| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: L5953 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1/24

L5953

September 2003

This is preliminary information on a new product now in development. Details are subject to change without notice.

s

PWM: ADJUSTABLE 2.5/10V - 1A

SWITCHING VOLTAGE REGULATOR

s

EXTERNAL POWER MOS ABILITY FOR

OUTPUT CURRENT ENHANCEMENT

s

SYNCHRONIZATION FUNCTION

s

REG1- LINEAR LOW DROP 3.3/5V - 250mA

STBY VOLTAGE REGULATOR (LOW

CURRENT CONSUMPTION) with RESET

s

REG2- LINEAR VOLTAGE REGULATOR 1.5V

to 3.3V EXTERNALLY ADJUSTABLE - 300mA

MAXIMUM CURRENT

s

HSD1 : 500mA HIGH SIDE DRIVER

s

HSD2 : 200mA HIGH SIDE DRIVER

s

SPI INTERFACE

s

SPI DIAGNOSTICS HSD1, HSD2

s

DOUBLE SWITCHING FREQUENCY SPI

SELECTABLE

s

DOUBLE INPUT LVW

SPI FUNCTIONS

s

INPUT CONTROLS

≠ Turn-on/off PWM

≠ Turn-on/off REG2

≠ Turn-on/off HSD1

≠ Turn-on/off HSD2

≠ Switching frequency selection f1- f2

s

OUTPUT FUNCTIONS:

≠ HSD1 & HSD2 short to gnd, open load and

short to battery (Test mode)

≠ Thermal warning

PROTECTIONS

s

OVERVOLTAGE PROTECTION

s

INTERNAL CURRENT LIMITING

s

THERMAL SHUTDOWN

s

ESD

DESCRIPTION

The L5953 is the integration of one switching regula-

tor, two linear voltage regulators, two low voltage

warnings and two high side drivers. It has a stand-by

operation mode (low current consumption) where

only the stand-by voltage regulator plus the low volt-

age warnings are active. The other regulators and

high side drivers are controlled by the SPI interface.

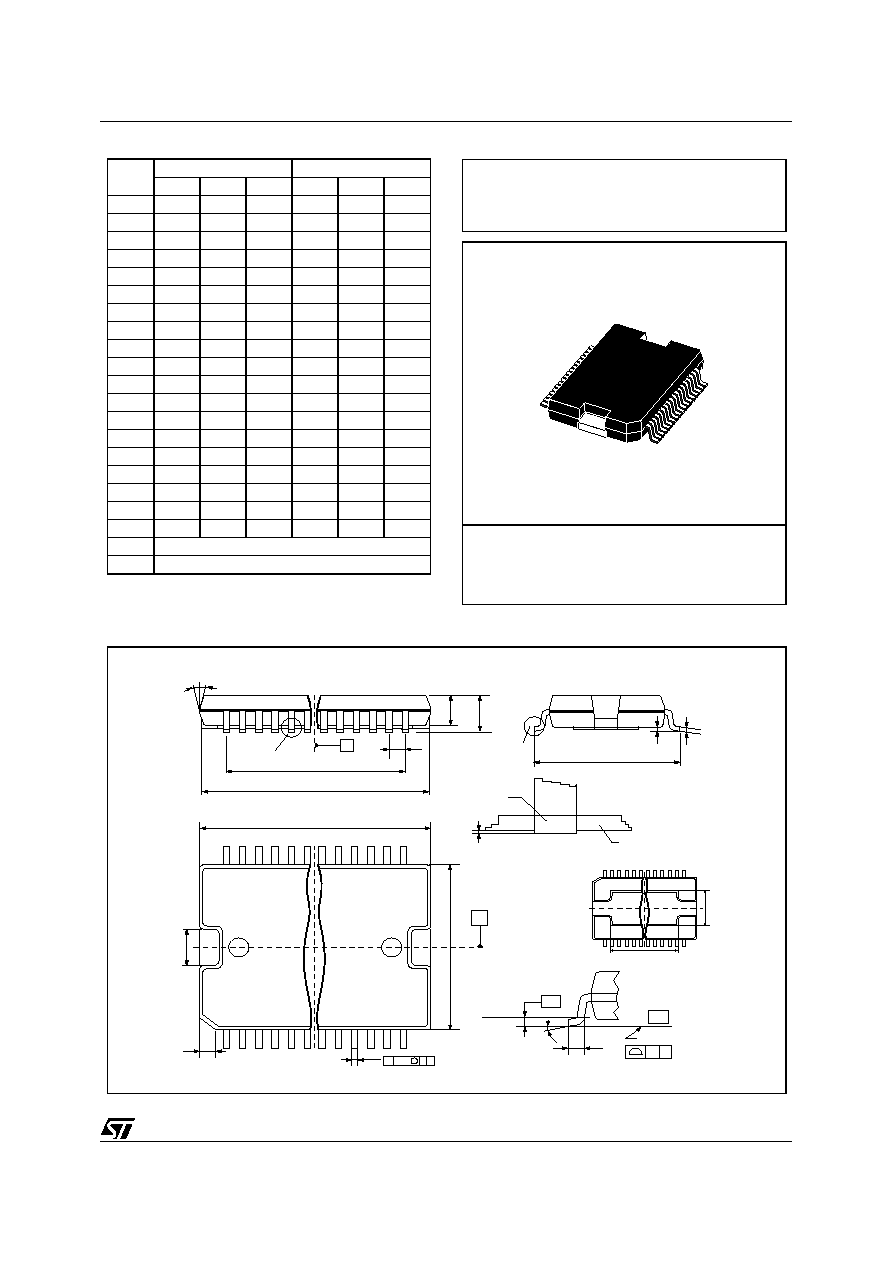

PowerSO36

ORDERING NUMBER: L5953

PRODUCT PREVIEW

MULTIPLE SWITCHING VOLTAGE REGULATOR

BLOCK DIAGRAM

VOLTAGE WARNING

SPI INTERFACE

REC2

LINEAR VOLTAGE

REGULATOR

1.5-3.3V/300mA

HSD1

HSD1

HSD2

HSD2

COMP

FB

GATEOUT

GATEIN

VSW

DRAINOUT

STRAP

ADJ

VSTBY

GND

SWGND

S1

W1

S2

W2

VDD-LIN

REC1

ST-BY LINEAR VOLTAGE

REGULATOR

3.3-5V/250mA

PWM

STEP DOWN

REGULATOR

2.5-10V/1A

OSCILLATOR &

SYNC

STCAP

CT

RES

VDD-SW

IRQ

Q

D

S

C

VLR

FBLR

VIN

SYNC

VSPI

DGND

FGND

D01AU1330A

L5953

2/24

ABSOLUTE MAXIMUM RATINGS

THERMAL DATA

PIN CONNECTION

Symbol

Parameter

Value

Unit

V

DD

DC Operating Supply Voltage

-0.6 to 30

V

Transient Supply Overvoltage (250ms)

50

V

V

SPI

Supply Voltage for SPI I/O

-0.6 to 6

V

I

O

Voltage Regulator Output Current

Internally limited

V

inlog

Input Voltage (C,D,Q,

S

,SYNC)

0 to 6

V

RESR

Output Capacitor Series Eq. Resistance (Linear reg.)(Allowed

range)

From 0.2 to 10

T

op

Operating Temperature Range

-40 to 85

∞C

T

stg

Storage Temperature Ranges

-55 to 150

∞C

T

j

Operative Junction Temperature

-40 to 150

∞C

Symbol

Parameter

Value

Unit

R

thj-case

Thermal Resistance Junction to Case

1.7

∞C/W

FGND

S2

S1

W2

IRQ

VDD-LIN

HSD2

N.C.

HSD1

DRAINOUT

N.C.

GND

GATEIN

VSW

STCAP

VSPI

VSTBY

ADJ

18

16

17

15

6

5

4

3

2

21

22

31

32

33

35

34

36

20

1

19

SWGND

VDD-SW

D02AU1345A

Q

DGND

S

GATEOUT

SYNC

STRAP

9

8

7

28

29

30

C

VLR

10

27

W1

D

CT

VIN

FB

FBLR

14

12

11

23

25

26

RES

COMP

13

24

3/24

L5953

PIN FUNCTION

Pin Number

Pin Name

Function

1

FGND

Analog Ground

2

S2

Input Voltage for LVW2

3

S1

Input Voltage for LVW1

4

W2

LVW2 Output

5

W1

LVW1 Output

6

RES

Reset

7

CT

Timing capacitor

8

D

SPI Serial Input

9

C

SPI Clock

10

Q

SPI Serial Output

11

S

SPI Chip Select

12

DGND

SPI Ground

13

IRQ

Interrupt

14

HSD2

HSD2 Output

15

VDD-LIN

Battery

16

N.C.

Not Connected

17

HSD1

HSD1 Output

18

SWGND

Switching Ground

19

VDD-SW

PWM Battery

20

DRAINOUT

Drain of the exrternal MOS

21

N.C.

