| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: 39SF020 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1

2 Megabit (256K x 8) Multi-Purpose Flash

SST39SF020

Preliminary Specifications

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

© 1998 Silicon Storage Technology, Inc. The SST logo and SuperFlash are registered trademarks of Silicon Storage Technology, Inc. MPF is a trademark of Silicon storage Technology, Inc.

326-10 12/98

These specifications are subject to change without notice.

FEATURES:

∑

Organized as 256 K X 8

∑

Single 5.0V Read and Write Operations

∑

Superior Reliability

≠ Endurance: 100,000 Cycles (typical)

≠ Greater than 100 years Data Retention

∑

Low Power Consumption:

≠ Active Current: 20 mA (typical)

≠ Standby Current: 10 µA (typical)

∑

Sector Erase Capability

≠ Uniform 4 KByte sectors

∑

Fast Read Access Time:

≠ 70 and 90 ns

∑

Latched Address and Data

∑

Fast Sector Erase and Byte Program:

≠ Sector Erase Time: 7 ms (typical)

≠ Chip Erase Time: 15 ms (typical)

≠ Byte Program time: 20 µs (typical)

≠ Chip Rewrite Time: 5 seconds (typical)

∑

Automatic Write Timing

- Internal V

pp

Generation

∑

End of Write Detection

≠ Toggle Bit

≠ Data# Polling

∑

TTL I/O Compatibility

∑

JEDEC Standard

≠ EEPROM Pinouts and command set

∑

Packages Available

≠ 32-Pin PDIP

≠ 32-Pin PLCC

≠ 32-Pin TSOP (8mm x 14mm)

PRODUCT DESCRIPTION

The SST39SF020 is a 256K x 8 CMOS Multi-Purpose

Flash (MPF) manufactured with SST's proprietary, high

performance CMOS SuperFlash technology. The split

gate cell design and thick oxide tunneling injector attain

better reliability and manufacturability compared with

alternate approaches. The SST39SF020 device writes

(Program or Erase) with a 5.0V-only power supply. The

SST39SF020 device conforms to JEDEC standard

pinouts for x8 memories.

Featuring high performance byte program, the

SST39SF020 device provides a maximum byte-pro-

gram time of 30 µsec. The entire memory can be erased

and programmed byte by byte typically in 5 seconds,

when using interface features such as Toggle Bit or

Data# Polling to indicate the completion of Program

operation. To protect against inadvertent write, the

SST39SF020 device has on-chip hardware and soft-

ware data protection schemes. Designed, manufac-

tured, and tested for a wide spectrum of applications, the

SST39SF020 device is offered with a guaranteed endur-

ance of 10,000 cycles. Data retention is rated at greater

than 100 years.

The SST39SF020 device is suited for applications that

require convenient and economical updating of program,

configuration, or data memory. For all system applica-

tions, the SST39SF020 device significantly improves

performance and reliability, while lowering power

consumption. The SST39SF020 inherently uses less

energy during erase and program than alternative flash

technologies. The total energy consumed is a function of

the applied voltage, current, and time of application.

Since for any given voltage range, the SuperFlash tech-

nology uses less current to program and has a shorter

erase time, the total energy consumed during any Erase

or Program operation is less than alternative flash tech-

nologies. The SST39SF020 device also improves flex-

ibility while lowering the cost for program, data, and

configuration storage applications.

The SuperFlash technology provides fixed Erase and

Program times, independent of the number of endurance

cycles that have occurred. Therefore the system soft-

ware or hardware does not have to be modified or de-

rated as is necessary with alternative flash technologies,

whose erase and program times increase with accumu-

lated endurance cycles.

To meet high density, surface mount requirements, the

SST39SF020 device is offered in 32-pin TSOP and 32-

pin PLCC packages. A 600 mil, 32-pin PDIP is also

available. See Figures 1 and 2 for pinouts.

Device Operation

Commands are used to initiate the memory operation

functions of the device. Commands are written to the

device using standard microprocessor write sequences.

A command is written by asserting WE# low while

2

© 1998 Silicon Storage Technology, Inc.

326-10 12/98

2 Megabit Multi-Purpose Flash

SST39SF020

Preliminary Specifications

keeping CE# low. The address bus is latched on the

falling edge of WE# or CE#, whichever occurs last. The

data bus is latched on the rising edge of WE# or CE#,

whichever occurs first.

Read

The Read operation of the SST39SF020 device is con-

trolled by CE# and OE#, both have to be low for the

system to obtain data from the outputs. CE# is used for

device selection. When CE# is high, the chip is dese-

lected and only standby power is consumed. OE# is the

output control and is used to gate data from the output

pins. The data bus is in high impedance state when either

CE# or OE# is high. Refer to the Read cycle timing

diagram for further details (Figure 3).

