| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: L4990D | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

L4990

L4990A

PRIMARY CONTROLLER

CURRENT-MODE CONTROL PWM

SWITCHING FREQUENCY UP TO 1MHz

LOW START-UP CURRENT < 0.45mA

HIGH-CURRENT OUTPUT DRIVE SUITABLE

FOR POWER MOSFET (1A)

FULLY LATCHED PWM LOGIC WITH DOU-

BLE PULSE SUPPRESSION

PROGRAMMABLE DUTY CYCLE

100% AND 50% MAXIMUM DUTY CYCLE

LIMIT

PROGRAMMABLE SOFT START

PRIMARY OVERCURRENT FAULT DETEC-

TION WITH RE-START DELAY

PWM UVLO WITH HYSTERESIS

IN/OUT SYNCHRONIZATION

DISABLE LATCHED

INTERNAL 100ns LEADING EDGE BLANK-

ING OF CURRENT SENSE

PACKAGE: DIP16 AND SO16W

DESCRIPTION

This primary controller I.C., developed in BCD60II

technology, has been designed to implement off

line or DC-DC power supply applications using a

fixed frequency current mode control.

Based on a standard current mode PWM control-

ler this device includes some features as pro-

grammable soft start, IN/OUT synchronization,

disable (to be used for over voltage protection

and for power management), precise maximum

Duty Cycle Control, 100ns (typ) leading edge

blanking on current sense, pulse by pulse current

limit and overcurrent protection with soft start in-

tervention.

July 1999

Æ

+

-

+

-

TIMING

2

3

+

-

14

T

Vref

CLK

2.5V

+

-

1.2V

13

BLANKING

PWM

FAULT

SOFT-START

R

S

Q

25V

16V/10V

VREF OK

DIS

+

-

E/A

1V

R

2R

DIS

2.5V

7

6

5

11

10

9

4

8

15

1

13V

PWM UVLO

12

SGND

COMP

SS

ISEN

DIS

DC

RCT

SYNC

DC-LIM

V

CC

VREF

D98IN1002

VFB

PGND

OUT

V

C

OVER CURRENT

BLOCK DIAGRAM

ORDERING NUMBERS: L4990/L4990A(DIP16)

L4990D/L4990AD (SO16W)

MULTIPOWER BCD TECHNOLOGY

DIP16

SO16W

1/24

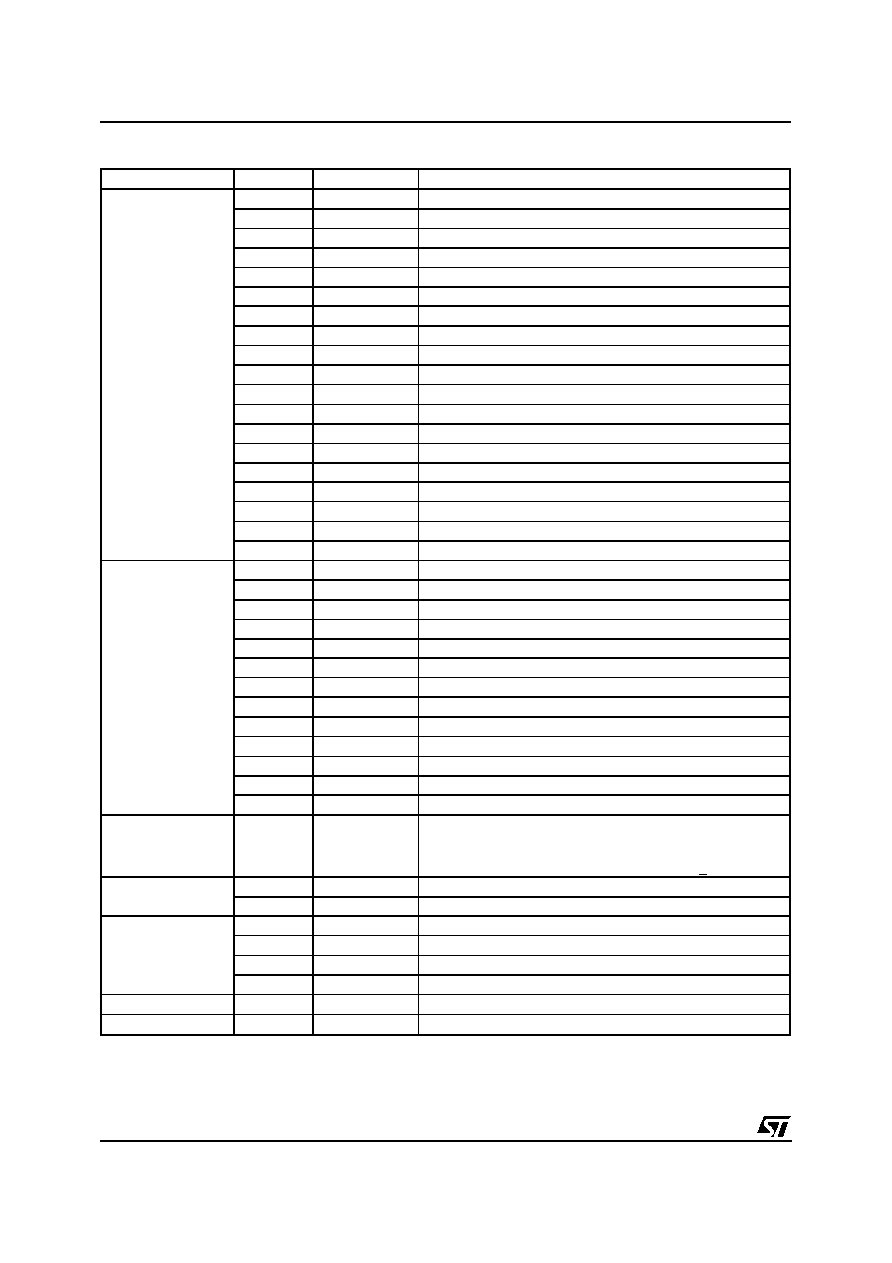

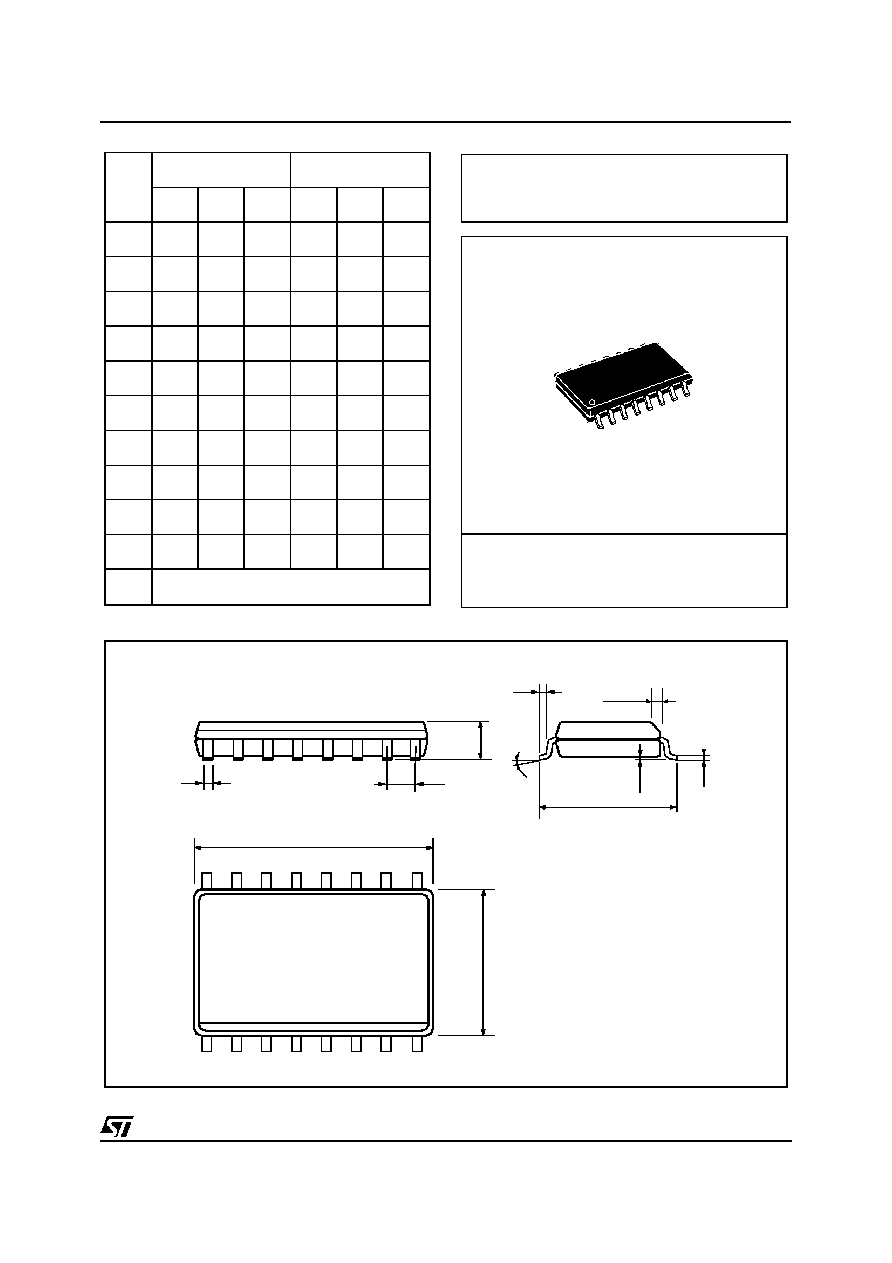

ABSOLUTE MAXIMUM RATINGS

Symbol

Parameter

Value

Unit

V

CC

Supply Voltage (I

CC

< 50mA) (*)

selflimit

V

I

OUT

Output Peak Pulse Current

1.5

A

Analog Inputs & Outputs (6,7)

-0.3 to 8

V

Analog Inputs & Outputs (1,2,3,4,5,15,14 13)

-0.3 to 6

V

P

tot

Power Dissipation @ T

amb

= 70

∞

C

1

W

T

j

Junction Temperature, Operating Range

-25 to 125

∞

C

T

stg

Storage Temperature, Operating Range

-55 to 150

∞

C

(*) maximum package power dissipation limits must be observed

THERMAL DATA

Symbol

Parameter

Value

Unit

R

th j-amb

Thermal Resistance Junction to Ambient

DIP16

80

∞

C/W

R

th j-amb

Thermal Resistance Junction to Ambient

SO16

120

∞

C/W

PIN FUNCTIONS

N.

Name

Fun ction

1

SYNC

Synchronization. A synchronization pulse terminates the PWM cycle and discharges Ct

2

RCT

Oscillator pin for external C

t

, R

t

components

3

DC

Duty Cycle control

4

VREF

5.0V +/-1.5% reference voltage

5

VFB

Error Amplifier Inverting input

6

COMP

Error Amplifier Output

7

SS

Soft start pin for external capacitor Css

8

V

CC

Supply for internal "Signal" circuitry

9

V

C

Supply for Power section

10

OUT

High current totem pole output

11

PGND

Power ground

12

SGND

Signal ground

13

ISEN

Current sense

14

DIS

Disable. It must never be left floating. Tie to SGND if not used.

15

DC-LIM

Connecting this pin to Vref, DC is limited to 50%. If it is left floating or grounded no limitation is

imposed

16

NC

Not connected

SYNC

RCT

DC

VREF

VFB

SS

COMP

1

3

2

4

5

6

7

OUT

SGND

PGND

ISEN

DIS

DC-LIM

N.C.

16

15

14

13

12

10

11

D95IN197

V

CC

8

V

C

9

PIN CONNECTION

L4990 - L4990A

2/24

ELECTRICAL CHARACTERISTICS (V

CC

= 15V; T

j

= 0 to 70

∞

C; unless otherwise specified.)

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

REFERENCE SECTION

V

O

Output Voltage

T

j

= 25

∞

C; I

O

= 1mA

4.925

5.0

5.075

V

Line Regulation

V

CC

= 12 to 20V

2.0

15

mV

Load Regulation

I

O

= 1 to 20mA

5.0

20

mV

T

S

Temperature Stability

0.4

mV/

∞

C

Total Variation

Line, Load, Temperature

4.875

5.0

5.125

V

I

OS

Short Circuit Current

Vref = 0V

30

150

mA

Power Down/UVLO

V

CC

= 8.5V; I

sink

= 0.5mA

0.2

0.5

V

OSCILLATOR SECTION

Initial Accuracy

T

j

= 25

∞

C; R

T

= 4.42k

;

C

T

= 1nF; pin 15 Vref

285

300

315

kHz

Accuracy

R

T

= 4.42K

; V

CC

= 12 to 20V;

C

T

= 1nF; pin 15 = Vref

279

300

321

kHz

Initial Accuracy

T

j

= 25

∞

C; R

T

= 4.42K

;

C

T

= 1nF; pin 15 OPEN

280

295

310

kHz

Accuracy

R

T

= 4.42K

; V

CC

= 12 to 20V;

C

T

= 1nF; pin 15 OPEN

275

295

315

kHz

Duty Cycle

pin 3 = 0,7V, pin 15 = Vref

pin 3 = 0.7V, pin 15 = OPEN

0

0

%

%

Duty Cycle

R

T

= 4.42k

C

T

= 1nF

pin 3 = 3.2V, pin 15 = Vref

pin 3 = 3.2V, pin 15 = OPEN

45

90

%

%

Duty Cycle Accuracy

pin 3 = 2.02V, pin 15 = OPEN

37

40

43

%

Oscillator Ramp Peak

3.0

V

Oscillator Ramp Valley

1.0

V

ERROR AMPLIFIER SECTION

Input Bias Current

V

FB

to GND

0.2

1.0

µ

A

V

I

Input Voltage

V

COMP

= V

FB

2.42

2.5

2.58

V

G

OPL

Open Loop Gain

V

COMP

= 2 to 4V

60

90

dB

SVR

Supply Voltage Rejection

V

CC

= 12 to 20V

85

dB

V

OL

Output Low Voltage

I

sink

= 2mA, V

FB

= 2.7V

1.1

V

V

OH

Output High Voltage

I

sou rce

= 0.5mA, V

FB

= 2.3V

5

6

V

I

O

Output Source Current

V

COMP

> 4V, V

FB

= 2.3V

0.5

1.3

mA

Output Sink Current

V

COMP

= 1.1V, V

FB

= 2.7V

2

6

mA

Unit Gain Bandwidth

2

4

MHz

S

R

Slew Rate

8

V/

µ

s

PWM CURRENT SENSE SECTION

I

b

Input Bias Current

I

sen

= 0

3

15

µ

A

I

S

Maximum Input Signal

V

COMP

= 5V

0.92

1.0

1.08

V

Delay to Output

100

ns

Gain

2.85

3

3.15

V/V

SOFT START

I

SSC

SS Charge Current

14

20

26

µ

A

I

SSD

SS Discharge Current

VSS = 0.6V

200

µ

A

V

SSSAT

SS Saturation Voltage

DC = 0%

0.6

V

V

SSCLAMP

SS Clamp Voltage

7

V

LEADING EDGE BLANKING

Internal Masking Time

100

ns

L4990 - L4990A

3/24

FUNCTIONAL DESCRIPTION

The I.C. contains a standard PWM current mode

control section with improved performance with

respect to the UC384X family.