Not Connected

22

GND

Ground

23

VSW

Source of the external MOS

24

GATEIN

Gate of the internal MOS

25

GATEOUT

Switching Output for power mos gate

26

STRAP

Bootstrap

27

SYNC

Synchronization

28

VLR

REG2 Linear Voltage Regulator Output

29

VIN

REG2 Linear Voltage Regulator Input

30

FBLR

REG2 Linear Voltage Regulator Feedback

31

COMP

PWM Compensation

32

FB

PWM Feedback

33

STCAP

ST-CAP

34

VSPI

Supply Voltage for SPI I/O

35

VSTBY

REG1 Stand-by Linear Voltage Regulator Output

36

ADJ

3.3V/5V REG1 Voltage Select

L5953

4/24

ELECTRICAL CHARACTERISTCS

( T

amb

= 25∞C, V

DD

= 14.4V)

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

I

Q,STBY

Quiescent current with regulators

and High-side drivers off

W1, W2, RES, IRQ, not active;

REG2, HSD1, HSD2, PWM off;

S, C, D fixed at high/low logic

level

100

µ

A

T

sd

Thermal Shutdown Junction

Temperature

150

∞C

SMPS.PWM

T

amb

= 25∞C, V

DD

= 14.4V, V

o

= 5V; unless otherwise specified.)

V

o,min

Minimum Output Voltage

I

o

= 200mA

2.4

2.5

2.6

V

V

o,max

Maximum Output Voltage

I

o

= 200mA

9.6

10

10.4

V

Vref,PWM

Voltage Reference

1.275

V

V

i

Input Voltage Range

V

o

= 5V; I

o

= 0.5A

6

18

V

V

o

Line Regulation

I

o

= 0.5A

100

mV

V

o

Load Regulation

V

o

= 5V; I

o

= 0.2A to 0.5A

50

mV

V

d

Dropout Voltage between Pin 19

and Pin 23

I

o

= 0.5A, V

o

= 5V

0.5

V

I

o

= 1A, V

o

= 5V

1

V

I

Lim

Current Limit

1.5

A

Efficiency

f = 260kHz; I

o

= 0.5A

f = 400kHz; I

o

= 0.5A

90

86

%

%

SVR

Supply Voltage Ripple Rejection

V

i

= 1Vrms;

f

ripple

= 300Hz; I

o

= 0.4A

50

dB

OSCILLATOR

f

1

Swiching frequency

249

260

271

kHz

f

2

Swiching frequency

384

400

416

kHz

Voltage Stability of Switching

Frequency

V

DD

= 8 to 18V

Tbd

%

Temperature Stability of Switching

Frequency

T

j

= -40∞C to 85∞C

Tbd

%

SYNC

V

IL

Low Input Voltage

0.8

V

V

IH

High Input Voltage

2

V

V

OL

Low Output Voltage

0.4

V

V

OH

High Output Voltage

I

SOURCE

=1.5mA

4

V

f

V

i

---------

f

T

j

---------

5/24

L5953

I

SLAVE

Slave Sink Current

100

µ

A

T

W

Output Pulse Width

300

ns

REG1 - 3.3V/5V STBY LINEAR VOLTAGE REGULATOR

V

STBY

Output Voltage

no load; ADJ pin = open

no load; ADJ pin = VSTBY pin

4.9

3.20

5

3.3

5.1

3.4

V

V

V

line

Line Regulation

no load; 7 < Vdd < 26V

5

50

mV

V

load

Load Regulation

5mA < I

o

< 250mA

12

80

mV

V

dropout

V

STCAP

- V

STBY

I

o

= 100mA, V

o

= 5V

I

o

= 100mA, V

o

= 3.3V

0.36

0.47

0.5

0.65

V

I

lim

Current Limit

Out short to GND

300

mA

SVR

Supply Voltage Rejection

V

DD

= 1Vrms: f = 300Hz

I

o

= 250mA

55

dB

REG2 - LINEAR VOLTAGE REGULATOR 1.5V to 3.3V

V

LR

Linear Regulator Output Voltage

no load; 4.75

V

IN

16V;

1+ (R5/R6) = 2.588

3.2

3.3

3.4

V

no load; 3.135

V

IN

16V;

1+ (R5/R6) = 1.176

1.45

1.5

1.55

V

IN

Input Voltage

I

O

= 150mA

1.5V

V

LR

2V

3.135

16

V

I

O

= 300mA

1.5V

V

LR

3.3V

4.75

16

V

V

load

Load Regulation

5mA

I

O

300mA

4.75V

V

IN

16V; 1.5V

V

LR

3.3V

12

mV

V

line

Line Regulation

no load;

4.75V

V

IN

16V; 1.5V

V

LR

3.3V

1

mV

V

ref,REG2

Voltage Reference

1.275

V

I

Lim

Current Limit

Out Short to ground

400

mA

SVR

Supply Voltage Rejection

V

IN

= 5Vdc, 0.5Vacpp, 300Hz

I

O

= 300mA; 1.5V

V

LR

3.3V

55

dB

V

IN

= 3.3Vdc, 0.5Vacpp, 300Hz

I

O

= 150mA; 1.5V

V

LR

2V

55

dB

HSD1

V

sat, peak

Saturation Voltage

I

O

= 0.5A

250

mV

I

lim

Current Limit

600

mA

L

load

Load Inductance

100

mH

ELECTRICAL CHARACTERISTCS (continued)

( T

amb

= 25∞C, V

DD

= 14.4V)

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

L5953

6/24

DIAGNOSTIC PARAMETERS

HSD2

V

sat, peak

Saturation Voltage

I

O

= 0.2A

250

mV

I

lim

Current Limit

300

mA

L

load

Load Inductance

100

mH

VOLTAGE WARNING

V

st

Sense Low Threshold

1.245

1.275

1.305

V

V

sth

Sense Threshold Hysteresis

35

45

60

mV

V

SL

Sense Output Low Voltage

I

o

= 1mA

0.4

V

I

SH

Sense Output Leakage

V

W

= 5V; V

SI

1.5V

10

µ

A

I

SI

Sense Input Current

V

SI

=5V

1

µ

A

RESET

V

RT

Reset Threshold Voltage

0.95 x

V

STBY

V

V

RTH

Reset Threhold Hysteresis

0.02 x

V

STBY

V

V

RL

Reset Output Voltage

I

o

= 1mA

0.4

V

I

RH

Reset Output Leakage

V

RT

= V

STBY

10

µ

A

V

CTth

Delay Comparator Threshold

0.5 x

V

STBY

V

CThy

Delay Comparator Threshold

Hysteresys

180

mV

I

CT1

Timing Capacitor Output Source

Current

7.5

µ

A

R

CT2

Timing Capacitor Output Pull-

Down equivalent Resistor

150

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

HSD1W1 High Side Driver 1 Overcurrent

Warning activation

0.95

A

HSD1W2 High Side Driver 1 Open Load

Warning activation

HSD1 output voltage in test mode

3

V

HSD1W2

TEST

High Side Driver 1 V

DD

Short

Warning activation in test mode

HSD1 in test mode

Measure V

VDD-LIN

-V

HSD1

1.5

V

HSD2W1 High Side Driver 2 Overcurrent

Warning activation

0.7

A

ELECTRICAL CHARACTERISTCS (continued)

( T

amb

= 25∞C, V

DD

= 14.4V)

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

7/24

L5953

SPI INTERFACE

HSD2W2 High Side Driver 2 Open Load

Warning activation

HSD2 output voltage in test mode

3

V

HSD2W3 High Side Driver 2 V

DD

Short

Warning activation in test mode

HSD2 in test mode

Measure V

VDD-LIN

-V

HSD1

1.5

V

THW

Thermal warning activation

145

∞C

IRQ - Interrupt Request Pin

IRQ-L

IRQ Low voltage

I

o

= 1mA

0.4

V

IRQ-H

IRQ Leakage

V

irq

= 5V

1

µ

A

Symbol

Alt

Parameter

Test Conditions

Min.

Max.

Unit

Recommended DC Operating Voltage

V

SPI

Supply Voltage for SPI I/O

3

5.5

V

Input Parameters (Tamb = 25∞C, f = 1MHz)

C

IN

Input Capacitance (D)

8

pF

C

IN

Input Capacitance (others pins)

6

pF

t

LPF

Input Signal Pulse Width

10

ns

DC Characteristics (T

amb

= -40 to 85∞C, V

SPI

= 3V to 5.5V)

