| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: L497B | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

L497

March 1998

HALL EFFECT PICKUP IGNITION CONTROLLER

.

DIRECT

DRIVING

OF

THE

EXTERNAL

POWER DARLINGTON

.

COIL CURRENT CHARGING ANGLE (dwell)

CONTROL

.

PROGRAMME COIL CURRENT PEAK LIMITA-

TION

.

PROGRAMMABLE DWELL RECOVERY TIME

WHEN 94 % NOMINAL CURRENT NOT

REACHED

.

RPM OUTPUT

.

PERMANENT CONDUCTION PROTECTION

.

OVERVOLTAGE PROTECTION FOR EXTER-

NAL DARLINGTON

.

INTERNAL SUPPLY ZENER

.

REVERSE BATTERY PROTECTION

DESCRIPTION

The L497 is an integratedelectronic ignition control-

ler for breakerless ignition systems using Hall effect

sensors.

ORDERING NUMBERS : L497B (DIP16)

L497D1 (SO16)

DIP16

SO16

The device drives an NPN external darlington to

control the coil current providingthe required stored

energy with low dissipation.

A special feature of the L497 is the programmable

time for the recovery of the correct dwell ratio T

d

/T

when the coil peak current fails to reach 94 % of the

nominal value. In this way only one spark may have

an energy less than 94 % of the nominal one during

fast acceleration or cold starts.

