| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: 10006F1 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1/6

EMIF06-10006F1

Æ

March 2004 - Ed: 2

Flip-Chip package

Æ

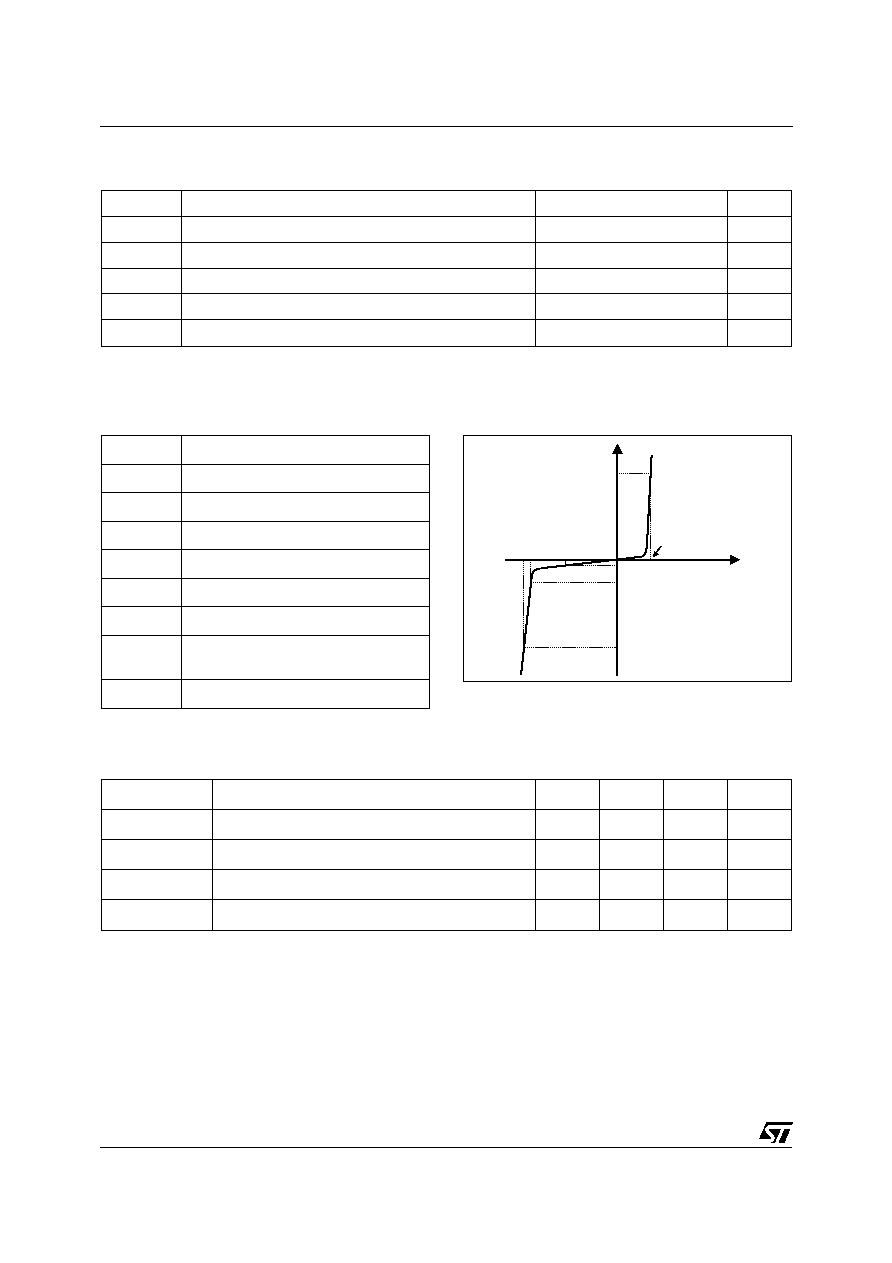

I4

O4

I1

O1

I6

Gnd

Gnd

Gnd

O6

I3

O3

I5

O5

I2

O2

9

8

7

6

5

4

3

2

1

A

B

C

PIN CONFIGURATION (ball side)

6 LINES EMI FILTER

AND ESD PROTECTION

IPAD

TM

TM : IPAD is a trademark of STMicroelectronics.

