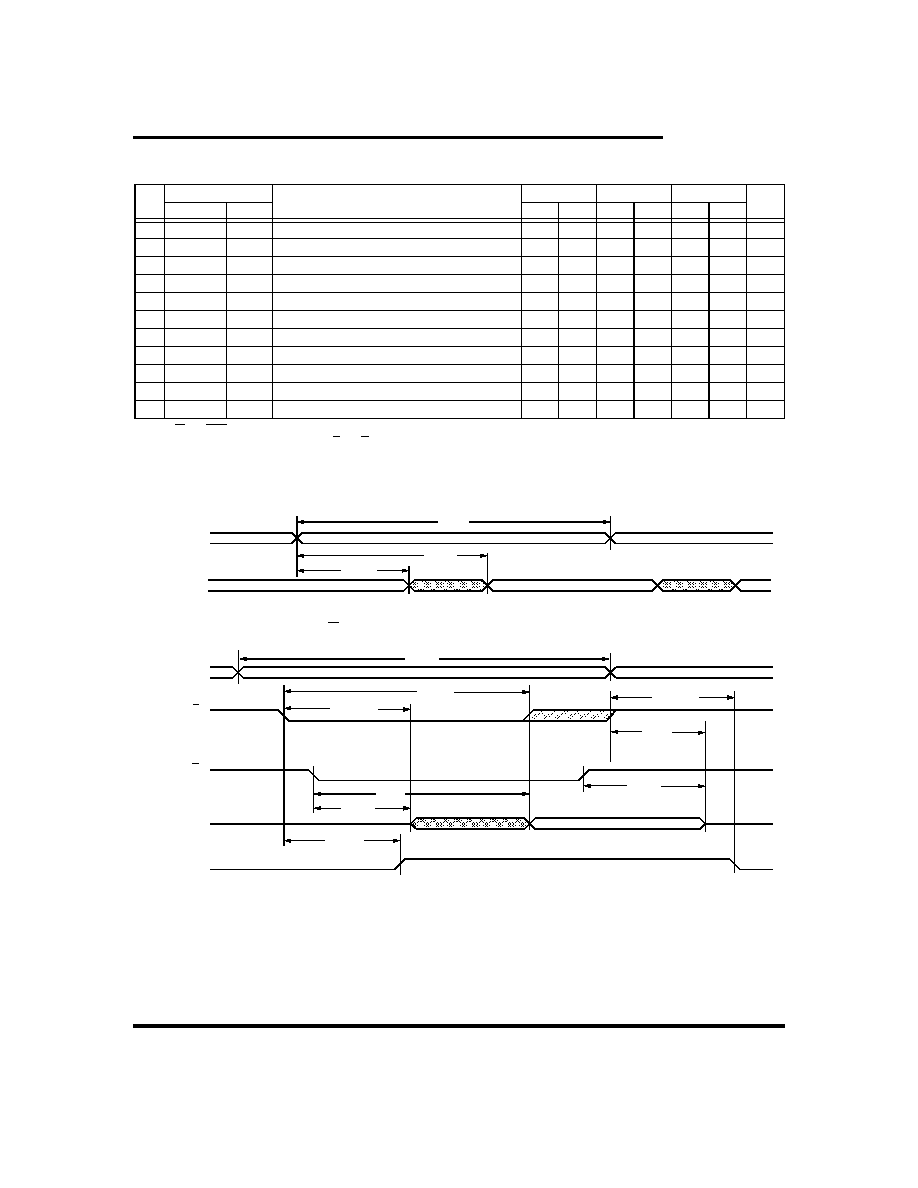

SRAM WRITE CYCLES #1 & #2

(V

CC

= 5.0V

±

10%)

e

Note j:

If W is low when E goes low, the outputs remain in the high-impedance state.

Note k: E or W must be

V

IH

during address transitions.

Note l:

HSB must be high during SRAM WRITE cycles.