I

LI

Input Leakage Current

2

µ

A

I

LO

Output Leakage Current

±2

µ

A

V

IL

Input Low Voltage

-0.3

0.3V

SPI

V

V

IH

Input High Voltage

0.7V

SPI

V

SPI

+1

V

V

OL

Output Low Voltage

I

OL

= 2mA

0.2V

SPI

V

V

OH

Output High Voltage

I

OH

= -2mA

0.8V

SPI

V

AC Characteristics (Tamb = -40 to 85∞C, V

SPI

= 3V to 5.5V

t

SCLH

t

SU

S Setup Time

50

ns

t

CLSH

t

SH

S Hold Time

50

ns

t

CH

t

WH

Clock High Time

200

ns

t

CL

t

WL

Clock Low Time

300

ns

t

CLCH

t

RC

Clock Rise Time

1

µ

s

t

CHCL

t

FC

Clock Fall Time

1

µ

s

t

DVCH

t

DSU

Data In Setup Time

50

ns

t

CHDX

t

DH

Data In Hold Time

50

ns

t

DLDH

t

RI

Data In Rise Time

1

µ

s

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

L5953

8/24

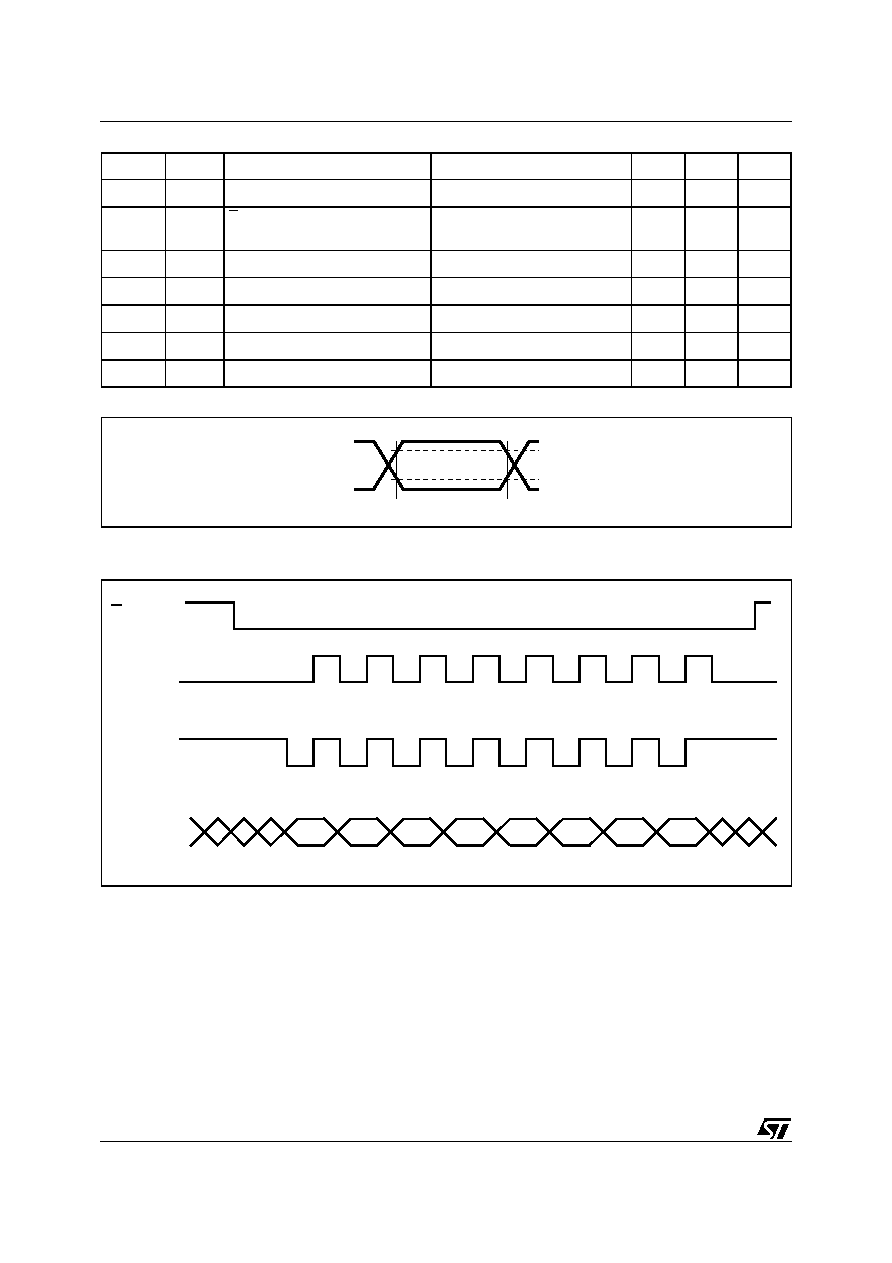

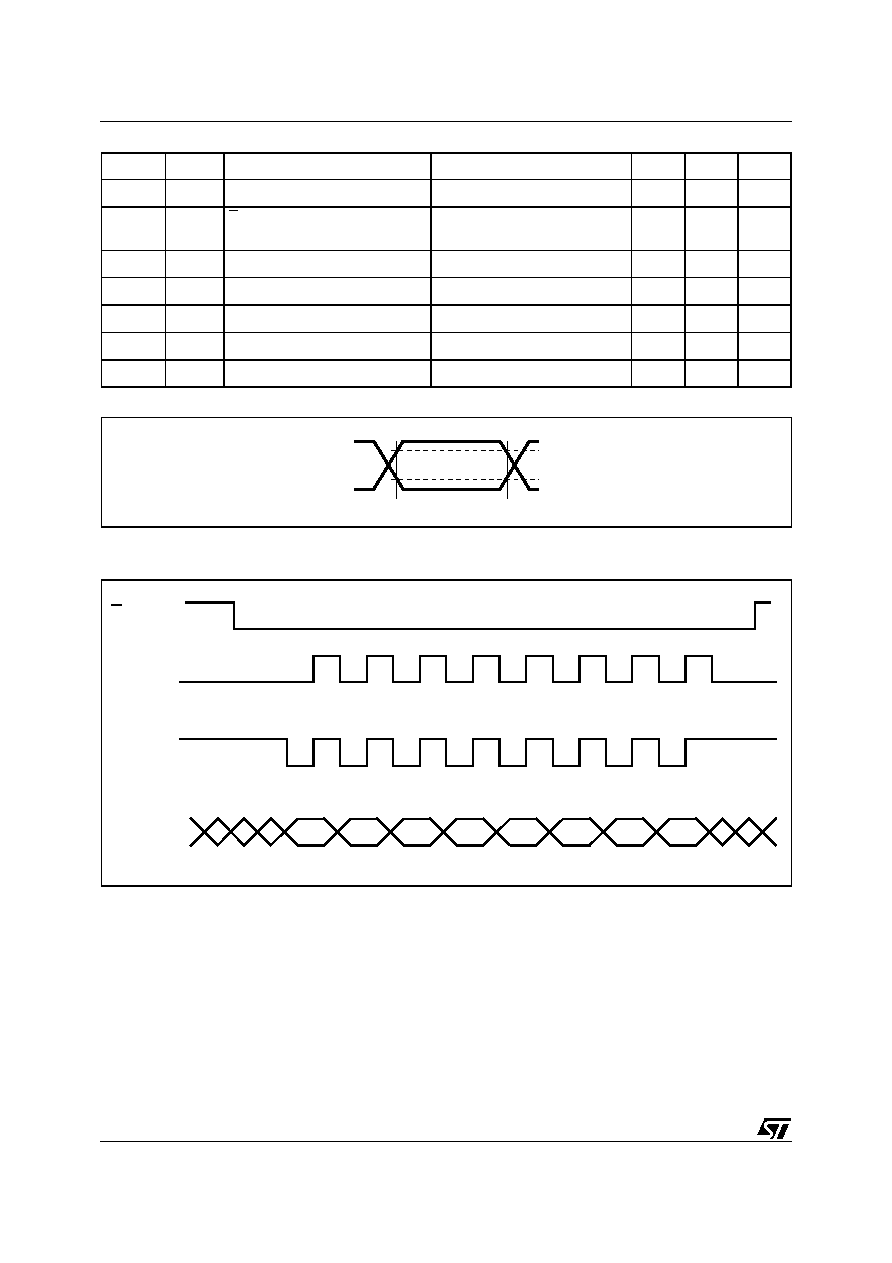

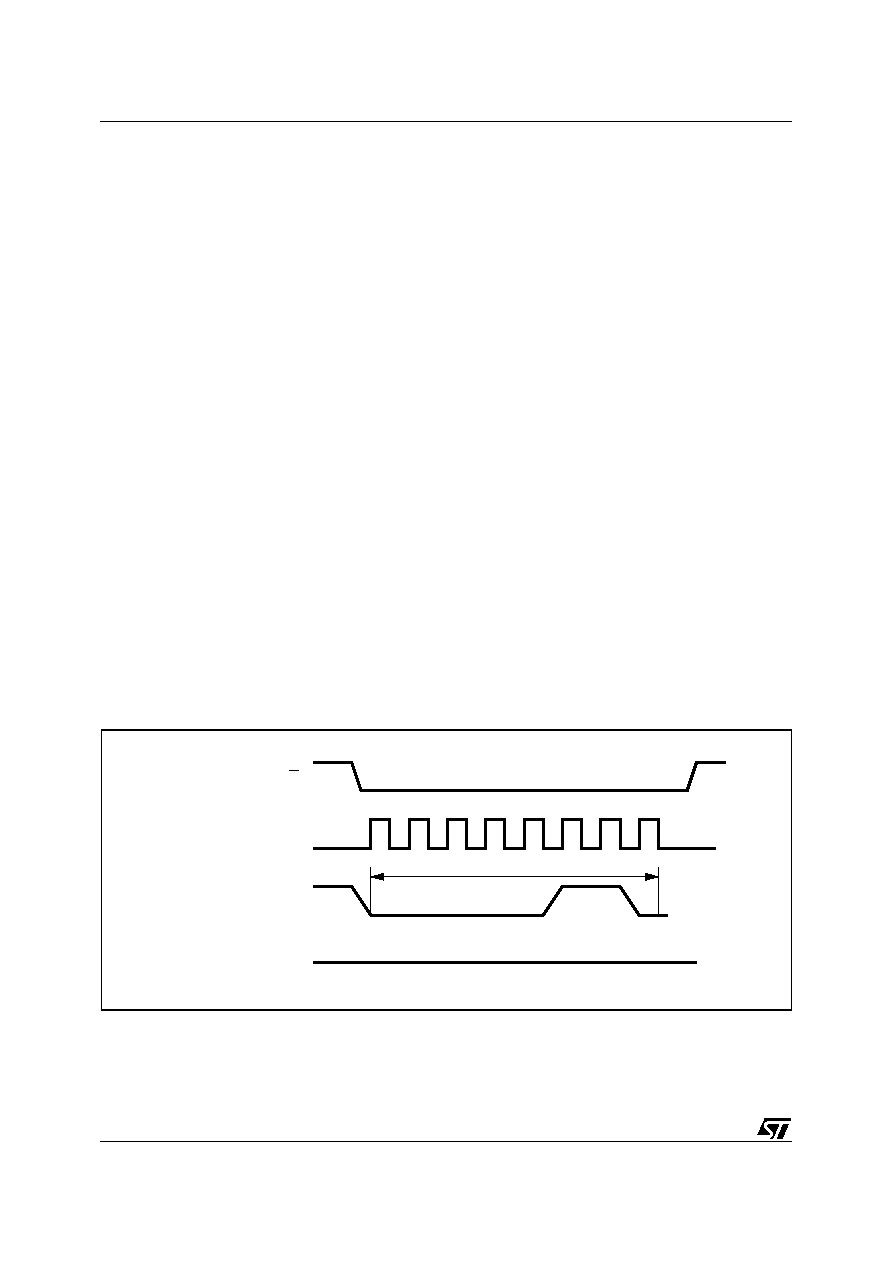

Figure 1. AC Testing Input Output WaveformsI

Figure 2. SPI Clocking Scheme

t

DHDL

t

FI

Data in Fall Time

1

µ

s

t

SHSL

t

CS

S Deselect Time

4.5V < V

SPI

< 5.5V

3V < V

SPI

< 4.5V

200

250

ns

ns

t

SHQZ

t

DIS

Output Disable Time

150

ns

t

QVCL

t

V

Clock Low to Output Valid

250

ns

t

CLQX

t

HO

Output Hold Time

0

ns

t

QLQH

t

RO

Output Rise Time

100

ns

t

QHQL

t

FO

Output Fall Time

100

ns

Symbol

Alt

Parameter

Test Conditions

Min.

Max.

Unit

0.8V

SPY

0.2V

SPY

0.7V

SPY

0.3V

SPY

D03AU1479

C

S

(MODE 0: CPOL=0,CPHA=0)

(MODE 3: CPOL=1,CPHA=1)