IEC 61000-4-2 level 4:

15kV

(air discharge)

8 kV

(contact discharge)

MIL STD 883E - Method 3015-6 Class 3: 30kV

COMPLIES WITH THE FOLLOWING STANDARDS :

EMI symmetrical (I/O) low-pass filter

High efficiency in EMI filtering

Very low PCB space consuming:

2.92mm x 1.29mm

Very thin package: 0.65 mm

High efficiency in ESD suppression

(IEC61000-4-2 level 4)

High reliability offered by monolithic integration

High reducing of parasitic elements through

integration and wafer level packaging.

BENEFITS

Where EMI filtering in ESD sensitive equipment is

required:

Mobile phones

Computers and printers

Communication systems

MCU Boards

MAIN PRODUCT CHARACTERISTICS

The EMIF06-10006F1 is a highly integrated devices

designed to suppress EMI/RFI noise in all systems

subjected to electromagnetic interferences. The

EMIF06 flip-chip packaging means the package size

is equal to the die size.

This filter includes an ESD protection circuitry which

prevents the device from destruction when subjected

to ESD surges up 15kV. This device includes 6 EMIF

filters.

DESCRIPTION

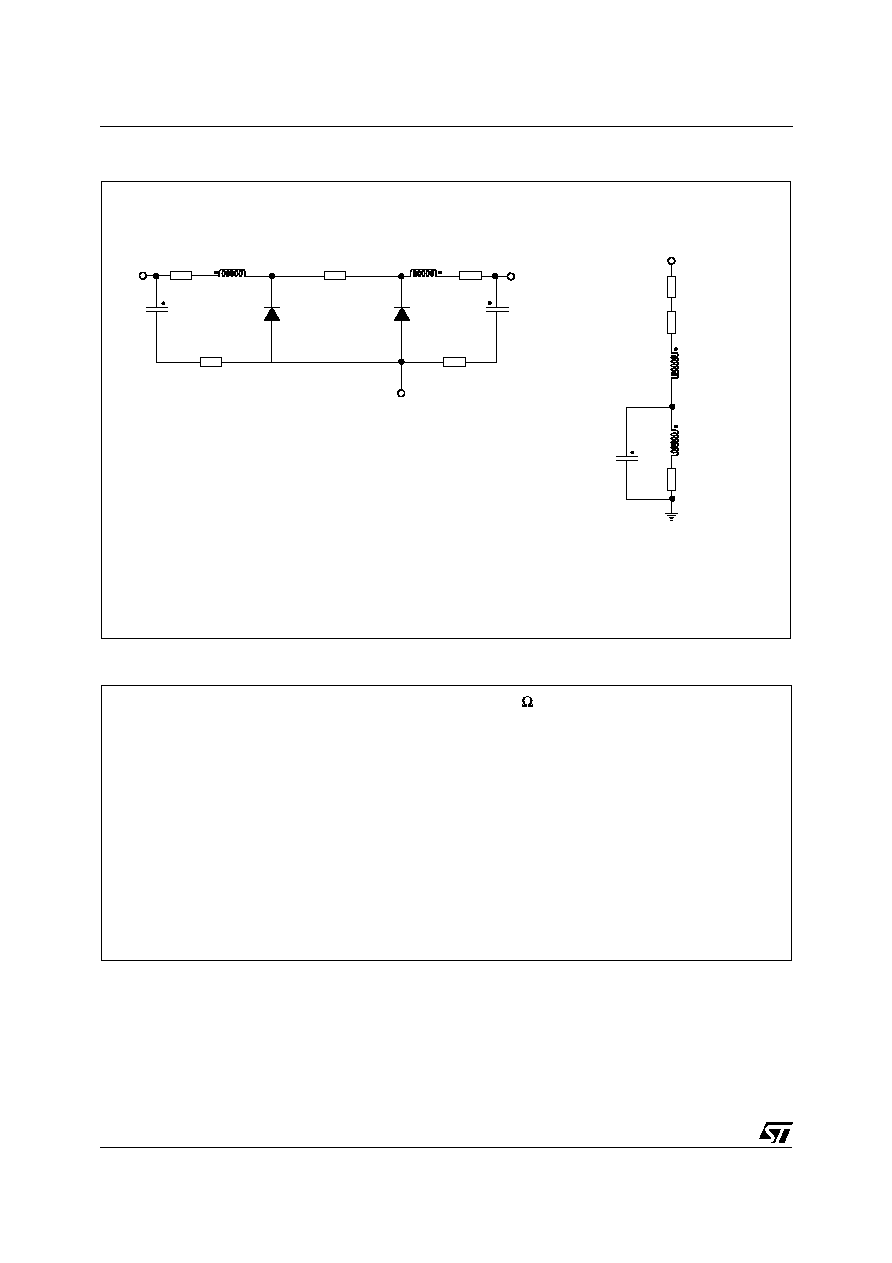

Output 4

Input 1

30pF

30pF

100

Output 1

Input 4

30pF

30pF

100

Output 5

Input 5

30pF

30pF

100

Output 6

Input 6

30pF

30pF

100

Input 2

30pF

30pF

100

Output 2

Input 3

30pF

30pF

100

Output 3

BASIC CELL CONFIGURATION

EMIF06-10006F1

2/6

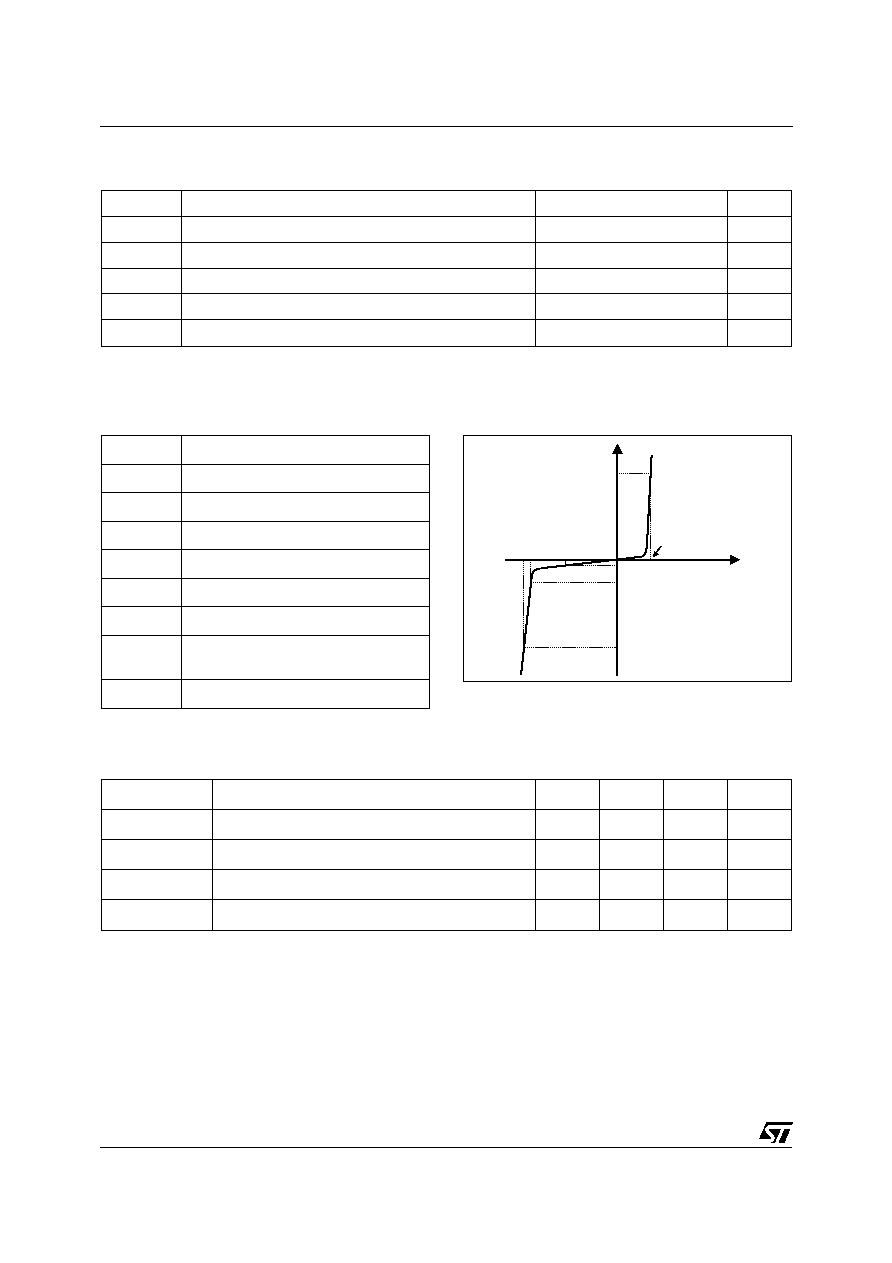

Symbol

Parameter and test conditions

Value

Unit

P

R

DC power per resistance

0.1

W

P

T

Total DC power per package

0.6

W

T

j

Maximum junction temperature

125

∞C

T

op

Operating temperature range

-40 to + 85

∞C

T

stg

Storage temperature range

125

∞C

ABSOLUTE RATINGS (limiting values)

Symbol

Parameter

V

BR

Breakdown voltage

I

RM

Leakage current @ V

RM

V

RM

Stand-off voltage

V

CL

Clamping voltage

R

d

Dynamic impedance

I

PP

Peak pulse current

R

I/O

Series resistance between Input

and Output

C

line

Capacitance per line

ELECTRICAL CHARACTERISTICS (T

amb

= 25 ∞C)

I

V

I

F

V

F

I

RM

I

R

I

PP

V

RM

V

BR

V

CL

Symbol

Test conditions

Min.

Typ.

Max.

Unit

V

BR

I

R

= 1 mA

5.5

7

9

V

I

RM

V

RM

