i

TABLE OF CONTENTS

LCD SEGMENT / COMMON DRIVER WITH CONTROLLER ............................................................... 1

FEATURES ............................................................................................................................................. 1

ORDERING INFORMATION .................................................................................................................. 2

BLOCK DIAGRAM ................................................................................................................................. 3

DIE PAD ARRANGEMENT .................................................................................................................... 4

PIN DESCRIPTION................................................................................................................................. 7

FUNCTIONAL BLOCK DESCRIPTIONS............................................................................................. 11

COMMAND TABLE .............................................................................................................................. 17

COMMAND TABLE .............................................................................................................................. 18

COMMAND DESCRIPTIONS ............................................................................................................... 24

MAXIMUM RATINGS ........................................................................................................................... 30

DC CHARACTERISTICS...................................................................................................................... 31

AC CHARACTERISTICS...................................................................................................................... 33

APPLICATION EXAMPLES ................................................................................................................. 36

INITIALIZATION ROUTINE .................................................................................................................. 39

SOLOMON SYSTECH

SEMICONDUCTOR TECHNICAL DATA

This document contains information on a new product under definition stage. Solomon Systech Limited reserves

the right to change or discontinue this product without notice.

http://www.solomon-systech.com

SSD0817

Rev 1.3

P 1

Jan 2003

Copyright

2003 Solomon Systech Limited

SSD0817

Advance Information

CMOS

LCD Segment / Common Driver with Controller

SSD0817 is a single-chip CMOS LCD driver with controllers for dot-matrix graphic liquid

crystal display system. It consists of 169 high-voltage driving outputs for driving maximum 104

Segments, 64 Commons and 1 icon line.

SSD0817 consists of 104 x 65 bits Graphic Display Data RAM (GDDRAM). Data/Commands are sent

from common MCU through I

2

C-bus Interface.

SSD0817 embeds DC-DC Converter with booster capacitors, On-Chip Oscillator and Bias Divider so

as to reduce the number of external components. With the advanced design for low power

consumption, stable LCD operating voltage and flexible die layout, SSD0817 is suitable for any

portable battery-driven applications requiring long operation period with compact size.

FEATURES

104 x 64 + 1 Icon Line

Single Supply Operation, 2.4 V - 3.5V

Minimum -12.0V LCD Driving Output Voltage

Low Current Sleep Mode

On-Chip Voltage Generator or External LCD Driving Power Supply Selectable

2X / 3X / 4X/ 5X On-Chip DC-DC Converter

On-Chip Oscillator

On-Chip Bias Divider

Programmable bias ratio [1/4 � 1/9]

I

2

C-bus Interface

On-Chip 104 X 65 Graphic Display Data RAM

Row Re-mapping and Column Re-mapping

Vertical Scrolling

Display Offset Control

64 Levels Internal Contrast Control & External Contrast Control

Programmable MUX ratio [2-64 MUX] (Partial display mode)