C

MSB

6

5

4

3

2

1

0

D

Q

9/24

L5953

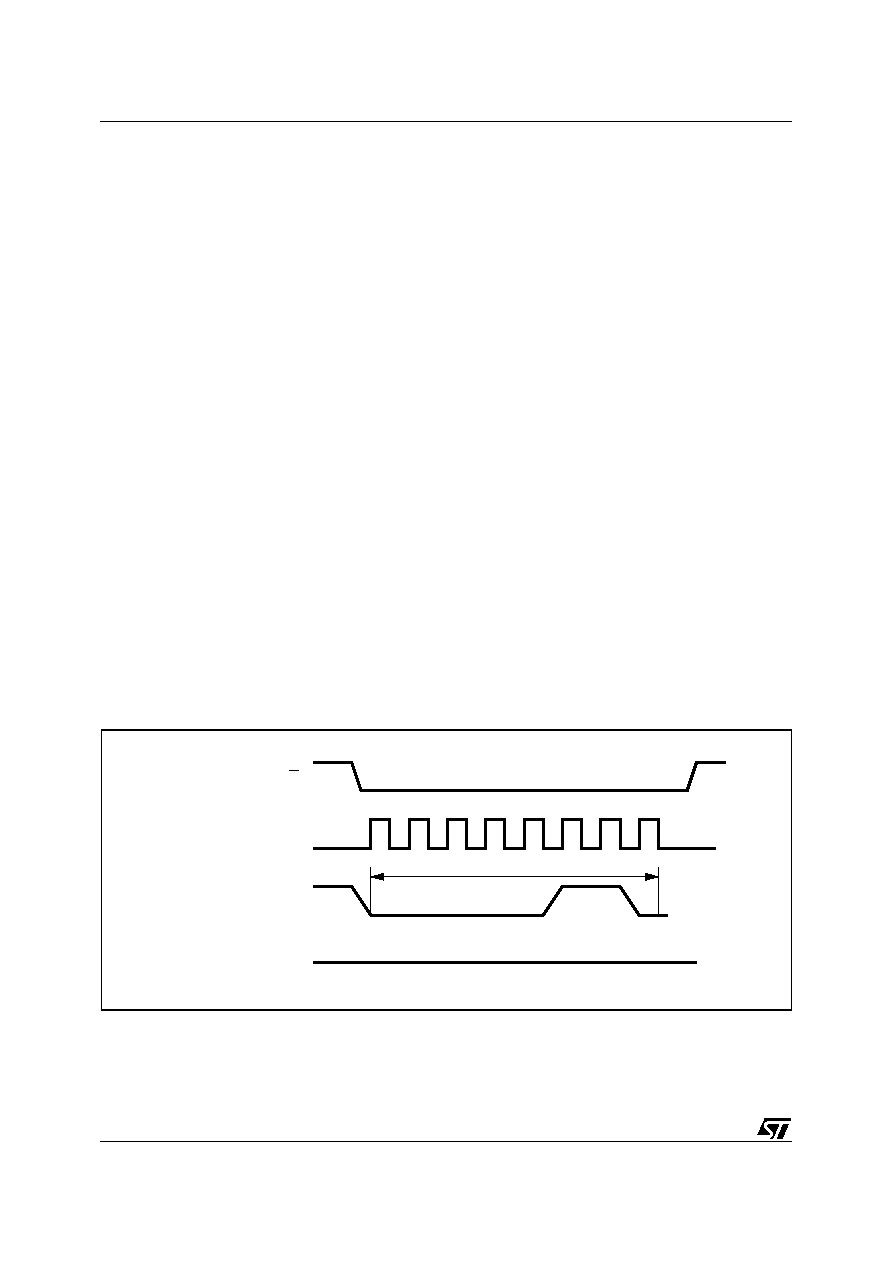

Figure 3. Output Timing

Figure 4. Serial Input Timing

FUNCTIONAL DESCRIPTION

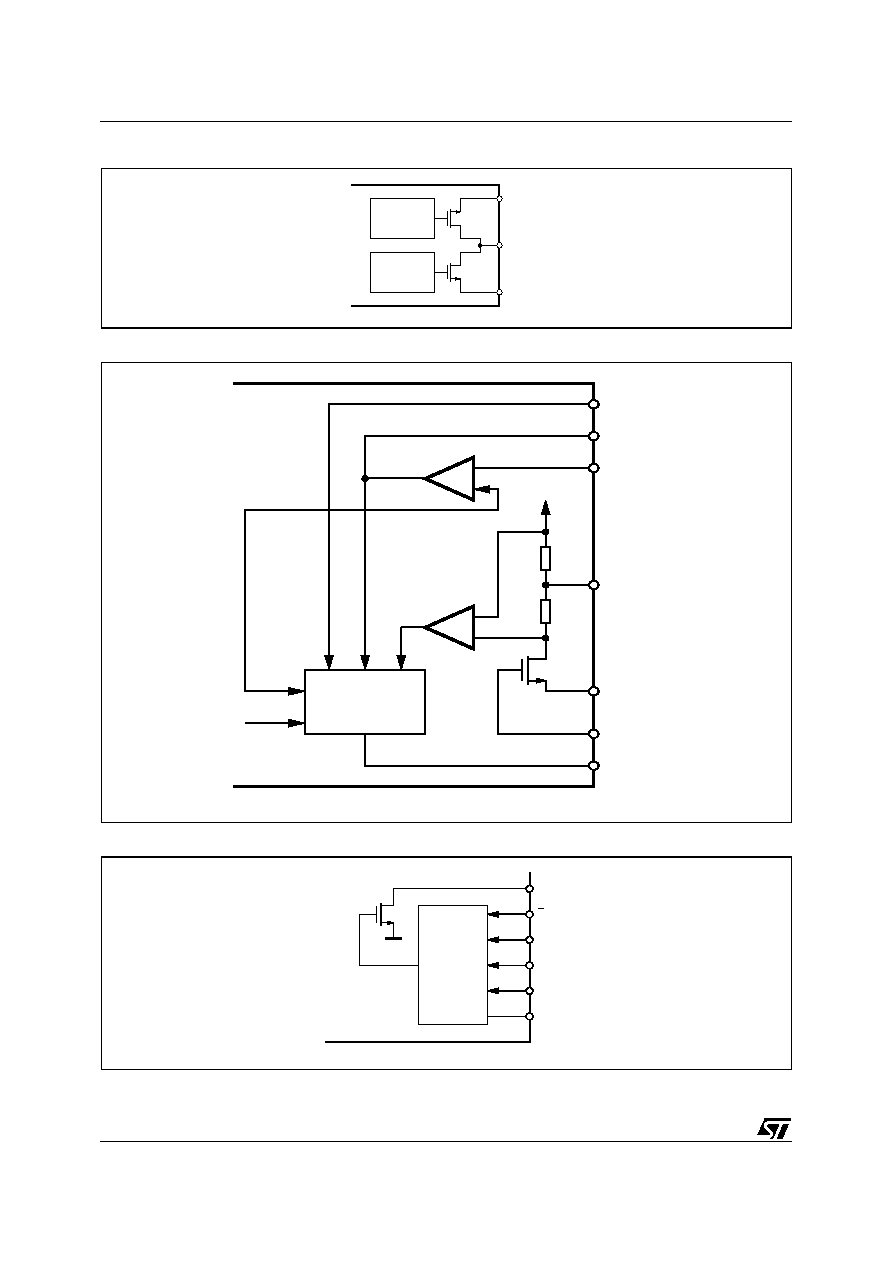

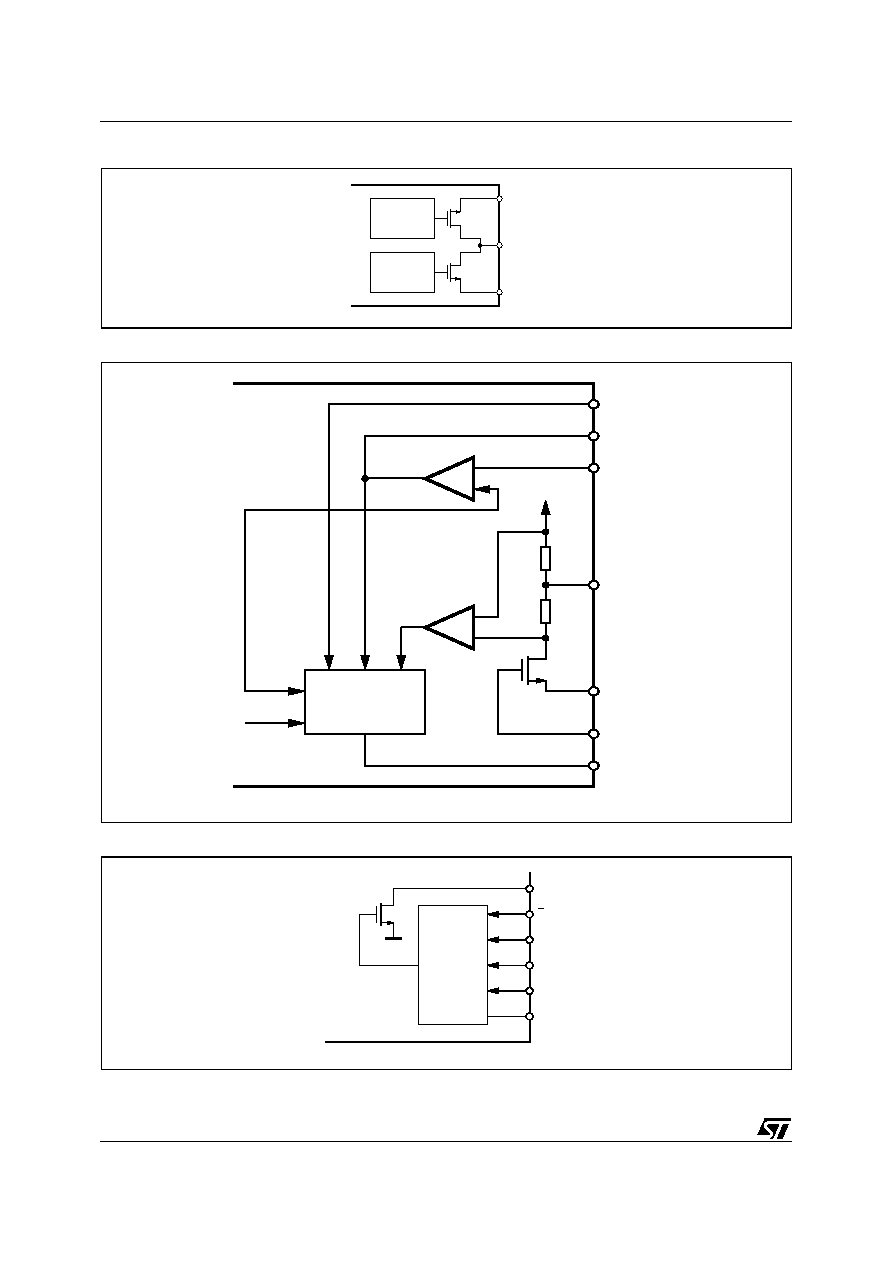

REG1 Stand-by Regulator (Figure 5)

The stand-by regulator output voltage can be 5V or 3.3V. It is externally selectable by means of the ADJ pin:

- leaving the ADJ pin open, the output voltage is 5V;

- connecting the ADJ pin to the Vstby pin the output voltage becomes 3.3V.

This regulator is supplied by STCAP pin and provide the reset information.

It has a current protection which limits the maximum allowable output current.

Reset (Figure 6)

The RES pin is an open collector that is activated (that is forced to zero) when the stand-by regulator is not in

regulation (including thermal shutdown and faults). The indication that REG1 is in regulation is delayed by a time

C

Q

AI01070B

S

MSB OUT

MSB-1 OUT

LSB OUT

D

ADDR.LSB IN

tSHQZ

tCH

tCL

tQLQH

(CPOL=0, CPHA=0)

tQHQL

tCLQX

tQVCL

C

D

AI01071

S

MSB IN

Q

tDVCH

HIGH IMPEDANCE

LSB IN

tSLCH

tCHDX

tDLDH

tDHDL

tCHCL

tCLCH

tCLSH

tSHSL

(CPOL=0, CPHA=0)

L5953

10/24

set up by the external capacitor CT.