Enhanced features include start-up bias current

reduced to < 270

µ

A (typ), improved E/A perform-

ance (4MHz B/W, 1.3mA Source Current, high-

slew rate) accurate 1MHz oscillator, and also re-

duced propagation delays in the critical path from

Current Sense to Output.

ADDITIONAL FEATURES

Soft Start (SS)

An external capacitor is charged by an internal

constant current source (20

µ

A) to generate a SS

signal which clamps the E/A output

The SS pin doubles as a Fault Reset Delay func-

tion as described below.

Current Limit / Reset Delay

An internal high-speed current limit comparator

ELECTRICAL CHARACTERISTICS (continued.)

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

OUTPUT SECTION

V

OL

Output Low Voltage

I

O

= 250mA

1.0

V

V

OH

Output High Voltage

I

O

= 20mA; V

CC

= 12V

10

10.5

V

I

O

= 200mA; V

CC

= 12V

9

10

V

V

OUT CLAMP

Output Clamp Voltage

I

O

= 5mA; V

CC

= 20V

13

V

Collector Leakage

V

CC

= 20V V

C

= 24V

100

200

µ

A

Fall Time

C

O

= 1nF

C

O

= 2.5nF

20

35

60

ns

ns

Rise Time

C

O

= 1nF

C

O

= 2.5nF

50

70

100

ns

ns

UVLO Saturation

V

CC

= 0V to V

CCON

; I

sink

= 10mA

1.0

V

SUPPLY SECTION

V

CCON

Startup voltage

L4990

L4990A

15

7.8

16

8.4

17

9

V

V

V

CCOFF

Minimum Operating Voltage

L4990

L4990A

9

7

10

7.6

11

8.2

V

v

V

hys

Voltage After Turn-on Hysteresis

L4990

L4990A

5.5

0.5

6

0.8

V

v

I

S

Start Up Current

Before Turn-on at:

V

CC

= V

CCON

- 0.5V

100

270

450

µ

A

I

op

Operating Current

C

T

= 1nF, R

T

= 4.42k

, C

O

=1nF

12

18

mA

I

q

Quiescent Current

(After turn on), Co =0nF

C

T

= 1nF, R

T

= 4.42k

,

7.0

10

mA

I

SH

Shutdown Current

100

270

450

µ

A

V

Z

Zener Voltage

I

8

= 20mA

21

25

30

V

SYNCHRONIZATION SECTION

Master Operation

V

1

Clock Amplitude

I

SOURCE

= 0.8mA

4

V

I

1

Clock Source Current

Vclock = 3.5V

7

mA

Slave Operation

V

1

Sync Pulse

Low Level

1

V

High Level

3.5

V

I

1

Sync Pulse Current

VSYNC = 3.5V

0.8

mA

OVER CURRENT PROTECTION

V

t

Fault Threshold Voltage

1.1

1.2

1.3

V

DISABLE SECTION

Shutdown threshold

2.4

2.5

2.6

V

L4990 - L4990A

4/24

referenced to 1.2V detects primary over-current

conditions. On detection of an overcurrent fault

the output is immediately shutdown and the fault

is also latched. A Fault Reset Delay is imple-

mented by discharging the external Soft Start

(SS) timing capacitor

before resetting the fault

latch and initiating a softstart cycle.

In case of a continuous fault condition the SS ca-

pacitor is charged to 5V before being discharged

again, to ensure that the fault frequency does not

exceed the programmed soft start frequency.

Duty Cycle Limit

A simple connection between the DC-LIM and the

available Vref activates an internal T- FlipFlop lim-

iting the DC to about 50%. If this pin is not con-

nected or grounded, the limit of the duty cycle is

extended to about 100%

Duty Cycle Control

Duty Cycle DC is externally programmed by set-

ting a voltage between 1V (0% DC) and 3V

(100% DC) at the DC pin. The programmed volt-

age is compared with the oscillator C

T

capacitor

charging waveform to determine the maximum

ON-time in each period. This function gives a fine

control of DC.

If this pin is floating the maximum duty cycle de-

pends on DC-LIM status.

Synchronization

A SYNC pin eases Synchronization of the IC to

the external world ( e.g.

another IC working in

parallel or to TV/monitor sync signal).

In TV/monitor applications the timing components

R

T

, C

T

are set for a frequency lower than the

minimum TV sync frequency. When the TV circuit

has powered-up it takes over and the system fre-

quency is that of the SYNC. Duty Cycle is control-

lable using the DC function.

In parallel operation of several IC's no Mas-

ter/Slave designation is required as the higher fre-

quency IC is automatically the master. Controllers

to be synchronized have their SYNC pins tied to-

gether and each SYNC pin operates as a bidirec-

tional circuit. The first IC to drive its SYNC pin is

the master and it initiates a discharge of the C

T

timing capacitor of every controller. The Sync in-

put signal is edge-triggered and sets an internal

"sync latch" which ensures full discharge of C

T

.

Disable Function

The DIS pin performs a logic level latched-shut-

down function. When pulled above 2.5V it shuts

down the complete IC with a standby current of

<270

µ

A (typ).

To reset the IC the V

CC

pin must be pulled-down

below the lower UVLO threshold (10V).

Leading Edge Blanking (LEB)

An LEB interval of 100ns has been incorporated

into the IC to blank out the current sense signal

during the first 100ns from switch turn-on.

This provides noise immunity to turn-on spikes

and reduces external RC filtering requirements on

the current-sense signal.

6

8

2 0

3 0

V1 4 = 0 , O SC= d isa bled

T j = 25

∞

C

0

4

8

1 2

1 6

2 0

2 4

0

0 .2

0 .4

0 .6

0 .8

1

V c c [V]

Iq [m A ]

X

Y

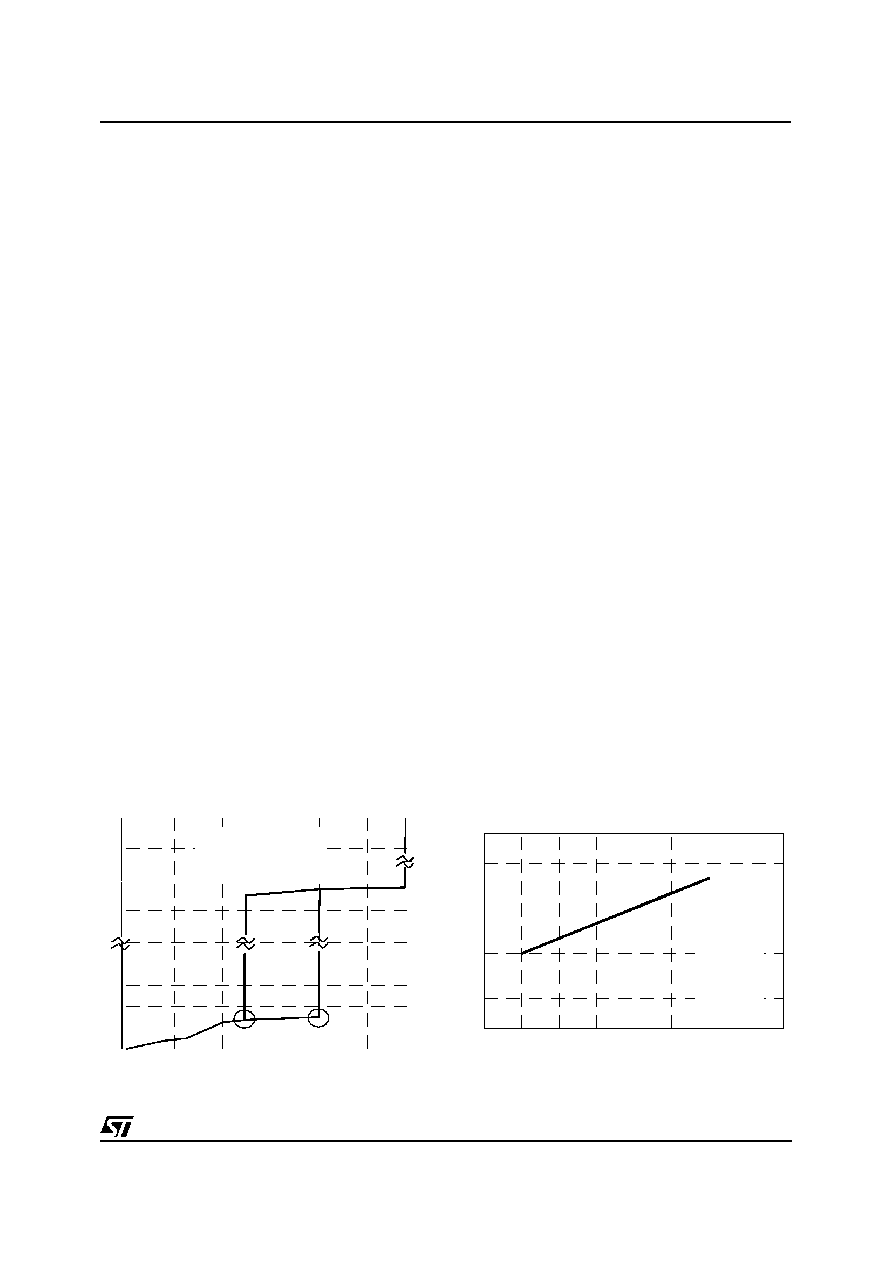

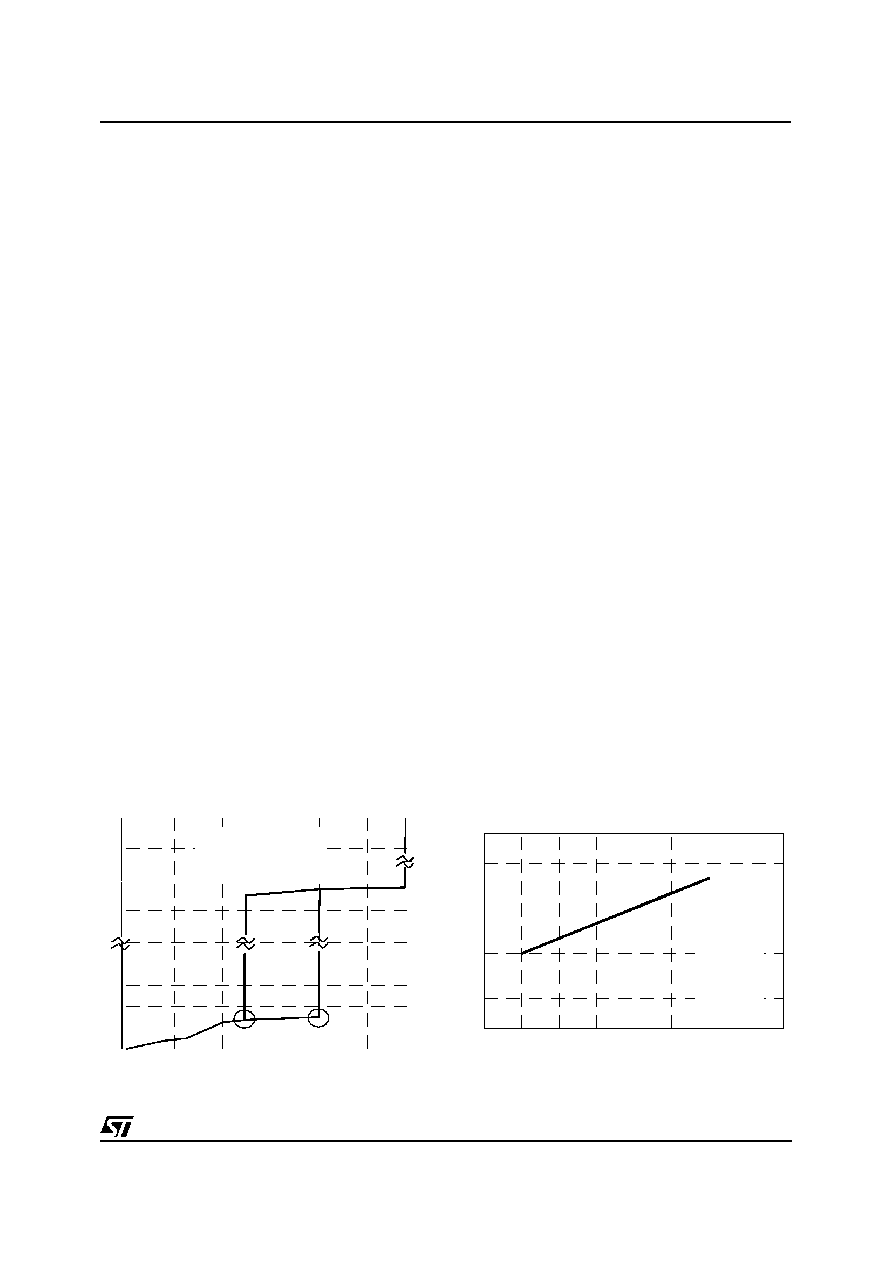

Figure 1. Quiescent current vs. input voltage.