Byte Program Operation

The SST39SF020 device is programmed on a byte-by-

byte basis. The Program operation consists of three

steps. The first step is the three-byte-load sequence for

Software Data Protection. The second step is to load

byte address and byte data. During the Byte Program

operation, the addresses are latched on the falling edge

of either CE# or WE#, whichever occurs last. The data is

latched on the rising edge of either CE# or WE#, which-

ever occurs first. The third step is the internal Program

operation which is initiated after the rising edge of the

fourth WE# or CE#, whichever occurs first. The Program

operation, once initiated, will be completed, within 30 µs.

See Figures 4 and 5 for WE# and CE# controlled

Program operation timing diagrams and Figure 14 for

flowcharts. During the Program operation, the only valid

reads are Data# Polling and Toggle Bit. During the

internal Program operation, the host is free to perform

additional tasks. Any commands written during the inter-

nal Program operation will be ignored.

Sector Erase Operation

The Sector Erase operation allows the system to erase

the device on a sector by sector basis. The sector

architecture is based on uniform sector size of 4 KByte.

The Sector Erase operation is initiated by executing a

six-byte-command load sequence for software data pro-

tection with sector erase command (30H) and sector

address (SA) in the last bus cycle. The address lines

A12-A17 will be used to determine the sector address.

The sector address is latched on the falling edge of the

sixth WE# pulse , while the command (30H) is latched on

the rising edge of the sixth WE# pulse. The internal Erase

operation begins after the sixth WE# pulse. The end of

Erase can be determined using either Data# Polling or

Toggle Bit methods. See Figure 8 for timing waveforms.

Any commands written during the Sector Erase opera-

tion will be ignored.

Chip-Erase Operation

The SST39SF020 device provides a Chip-Erase opera-

tion, which allows the user to erase the entire memory

array to the "1's" state. This is useful when the entire

device must be quickly erased.

The Chip Erase operation is initiated by executing a six-

byte software data protection command sequence with

Chip Erase command (10H) with address 5555H in the

last byte sequence. The Erase operation begins with the

rising edge of the sixth WE# or CE#, whichever occurs

first. During the Erase operation, the only valid read is

Toggle Bit or Data# Polling. See Table 4 for the command

sequence, Figure 9 for timing diagram, and Figure 17 for

the flowchart. Any commands written during the Chip

Erase operation will be ignored.

Write Operation Status Detection

The SST39SF020 device provides two software means

to detect the completion of a Write (Program or Erase)

cycle, in order to optimize the system write cycle time.

The software detection includes two status bits : Data#

Polling (DQ

7

) and Toggle Bit (DQ

6

). The end of write

detection mode is enabled after the rising edge of WE#

which initiates the internal program or erase cycle.

The actual completion of the nonvolatile write is asyn-

chronous with the system; therefore, either a Data#

Polling or Toggle Bit read may be simultaneous with the

completion of the Write cycle. If this occurs, the system

may possibly get an erroneous result, i.e., valid data may

appear to conflict with either DQ

7

or DQ

6

. In order to

prevent spurious rejection, if an erroneous result occurs,

the software routine should include a loop to read the

accessed location an additional two (2) times. If both

reads are valid, then the device has completed the Write

cycle, otherwise the rejection is valid.

Data# Polling (DQ

7

)

When the SST39SF020 device is in the internal Program

operation, any attempt to read DQ

7

will produce the

complement of the true data. Once the Program opera-

tion is completed, DQ

7

will produce true data. The device

is then ready for the next operation. During internal Erase

operation, any attempt to read DQ7 will produce a `0'.

Once the internal Erase operation is completed, DQ7 will

produce a `1'. The Data# Polling is valid after the rising

edge of fourth WE# (or CE#) pulse for Program opera-

tion. For sector or chip erase, the Data# Polling is valid

after the rising edge of sixth WE# (or CE#) pulse. See

Figure 6 for Data# Polling timing diagram and Figure 15

for a flowchart.

3

© 1998 Silicon Storage Technology, Inc.