BLOCK DIAGRAM

1/11

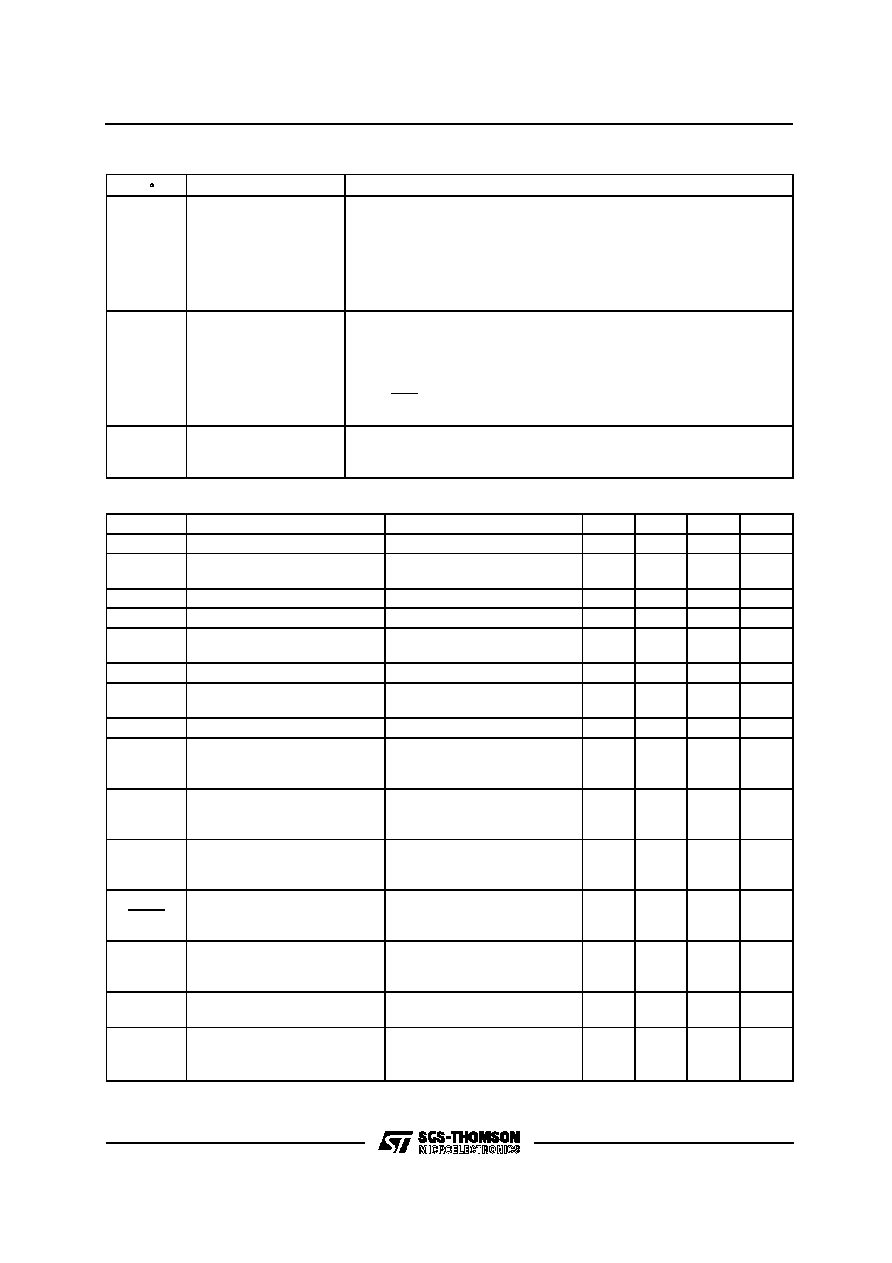

ABSOLUTE MAXIMUM RATINGS

Symbol

Parameter

Value

Unit

I

3

D.C. Supply current

Transient Supply Current (t

f

fall time constant = 100ms)

200

800

mA

mA

V

3

Supply Voltage

Int. Limited to Vz

3

V

6

RPM Voltage

28

V

I

16

D.C. Driver Collector Current

Pulse "

"(t <= 3ms)

300

600

mA

mA

V

16

Driver Collector Voltage

28

V

I

7

Auxiliary Zener Current

40

mA

I

15

D.C. Overvoltage Zener Current

Pulse "

" t

fall

= 300

µ

s,

tr

ep

Repetition Time > = 3ms

15

35

mA

mA

V

R

Reverse Battery Voltage if Application Circuit of Fig. 4 is used

≠ 16

V

T

j

, T

stg

Junction and StorageTemperature Range

≠ 55 to 150

∞

C

P

tot

Power Dissipation

at T

aluminia

= 90

∞

C for SO-16

T

amb

= 90

∞

C for DIP-16

1.2

0.65

W

W

PIN CONNECTION (top view)

THERMAL DATA

Symbol

Parameter

Value

Unit

R

th j-amb

R

th j-alumin

(*)

Thermal Resistance Junction-ambient for DIP-16

Thermal Resistance Junction-alumina for SO-16

Max

Max

90

50

∞

C/W

∞

C/W

(* ) Thermal resistance ju nction-aluminia wi th the device soldered on the mi ddle of an aluminia supporting substrate mesuri ng

15 x 20 ; 0.65 mm thickness.

L497

2/11

PIN FUNCTIONS (refer to fig. 4)

N

∞

Name

Function

1

GND

This pin must be connected to ground.

2

SIGNAL GND

This pin must be connected to ground.

3

POWER SUPPLY

Supply Voltage Input. An internal 7.5 V (typ) zener zener limits the voltage

at this pin. The external resistor R

5

limits the current through the zener for

high supply voltages.

4

N.C.

This pin must be connected to ground or left open.

5

HALL-EFFECT INPUT

Hall-effect Pickup Signal Input. This input is dwell control circuit output in

order to enable the current driving into the coil. The spark occurs at the

high-to-low transition of the hall-effect pickup signal.

Furthermore this input signal enables the slow recovery and permanent

conduction protection circuits. The input signal, supplied by the open

collector output stage of the Hall effect sensor, has a duty-cycle typically

about 70 %. V

5

is internally clamped to V

3

and ground by diodes

6

RPM OUTPUT

Open collector output which is at a low level when current flows in the

ignition coil. For high voltages protection of this output, connection to the

pin 7 zener is recommended.

In this situation R

8

must limit the zener current, too, and R

1

limits pin 6

current if RPM module pad is accidentally connected to V

S

.

7

AUX. ZENER

A 21 V (typ) General Purpose Zener. Its current must be limited by an

external resistor.

8

RECOVERY TIME

A capacitor connected between this pin and ground sets the slope of the

dwell time variation as it rises from zero to the correct value. This occurs

after the detection of I

coll

94 % I

nom

, just before the low transition of the

hall-effect signal pulse.

The duration of the slow recovery is given by :

t

src

= 12,9 R

7

C

src

(ms)

where R

7

is the biasing resistor at pin 12 (in K

) and C

src

is the delay

capacitor at pin 8 (in

µ

F).

9

MAX CONDUCTION

TIME

A capacitor connected between this pin and ground determines the

intervention delay of the permanent conduction protection. After this delay

time the coil current is slowly reduced to zero.