Programmable LCD Driving Voltage Temperature Coefficients

Available in Gold Bump Die

Solomon Systech

Jan 2003

P 2/40

Rev 1.3

SSD0817

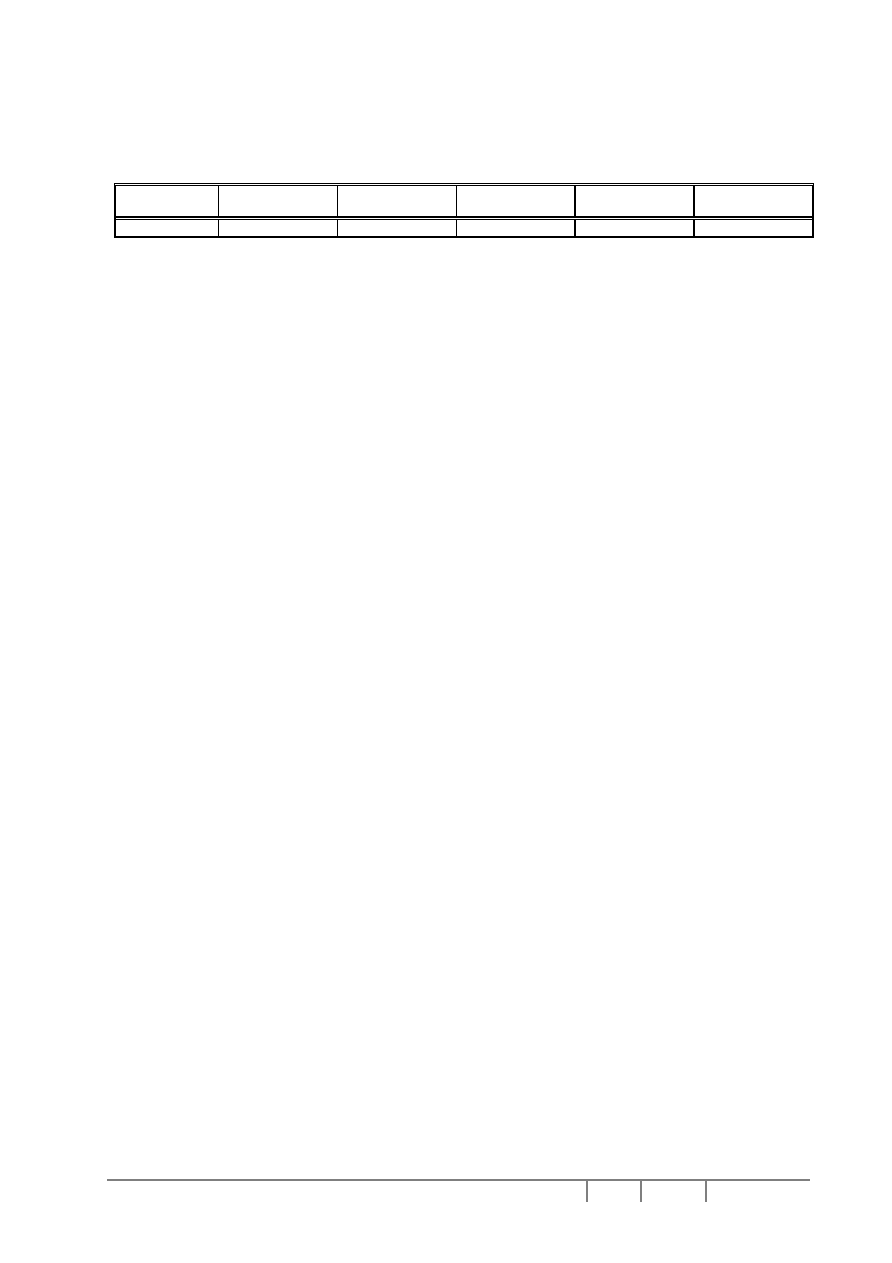

ORDERING INFORMATION

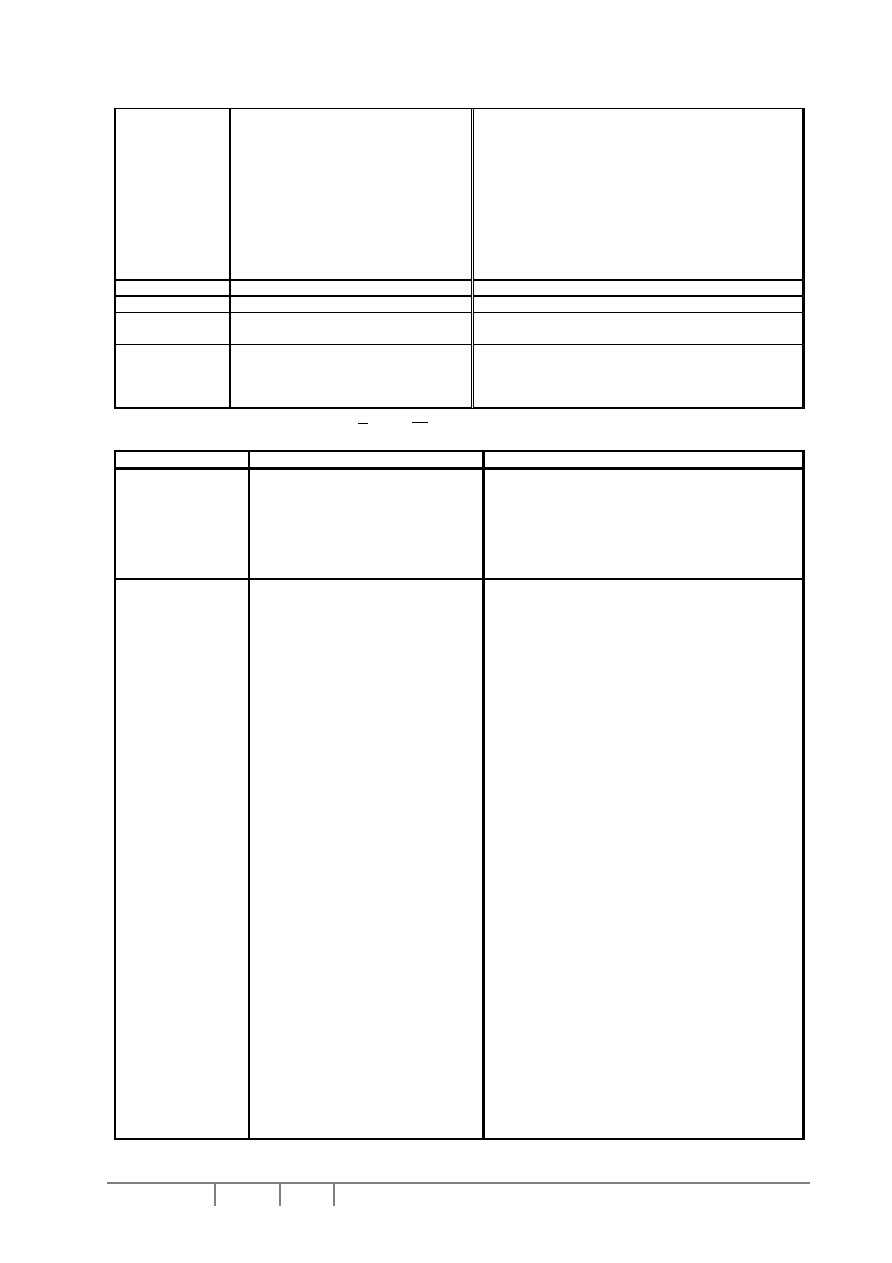

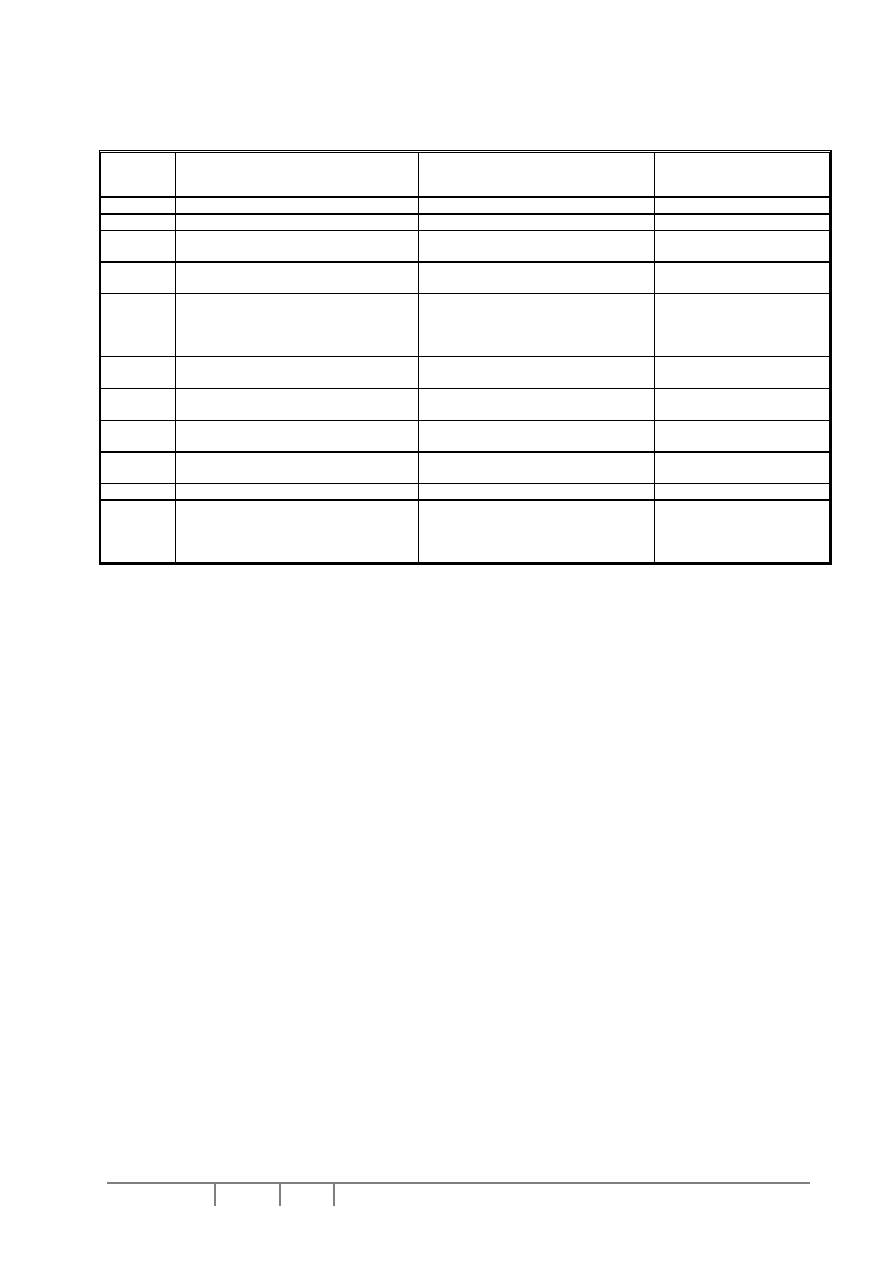

Table 1 - Ordering Information

Ordering Part

Number

SEG

COM

Default Bias

Package Form

Reference

SSD0817Z

104

64 + 1

1/9, 1/7

Gold Bump Die

SSD0817

Rev 1.3

P 3/40

Jan 2003

Solomon Systech

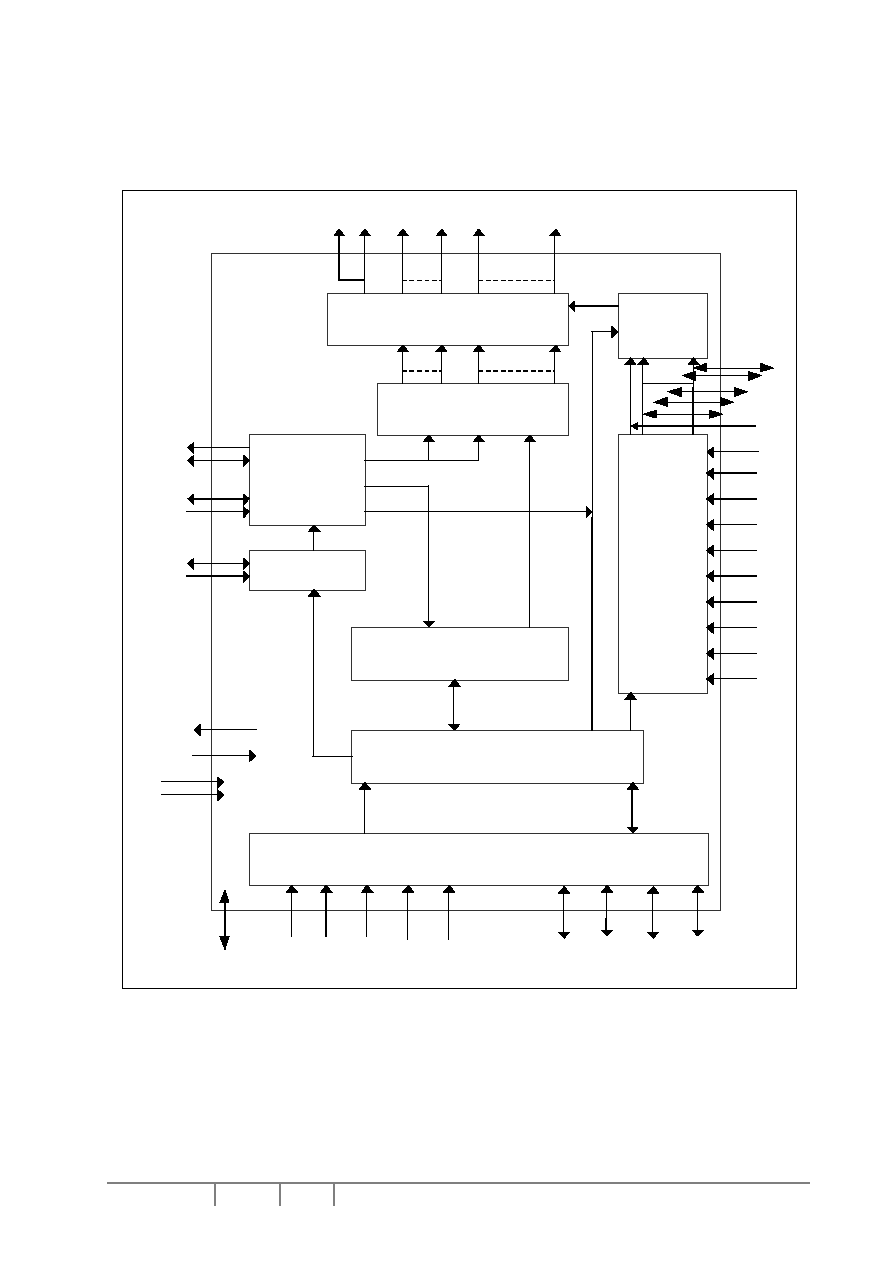

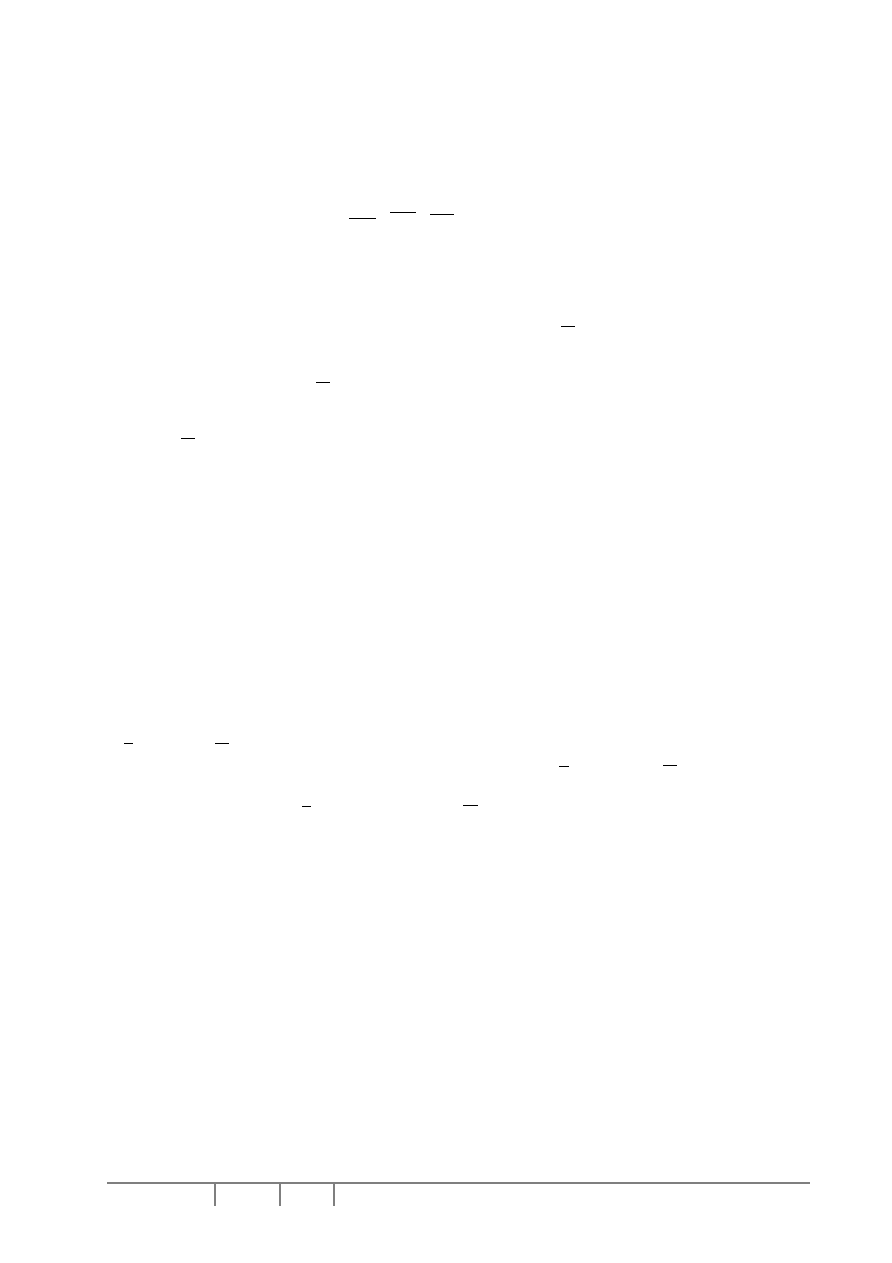

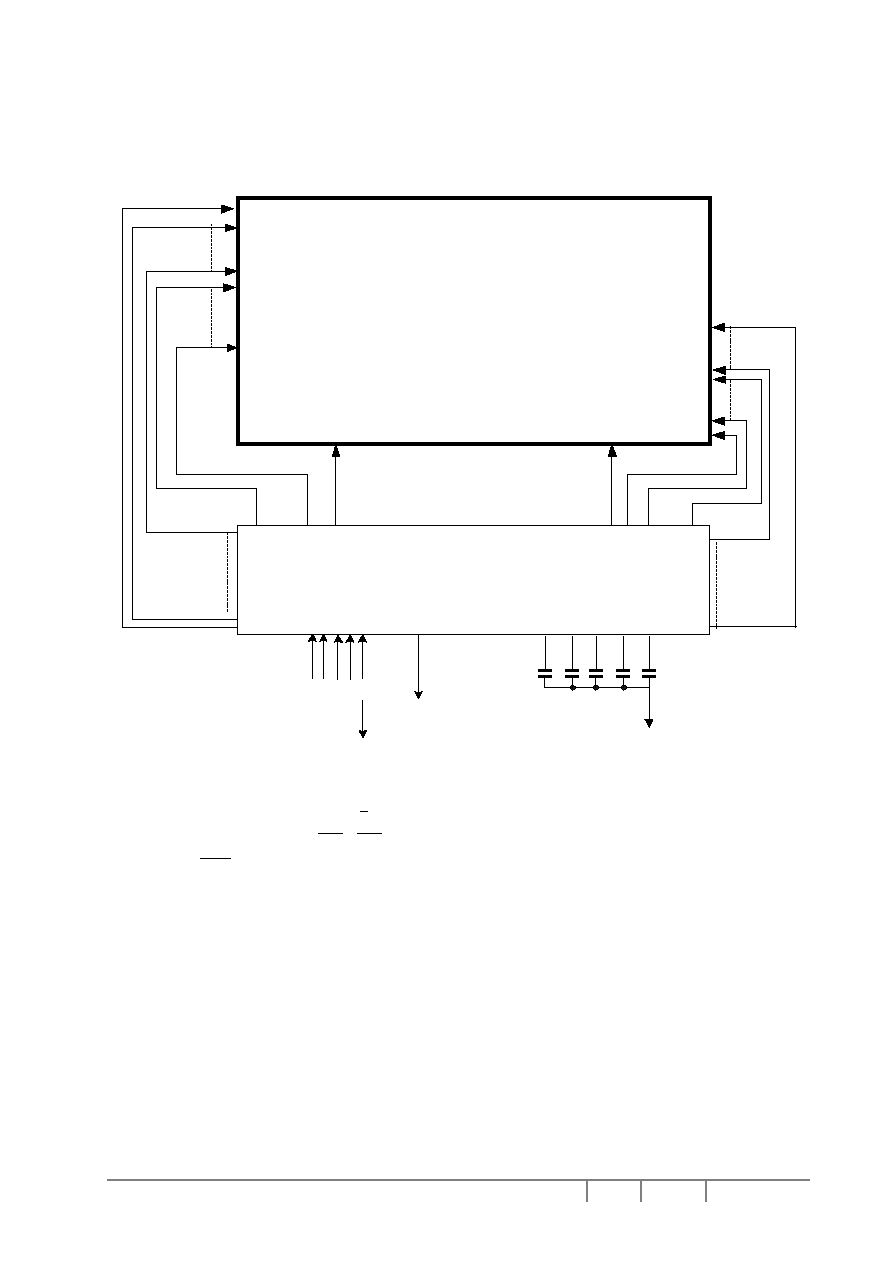

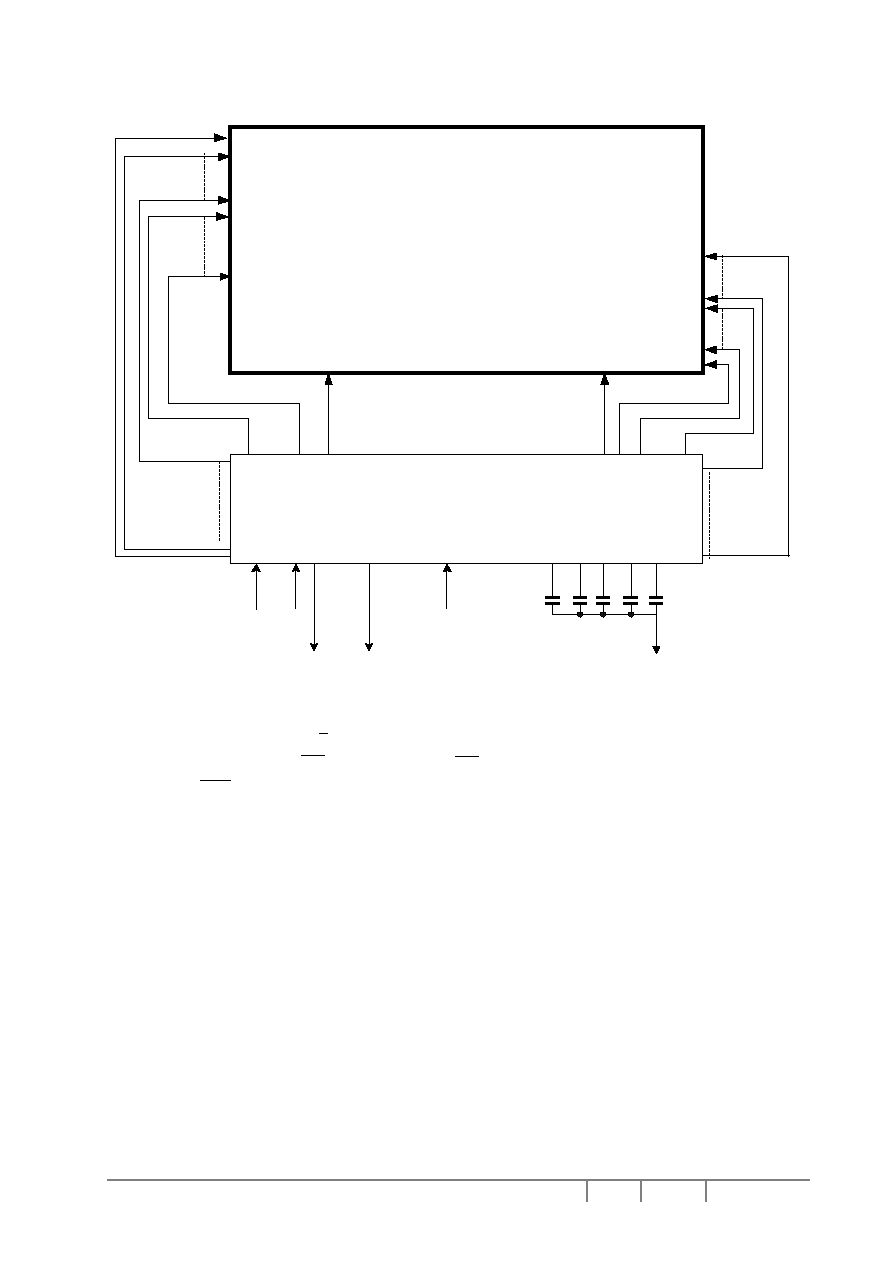

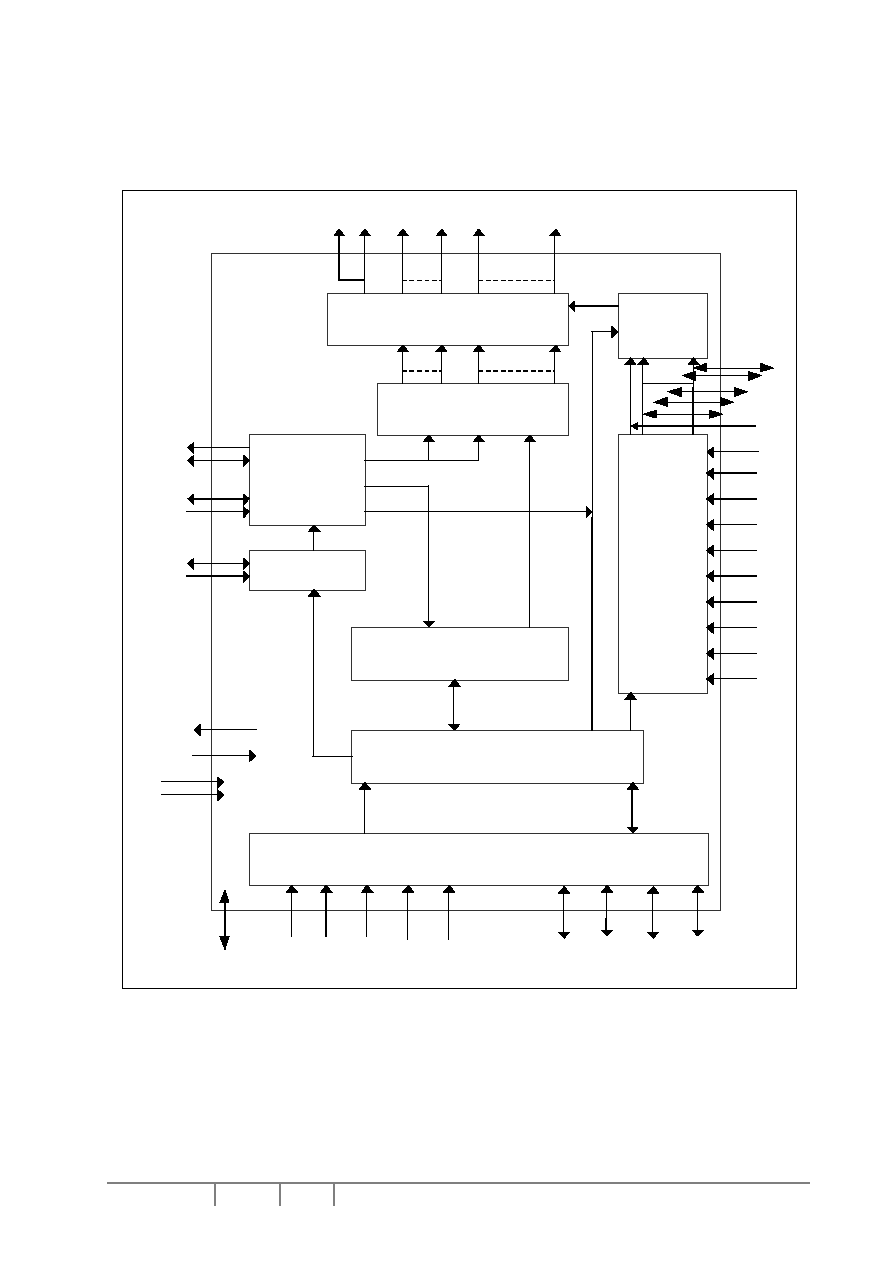

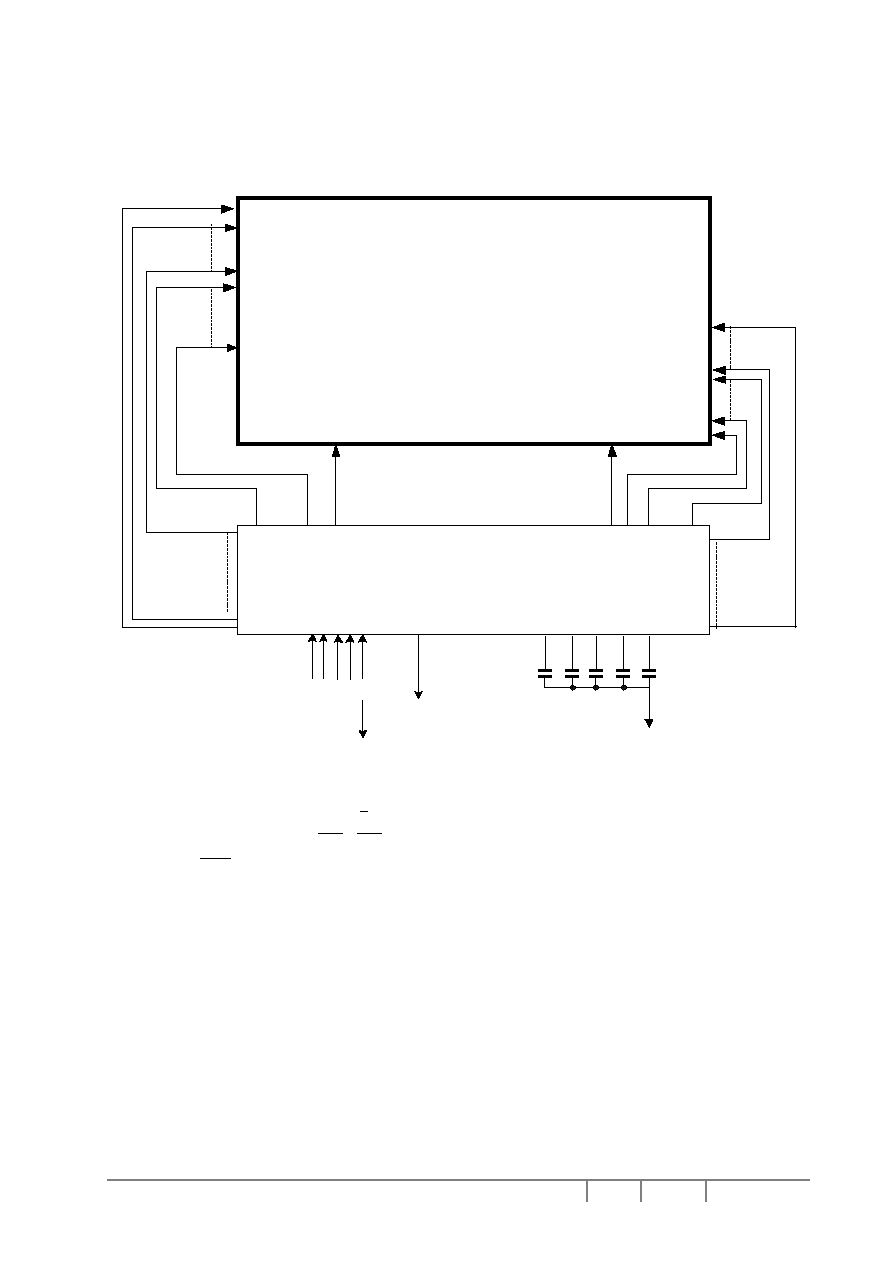

BLOCK DIAGRAM

Figure 1 � SSD0817 Block Diagram

ICONS ROW0 ~

ROW63 SEG0 ~SEG103

HV Buffer Cell Level Shifter

Display Data Latch

GDDRAM

104 X 65 Bits

Display

Timing

Generator

Oscillator

Level

Selector

Command Decoder

IIC communication interface

MSTAT

M

DOF

M/S

CL

CLS

V

SS

V

DD

C

0

C

1

V

L6

V

L5

V

L4

V

L3

V

L2

V

DD

V

EE

V

SS1

C

4N

C

3N

C

1P

C

1N

C

2N

C

2P

IRS

/RES

/IIC1

SA 0

SCL

SDA in

SDA out

/CS1

CS2

IIC2

Test pins (TEST0 -TEST7),

(T0 - T6)

LCD Driving

Voltage

Generator

2X/ 3X/ 4X/ 5X

DC/ DC Converter,

Voltage Regulator,

Contrast Control,

Bias Divider with

integrated

capacitors,

Temperature

Compensation

V

F

Solomon Systech

Jan 2003

P 4/40

Rev 1.3

SSD0817

DIE PAD ARRANGEMENT

Figure 2 � SSD0817 Pin Assignment

Gold Bump Alignment Mark

This alignment mark contains gold

bump for IC bumping process

alignment and IC identifications. No

conductive tracks should be laid

underneath this mark to avoid short

circuit.