(X = 7.6V and Y = 8.4V for L4990A)

8

10

12

14

16

18

20

22

24

21 0

24 0

27 0

30 0

Vcc

[V ]

Iq

[uA]

V14 = Vref

T j = 25

∞

C

Figure 2. Quiescent current vs. input voltage

(after disable).

L4990 - L4990A

5/24

8

10

12

14

16

18

20

22

24

7.0

7.5

8.0

8.5

9.0

V cc

[V ]

Iq [m A ]

V 14 = 0, V5 = Vr ef

Rt = 4.5Kohm,Tj = 25

∞

C

5 0 0K h z

3 0 0K h z

1M h z

1 0 0 Kh z

Figure 3. Quiescent current vs. input voltage.

-50

-25

0

25

50

75

100

125

150

4.9

4.95

5

5.05

5.1

Tj (

∞

C)

Vref [V])

Vcc = 15V

Iref = 1mA

Figure 7. Vref vs. junction temperature.

-50

-25

0

25

50

75

100

125

150

4.9

4.95

5

5.05

5.1

Tj (

∞

C)

Vref [V]

Vcc = 15V

Iref= 20mA

Figure 8. Vref vs. junction temperature.

8

10

12

14

16

18

20

22

0

6

12

18

24

30

36

Vcc [V]

Iq [mA]

Co = 1nF, Tj = 25

∞

C

DC = 1 00%

1M H z

50 0KH z

3 00KH z

10 0KH z

Figure 5. Quiescent current vs. input voltage

and switching frequency.

0

5

10

15

20

25

4.9

4.95

5

5.05

5.1

Iref [mA]

Vref [V]

Vcc=15V

Tj = 25

∞

C

Figure 6. Reference voltage vs. load current.

8

10

12

14

16

1 8

20

22

0

6

12

18

24

30

36

V c c [V ]

I q [mA ]

C o = 1 n F, Tj = 2 5

∞

C

D C = 0 %

1M Hz

500K Hz

300K Hz

100KHz

Figure 4. Quiescent current vs. input voltage

and switching frequency.

L4990 - L4990A

6/24

-50

-25

0

25

50

75

100

125

150

280

290

300

310

320

Tj (

∞

C)

fsw (KHz)

Rt= 4.5Kohm, Ct = 1nF

Vcc = 15V, V15=Vref

Figure 14. Switching frequency vs. temperature.

10

0

0.2

0.4

0.6

0.8

1

1.2

6

8

10

12

14

16

Isourc e [A]

V sat = V [V]

Vcc = 15V

Tj = 25

∞

C

Figure 10. Output saturation.

0

0.2

0.4

0.6

0.8

1

1.2

0

0.5

1

1.5

2

2.5

Is ink [A]

10

Vsat = V

[V ]

Vcc = 15V

Tj = 25

∞

C

Figure 11. Output saturation.

1

10

100

1000

10000

0

40

80

120

fsw (Hz)

SVRR (dB)

Vcc=15V

Vp-p=1V

Figure 9. Vref SVRR vs. switching frequency.

10

20

30

40

10

20

50

100

200

500

1000

2000

5000

Rt (kohm)

fsw(KHz)

100pF

220pF

470pF

1nF

2.2nF

5.6nF

Tj= 25

∞

C

Vcc =15V, V15 =0V

Figure13. Timingresistorvs.switchingfrequency.

0

200

400

600

800

1,000 1,200 1,400

0

10

20

30

40

50

Vpin10 [mV]

Ipin10 [mA]

Vcc < Vccon

before turn-on

Figure 12. UVLO Saturation

L4990 - L4990A

7/24

0.01

0.1

1

10

100

1000

10000 100000

0

50

100

150

20

40

60

80

100

120

140

f (KHz)

G [dB]

Phase

Figure 19. E/A frequency response.

0

10

20

30

40

50

60

70

80

90 100

1

1.5

2

2.5

3

3.5

Duty C y cle [% ]

DC Control Voltage V pin3 [V]

Rt = 4.5Kohm ,

Ct = 1nF

V15 = 0 V

V1 5 = Vr ef

Figure 17. Maximum Duty Cycle vs Vpin3.

-50

-25

0

25

50

75

100

125

150

60

70

80

90

100

110

120

130

Tj (

∞

C)

Delay to output (ns)

PIN10 = OPEN

1V pulse

on PIN13

Figure18.Delayto output vs junctiontemperature.

-50

-25

0

25

50

75

100

125

150

280

290

300

310

320

Tj (

∞

C)

fsw (KHz)

Rt= 4.5Kohm, Ct = 1nF

Vcc = 15V, V15= 0

Figure 15. Switching frequency vs. temperature.

2

4

6

8

10

300

600

900

1,200

1,500

Timing capacitor Ct [nF]

Dead time [ns]

Rt =4.5Kohm

V15 = 0V

V15 = Vref

Figure 16. Dead time vs Ct.

L4990 - L4990A

8/24

APPLICATION INFORMATION

Detailed Pin Functions Description

Pin 1. SYNC (In/Out Synchronization). This func-

tion allows the IC's oscillator either to synchronize

other controllers (master) or to be synchronized to

an external frequency (slave).

As a master, the pin delivers positive pulses dur-

ing the ramp-down of the oscillator (see pin 2). In

slave operation the circuit is edge triggered. Refer

to fig. 21 to see how it works. When several IC

work in parallel no master-slave designation is

needed because the fastest one becomes auto-

matically the master.

During the ramp-up of the oscillator the pin is

pulled low by a 600

µ

A generator. During the

ramp-down, that is when the pulse is released,

the 600

µ

A pull-down is disconnected. The pin be-

comes a generator whose source capability is

typically 7mA (with a voltage still higher than

3.5V).

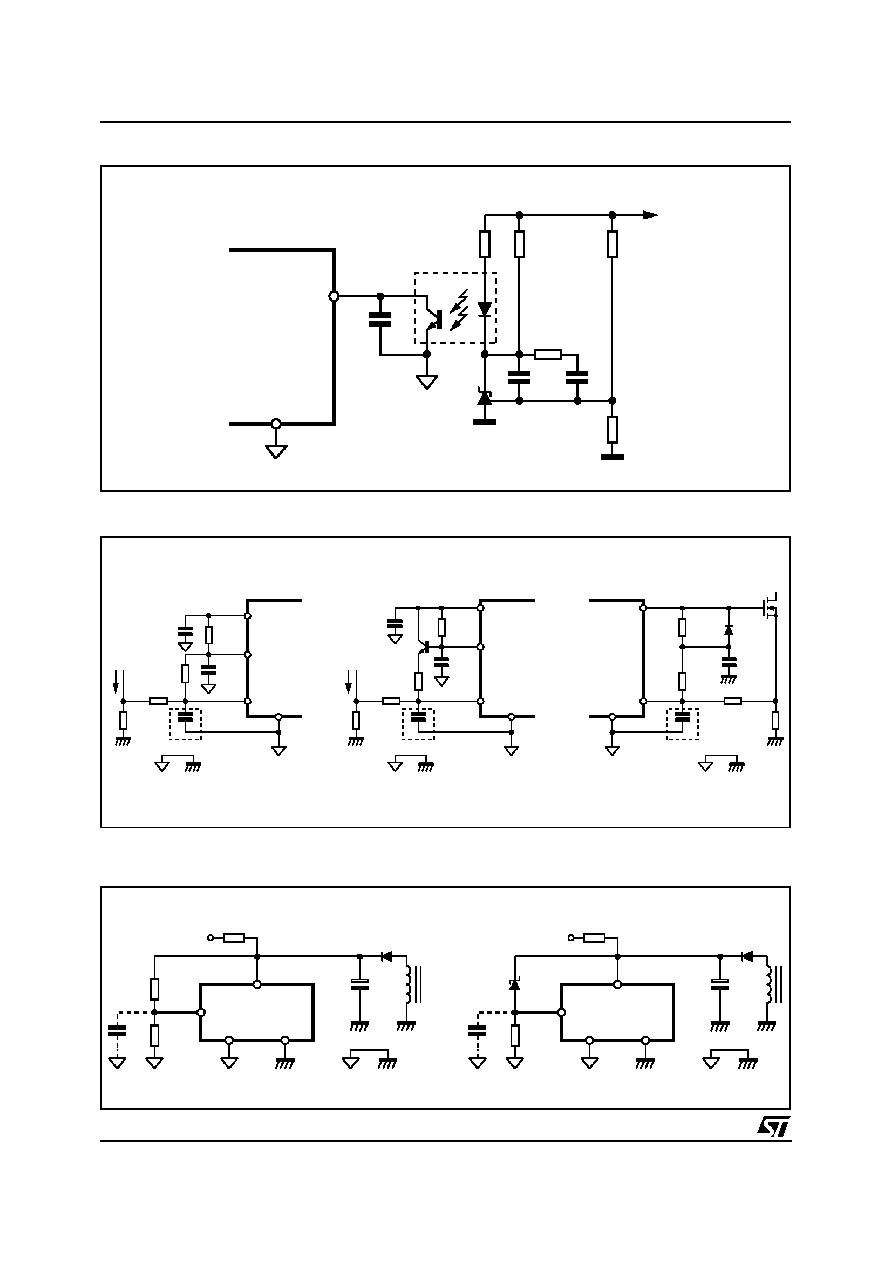

In fig. 20, some practical examples of synchroniz-

ing the L4990 are given.

L4990

L4990

R

T

VREF

SYNC

SYNC

RCT

RCT

L4981A

(MASTER)

L4990

(SLAVE)

R

T

VREF

SYNC

RCT

R

OSC

C

OSC

C

T

L4990

(MASTER)

L4981A

(SLAVE)

SYNC

R

OSC

C

T

C

OSC

SYNC

(a)

(b)

(c)

R

T

D97IN494A

C

T

VREF

4

1

2

1

2

16

18

17

4

2

1

RCT

1

2

4

16

17

18

Figure 20. Synchronizing the L4990.