Delay Time T

p

is given by :

T

p

=16 C

p

R

7

(ms)

where R

7

is the biasing resistor at pin 12 (in K

) and C

P

is the delay

capacitor at pin 9 (in

µ

F).

10

DWELL CONTROL

TIMER

A capacitor C

T

connected between this pin and ground is charged when the

HAll effect output is High and is discharged at the High to Low transition of

the Hall effect signal.

The recommended value is 100 nF using a 62 K

resistor at pin 12.

11

DWELL CONTROL

The average voltage on the capacitor CW connected between this pin and

ground depends on the motor speed and the voltage supply. The

comparison between V

CW

and V

CT

voltage determines the timing for the

dwell control. For the optimized operation of the device C

T

= C

W

; the

recommended value is 100 nF using a 62 K

resistor at pin 12.

12

BIAS CURRENT

A resistor connected between this pin and ground sets the internal current

used to drive the external capacitors of the dwell control

(pin 10 and 11) permanent conduction protection (pin 9) and slow recovery

time (pin 8). The recommended value is 62 K

.

13

CURRENT SENSING

Connection for the Coil Current Limitation. The current is measured on the

sensing resitor R

S

and taken through the divider R

10

/R

11

. The current

limitation value is given by :

I

sens

=

0.32

R

10

+

R

11

R

S

R

11

L497

3/11

PIN FUNCTIONS (continued)

N

∞

Name

Function

14

DRIVER EMITT ER

OUTPUT

Current Driver for the External Darlington. To ensure stability and precision

of T

desat

C

c

and R

9

must be used. Recommended value for R

9

is 2 K

in

order not to change the open loop gain of the system.

R

c

may be added to C

c

to obtain greater flexibility in various application

situations.

C

c

and R

c

values ranges are 1 to 100 nF and 5 to 30 K

depending on the

external darlington type.

15

OVERVOLTAGE LIMIT

The darlington is protected against overvoltage by means of an internal

zener available at this pin and connected to pin 14. The internal divider

R

3

/R

2

defines the limitation value given by :

V

ovp

=

22.5

R

3

+

5.10

-

3

R

2

+

22.5

16

DRIVER COLLECTOR

INPUT

The collector current of the internal driver which drives the external

darlington is supplied through this pin. Then the external resistor R

6

limits

the maximum current supplied to the base of the external darlington.