Note:

1. The gold bumps face up in this

diagram

2. All dimensions in �m and (0,0) is the

center of the chip

Die Size:

8.66 mm X 1.48 mm

Die Thickness: 550 +/- 25 um

Bump Pitch:

60 um [Min]

Bump Height: Nominal 18 um

Tolerance

< 4 um within die

< 8 um within lot

PIN #1

(-3878.7, 237.475)

X

35

8.75

26.

25 26.

25 26.

25

X

Center (-3876.1625, 323.6625)

26.25 26.25 26.25

26.

25 52.

5

X

Center (2751.9625, 323.6625)

26.25 26.25 26.25

16.

8 13.

65

12.

6

Center (3875.55, 149.275)

16.8 13.65 12.6

73.

5

73.5

X

8.75

(2755.725, 237.475)

35

T5

T4

VF

IIC2

VSS

IRS

VDD

C1

VSS

C0

VDD

/IIC1

TEST7

VSS

CLS

M/S

VDD

T6

VL6

VL6

VL6

VL5

VL5

VL5

VL4

VL4

VL4

VEE

VL3

VL3

VL3

VL2

VL2

VL2

VEE

C4N

C4N

C4N

C2P

C2P

C2P

C2N

C2N

C2N

VEE

C1N

C1N

C1N

C1P

C1P

C1P

C3N

C3N

C3N

T2

VEE

VEE

VEE

VEE

VEE

VEE

VSS1

VSS1

VSS1

VSS1

VSS1

VSS

VSS

VSS

T1

T0

VDD

VDD

VDD

VDD

VDD

VDD

VDD

TEST6

TEST5

SA0

SCL

TEST4

TEST3

SDA in

SDA out

VDD

TEST2

TEST1

VSS

TEST0

VEE

VEE

/RES

VDD

CS2

/CS1

VSS

/DOF

CL

M

MSTAT

NC

RO

W

11

RO

W

12

RO

W

13

RO

W

14

RO

W

15

RO

W

16

RO

W

17

RO

W

18

RO

W

19

RO

W

20

RO

W

21

RO

W

22

RO

W

23

RO

W

24

RO

W

25

RO

W

26

RO

W

27

RO

W

28

RO

W

29

RO

W

30

RO

W

31

NC

ROW10

ROW9

ROW8

ROW7

ROW6

ROW5

ROW4

ROW3

ROW2

ROW1

ROW0

ICONS

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

SEG17

SEG18

SEG19

SEG20

SEG21

SEG22

SEG23

SEG24

SEG25

SEG26

SEG27

SEG28

SEG29

SEG30

SEG31

SEG32

SEG33

SEG34

SEG35

SEG92

SEG93

SEG94

SEG95

SEG96

SEG97

SEG98

SEG99

SEG100

SEG101

SEG102

SEG103

ROW32

ROW33

ROW34

ROW35

ROW36

ROW37

ROW38

ROW39

ROW40

ROW41

ROW42

ROW43

254 255

1

C

enter: 2751.9625, 323.6625

C

enter: -3876.1625,

323.6625

C

enter: -3875.55, 149.275

S

i

ze:

88.2

x

88.2

277

276

126

125

104 103

(-3878.7, 237.475)

(2755.725, 237.475)

SSD0817

Rev 1.3

P 5/40

Jan 2003

Solomon Systech

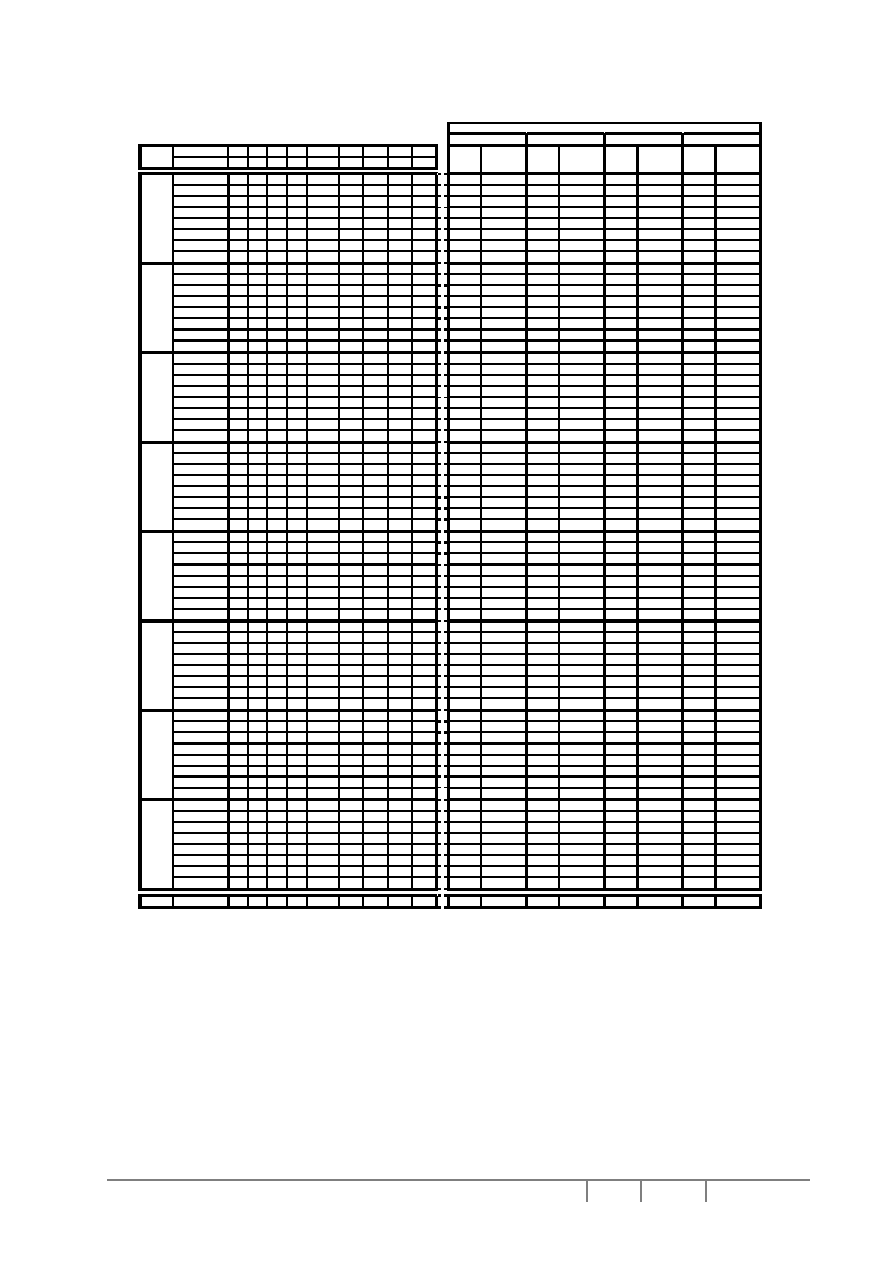

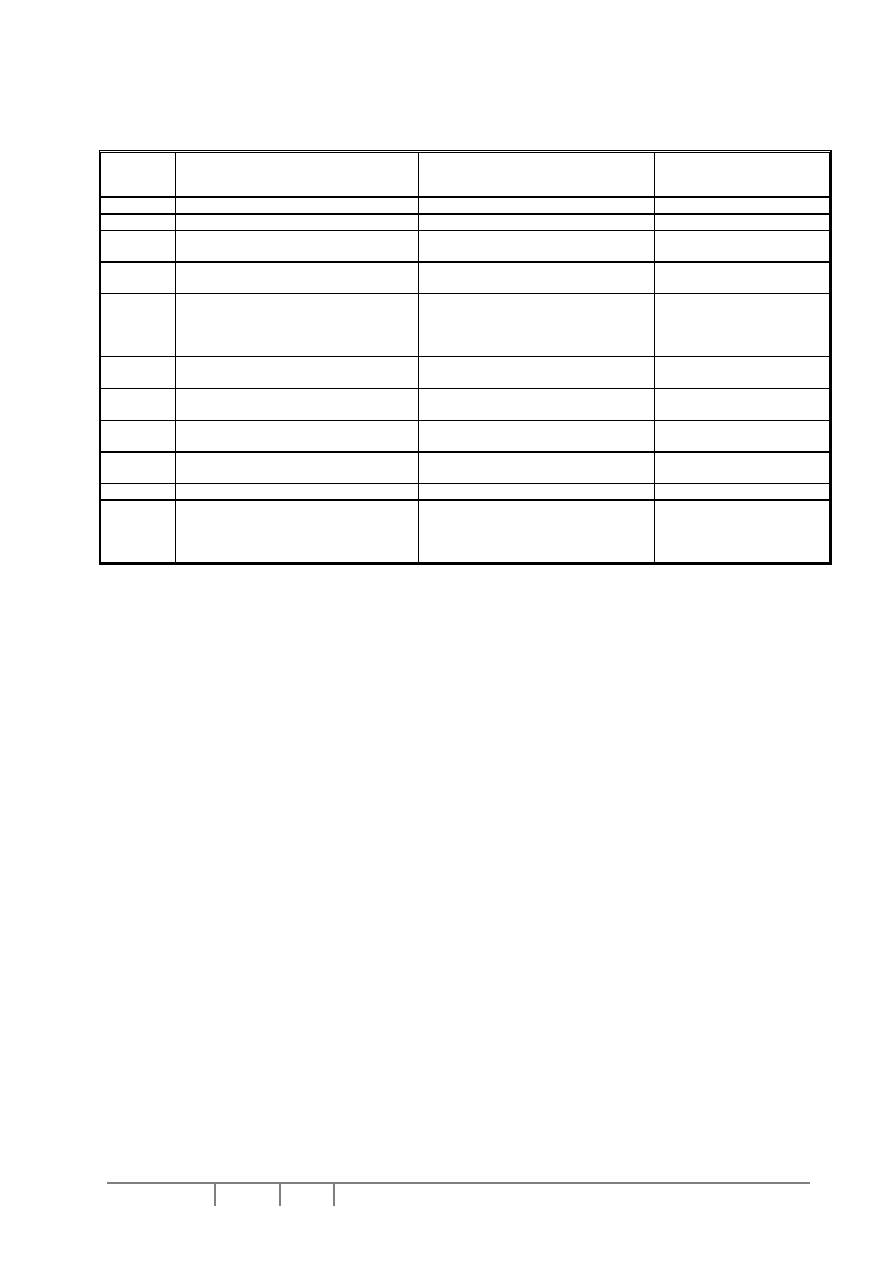

Table 2 � SSD0817 Series Bump Die Pad Coordinates (Bump center)

Pad #

Signal X-pos

Y-pos

Pad #

Signal X-pos

Y-pos

Pad #

Signal X-pos

Y-pos

1 MSTAT

-3873.80

-581.35 51 C3N -27.48

-581.35

101 T4 3799.95 -581.35

2 M

-3797.50

-581.35

52

C1P

48.83

-581.35

102

T5

3876.25 -581.35

3 CL

-3721.20

-581.35

53

C1P

125.13

-581.35

103

NC

4178.48 -655.03

4 /DOF

-3644.90

-581.35

54 C1P

201.43

-581.35

104

ROW31

4178.48 -594.83

5 VSS

-3568.60

-581.35

55 C1N

277.73

-581.35

105

ROW30

4178.48 -534.63

6 /CS1

-3492.30

-581.35

56 C1N

354.03

-581.35

106

ROW29

4178.48 -474.43

7 CS2

-3416.00

-581.35

57 C1N

430.33

-581.35

107

ROW28

4178.48 -414.23

8 VDD

-3339.70

-581.35

58 VEE

506.63

-581.35

108

ROW27

4178.48 -354.03

9 /RES

-3263.40

-581.35

59 C2N

582.93

-581.35

109

ROW26

4178.48 -293.83

10 VEE

-3178.35

-581.35

60 C2N

659.23

-581.35

110

ROW25

4178.48 -233.63

11 VEE

-3102.05

-581.35

61 C2N

735.53

-581.35

111

ROW24

4178.48 -173.43

12 TEST0

-3017.00

-581.35 62 C2P 811.83

-581.35

112 ROW23

4178.48 -113.23

13 VSS

-2940.70

-581.35

63 C2P

888.13

-581.35

113

ROW22

4178.48 -53.03

14 TEST1

-2864.40

-581.35 64 C2P 964.43

-581.35

114 ROW21

4178.48

7.18

15 TEST2

-2788.10

-581.35 65 C4N

1040.73 -581.35

115 ROW20

4178.48

67.38

16 VDD

-2711.80

-581.35

66 C4N

1117.03 -581.35

116

ROW19

4178.48 127.58

17 SDA

out

-2635.50

-581.35 67 C4N 1193.33 -581.35

117 ROW18

4178.48 187.78

18 SDA

in

-2557.63

-581.35 68 VEE

1269.63 -581.35

118 ROW17

4178.48 247.98

19 TEST3

-2481.33

-581.35 69 VL2

1345.93 -581.35

119 ROW16

4178.48 308.18

20 TEST4

-2403.10

-581.35 70 VL2

1422.23 -581.35

120 ROW15

4178.48 368.38

21 SCL

-2325.23

-581.35

71 VL2

1498.53 -581.35

121

ROW14

4178.48 428.58

22 SA0

-2248.93

-581.35

72 VL3

1574.83 -581.35

122

ROW13

4178.48 488.78

23 TEST5

-2172.63

-581.35 73 VL3

1651.13 -581.35

123 ROW12

4178.48 548.98

24 TEST6

-2096.33

-581.35 74 VL3

1727.43 -581.35

124 ROW11

4178.48 609.18

25 VDD

-2020.03

-581.35

75 VEE

1803.73 -581.35

125 NC

4178.48 663.25

26 VDD

-1943.73

-581.35

76 VL4

1880.03 -581.35

126

ROW10

3834.60 587.83

27 VDD

-1867.43

-581.35

77 VL4

1956.33 -581.35

127

ROW9

3774.40 587.83

28 VDD

-1791.13

-581.35

78 VL4

2032.63 -581.35

128

ROW8

3714.20 587.83

29 VDD

-1714.83

-581.35

79 VL5

2108.93 -581.35

129

ROW7

3654.00 587.83

30 VDD

-1638.53

-581.35

80 VL5

2185.23 -581.35

130

ROW6

3593.80 587.83

31 VDD

-1562.23

-581.35

81 VL5

2261.53 -581.35

131

ROW5

3533.60 587.83

32 T0

-1485.93

-581.35

82 VL6

2337.83 -581.35

132

ROW4

3473.40 587.83

33 T1

-1409.63

-581.35

83 VL6

2414.13 -581.35

133

ROW3

3413.20 587.83

34 VSS

-1333.33

-581.35

84 VL6

2490.60 -581.35

134

ROW2

3353.00 587.83

35 VSS

-1257.03

-581.35

85 T6

2566.73 -581.35

135

ROW1

3292.80 587.83

36 VSS

-1180.73

-581.35

86 VDD

2651.78 -581.35

136

ROW0

3232.60 587.83

37 VSS1

-1095.68

-581.35 87 M/S

2728.08 -581.35

137

ICONS

3172.40 587.83

38 VSS1

-1019.38

-581.35 88 CLS

2804.38 -581.35

138 SEG0

3112.20 587.83

39 VSS1

-943.08

-581.35 89 VSS

2880.68 -581.35

139 SEG1

3052.00 587.83

40 VSS1

-866.78

-581.35 90 TEST7

2956.98 -581.35

140 SEG2

2991.80 587.83

41 VSS1

-790.48

-581.35 91 /IIC1

3033.28 -581.35

141 SEG3

2931.60 587.83

42 VEE

-714.18

-581.35

92 VDD

3109.58 -581.35

142

SEG4

2871.40 587.83

43 VEE

-637.88

-581.35

93 C0

3185.88 -581.35

143

SEG5

2811.20 587.83

44 VEE

-561.58

-581.35

94 VSS

3262.18 -581.35

144

SEG6

2751.00 587.83

45 VEE

-485.28

-581.35

95 C1

3338.48 -581.35

145

SEG7

2690.80 587.83

46 VEE

-408.98

-581.35

96 VDD

3414.78 -581.35

146

SEG8

2630.60 587.83

47 VEE

-332.68

-581.35

97 IRS

3491.08 -581.35

147

SEG9

2570.40 587.83

48 T2

-256.38

-581.35

98 VSS

3567.38 -581.35

148

SEG10

2510.20 587.83

49 C3N

-180.08

-581.35

99 IIC2

3643.68 -581.35

149

SEG11

2450.00 587.83

50 C3N

-103.78

-581.35

100 VF

3723.65 -581.35

150

SEG12

2389.80 587.83

Solomon Systech

Jan 2003

P 6/40

Rev 1.3

SSD0817

Pad #

Signal X-pos

Y-pos

Pad #

Signal X-pos

Y-pos

Pad #

Signal

X-pos

Y-pos

151 SEG13

2329.60

587.83 201 SEG63 -680.40 587.83

251 ROW41

-3690.40 587.83

152 SEG14

2269.40

587.83 202 SEG64 -740.60 587.83

252 ROW42

-3750.60 587.83

153 SEG15

2209.20

587.83 203 SEG65 -800.80 587.83

253 ROW43

-3810.80 587.83

154 SEG16

2149.00

587.83 204 SEG66 -861.00 587.83

254 NC -4178.48 663.25

155 SEG17

2088.80

587.83 205 SEG67 -921.20 587.83

255 ROW44

-4178.48 609.18

156 SEG18

2028.60

587.83 206 SEG68 -981.40 587.83

256 ROW45

-4178.48 548.98

157 SEG19

1968.40

587.83 207 SEG69 -1041.60 587.83

257 ROW46

-4178.48 488.78

158 SEG20

1908.20

587.83 208 SEG70 -1101.80 587.83

258 ROW47

-4178.48 428.58

159 SEG21

1848.00

587.83 209 SEG71 -1162.00 587.83

259 ROW48

-4178.48 368.38

160 SEG22

1787.80

587.83 210 SEG72 -1222.20 587.83

260 ROW49

-4178.48 308.18

161 SEG23

1727.60

587.83 211 SEG73 -1282.40 587.83

261 ROW50

-4178.48 247.98

162 SEG24

1667.40

587.83 212 SEG74 -1342.60 587.83

262 ROW51

-4178.48 187.78

163 SEG25

1607.20

587.83 213 SEG75 -1402.80 587.83

263 ROW52

-4178.48 127.58

164 SEG26

1547.00

587.83 214 SEG76 -1463.00 587.83

264 ROW53

-4178.48 67.38

165 SEG27

1486.80

587.83 215 SEG77 -1523.20 587.83

265 ROW54

-4178.48

7.18

166 SEG28

1426.60

587.83 216 SEG78 -1583.40 587.83

266 ROW55

-4178.48 -53.03

167 SEG29

1366.40

587.83 217 SEG79 -1643.60 587.83

267 ROW56

-4178.48 -113.23

168 SEG30

1306.20

587.83 218 SEG80 -1703.80 587.83

268 ROW57

-4178.48 -173.43

169 SEG31

1246.00

587.83 219 SEG81 -1764.00 587.83

269 ROW58

-4178.48 -233.63

170 SEG32

1185.80

587.83 220 SEG82 -1824.20 587.83

270 ROW59

-4178.48 -293.83

171 SEG33

1125.60

587.83 221 SEG83 -1884.40 587.83

271 ROW60

-4178.48 -354.03

172 SEG34

1065.40

587.83 222 SEG84 -1944.60 587.83

272 ROW61

-4178.48 -414.23

173 SEG35

1005.20

587.83 223 SEG85 -2004.80 587.83

273 ROW62

-4178.48 -474.43

174 SEG36

945.00

587.83 224 SEG86 -2065.00 587.83

274 ROW63

-4178.48 -534.63

175 SEG37

884.80

587.83 225 SEG87 -2125.20 587.83

275 ICONS

-4178.48 -594.83

176 SEG38

824.60

587.83 226 SEG88 -2185.40 587.83

276 NC -4178.48 -655.03

177 SEG39

764.40

587.83 227 SEG89 -2245.60 587.83

277 NC -3875.55 149.28

179 SEG41

644.00

587.83 229 SEG91 -2366.00 587.83

180

SEG42

583.80

587.83

230

SEG92 -2426.20 587.83

181

SEG43

523.60

587.83

231

SEG93 -2486.40 587.83

182

SEG44

463.40

587.83

232

SEG94 -2546.60 587.83

183

SEG45

403.20

587.83

233

SEG95 -2606.80 587.83

184

SEG46

343.00

587.83

234

SEG96 -2667.00 587.83

185 SEG47

282.80

587.83 235 SEG97 -2727.20 587.83

Bump Size

186

SEG48 222.60 587.83

236

SEG98 -2787.40 587.83

PAD#

X [um] Y [um]