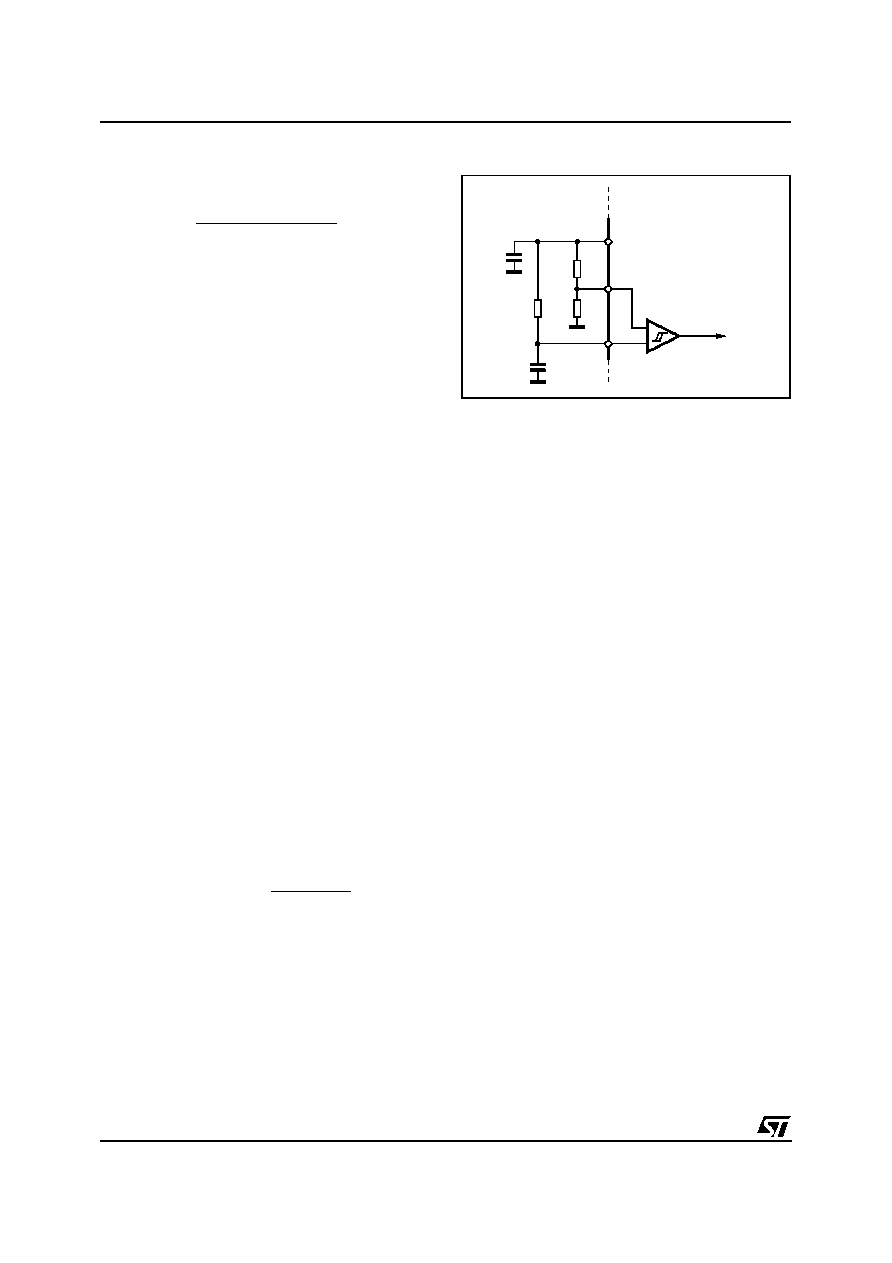

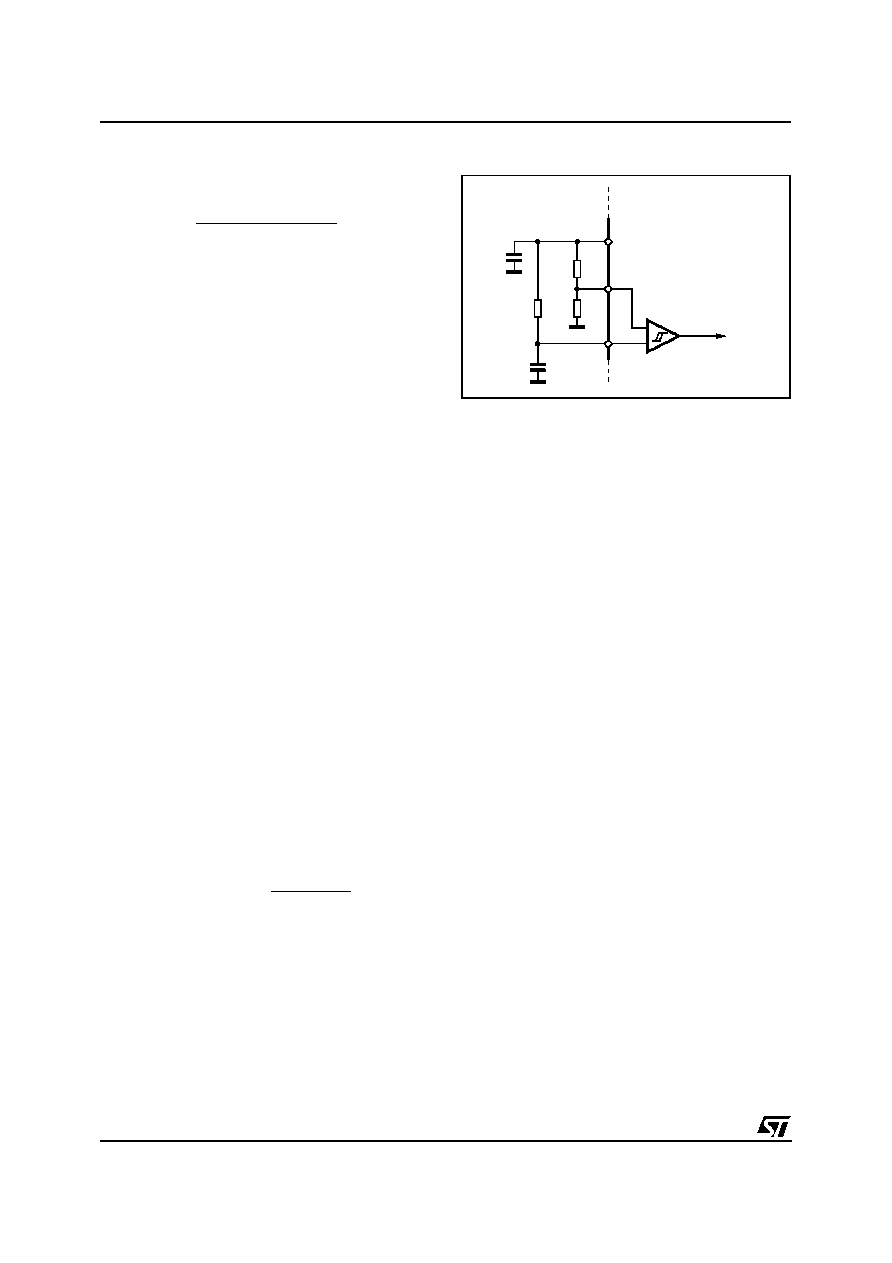

Pin 2. RCT (Oscillator). A resistor (R

T

) and a ca-

pacitor (C

T

), connected as shown in fig. 21 set the

operating frequency f

osc

of the oscillator.

C

T

is charged through R

T

until its voltage reaches

3V, then is quickly internally discharged. As the

voltage has dropped to 1V it starts being charged

again

+

-

R2

R3

R1

CLAMP

D1

50

R

T

C

T

D

R

Q

600

µ

A

D97IN500B

V

REF

RCT

SYNC

CLK

2

4

1

Figure 21. Oscillator and synchronization internal schematic.

L4990 - L4990A

9/24

The frequency can be established with the aid of

fig. 13 diagrams or considering the approximate

relationship:

f

osc

1

C

T

(

0.693

R

T

+

K

T

)

(

1

)

where K

T

is defined as:

K

T

=

90, V

15

=

VREF

160 V

15

=

GND/OPEN

(

2

)

and is linked to the duration of the falling edge of

the sawtooth:

T

d

30

10

-9

+ K

T

C

T

(3)

T

d

is also the duration of the sync pulses deliv-

ered at pin 1 and defines the upper extreme of

the duty cycle range, D

x

(see pin 15 for D

x

defini-

tion and calculation).

In case V

15

is connected to VREF, however, the

switching freque ncy of the system will be as

high as half f

osc

.

If the IC is to be synchronized to an external oscil-

lator, R

T

and C

T

should be selected for a f

osc

lower than the master frequency in any condition

(typically, 10-20% ), depending on the tolerance

of R

T

and C

T

itself.

Pin 3. DC (Duty Cycle Control). By biasing this

pin with a voltage between 1 and 3 V it is possible

to set the maximum duty cycle between 0 and the

upper extreme D

x

(see pin 15).

If D

max

is the desired maximum duty cycle, the

voltage V3 to be applied to pin 3 is:

V

3

= 5 - 2

(2-Dmax)

(4)

D

max

is determined by internal comparison be-

tween V3 and the oscillator ramp (see fig. 22),

thus in case the device is synchronized to an ex-

ternal frequency f

ext

(and therefore the oscillator

amplitude is reduced), (4) changes into:

V

3

=

5

-

4

exp

-

D

max

R

T

C

T

f

ext

(5)

A voltage below 1V will inhibit the driver output

stage. This could be used for a not-latched device

disable, for example in case of overvoltage pro-

tection (see application ideas).

If no limitation on the maximum duty cycle is re-

quired (i.e. D

MAX

= D

X

), the pin has to be left float-

ing. An internal pull-up holds the voltage above

3V. Should the pin pick up noise (e.g. during ESD

tests), it can be connected to V

REF

through a

4.7k

resistor.

Pin 4. VREF (Reference Voltage). An internal

generator furnishes an accurate voltage reference

(5V

±

1.5%) that can be used to supply an external

circuit (consider some ten mA).

A small film capacitor (1

µ

F typ.), connected be-

tween this pin and SGND, is recommended to

preventswitching noise from affecting the reference.

Before device turn-on, this pin has a sink current ca-

pability of 0.5mA.

Pin 5. VFB (Error Amplifier Inverting Input). The

feedback signal is applied to this pin and is com-

pared to the E/A internal reference (2.5V). The

E/A output generates the control voltage which

fixes the duty cycle.

The E/A features high gain-bandwidth product,

which allows to broaden the bandwidth of the

overall control loop, high slew-rate and current

capability, which improves its large signal behav-

ior. Usually the compensation network, which sta-

bilizes the overall control loop, is connected be-

tween this pin and COMP (pin 6).

Pin 6. COMP (Error Amplifier Output). Usually,

this pin is used for frequency compensation and

the relevant network is connected between this

pin and VFB (pin 5). Compensation networks to-

wards ground are not possible since the L4990

E/A is a voltage mode amplifier (low output im-

pedance). See application ideas for some exam-

ple of compensation techniques.

Pin 7. SS (Soft-Start). At device start-up, a ca-

pacitor (Css) connected between this pin and

SGND (pin 12) is charged by an internal current

generator, ISSC, up to about 7V. During this

ramp, the E/A output is clamped by the voltage

across Css itself and allowed to rise linearly, start-

ing from zero, up to the steady-state value im-

posed by the control loop. The maximum time in-

terval during which the E/A is clamped, referred to

as soft-start time, is approximately:

+

-

R2

R1

R

T

C

T

D97IN501A

V

REF

RCT

DC

TO PWM LOGIC

4

3

2

Figure 22. Duty cycle control.

L4990 - L4990A

10/24

T

ss

3

R

sense

I

Qpk

I

SSC

C

ss

(6)

where R

sense

is the current sense resistor (see pin

13) and I

Qpk

is the switch peak current (flowing

through R

sense

), which depends on the output

load. Usually, C

SS

is selected for a T

SS

in the or-

der of milliseconds.

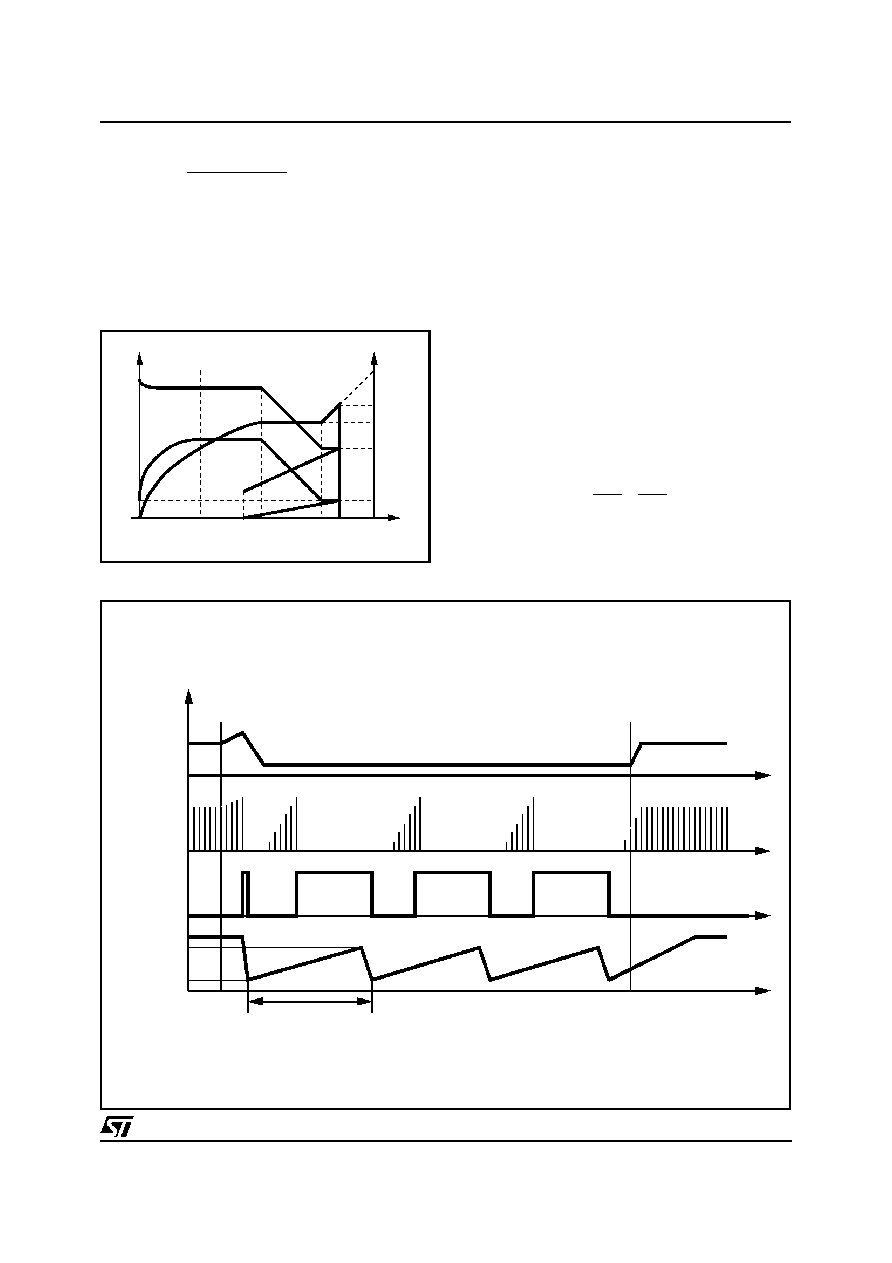

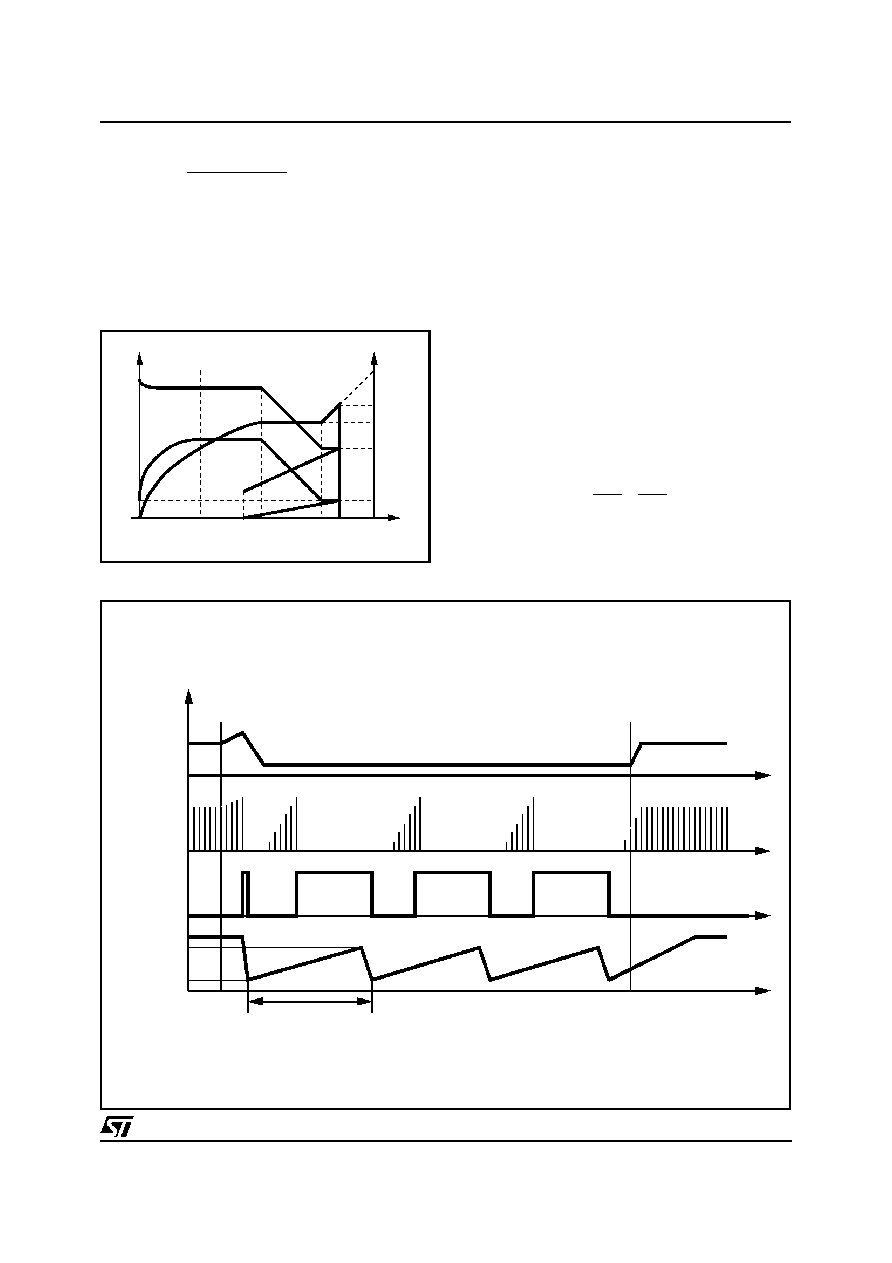

As mentioned before, the soft-start intervenes

also in case of severe overload or short circuit on

the output. Referring to fig. 23, pulse-by-pulse

current limitation is somehow effective as long as

the ON-time of the power switch can be reduced

(from A to B). After the minimum ON-time is

reached (from B onwards) the current is out of

control.