When the RES is switched on, HSD1, HSD2, REG2, PWM are turned off and until the RES is forced to zero

only the REG1 and low Voltage Warnings are active.

Low Voltage Warning(Figure 7)

This circuit is able to sense two different voltages through external resistors to increase the overall flexibility.

If S1 pin voltage is higher than Vst, the output mos M1 is off: W1 is floating and can be pulled up by an external

resistor. If S1 pin voltage goes down and becomes lower than Vst, the mos M1 is turned on and forces W1 to

zero. The same thing happens for S2 - W2.

The outputs W1 and W2 can be connected together to get a single output.

REG2 Linear Voltage Regulator (Figure 5)

REG2 is a linear voltage regulator with a dedicated supply pin VIN. The output voltage (between 1.5V and 3.3V)

is fixed by an external divider. It can be turned on/off by SPI. It has a current protection which limits the maximum

allowable output current.

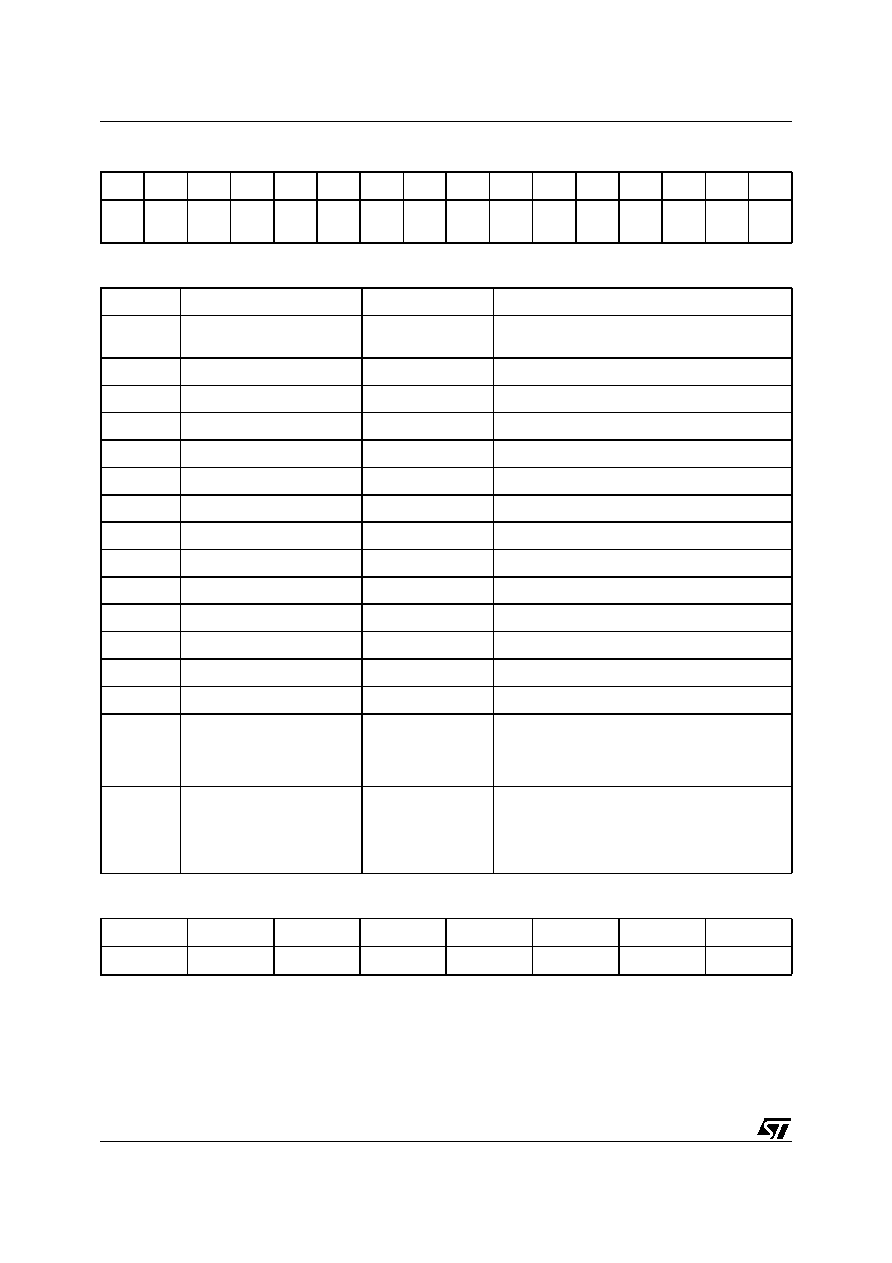

High Side Drivers (Figure 8)

Two high-side driver with charge pump controlled by SPI are available inside L5953. They are protected against

short to ground: the short circuit potection limits the maximum output current.

A diagnostic procedure is available to detect open load, short to battery and overcurrent.