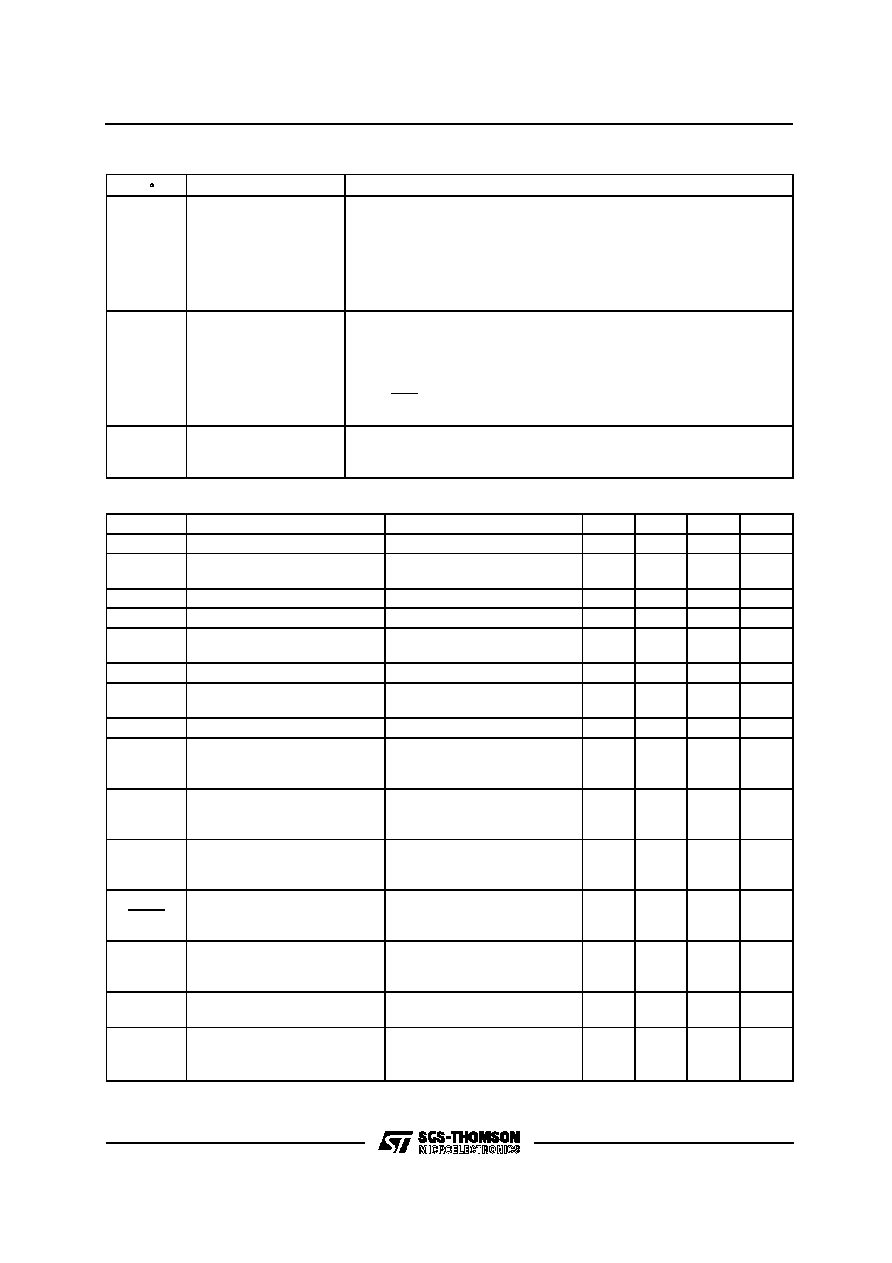

ELECTRICAL CHARACTERISTICS (V

S

= 14.4 V, ≠ 40

∞

C < T

j

< 125

∞

C unless otherwise specified)

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

V

3

Min Op. Voltage

3.5

V

I

3

Supply Current

V

3

= 6 V

V

3

= 4 V

5

7

18

25

13

mA

mA

V

S

Voltage Supply

28

V

V

Z3

Supply Clamping Zener Voltage

I

Z3

= 70 mA

6.8

7.5

8.2

V

V

5

Input Voltage

Low Status

High Status

2.5

0.6

V

V

I

5

Input Current

V

5

= LOW

≠ 400

≠ 50

µ

A

V

16≠14

Darlington Driver Sat. Current

I

14

= 50 mA

I

14

= 180 mA

0.5

0.9

V

V

V

SENS

Current Limit. Sensing Voltage

V

S

= 6 to 16 V

260

320

370

mV

I

11C

C

W

Charge Current

V

S

= 5.3 to 16V

V

11

= 0.5V

T = 10 to 33ms

≠ 11.0

≠ 9.3

≠ 7.8

µ

A

I

11D

CW Charge Current

V

S

= 5.3 to 16V

V

11

= 0.5V

T = 10 to 33ms

0.5

0.7

1.0

µ

A

I

11C

/ I

11D

VS = 5.3 to 16V

V

11

= 0.5V

T = 10 to 33ms

See Note 1

7.8

22.0

I

SRC

I

SENSE

Percentage of Output Current

Determining the Slow Recovery

Control Start (fig. 2), note 1

90

94

98.5

%

T

SRC

Duration of Altered Small Contr.

Ratio after SRC Function Start

(fig. 2)

C

SRC

= 1

µ

F

R

7

= 62 K

0.8

s

V

Z15

External Darlington over V Prot.

Zener Voltage

I

15

= 5 mA

I

15

= 2 mA

19

18

22.5

21.5

26

25

V

V

T

P

Permanent Conduction Time

V

5

= High

C

P

= 1

µ

F

R

7

= 62K

0.4

1.1

1.8

s

L497

4/11

ELECTRICAL CHARACTERISTICS (continued)

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

V

6SAT

RPM Output Saturation Voltage

I

6

= 18.5 mA

I

6

= 25 mA

0.5

0.8

V

V

I

6 leak

RPM Output Leakage Current

V

S

= 20 V

50

µ

A

V

Z7

Auxiliary Zener Voltage

I

7

= 20 mA

19

27

V

V

12

Reference Voltage

1.20

1.25

1.30

V

Figure 1 : Main Waveforms.

APPLICATION INFORMATION

N otes : 1.

2.

td/t desaturation ratio is given by:

td

T

=

1

1

+

I

11C

/

I

11D

I

sense

= I

coil

when the external Darlington is in the active region.

L497

5/11