To prevent this risk, a comparator trips an over-

current handling procedure, named 'hiccup' mode

operation, when a voltage above 1.2V (point C) is

detected on current sense input (ISEN, pin 13).

Basically, the IC is turned off and then soft-started

as long as the fault condition is detected. As a re-

sult, the operating point is moved abruptly to D,

creating a foldback effect. Fig. 24 illustrates the

operation.

The oscillation frequency appearing on the soft-

start capacitor in case of permanent fault, referred

to as 'hiccup" period, is approximately given by:

T

hic

4.5

1

I

SSC

+

1

I

SSD

C

ss

(

7

)

Since the system tries restarting each hiccup cy-

cle, there is not any latchoff risk.

V

OUT

T

ON

D.C.M.

C.C.M.

D

A

B

C

I

Qpk

T

ON(min)

1-2 ∑I

Qpk

I

Qpk(max)

I

OUT

I

SHORT

I

OUT(max)

D97IN495

Figure 23. Regulation characteristic and re-

lated quantities

7V

T

hic

time

SHORT

I

OUT

I

SEN

FAULT

SS

5V

0.5V

D97IN496

Figure 24. Hiccup mode operation.

L4990 - L4990A

11/24

"Hiccup" keeps the system in control in case of

short circuits but does not eliminate power com-

ponents overstress during pulse-by-pulse limita-

tion (from A to C). Other external protection cir-

cuits are needed if a better control of overloads is

required.

Pin 8. VCC (Controller Supply). This pin supplies

the signal part of the IC. The device is enabled as

VCC voltage exceeds the start threshold and

works as long as the voltage is above the UVLO

threshold. Otherwise the device is shut down and

the current consumption is extremely low.

An internal Zener limits the voltage on VCC to

25V. Below this value the IC current consumption

is low but increases considerably if this limit is ex-

ceeded.

A small film capacitor between this pin and SGND

(pin 12), placed as close as possible to the IC, is

recommended to filter high frequency noise.

Pin 9. VC (Supply of the Power Stage). It sup-

plies the driver of the external switch and there-

fore absorbs a pulsed current. Thus it is recom-

mended to place a buffer capacitor (towards

PGND, pin 11, as close as possible to the IC)

able to sustain these current pulses and in order

to avoid them inducing disturbances.

This pin can be connected to the buffer capacitor

directly or through a resistor, as shown in fig. 25,

to control separately the turn-on and turn-off

speed of the external switch, typically a Power-

MOS. At turn-on the gate resistance is R

g

+ R

g'

and turn-off is R

g

only.

Pin 10. OUT (Driver Output). This pin is the out-

put of the driver stage of the external power

switch. Usually, this will be a PowerMOS, al-

though the driver is powerful enough to drive

BJT's (1.6A source, 2A sink, peak).

The driver is made up of a totem pole with a high-

side NPN Darlington and a low-side VDMOS, and

delivers a voltage internally clamped, as shown in

fig. 25. Thus it is possible to supply the driver (pin

9) with higher voltages without any problem of

damage for the gate oxide of the external MOS,

but, of course, the power dissipation on the IC will

increase.

In UVLO conditions an internal circuit (shown in

fig.26) holds the pin low in order to ensure that

the external MOS cannot be turned on acciden-

tally. The peculiarity of this circuit is its ability to

mantain the same sink capability (typically, 20mA

@ 1V) from V

CC

= 0V up to the start-up threshold.

When the threshold is exceeded and the L4990

starts operating, V

REFOK

is pulled high (refer to

fig. 26) and the circuit is disabled.

It is then possible to omit the "bleeder" resistor

(connected between the gate and the source of

the MOS) ordinarily used to prevent undesired

switching-on of the external MOS because of

some leakage current.

Pin 11. PGND (Power Ground). The current loop

during the discharge of the gate of the external

MOS is closed through this pin. This loop should

be as short as possible to reduce EMI and run

separately from signal currents return.

Pin 12. SGND (Signal Ground). This ground ref-

erences the control circuitry of the IC, so all the

ground connections of the external parts related

to control functions must lead to this pin. In laying

out the PCB, care must be taken in preventing

switched high currents from flowing through the

SGND path.

Pin 13. ISEN (Current Sense). This pin is to be

connected to the "hot" lead of the current sense

resistor R

sense

(being the other one grounded), to

get a voltage ramp which is an image of the cur-

rent of the switch, (I

Q

). When this voltage is equal

to:

OUT

Rg

DRIVE &

CONTROL

13V

V

C

V

CC

Rg'

PGND

Rg(ON)=Rg+Rg'

Rg(OFF)=Rg

D97IN497A

L4990

9

10

11

8

17

13

(V)

Figure25.Turn-on and turn-off speeds adjustment

10

12

SGND

OUT

V

REFOK

D97IN538

Figure 26. Pull-Down of the output in UVLO.

L4990 - L4990A

12/24

V

13pk

=

I

Qpk

R

sense

= (

V

COMP

-

1.4

)

3

(

8

)

the conduction of the switch is terminated.

To increase the noise immunity, a "Leading Edge

Blanking" of about 100ns is internally realized as

shown in fig. 27. Because of that, the smoothing

RC filter between this pin and R

sense

could be re-

moved or, at least, considerably reduced.

+

-

I

D97IN503

ISEN

0

3V

CLK

2V

+

-

+

-

1.2V

FROM E/A

OVERCURRENT

COMPARATOR

PWM

COMPARATOR

TO PWM

LOGIC

TO FAULT

LOGIC

13

Figure 27. Internal LEB

Pin 14. DIS (Device Disable). When the voltage

on pin 14 rises above 2.5V the IC is shut down

and it is necessary to pull VCC (IC supply volt-

age, pin 8) below the UVLO threshold to allow the

device to restart. When disabled, the current con-

sumption of the IC is as low as before start-up.

The pin can be driven by an external logic signal

in case of power management, as shown in fig.

28. It is also possible to realize an overvoltage

protection, as shown in the section " Application

Ideas".

If used, bypass this pin to ground with a filter ca-

pacitor to avoid spurious activation due to noise

spikes. If not, it is advisable to connect the pin to

SGND, even though it might be left floating.

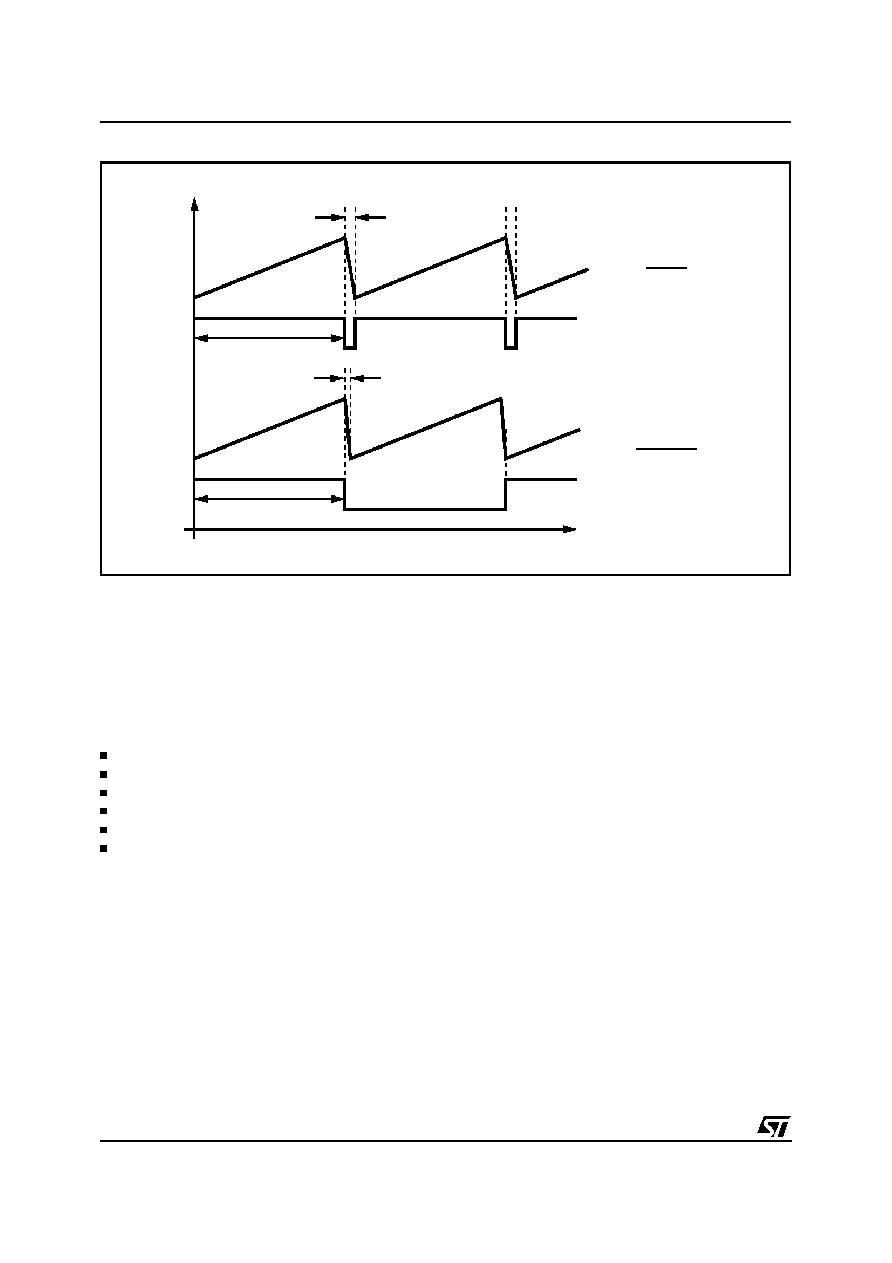

Pin 15. DC-LIM (Maximum Duty Cycle Limit). The

upper extreme, Dx, of the duty cycle range de-

pends on the voltage applied to this pin. Approxi-

mately,

D

x

R

T

R

T

+

230

(

9

)

if DC-LIM is grounded or left floating. Instead,

connecting DC-LIM to VREF (half duty cycle op-

tion), Dx will be set approximately to:

D

x

R

T

2

R

T

+

260

(

10

)

and the output switching frequency will be halved

with respect to the oscillator one because an in-

ternal T flip-flop (see block diagram, fig. 1) is acti-

vated. Fig. 29 shows the operation.

The half duty cycle option speeds up the dis-

charge of the timing capacitor C

T

(in order to get

duty cycles as close as possible to 50%) so the

oscillator frequency - with the same R

T

and C

T

-

will be slightly higher.

The halving of frequency can be used to reduce

losses at light load in all those systems that must

comply with requirements regarding energy con-

sumption (e.g. monitor displays).

+

-

C

D97IN502

DIS

D

R

Q

DISABLE

UVLO

2.5V

14

DISABLE

SIGNAL

Figure 28. Disable (Latched)

L4990 - L4990A

13/24

DEMONSTRATION BOARD

To evaluate the device performance, a demon-

stration board has been realized. Despite its sim-

plicity, it exploits most of the features of the

L4990.

The board embodies an application based on the

following specification of universal mains AC-DC

adapter:

Input voltage range: 85-270 Vac (50/60 Hz)

Output voltage: 15 V

Output current: 0.5 to 2A

Output voltage ripple : 300 mV (max.)

Load regulation:

±

5% (0.5 to 2 A load change)

Target efficiency @ Iout = 2 A: ; 80% over the

input voltage full range

Some preliminary decisions, concerning topology,

operating mode, switching frequency, maximum

duty cycle allowed and control technique, have

been made.

As for topology, at this power level and output

voltage, flyback is the most advantageous one,

mainly because of its simplicity, which means low

parts count, low cost and inherent high efficiency.

A peculiar design choice aiming at optimizing the

overall system concerns the operating mode: the

converter will work in continuous current mode at

low input voltages, when input current is greater,

and in discontinuous mode at higher input volt-

ages. Numerous benefits originate from that.

Compared to discontinuous current mode, con-

tinuous operation involves lower peak currents

(typ. -40%) at the same throughput power. This

implies less stress for all power components.