Open load and short to battery can be reveal only in test mode while overcurrent is active only during normal

operationof the device. (see OPERATION -page 13

PWM Step Down Voltage Regulator (Figure 9)

The switching regulator inside the L5953 is a voltage control mode (also known as "direct duty cycle") Buck reg-

ulator: the error signal coming from the error amplifier is compared with a sawtooth to set on and off times of the

power switch.

The feedforward control is introduced to get a quickly response to input voltage changes: the sawtooh has a

fixed frequency and an amplitude variable with the battery voltage.

Continuous mode operation is recommended in order to reduce the stress of the output capacitor and of the

free-wheeling diode.

Error amplifier and compensation network

The error amplifier (EA) is a voltage amplifier whose non-inverting input is fixed to the reference voltage (1.275V

bandgap voltage) and whose inverting input and output are externally available for feedback and frequency

compensation.

11/24

L5953

Figure 5. Linear regulators - Internal pin connections

Figure 6. Reset Internal pin Connection

Figure 7. Low Voltage Warning Block Diagram.

POWER MOS

V

STBY

V

STBY

CONTROLLER

LINEAR REGULATOR

CONTROLLER

V

REF

1.275V

V

REF

1.275V

STCAP

VSTBY

ADJ

FGND

FBLR

VLR

VIN

POWER MOS

D03AU1493

Vref

2.5V/1.65V

FROM VST-BY

RES

CT

Vref 1.275V

7.5

µ

A

D03AU1480

S2

S1

V1

V2

W2

W1

M2

Vref =1.275V

+

-

M1

D03AU1478

Vref =1.275V

+

-

L5953

12/24

Figure 8. HSD - Internal pin connections

Figure 9. PWM - Internal pin connections

Figure 10. SPI & IRQ Internal pin connections

HSD2

VDD-LIN

HSD1

HSD2

CONTROLLER

HSD1

CONTROLLER

POWER

MOS

HSD1

POWER

MOS

HSD2

D01AU1333

PWM

CONTROLLER

VREF

1.275V

FROM THE

OSCILLATOR

ERROR AMPLIFIER

CURRENT

SENSING

DRAINOUT

R

S2

R

S1

POWER

MOS

VDD-SW

FB

COMP

STRAP

VSW

GATEOUT

GATEIN

D03AU1482

SPI

INTERFACE

IRQ

Q

S

D

DGND

C

D03AU1481

13/24

L5953

SPI INTERFACE

Signals Description (Figure 10)

The SPI interface available inside L5953 is able to work both in Mode 0 and Mode 3.

Serial Output (Q). The output pin is used to transfer data serially out of the L5953. Data is shifted out on the

falling edge of the serial clock.

Serial Input (D). The input pin is used to transfer data serially into the device. It receives instructions, address-

es, and data to be written. Input is latched on the rising edge of the serial clock.

Serial Clock (C). The serial clock provides the timing of the serial interface. Instructions, addresses, or data

present at the input pin are latched on the rising edge of the clock input, while data on the Q pin changes after

the falling edge of the clock input.

Chip Select (S). This input is used to select the L5953. The chip is selected by a high to low transition on the

S pin. At any time, the chip is deselected by a low to high transition on the S pin. As soon as the chip is dese-

lected, the Q pin is at high impedance state. The pin allows multiple L5953 to share the same SPI bus. After

power up, the chip is at the deselect state.

SPI Input/Output are supplied by an external supply voltage VSPI while the core is supplied by the stand-by

regulator VSTBY. The SPI is resetted by an internal signal whose buffered version is RES .

OPERATIONS

All instructions, addresses and data are shifted in and out of the chip MSB first. Data input (D) is sampled on

the first rising edge of clock (C) after the chip select (S) goes low. Prior to any operation, a one-byte instruction

code must be entered in the chip. This code is entered in the chip. This code is entered via the data input (D),

and latched on the rising edge of the clock input (C). To enter an instruction code, the product must have been

previously selected (S = low). Table 1 shows the instruction set and format for device operation. An invalid in-

struction (one not contained in table 1) leaves the chip as previously selected.

Write Enable (WREN and Write Disable (WRDI)

The L5953 contains a write enable latch. This latch must be set prior to every WRITE operation. The WREN

instruction will set the latch and the WRDI istruction will reset the latch. The latch is reset under all the following

conditions:

≠ Power on

≠ WRDI instruction executed

As soon as the WREN or WRDI instruction is received by the L5953, the circuit executes the instruction and

enters a wait mode until it is deselected.

Table 1. Instruction Set.

Instruction

Description

Instruction Format

WREN

Set Write Enable Latch

00000110

WRDI

Reset Write Enable Latch

00000100

WSTA

Write Status Register

00000010

RDIA

Read Diagnostic Register

00000101

RSTA

Read Status Register

00000011

L5953

14/24

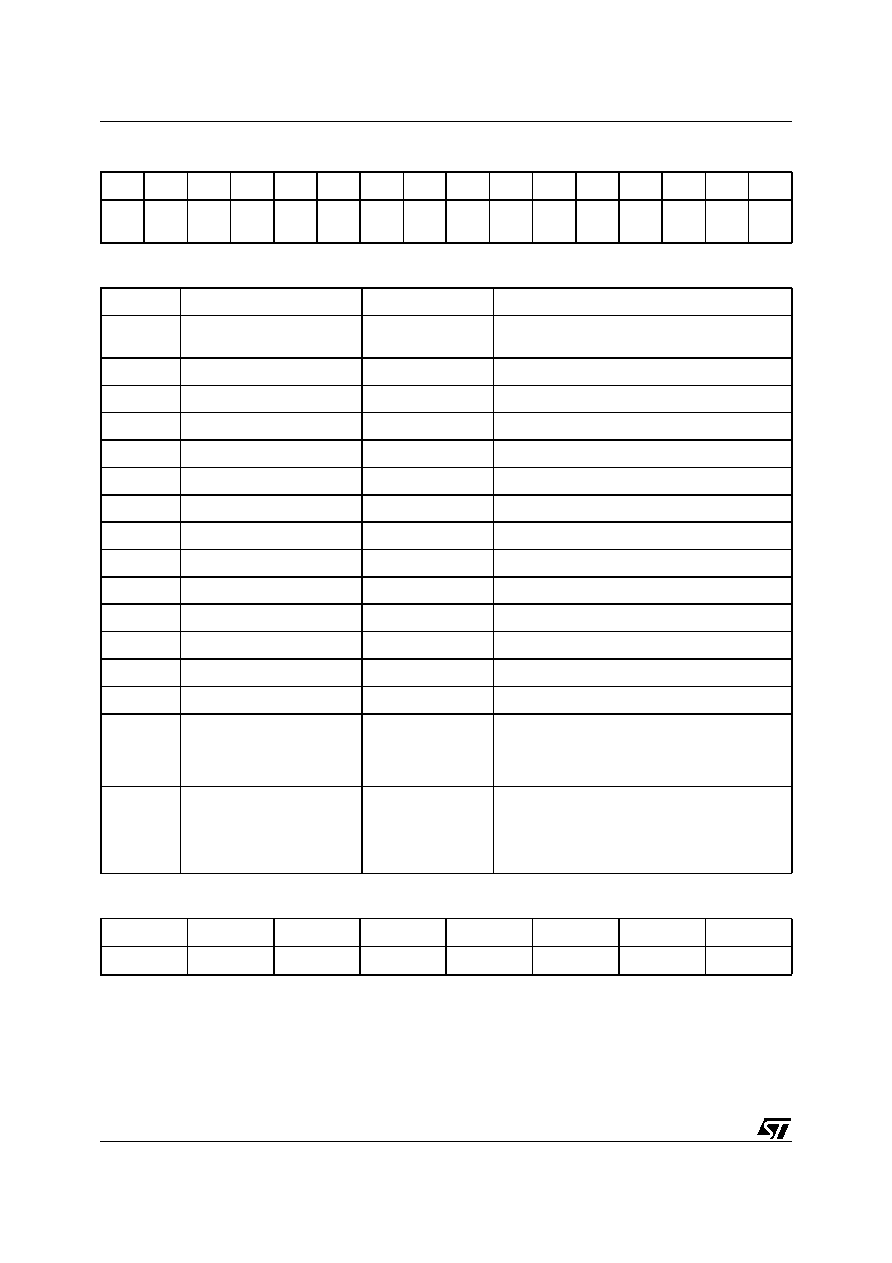

Table 2. Status Register.

Table 3. Status Register Description

Table 4. Diagnostic Register.

s15

s14

s13

s12

s11

s10

s9

s8

s7

s6

s5

s4

s3

s2

s1

s0

REG2 HSD1

HSD2

TBD

TBD

PWM

Freq.

PWM

TBD

TBD

TBD

TBD

TBD

TBD

TBD

Test

Mode

START

DIAG

0

1

s15

REG2 Linear Voltage

Regulator 1.5 to 3.3V

Regulator off

Regulator on

s14

High Side Driver 1

HSD1 off

HSD1 on

s13

High Side Driver 2

HSD2 off

HSD2 on

s12

TBD

s11

TBD

s10

PWM switching frequency

260kHz

400kHz

s9

PWM Voltage Regulator

PWM1 off

PWM1 on

s8

TBD

s7

TBD

s6

TBD

s5

TBD

s4

TBD

s3

TBD

s2

TBD

s1

Test Mode

Test Mode off

Test Mode on

NOTE: in this case the bits s15 - s2 are internally

set to 0 (regulators and high side drivers are in off

condition)

s0

Diagnostic

Diagnostic off

Starts the diagnostic procedure:

- in Test Mode if s1=1;

- during normal operation if s1=0

If s1=0 and s0=1, must be s14 = 1 (HSD1 ON)

and s13=1 (HSD2 ON)

d7

d6

d5

d4

d3

d2

d1

d0

Test mode

HSD1W1

HSD1W2

HSD1W3

HSD2W1

HSD2W2

HSD2W3

THW

15/24

L5953

Table 5. Diagnostic Register Description.