326-10 12/98

2 Megabit Multi-Purpose Flash

SST39SF020

Preliminary Specifications

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Toggle Bit (DQ

6

)

During the internal Program or Erase operation, any con-

secutive attempts to read DQ

6

will produce alternating 0's

and 1's, i.e., toggling between 0 and 1. The Toggle Bit will

begin with "1". When the internal Program or Erase opera-

tion is completed, the toggling will stop. The device is then

ready for the next operation. The Toggle Bit is valid after the

rising edge of fourth WE# (or CE#) pulse for Program

operation. For Sector or Chip Erase, the Toggle Bit is valid

after the rising edge of sixth WE# (or CE#) pulse. See

Figure 7 for Toggle Bit timing diagram and Figure 15 for a

flowchart.

Data Protection

The SST39SF020 device provides both hardware and

software features to protect nonvolatile data from inadvert-

ent writes.

Hardware Data Protection

Noise/Glitch Protection: A WE# or CE# pulse of less than

5 ns will not initiate a write cycle.

V

CC

Power Up/Down Detection: The write operation is

inhibited when V

CC

is less than 2.5V.

Write Inhibit Mode: Forcing OE# low, CE# high, or WE#

high will inhibit the Write operation. This prevents inadvert-

ent writes during power-up or power-down.

Software Data Protection (SDP)

The SST39SF020 provides the JEDEC approved soft-

ware data protection scheme for all data alteration opera-

tions, i.e., Program and Erase. Any Program operation

requires the inclusion of a series of three byte sequence.

The three byte-load sequence is used to initiate the Pro-

gram operation, providing optimal protection from inad-

vertent write operations, e.g., during the system power-up

or power-down. Any Erase operation requires the inclusion

of six byte load sequence. The SST39SF020 device is

shipped with the software data protection permanently

enabled. See Table 4 for the specific software command

codes. During SDP command sequence, invalid com-

mands will abort the device to read mode, within TRC.

Product Identification

The product identification mode identifies the device as the

SST39SF020 and manufacturer as SST. This mode may

be accessed by hardware or software operations. The

hardware operation is typically used by a programmer to

identify the correct algorithm for the SST39SF020 device.

Users may wish to use the software product identification

operation to identify the part (i.e., using the device code)

when using multiple manufacturers in the same socket. For

details, see Table 3 for hardware operation or Table 4 for

software operation, Figure 10 for the software ID entry and

read timing diagram and Figure 16 for the ID entry com-

mand sequence flowchart.

Product Identification Mode Exit/Reset

In order to return to the standard read mode, the Software

Product Identification mode must be exited. Exiting is

accomplished by issuing the Exit ID command sequence,

which returns the device to the Read operation. Please

note that the software reset command is ignored during an

internal Program or Erase operation. See Table 4 for

software command codes, Figure 11 for timing waveform

and Figure 16 for a flowchart.

F

UNCTIONAL

B

LOCK

D

IAGRAM

OF

SST39SF020

T

ABLE

1: P

RODUCT

I

DENTIFICATION

T

ABLE

Address

Data

Manufacturer's Code

0000H

BF H

Device Code

0001H

B6 H

326 PGM T1.2

Y-Decoder

I/O Buffers and Data Latches

326 ILL B1.3

Address Buffers & Latches

X-Decoder

DQ7 - DQ0

A17 - A0

OE#

CE#

WE#

2,097,152 bit

EEPROM

Cell Array

Control Logic

4

© 1998 Silicon Storage Technology, Inc.