= 3.3 V per line

500

nA

R

I/O

I = 10 mA

80

100

120

C

line

V

R

= 2.5 V, F = 1 MHz, 30 mV (on filter cells)

50

60

70

pF

EMIF06-10006F1

3/6

100.0k

1.0M

10.0M

100.0M

1.0G

-50.00

-37.50

-25.00

-12.50

0.00

dB

f/Hz

Simulation

Measurement

100.0k

1.0M

10.0M

100.0M

1.0G

-50.00

-37.50

-25.00

-12.50

0.00

dB

f/Hz

Simulation

Measurement

Simulation

Measurement

Fig. 1: S21 (dB) attenuation measurements and

Aplac simulation.

Aplac 7.62 User: ST Microelectronics

100k

1M

10M

100M

1G

00

-25

-50

-75

-100

Aplac 7.62 User: ST Microelectronics

dB

dB

i3_o2.s2p

f/Hz

Fig. 2: Analog crosstalk measurements.

Fig. 3: Digital crosstalk measurements.

Fig. 4: ESD response to IEC61000-4-2 (+15kV air

discharge) on one input V(in) and one output V(out).

Fig. 5: ESD response to IEC61000-4-2 (-15kV air

discharge) on one input V(in) and one output V(out).

0

10

20

30

40

50

60

70

80

90

100

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

V (V)

R

C(pF)

F=1MHz

V

osc

=30mV

RMS

T

j

=25∞C

Fig. 6: Line capacitance versus applied voltage for

filter.