SUMMARY OF THE MAIN OPERATIONS

Operation A

s

Test Mode Diagnostic Procedure Start

s

1) WREN instruction (Fig.11)

s

2) WSTA instruction (Fig.12)

Operation B

s

Read the Diagnostic Register

Case1: after a Test Mode Diagnostic Procedure Start

1) RDIA instruction (Fig.13)

2) Diagnostic Register output (Fig.13)

s

NOTE: an operation B must follow an operation A. The delay between the end of the operations A to

the start of the operations B must be longer than 100

µ

S

Operation C

s

Write the Status Register

0

1

d7

Test mode

The Diagnostic Register is

referred to a test performed

during the normal working

of the L5953

The Diagnostic Register is

referred to a test performed

in Test mode

d6

HSD1W1

If d7=0: HSD1 in normal

condition;

If d7=1: bit value

meaningless

If d7=0: HSD1 is in

overcurrent

If d7=1: bit value

meaningless

d5

HSD1W2

If d7=0: bit value

meaningless;

If d7=1: HSD1 in normal

condition

If d7=0: bit value

meaningless

If d7=1: an open load is

present on HSD1

d4

HSD1W3

If d7=0: bit value

meaningless;

If d7=1: HSD1 in normal

condition

If d7=0: bit value

meaningless

If d7=1: HSD1 is shorted to

the supply voltage VDD

d3

HSD2W1

If d7=0: HSD1 in normal

condition;

If d7=1: bit value

meaningless

If d7=0: HSD2 is in

overcurrent;

If d7=1: bit value

meaningless

d2

HSD2W2

If d7=0: bit value

meaningless

If d7=1: HSD2 in normal

condition

If d7=0: bit value

meaningless

If d7=1: an open load is

present on HSD2

d1

HSD1W3

If d7=0: bit value

meaningless

If d7=1: HSD2 in normal

condition;

If d7=0: bit value

meaningless

If d7=1: HSD1 is shorted to

the supply voltage VDD

d0

Thermal Warning

Normal condition

Overtemperature protection

activated(Tj>150∞C)

L5953

16/24

1) WREN instruction (Fig.11)

2) WSTA instruction (Fig.16)

Operation D

s

Read the Status Register

1) RSTA instruction (Fig.17)

2) Status Register output (Fig.17)

Operation E

s

Diagnostic Procedure Start

1) WREN instruction (Fig.11)

2) WSTA instruction (Fig.14)

Operation F

s

Read the Diagnostic Register

Case 2: after a Diagnostic Procedure Start

1) RDIA instruction (Fig.15)

2) Diagnostic Register output (Fig.15)

An operation F must follow an operation E if the pin IRQ is not activated.

The delay between the Operation E and an Operation F must be longer than 100

µ

s.

To be recognized, the fault must be present without interruptions during all the delay above mentionned .

After an Operation F, the bit s0 of the Status Register is resettled (0)

Operation G

s

Write operation disabled

1) WRDI instruction (Table 1)

Operation H

s

Read the Diagnostic Register case 3: after an IRQ pin activation

1) RDIA instruction (Fig. 15)

2) Diagnostic Register Output (Fig. 15)

The delay between the IRQ activation and an Operation F must be longer than 100

µ

s

Figure 11. Write Enable Latch Sequence

00

01

02

03

04

HIGH IMPEDANCE

05

06

07

S

C

CPOL=0

CPHA=0

D

Q

D03AU1483

17/24

L5953

Figure 12. Test Mode Diagnostic Procedure Start (after a Write Enable Latch Sequence, Fig.11)

Figure 13. Read the Diagnostic registerCase1: after a Test Mode diagnostic procedure start (Fig.

12)

Figure 14. Diagnostic Procedure Start (after a Write Enable Latch Sequence, operation A)

Figure 15. Read the Diagnostic RegisterCase2: during the normal working of the L5953 (after a

Diagnostic Procedure Start, Fig.14)

00

01

02

03

04

HIGH IMPEDANCE

INSTRUCTION

STATUS REGISTER

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

s15

s14

s13

s12

s11

s10

s9

s8

s7

s6

s5

s4

s3

s2

s1

s0

S

C

D

Q

D03AU1484

CPOL=0, CPHA=0

00

01

02

03

04

HIGH IMPEDANCE

INSTRUCTION

DIAGNOSTIC REGISTER OUT

05

06

07

08

09

10

11

12

13

14

15

d7

d6

d5

d4

d3

d2

d1

d0

S

C

D

Q

D03AU1485

CPOL=0, CPHA=0

00

01

02

03

04

HIGH IMPEDANCE

INSTRUCTION

STATUS REGISTER

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

s15

s14

s13

s12

s11

s10

s9

s8

s7

s6

s5

s4

s3

s2

s1

s0

S

C

D

Q

D03AU1486

CPOL=0, CPHA=0

00

01

02

03

04

HIGH IMPEDANCE

INSTRUCTION

DIAGNOSTIC REGISTER OUT

05

06

07

08

09

10

11

12

13

14

15

d7

d6

d5

d4

d3

d2

d1

d0

S

C

D

Q

D03AU1487

CPOL=0, CPHA=0

L5953

18/24

Figure 16. Write the Status Register (after a Write Enable Latch Sequence, operation A)

Figure 17. Read the Status Register

IRQ - Interrupt Request Pin

s

It is an open drain pin activated (low) every time a variation occurs in the Diagnostic Register.

s

Purpose: to alert the

µ

P that one or more warning bit of the Diagnostic Register has changed from 0 to

1 or from 1 to 0.

s

An activation of this pin puts the bit s0 of the Status Register to 1 (START DIAGNOSTIC) like an

Operation E (Diagnostic Procedure Start). Then an Operation F has to be executed without an

Operation E before.

s

After an Operation F, the IRQ pin is disactivated, and goes to 1 if connected to a pull-up resistor.

L5953 - Application Note

00

01

02

03

04

HIGH IMPEDANCE

INSTRUCTION

STATUS REGISTER

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

s15

s14

s13

s12

s11

s10

s9

s8

s7

s6

s5

s4

s3

s2

s1

s0

S

C

D

Q

D03AU1488

CPOL=0, CPHA=0

00

01

02

03

04

HIGH IMPEDANCE

INSTRUCTION

STATUS REGISTER OUT

05

06

07

08

09

10

11

12

13

14

15

S

C

D

Q

D03AU1489

16

17

18

19

20

21

22

23

s15

s14

s13

s12

s11

s10

s9

s8

s7

s6

s5

s4

s3

s2

s1

s0

CPOL=0, CPHA=0

19/24

L5953

Figure 18. Block and Application Diagram

Figure 19. Block Diagram And Application With External Power MOS

VOLTAGE WARNING

SPI INTERFACE

REG2

LINEAR VOLTAGE

REGULATOR

1.5-3.3V/300mA

HSD1

HSD1

HSD2

C4

C3

D1

C6

HSD2

COMP

FB

GATEOUT

GATEIN

D2

R4

R5

R6

R3

C9

R2

R1

C8

VSW

DRAINOUT

STRAP

ADJ

VSTBY

GND

SWGND

S1

W1

S2

W2

VDD

Vo

VDD-LIN

REG1

ST-BY LINEAR VOLTAGE

REGULATOR

3.3-5V/250mA

PWM

STEP DOWN

REGULATOR

2.5-10V/1A

OSCILLATOR &

SYNC

STCAP

CT

RES

VDD-SW

IRQ

Q

D

S

C

VLR

FBLR

VIN

SYNC

DGND

FGND

D01AU1331B

L1

C1

C2

C5

C11

C10

C7

VSPI

VOLTAGE WARNING

SPI INTERFACE

REG2

LINEAR VOLTAGE

REGULATOR

1.5-3.3V/300mA

HSD1

HSD1

HSD2

C4

C3

D1

C6

HSD2

COMP

FB

GATEOUT

GATEIN

D2

M1

R4

R5

R6

R3

C9

R2

R1

C8

VSW

DRAINOUT

STRAP

ADJ

VSTBY

GND

SWGND

S1

W1

S2

W2

VDD

Vo

VDD-LIN

REG1

ST-BY LINEAR VOLTAGE

REGULATOR

3.3-5V/250mA

PWM

STEP DOWN

REGULATOR

2.5-10V/1A

OSCILLATOR &

SYNC

STCAP

CT

RES

VDD-SW

IRQ

Q

D

S

C

VLR

FBLR

VIN

SYNC

DGND

FGND

D01AU1332B

L1

C10

C7

VSPI

C2

C1

C5

L5953

20/24

PART LIST on Evaluation Board

REG1 OUTPUT VOLTAGE

V

STBY

= 5V if pin ADJ left floating

V

STBY

= 3.3V if pin ADJ is conneted to the pin V

STBY

Timing Capacitor

The value for this capacitor has to be chosen according the wanted power-on delay T

d

:

where I

CT1

is the source current used to charge the timing capacitor and V

STBY

is the REG1 output voltage.

Feedback resistors for REG2

where VLR is the required output voltage for REG2.

External components for PWM regulator

Bootstrap capacitor

The suggested value for the bootstrap capacitor is C6 = 100nF

Here following you find the criteria for the selection of the inductor L1, the free-wheeling diode D2, the output

filter capacitor C7, the feedback resistor R1, R2 and the compensation network R3, C8, R4, C9 to have a Buck

regulator working in Continuos mode. Continuous mode operation is recommended in order to reduce the stress

of the output capacitor and of the free-wheeling diode.