The transformer inductance is higher and, there-

fore, a smaller air gap is required for a given core:

this increases primary-to-secondary coupling and,

as a consequence, reduces leakage inductance

and improves energy transfer. Both efficiency and

load regulation will take advantage of that.

Another point in favor is a reduction of the mini-

mum output power that the system is able to de-

liver keeping the output well regulated.

Few components are required in addition for

slope compensation.

Actually, continuous mode flyback suffers also

from a poor dynamic behavior during load tran-

sients because of the narrow bandwidth of the

control loop due to stability problems. However,

great dynamic performance is not required to AC-

DC adapters, so this problem is of no concern.

The boundary between the two operating modes

has been set at about 150 Vac (@ Iout=2A).

The selection of the switching frequency is a mat-

ter of trade-off between achieving a small trans-

former size and high efficiency. 200 kHz seems to

be a good compromise.

In this application, the wide input voltage range

requires a large duty cycle sweep. The higher is

the maximum duty cycle, the larger is the operat-

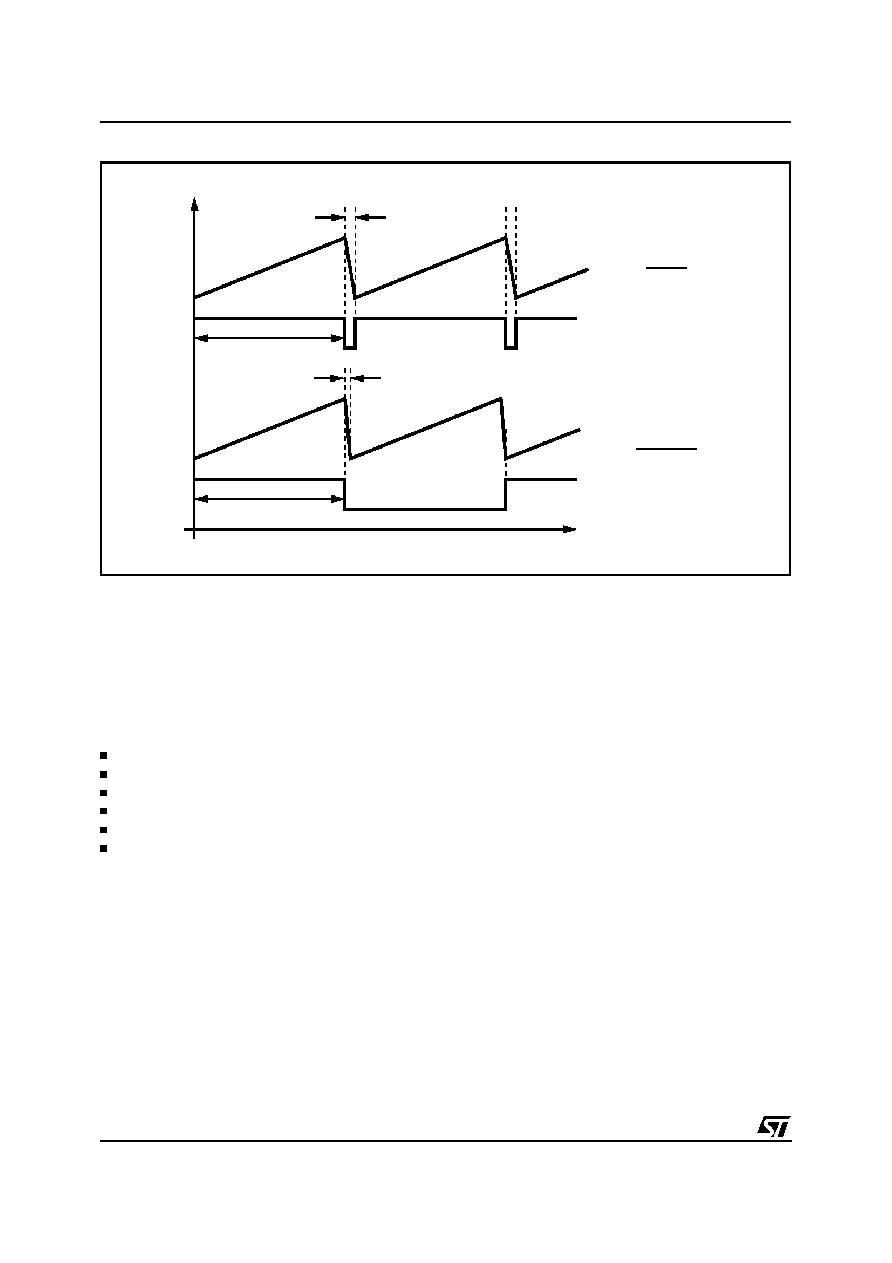

V15=GND

V5=V13=GND

V15=VREF

V5=V13=GND

t

d

t

d

tc

tc

V2

V10

V2

V10

D

X

=

tc

tc + td

D

X

=

tc

2 ∑tc + td

D97IN498

Figure 29. Half duty cycle option.

L4990 - L4990A

14/24

ing conditions range, in terms of input voltage and

output current, that the converter is able to cover

but, on the other hand, the higher is the peak cur-

rent on the secondary side.

As to this point, the L4990 turns out to be particu-

larly useful since it allows to set any maximum

duty cycle greater (and lower) than 50% with very

good precision. In the present case, a maximum

duty cycle of 60% for steady state operation has

been selected and an extra 5% is allowed to take

transients into account.

Since it is not requested a very tight tolerance on

the output, the feedback employs a primary side

voltage sensing technique to reduce cost and

complexity of the circuit. The same technique has

been used to protect against output overvoltages.

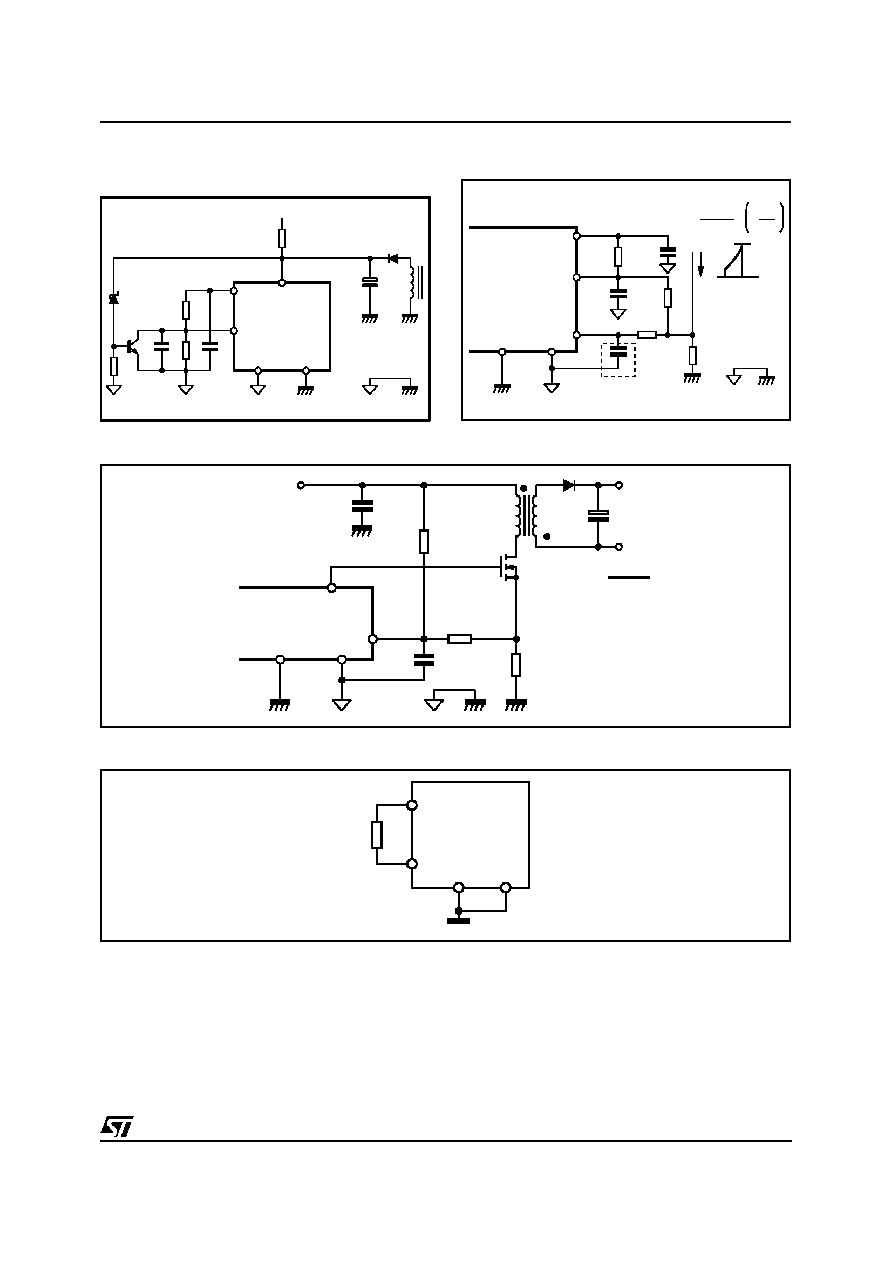

The electric schematic is shown in fig. 30. The

PCB layout is shown in figg. 31 and 32. Table 1

and 2 summarize typical system performance,

while table 3 lists the relevant bill of material,

where details are given only for critical compo-

nents and/or where useful.

Warning: the NTC for inrush current limitation is

not assembled, thus use caution when connecting

the demo board to the mains directly. The use of

a variac or an isolation transformer is recom-

mended.

Table 1. System efficiency.

I

out

= 1A

I

out

= 2A

V

in

(Vac)

V

out

(V)

Effic. %

V

ou t

(V)

Effic. %

85

14.93

83.7

14.53

84.3

110

14.95

82.5

14.55

84.9

220

14.95

81.4

14.57

85.2

270

14.96

76

14.59

81.6

Table 2. System performance.

Line regulation

V

in

= 85 to 270 Vac

I

out

= 0.5A

30mV

Load regulation

I

out

= 0.5A to 2A

V

in

= 85 Vac

V

in

= 270 Vac

0.95V

0.90V

Maximum effic.

V

in

= 190 Vac

I

out

= 2A

86.2%

Output ripple

V

in

= 85 to 270 Vac

I

out

= 2A

< 200mV

Minimum load

V

in

= 270 Vac

V

out

< 20V

150mA

Transition Volt.

From C.C.M to D.C.M

I

out

= 2A

160V

85 to

270

Vac

B1

C1

R12

R19

C8

NTC

10

R7

13

R24

15

12

R11

8

14

6

R6

R15

R2

4

3

2

R9

C4

R10

7

R23

Q1

R16

C12

D3

D4

C2

R17

GND

D97IN499B

L4990

R13

R1

C10

C13

D2

R14

R5

C3

R3

C7

R4

5

9

DCC

R8

VREF

C5

C6

Q2

RCT

SS

R22

C15

DC-LIM

SGND

C14

R20

R21

C11

11

PGND

ISEN

OUT

VC

VCC

DIS

COMP

VFB

T1

15V/2A

D1

Figure 30. AC-DC adaptor electric schematic

L4990 - L4990A

15/24

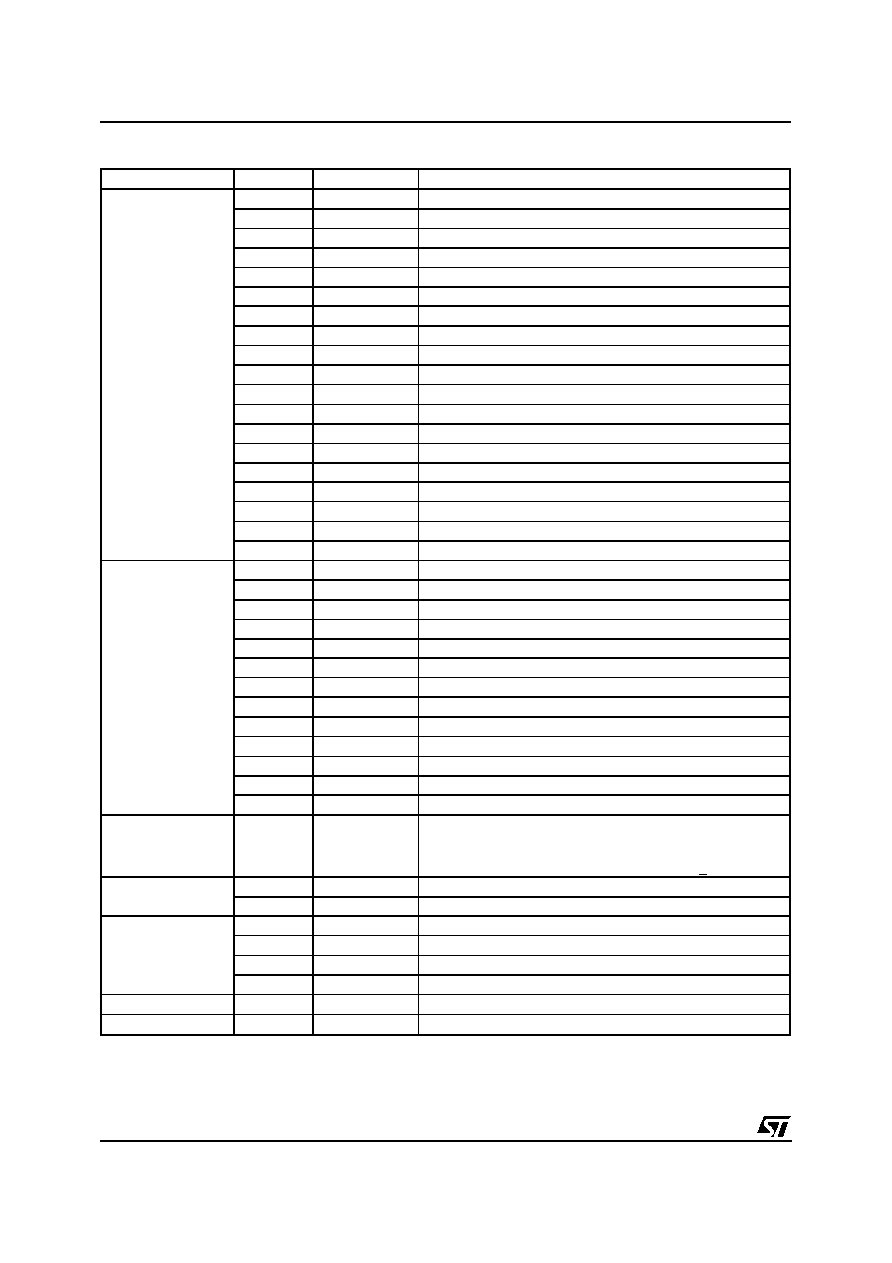

Table 3. Components List of the Fig. 30 AC-DC adaptor electric schematic.