187

SEG49 162.40 587.83

237

SEG99 -2847.60 587.83

1 � 102

50.05

50.05

188

SEG50 102.20 587.83

238

SEG100 -2907.80 587.83

103 � 124

66.675 40.95

189 SEG51 42.00 587.83 239 SEG101 -2968.00 587.83

125

66.675

28.7

190

SEG52 -18.20 587.83

240

SEG102 -3028.20 587.83

126 � 253

40.95

66.675

191 SEG53

-78.40 587.83 241 SEG103 -3088.40 587.83

254

66.675

28.7

192

SEG54 -138.60 587.83

242

ROW32 -3148.60 587.83

255 � 276

66.675 40.95

193 SEG55

-198.80

587.83 243 ROW33 -3208.80 587.83

277

88.2 88.2

195

SEG57

-319.20

587.83

245

ROW35 -3329.20 587.83

196

SEG58

-379.40

587.83

246

ROW36 -3389.40 587.83

197

SEG59

-439.60

587.83

247

ROW37 -3449.60 587.83

198

SEG60

-499.80

587.83

248

ROW38 -3509.80 587.83

199

SEG61

-560.00

587.83

249

ROW39 -3570.00 587.83

200

SEG62

-620.20

587.83

250

ROW40 -3630.20 587.83

SSD0817

Rev 1.3

P 7/40

Jan 2003

Solomon Systech

PIN DESCRIPTION

MSTAT

This pin is the static indicator driving output. It is only active in master operation. The frame signal

output pin, M, should be used as the back plane signal for the static indicator. The duration of

overlapping can be programmable. This pin, MSTAT, becomes high impedance if the chip is operating

in slave mode. Please see the Extended Command Table for reference.

M

This pin is the frame signal input/output. In master mode, this pin supplies the frame signal to slave

devices. In slave mode, this pin receives the frame signal from the master device.

CL

This pin is the system clock input/output. When both the internal oscillator (CLS pin pulled high) and

the master mode (M/S pin pulled high) are enabled, the CL pin will supplies system clock signal to the

slave device. When both internal oscillator and the slave mode are enabled, the CL pin receives

system clock signal from either the master device or the external clock source.

DOF

DOF

This pin is the display blanking signal control pin. In master mode, the

DOF pin supplies "display on"

or "display off" signal (blanking signal) to the slave devices. In slave mode, the DOF pin receives

"display on" or "display off" signal from the master device.

1

CS

, CS2

These pins are the chip selection inputs. The chip is enabled for MCU communication only

when

1

CS

is pulled low and CS2 is pulled high.

RES

This pin is the reset signal input. Initialization of the chip is started once the reset pin is pulled low.

The minimum pulse width for completion of the reset procedure is 5 -10 us.

SA0, SCL, SDA

out

, SDA

in

These pins are bi-directional data bus to be connected to the MCU in I

2

C-bus interface. Please refer

to the section: I

2

C Communication interface on page 11 for detail pin descriptions.

V

DD

The V

DD

is the Chip's Power Supply pins. V

DD

is also acted as a reference level of both the DC-DC

Converter and the LCD driving output.

V

SS

The V

ss

is the grounding of the chip. V

ss

is also acted as a reference level of the logic input/output.

V

SS1

The V

SS1

is the input of the internal DC-DC converter. The generated voltage from the internal DC-DC

converter, V

EE

, is equal to the multiple factors (2X, 3X, 4X, 5X) times the potential different between

V

SS1

, and V

DD

. The multiple factors, 2X, 3X, 4X or 5X are selected by different arrangements of the

external boosting capacitors.

Note: the potential at this input pin must lower than or equal to V

SS

.

V

EE

This is the most negative voltage supply pin of the chip. It can be supplied externally or generated by

the internal DC-DC converter. If the internal DC-DC converter generates the voltage level at V

EE

, the

Solomon Systech

Jan 2003

P 8/40

Rev 1.3

SSD0817

voltage level is used for internal referencing only. The voltage level at V

EE

pins is not used for driving

external circuitry.

C

1P

, C

1N

, C

2N

, C

2P

C

3N

and C

4N

When internal DC-DC voltage converter is used, external capacitor(s) is/are connected between these

pins. Different connections result in different DC-DC converter multiple factors, for example, 2X, 3X,

4X or 5X. Please refer to the voltage converter section in the functional block description for detail

description.

V

L2

, V

L3

, V

L4

and V

L5

These pins are outputs with voltage levels equal to the LCD driving voltage. All these voltage levels

are referenced to V

DD

. The voltage levels can be supplied externally or generated by the internal bias

divider. The bias divider is turned on once the output op-amp buffers are enabled. Please refer to the

Set Power Control Register command for detail description.

The voltage potential relationship is given as: V

DD

> V

L2

> V

L3

> V

L4

> V

L5

> V

L6

In addition, assume the bias factor is known as a,

VL2 - VDD = 1/a * (VL6 - VDD)

VL3 - VDD = 2/a * (VL6 - VDD)

VL4 - VDD = (a-2)/a * (VL6 - VDD)

VL5 - VDD = (a-1)/a * (VL6 - VDD)

V

L6

This pin outputs the most negative LCD driving voltage level. The V

L6

can be supplied externally or

generated by the internal regulator. Please refer to the Set Power Control Register command for

detail description.

M/ S

This pin is the master/slave mode selection input. When this pin is pulled high, master mode is

selected. CL, M, MSTAT and DOF signals will become output pins of the slave devices.

When this pin is pulled low, slave mode is selected. CL, M, DOF will become input pins. The CL, M,

DOF signals are received from the master device. The MSTAT pin will stay at high impedance state.

V

F

This pin is the input of the built-in voltage regulator for generating V

L6

. When external resistor network

is selected (IRS pulled low) to generate the LCD driving level, V

L6

, two external resistors should be

added. R

1

should be connected between V

DD

and V

F

. R

2

should be connected between V

F

and V

L6.

CLS

This pin is the internal clock enable pin. When this pin is pulled high, the internal clock is enabled.

The internal clock will be disabled when CLS is pulled low. Under such circumstances, an external

clock source must be fed into the CL pin.

1

IIC

, IIC2

These pins are I

2

C-bus interface selection inputs. The IIC communication interface is enabled only

when

1

IIC is pulled low and IIC2 is pulled high.

SSD0817

Rev 1.3

P 9/40

Jan 2003

Solomon Systech

C1, C0

These two pins are the Chip Mode Selection input. The chip mode is determined by multiplex ratio.

Altogether there are four chip modes. Please see the following list for reference.

C1 C0 Chip

Mode

0 0 48

MUX

Mode

0 1 54

MUX

Mode

1 0 32

MUX

Mode

1 1 64

MUX

Mode

ROW0 - ROW63

These pins provide the driving signals, COMMON, to the LCD panel. Please refer to the Table 3 on

Page 10 for the COM signal mapping in different MUX.

SEG0 - SEG103

These pins provide the LCD driving signals, SEGMENT, to the LCD panel. The output voltage level of

these pins is V

DD

during sleep mode or standby mode.

ICONS

There are two ICONS pins (pin137 and 275) on the chip. Both pins output exactly the same signal.

The duplicated ICON pins will enhance the flexibility of the LCD layout.

IRS

This is the input pin to enable the internal resistors network for the voltage regulator. When this pin is

pulled high, the internal feedback resistors of the internal regulator for generating V

L6

will be enabled.

When it is pulled low, external resistors, R

1

should be connected to V

DD

and V

F

. R

2

should be

connected between V

F

and V

L6

, respectively.

TEST0-TEST7

These are input pins that reserved for testing purpose. These pins should be connected to VDD.

NC/T0 � T6

These are the No Connection pins. These pins should be left open and they are prohibited to have

any connections with one another.

Solomon Systech

Jan 2003

P 10/40 Rev 1.3

SSD0817

Table 3 - Example of ROW pin assignment for different programmable MUX of SSD0817

48 MUX Mode

54 MUX Mode

32 MUX Mode

64 MUX Mode

ROW0 COM0 COM0 COM0 COM0

ROW1 COM1 COM1 COM1 COM1

ROW2 COM2 COM2 COM2 COM2

ROW3 COM3 COM3 COM3 COM3

ROW4 COM4 COM4 COM4 COM4

ROW5 COM5 COM5 COM5 COM5

ROW6 COM6 COM6 COM6 COM6

ROW7 COM7 COM7 COM7 COM7

ROW8 COM8 COM8 COM8 COM8

ROW9 COM9 COM9 COM9 COM9

ROW10 COM10 COM10 COM10 COM10

ROW11 COM11 COM11 COM11 COM11

ROW12 COM12 COM12 COM12 COM12

ROW13 COM13 COM13 COM13 COM13

ROW14 COM14 COM14 COM14 COM14

ROW15 COM15 COM15 COM15 COM15

ROW16 COM16 COM16 NC COM16

ROW17 COM17 COM17 NC COM17

ROW18 COM18 COM18 NC COM18

ROW19 COM19 COM19 NC COM19

ROW20 COM20 COM20 NC COM20

ROW21 COM21 COM21 NC COM21

ROW22 COM22 COM22 NC COM22

ROW23 COM23 COM23 NC COM23

ROW24 NC COM24 NC COM24

ROW25 NC COM25 NC COM25

ROW26 NC COM26 NC COM26

ROW27

NC NC NC

COM27

ROW28

NC NC NC

COM28

ROW29

NC NC NC

COM29

ROW30

NC NC NC

COM30

ROW31

NC NC NC

COM31

ROW32 COM24 COM27 COM16 COM32

ROW33 COM25 COM28 COM17 COM33

ROW34 COM26 COM29 COM18 COM34

ROW35 COM27 COM30 COM19 COM35

ROW36 COM28 COM31 COM20 COM36

ROW37 COM29 COM32 COM21 COM37

ROW38 COM30 COM33 COM22 COM38

ROW39 COM31 COM34 COM23 COM39

ROW40 COM32 COM35 COM24 COM40

ROW41 COM33 COM36 COM25 COM41

ROW42 COM34 COM37 COM26 COM42

ROW43 COM35 COM38 COM27 COM43

ROW44 COM36 COM39 COM28 COM44

ROW45 COM37 COM40 COM29 COM45

ROW46 COM38 COM41 COM30 COM46

ROW47 COM39 COM42 COM31 COM47

ROW48 COM40 COM43 NC COM48

ROW49 COM41 COM44 NC COM49

ROW50 COM42 COM45 NC COM50

ROW51 COM43 COM46 NC COM51

ROW52 COM44 COM47 NC COM52

ROW53 COM45 COM48 NC COM53

ROW54 COM46 COM49 NC COM54

ROW55 COM47 COM50 NC COM55

ROW56 NC COM51 NC COM56

ROW57 NC COM52 NC COM57

ROW58 NC COM53 NC COM58

ROW59

NC NC NC

COM59

ROW60

NC NC NC

COM60

ROW61

NC NC NC

COM61

ROW62

NC NC NC

COM62

ROW63

NC NC NC

COM63

(Note: X - output non-selected COM signal)

SSD0817

Rev 1.3

P 11/40 Jan 2003

Solomon Systech

FUNCTIONAL BLOCK DESCRIPTIONS

IIC communication Interface

The IIC communication interface consists of slave address bit (SA0), I

2

C-bus data signal (SDA) and

I

2

C-bus clock signal (SCL). Both the SDA and the SCL must be connected to pull-up resistors. There

are also five input signals including,

RES

,

1

CS ,

IIC1

, CS2, IIC2, which is used for the initialization of

device.

a) Slave address bit (SA0)

SSD0817 have to recognize the slave address before transmitting or receiving any

information by the I

2

C-bus. The device will responds to the slave address following by the

slave address bit ("SA0" bit) and the read/write select bit ("

R/

W

" bit) with the following byte

format,

b

7

b

6

b

5

b

4

b

3

b

2

b

1

b

0

0 1 1 1 1 0 SA0

R/W

"SA0" bit provides an extension bit for the slave address. Either "0111100" or "0111101", can

be selected as the slave address of SSD0817.

"

R/W

" bit determines the I

2

C-bus interface is operating at either write mode or read status

mode.

b) I

2

C-bus data signal (SDA)

SDA acts as a communication channel between the transmitter and the receiver. The data

and the acknowledgement are sent through the SDA. If SDA in is connected to the "SDA out",

the device becomes fully IIC bus compatible.

It should be noticed that the ITO track resistance and the pulled-up resistance at "SDA" pin

becomes a voltage potential divider. As a result, the acknowledgement would not be possible

to attain a valid logic 0 level in "SDA".

The "SDA out" pin may be disconnected from the "SDA in" pin. With such arrangement, the

acknowledgement signal will be ignored in the I

2

C-bus.

c) I

2

C-bus clock signal (SCL)

The transmission of information in the I

2

C-bus is following a clock signal, SCL. Each

transmission of data bit is taken place during a single clock period of SCL.

Command Decoder

Input is directed to the command decoder based on the input of control byte which consists of a

D/ C

bit and a

R/W

bit. For further information about the control byte, please refer to the section "I

2

C-

bus Write data and read register status" on page 21. If both the

D/ C

bit and the

R/W

bit are low, the

input signal is interpreted as a Command. It will be decoded and written to the corresponding

command register. If the

D/ C

bit is high and the

R/W

bit is low, input signal is written to Graphic

Display Data RAM (GDDRAM).

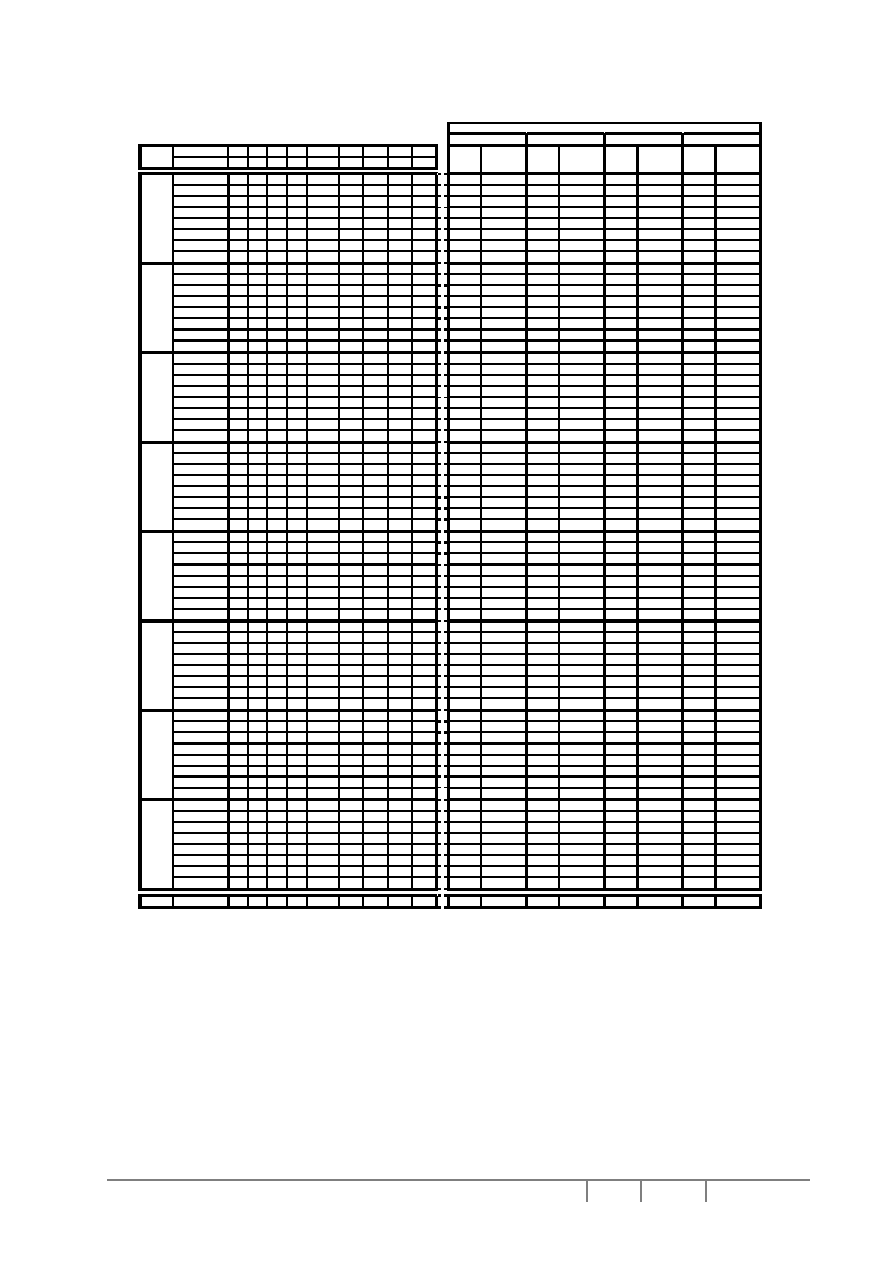

Graphic Display Data RAM (GDDRAM)

The GDDRAM is a bit mapped static RAM holding the bit pattern to be displayed. The size of the RAM

is 104 x 65 = 6760 bits. Table 4 on Page 12 is a description of the GDDRAM address map. For

mechanical flexibility, re-mapping on both Segment and Common outputs can be selected by

software.