326-10 12/98

2 Megabit Multi-Purpose Flash

SST39SF020

Preliminary Specifications

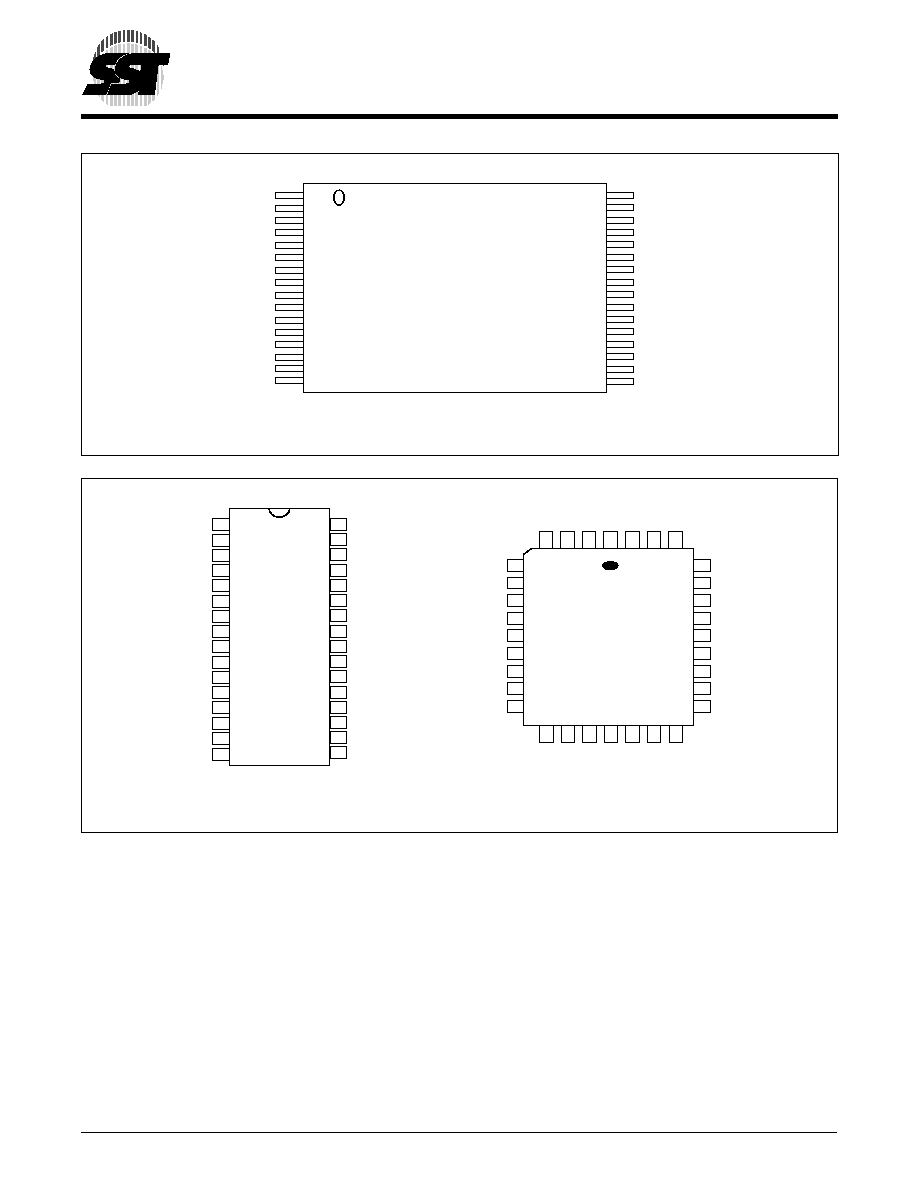

F

IGURE

1: P

IN

A

SSIGNMENTS

FOR

32-

PIN

TSOP P

ACKAGES

(8mm x 14mm)