Component

Reference

Value

Description

Resistors

R1

1.6k

2%, 1/8W

R2

9.1k

2%, 1/8W

R3, R14

10

5%, 1/8W

R4

360k

2%, 1/8W

R5

27k

2%, 1/8W

R6

200k

2%, 1/8W

R7

4.7

2%, 1/8W

R8, R9

4.7k

2%, 1/8W

R10

5.6k

2%, 1/8W

R11

1

2%, 1/2W, metallic film (low inductance)

R12, R13

24k

2%, 1/2W

R15

330

5%, 1/8W

R16

-

Not used

R17

390

5%,1W, 2 paralleled resistors (not used)

R19

100k

5%, 1W

R20, R21

470k

2%, 1/8W

R22

200

5%, 1/8W

R23

2k

2%, 1/8W

R24

1k

5%, 1/8W

Capacitors

C1

100

µ

F

400V, NCC-SMH or equiv.

C2

330

µ

F

25V, NCC-LXF or equiv., 3 paralleled capacitors

C3

47

µ

F

25V, electrolytic

C4

1

µ

F

10V, electrolytic

C5

1nF

J precision

C6, C15

10nF

C7, C14

330pF

C8

330pF

160V, polypropilene

C9

100nF

C10

220nF

C11

100pF

ceramic

C12

-

Not used

C13

4.7nF

630V

Transformer

T1

380

µ

H

Core: EFD25, Philips, 3F3 ferrite (or equivalent)

Primary: 46 T, litz wire 20 x 0.1, interleaved assembly

Secondary: 6 T, 4 paralleled litz wire 20 x 0.1

Auxiliary: 7 T (evenly spaced),

0.2 mm GAP ~ 0.7mm

Transistors

Q1

STP5NA80

ST, TO220 package

Q2

2N2222

ST (or equivalent)

Diodes

B1

DF04M

GI (or equivalent)

D1

STPS20100CT

ST, Shottky, TO220 package

D2, D3

1N4148

ST (or equivalent)

D4

BYT11-600

ST, F126 package

Fuse

Fuse

T2A250V

ELU (or equivalent)

NTC

NTC

-

Not used (see warning)

L4990 - L4990A

16/24

Figure 31. AC-DC adaptor PCB layout (1.25 :1 scale) - Component Side.

Figure 32. AC-DC adaptor PCB layout (1.25 :1 scale) - Back Side.

L4990 - L4990A

17/24

Layout hints. Generally speaking a proper cir-

cuitboard layout is vital for correct operation but is

not an easy task. Careful component placing, cor-

rect traces routing, appropriate traces widths and,

in case of high voltages, compliance with isolation

distances are the major issues. The L4990 eases

this task by putting two pins at disposal for sepa-

rate current returns of bias (SGND) and switch

drive currents (PGND) The matter is complex and

only few important points will be here reminded.

1) All current returns (signal ground, power

ground, shielding, etc.) should be routed sepa-

rately and should be connected only at a single

ground point.

2) Noise coupling can be reduced by minimizing

the area circumscribed by current loops. This

applies particularly to loops where high pulsed

currents flow.

3) For high current paths, the traces should be

doubled on the other side of the PCB whenever

possible: this will reduce both the resistance

and the inductance of the wiring.

4) Magnetic field radiation (and stray inductance)

can be reduced by keeping all traces carrying

switched currents as short as possible.

5) In general, traces carrying signal currents

should run far from traces carrying pulsed cur-

rents or with quickly swinging voltages. From

this viewpoint, particular care should be taken

of the high impedance points (current sense in-

put, feedback input, ...). It could be a good idea

to route signal traces on one PCB side and

power traces on the other side.

6) Provide adequate filtering of some crucial

points of the circuit, such as voltage refer-

ences, IC's supply pins, etc.

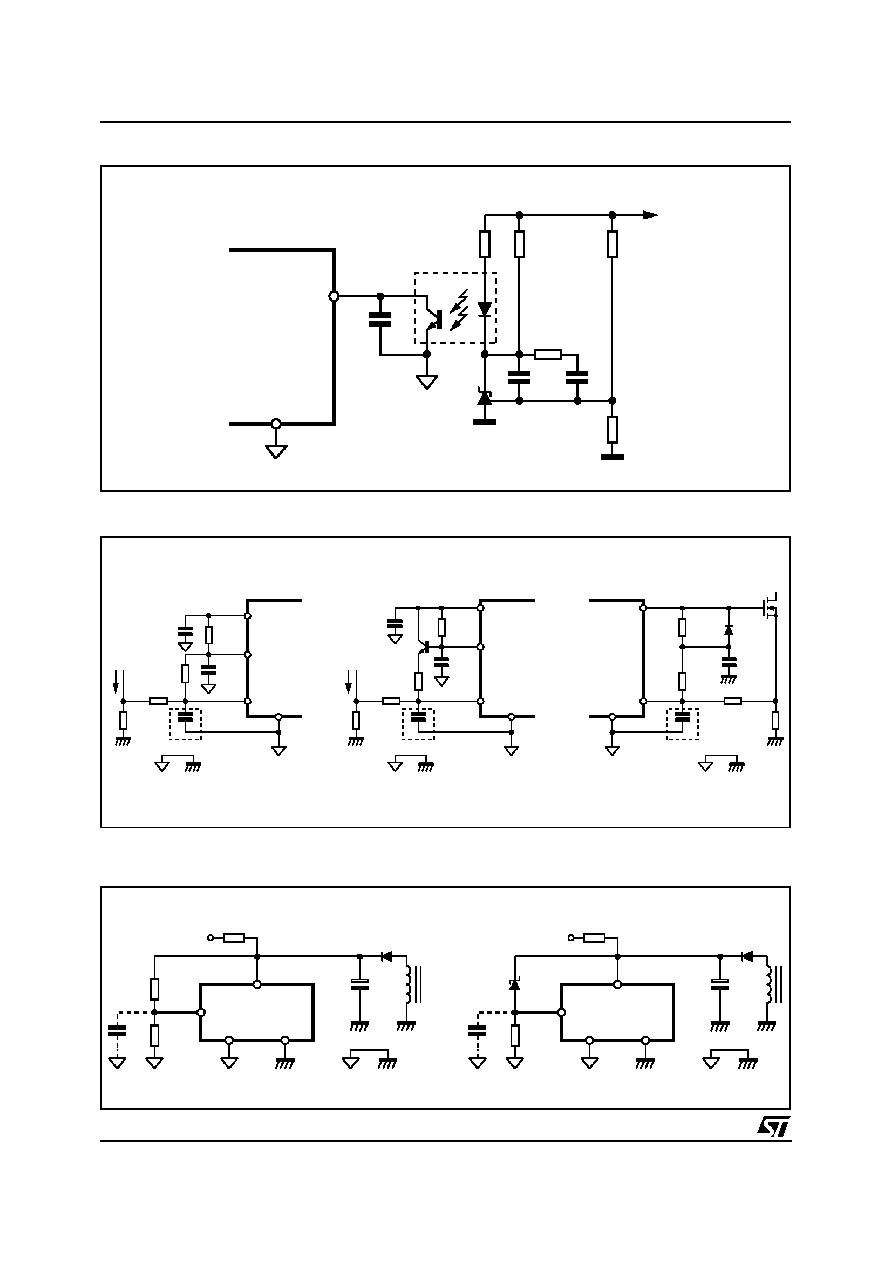

APPLICATION IDEAS

Here follows a series of ideas/suggestionsaimed at

either improving performance or solving common

application problems of L4990-basedsupplies.

D97IN504

L4990

PGND

ISEN

OUT

V

C

SGND

V

IN

ISOLATION

BOUNDARY

10

9

13

11

12

Figure 33. Isolated MOSFET Drive & Current Transformer Sensing in 2-switch Topologies.

L4990

V

REF

T

STD1NB50-1

V

CC

V

IN

22V

D97IN505A

2.2M

33K

SELF-SUPPLY

WINDING

8

4

12

11

47K

Figure 34. Low consumption start-up

L4990 - L4990A

18/24

D97IN506

L4990

PGND

ISEN

OUT

V

C

V

IN

9

10

13

11

8

V

CC

Figure 35. Bipolar Transistor Drive

D97IN507

+

-

EA

R

i

+

1.3mA

R

d

R

2R

12

C

f

R

f

6

5

From V

O

2.5V

+

-

EA

R

P

+

1.3mA

R

d

R

2R

12

C

f

R

f

6

5

From V

O

2.5V

Error Amp compensation circuit for stabilizing any current-mode topology except

for boost and flyback converters operating with continuous inductor current.

C

P

R

i

Error Amp compensation circuit for stabilizing current-mode boost and flyback

topologies operating with continuous inductor current.

VFB

VFB

COMP

COMP

SGND

SGND

Figure 36. Typical E/A compensation networks.

L4990 - L4990A

19/24

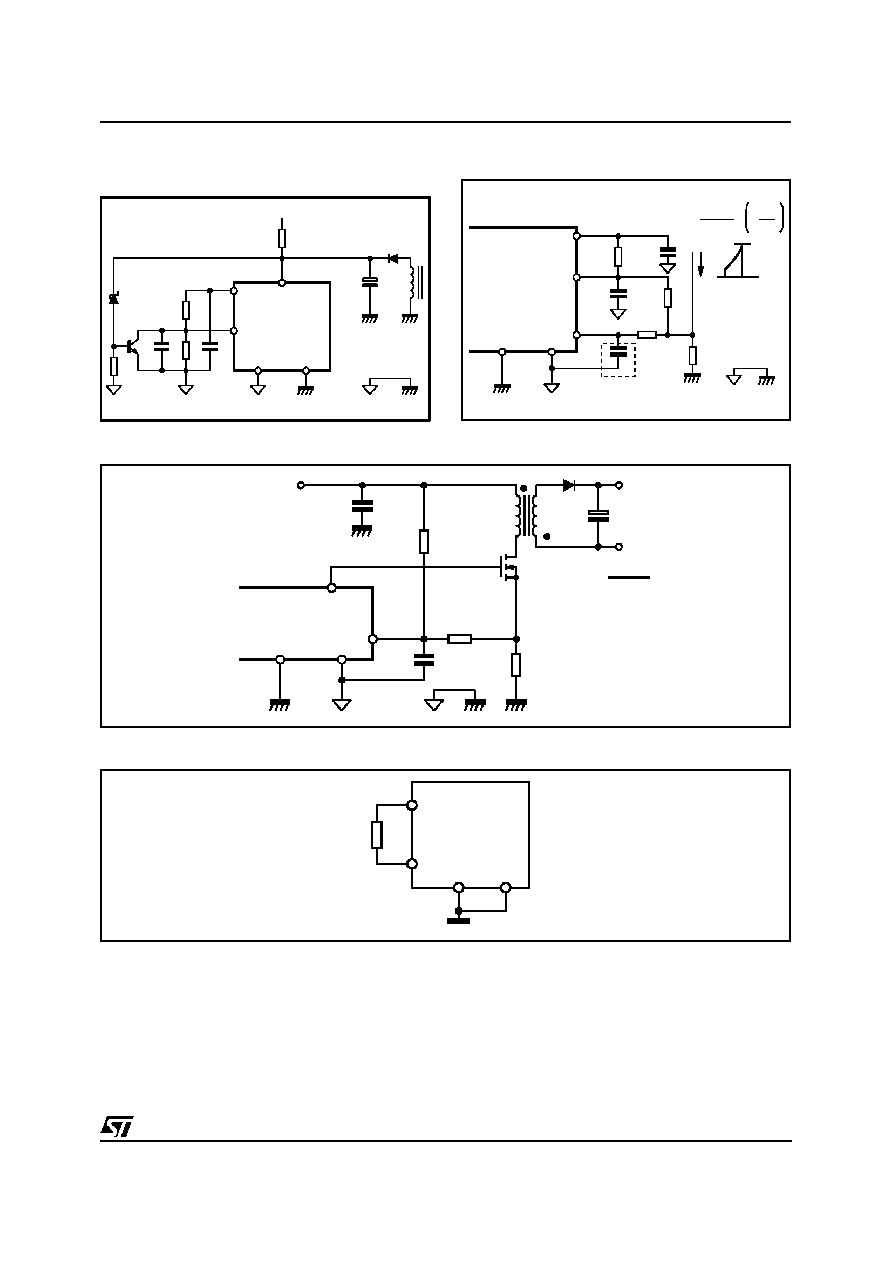

L4990

COMP

D97IN508

TL431

V

OUT

VFB

6

5

Figure 37. Feedback with optocoupler

L4990

OPTIONAL

D97IN509A

I

V

REF

SGND

R

T

C

T

RCT

R

SLOPE

R

SENSE

ISEN

L4990

OPTIONAL

I

V

REF

SGND

R

T

C

T

RCT

R

SLOPE

R

SENSE

ISEN

L4990

OPTIONAL

OUT

SGND

R

R

R

SLOPE

R

SENSE

ISEN

C

SLOPE

4

2

13

12

4

2

13

12

13

12

10

Figure 38. Slope compensation techniques

Figure 39. Protection against overvoltage/feedbackdisconnection (latched)

L4990

D97IN510

SGND

DIS

V

CC

R

START

PGND

8

14

12

11

L4990

D98IN904

SGND

DIS

V

CC

R

START

PGND

8

14

12

11

V

Z

2.2K

L4990 - L4990A

20/24

L4990

D97IN511A

DC

V

CC

VREF

R

START

3

12

8

4

11

Figure 40. Protection against overvol-

tage/feedback disconnection (not

latched)

D97IN512A

PGND

L4990

OPTIONAL

VREF

SGND

DIS

ISEN

I

4

14

13

12

11

R

SENSE

R

2

R

1

I

pk

I

pk max

2.5

R

SENSE

1-

R

2

R

1

∑

Figure 41. Device shutdown on overcurrent

D97IN513

PGND

L4990

OUT

SGND

ISEN

Lp

R

FF

R

V

IN

R

FF

= 5∑10

6

R∑Lp

RSENSE

RSENSE

13

10

12

11

80

˜

400V

DC

Figure 42. Constant power in pulse-by-pulse current limitation (flyback discontinuous)

REFERENCES

[1] Efficient active Clamp for Off-line Applications using L4990 and L6380 (N.Tricomi, G. Gattavari,

C. Adragna, PCIM96 - NURBERG).

[2] 25W Off-Line Autoranging Battery Charger with L4990 (AN889)

[3] 300W Secondary Controlled Two-Switch Forward Converter with L4990 (AN890)

[4] SMPS with L4990 for Multisync Monitors (AN891)

[5] High performance VRM using L4990A, for Pentium Pro

Æ

processor (AN908).