During the vertical scrolling of the display, an internal register (display start line register) stores the

address of the display start line. The re-mapping operation can be started at the address of the

display start line according to the internal register. Table 4 on Page 12 shows the case in which the

display start line register is set to 38h.

For those GDDRAM out of the display common range, they can be accessed for either the

preparation of vertical scrolling data or the system usage.

Solomon Systech

Jan 2003

P 12/40 Rev 1.3

SSD0817

Normal

00h

01h

02h

03h � � � � � �

64h

65h

66h

67h

Remapped

67h

66h

65h

64h � � � � � �

03h

02h

01h

00h

00h

D0 (LSB)

� � � � � �

8

39

8

45

8

23

8

55

01h

D1

� � � � � �

9

38

9

44

9

22

9

54

02h

D2

� � � � � �

10

37

10

43

10

21

10

53

03h

D3

� � � � � �

11

36

11

42

11

20

11

52

04h

D4

� � � � � �

12

35

12

41

12

19

12

51

05h

D5

� � � � � �

13

34

13

40

13

18

13

50

06h

D6

� � � � � �

14

33

14

39

14

17

14

49

07h

D7 (MSB)

� � � � � �

15

32

15

38

15

16

15

48

08h

D0 (LSB)

� � � � � �

16

31

16

37

16

15

16

47

09h

D1

� � � � � �

17

30

17

36

17

14

17

46

0Ah

D2

� � � � � �

18

29

18

35

18

13

18

45

0Bh

D3

� � � � � �

19

28

19

34

19

12

19

44

0Ch

D4

� � � � � �

20

27

20

33

20

11

20

43

0Dh

D5

� � � � � �

21

26

21

32

21

10

21

42

0Eh

D6

� � � � � �

22

25

22

31

22

9

22

41

0Fh

D7 (MSB)

� � � � � �

23

24

23

30

23

8

23

40

10h

D0 (LSB)

� � � � � �

24

23

24

29

24

7

24

39

11h

D1

� � � � � �

25

22

25

28

25

6

25

38

12h

D2

� � � � � �

26

21

26

27

26

5

26

37

13h

D3

� � � � � �

27

20

27

26

27

4

27

36

14h

D4

� � � � � �

28

19

28

25

28

3

28

35

15h

D5

� � � � � �

29

18

29

24

29

2

29

34

16h

D6

� � � � � �

30

17

30

23

30

1

30

33

17h

D7 (MSB)

� � � � � �

31

16

31

22

31

0

31

32

18h

D0 (LSB)

� � � � � �

32

15

32

21

X

X

32

31

19h

D1

� � � � � �

33

14

33

20

X

X

33

30

1Ah

D2

� � � � � �

34

13

34

19

X

X

34

29

1Bh

D3

� � � � � �

35

12

35

18

X

X

35

28

1Ch

D4

� � � � � �

36

11

36

17

X

X

36

27

1Dh

D5

� � � � � �

37

10

37

16

X

X

37

26

1Eh

D6

� � � � � �

38

9

38

15

X

X

38

25

1Fh

D7 (MSB)

� � � � � �

39

8

39

14

X

X

39

24

20h

D0 (LSB)

� � � � � �

40

7

40

13

X

X

40

23

21h

D1

� � � � � �

41

6

41

12

X

X

41

22

22h

D2

� � � � � �

42

5

42

11

X

X

42

21

23h

D3

� � � � � �

43

4

43

10

X

X

43

20

24h

D4

� � � � � �

44

3

44

9

X

X

44

19

25h

D5

� � � � � �

45

2

45

8

X

X

45

18

26h

D6

� � � � � �

46

1

46

7

X

X

46

17

27h

D7 (MSB)

� � � � � �

47

0

47

6

X

X

47

16

28h

D0 (LSB)

� � � � � �

X

X

48

5

X

X

48

15

29h

D1

� � � � � �

X

X

49

4

X

X

49

14

2Ah

D2

� � � � � �

X

X

50

3

X

X

50

13

2Bh

D3

� � � � � �

X

X

51

2

X

X

51

12

2Ch

D4

� � � � � �

X

X

52

1

X

X

52

11

2Dh

D5

� � � � � �

X

X

53

0

X

X

53

10

2Eh

D6

� � � � � �

X

X

X

X

X

X

54

9

2Fh

D7 (MSB)

� � � � � �

X

X

X

X

X

X

55

8

30h

D0 (LSB)

� � � � � �

X

X

X

X

X

X

56

7

31h

D1

� � � � � �

X

X

X

X

X

X

57

6

32h

D2

� � � � � �

X

X

X

X

X

X

58

5

33h

D3

� � � � � �

X

X

X

X

X

X

59

4

34h

D4

� � � � � �

X

X

X

X

X

X

60

3

35h

D5

� � � � � �

X

X

X

X

X

X

61

2

36h

D6

� � � � � �

X

X

X

X

X

X

62

1

37h

D7 (MSB)

� � � � � �

X

X

X

X

X

X

63

0

38h

D0 (LSB)

� � � � � �

0

47

0

53

0

31

0

63

39h

D1

� � � � � �

1

46

1

52

1

30

1

62

3Ah

D2

� � � � � �

2

45

2

51

2

29

2

61

3Bh

D3

� � � � � �

3

44

3

50

3

28

3

60

3Ch

D4

� � � � � �

4

43

4

49

4

27

4

59

3Dh

D5

� � � � � �

5

42

5

48

5

26

5

58

3Eh

D6

� � � � � �

6

41

6

47

6

25

6

57

3Fh

D7 (MSB)

� � � � � �

7

40

7

46

7

24

7

56

Page 8

D0 (LSB)

� � � � � �

ICONS

ICONS

ICONS

ICONS

ICONS

ICONS

ICONS

ICONS

Segment Pins

0

1

2

3

� � � � � �

100

101

102

103

Page 6

Page 7

Normal

Remapped

Page 2

Page 3

Page 4

Page 5

Page 0

Page 1

Normal

Remapped

Normal

Remapped

RAM

Row

RAM

Column

Normal

Remapped

Common Pins

48 MUX Mode

54 MUX Mode

32 MUX Mode

64 MUX Mode

Remarks : DB0 � DB7 represent the data bit of the GDDRAM

Table 4 - Graphic Display Data RAM (GDDRAM) Address Map with Display Start Line

set to 38h LCD Driving Voltage Generator and Regulator

SSD0817

Rev 1.3

P 13/40 Jan 2003

Solomon Systech

LCD Driving Voltage Generator and Regulator

This module generates the LCD voltage required for display driving output. With reference to V

DD

, it

takes a single supply input, V

SS

, and generates all the necessary voltage levels. This block consists

of:

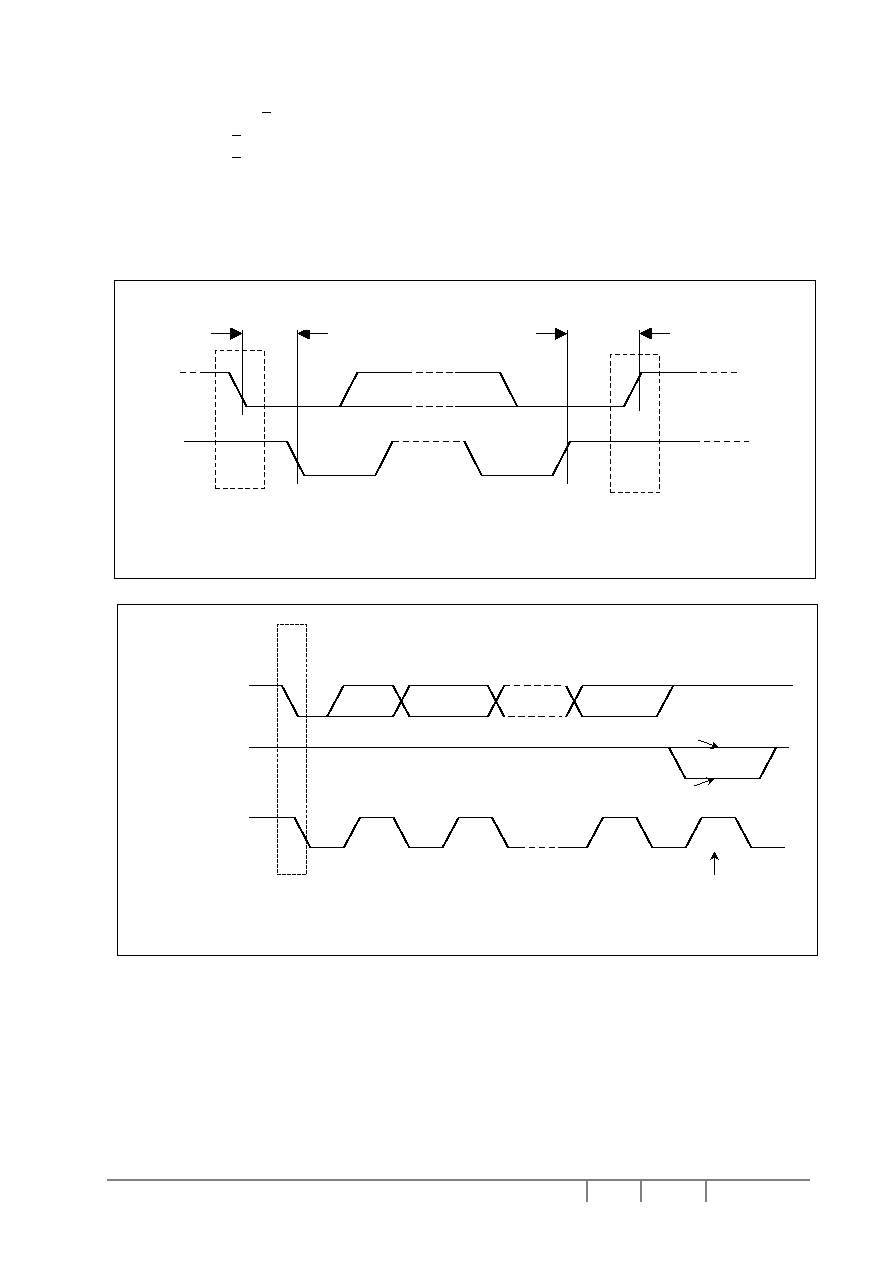

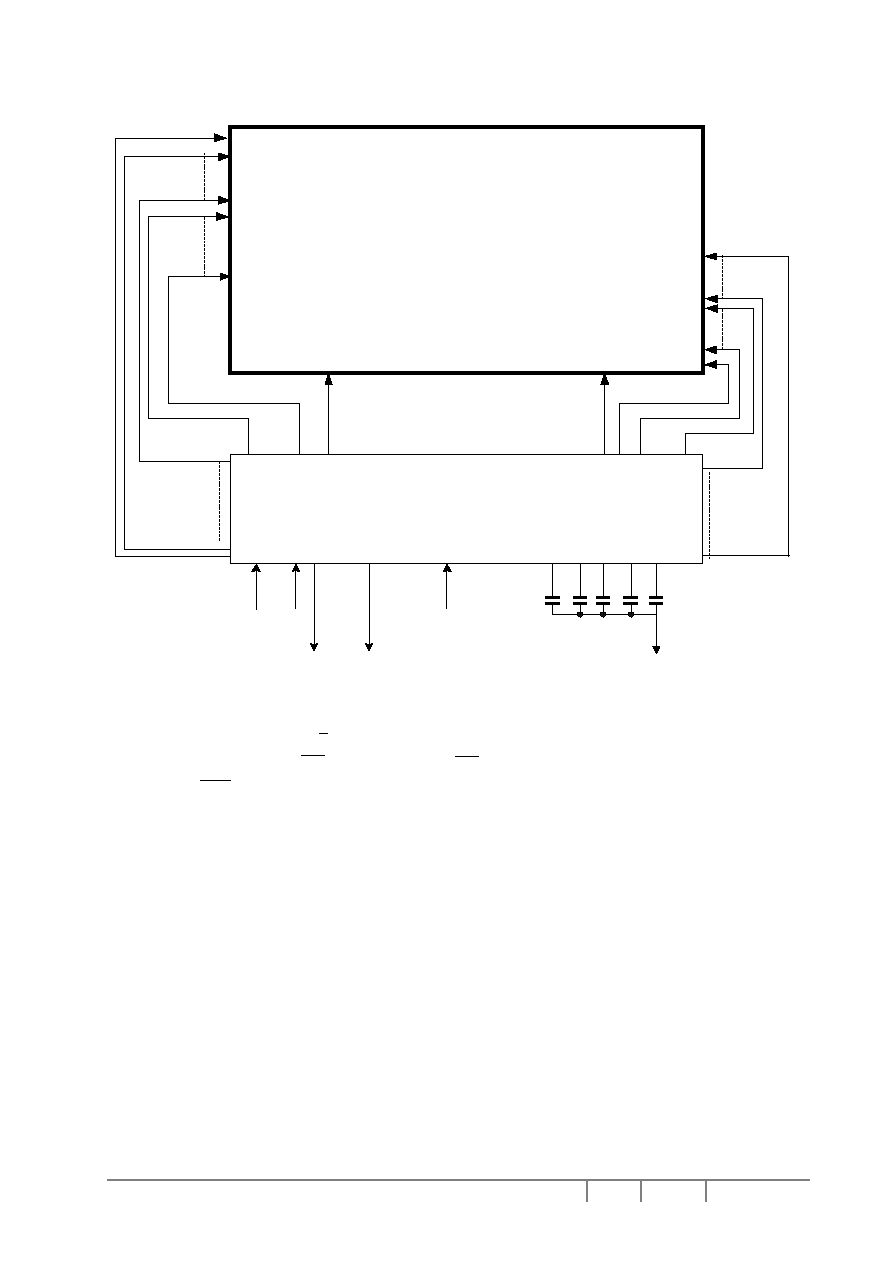

1. 2X, 3X, 4X and 5X DC-DC voltage converter

The built-in DC-DC voltage converter is used to generate the negative voltage with reference to VDD

from the voltage input (VSS1). For SSD0817, it is possible to produce 2X, 3X, 4X or 5X boosting from

the potential different between V

SS1

- V

DD

. Detailed configurations of the DC-DC converter for different

boosting multiples are given in Figure 3.

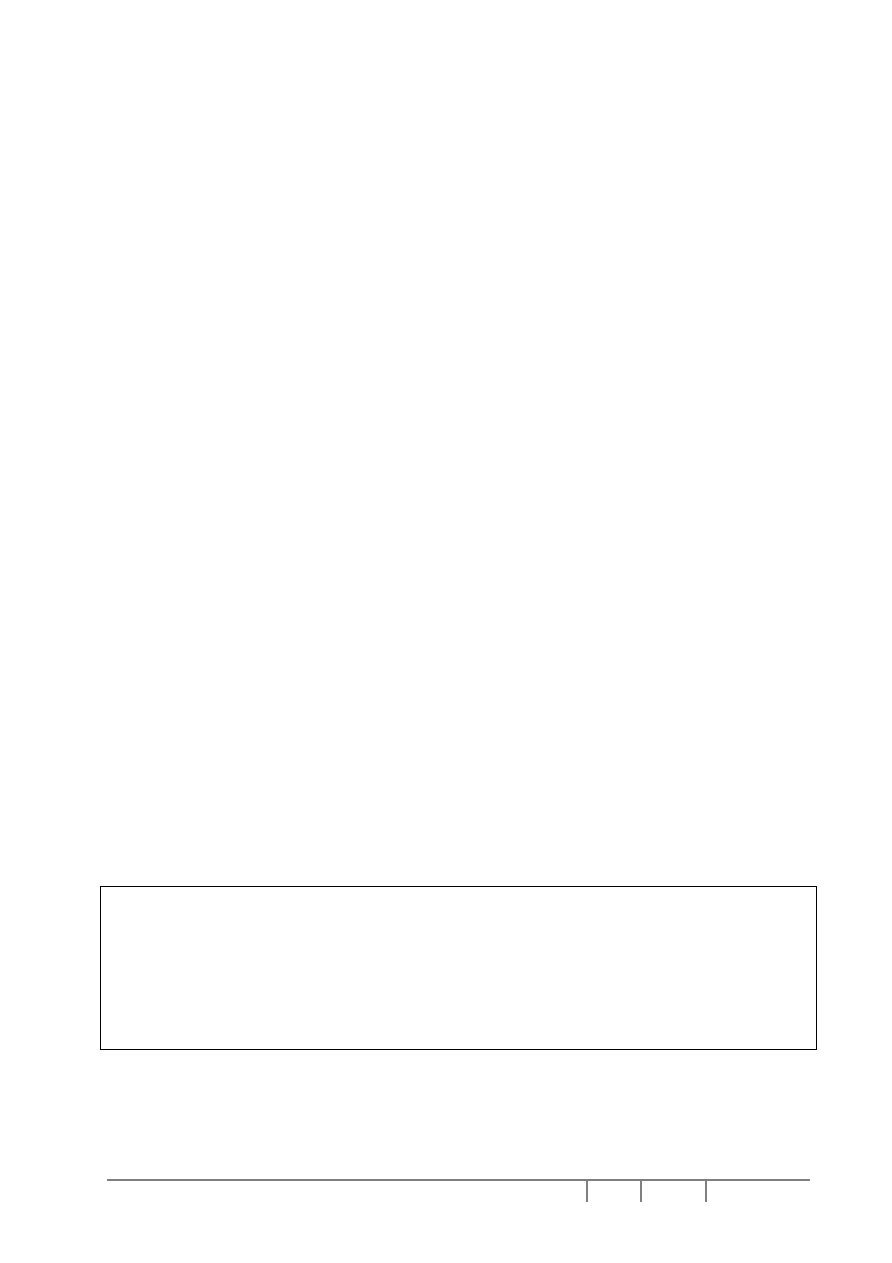

Figure 3 - DC-DC Converter Configurations

2. Voltage Regulator (Voltages referenced to V

DD

)

Internal (IRS pin = H) feedback gain can control the LCD driving contrast curves.