SRAM WRITE CYCLE #1: W Controlled

k, l

SRAM WRITE CYCLE #2: E Controlled

k, l

NO.

SYMBOLS

PARAMETER

STK22C48-25

STK22C48-35

STK22C48-45

UNITS

#1

#2

Alt.

MIN

MAX

MIN

MAX

MIN

MAX

12

t

AVAV

t

AVAV

t

WC

Write Cycle Time

25

35

45

ns

13

t

WLWH

t

WLEH

t

WP

Write Pulse Width

20

25

30

ns

14

t

ELWH

t

ELEH

t

CW

Chip Enable to End of Write

20

25

30

ns

15

t

DVWH

t

DVEH

t

DW

Data Set-up to End of Write

10

12

15

ns

16

t

WHDX

t

EHDX

t

DH

Data Hold after End of Write

0

0

0

ns

17

t

AVWH

t

AVEH

t

AW

Address Set-up to End of Write

20

25

30

ns

18

t

AVWL

t

AVEL

t

AS

Address Set-up to Start of Write

0

0

0

ns

19

t

WHAX

t

EHAX

t

WR

Address Hold after End of Write

0

0

0

ns

20

t

WLQZ

i, j

t

WZ

Write Enable to Output Disable

10

13

15

ns

21

t

WHQX

t

OW

Output Active after End of Write

5

5

5

ns

PREVIOUS DATA

DATA OUT

E

ADDRESS

12

t

AVAV

W

16

t

WHDX

DATA IN

19

t

WHAX

13

t

WLWH

18

t

AVWL

17

t

AVWH

DATA VALID

20

t

WLQZ

15

t

DVWH

HIGH IMPEDANCE

21

t

WHQX

14

t

ELWH

DATA OUT

E

ADDRESS

12

t

AVAV

W

DATA IN

13

t

WLEH

17

t

AVEH

DATA VALID

HIGH IMPEDANCE

14

t

ELEH

18

t

AVEL

15

t

DVEH

19

t

EHAX

16

t

EHDX

STK22C48

September 2003

5

Document Control # ML0004 rev 0.1

HARDWARE MODE SELECTION

Note m: HSB STORE operation occurs only if an SRAM write has been done since the last nonvolatile cycle. After the STORE (if any) completes, the

part will go into standby mode, inhibiting all operations until HSB rises.

Note n: I/O state assumes G < V

IL

. Activation of nonvolatile cycles does not depend on state of G.

HARDWARE STORE CYCLE

(V

CC

= 5.0V

±

10%)

e

Note o: E and G low for output behavior.

Note p: E and G low and W high for output behavior.

Note q: t

RECOVER

is only applicable after t

STORE

is complete.

HARDWARE STORE CYCLE

E

W

HSB

A

12

- A

0

(hex)

MODE

I/O

POWER

NOTES

H

X

H

X

Not Selected

Output High Z

Standby

L

H

H

X

Read SRAM

Output Data

Active

n

L

L

H

X

Write SRAM

Input Data

Active

X

X

L

X

Nonvolatile

STORE

Output High Z

l

CC2

m

NO.

SYMBOLS

PARAMETER

STK22C48

UNITS NOTES

Standard

Alternate

MIN

MAX

22

t

STORE

t

HLHZ

STORE Cycle Duration

10

ms

i, o

23

t

DELAY

t

HLQZ

Time Allowed to Complete SRAM Cycle

1

µ

s

i, p

24

t

RECOVER

t

HHQX

Hardware STORE High to Inhibit Off

700

ns

o, q

25

t

HLHX

Hardware STORE Pulse Width

15

ns

26

t

HLBL

Hardware STORE Low to Store Busy

300

ns

DATA VALID

HSB (IN)

DATA VALID

25

t

HLHX

23

t

DELAY

22

t

STORE

24

t

RECOVER

HSB (OUT)

HIGH IMPEDANCE

26

t

HLBL

HIGH IMPEDANCE

DQ (DATA OUT)