L4990

DC

10K

COMP

3

6

12

13

SGND

ISEN

D97IN570A

Figure 43. Voltage mode operation.

L4990 - L4990A

21/24

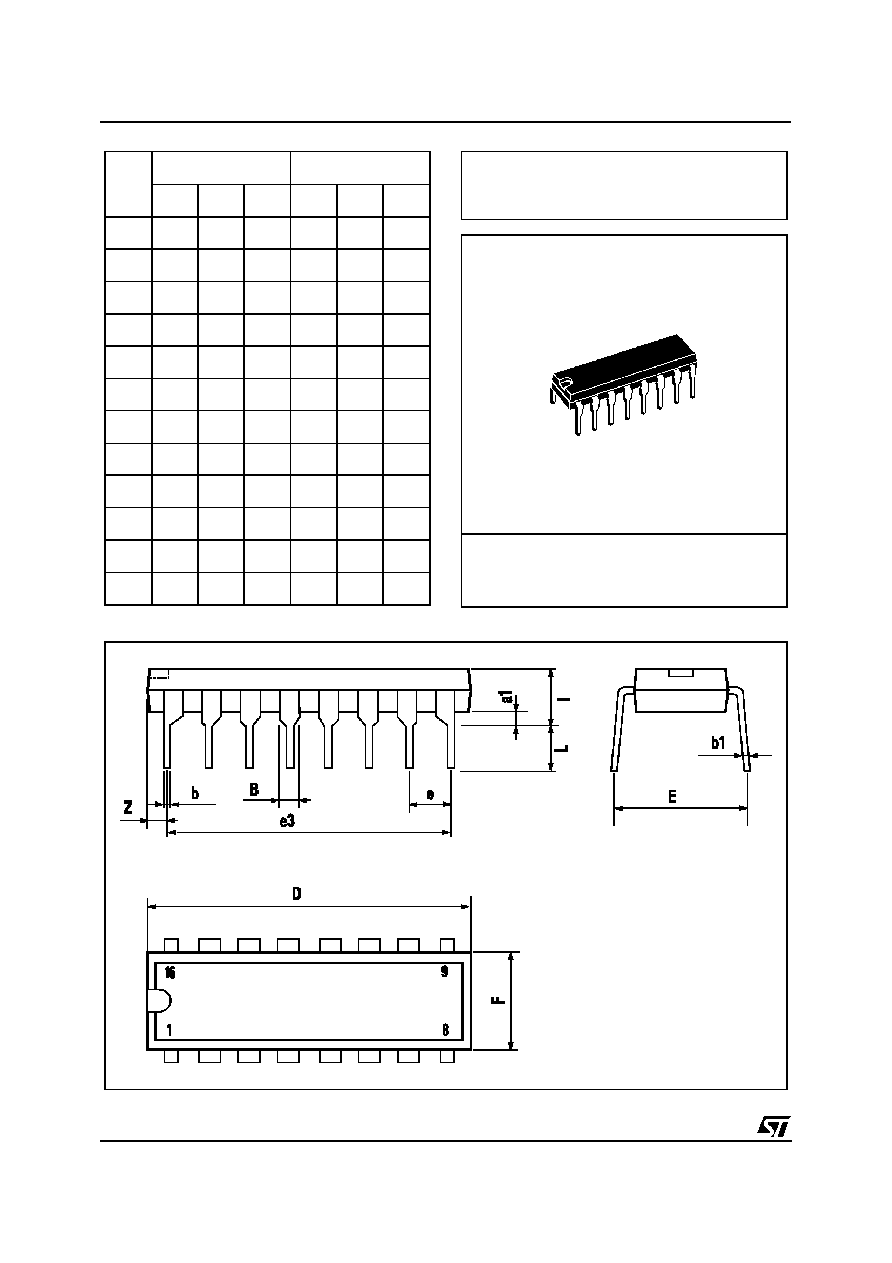

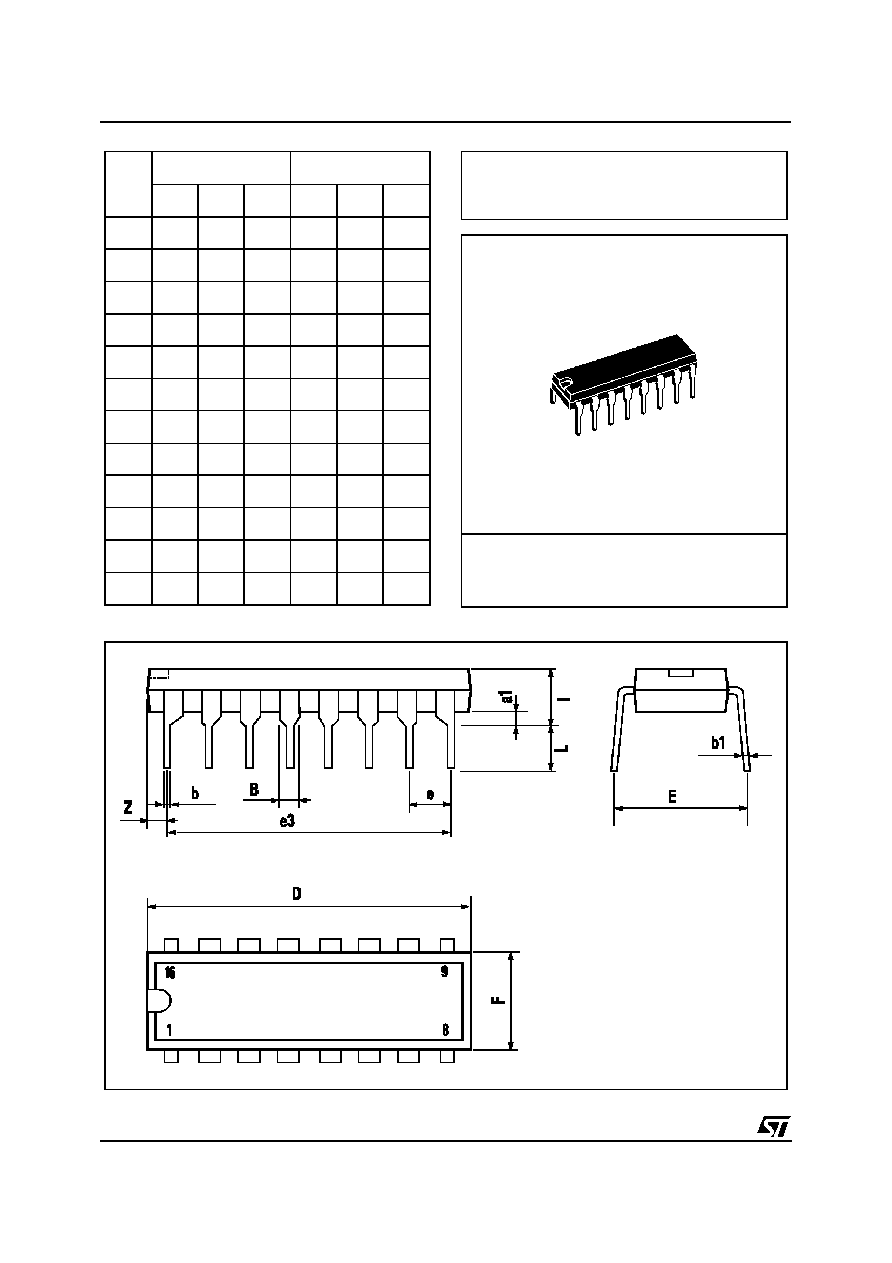

DIP16

DIM.

mm

inch

MIN.

TYP.

MAX.

MIN.

TYP.

MAX.

a1

0.51

0.020

B

0.77

1.65

0.030

0.065

b

0.5

0.020

b1

0.25

0.010

D

20

0.787

E

8.5

0.335

e

2.54

0.100

e3

17.78

0.700

F

7.1

0.280

I

5.1

0.201

L

3.3

0.130

Z

1.27

0.050

OUTLINE AND

MECHANICAL DATA

L4990 - L4990A

22/24

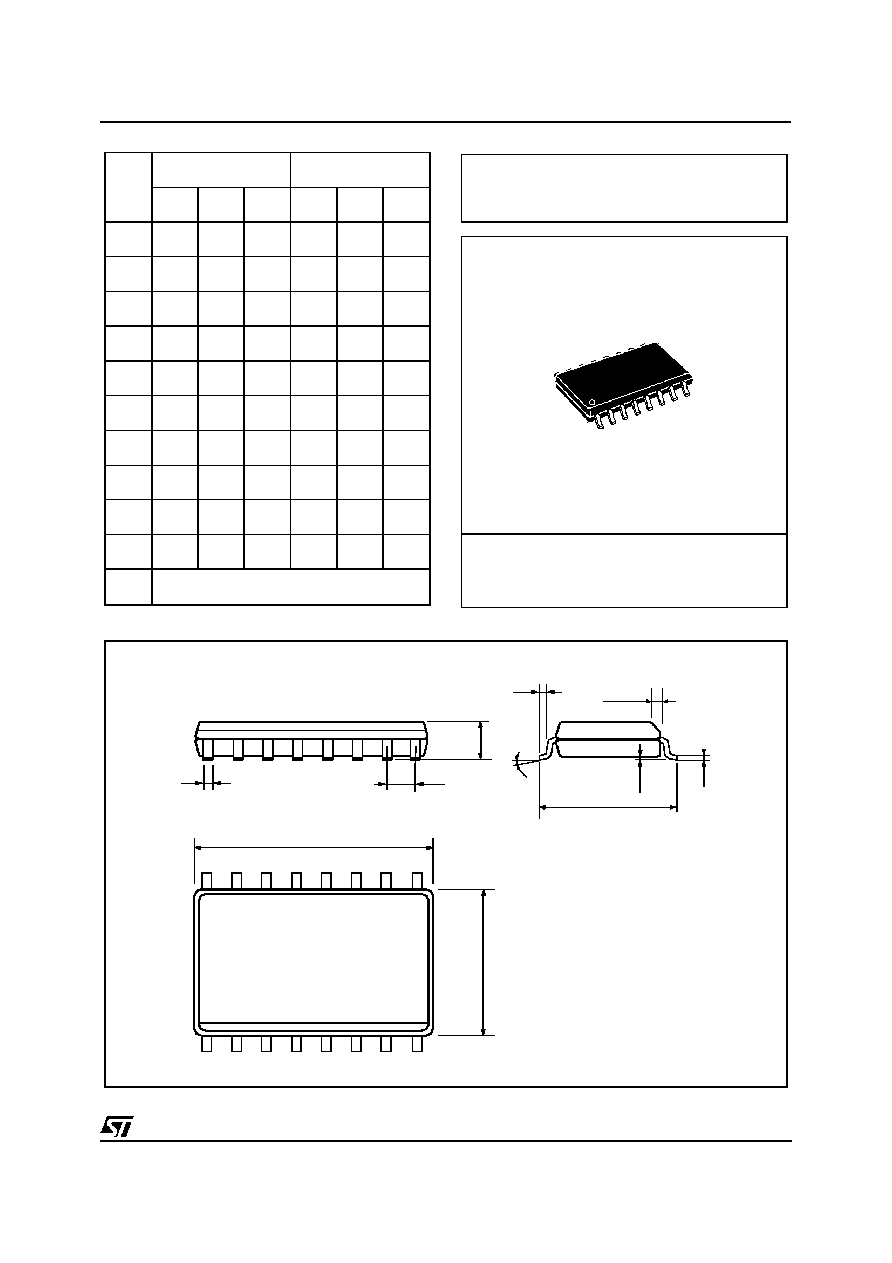

DIM.

mm

inch

MIN.

TYP.

MAX.

MIN.

TYP.

MAX.

A

2.35

2.65

0.093

0.104

A1

0.1

0.3

0.004

0.012

B

0.33

0.51

0.013

0.020

C

0.23

0.32

0.009

0.013

D

10.1

10.5

0.398

0.413

E

7.4

7.6

0.291

0.299

e

1.27

0.050

H

10

10.65

0.394

0.419

h

0.25

0.75

0.010

0.030

L

0.4

1.27

0.016

0.050

K

0

∞

(min.)8

∞

(max.)

h x 45

A

e

B

D

E

A1

H

L

C

K

16

1

8

9

SO16 Wide

OUTLINE AND

MECHANICAL DATA

L4990 - L4990A

23/24

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parti es which may result from its use. No license is

granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specification mentioned in this publication are

subject to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

©

1999 STMicroelectronics ≠ Printed in Italy ≠ All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

L4990 - L4990A

24/24