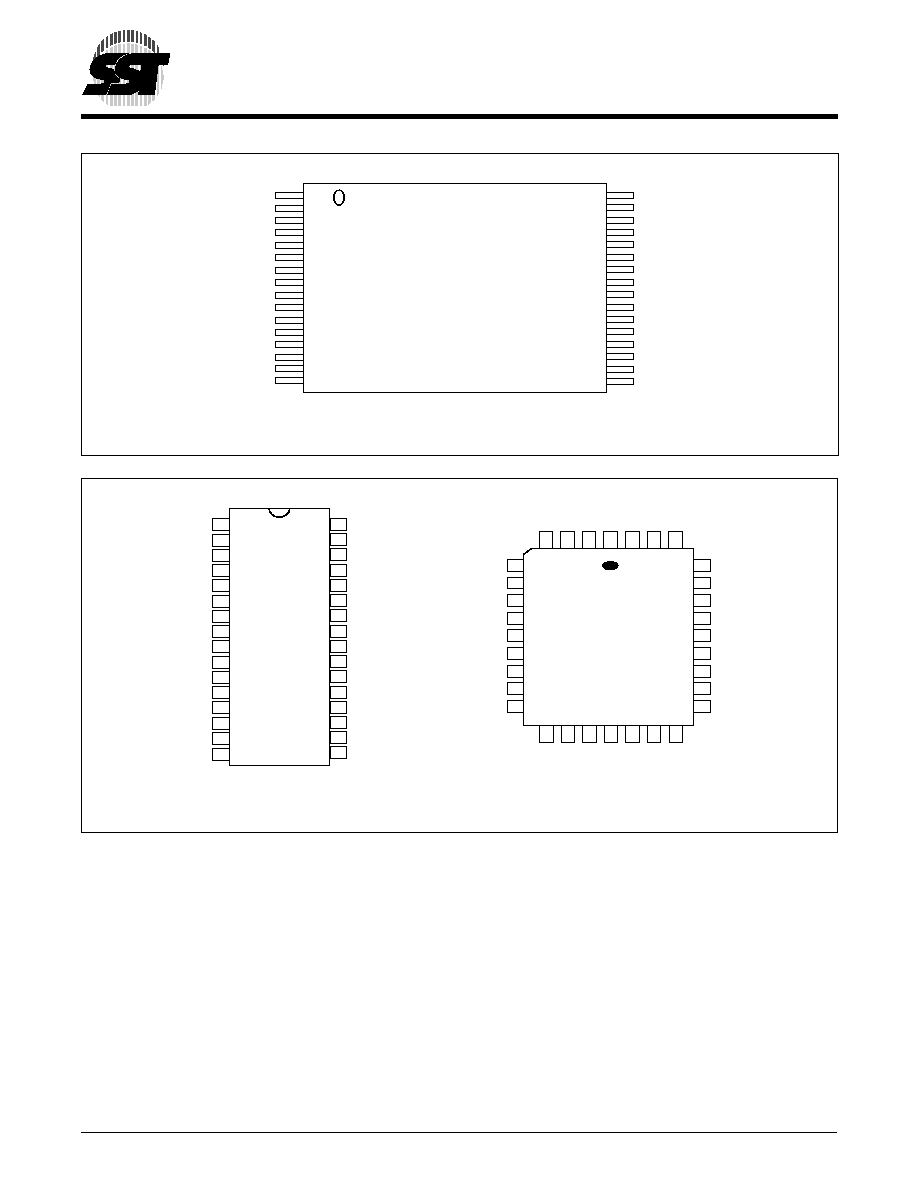

F

IGURE

2: P

IN

A

SSIGNMENTS

FOR

32-

PIN

PDIP

S

AND

32-

LEAD

PLCC

S

A11

A9

A8

A13

A14

A17

WE#

VCC

NC

A16

A15

A12

A7

A6

A5

A4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

OE#

A10

CE#

DQ7

DQ6

DQ5

DQ4

DQ3

VSS

DQ2

DQ1

DQ0

A0

A1

A2

A3

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

326 ILL F01.0

Standard Pinout

Top View

Die Up

5

6

7

8

9

10

11

12

13

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

29

28

27

26

25

24

23

22

21

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

A14

A13

A8

A9

A11

OE#

A10

CE#

DQ7

4 3 2 1 32 31 30

A12

A15

A16

NC

V

CC

WE#

A17

32-Lead PLCC

Top View

32-Pin

PDIP

Top View

326 ILL F02.0

14 15 16 17 18 19 20

DQ1

DQ2

V

SS

DQ3

DQ4

DQ5

DQ6

NC

A16

A15

A12

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

DQ1

DQ2

VSS

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

VCC

WE#

A17

A14

A13

A8

A9

A11

OE#

A10

CE#

DQ7

DQ6

DQ5

DQ4

DQ3

5

© 1998 Silicon Storage Technology, Inc.

326-10 12/98

2 Megabit Multi-Purpose Flash

SST39SF020

Preliminary Specifications

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

T

ABLE

2: P

IN

D

ESCRIPTION

Symbol

Pin Name

Functions

A

17

-A

0

Address Inputs

To provide memory addresses. During sector erase A

17

-A

12

address lines

will select the sector.

DQ

7

-DQ

0

Data Input/output

To output data during read cycles and receive input data during write

cycles. Data is internally latched during a write cycle. The outputs are in

tri-state when OE# or CE# is high.

CE#

Chip Enable

To activate the device when CE# is low.

OE#

Output Enable

To gate the data output buffers.

WE#

Write Enable

To control the write operations.

Vcc

Power Supply

To provide 5-volt supply (± 10%)

Vss

Ground

NC

No Connection

Unconnected pins.

326 PGM T2.1

T

ABLE

3: O

PERATION

M

ODES

S

ELECTION

Mode

CE#

OE#

WE#

A9

DQ

Address

Read

V

IL

V

IL

V

IH

A

IN

D

OUT

A

IN

Program

V

IL

V

IH

V

IL

A

IN

D

IN

A

IN

Erase

V

IL

V

IH

V

IL

X

X

Sector address, XXh for

chip erase

Standby

V

IH

X

X

X

High Z

X

Write Inhibit

X

V

IL

X

X

High Z/D

OUT

X

X

X

V

IH

X

High Z/D

OUT

X

Product Identification

Hardware Mode

V

IL

V

IL

V

IH

V

H

Manufacturer Code (BF)

A

17

- A

1

= V

IL

, A

0

= V

IL

Device Code (B6)

A

17

- A

1

= V

IL

, A

0

= V

IH

Software Mode

V

IL

V

IL

V

IH

A

IN

ID Code

See Table 4

326 PGM T3.4