If internal resistor network is enabled, eight settings can be selected through software command.

If external control is selected, external resistors are connected between V

DD

and V

F

(R1), and

between V

F

and V

L6

(R2).

3. Contrast Control (Voltage referenced to V

DD

)

Software control of the 64-contrast voltage levels at each voltage regulator feedback gain.

The equation of calculating the LCD driving voltage is given as:

SSD0817

5X Boosting Configuration

V

SS1

V

EE

C

3N

C

1P

C

1N

C

2N

C

2P

C

4N

C1

+

+

+

C1

C1

C1

+

+

C1

4X Boosting Configuration

V

SS1

V

EE

C

3N

C

1P

C

1N

C

2N

C

2P

C

4N

C1

+

+

+

C1

C1

+

SSD0817

3X Boosting Configuration

V

SS1

V

EE

C

3N

C

1P

C

1N

C

2N

C

2P

C

4N

C1

+

+

C1

C1

+

SSD0817

2X Boosting Configuration

V

SS1

V

EE

C

3N

C

1P

C

1N

C

2N

C

2P

C

4N

C1

+

+

C1

SSD0817

Remarks:

1. C1= 0.47 � 4.7uF

2. Boosting input from VSS1

3. VSS1 should be lower potential than or equal to VSS

4. All voltages are referenced to VDD

C1

Solomon Systech

Jan 2003

P 14/40 Rev 1.3

SSD0817

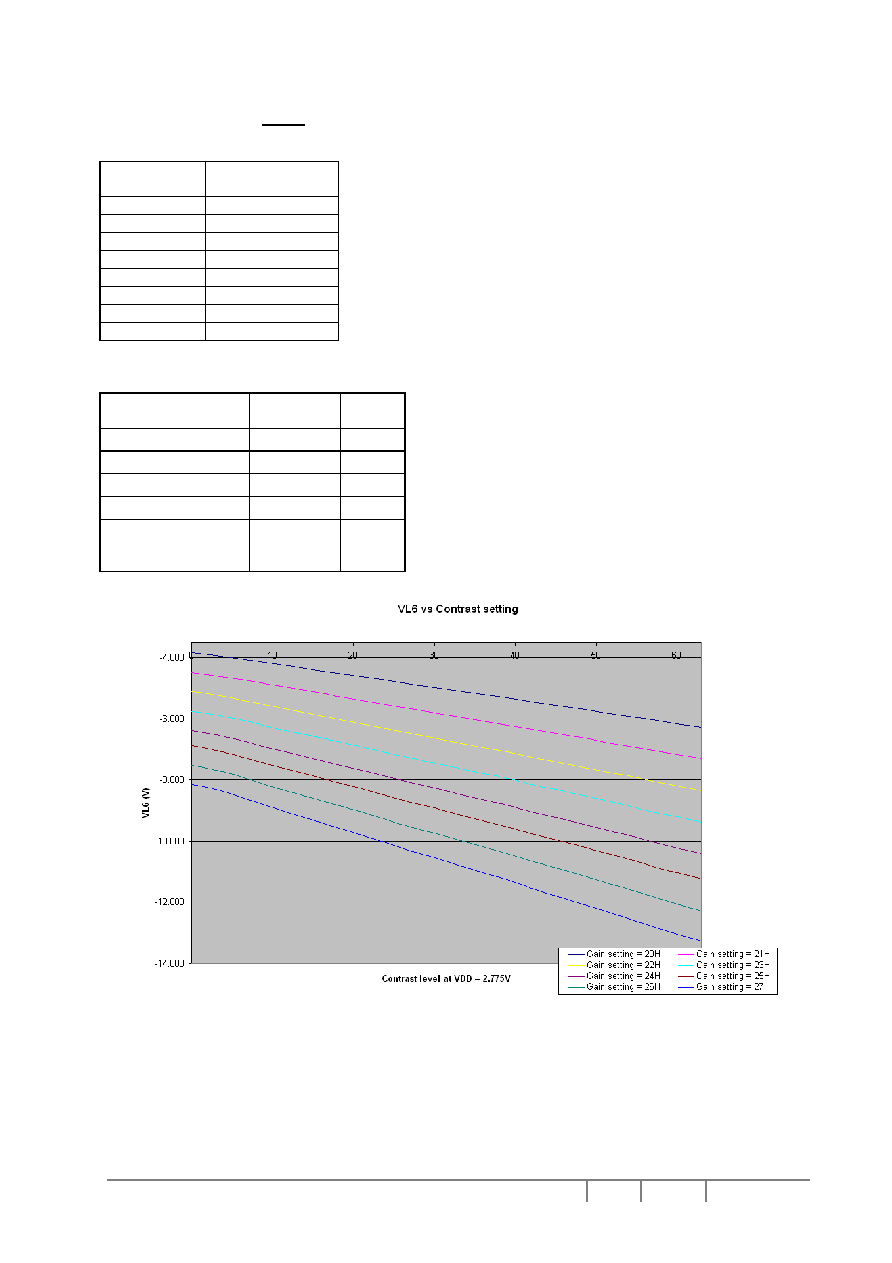

V

L6

�V

DD

= Gain * [1 + (18 +

)] * V

ref

stands for the contrast set (0 to 63)

81

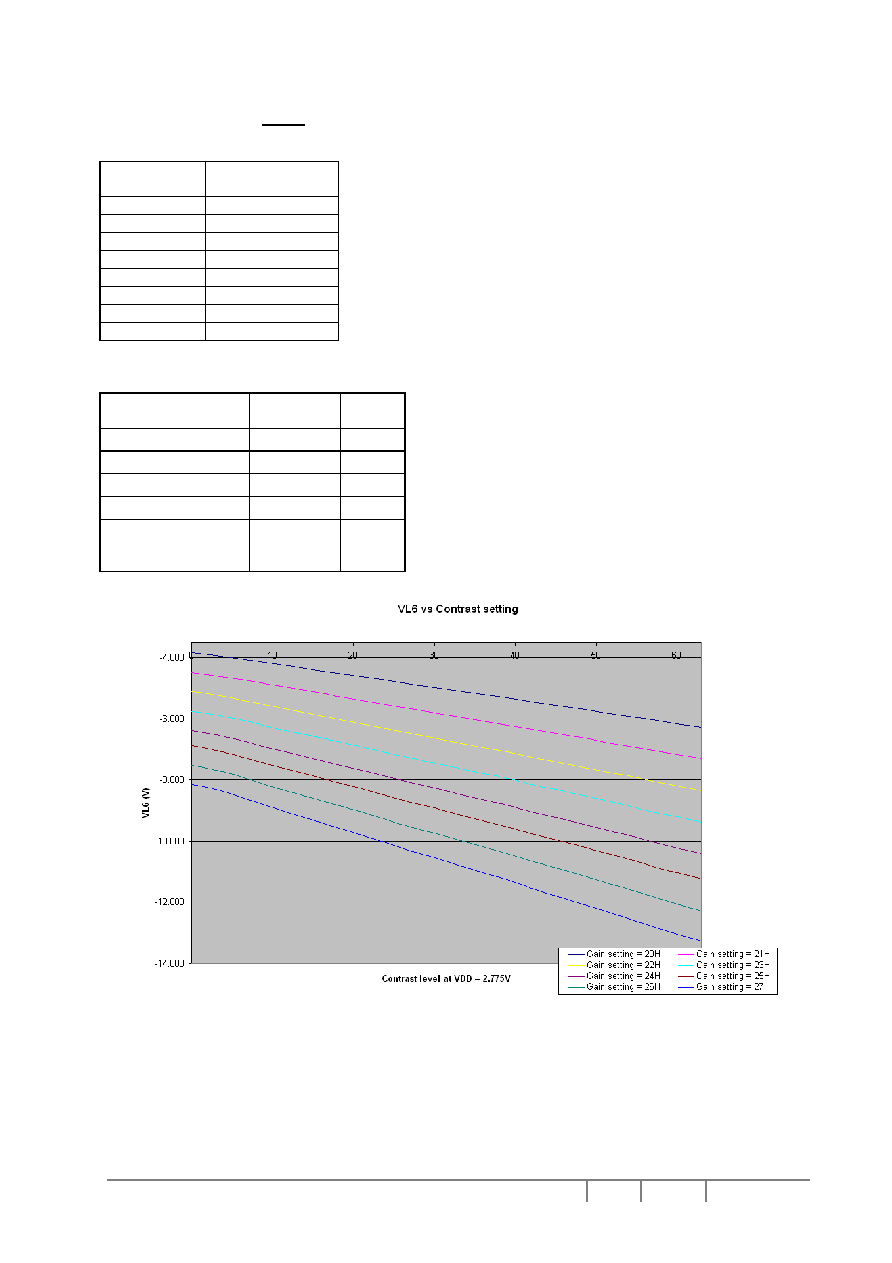

Gain = (1 + Rb/Ra), the reference value is shown in table 5.

Register ratio

D2 D1 D0

Thermal Gradient

= -0.07 %/

o

C

0 0 0

2.92

0 0 1

3.40

0 1 0

3.89

0 1 1

4.37

1 0 0

4.85

1 0 1

5.23

1 1 0

5.72

1 1 1

6.19

Table 5 Gain value at different register ratio and thermal gradient settings

V

ref

is a fixed IC�internal voltage supply and its voltage at room temperature (25

o

C) is shown in table

6 for reference.

Type Thermal

Gradient

V

ref

TC 0

-0.07 %/

o

C -1.08V

TC 2

-0.13 %/

o

C -1.12V

TC 4

-0.26 %/

o

C -1.09V

TC 7

-0.29 %/

o

C -1.10V

External resistor

gain mode [Gain =

5.00] @ TC0

-0.07 %/

o

C -1.08V

Table 6 V

ref

values at different thermal gradient settings

The voltage regulator output for different gain/contrast settings is shown in figure 4.

Figure 4 � Voltage Regulator Output for different Gain/Contrast Settings

4. Bias Ratio Selection circuitry

The bias ratios can be software selected from 1/4, 1/5, 1/6, 1/7, 1/8 and 1/9.

Since there will be slightly different in command pattern for different MUX, please refer to Command

Descriptions section of this data sheet. If the output op-amp buffer option in Set Power Control

Register command is enabled, this circuit block will divide the regulator output (V

L6

) to give the LCD

driving levels (V

L2

~ V

L5

). A low power consumption circuit design in this bias divider saves most of the

display current comparing to the traditional design. Stabilizing Capacitors (0.1uF ~ 0.47uF) are

SSD0817

Rev 1.3

P 15/40 Jan 2003

Solomon Systech

SSD1815B

V

DD

V

L2

V

L3

V

L4

V

L5

V

L6

R3

R1

R2

R4

+

V

DD

C5

+ C4

+ C3

+ C2

+ C1

Remark: 1. C1 ~ C5 = 0.01 ~ 0.47uF

2. R1 ~ R4 = 100k~ 1M

SSD0817

required to be connected between these voltage level pins (V

L2

~ V

L5

) and (V

DD

). If the LCD panel

loading is heavy, four additional resistors are suggested to add to the application circuit as follows:

5. Self adjust temperature compensation circuitry

This block provides 4 different compensation settings to satisfy various liquid crystal temperature

grades by software control. The default temperature coefficient (TC) setting is TC0.

Oscillator Circuit

This module is an On-Chip low power RC oscillator circuitry (Figure 5). The oscillator generates the

clock for the DC-DC voltage converter. This clock is also used in the Display Timing Generator.

enable

Oscillation Circuit

enable

Buffer

Internal resistor

OSC2

OSC1

Oscillator

enable

(CL)

Figure 5 - On-Chip low power RC oscillator circuitry

Remark: 1. C1 ~ C5 = 0.1uF ~ 0.47uF

2. R1 ~ R4 = 100k ~1M

Solomon Systech

Jan 2003

P 16/40 Rev 1.3

SSD0817

Reset Circuit

This block includes Power On Reset (POR) circuitry and the hardware reset pin,

RES

. The POR and

Hardware reset performs the same reset function. Once

RES

receives a reset pulse, all internal

circuitry will start to initialize. Minimum pulse width the reset sequence is 5 -10us. Status of the chip

after reset is given by:

Display is turned OFF

Default Display Mode

64 MUX: 104 x 64 + 1 Icon Line

Normal segment and display data column address mapping (Seg0 mapped to Row address 00h)

Read-modify-write mode is OFF

Power control register is set to 000b

Register data clear in I

2

C-bus interface

Bias ratio is set to default

64 MUX: 1/9

Static indicator is turned OFF

Display start line is set to GDDRAM column 0

Column address counter is set to 00h

Page address is set to 0

Normal scan direction of the COM outputs

Contrast control register is set to 20h

Test mode is turned OFF

Temperature Coefficient is set to TC0

Display Data Latch

This block is a series of latches carrying the display signal information. These latches hold the data,

which will be fed to the HV Buffer Cell and Level Selector to output the required voltage level.

The numbers of latches of different members are given by:

64 MUX: 104 + 65 = 169

HV Buffer Cell (Level Shifter)

HV Buffer Cell works as a level shifter which translates the low voltage output signal to the required

driving voltage. The output is shifted out with reference to the internal FRM clock which comes from

the Display Timing Generator. The voltage levels are given by the level selector which is synchronized

with the internal M signal.

Level Selector

Level Selector is a control of the display synchronization. Display voltage levels can be separated into

two sets and used with different cycles. Synchronization is important since it selects the required LCD

voltage level to the HV Buffer Cell, which in turn outputs the COM or SEG LCD waveform.

SSD0817

Rev 1.3

P 17/40 Jan 2003

Solomon Systech

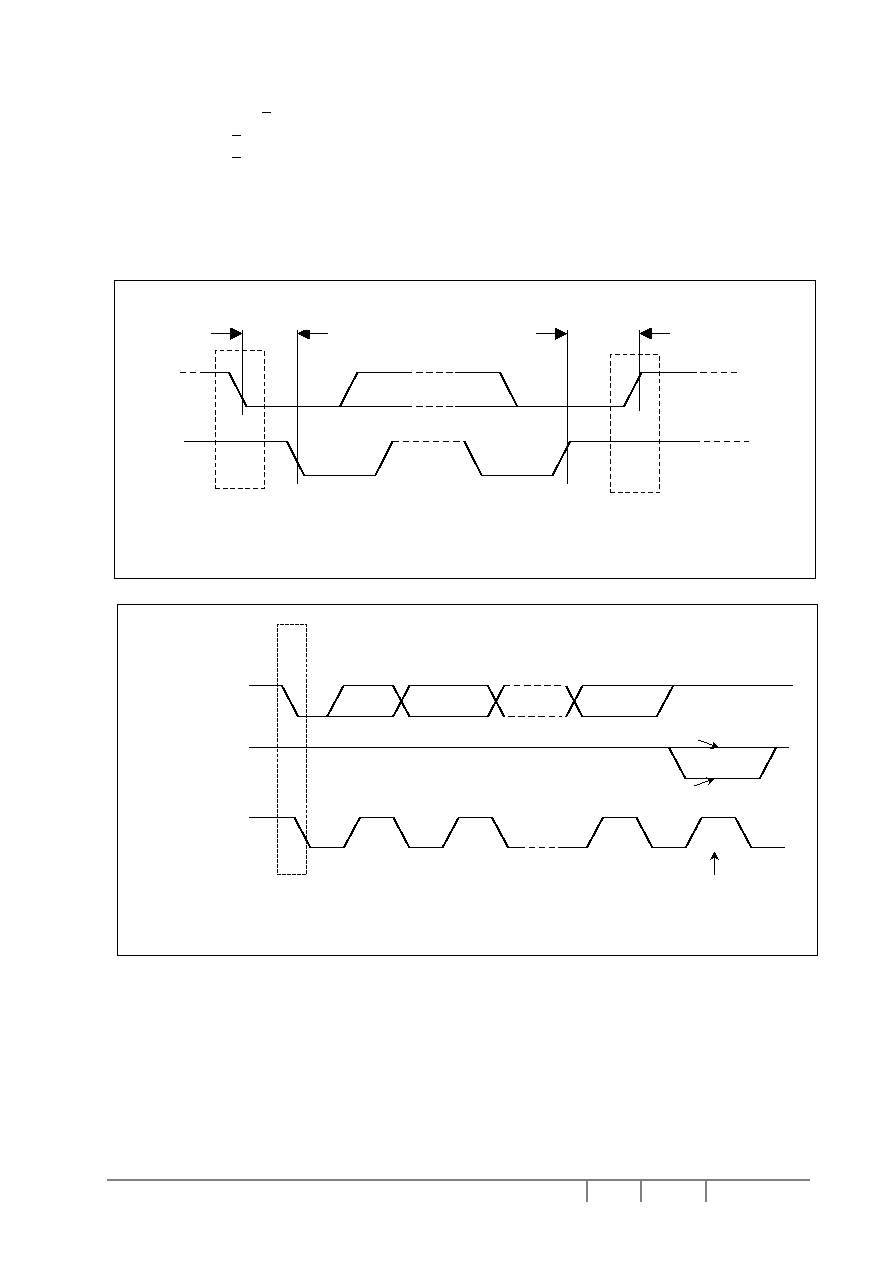

LCD Panel Driving Waveform

Figure 6 is an example of how the Common and Segment drivers may be connected to a LCD panel.

The waveforms illustrate the desired multiplex scheme.

COM1

COM2

COM3

COM4

COM5

COM6

COM7

E

G

1

E

G

2

E

G

3

E

G

4

COM0

E

G

0

TIME SLOT

COM0

COM1

SEG0

SEG1

M

V

DD

V

L2

V

L3

V

L4

V

L5

V

L6

V

DD

V

L2

V

L3

V

L4

V

L5

V

L6

V

DD

V

L2

V

L3

V

L4

V

L5

V

L6

V

DD

V

L2

V

L3

V

L4

V

L5

V

L6

* Note 1: N+1 is the number of multiplex ratio including Icon.

1

2

3

4

5

6

7

8

9

. . .