Inductor Selection

The minimum value of the inductor L7 has to be so that the maximum inductor current ripple

I

L,max

is 20% to

30% of the maximum load current load I

o,max

.The maximum ripple is present when the switching frequency is

minimum ( f

sw,min

) and the input voltage is maximum ( V

in,max

) so the minimum value for the inductor L

min

is :

Output Capacitor Selection

The criteria for the selection of the capacitor C7 is based on the output voltage ripple requirements. The ripple

on the output voltage is due to a capacitive contribute, often negligible, equal to

C1 = 470

µ

F

C2 = 220 nF

C3 = 470

µ

F

C4 = 10

µ

F

C5 = 1

µ

F

C6 = 100 nF

C7 = 470

µ

F

ESR=65 m

C8 = 56nF

C9 = 2.7 nF

C10 = 10

µ

F

C11 = 4.7 nF

R1 = 2.2 k

R2 = 2 x 1.5 k

in parallel

R3 = 10 k

R4 = 220 k

R5 = 3.3 k

R6 = 1 k

L1 = 180

µ

H

D1 = 1N4007 or

MBR160

D2 = MBR360

C11

I

CT 1

T

d

0.5 V

S TB Y

(

)

V

C TL Ry

+

--------------------------------------------------------------

=

R5

R6

V

LR

V

r ef R EG 2

,

--------------------------

1

≠

=

L

m in

V

O

I

L m ax

,

--------------------

1

V

O

V

i m ax

,

-----------------

1

f

s w m in

,

------------------

≠

=

21/24

L5953

and a resistive contribute given by the ESR of the capacitor and which is equal to

VC fixes the value for C7 while

VESR limits the ESR of the capacitor.Usually the capacitor is chosen so that

the total ripple on the output regulated voltage Vo is equal to 1% of the value of Vo. If V

ripple

is the maximum

allowed voltage ripple on Vo then it should result:

More often the minimum value of C7 is imposed by other considerations such as to get a good dynamic behav-

iour of the output voltage in case of large load variations.

Free-wheeling diode

The diode must withstand an average current Id equal to Id = I

lim

( 1- D

min

)

where I

lim

is the current of intervention of the short circuit protection and D

min

is the minimum duty cycle. As D

min

is vey low, the current Id can be assumed equal to I

lim

.

Compensation Network

In continuous mode, the voltage controlled buck converter showes two poles due to the output LC filter and one

zero due to the ESR of the output capacitor. The suggested compensation network introduces two zeros and

two poles:

≠ the zeros compensate the double poles of the LC filter

≠ one pole compensates the zero due to ESR of the output capacitor

≠ the second pole is nominally located in the origin which means an infinite gain at frequency null. In

the reality the DC value of the closed loop gain can not be greater than the DC value of the EA open

loop gain and the pole is located at very low frequency.

The values for the components of the compensation network can be fixed when the inductor L1 and the output

capacitor C7 are chosen.

The necessary steps are following:

1.fix the cross-over frequency f

C

of the overall loop gain.

Usually

where f

sw,min

is the minimum switching frequency

2.Calculate the high frequency error amplifier gain

3.Chose R3 and calculate

The value for R3 has not to be very high (for example 10K

) so to limit the error due to an error amplifier input

offset current.

V

c

I

L m ax

,

8 C7 f

s w m in

,

---------------------------------------

=

V

ESR

ESR

I

L m a x

,

=

V

ri ppl e

V

c

2

V

ES R

2

+

f

c

0.1 f

s w,min

=

G

c

0.25 f

c

2

L1

ESR

-------------

=

C8

2

L1 C7

R3

-----------------------

=

L5953

22/24

4.Calculate

5.Finally calculate

and

R

p

R3

2

E SR

-------------

L1

C7

--------

1

≠

---------------------------------------------

=

RA

R

p

V

O

V

ref PWM

,

-------------------------

=

R2

R

p

1

V

r ef,PWM

V

O

-----------------------

≠

---------------------------------

=

R4

G

C

R1

=

C9

2

L1 C7

R4

-----------------------

=

23/24

L5953

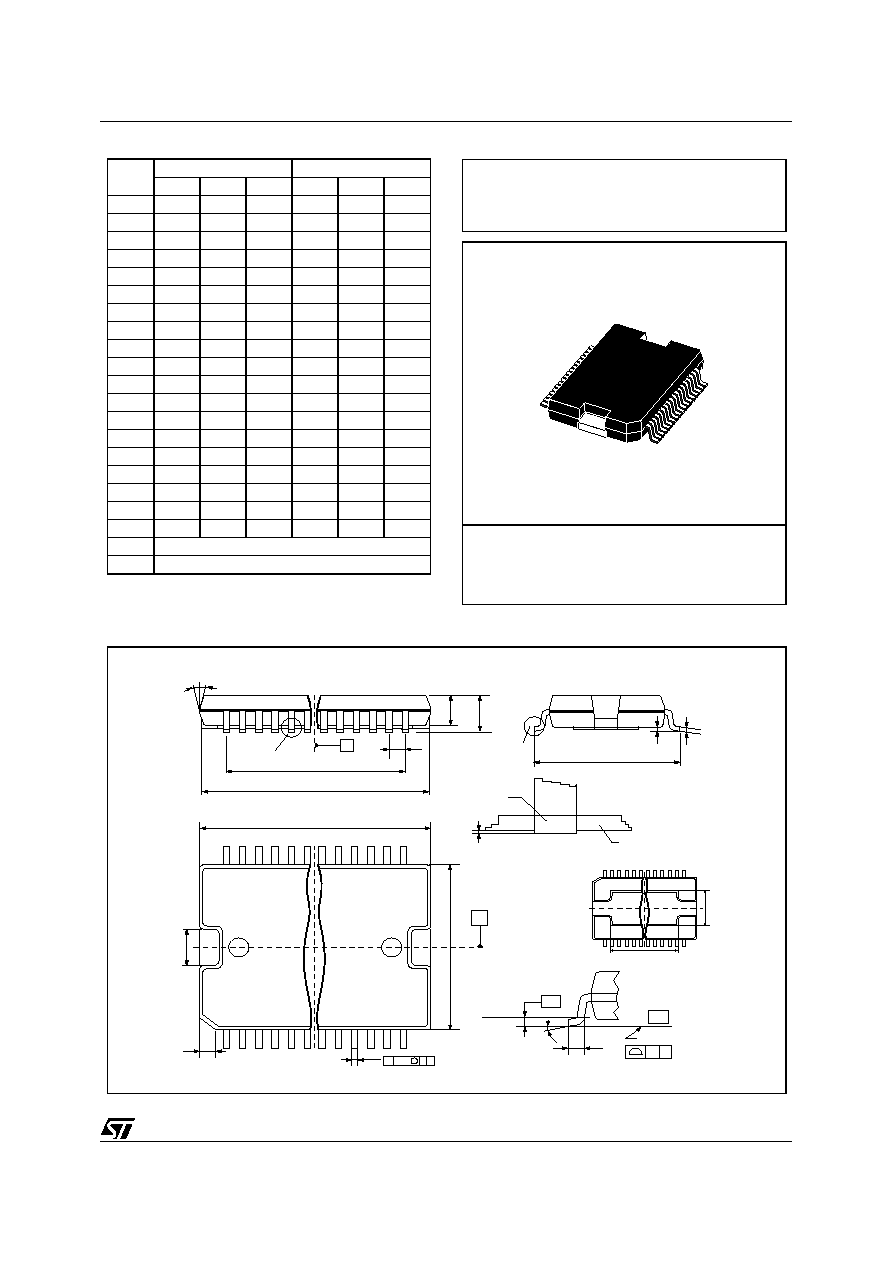

DIM.

mm

inch

MIN.

TYP.

MAX.

MIN.

TYP.

MAX.

A

3.60

0.141

a1

0.10

0.30

0.004

0.012

a2

3.30

0.130

a3

0

0.10

0

0.004

b

0.22

0.38

0.008

0.015

c

0.23

0.32

0.009

0.012

D (1)

15.80

16.00

0.622

0.630

D1

9.40

9.80

0.370

0.385

E

13.90

14.50

0.547

0.570

e

0.65

0.0256

e3

11.05

0.435

E1 (1)

10.90

11.10

0.429

0.437

E2

2.90

0.114

E3

5.80

6.20

0.228

0.244

E4

2.90

3.20

0.114

0.126

G

0

0.10

0

0.004

H

15.50

15.90

0.610

0.626

h

1.10

0.043

L

0.80

1.10

0.031

0.043

N

10

∞

(max.)

S

8

∞

(max.)

(1): "D" and "E1" do not include mold flash or protrusions

- Mold flash or protrusions shall not exceed 0.15mm (0.006 inch)

- Critical dimensions are "a3", "E" and "G".

PowerSO36

e

a2

A

E

a1

PSO36MEC

DETAIL A

D

1

1

8

19

36

E1

E2

h x 45∞

DETAIL A

lead

slug

a3

S

Gage Plane

0.35

L

DETAIL B

DETAIL B

(COPLANARITY)

G

C

- C -

SEATING PLANE

e3

c

N

N

M

0.12

A B

b

B

A

H

E3

D1

BOTTOM VIEW

OUTLINE AND

MECHANICAL DATA

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2003 STMicroelectronics - All rights reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States

www.st.com

24/24

L5953