EMIF06-10006F1

4/6

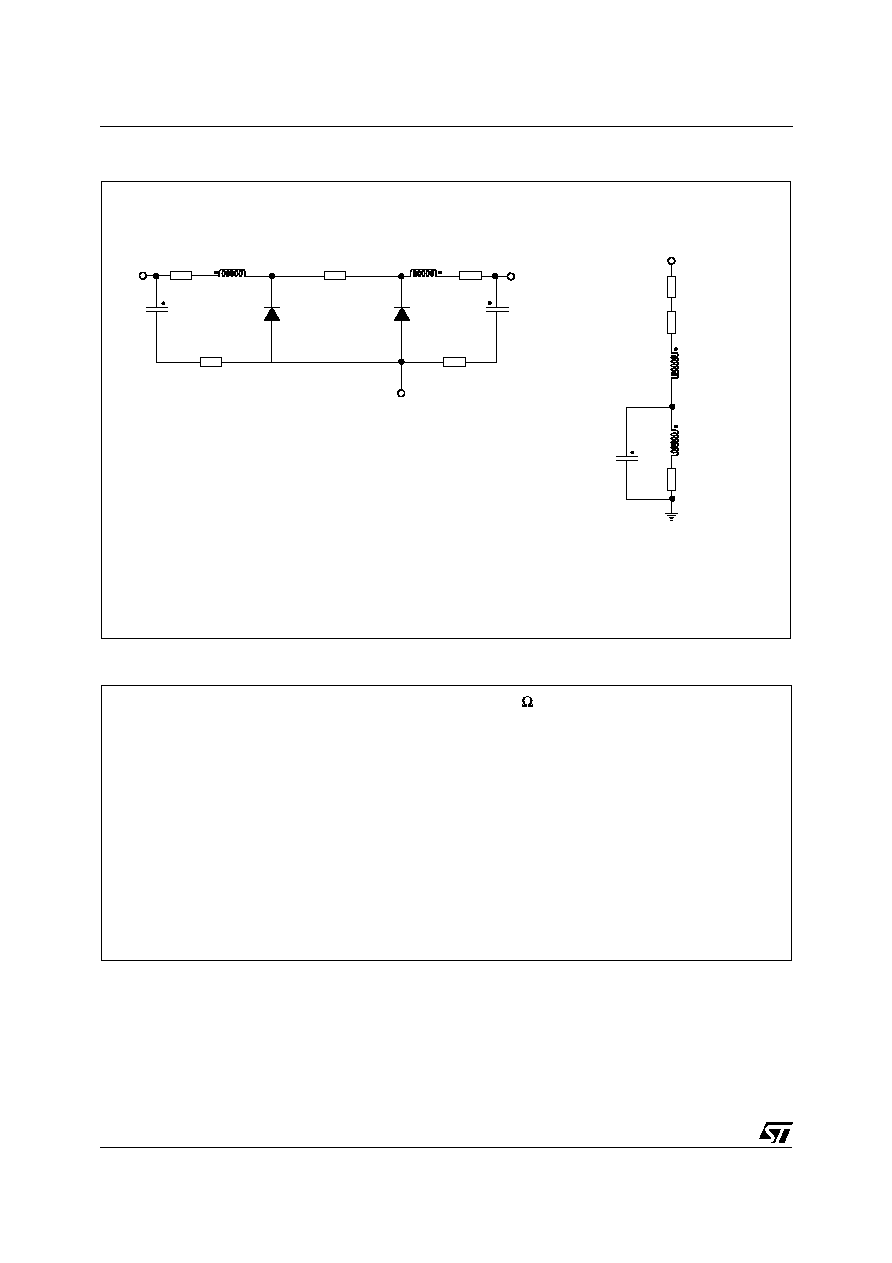

Oi * = Output of each cell

Ii* = Input of each cell

Oi*

Cz=41pF@0V

Cz=41pF@0V

sub

Rs=100

Lbump

Rbump

Rsub

Cbump

Ii*

Rsub

Lbump

Rbump

Cbump

sub

Lbump

Rbump

sub

Rsub

Lgnd

Rgnd

Cgnd

Cgnd

Cgnd

EMIF06-10006F1 model

Ground return for each GND bump

Aplac model

aplacvar Rs

100

aplacvar Cz

41 pF

aplacvar Lbump

50 pH

aplacvar Rbump

20 m

aplacvar Cbump

1.2 pF

aplacvar Rsub

100 m

aplacvar Rgnd

100 m

aplacvar Lgnd

100 pH

aplacvar Cgnd

0.15 pF

Aplac parameters

EMIF06-10006F1

5/6

EMIF yy

xxx zz F 1

-

EMI Filter

Number of lines

x: resistance value ( ) z: capacitance value / 10 (pF)

or

application (3 letters) and version (2 digits)

FLIP CHIP

Pitch = 500µm

Bump = 315µm

ORDER CODE

2.92mm ± 50µm

1.29mm ± 50µm

435µm ± 50

315µm ± 50

501µm

±

50

500µm ± 50

250µm ± 50

650µm ± 65

PACKAGE MECHANICAL DATA

545

545

400

100

230

x

y

x

w

x

w

Dot, ST logo

xxx = marking

yww = datecode

(y = year

ww = week)

All dimensions in µm

MARKING

Copper pad Diameter :

250µm recommended , 300µm max

Solder stencil opening : 330µm

Solder mask opening recommendation :

340µm min for 300µm copper pad diameter

FOOT PRINT RECOMMENDATIONS