N+1

*

1

2

3

4

5

6

7

8

9

. .

N+1

*

1

2

3

4

5

6

7

8

9

. .

N+1

*

1

2

3

4

5

6

7

8

9

. . .

N+1

*

Figure 6 - LCD Driving Waveform for Displaying "0"

Solomon Systech

Jan 2003

P 18/40 Rev 1.3

SSD0817

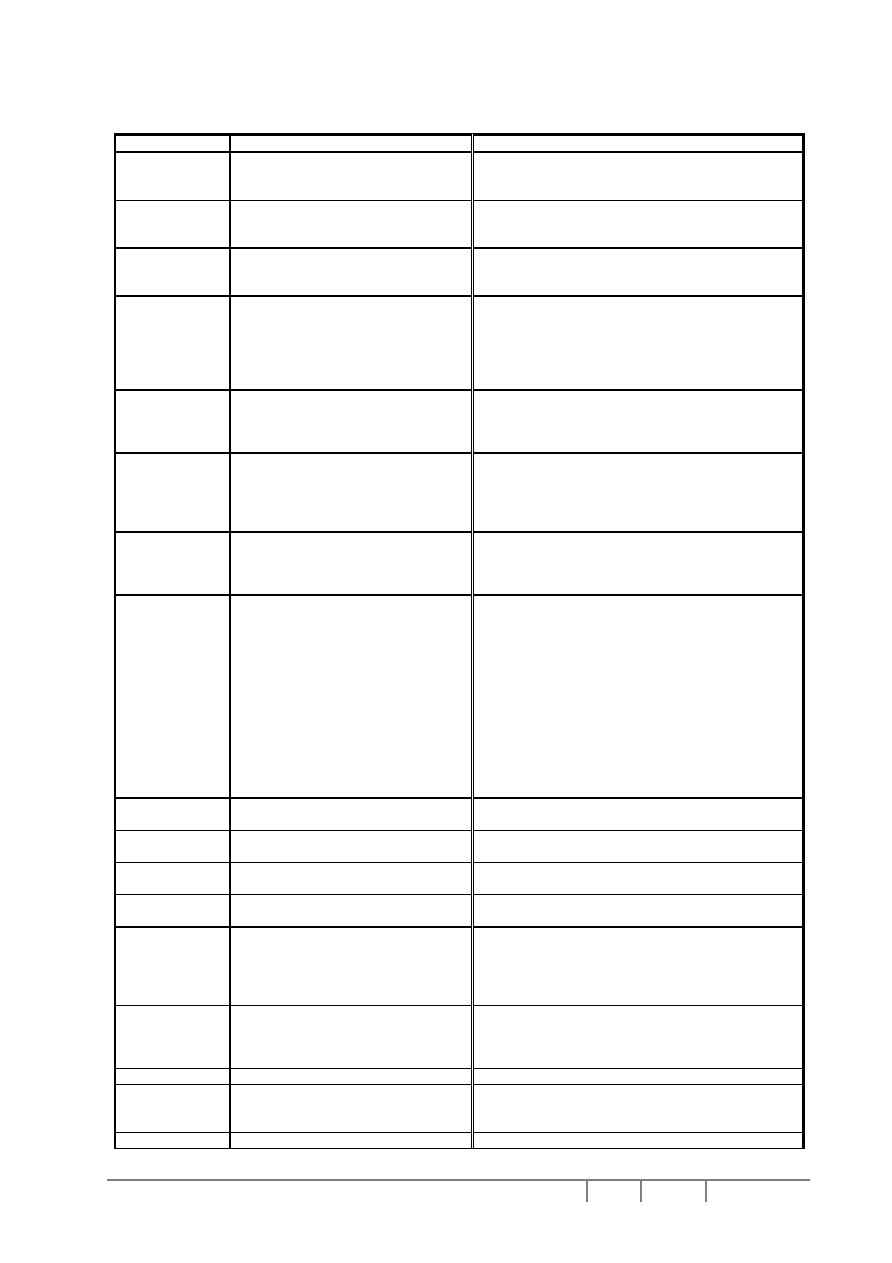

COMMAND TABLE

Bit Pattern

Command

Description

0000X

3

X

2

X

1

X

0

Set Lower Column Address

Set the lower nibble of the column address register

using X

3

X

2

X

1

X

0

as data bits. The lower nibble of

column address is reset to 0000b after POR

0001X

3

X

2

X

1

X

0

Set Higher Column Address

Set the higher nibble of the column address register

using X

3

X

2

X

1

X

0

as data bits. The higher nibble of

column address is reset to 0000b after POR.

00100X

2

X

1

X

0

Set Internal Regulator Resistor Ratio

Feedback gain of the internal regulator generating

VL6 increases as X

2

X

1

X

0

increased from 000b to

111b. After POR, X

2

X

1

X

0

= 100b

00101X

2

X

1

X

0

Set Power Control Register

X

0

=0: turns off the output op-amp buffer (POR)

X

0

=1: turns on the output op-amp buffer

X

1

=0: turns off the internal regulator (POR)

X

1

=1: turns on the internal regulator

X

2

=0: turns off the internal voltage booster (POR)

X

2

=1: turns on the internal voltage booster

01X

5

X

4

X

3

X

2

X

1

X

0

Set Display Start Line

Set GDDRAM display start line register from 0-63

using X

5

X

4

X

3

X

2

X

1

X

0

.

Display start line register is reset to 000000 after

POR.

10000001

** X

5

X

4

X

3

X

2

X

1

X

0

Set Contrast Control Register

Select contrast level from 64 contrast steps.

Contrast increases (VL6 decreases) as

X

5

X

4

X

3

X

2

X

1

X

0

is increased from 000000b to

111111b.

X

5

X

4

X

3

X

2

X

1

X

0

= 100000b after POR

1010000X

0

Set Segment Re-map

X

0

=0: column address 00h is mapped to SEG0

(POR)

X

0

=1: column address 67h is mapped to SEG0

Refer to Table 4 on page 12 for example.

1010001X

0

Set LCD Bias

X

0

=0: POR default bias

48 MUX Mode: 1/8

54 MUX Mode: 1/8.4

32 MUX Mode: 1/6

64 MUX Mode: 1/9

X

0

=1: alternate bias

48 MUX Mode: 1/6

54 MUX Mode: 1/6

32 MUX Mode: 1/5

64 MUX Mode: 1/7

For other bias ratio settings, see "Set 1/4 Bias Ratio"

and "Set Bias Ratio" in Extended Command Set.

1010010X

0

Set Entire Display On/Off

X

0

=0: normal display (POR)

X

0

=1: entire display on

1010011X

0

Set Normal/Inverse Display

X

0

=0: normal display (POR)

X

0

=1: inverse display

1010111X

0

Set Display On/Off

X

0

=0: turns off LCD panel (POR)

X

0

=1: turns on LCD panel

1011X

3

X

2

X

1

X

0

Set Page Address

Set GDDRAM Page Address (0-8) for read/write

using X

3

X

2

X

1

X

0

1100X

3

* * *

Set COM Output Scan Direction

X

3

=0: normal mode (POR)

X

3

=1: remapped mode,

COM 0 to COM [N-1] becomes COM [N-1] to COM 0

when Multiplex ratio is equal to N.

See Figure 5 on page 17 for detail mapping.

11100000

Set Read-Modify-Write Mode

Read-Modify-Write mode will be entered in which

the column address will not be increased during

display data read. After POR, Read-modify-write

mode is turned OFF.

11100010

Software Reset

Initialize internal status registers

11101110

Set End of Read-Modify-Write Mode

Exit Read-Modify-Write mode. RAM Column

address before entering the mode will be restored.

After POR, Read-modify-write mode is OFF.

1010110X

0

Indicator Display Mode

This second byte command is required ONLY when

SSD0817

Rev 1.3

P 19/40 Jan 2003

Solomon Systech

* * * * * * X

1

X

0

Set Indicator

On/Off

"Set Indicator On" command is sent.

X

0

= 0: indicator off (POR, second command byte is

not required)

X

0

= 1: indicator on (second command byte

required)

X

1

X

0

= 00: indicator off

X

1

X

0

= 01: indicator on and blinking at ~1 second

interval

X

1

X

0

= 10: indicator on and blinking at ~1/2 second

interval

X

1

X

0

= 11: indicator on constantly

11100011

NOP

Command result in No Operation

11110000

Test Mode Reset

Reserved for IC testing. Do NOT use

1111 * * * *

Set Test Mode

Reserved for IC testing. Do NOT use.

10101110

10100101

Set Power Save Mode

(Standby or Sleep)

Standby or sleep mode

will be entered using compound commands.

Issue compound commands "Set Display Off"

followed by "Set Entire Display On".

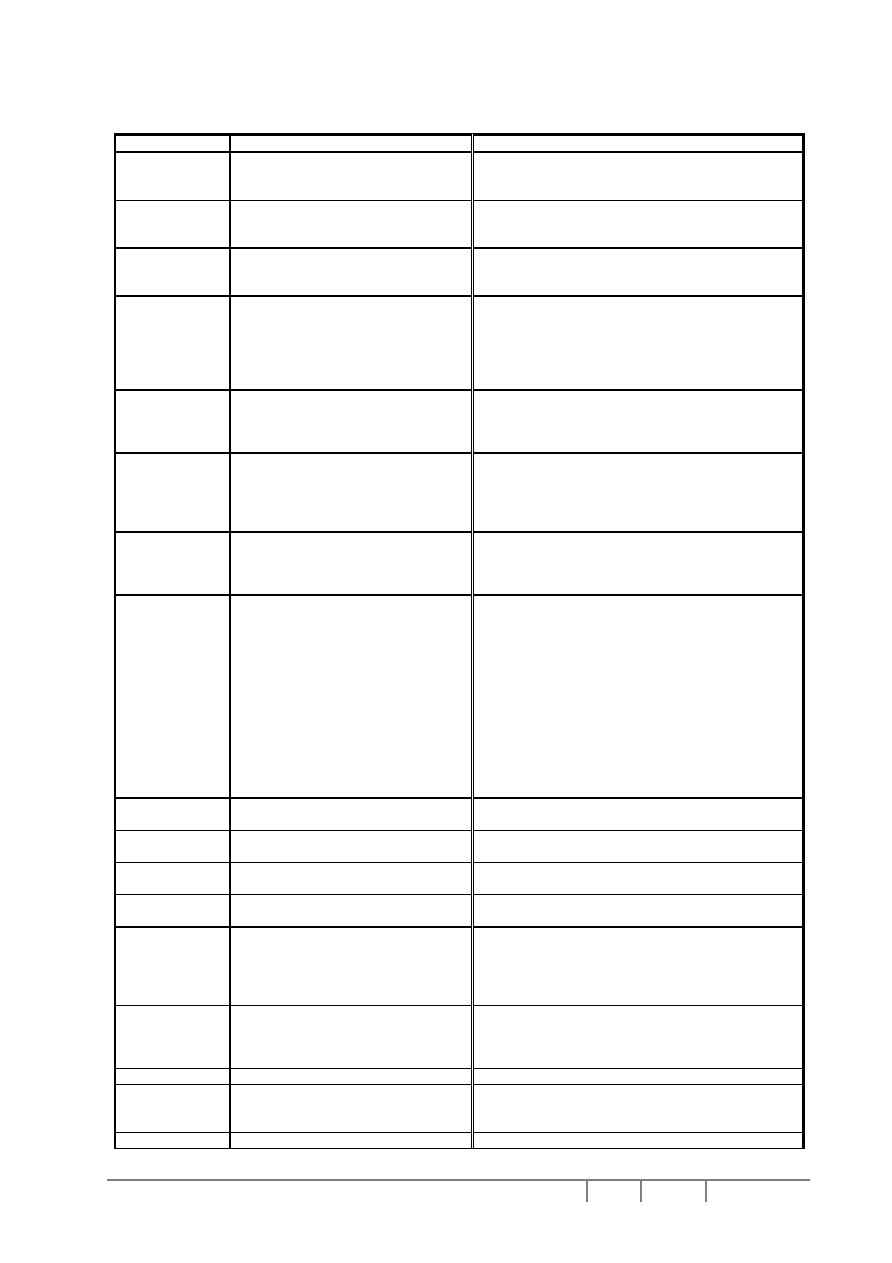

Table 7 - Write Command Table (D/ C =0, R/

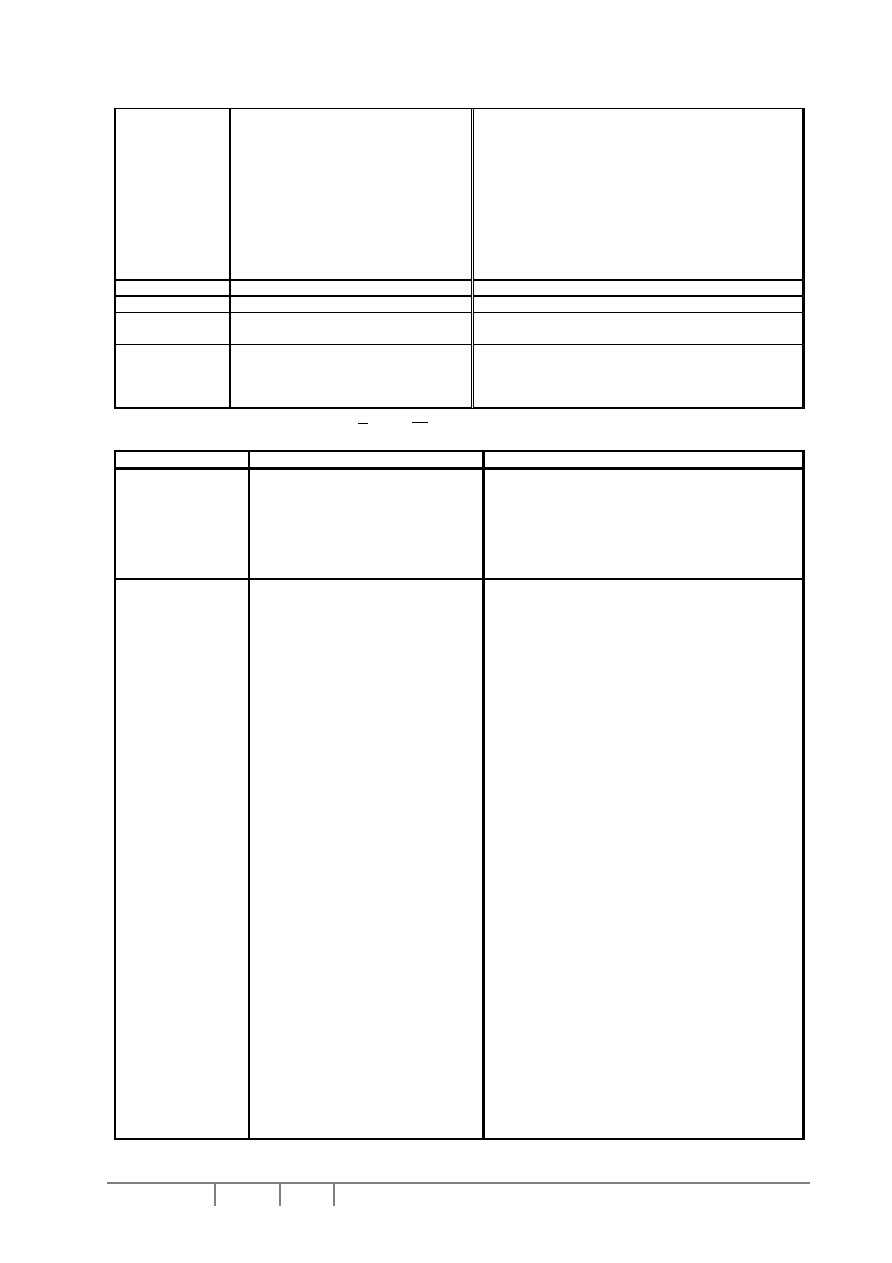

W

=0)

Bit Pattern

Command

Description

10101000

00X

5

X

4

X

3

X

2

X

1

X

0

Set Multiplex Ratio

To select multiplex ratio N from 2 to the maximum

multiplex ratio (POR value) for each member

(including icon line).

Max. MUX ratio:

64 MUX: 65

N = X

5

X

4

X

3

X

2

X

1

X

0

+ 2,

e.g. N = 001111b + 2 = 17

10101001

X

7

X

6

X

5

X

4

X

3

X

2

X

1

X

0

Set Bias Ratio (X

1

X

0

)

Set TC Value (X

4

X

3

X

2

)

Modify Osc. Freq. (X

7

X

6

X

5

)

For 64 MUX Mode

X

1

X

0

=

00(POR) 01 10 11

1/9 or 1/7 1/5 1/6 1/8

For 54 MUX Mode

X

1

X

0

=

00(POR) 01 10 11

1/8.4 or 1/6 1/5 1/6 1/8

For 48 MUX Mode

X

1

X

0

=

00(POR) 01 10 11

1/8 or 1/6 1/5 1/6 1/8

For 32 MUX Mode

X

1

X

0

=

00(POR) 01 10 11

1/6 or 1/5 1/5 1/6 1/8

X

4

X

3

X

2

= 000: (TC0) Typ. �0.07%/

o

C

X

4

X

3

X

2

= 010: (TC1) Typ. �0.13%/

o

C

X

4

X

3

X

2

= 100: (TC5) Typ. �0.26%/

o

C

X

4

X

3

X

2

= 111: (TC7) Typ. �0.29%/

o

C

X

4

X

3

X

2

= 001, 011, 101, 110: Reserved

Increase the value of X

7

X

6

X

5

will increase the

oscillator frequency and vice versa.

Default Mode:

X

7

X

6

X

5

= 011

(POR for 48 MUX Mode, 54 MUX Mode) :

Typ. 31.5kHz

X

7

X

6

X

5

= 011

(POR for 32 MUX Mode, 64 MUX Mode) :

Typ. 18.7Hz

Solomon Systech

Jan 2003

P 20/40 Rev 1.3

SSD0817

Remarks: By software program the multiplex ratio,

the typical oscillator frequency is listed above.

1010101X

0

Set 1/4 Bias Ratio

X

0

= 0: use normal setting (POR)

X

0

= 1: fixed at 1/4 bias regardless of other bias

setting commands

11010100

00X

5

X

4

0000

Set Total Frame Phases

The On/Off of the Static Icon is given by 3 phases

/ 1 phase overlapping of the M and MSTAT

signals. This command set total phases of the

M/MSTAT signals for each frame.

The more the total phases, the less the

overlapping time and thus the lower the effective

driving voltage.

X

5

X

4

= 00: 5 phases

X

5

X

4

= 01: 7 phases

X

5

X

4

= 10: 9 phases (POR)

X

5

X

4

= 11: 16 phases

11010011

00X

5

X

4

X

3

X

2

X

1

X

0

Set Display Offset

After POR, X

5

X

4

X

3

X

2

X

1

X

0

= 0

After setting MUX ratio less than default value,

data will be displayed at Center of display matrix.

To move display towards Row 0 by L,

X

5

X

4

X

3

X

2

X

1

X

0

= L

To move display away from Row 0 by L,

X

5

X

4

X

3

X

2

X

1

X

0

= 64-L

Note: max. value of L = (POR default MUX ratio �

display MUX)/2

11010110

001111X

1

X

0

Enable Band Gap Reference Circuit

X

1

X

0

=

00 01 10 11(POR)

100 ms 200 ms 400 ms 800 ms

Approx. band gap clock period

This command should execute if divider is used

without capacitor at VL2 to VL5.

Recommendation: set the band gap clock period to

approx. 200ms

Table 8 - Extended Command Table

Note: Command patterns other than that given in Command Table and Extended Command Table are prohibited.

Otherwise, unexpected result will occur.

SSD0817

Rev 1.3

P 21/40 Jan 2003

Solomon Systech

I

2

C-bus Write data and read register status

The I

2

C-bus interface gives access to write data and command into the device. Please refer to figure

7 for the write mode of I

2

C-bus in chronological order.

Figure 7 I

2

C-bus data format

Write mode

1) The master device initiates the data communication by a start condition. The definition of the

start condition is shown in figure 8 on page 22. The start condition is established by pulling

the SDA from high to low while the SCL stays high.

2) The slave address is following the start condition for recognition use. For the SSD0817, the

slave address is either "b0111100" or "b0111101" by changing the SA0 to high or low.

3) The write mode is established by setting the

R/W

bit to logic "0".

4) An acknowledgement signal will be generated after receiving one byte of data, including the

slave address and the

R/W

bit. Please refer to the figure 9 on page 22 for the graphical

representation of the acknowledge signal. The acknowledge bit is defined as the SDA line is

pulled down during the high period of the acknowledgement related clock pulse.

5) After the transmission of the slave address, either the control byte or the data byte may be

sent across the SDA. A control byte mainly consists of Co and

D/ C

bits following by six "0" `s.

a. If the Co bit is set as logic "0", the transmission of the following information will

contain data bytes only.

0 1 1 1 1 0

SA0

P

Slave Address

m 0 words

n 0 bytes

MSB ...................LSB

1 byte

Write mode

Slave Address

SSD0817

Slave Address

Read mode

R/

W

D/

C

Co

A

CK

A

CK

Control byte

Data byte

A

CK

Co

D/

C

Control byte

A

CK

Data byte

A

CK

S

0 1 1 1 1 0

0 1 1 1 1 0

S

SA0

A

CK

Status bytes

A

CK

P

SA0

R/

W

Co

D/

C

A

CK

Control byte

Note:

Co � Continuation bit

D/ C

� Data / Command Selection bit

ACK � Acknowledgement

SA0 � Slave address bit

R/W

� Read / Write Selection bit

S � Start Condition / P � Stop Condition

0 0 0 0 0 0

0 1 1 1 1 0

R/

W

Solomon Systech

Jan 2003

P 22/40 Rev 1.3

SSD0817

DATA OUTPUT

BY RECEIVER

DATA OUTPUT

BY TRANSMITTER

SCL FROM

MASTER

S

START

Condition

Clock pulse for

acknowledgement

1

8

9

Non-acknowledge

2

Acknowledge

S

START condition

SDA

SCL

P

STOP condition

SDA

SCL

T

DH

,

START

T

DS

,

STOP

b. The

D/ C

bit determines the next data byte is acted as a command or a data. If the

D/ C

bit is set to logic "0", it defines the following data byte as a command. If the

D/ C

bit is set to logic "1", it defines the following data byte as a data which will be

stored at the GDDRAM. The GDDRAM column address pointer will be increased by

one automatically after each data write.

6) Acknowledge bit will be generated after receiving each control byte or data byte.

7) The write mode will be finished when a stop condition is applied. The stop condition is also

defined in figure 8 on page 22. The stop condition is established by pulling the "SDA in" from

low to high while the "SCL" stays high.

Figure 8 Definition of the start and stop condition

Figure 9 Definition of the acknowledgement condition

Please be noted that the transmission of the data bit has some limitations.

1. The data bit, which is transmitted during each SCL pulse, must keep at a stable state within

the "high" period of the clock pulse. Please refer to the figure 10 for graphical

representations. Except in start or stop conditions, the data line can be switched only when

the SCL is low.

2. Both the data line (SDA) and the clock line (SCL) should be pulled up by external resistors.

SSD0817

Rev 1.3

P 23/40 Jan 2003

Solomon Systech

Figure 10 Definition of the data transfer condition

Read mode (Read status register)

1) The master device firstly initiates the data communication by a start condition. The definition

of the start condition is shown in figure 8 on page 22.

2) The slave address is following the start condition for recognition use. For the SSD0817, the

slave address is either "b0111100" or "b0111101".

3) The read mode is established by setting

R/W

bit to logic "1". The read mode allows the MCU

to monitor the internal status of the chip.

4) An acknowledgement signal will be generated after sending one byte of data, including the

slave address and the

R/W

bit. Please refer to the figure 9 on page 22 for the graphical

representation of the acknowledge signal.

5) The status of the register will be read at the next status byte. Please refer to the Table 9 for

the explanation of the status byte.

6) The read mode will be finished when a stop condition is applied. The stop condition is also

defined in figure 8 on page 22.

S

7

S

6

S

5

S

4

S

3

S

2

S

1

S

0

Status Register Read

S

7

=0:

indicates the driver is ready for

command.

S

7

=1:

indicates the driver is Busy.

S

6

=0:

indicates reverse segment mapping with

column address.

S

6

=1:

indicates normal segment mapping with

column address.

S

5

=0:

indicates the display is ON.

S

5

=1:

indicates the display is OFF.

S

4

=0:

initialization is completed.

S

4

=1:

initialization process is in progress after

RES or software reset.

S

3

S

2

S

1

S

0

= 1001, the 4-bit is fixed to 1001 which

could be used to identify as Solomon-Systech

Device.

Table 9 - Read Command Table (R/

W

bit =1)

Change

of data is

allowed

data line is

stable; data is

valid

SDA

SCL

Solomon Systech

Jan 2003

P 24/40 Rev 1.3

SSD0817

COMMAND DESCRIPTIONS

Set Lower Column Address

This command specifies the lower nibble of the 8-bit column address of the display data RAM. The

column address will be increased by each data access after it is pre-set by the MCU.

Set Higher Column Address

This command specifies the higher nibble of the 8-bit column address of the display data RAM. The

column address will be increased by each data access after it is pre-set by the MCU.

Set Internal Regulator Resistors Ratio

This command is to enable any one of the eight internal resistor sets for different regulator gain when

using internal regulator resistor network (IRS pin pulled high). In other words, this command is used to

select which contrast curve from the eight possible selections. Please refer to Functional Block

Descriptions section for detail calculation of the LCD driving voltage.

Set Power Control Register

This command turns on/off the various power circuits associated with the chip. There are three related

power sub-circuits could be turned on/off by this command.

Internal voltage booster is used to generate the negative voltage supply (V

EE

) from the voltage input

(V

SS1

- V

DD

). An external negative power supply is required if this option is turned off.

Internal regulator is used to generate the LCD driving voltage, V

L6

, from the negative power supply,

V

EE

.

Output op-amp buffer is the internal divider for dividing the different voltage levels (V

L2

, V

L3

, V

L4

, V

L5

)

from the internal regulator output, V

L6

. External voltage sources should be fed into this driver if this

circuit is turned off.

Set Display Start Line

This command is to set Display Start Line register to determine starting address of display RAM to be

displayed by selecting a value from 0 to 63. With value equals to 0, D0 of Page 0 is mapped to COM0.

With value equals to 1, D1 of Page0 is mapped to COM0 and so on. Display start line values of 0 to

63 are assigned to Page 0 to 7.

Please refer to Table 4 on Page 12 as an example for display start line set to 56 (38h).

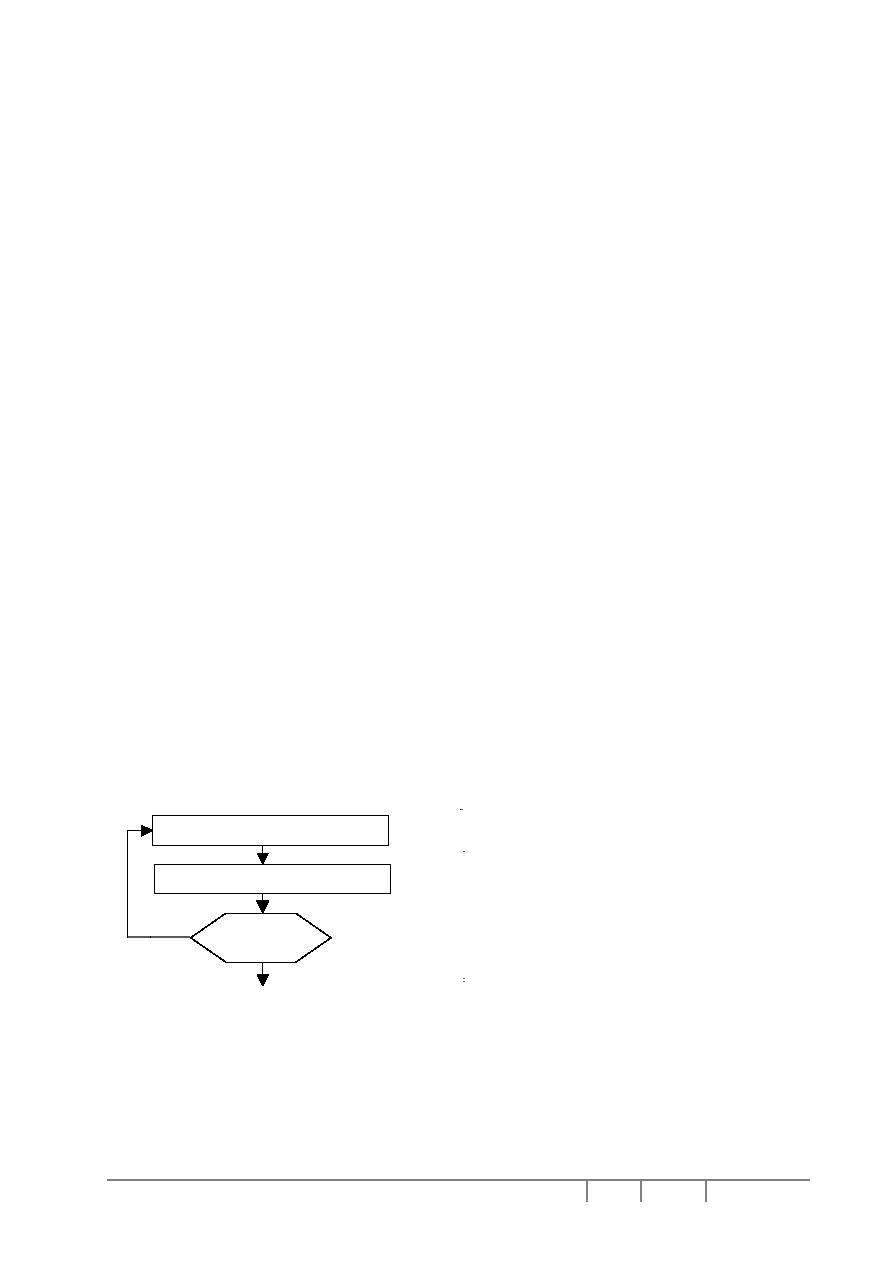

Set Contrast Control Register

This command adjusts the contrast of the LCD panel by changing the LCD driving voltage, V

L6

,

provided by the On-Chip power circuits. V

L6

is set with 64 steps (6-bit) in the contrast control register

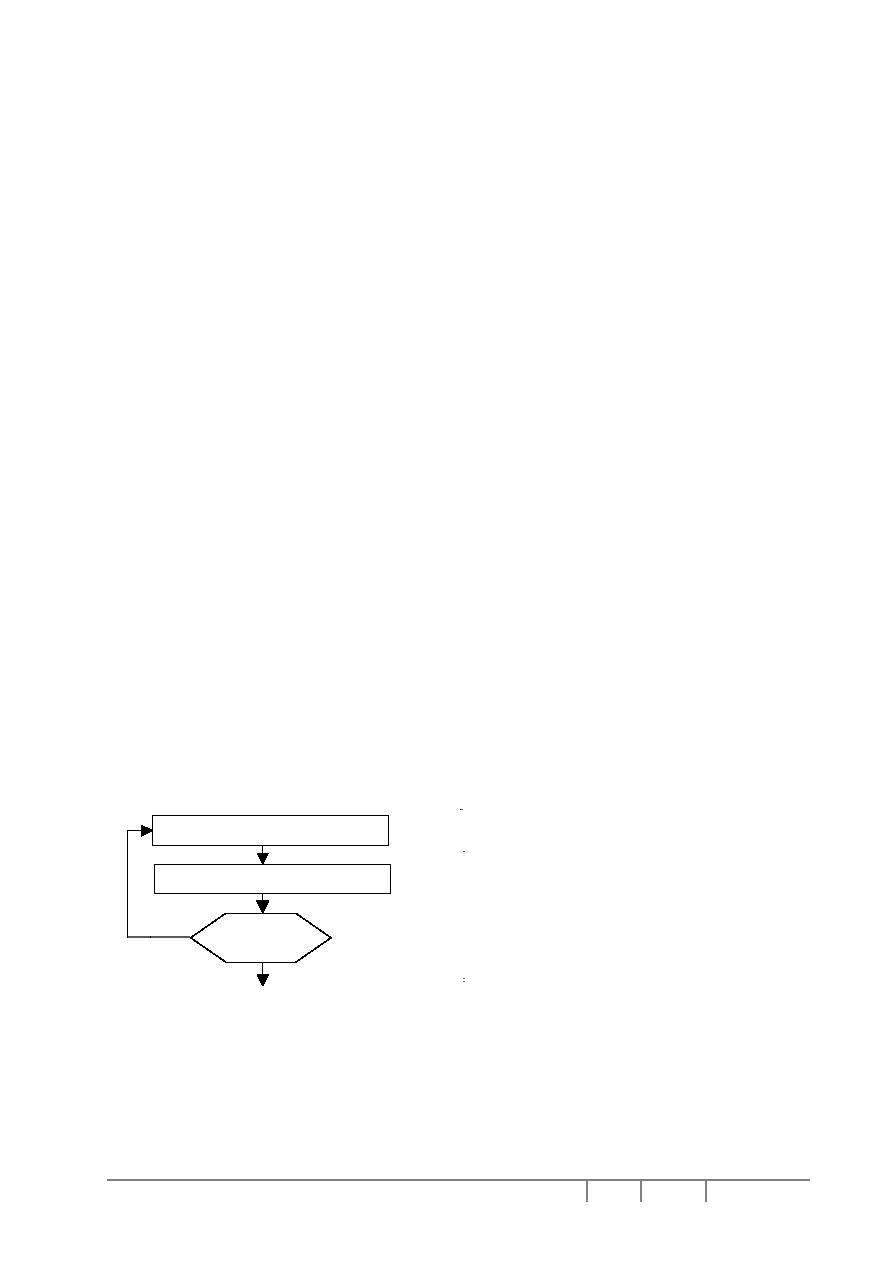

by a set of compound commands. See Figure 11 for the contrast control flow.

Figure 11 - Contrast Control Flow

Changes

Complete?

No

Yes

Set Contrast Control Register

Contrast Level Data

SSD0817

Rev 1.3

P 25/40 Jan 2003

Solomon Systech

Set Segment Re-map

This command changes the mapping between the display data column addresses and segment

drivers. It allows flexibility in mechanical layout of LCD glass design. Please refer to Table 4 on Page

12 for example.

Set LCD Bias

This command is used to select a suitable bias ratio required for driving the particular LCD panel in

use.

The selectable values of this command for 64 MUX are 1/9 or 1/7.

For other bias ratio settings, extended commands should be used.

Set Entire Display On/Off

This command forces the entire display, including the icon row, to be illuminated regardless of the

contents of the GDDRAM. In addition, this command has higher priority than the normal/inverse

display.

This command is used together with "Set Display ON/OFF" command to form a compound command

for entering power save mode. See "Set Power Save Mode" later in this section.

Set Normal/Inverse Display

This command turns the display to be either normal or inverse. In normal display mode, a RAM data

of 1 indicates an illumination on the corresponding pixel. In inverse display mode, a RAM data of 0 will

turn on the pixel.

It should be noted that the icon line is not affect. The icon line is not inversed by this

command.

Set Display On/Off

This command is used to turn the display on or off. When display off is issued with entire display is on,

power save mode will be entered. See "Set Power Save Mode" later in this section for details.

Set Page Address

This command enters the page address from 0 to 8 to the RAM page register for read/write

operations. Please refer to Table 4 on Page 12 for detail mapping.

Set COM Output Scan Direction

This command sets the scan direction of the COM output allowing layout flexibility in LCD module

assembly. See Table 4 on Page 12 for the relationship between turning on or off of this feature.

In addition, the display will have immediate effect once this command is issued. That is, if this

command is sent during normal display, the graphic display will have vertical flipping effect.

Set Read-Modify-Write Mode

This command puts the chip in read-modify-write mode in which:

1. The column address is saved before entering the mode

2. The column address is increased only after display data write but not after display data read.

This Read-Modify-Write mode is used to save the MCU 's loading when a very portion of display area

is being updated frequently.

As reading the data will not change the column address, it could be get back from the chip and do

some operation in the MCU. Then the updated data could be written back to the GDDRAM with

automatic address increment.

After updating the area, "Set End of Read-Modify-Write Mode" is sent to restore the column address

and ready for next update sequence.

Solomon Systech

Jan 2003

P 26/40 Rev 1.3

SSD0817

Software Reset

Issuing this command causes some of the chip's internal status registers to be initialized:

Read-Modify-Write mode is off

Static indicator is turned OFF

Display start line register is cleared to 0

Column address counter is cleared to 0

Page address is cleared to 0

Normal scanning direction of the COM outputs

Internal regulator resistors Ratio is set to 4

Contrast control register is set to 20h

Set End of Read-Modify-Write Mode